Antimicrobial Nanofiber Based Filters for High Filtration Efficiency Respirators

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Solution Preparation and Characterization

2.3. Electrospinning

2.4. Mat Morphology

2.5. Antimicrobial Activity

2.6. Filter Performance

3. Results and Discussion

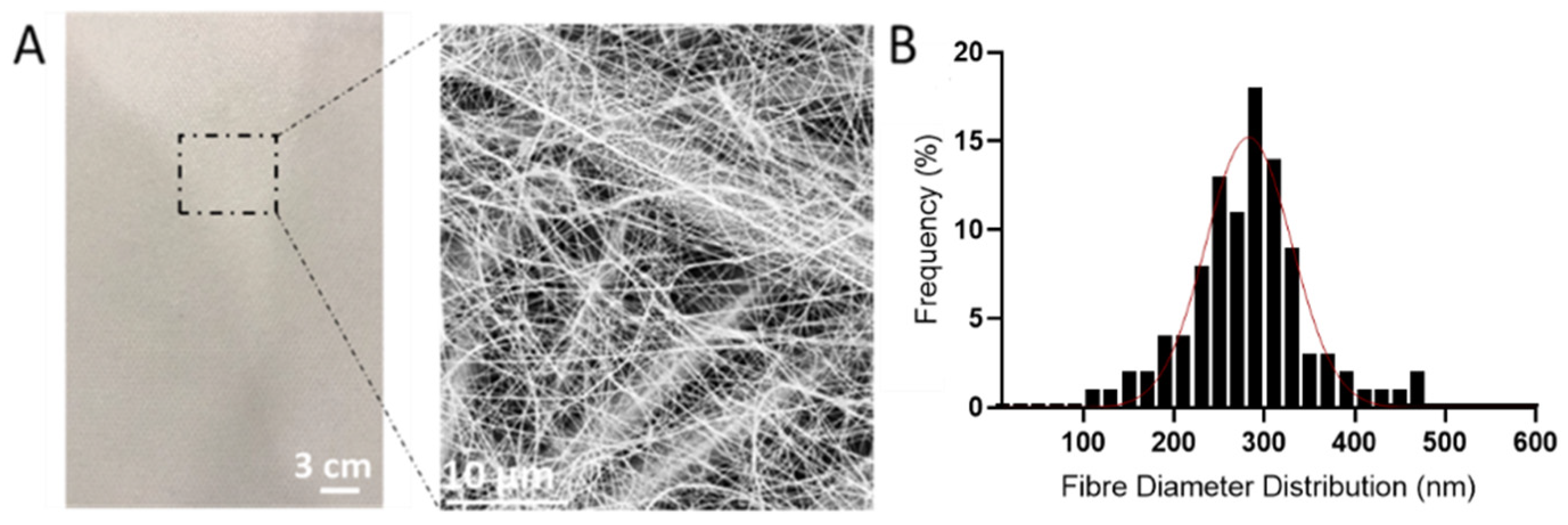

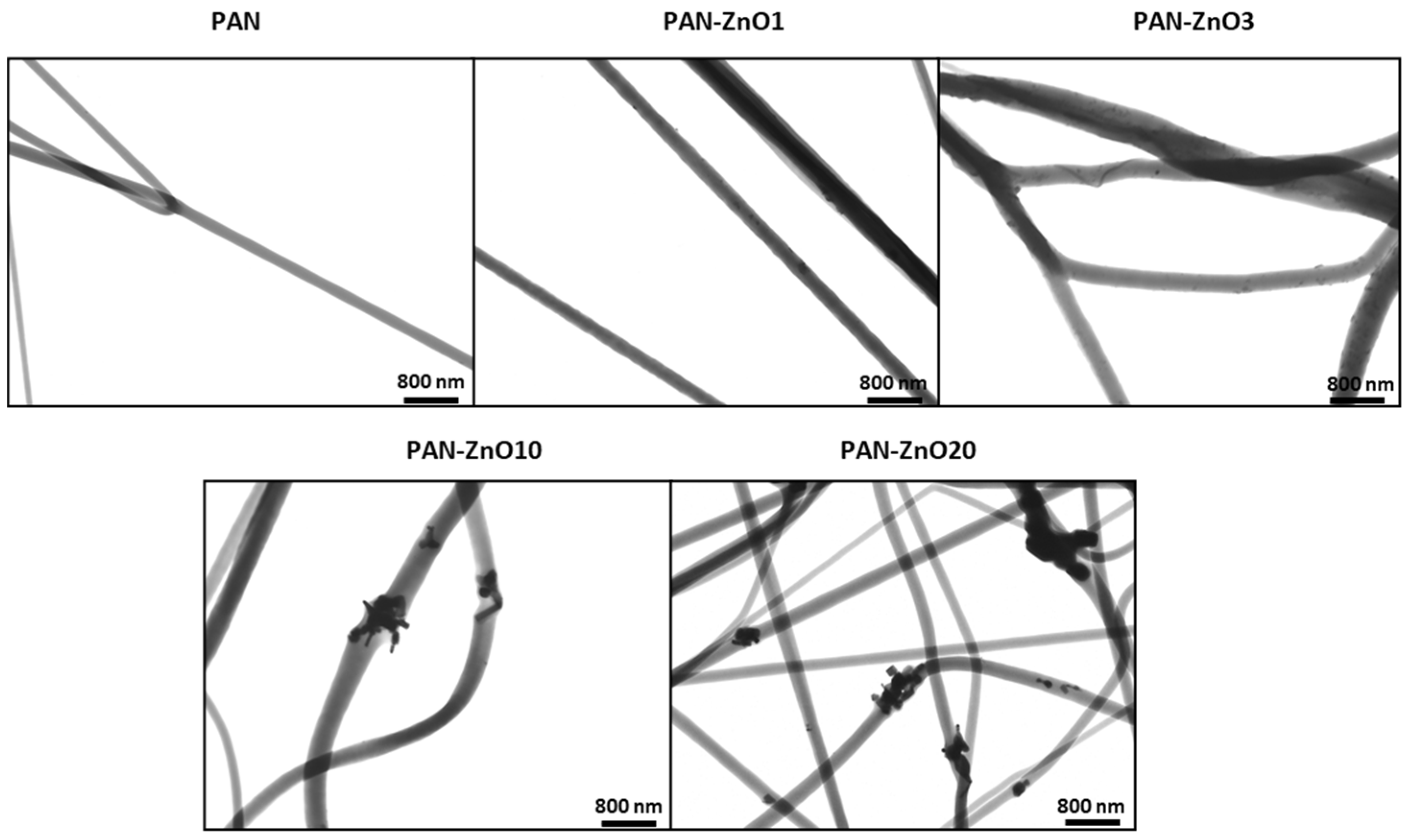

3.1. Fiber Morphology

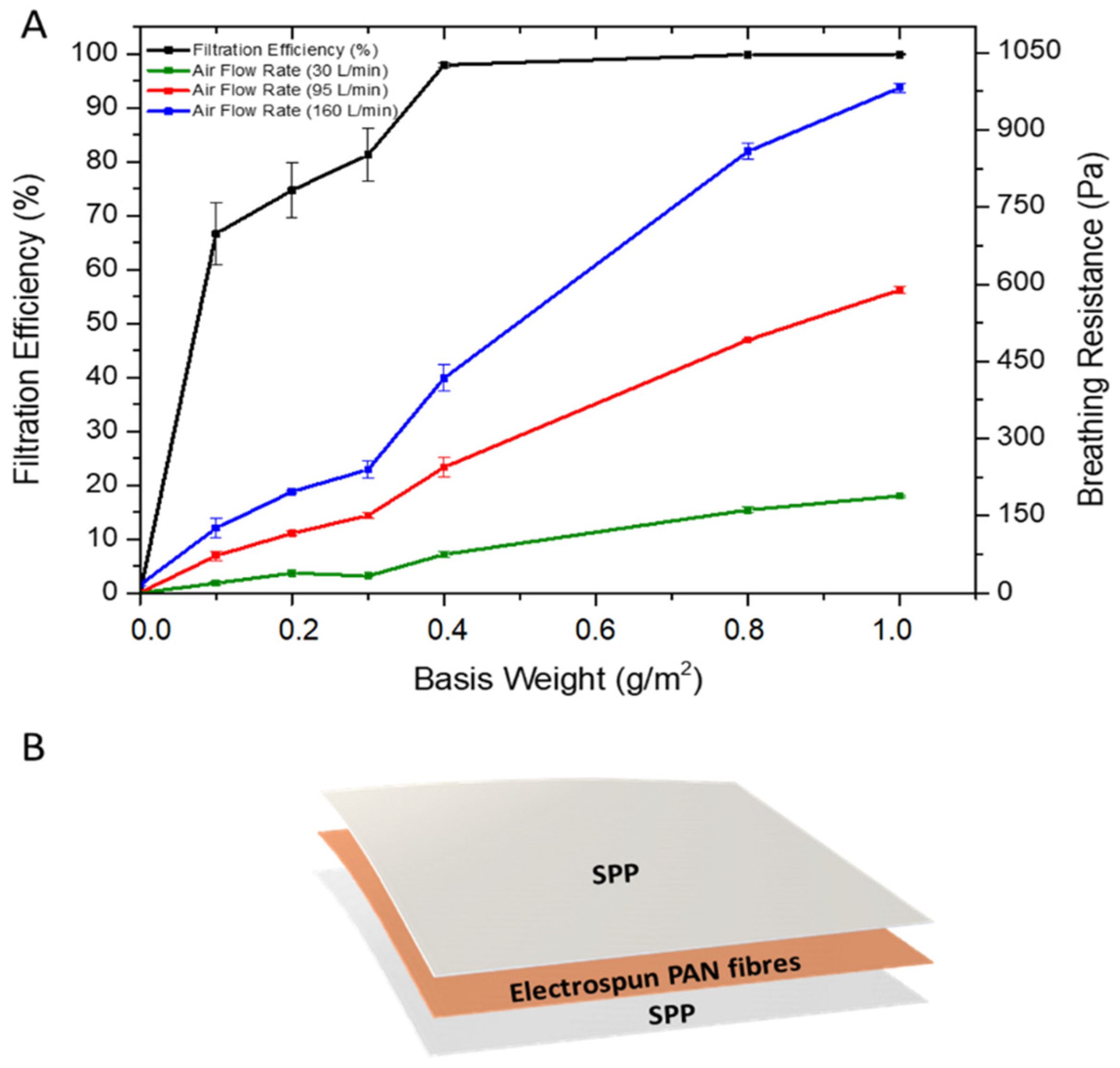

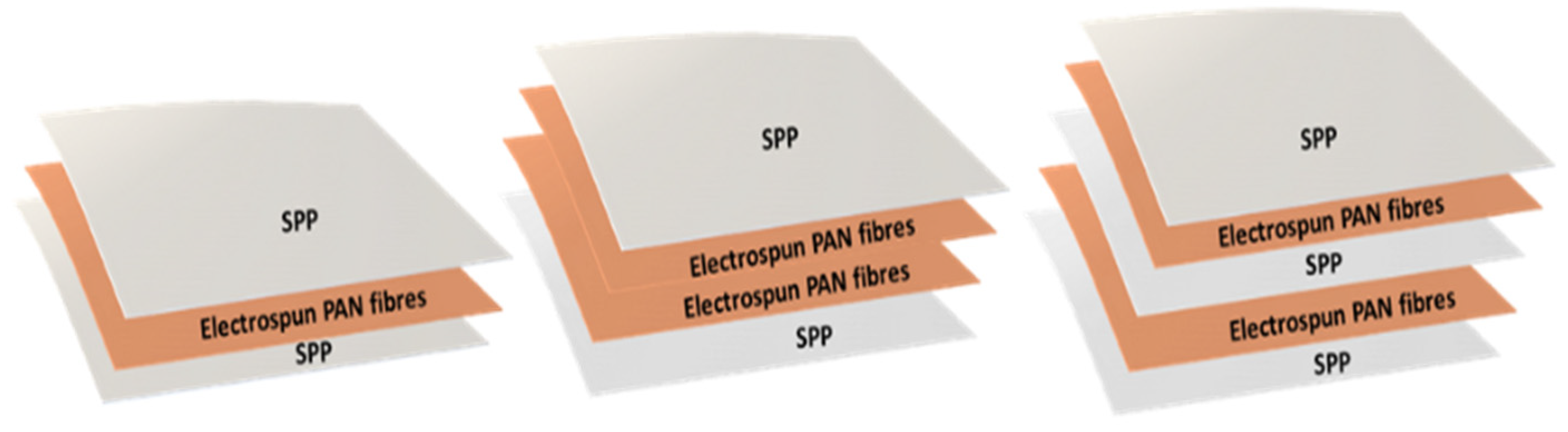

3.2. Filter Performance Using Mono and Multilayer Electrospun Fibers

3.3. Antimicrobial Activity of the Multilayer Electrospun Filters

3.4. Filtration Performance of the Antimicrobial Multilayer Filters

4. Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Leung, W.W.F.; Sun, Q. Electrostatic charged nanofiber filter for filtering airborne novel coronavirus (COVID-19) and nano-aerosols. Sep. Purif. Technol. 2020, 250, 116886. [Google Scholar] [CrossRef]

- Glass, C.A.; Cash, J.C.; Mullen, J. Coronavirus Disease (COVID-19). Fam. Pract. Guidel. 2020. [Google Scholar] [CrossRef]

- European Centre for Disease Prevention and Control: An Agency of the European Union. Available online: https://www.ecdc.europa.eu/en/geographical-distribution-2019-ncov-cases (accessed on 17 November 2020).

- Chan, J.F.W.; To, K.K.W.; Tse, H.; Jin, D.Y.; Yuen, K.Y. Interspecies transmission and emergence of novel viruses: Lessons from bats and birds. Trends Microbiol. 2013, 10, 544–555. [Google Scholar] [CrossRef]

- Cascella, M.; Rajnik, M.; Cuomo, A.; Dulebohn, S.C.; Di Napoli, R. Features, Evaluation and Treatment Coronavirus (COVID-19); StatPearls Publishing LLC.: Treasure Island, FL, USA, 2021. [Google Scholar]

- Guo, Y.R.; Cao, Q.D.; Hong, Z.S.; Tan, Y.Y.; Chen, S.D.; Jin, H.J.; Tan, K.S.; Wang, D.Y.; Yan, Y. The origin, transmission and clinical therapies on coronavirus disease 2019 (COVID-19) outbreak- A n update on the status. Mil. Med. Res. 2020, 7, 1–10. [Google Scholar] [CrossRef]

- Shereen, M.A.; Khan, S.; Kazmi, A.; Bashir, N.; Siddique, R. COVID-19 infection: Origin, transmission, and characteristics of human coronaviruses. J. Adv. Res. 2020, 24, 91–98. [Google Scholar] [CrossRef]

- Nicola, M.; Alsafi, Z.; Sohrabi, C.; Kerwan, A.; Al-Jabir, A.; Iosifidis, C.; Agha, M.; Agha, R. The socio-economic implications of the coronavirus pandemic (COVID-19): A review. Int. J. Surg. 2020, 78, 185–193. [Google Scholar] [CrossRef]

- BOE-A-2020-5142 Boletín Oficial del Estado. 2020, Volume 142, pp. 33600–33602. Available online: https://www.boe.es/eli/es/o/2020/05/19/snd422 (accessed on 19 May 2020).

- Li, J.; Zhang, D.; Jiang, X.; Zhao, X.; Hu, R.; Zhong, Y.; Zhu, H. Nest-like multilevel structured graphene oxide-on-polyacrylonitrile membranes for highly efficient filtration of ultrafine particles. J. Mater. 2019, 5, 422–427. [Google Scholar] [CrossRef]

- Kadam, V.; Kyratzis, I.L.; Truong, Y.B.; Schutz, J.; Wang, L.; Padhye, R. Electrospun bilayer nanomembrane with hierarchical placement of bead-on-string and fibers for low resistance respiratory air filtration. Sep. Purif. Technol. 2019, 224, 247–254. [Google Scholar] [CrossRef]

