Effect of Morphologically Controlled Hematite Nanoparticles on the Properties of Fly Ash Blended Cement

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis and Characterization of α-Fe2O3

2.3. FA Blended Cement Preparation

2.4. Hydration Analysis

2.5. Workability and Compressive Strength

2.5.1. Setting Time

2.5.2. Mini-Slump Test and Flow Table Test

2.5.3. Compressive Strength

2.6. Morphology of Cement Paste

3. Results and Discussion

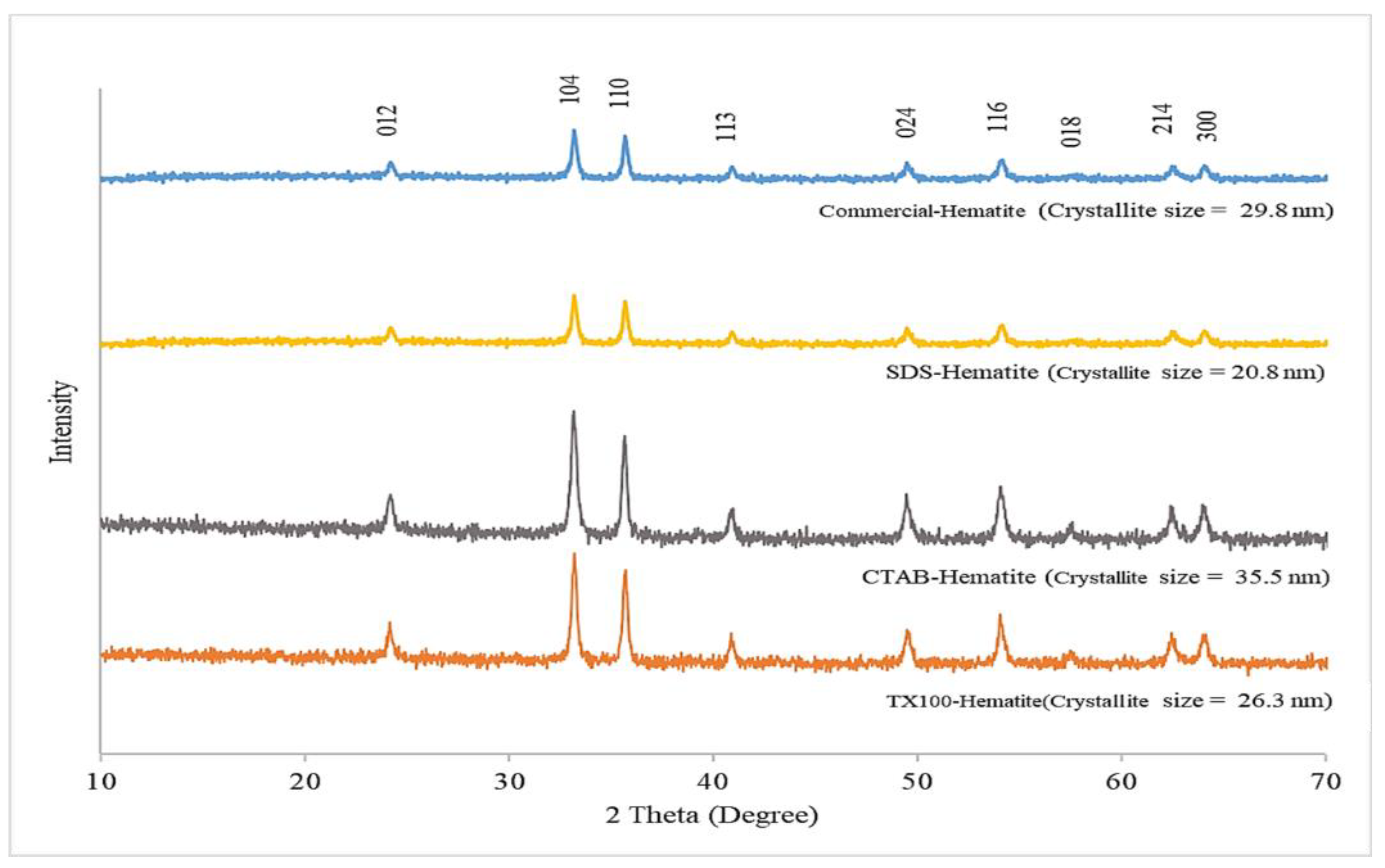

