Thermal, Mechanical and Electrical Properties of Carbon Fiber Fabric and Graphene Reinforced Segmented Polyurethane Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Segmented Polyurethane (SPU)

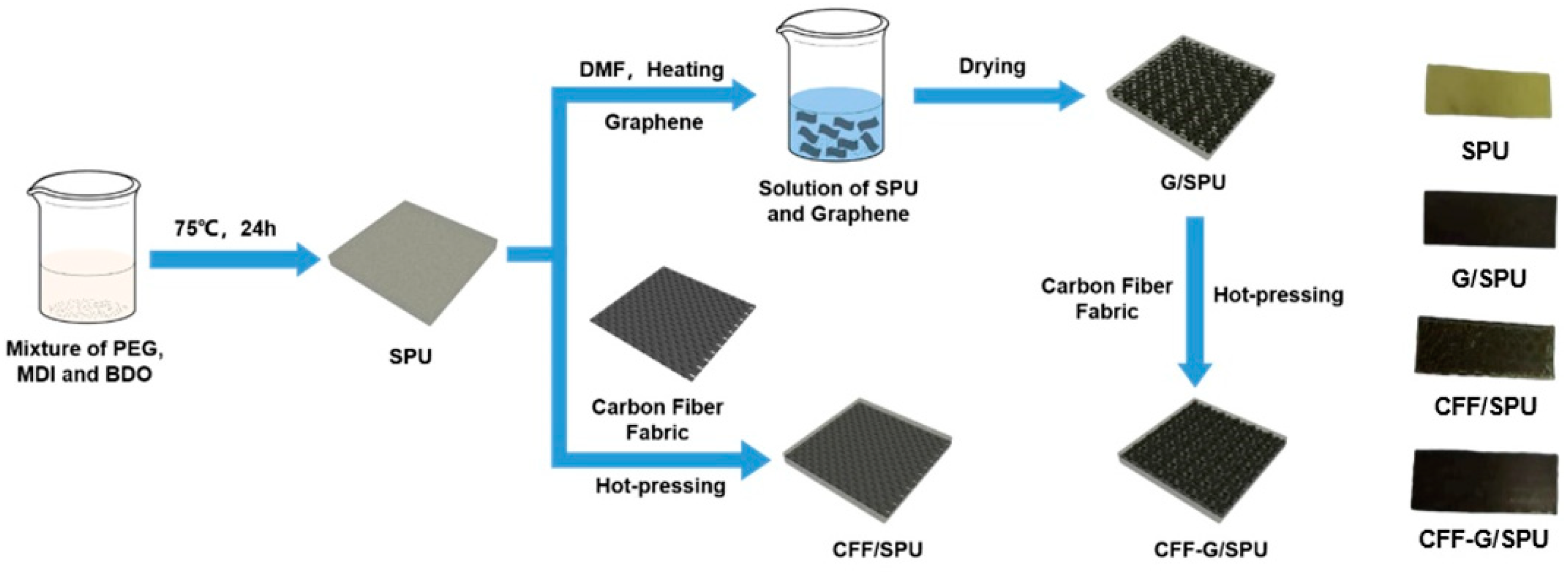

2.3. Preparation of Composites

2.4. Characterization

3. Results and Discussion

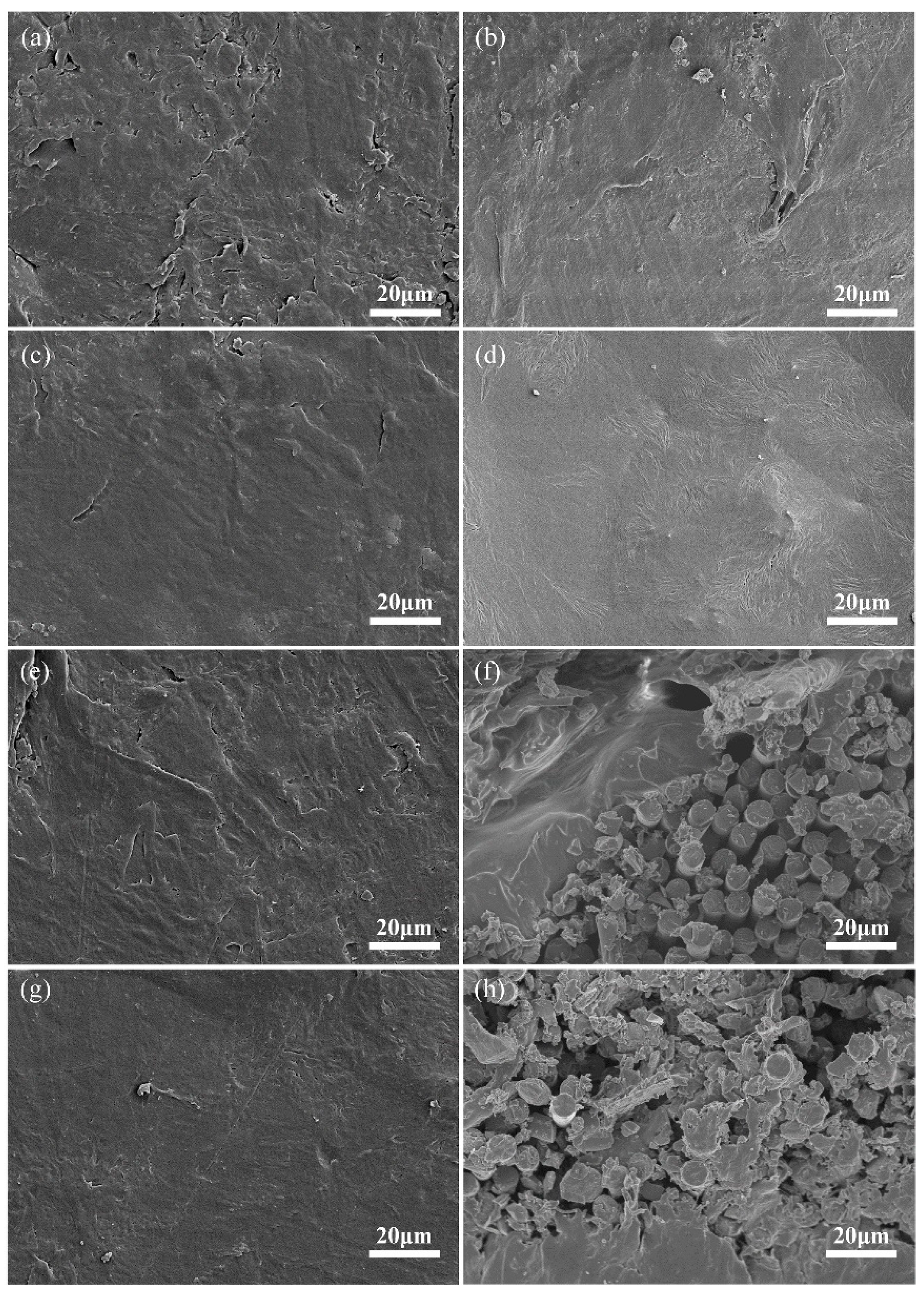

3.1. Microstructures

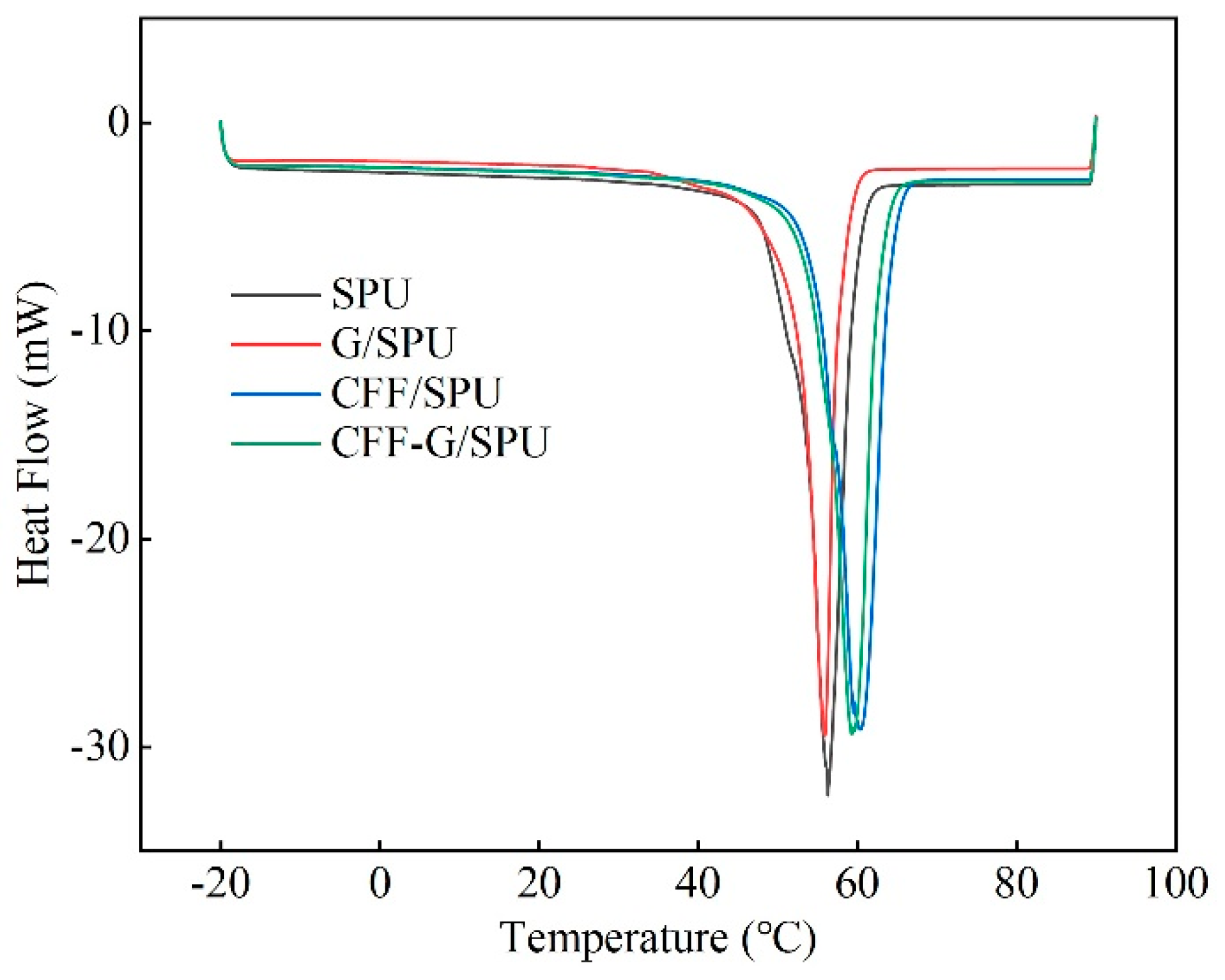

3.2. Thermal Properties

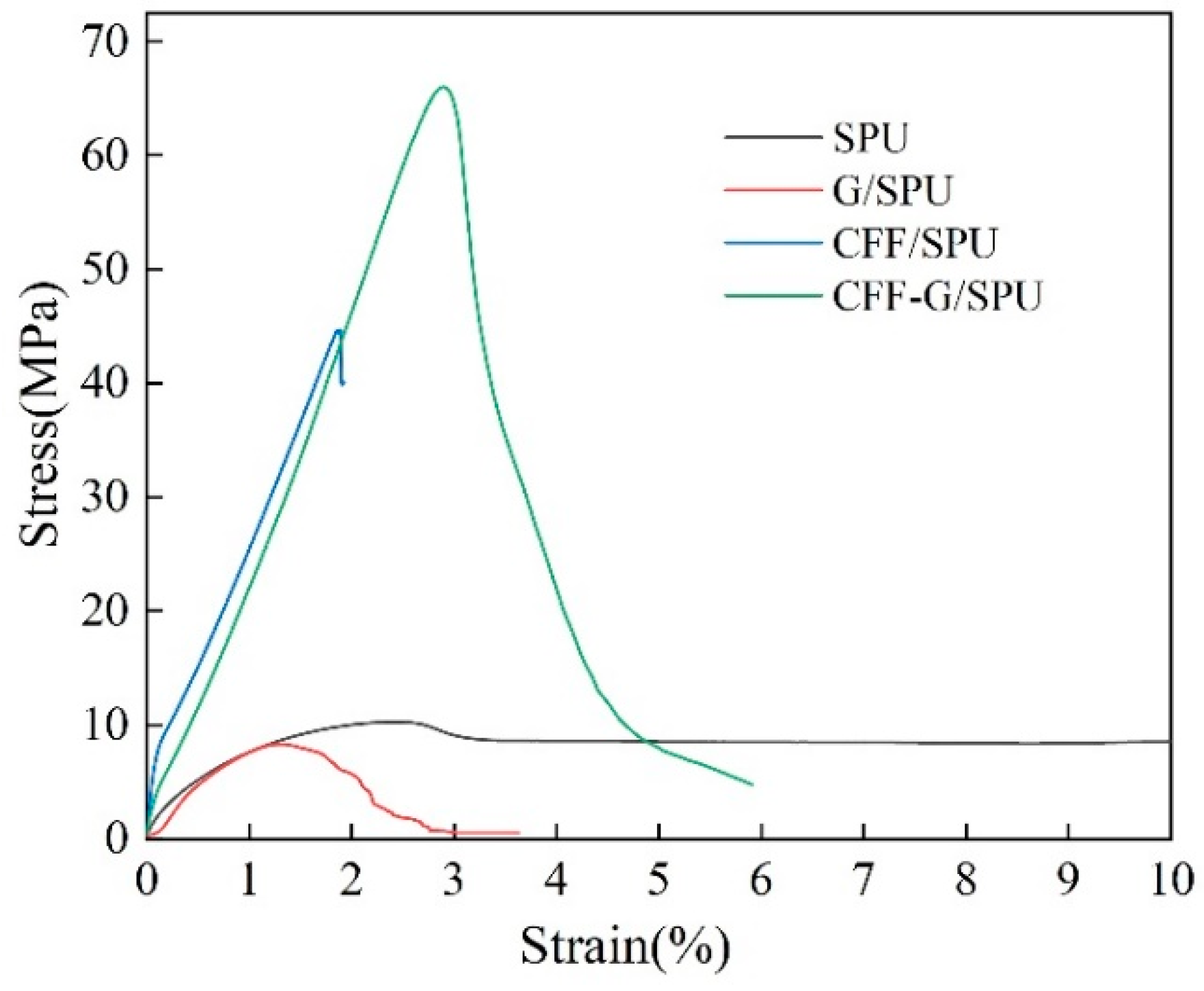

3.3. Mechanical Properties

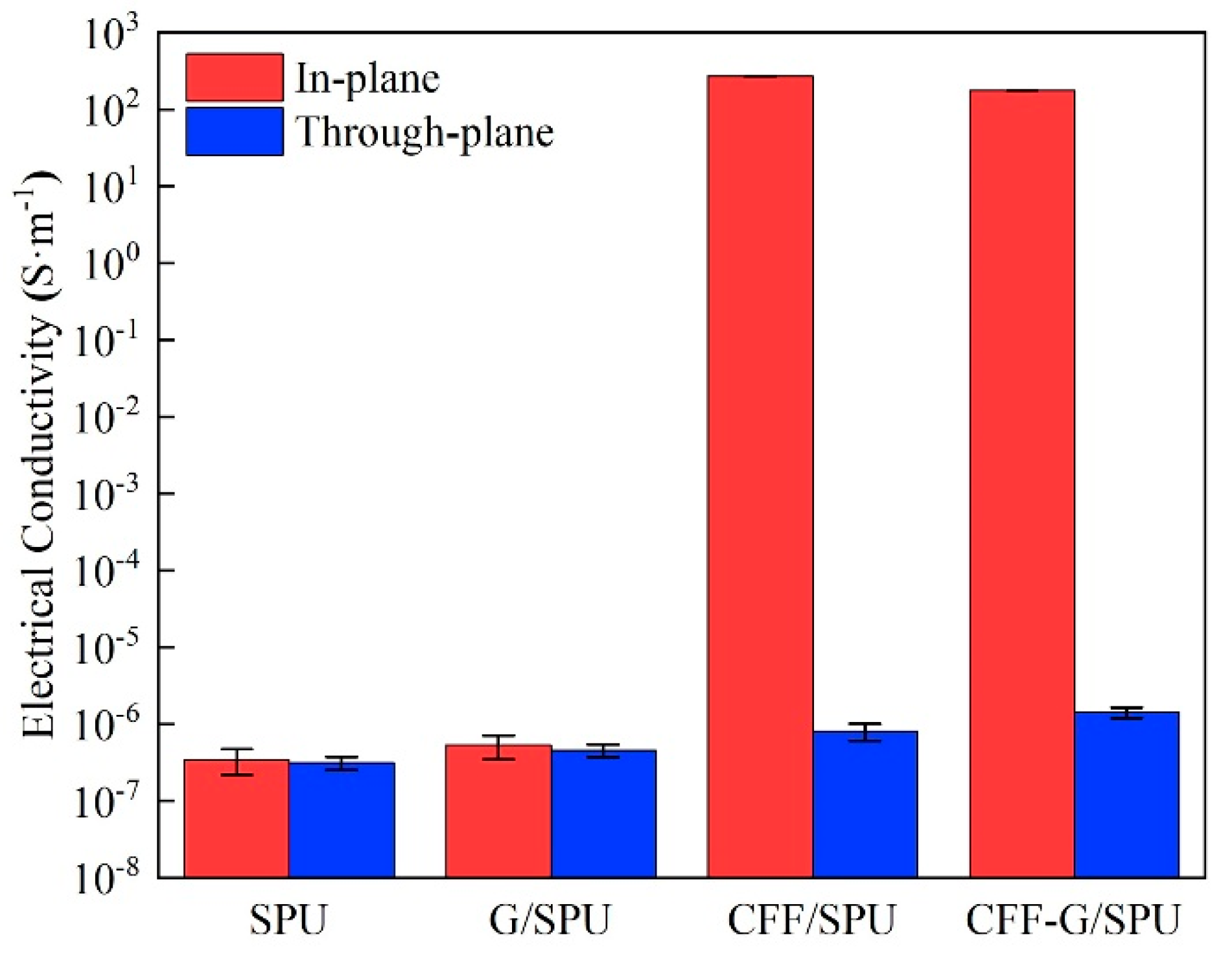

