Substrate-Induced Strain Effect on Structural and Magnetic Properties of La0.5Sr0.5CoO3 Films

Abstract

:1. Introduction

2. Experimental Section

3. Results and Discussion

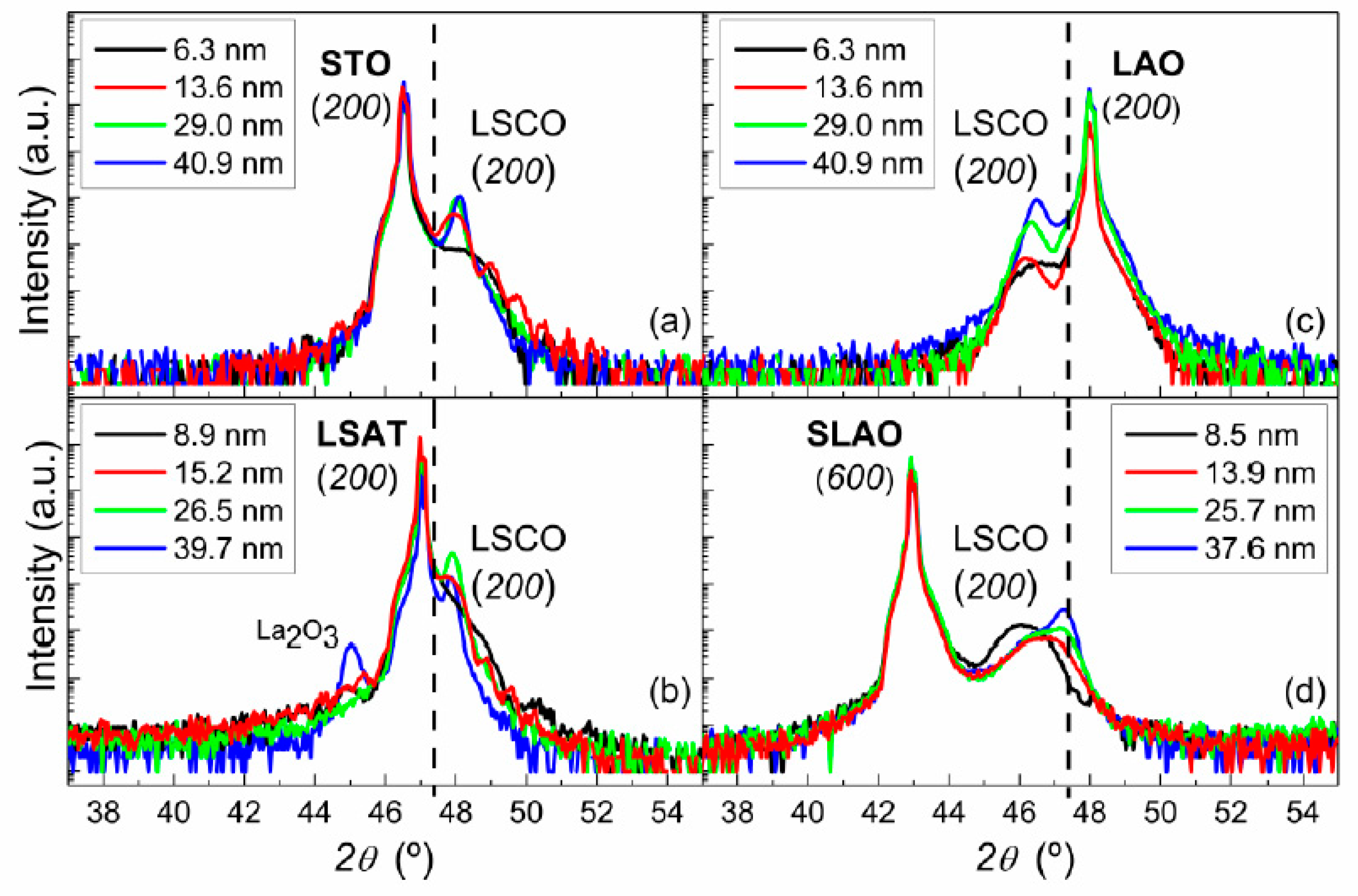