- Ullah, S.; Ullah, A.; Lee, J.; Jeong, Y.; Hashmi, M.; Zhu, C.; Joo, K.I.; Cha, H.J.; Kim, I.S. Reusability Comparison of Melt-Blown vs Nanofiber Face Mask Filters for Use in the Coronavirus Pandemic. ACS Appl. Nano Mater. 2020, 3, 7231–7241. [Google Scholar] [CrossRef]

- Maze, B.; Vahedi Tafreshi, H.; Wang, Q.; Pourdeyhimi, B. A simulation of unsteady-state filtration via nanofiber media at reduced operating pressures. J. Aerosol Sci. 2007, 38, 550–571. [Google Scholar] [CrossRef]

- Akduman, C.; Akcakoca Kumbasar, E.P. Nanofibers in face masks and respirators to provide better protection. IOP Conf. Ser. Mater. Sci. Eng. 2018, 460, 012013. [Google Scholar] [CrossRef]

- Sun, Q.; Leung, W.W. Charged PVDF multi-layer filters with enhanced filtration performance for filtering nano-aerosols. Sep. Purif. Technol. 2019, 212, 854–876. [Google Scholar] [CrossRef]

- Leung, W.W.F.; Sun, Q. Charged PVDF multilayer nanofiber filter in filtering simulated airborne novel coronavirus (COVID-19) using ambient nano-aerosols. Sep. Purif. Technol. 2020, 245, 116887. [Google Scholar] [CrossRef] [PubMed]

- Vinh, N.D.; Kim, H.M. Electrospinning fabrication and performance evaluation of polyacrylonitrile nanofiber for air filter applications. Appl. Sci. 2016, 6, 235. [Google Scholar] [CrossRef]

- Khan, Z.; Kafiah, F.; Zahid Shafi, H.; Nufaiei, F.; Ahmed Furquan, S.; Matin, A. Morphology, Mechanical Properties and Surface Characteristics of Electrospun Polyacrylonitrile (PAN) Nanofiber Mats. Int. J. Adv. Eng. Nano Technol. 2015, 2, 15–22. [Google Scholar]

- Song, Y.; Wang, Y.; Xu, L.; Wang, M. Fabrication and characterization of electrospun aligned porous PAN/Graphene composite nanofibers. Nanomaterials 2019, 9, 1782. [Google Scholar] [CrossRef] [PubMed]

- Kadam, V.; Truong, Y.B.; Kyratzis, I.L.; Wang, L.; Padhye, R. Bilayer electrospun nanofibre structures to improve quality factor in air filtration. In Proceedings of the World Congress on New Technologies, Rome, Italy, 6–8 June 2017. [Google Scholar]

- Wu, J.; Wang, N.; Zhao, Y.; Jiang, L. Electrospinning of multilevel structured functional micro-/nanofibers and their applications. J. Mater. Chem. A 2013, 1, 7290. [Google Scholar] [CrossRef]

- Figueroa-Lopez, K.J.; Torres-Giner, S.; Enescu, D.; Cabedo, L.; Cerqueira, M.A.; Pastrana, L.M.; Lagaron, J.M. Electrospun active biopapers of food waste derived poly(3-hydroxybutyrate-co-3-hydroxyvalerate) with short-term and long-term antimicrobial performance. Nanomaterials 2020, 10, 506. [Google Scholar] [CrossRef]

- Bortolassi, A.C.C.; Guerra, V.G.; Aguiar, M.L.; Soussan, L.; Cornu, D.; Miele, P.; Bechelany, M. Composites based on nanoparticle and pan electrospun nanofiber membranes for air filtration and bacterial removal. Nanomaterials 2019, 9, 1740. [Google Scholar] [CrossRef]

- Song, K.; Wu, Q.; Zhang, Z.; Ren, S.; Lei, T.; Negulescu, I.I.; Zhang, Q. Porous Carbon Nanofibers from Electrospun Biomass Tar/Polyacrylonitrile/Silver Hybrids as Antimicrobial Materials. ACS Appl. Mater. Interfaces 2015, 7, 15108–15116. [Google Scholar] [CrossRef] [PubMed]