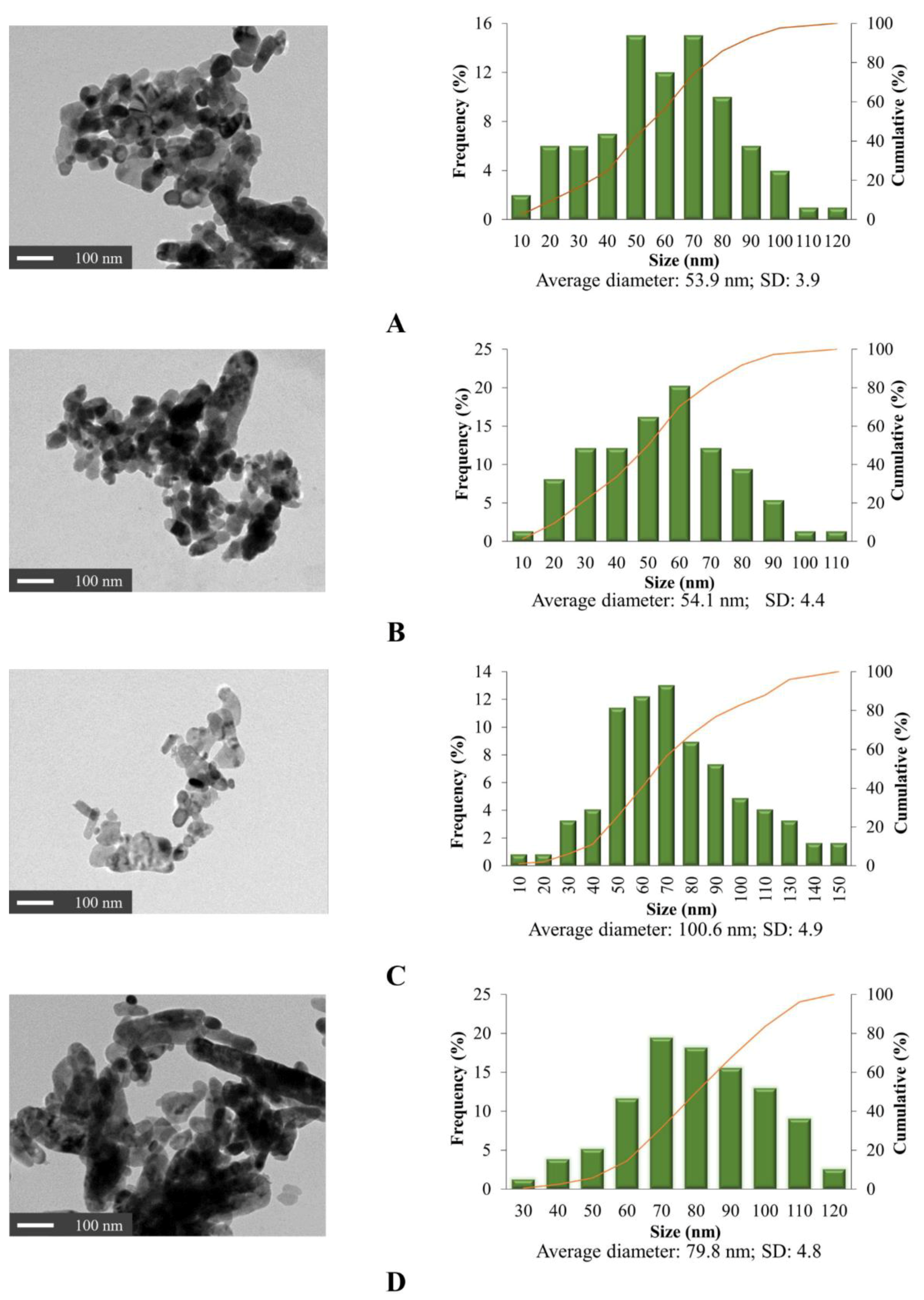

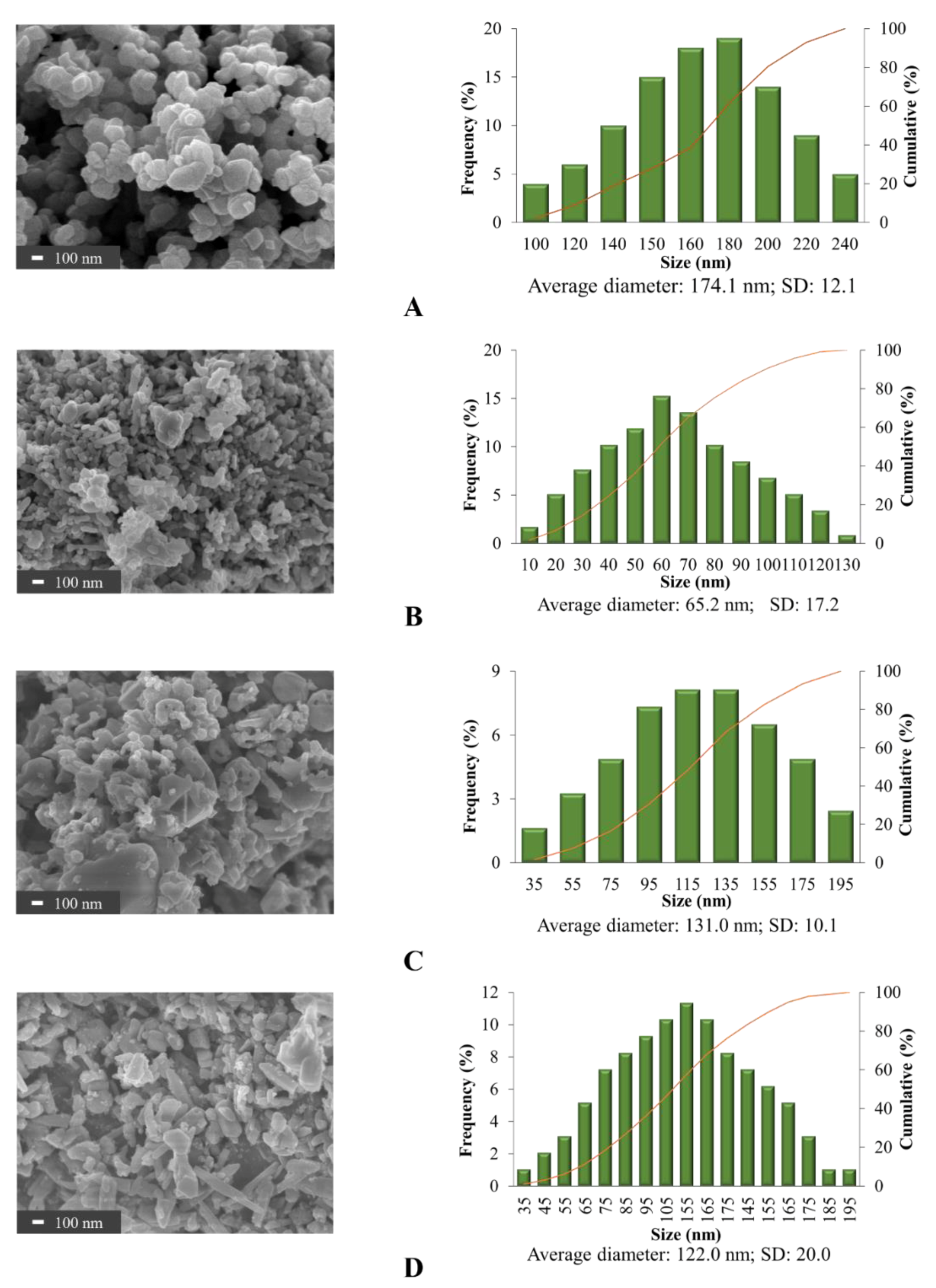

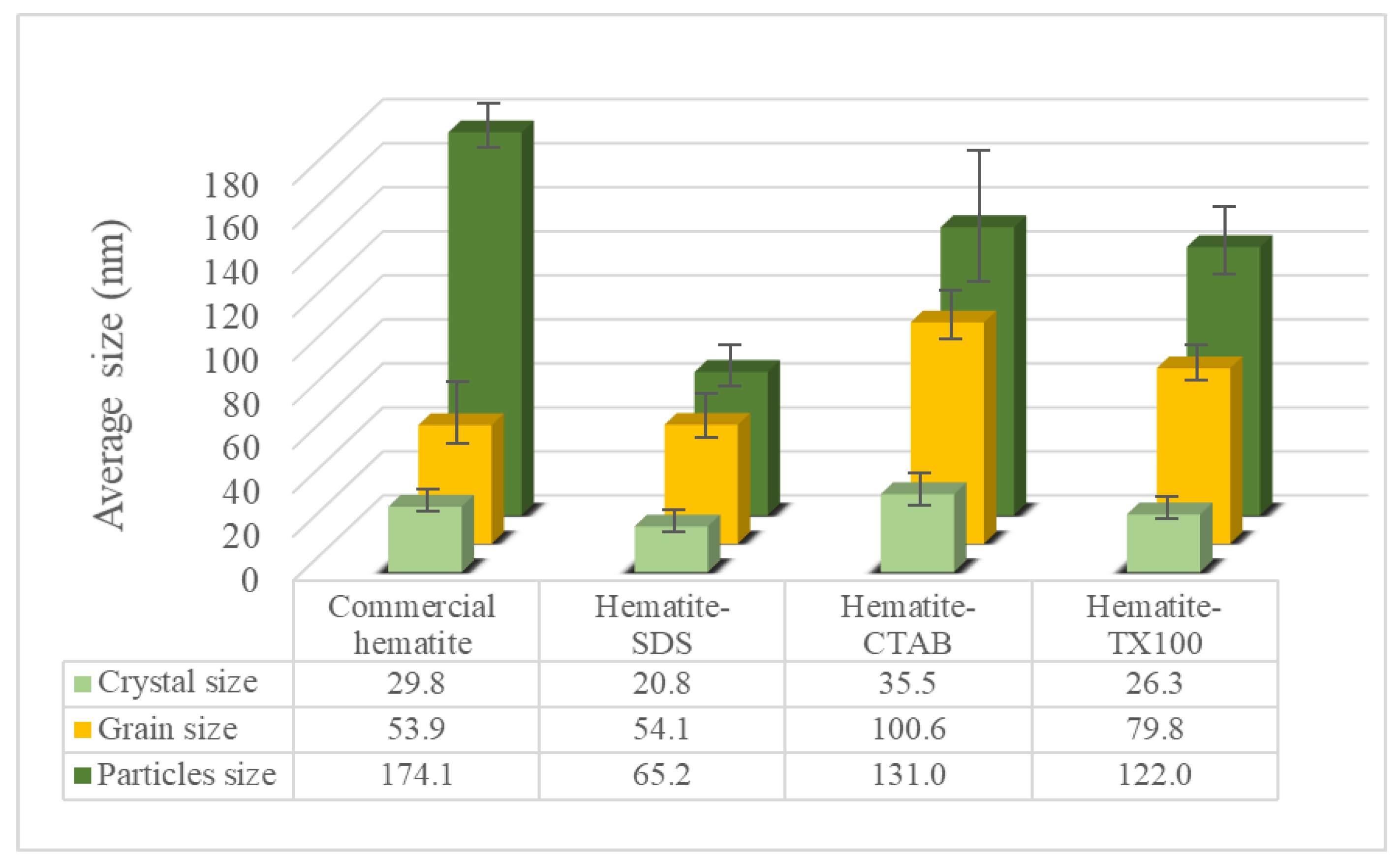

3.1. Synthesized α-Fe2O3 Characterization

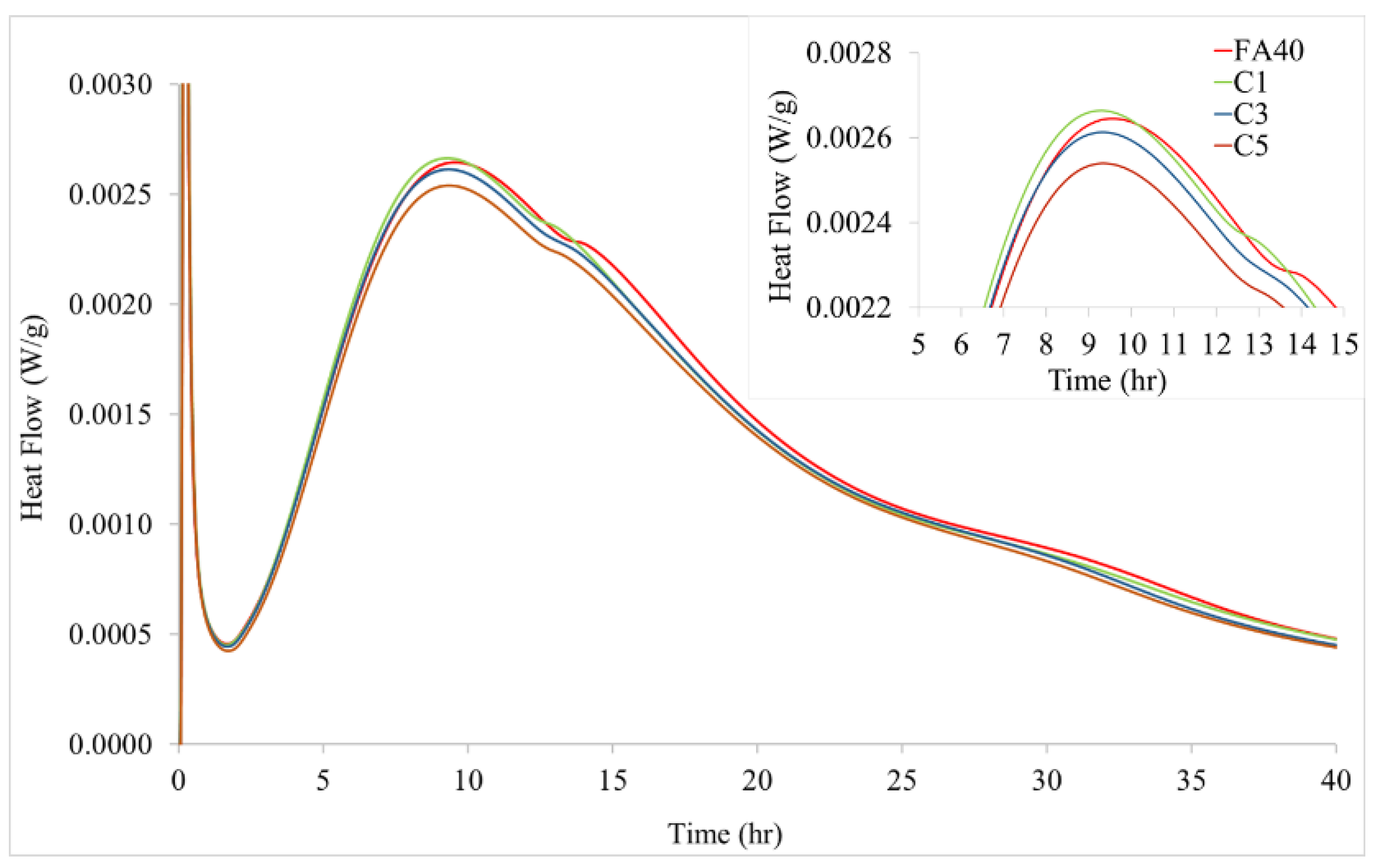

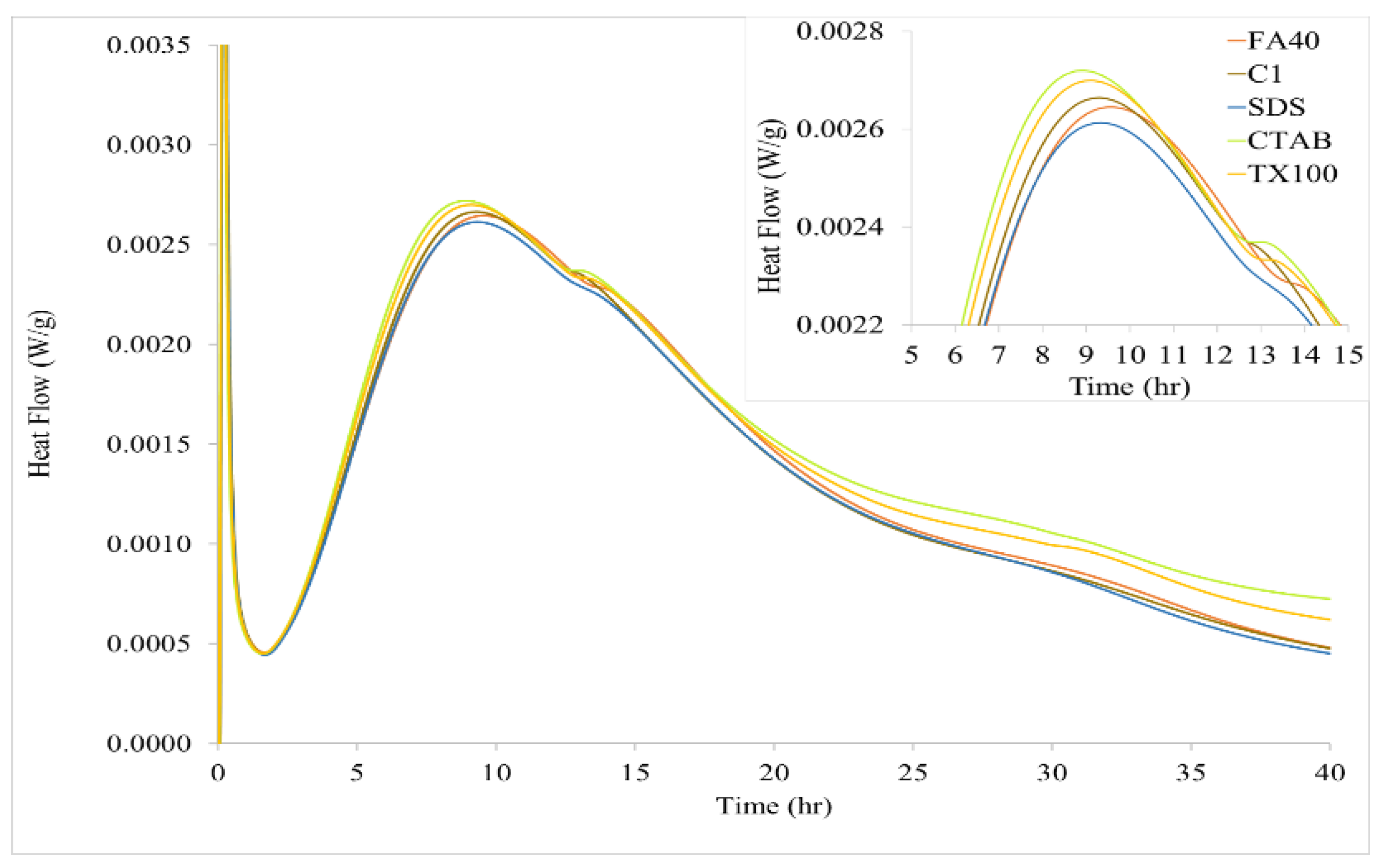

3.2. Hydration of FA Blended Cement: Effect of Amount and Types of α-Fe2O3 Addition

3.3. Workability and Compressive Strength of FA Blended Cement: Effect of α-Fe2O3 Addition

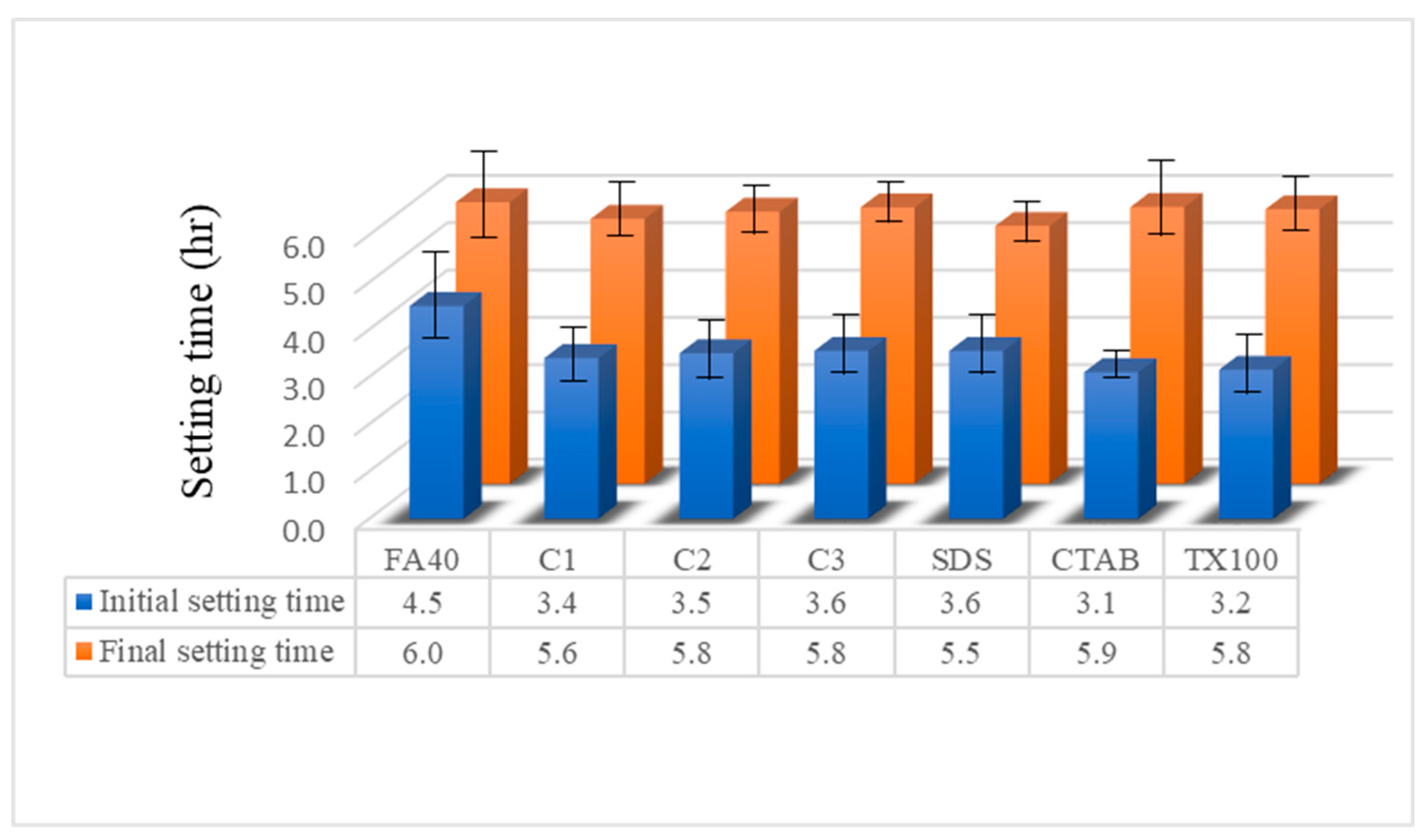

3.3.1. Setting Time