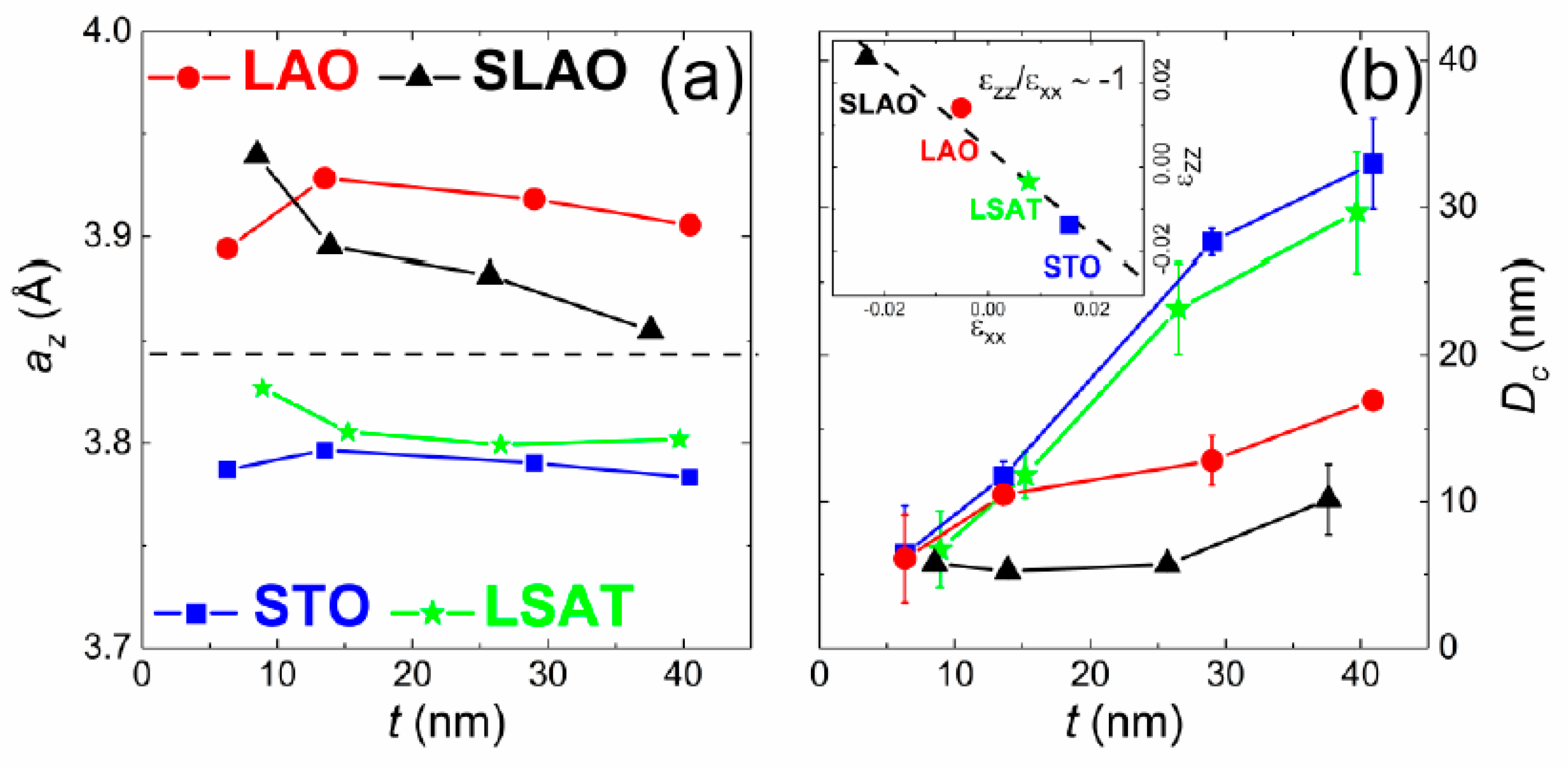

3.1. Structural Characterization

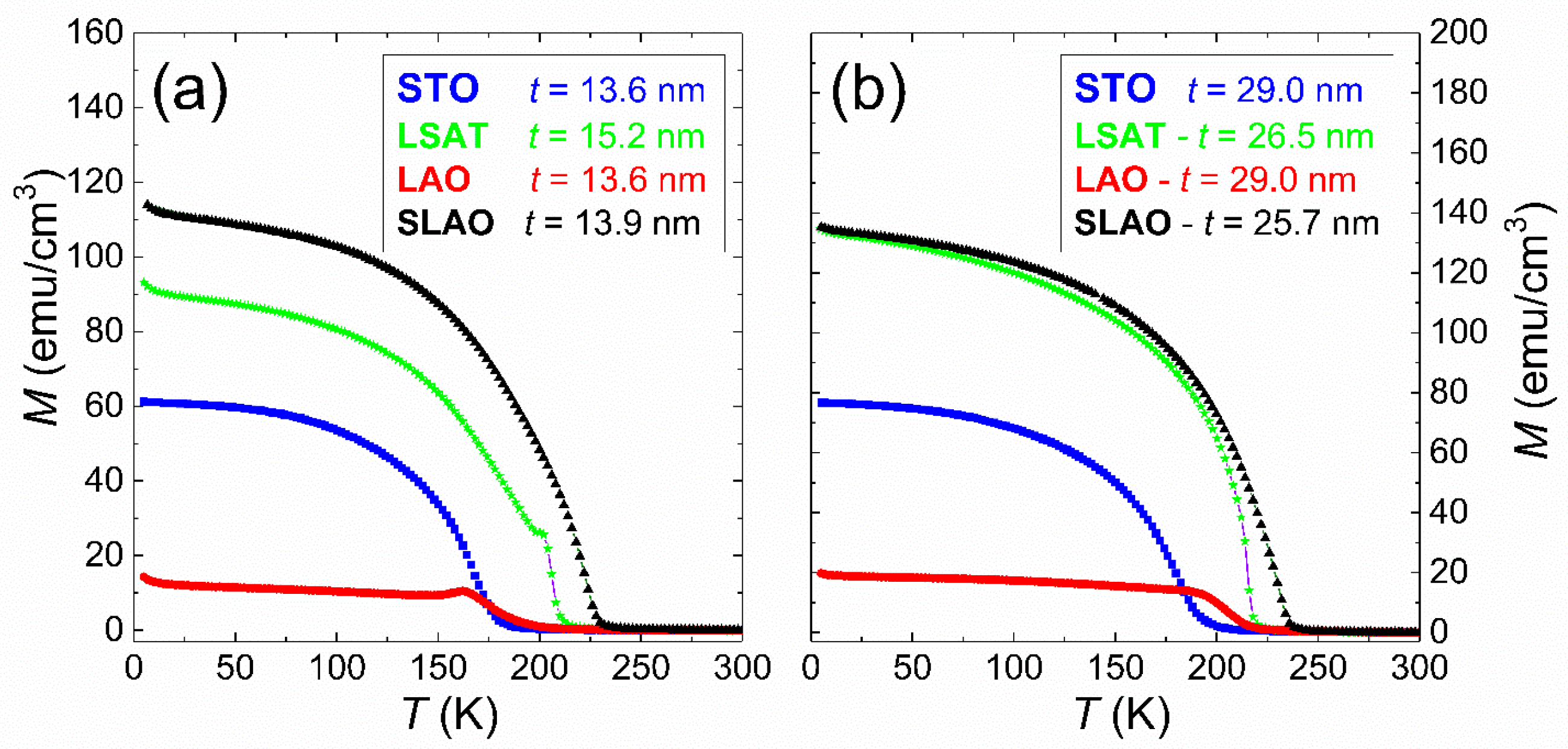

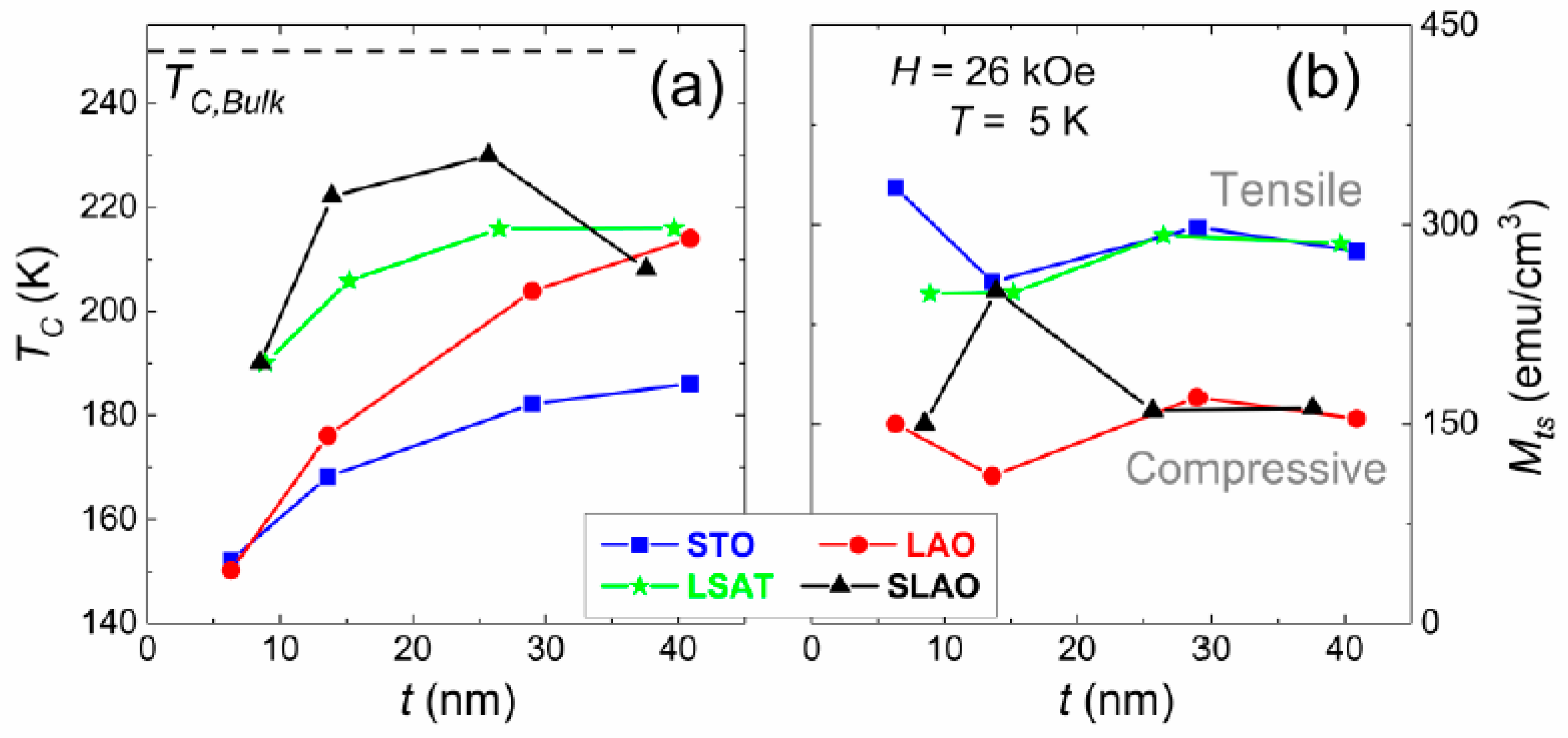

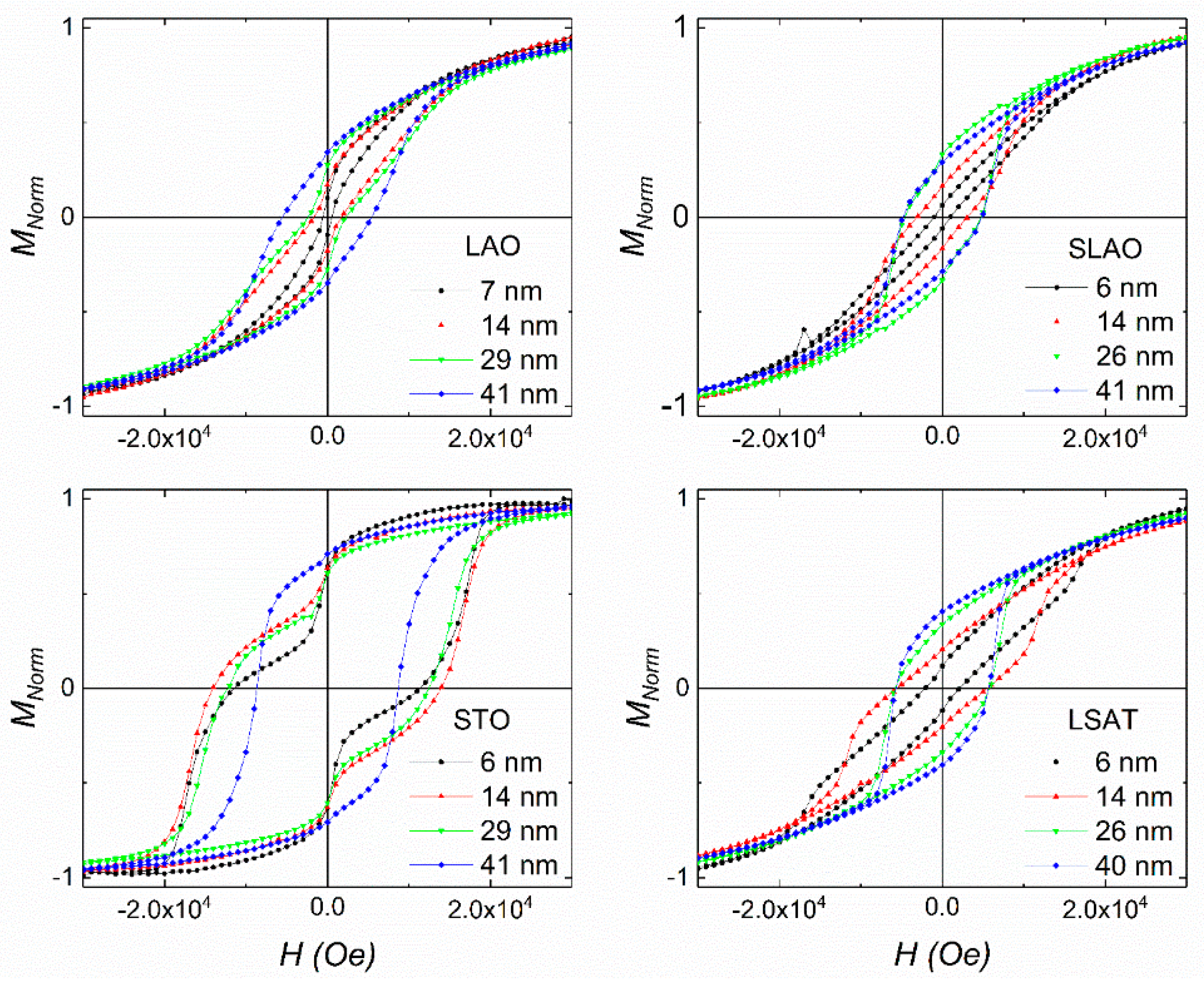