3.4. Electrical Properties

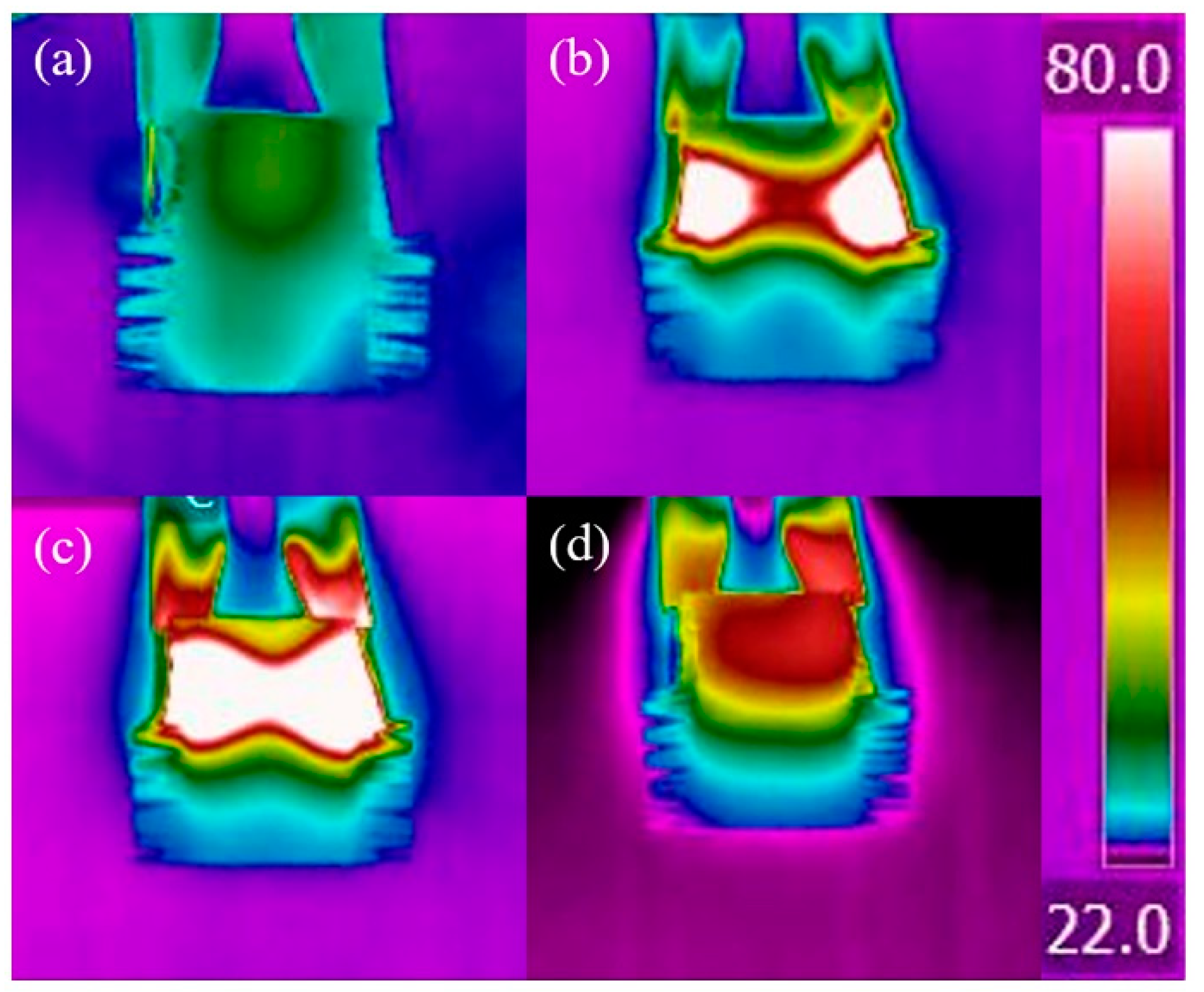

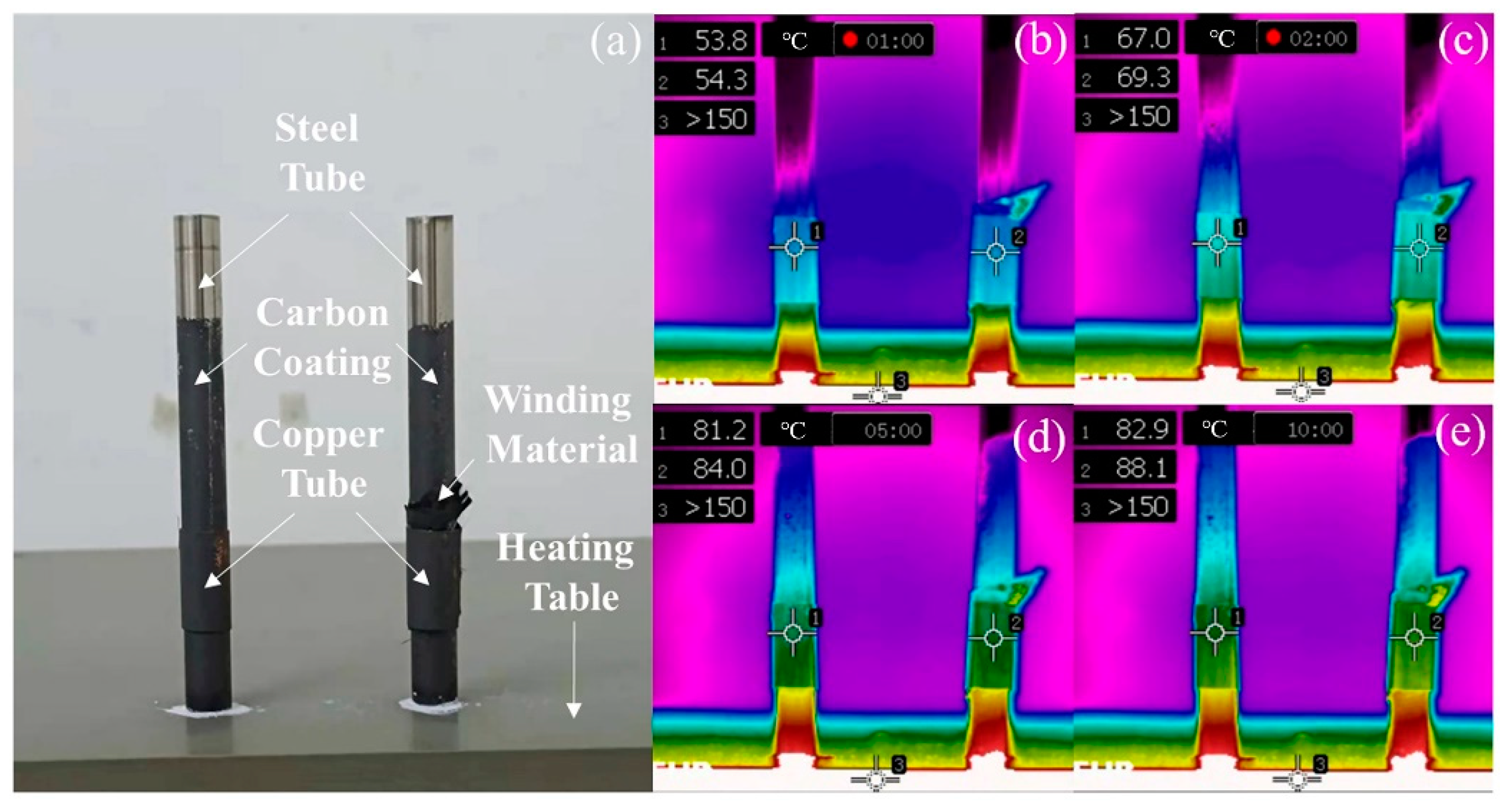

3.5. Electric-Driven Self-Heating Effect and Thermal Interface Material Application

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ma, J.K.; Shang, T.Y.; Ren, L.L.; Yao, Y.M.; Zhang, T.; Xie, J.Q.; Zhang, B.T.; Zeng, X.L.; Sun, R.; Xu, J.B.; et al. Through-plane assembly of carbon fibers into 3D skeleton achieving enhanced thermal conductivity of a thermal interface material. Chem. Eng. J. 2020, 380, 122550. [Google Scholar] [CrossRef]