- Castro-Mayorga, J.L.; Fabra, M.J.; Lagaron, J.M. Stabilized nanosilver based antimicrobial poly(3-hydroxybutyrate-co-3-hydroxyvalerate) nanocomposites of interest in active food packaging. Innov. Food Sci. Emerg. Technol. 2016, 33, 524–533. [Google Scholar] [CrossRef]

- López de Dicastillo, C.; Patiño, C.; Galotto, M.J.; Palma, J.L.; Alburquenque, D.; Escrig, J. Novel antimicrobial titanium dioxide nanotubes obtained through a combination of atomic layer deposition and electrospinning technologies. Nanomaterials 2018, 8, 128. [Google Scholar] [CrossRef]

- Cherpinski, A.; Gozutok, M.; Sasmazel, H.T.; Torres-Giner, S.; Lagaron, J.M. Electrospun oxygen scavenging films of poly(3-hydroxybutyrate) containing palladium nanoparticles for active packaging applications. Nanomaterials 2018, 8, 469. [Google Scholar] [CrossRef]

- Padmavathy, N.; Vijayaraghavan, R. Enhanced bioactivity of ZnO nanoparticles—An antimicrobial study. Sci. Technol. Adv. Mater. 2008, 9, 035004. [Google Scholar] [CrossRef]

- Espitia, P.J.P.; Soares, N. de F.F.; Coimbra, J.S. dos R.; de Andrade, N.J.; Cruz, R.S.; Medeiros, E.A.A. Zinc Oxide Nanoparticles: Synthesis, Antimicrobial Activity and Food Packaging Applications. Food Bioprocess Technol. 2012, 5, 1447–1464. [Google Scholar] [CrossRef]

- Ditaranto, N.; Basoli, F.; Trombetta, M.; Cioffi, N.; Rainer, A. Electrospun nanomaterials implementing antibacterial inorganic nanophases. Appl. Sci. 2018, 8, 1643. [Google Scholar] [CrossRef]

- Kowsalya, E.; MosaChristas, K.; Balashanmugam, P.; Rani, J.C. Biocompatible silver nanoparticles/poly(vinyl alcohol) electrospun nanofibers for potential antimicrobial food packaging applications. Food Packag. Shelf Life 2019, 21. [Google Scholar] [CrossRef]

- Martínez-Abad, A.; Lagaron, J.M.; Ocio, M.J. Development and characterization of silver-based antimicrobial ethylene-vinyl alcohol copolymer (EVOH) films for food-packaging applications. J. Agric. Food Chem. 2012, 30, 5350–5359. [Google Scholar] [CrossRef]

- Figueroa-Lopez, K.; Castro-Mayorga, J.; Andrade-Mahecha, M.; Cabedo, L.; Lagaron, J. Antibacterial and Barrier Properties of Gelatin Coated by Electrospun Polycaprolactone Ultrathin Fibers Containing Black Pepper Oleoresin of Interest in Active Food Biopackaging Applications. Nanomaterials 2018, 28, 199. [Google Scholar] [CrossRef]

- Torres-Giner, S.; Torres, A.; Ferrándiz, M.; Fombuena, V.; Balart, R. Antimicrobial activity of metal cation-exchanged zeolites and their evaluation on injection-molded pieces of bio-based high-density polyethylene. J. Food Saf. 2017. [Google Scholar] [CrossRef]

- World Health Organization. Infection Prevention and Control during Health Care when Coronavirus Disease (COVID-19) Is Suspected or Confirmed 2020; World Health Organization: Geneva, Switzerland, 2020; pp. 1–13. [Google Scholar]

- Li, L.; Frey, M.W.; Green, T.B. Modification of Air Filter Media with Nylon-6 Nanofibers. J. Eng. Fiber. Fabr. 2006, 1. [Google Scholar] [CrossRef]

- Jaroszczyk, T.; Donahue, K.; Petrik, S. Recent development in heavy duty engine air filtration and the role of nanofiber filter media. J. KONES 2009, 16, 207–216. [Google Scholar]

- Zhang, L.; Li, L.; Wang, L.; Nie, J.; Ma, G. Multilayer electrospun nanofibrous membranes with antibacterial property for air filtration. Appl. Surf. Sci. 2020, 515, 145962. [Google Scholar] [CrossRef]