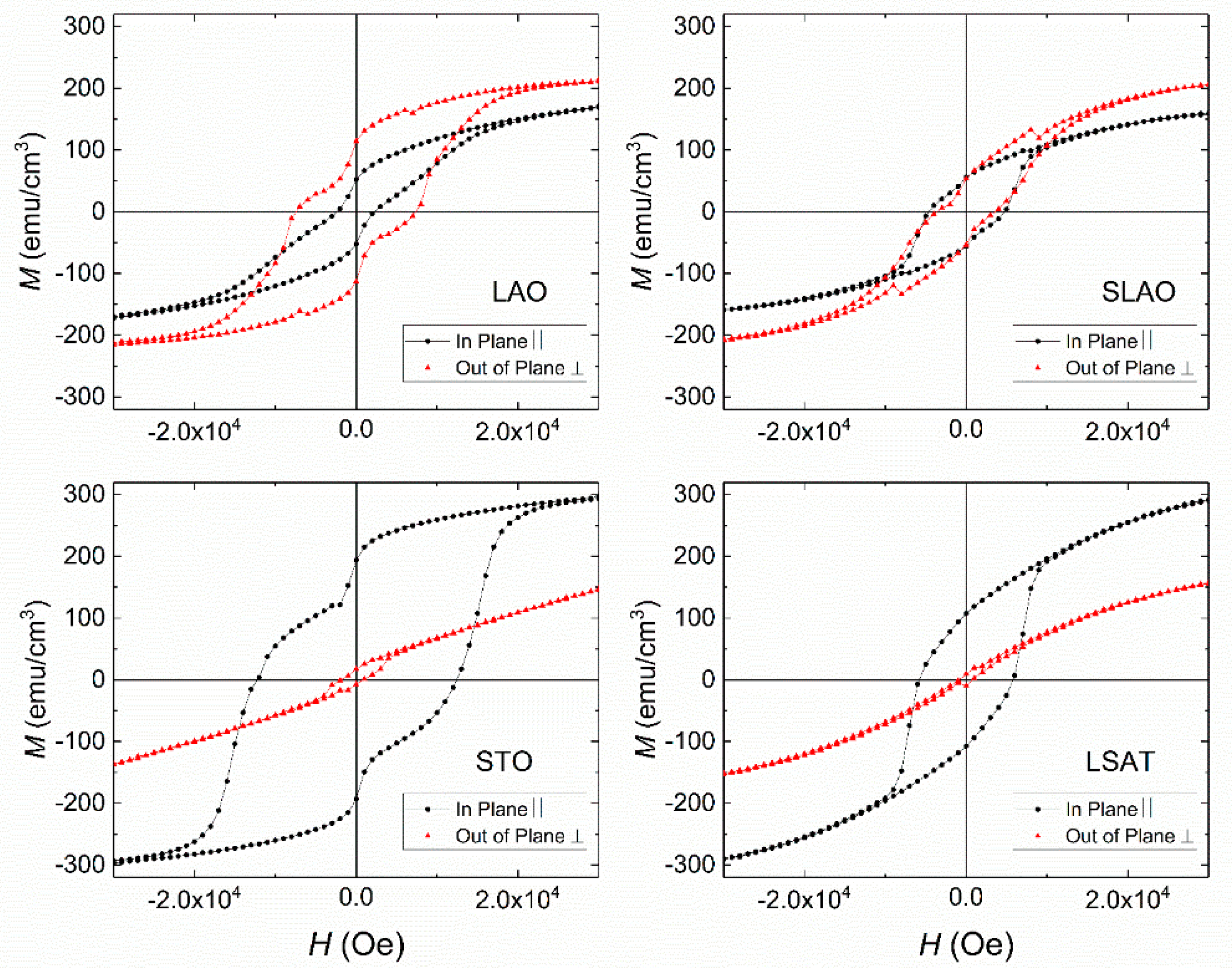

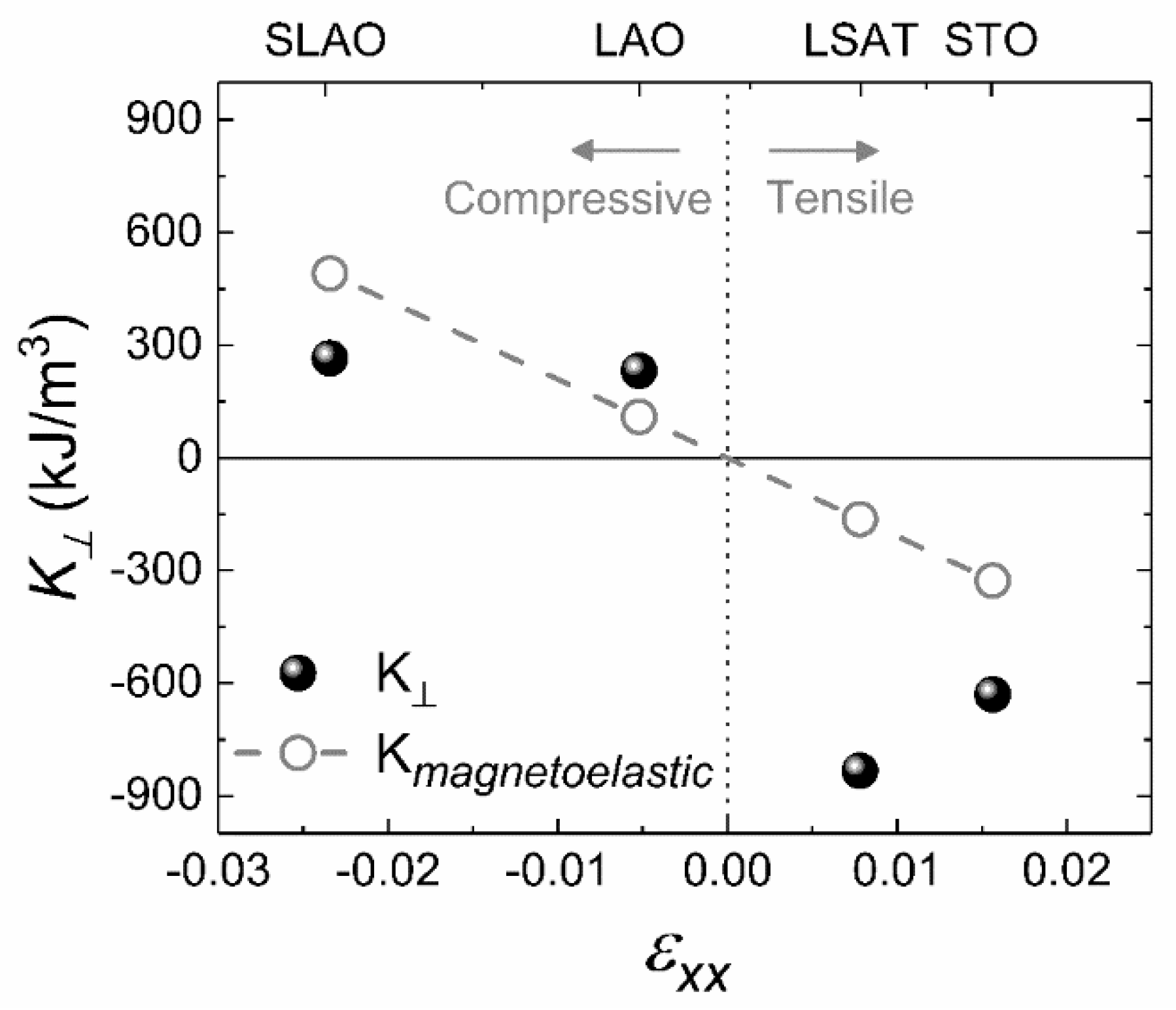

3.2. Magnetic Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Schwartz, R.; Sebastian, M.; Raymond, M. Evaluation of LSCO Electrodes for Sensor Protection Devices. MRS Proc. 2000, 623, 365–370. [Google Scholar] [CrossRef]

- Othmen, Z.; Schulman, A.; Daoudi, K.; Boudard, M.; Acha, C.; Roussel, H.; Oueslati, M.; Tsuchiya, T. Structural, electrical and magnetic properties of epitaxial La0.7Sr0.3CoO3 thin films grown on SrTiO3 and LaAlO3 substrates. Appl. Surf. Sci. 2014, 306, 60–65. [Google Scholar] [CrossRef]