- Grenier, S.; Sandig, M.; Mequanint, K. Polyurethane biomaterials for fabricating 3D porous scaffolds and supporting vascular cells. J. Biomed. Mater. Res. Part A 2007, 82, 802–809. [Google Scholar] [CrossRef] [PubMed]

- Cai, D.; Yusoh, K.; Song, M. The mechanical properties and morphology of a graphite oxide nanoplatelet/polyurethane composite. Nanotechnology 2009, 20, 085712. [Google Scholar] [CrossRef]

- Xiang, C.S.; Lu, W.; Zhu, Y.; Sun, Z.Z.; Yan, Z.; Hwang, C.C.; Tour, J.M. Carbon nanotube and graphene nanoribbon-coated conductive Kevlar fibers. ACS Appl. Mater. Interfaces 2012, 4, 131–136. [Google Scholar] [CrossRef] [PubMed]

- Loh, T.W.; Tran, P.; Das, R.; Ladani, R.B.; Orifici, A.C. Thermoplastic polyurethane-cellulose nanocomposite for transparent armour: Characterisation of adhesion and thermal aging. Compos. Commun. 2020, 22, 100465. [Google Scholar] [CrossRef]

- Li, W.; Pei, Z. Strain-sensing fiber with a core–sheath structure based on carbon black/polyurethane composites for smart textiles. Text. Res. J. 2021. [Google Scholar] [CrossRef]