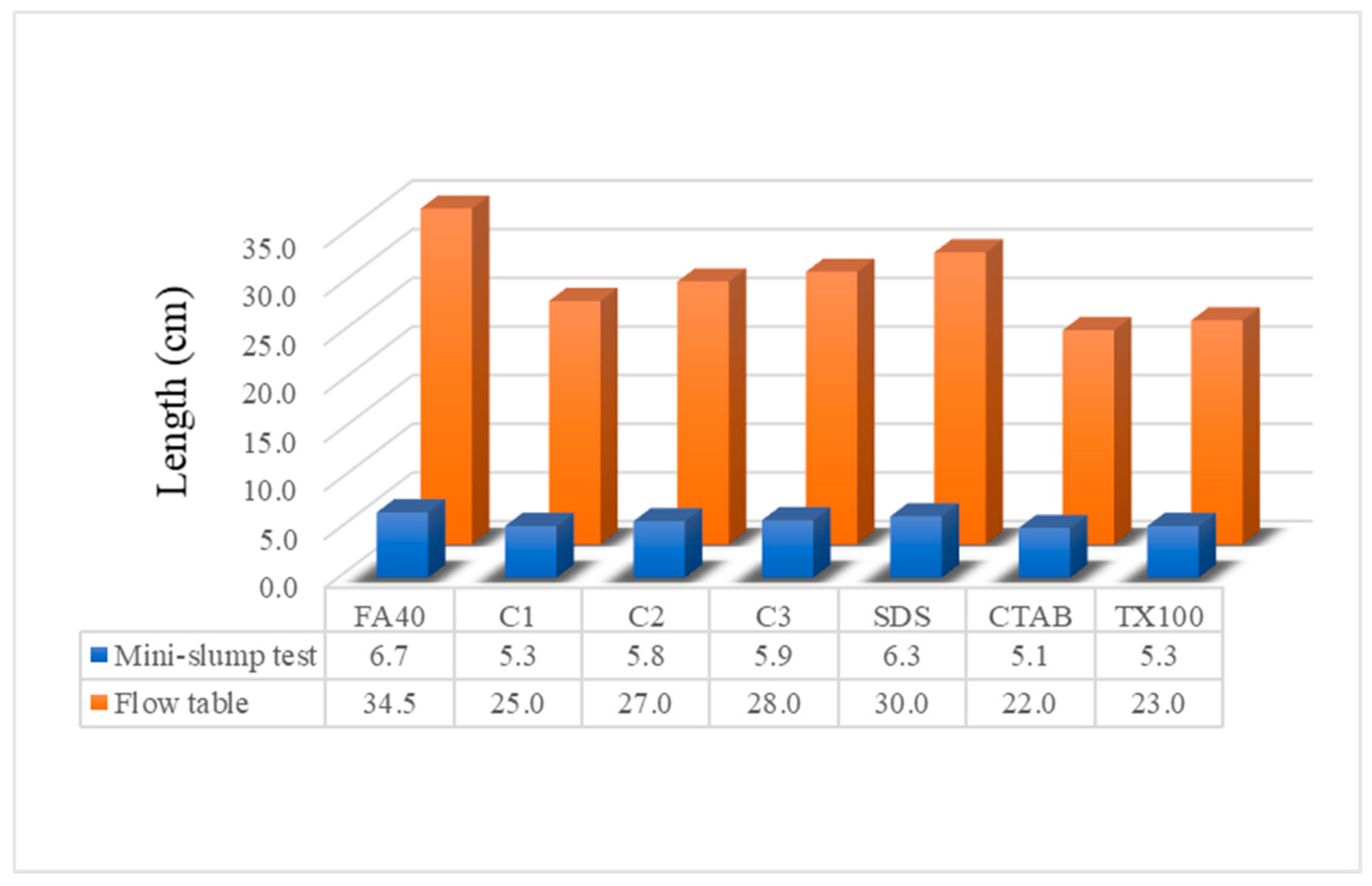

3.3.2. Mini-Slump Test and Flow Table

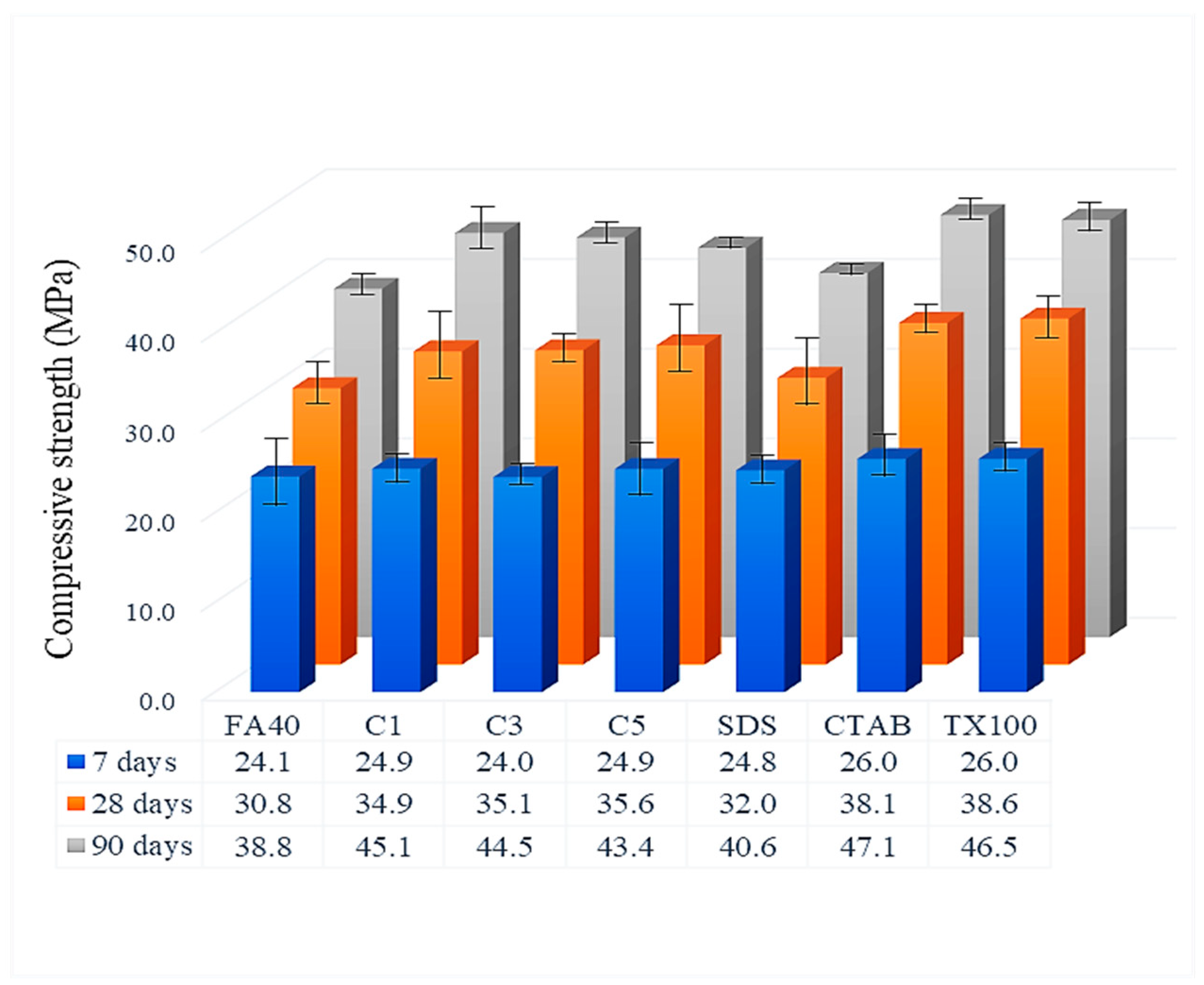

3.3.3. Compressive Strength

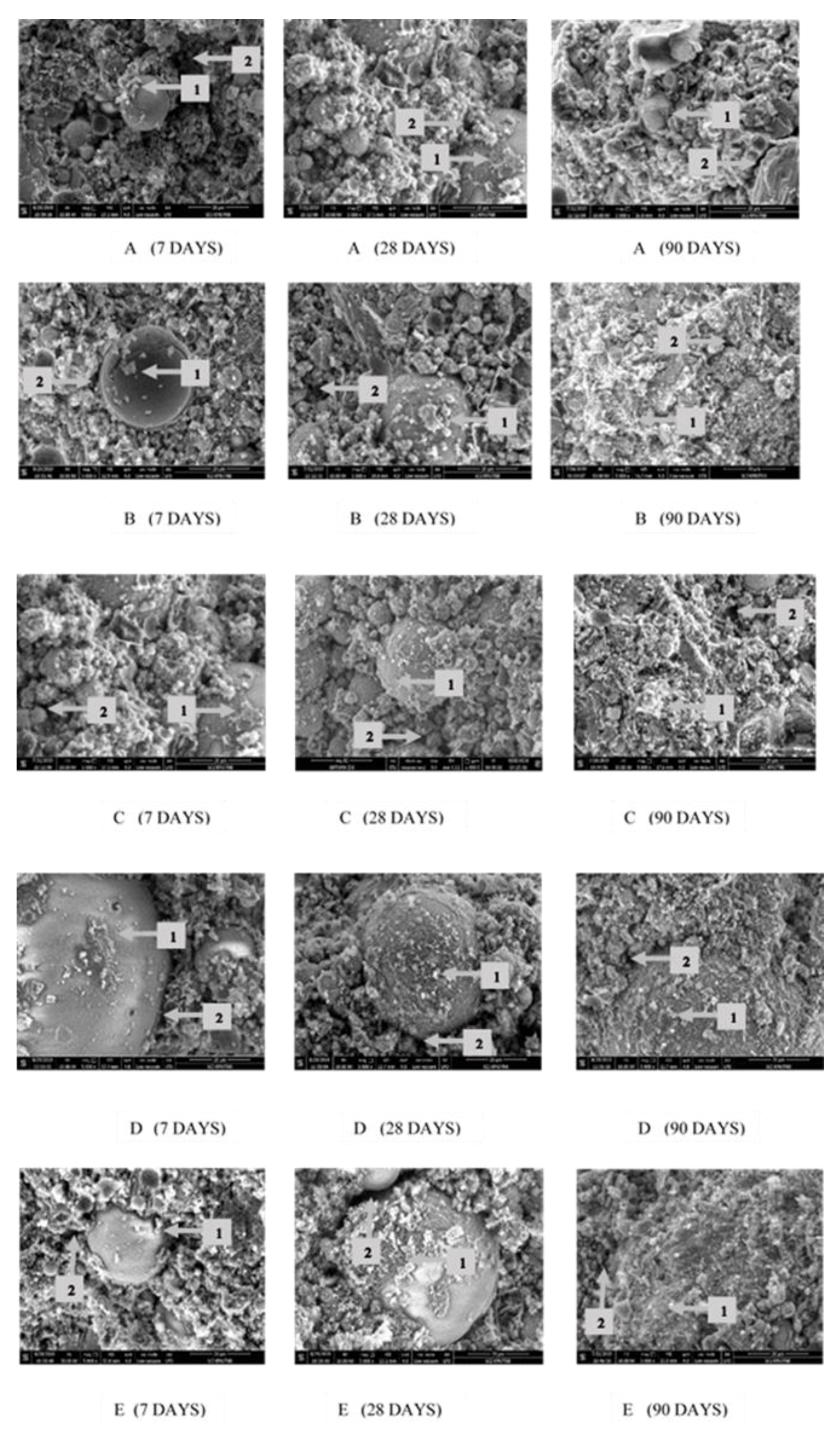

3.4. Microstructural Analysis of FA Blended Cement Added α-Fe2O3 by SEM Images

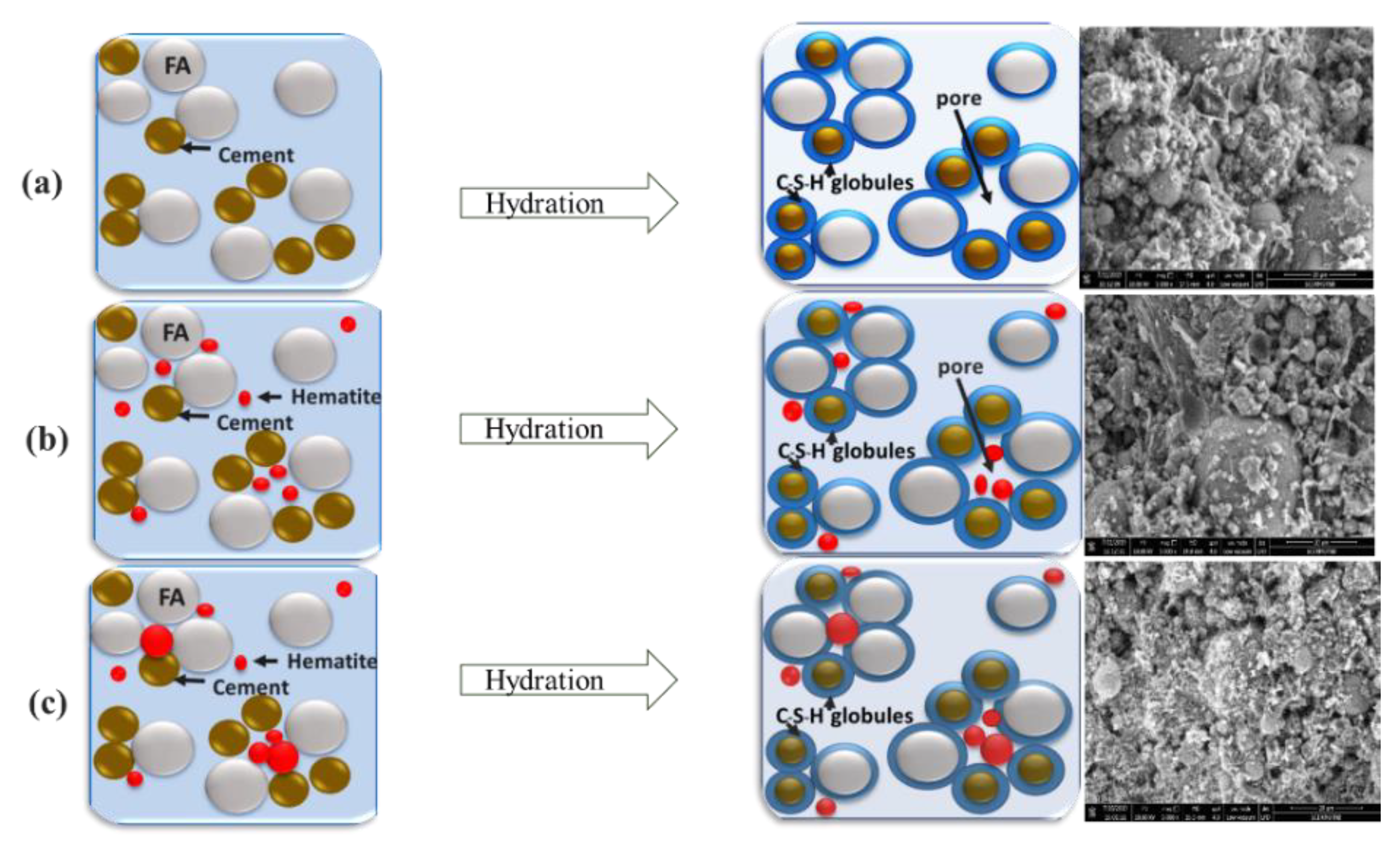

3.5. Structural Model of α-Fe2O3 Nanoparticle Modified FA Cement

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| α-Fe2O3 | Hematite nanoparticles |

| OPC | Ordinary Portland Cement |