- Jonker, G.H.; Van Santen, J.H. Magnetic compounds wtth perovskite structure III. ferromagnetic compounds of cobalt. Physica 1953, 19, 120–130. [Google Scholar] [CrossRef]

- Goodenough, J.B. An interpretation of the magnetic properties of the perovskite-type mixed crystals La1−xSrxCoO3−δ. J. Phys. Chem. Solids 1958, 6, 287–297. [Google Scholar] [CrossRef]

- Caciuffo, R.; Rinaldi, D.; Barucca, G.; Mira, J.; Rivas, J.; Senarís-Rodríguez, M.; Radaelli, P.G.; Fiorani, D.; Goodenough, J.B. Structural details and magnetic order of La1−xSrxCoO3 (x ≤ 0.3). Phys. Rev. B 1999, 59, 1068. [Google Scholar] [CrossRef]

- Androulakis, J.; Katsarakis, N.; Giapintzakis, J. Ferromagnetic and antiferromagnetic interactions in lanthanum cobalt oxide at low temperatures. Phys. Rev. B 2001, 64, 1–7. [Google Scholar] [CrossRef]

- Klie, R.; Zheng, J.; Zhu, Y.; Varela, M.; Wu, J.; Leighton, C. Direct measurement of the low-temperature spin-state transition in LaCoO3. Phys. Rev. Lett. 2007, 99, 1–4. [Google Scholar] [CrossRef]

- Davies, J.; Wu, J.; Leighton, C.; Liu, K. Magnetization reversal and nanoscopic magnetic phase separation in doped La1−xSrxCoO3. Phys. Rev. B 2005, 72, 134419. [Google Scholar] [CrossRef] [Green Version]

- Yan, J.-Q.; Zhou, J.-S.; Goodenough, J. Ferromagnetism in LaCoO3. Phys. Rev. B 2004, 70, 2–6. [Google Scholar] [CrossRef]

- English, S.R.; Wu, J.; Leighton, C. Thermally excited spin-disorder contribution to the resistivity of LaCoO3. Phys. Rev. B 2002, 65, 220407(R). [Google Scholar] [CrossRef]

- Schmidt, R.; Wu, J.; Leighton, C.; Terry, I. Dielectric response to the low-temperature magnetic defect structure and spin state transition in polycrystalline LaCoO3. Phys. Rev. B 2009, 79, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Ravindran, P.; Fjellvåg, H.; Kjekshus, A.; Blaha, P.; Schwarz, K.; Luitz, J. Itinerant metamagnetism and possible spin transition in LaCoO3 by temperature/hole doping. J. Appl. Phys. 2002, 91, 291–303. [Google Scholar] [CrossRef] [Green Version]

- Mahendiran, R.; Raychaudhuri, A.K. Magnetoresistance of the spin-state-transition compound La1−xSrxCoO3. Phys. Rev. B 1996, 54, 16044. [Google Scholar] [CrossRef]

- Aarbogh, H.M.; Wu, J.; Wang, L.; Zheng, H.; Mitchell, J.F.; Leighton, C. Magnetic and electronic properties of La1−xSrxCoO3 single crystals across the percolation metal-insulator transition. Phys. Rev. B 2006, 74, 134408. [Google Scholar] [CrossRef]

- Durá, O.J.; Rogl, P.; Falmbigl, M.; Hilscher, G.; Bauer, E. Thermoelectric and magnetic properties of nanocrystalline La0.7Sr0.3CoO3. J. Appl. Phys. 2012, 111, 063722. [Google Scholar] [CrossRef]

- Torija, M.A.; Sharma, M.; Gazquez, J.; Varela, M.; He, C.; Schmitt, J.; Borchers, J.A.; Laver, M.; El-Khatib, S.; Leighton, C. Chemically driven nanoscopic magnetic phase separation at the SrTiO3(001)/La1−xSrxCoO3 interface. Adv. Mater. 2011, 23, 2711–2715. [Google Scholar] [CrossRef]

- Wu, J.; Leighton, C. Glassy ferromagnetism and magnetic phase separation in La1−xSrxCoO3. Phys. Rev. B 2003, 67, 1–16. [Google Scholar] [CrossRef]

- Golovanov, V.; Mihaly, L.; Moodenbaugh, A.R. Magnetoresistance La1−xSrxCoO3 for 0.05 ≤ x ≥ 0.25. Phys. Rev. B 1996, 53, 8207. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hoch, M.; Kuhns, P.; Moulton, W.; Reyes, A.P.; Wu, J.; Leighton, C. Spin dynamics in La1−xSrxCoO3. Phys. Rev. B 2004, 69, 1–7. [Google Scholar] [CrossRef]

- He, C.; Eisenberg, S.; Jan, C.; Zheng, H.; Mitchell, J.F.; Leighton, C. Heat capacity study of magnetoelectronic phase separation in La1-xSrxCoO3 single crystals. Phys. Rev. B 2009, 80, 214411. [Google Scholar] [CrossRef]

- Torija, M.A.; Sharma, M.; Fitzsimmons, M.R.; Varela, M.; Leighton, C. Epitaxial La0.5Sr0.5CoO3 thin films: Structure, magnetism, and transport. J. Appl. Phys. 2008, 104, 023901. [Google Scholar] [CrossRef]

- Samal, D.; Kumar, A. A critical re-examination and a revised phase diagram of La1−xSrxCoO3. J. Phys. Conds. Matter 2011, 23, 16001. [Google Scholar] [CrossRef] [PubMed]