- Gedam, S.S.; Chaudhary, A.K.; Vijayakumar, R.P.; Goswami, A.K.; Bajad, G.S.; Pal, D. Thermal, mechanical and morphological study of carbon nanotubes-graphene oxide and silver nanoparticles based polyurethane composites. Mater. Res. Express 2019, 6, 085308. [Google Scholar] [CrossRef]

- Pourmohammadi-Mahunaki, M.; Haddadi-Asl, V.; Roghani-Mamaqani, H.; Koosha, M.; Yazdi, M. Preparation of polyurethane composites reinforced with halloysite and carbon nanotubes. Polym. Compos. 2020, 42, 460–461. [Google Scholar]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef]

- Balandin, A.A.; Ghosh, S.; Bao, W.Z.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior thermal conductivity of single-layer graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef]

- Pan, D.; Zhang, J.; Li, Z.; Wu, M. Hydrothermal route for cutting graphene sheets into blue-luminescent graphene quantum dots. Adv. Mater. 2010, 22, 734–738. [Google Scholar] [CrossRef]

- Trache, D.; Thakur, V.K.; Boukherroub, R. Cellulose nanocrystals/graphene hybrids-a promising new class of materials for advanced applications. Nanomaterials 2020, 10, 1523. [Google Scholar] [CrossRef] [PubMed]

- Platnieks, O.; Gaidukovs, S.; Neibolts, N.; Barkane, A.; Gaidukova, G.; Thakur, V.K. Poly (butylene succinate) and graphene nanoplatelet–based sustainable functional nanocomposite materials: Structure-properties relationship. Mater. Today Chem. 2020, 18, 100351. [Google Scholar] [CrossRef]

- Sharma, B.; Thakur, S.; Trache, D.; Nezhad, H.Y.; Thakur, V.K. Microwave-assisted rapid synthesis of reduced graphene oxide-based gum tragacanth hydrogel nanocomposite for heavy metal ions adsorption. Nanomaterials 2020, 10, 1616. [Google Scholar] [CrossRef] [PubMed]