| FA | Fly ash |

| C3A | Tricalcium aluminate or 3CaO.Al2O3 |

| C3S | Alite or 3CaO.SiO2 |

| C2S | Belite or 2CaO.SiO2 |

| C-S-H gel | Calcium-silicate-hydrate gel |

| CAS− | Calcium sulfoaluminate or Ca4Al2(SO4)(OH)12.6H2O |

| C4AF | Ferrite phase or 4CaO.Al2O3.Fe2O3 |

References

- Paul, S.C.; Van Rooyen, A.S.; Van Zijl, G.P.; Petrik, L.F. Properties of cement-based composites using nanoparticles: A comprehensive review. Constr. Build. Mater. 2018, 189, 1019–1034. [Google Scholar] [CrossRef]

- Balapour, M.; Joshaghani, A.; Althoey, F. Nano-SiO2 contribution to mechanical, durability, fresh and microstructural characteristics of concrete: A review. Constr. Build. Mater. 2018, 181, 27–41. [Google Scholar] [CrossRef]

- Demirboğa, R. Influence of mineral admixtures on thermal conductivity and compressive strength of mortar. Energy Build. 2003, 35, 4. [Google Scholar] [CrossRef]

- Subramanian, N. Introduction to Reinforced Concrete. In Design of Reinforced Concrete Structures; Harper & Row: New York, NY, USA, 2013. [Google Scholar]

- Chindaprasirt, P.; Jaturapitakkul, C.; Sinsiri, T. Effect of fly ash fineness on compressive strength and pore size of blended cement paste. Cem. Concr. Compos. 2005, 27, 425–428. [Google Scholar] [CrossRef]

- Zeng, Q.; Li, K.; Fen-Chong, T.; Dangla, P. Pore structure characterization of cement pastes blended with high-volume fly-ash. Cem. Concr. Res. 2012, 42, 194–204. [Google Scholar] [CrossRef]