- Németh, Z.; Szabó, A.; Knížek, K.; Sikora, M.; Chernikov, R.; Sas, N.; Bogdán, C.; Nagy, D.L.; Vankó, G. Microscopic origin of the magnetoelectronic phase separation in Sr-doped LaCoO3. Phys. Rev. B Condens. Matter Mater. Phys. 2013, 88, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Dagotto, E.; Hotta, T.; Moreo, A. Colossal magnetoresistant materials: The key role of phase separation. Phys. Rep. 2001, 344, 1–153. [Google Scholar] [CrossRef] [Green Version]

- Kuhns, P.L.; Hoch, M.J.R.; Moulton, W.G.; Reyes, A.P.; Wu, J.; Leighton, C. Magnetic phase separation in La1−xSrxCoO3 by 59Co nuclear magnetic resonance. Phys. Rev. Lett. 2003, 91, 127202. [Google Scholar] [CrossRef] [PubMed]

- Gazquez, J.; Bose, S.; Sharma, M.; Torija, M.A.; Pennycook, S.J.; Leighton, C.; Varela, M. Lattice mismatch accommodation via oxygen vacancy ordering in epitaxial La0.5Sr0.5CoO3−δ thin films. APL Mater. 2013, 1, 012105. [Google Scholar] [CrossRef]

- Mandal, P.; Hassen, A.; Choudhury, P. Transport properties of metallic La1−xSrxCoO3 (0.30 ≤ x ≤ 0.50) ferromagnet. J. Appl. Phys. 2006, 100, 103912. [Google Scholar] [CrossRef]

- Hanashima, T.; Azuhata, S.; Yamawaki, K.; Shimizu, N.; Mori, T.; Tanaka, M.; Sasaki, S. Compositional dependence of X-ray absorption spectra on magnetic circular dichroism and near-edge structure at Co K edge in La1−xSrxCoO3 (0 ≤ x ≤ 0.6). Jpn. J. Appl. Phys. 2004, 43, 4171–4178. [Google Scholar] [CrossRef]

- Roy, B.; Das, S. Size-induced metal insulator transition and glassy magnetic behavior in La0.5Sr0.5CoO3 nanoparticles. Appl. Phys. Lett. 2008, 92, 2008–2010. [Google Scholar] [CrossRef]

- Fuchs, D.; Schwarz, T.; Morán, O.; Schweiss, P.; Schneider, R. Finite-size shift of the Curie temperature of ferromagnetic lanthanum cobaltite thin films. Phys. Rev. B 2005, 71, 092406. [Google Scholar] [CrossRef]

- Fuchs, D.; Pinta, C.; Schwarz, T.; Schweiss, P.; Nagel, P.; Schuppler, S.; Schneider, R.; Merz, M.; Roth, G.; Löhneysen, H.V. Ferromagnetic order in epitaxially strained LaCoO3 thin films. Phys. Rev. B 2007, 75, 144402. [Google Scholar] [CrossRef]

- Fuchs, D.; Arac, E.; Pinta, C.; Schuppler, S.; Schneider, R.; Löhneysen, H.V. Tuning the magnetic properties of LaCoO3 thin films by epitaxial strain. Phys. Rev. B 2008, 77, 014434. [Google Scholar] [CrossRef]

- Heo, Y.; Kan, D.; Anada, M.; Wakabayashi, Y.; Tajiri, H.; Shimakawa, Y. Correlations between oxygen octahedral distortions and magnetic and transport properties in strained La0.5Sr0.5CoO3 thin films. Phys. Rev. B 2019, 99. [Google Scholar] [CrossRef]

- Lucy, J.; Ball, M.; Restrepo, O.; Hauser, A.; Soliz, J.; Freeland, J.; Woodward, P.; Windl, W.; Yang, F. Strain-tunable, extraordinary magnetocrystalline anisotropy in Sr2CrReO6 Epitaxial films. Phys. Rev. B 2014, 90, 180401. [Google Scholar] [CrossRef] [Green Version]

- Hu, R.; Soh, A.K.; Ni, Y. Micromagnetic simulation of size effects on the properties of ferromagnetic materials. J. Phys. D Appl. Phys. 2006, 39, 1987. [Google Scholar] [CrossRef]

- Zhang, J.; Baishun, Y.; Zheng, H.; Han, X.; Yan, Y. Large magnetic anisotropy and strain induced enhancement of magnetic anisotropy in monolayer TaTe2. Phys. Chem. Chem. Phys. 2017, 19. [Google Scholar] [CrossRef] [PubMed]

- Goyal, R.; Lamba, S.; Annapoorni, S. Modelling of strain induced magnetic anisotropy in Au additive FePt thin films. Prog. Nat. Sci. Mater. Int. 2019, 29, 517–524. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, J.; Shen, X.; Guan, X.; Yao, Y.; Li, J.; Gu, C.; Sun, J.; Zhu, Y.; Tao, J.; et al. Out-of-plane magnetic anisotropy enhancement in La1−xSrxCoO3−δ/La2/3Sr1/3MnO3/La1−xSrxCoO3−δ thin films. Phys. Rev. B 2020, 101, 24406. [Google Scholar] [CrossRef]

- Cabero, M.; Nagy, K.; Gallego, F.; Sander, A.; Rio, M.; Cuellar, F.A.; Tornos, J.; Hernandez-Martin, D.; Nemes, N.M.; Mompean, F.; et al. Modified magnetic anisotropy at LaCoO3/La0.7Sr0.3MnO3 interfaces. APL Mater. 2017, 5, 096104. [Google Scholar] [CrossRef] [Green Version]