- Aliabadi, M. Effect of electrospinning parameters on the air filtration performance using electrospun polyamide-6 nanofibers. Chem. Ind. Chem. Eng. Q. 2017, 23, 441–446. [Google Scholar] [CrossRef]

- Leung, W.W.F.; Hung, C.H. Multilayer Nanofibre Filter 2013. U.S. Patent US8523971B2, 3 September 2013. [Google Scholar]

- Castro-Mayorga, J.L.; Fabra, M.J.; Pourrahimi, A.M.; Olsson, R.T.; Lagaron, J.M. The impact of zinc oxide particle morphology as an antimicrobial and when incorporated in poly(3-hydroxybutyrate-co-3-hydroxyvalerate) films for food packaging and food contact surfaces applications. Food Bioprod. Process. 2017, 101, 32–44. [Google Scholar] [CrossRef]

- García-Mateos, F.J.; Ruiz-Rosas, R.; Rosas, J.M.; Rodríguez-Mirasol, J.; Cordero, T. Controlling the composition, morphology, porosity, and surface chemistry of lignin-based electrospun carbon materials. Front. Mater. 2019, 6, 1–16. [Google Scholar] [CrossRef]

- Nataraj, S.K.; Kim, B.H.; Yun, J.H.; Lee, D.H.; Aminabhavi, T.M.; Yang, K.S. Electrospun Nanocomposite Fiber Mats of Zinc-Oxide Loaded Polyacrylonitrile. Carbon Lett. 2008, 9, 108–114. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, C.; Pan, Z. Porous bead-on-string poly(lactic acid) fibrous membranes for air filtration. J. Colloid Interface Sci. 2015, 441, 121–129. [Google Scholar] [CrossRef]

- Sawai, J.; Yoshikawa, T. Quantitative evaluation of antifungal activity of metallic oxide powders (MgO, CaO and ZnO) by an indirect conductimetric assay. J. Appl. Microbiol. 2004, 96, 803–809. [Google Scholar] [CrossRef]

- Eskandari, M.; Haghighi, N.; Ahmadi, V.; Haghighi, F.; Mohammadi, S.R. Growth and investigation of antifungal properties of ZnO nanorod arrays on the glass. Phys. B Condens. Matter 2011, 406, 112–114. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, Y.; Ding, Y.; Daskalakis, N.; Jeuken, L.; Povey, M.; O’Neill, A.J.; York, D.W. Mechanistic investigation into antibacterial behaviour of suspensions of ZnO nanoparticles against E. coli. J. Nanoparticle Res. 2010, 12, 1625–1636. [Google Scholar] [CrossRef]

- Salah, N.; AL-Shawafi, W.M.; Alshahrie, A.; Baghdadi, N.; Soliman, Y.M.; Memic, A. Size controlled, antimicrobial ZnO nanostructures produced by the microwave assisted route. Mater. Sci. Eng. C 2019, 99, 1164–1173. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Umar, A.; Kumar, G.; Nalwa, H.S. Antimicrobial properties of ZnO nanomaterials: A review. Ceram. Int. 2017, 43, 3940–3961. [Google Scholar] [CrossRef]

- Yao, L.R.; Song, X.M.; Zhang, G.Y.; Xu, S.Q.; Jiang, Y.Q.; Cheng, D.H.; Lu, Y.H. Preparation of Ag/HBP/PAN Nanofiber Web and Its Antimicrobial and Filtration Property. J. Nanomater. 2016, 2016, 4515769. [Google Scholar] [CrossRef]