- Feng, J.; Sun, J.; Yan, P. The Influence of Ground Fly Ash on Cement Hydration and Mechanical Property of Mortar. Adv. Civ. Eng. 2018, 2018, 4023178. [Google Scholar] [CrossRef]

- Siddique, R. Effect of fine aggregate replacement with Class F fly ash on the abrasion resistance of concrete. Cem. Concr. Res. 2003, 33, 1877–1881. [Google Scholar] [CrossRef]

- Wang, H.; Li, H.; Liang, X.; Zhou, H.; Xie, N.; Dai, Z. Investigation on the mechanical properties and environmental impacts of pervious concrete containing fly ash based on the cement-aggregate ratio. Constr. Build. Mater. 2019, 202, 387–395. [Google Scholar] [CrossRef]

- Artioli, G.; Bullard, J.W. Cement hydration: The role of adsorption and crystal growth. Cryst. Res. Technol. 2013, 48, 903–918. [Google Scholar] [CrossRef]

- Gani, M.S.J. Cement and Concrete; CRC Press: Boca Raton, FL, USA, 1997. [Google Scholar]

- Yuenyongsuwan, J.; Sinthupinyo, S.; O’Rear, E.A.; Pongprayoon, T. Hydration accelerator and photocatalyst of nanotitanium dioxide synthesized via surfactant-assisted method in cement mortar. Cem. Concr. Compos. 2019, 96, 182–193. [Google Scholar] [CrossRef]

- Scrivener, K.; Ouzia, A.; Juilland, P.; Mohamed, A.K. Advances in understanding cement hydration mechanisms. Cem. Concr. Res. 2019, 124. [Google Scholar] [CrossRef]

- Scrivener, K.L.; Juilland, P.; Monteiro, P.J. Advances in understanding hydration of Portland cement. Cem. Concr. Res. 2015, 78, 38–56. [Google Scholar] [CrossRef]

- Kocaba, V.; Gallucci, E.; Scrivener, K.L. Methods for determination of degree of reaction of slag in blended cement pastes. Cem. Concr. Res. 2012, 42, 511–525. [Google Scholar] [CrossRef]

- Monteagudo, S.; Moragues, A.; Gálvez, J.; Casati, M.; Reyes, E. The degree of hydration assessment of blended cement pastes by differential thermal and thermogravimetric analysis. Morphological evolution of the solid phases. Thermochim. Acta 2014, 592, 37–51. [Google Scholar] [CrossRef]

- Vidhya, R.D.K. An Experimental Investigation on Strength Characteristic of High Density Concrete Incorporating Hematite. Int. J. Innov. Res. Sci. Technol. 2015, 2, 6. [Google Scholar]

- Tobbala, D. Effect of Nano-ferrite addition on mechanical properties and gamma ray attenuation coefficient of steel fiber reinforced heavy weight concrete. Constr. Build. Mater. 2019, 207, 48–58. [Google Scholar] [CrossRef]

- Li, H.; Xiao, H.-G.; Yuan, J.; Ou, J. Microstructure of cement mortar with nano-particles. Compos. Part B Eng. 2004, 35, 185–189. [Google Scholar] [CrossRef]

- Jennings, H.M.; Kumar, A.; Sant, G. Quantitative discrimination of the nano-pore-structure of cement paste during drying: New insights from water sorption isotherms. Cem. Concr. Res. 2015, 76, 27–36. [Google Scholar] [CrossRef]

- Babay, S.; Mhiri, T.; Toumi, M. Synthesis, structural and spectroscopic characterizations of maghemite γ-Fe2O3 prepared by one-step coprecipitation route. J. Mol. Struct. 2015, 1085, 286–293. [Google Scholar] [CrossRef]

- Tadic, M.; Panjan, M.; Damnjanovic, V.; Milosevic, I. Magnetic properties of hematite (α-Fe2O3) nanoparticles prepared by hydrothermal synthesis method. Appl. Surf. Sci. 2014, 320, 183–187. [Google Scholar] [CrossRef]

- Kongsat, P.; Kudkaew, K.; Tangjai, J.; O’Rear, E.A.; Pongprayoon, T. Synthesis of structure-controlled hematite nanoparticles by a surfactant-assisted hydrothermal method and property analysis. J. Phys. Chem. Solids 2021, 148, 109685. [Google Scholar] [CrossRef]

- Vaidya, S.; Ganguli, A.K. Microemulsion Methods for Synthesis of Nanostructured Materials. Compr. Nanosci. Nanotechnol. 2019, 1–12. [Google Scholar] [CrossRef]

- Shaikuthali, S.A.; Mannan, M.A.; Dawood, E.T.; Teo, D.C.L.; Ahmadi, R.; Ismail, I. Workability and compressive strength properties of normal weight concrete using high dosage of fly ash as cement replacement. J. Build. Pathol. Rehabil. 2019, 4, 26. [Google Scholar] [CrossRef]

- Gilson, R.; Lomboy, K.W.; Sundararajan, S. Nanoscale Characterization of Cementitious Materials. In Nanotechnology in Construction Proceedings of NICOM5; Sobolev, S.P.S.K., Ed.; Springer International Publishing: Heidelberg, Germany, 2015; p. 45. [Google Scholar]

- Kim, S.-J.; Yang, K.-H.; Moon, G.-D. Hydration Characteristics of Low-Heat Cement Substituted by Fly Ash and Limestone Powder. Materials 2015, 8, 5847–5861. [Google Scholar] [CrossRef]

- Elahi, A.; Basheer, P.; Nanukuttan, S.; Khan, Q. Mechanical and durability properties of high performance concretes containing supplementary cementitious materials. Constr. Build. Mater. 2010, 24, 292–299. [Google Scholar] [CrossRef]

- Atkin, R.; Craig, V.; Wanless, E.; Biggs, S. Mechanism of cationic surfactant adsorption at the solid–aqueous interface. Adv. Colloid Interface Sci. 2003, 103, 219–304. [Google Scholar] [CrossRef]

- Lu, Y.; Yue, Z.; Xie, J.; Wang, W.; Zhu, H.; Zhang, E.; Cao, Z. Micelles with ultralow critical micelle concentration as carriers for drug delivery. Nat. Biomed. Eng. 2018, 2, 318–325. [Google Scholar] [CrossRef]

- Das, N.C.; Cao, H.; Kaiser, H.; Warren, G.T.; Gladden, J.R.; Sokol, P.E. Shape and Size of Highly Concentrated Micelles in CTAB/NaSal Solutions by Small Angle Neutron Scattering (SANS). Langmuir 2012, 28, 11962–11968. [Google Scholar] [CrossRef] [PubMed]

- Paradies, H.H. Shape and size of a nonionic surfactant micelle. Triton X-100 in aqueous solution. J. Phys. Chem. 1980, 84, 599–607. [Google Scholar] [CrossRef]

- Jing, Z.; Han, D.; Wu, S. Morphological evolution of hematite nanoparticles with and without surfactant by hydrothermal method. Mater. Lett. 2005, 59, 804–807. [Google Scholar] [CrossRef]

- Colombo, C.; Palumbo, G.; Di Iorio, E.; Song, X.; Jiang, Z.; Liu, Q.; Angelico, R. Influence of hydrothermal synthesis conditions on size, morphology and colloidal properties of Hematite nanoparticles. Nano-Struct. Nano-Objects 2015, 2, 19–27. [Google Scholar] [CrossRef]

- Kiamahalleh, M.V.; Alishah, A.; Yousefi, F.; Astani, S.H.; Gholampour, A.; Kaiamahalleh, M.V. Iron oxide nanoparticle incorporated cement mortar composite: Correlation between physico-chemical and physico-mechanical properties. Mater. Adv. 2020, 1, 1835–1840. [Google Scholar] [CrossRef]