- Pesquera, D.; Herranz, G.; Barla, A.; Pellegrin, E.; Bondino, F.; Magnano, E.; Sánchez, F.; Fontcuberta, J. Surface symmetry-breaking and strain effects on orbital occupancy in transition metal perovskite epitaxial films. Nat. Commun. 2012, 3, 1189. [Google Scholar] [CrossRef]

- Zhang, J.; Zhong, Z.; Guan, X.; Shen, X.; Zhang, J.; Han, F.; Zhang, H.; Zhang, H.; Yan, X.; Zhang, Q.; et al. Symmetry mismatch-driven perpendicular magnetic anisotropy for perovskite/brownmillerite heterostructures. Nat. Commun. 2018, 9, 1923. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Yu, L.; Wang, J.; Chen, L.; Gao, W.; Du, X.; Biao, L. Porous microstructure modification of La1−xSrxCoO3 (0 ≤ x ≤ 1) ceramics via Sr content. Mater. Lett. 2012, 75, 39–41. [Google Scholar] [CrossRef]

- Parratt, L.G. Surface studies of solids by total reflection of x-rays. Phys. Rev. 1954, 95, 359–369. [Google Scholar] [CrossRef]

- Huang, T.C.; Gilles, R.; Will, G. Thin-film thickness and density determination from x-ray reflectivity data using a conventional power diffractometer. Thin Solid Films 1993, 230, 99–101. [Google Scholar] [CrossRef]

- Kobayashi, S. X-ray thin-film measurement techniques IV. In-plane diffraction measurements. Rigaku J. 2010, 26, 3–11. [Google Scholar]

- Dong, L.; Schnitker, J.; Smith, R.W.; Srolovitz, D.J. Stress relaxation and misfit dislocation nucleation in the growth of misfitting films: A molecular dynamics simulation study. J. Appl. Phys. 1998, 83, 217–227. [Google Scholar] [CrossRef] [Green Version]

- Hopkinson, J. Magnetic properties of alloys of Nickel and Iron. Proc. R. Soc. Lond. 1890, 48. [Google Scholar] [CrossRef]

- Chikazumi, S. Physics of Magnetism; Wiley: New York, NY, USA, 1964. [Google Scholar]

- Rata, A.D.; Herklotz, A.; Nenkov, K.; Schultz, L.; Dörr, K. Strain-induced insulator state and giant gauge factor of La0.7Sr0.3CoO3 Films. Phys. Rev. Lett. 2008, 100, 076401. [Google Scholar] [CrossRef] [Green Version]

- Xie, C.; Budnick, J.; Hines, W.; Wells, B.; Woicik, J. Strain-induced change in local structure and its effect on the ferromagnetic properties of La0.5Sr0.5CoO3 thin films. Appl. Phys. Lett. 2008, 93, 182507. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.W.; Zhang, H.R.; Li, Y.; Wang, S.F.; Shen, X.; Lan, Q.Q.; Meng, S.; Yu, R.C.; Shen, B.G.; Sun, J.R. Anomalous magnetism in strained La1−xSrxCoO3 epitaxial films (0 ≤ x ≤ 0.5). Sci. Rep. 2014, 4, 6206. [Google Scholar] [CrossRef]

- Kelly, S.; Galli, F.; Aarts, J.; Bose, S.; Sharma, M.; Leighton, C. Direct real space observation of magneto-electronic inhomogeneity in ultra-thin film La0.5Sr0.5CoO3−δ on SrTiO3(001). Appl. Phys. Lett. 2014, 105, 112909. [Google Scholar] [CrossRef] [Green Version]

- Yi, D.; Lu, N.; Chen, X.; Shen, S.; Yu, P. Engineering magnetism at functional oxides interfaces: Manganites and beyond. J. Phys. Condens. Matter 2017, 29. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rigato, F.; Geshev, J.; Skumryev, V. The magnetization of epitaxial nanometric CoFe2O4(001) layers. J. Appl. Phys. 2009, 106. [Google Scholar] [CrossRef] [Green Version]

- Woicik, J.C.; Xie, C.K.; Wells, B.O. Effect of strain on the local perovskite structure: La0.5Sr0.5CoO3. J. Appl. Phys. 2011, 109, 083519. [Google Scholar] [CrossRef]

- Ciubotariu, O.; Semisalova, A.; Lenz, K.; Albrecht, M. Strain-induced perpendicular magnetic anisotropy and Gilbert damping of Tm3Fe5O12 thin films. Sci. Rep. 2019, 9, 17474. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sánchez-Pérez, M.; Andrés, J.P.; González, J.A.; López Antón, R.; López de la Torre, M.A.; Juan Dura, O. Substrate-Induced Strain Effect on Structural and Magnetic Properties of La0.5Sr0.5CoO3 Films. Nanomaterials 2021, 11, 781. https://doi.org/10.3390/nano11030781

Sánchez-Pérez M, Andrés JP, González JA, López Antón R, López de la Torre MA, Juan Dura O. Substrate-Induced Strain Effect on Structural and Magnetic Properties of La0.5Sr0.5CoO3 Films. Nanomaterials. 2021; 11(3):781. https://doi.org/10.3390/nano11030781

Chicago/Turabian StyleSánchez-Pérez, Miriam, Juan Pedro Andrés, Juan Antonio González, Ricardo López Antón, Marco Antonio López de la Torre, and Oscar Juan Dura. 2021. "Substrate-Induced Strain Effect on Structural and Magnetic Properties of La0.5Sr0.5CoO3 Films" Nanomaterials 11, no. 3: 781. https://doi.org/10.3390/nano11030781