| Sample | Basis Weight (g/m2) | Filtration Efficiency (%) |

|---|---|---|

| SPP/PAN/SPP | 0.8 | 99.84 ± 0.02 |

| SPP/PAN/PAN/SPP | 0.4/0.4 | 99.86 ± 0.03 |

| SPP/PAN/SPP/PAN/SPP | 0.4/0.4 | 99.91 ± 0.04 |

| SPP/PAN/SPP | 0.4 | 97.95 ± 0.46 |

| SPP/PAN/PAN/SPP | 0.2/0.2 | 97.01 ± 0.42 |

| SPP/PAN/SPP/PAN/SPP | 0.2/0.2 | 98.31 ± 0.17 |

| Sample | Basis Weight (g/cm2) | Mat Porosity (%) |

|---|---|---|

| PAN monolayer | 0.2 | 88.86 ± 1.06 |

| PAN monolayer | 0.4 | 87.90 ± 0.58 |

| PAN monolayer | 0.8 | 74.39 ± 2.65 |

| Sample | Viscosity (cP) | Conductivity (µS/cm) |

|---|---|---|

| PAN | 804.2 ± 0.95 | 65.98 ± 0.40 |

| PAN ZNO1 | 808.9 ± 0.88 | 66.66 ± 0.87 |

| PAN ZnO3 | 812.0 ± 3.53 | 69.79 ± 0.22 |

| PAN ZNO10 | 924.85 ± 2.04 | 72.15 ± 1.54 |

| PAN ZNO20 | 954.1 ± 1.11 | 72.89 ± 0.08 |

| Microorganism | ZnO (wt.%) | Control (PAN) Log (CFU/mL) | PAN-ZnO Log (CFU/mL) | R |

|---|---|---|---|---|

| S. aureus | 1 | 8.11 ± 0.23 | 4.85 ± 0.18 | 3.26 |

| 3 | No Counts | R > 3 | ||

| 10 | 3.20 ± 0.20 | 4.91 | ||

| 20 | 2.85 ± 0.14 | 5.26 | ||

| E. coli | 1 | 8.01 ± 0.17 | 4.99 ± 0.12 | 3.02 |

| 3 | 1.25 ± 0.15 | 6.76 | ||

| 10 | 3.85 ± 0.23 | 4.16 | ||

| 20 | 3.56 ± 0.17 | 4.45 |

| Microorganism | Time (h) | Control Log (CFU/mL) | PAN-ZnO3 Log (CFU/mL) | R |

|---|---|---|---|---|

| S. aureus | 1 | 6.01 ± 0.11 | 3.76 ± 0.21 | 2.25 |

| 3 | 6.86 ± 0.17 | 3.68 ± 0.15 | 3.18 | |

| 6 | 7.18 ± 0.19 | 3.10 ± 0.18 | 4.08 | |

| 8 | 7.86 ± 0.13 | 2.99 ± 0.17 | 4.87 | |

| E. coli | 1 | 5.98 ± 0.09 | 3.96 ± 0.11 | 2.02 |

| 3 | 6.36 ± 0.10 | 3.29 ± 0.13 | 3.07 | |

| 6 | 7.01 ± 0.14 | 3.32 ± 0.10 | 3.69 | |

| 8 | 7.88 ± 0.11 | 3.28 ± 0.15 | 4.60 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pardo-Figuerez, M.; Chiva-Flor, A.; Figueroa-Lopez, K.; Prieto, C.; Lagaron, J.M. Antimicrobial Nanofiber Based Filters for High Filtration Efficiency Respirators. Nanomaterials 2021, 11, 900. https://doi.org/10.3390/nano11040900

Pardo-Figuerez M, Chiva-Flor A, Figueroa-Lopez K, Prieto C, Lagaron JM. Antimicrobial Nanofiber Based Filters for High Filtration Efficiency Respirators. Nanomaterials. 2021; 11(4):900. https://doi.org/10.3390/nano11040900

Chicago/Turabian StylePardo-Figuerez, Maria, Alberto Chiva-Flor, Kelly Figueroa-Lopez, Cristina Prieto, and Jose M. Lagaron. 2021. "Antimicrobial Nanofiber Based Filters for High Filtration Efficiency Respirators" Nanomaterials 11, no. 4: 900. https://doi.org/10.3390/nano11040900

APA StylePardo-Figuerez, M., Chiva-Flor, A., Figueroa-Lopez, K., Prieto, C., & Lagaron, J. M. (2021). Antimicrobial Nanofiber Based Filters for High Filtration Efficiency Respirators. Nanomaterials, 11(4), 900. https://doi.org/10.3390/nano11040900