- Pustovgar, E.; Sangodkar, R.P.; Andreev, A.S.; Palacios, M.; Chmelka, B.F.; Flatt, R.J.; De Lacaillerie, J.-B.D. Understanding silicate hydration from quantitative analyses of hydrating tricalcium silicates. Nat. Commun. 2016, 7, 10952. [Google Scholar] [CrossRef]

- Cao, B.; Fan, S.; Tan, X.; Li, M.; Hu, Y. Cementitious materials modified with hematite nanoparticles for enhanced cement hydration and uranium immobilization. Environ. Sci. Nano 2017, 4, 1670–1681. [Google Scholar] [CrossRef]

- Abo-El-Enein, S.; El-Hosiny, F.; El-Gamal, S.; Amin, M.; Ramadan, M. Gamma radiation shielding, fire resistance and physicochemical characteristics of Portland cement pastes modified with synthesized Fe2O3 and ZnO nanoparticles. Constr. Build. Mater. 2018, 173, 687–706. [Google Scholar] [CrossRef]

- Kishar, E.A.; Alasqalani, M.Y.; Sarraj, Y.R.; Ahmed, D.A. The Effect of Using Commercial Red and Black Iron Oxides as a Concrete Admixtures on its Physiochemical and Mechanical Properties. Int. J. Sci. Res. 2015, 4, 5. [Google Scholar]

- Berodier, E.; Scrivener, K. Understanding the Filler Effect on the Nucleation and Growth of C-S-H. J. Am. Ceram. Soc. 2014, 97, 3764–3773. [Google Scholar] [CrossRef]

- Lin, K.L.; Chang, W.C.; Lin, D.F.; Luo, H.L.; Tsai, M.C. Effects of nano-SiO(2) and different ash particle sizes on sludge ash-cement mortar. J. Environ. Manag. 2008, 88, 708–714. [Google Scholar] [CrossRef]

- Li, H.; Ding, S.; Zhang, L.; Ouyang, J.; Hna, B. Effects of particle size, crystal phase and surface treatment of nano-TiO2 on the rheological parameters of cement paste. Constr. Build. Mater. 2020, 239, 117897. [Google Scholar] [CrossRef]

- Wang, Y.; Jin, Z.; Liu, S.; Yang, L.; Luo, S. Physical filling effect of aggregate micro fines in cement concrete. Constr. Build. Mater. 2013, 41, 812–814. [Google Scholar] [CrossRef]

- Zhao, M.; Zhang, X.; Zhang, Y. Effect of free water on the flowability of cement paste with chemical or mineral admixtures. Constr. Build. Mater. 2016, 111, 571–579. [Google Scholar] [CrossRef]

- Mehdipour, I.; Khayat, K.H. Effect of particle-size distribution and specific surface area of different binder systems on packing density and flow characteristics of cement paste. Cem. Concr. Compos. 2017, 78, 120–131. [Google Scholar] [CrossRef]

- Ali Nazari, S.R.; Riahi, S.; Shamekhi, S.F.; Khademno, A. Benefits of Fe2O3 nanoparticles in concrete mixing matrix. J. Am. Sci. 2010, 6, 5. [Google Scholar]

- Abd Elaty, M.A.A. Compressive strength prediction of Portland cement concrete with age using a new model. HBRC J. 2019, 10, 145–155. [Google Scholar] [CrossRef]

- Ghazanlou, S.I.; Jalaly, M.; Sadeghzadeh, S.; Korayem, A.H. A comparative study on the mechanical, physical and morphological properties of cement-micro/nanoFe3O4 composite. Sci. Rep. 2020, 10, 2859. [Google Scholar] [CrossRef]

- Chung, C.-W.; Chun, J.; Wang, G.; Um, W. Effects of iron oxides on the rheological properties of cementitious slurry. Colloids Surf. A Physicochem. Eng. Asp. 2014, 453, 94–100. [Google Scholar] [CrossRef]

- Shi, C.; Day, R.L. Pozzolanic reaction in the presence of chemical activators Part II. Reaction products and mechanism. Cem. Concr. Res. 2000, 30, 607–613. [Google Scholar]

- Manfroi, E.P.; Cheriaf, M.; Rocha, J.C. Microstructure, mineralogy and environmental evaluation of cementitious composites produced with red mud waste. Constr. Build. Mater. 2014, 67, 29–36. [Google Scholar] [CrossRef]

- Zarzuela, R.; Luna, M.; Carrascosa, L.M.; Yeste, M.P.; Garcia-Lodeiro, I.; Blanco-Varela, M.T.; Cauqui, M.A.; Rodríguez-Izquierdo, J.M.; Mosquera, M.J. Producing C-S-H gel by reaction between silica oligomers and portlandite: A promising approach to repair cementitious materials. Cem. Concr. Res. 2020, 130, 106008. [Google Scholar] [CrossRef]

- Yazdi, N.A.; Arefi, M.R.; Mollaahmadi, E.; Nejand, B.A. To study the effect of adding Fe2O3 nanoparticles on the morphology properties and microstructure of cement mortar. Life Sci. J. 2011, 8, 5. [Google Scholar]

- Ng, D.S.; Paul, S.C.; Anggraini, V.; Kong, S.Y.; Qureshi, T.S.; Rodriguez, C.R.; Liu, Q.-F.; Šavija, B. Influence of SiO2, TiO2 and Fe2O3 nanoparticles on the properties of fly ash blended cement mortars. Constr. Build. Mater. 2020, 258, 119627. [Google Scholar]

| Sample Name | Proportions | ||

|---|---|---|---|

| OPC | Fly Ash | Amount and Type of α-Fe2O3 | |

| FA40 | 60% | 40% | No α -Fe2O3 used as reference |

| C1 | 59% | 40% | 1.0% commercial α-Fe2O3 |

| C3 | 57% | 40% | 3.0% commercial α-Fe2O3 |

| C5 | 55% | 40% | 5.0% commercial α-Fe2O3 |

| SDS | 59% | 40% | 1.0% α-Fe2O3 synthesized with SDS |

| CTAB | 59% | 40% | 1.0% α-Fe2O3 synthesized with CTAB |

| TX100 | 59% | 40% | 1.0% α-Fe2O3 synthesized with Triton X 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kongsat, P.; Sinthupinyo, S.; O’Rear, E.A.; Pongprayoon, T. Effect of Morphologically Controlled Hematite Nanoparticles on the Properties of Fly Ash Blended Cement. Nanomaterials 2021, 11, 1003. https://doi.org/10.3390/nano11041003

Kongsat P, Sinthupinyo S, O’Rear EA, Pongprayoon T. Effect of Morphologically Controlled Hematite Nanoparticles on the Properties of Fly Ash Blended Cement. Nanomaterials. 2021; 11(4):1003. https://doi.org/10.3390/nano11041003

Chicago/Turabian StyleKongsat, Pantharee, Sakprayut Sinthupinyo, Edgar A. O’Rear, and Thirawudh Pongprayoon. 2021. "Effect of Morphologically Controlled Hematite Nanoparticles on the Properties of Fly Ash Blended Cement" Nanomaterials 11, no. 4: 1003. https://doi.org/10.3390/nano11041003

APA StyleKongsat, P., Sinthupinyo, S., O’Rear, E. A., & Pongprayoon, T. (2021). Effect of Morphologically Controlled Hematite Nanoparticles on the Properties of Fly Ash Blended Cement. Nanomaterials, 11(4), 1003. https://doi.org/10.3390/nano11041003