- Siwal, S.S.; Zhang, Q.; Sun, C.; Thakur, V.K. Graphitic carbon nitride doped copper–manganese alloy as high–performance electrode material in supercapacitor for energy storage. Nanomaterials 2020, 10, 2. [Google Scholar] [CrossRef]

- Shante, V.K.S.; Kirkpatrick, S. An introduction to percolation theory. Phys. Today 1987, 40, 122–123. [Google Scholar] [CrossRef]

- Kolonelou, E.; Loupou, E.; Klonos, P.; Sakellis, A.E.; Valadorou, D.; Kyritsis, A.; Papathanassiou, A.N. Thermal and electrical characterization of poly(vinyl)alcohol)/poly (vinylidene fluoride) blends reinforced with nano-graphene platelets. Polymer 2021, 224, 123731. [Google Scholar] [CrossRef]

- Pettes, M.T.; Ji, H.X.; Ruoff, R.S.; Shi, L. Thermal transport in three-dimensional foam architectures of few-layer graphene and ultrathin graphite. Nano Lett. 2012, 12, 2959–2964. [Google Scholar] [CrossRef]

- Jia, J.J.; Sun, X.Y.; Lin, X.Y.; Shen, X.; Mai, Y.W.; Kim, J.K. Exceptional electrical conductivity and fracture resistance of 3D interconnected graphene foam/epoxy composites. ACS Nano 2014, 8, 5774–5783. [Google Scholar] [CrossRef] [PubMed]

- Tang, L.G.; Kardos, J.L. A review of methods for improving the interfacial adhesion between carbon fiber and polymer matrix. Polym. Compos. 1997, 18, 100–113. [Google Scholar] [CrossRef]

- Zhang, L.B.; Li, R.Y.; Tang, B.; Wang, P. Solar-thermal conversion and thermal energy storage of graphene foam-based composites. Nanoscale 2016, 8, 14600–14607. [Google Scholar] [CrossRef]

- Zhu, S.; Shi, R.J.; Qu, M.C.; Zhou, J.F.; Ye, C.H.; Zhang, L.Y.; Cao, H.J.; Ge, D.T.; Chen, Q.J. Simultaneously improved mechanical and electromagnetic interference shielding properties of carbon fiber fabrics/epoxy composites via interface engineering. Compos. Sci. Technol. 2021, 207, 108696. [Google Scholar] [CrossRef]

- Rahmani, H.; Najafi, S.H.M.; Ashori, A. Mechanical performance of epoxy/carbon fiber laminated composites. J. Reinf. Plast. Compos. 2014, 33, 733–740. [Google Scholar] [CrossRef]

- Kim, J.; Cha, J.; Chung, B.; Ryu, S.; Hong, S.H. Fabrication and mechanical properties of carbon fiber/epoxy nanocomposites containing high loadings of noncovalently functionalized graphene nanoplatelets. Compos. Sci. Technol. 2020, 192, 108101. [Google Scholar] [CrossRef]

- Forintos, N.; Czigany, T. Multifunctional application of carbon fiber reinforced polymer composites: Electrical properties of the reinforcing carbon fibers—A short review. Compos. Part B Eng. 2019, 162, 331–343. [Google Scholar] [CrossRef]

- Fan, W.; Li, J.L.; Zheng, Y.Y.; Liu, T.J.; Tian, X.; Sun, R.J. Influence of thermo-oxidative aging on the thermal conductivity of carbon fiber fabric reinforced epoxy composites. Polym. Degrad. Stabil. 2016, 123, 162–169. [Google Scholar] [CrossRef]

- Yu, S.; Park, K.; Lee, J.W.; Hong, S.M.; Park, C.; Han, T.H.; Koo, C.M. Enhanced thermal conductivity of epoxy/Cu-plated carbon fiber fabric composites. Macromol. Res. 2017, 25, 559–564. [Google Scholar] [CrossRef]

- Chen, S.; Feng, J. Epoxy laminated composites reinforced with polyethyleneimine functionalized carbon fiber fabric: Mechanical and thermal properties. Compos. Sci. Technol. 2014, 101, 145–151. [Google Scholar] [CrossRef]

- Duan, N.M.; Shi, Z.Y.; Wang, J.L.; Wang, G.L.; Zhang, X.Z. Strong and flexible carbon fiber fabric reinforced thermoplastic polyurethane composites for high-performance EMI shielding applications. Macromol. Mater. Eng. 2020, 305, 1900829. [Google Scholar] [CrossRef]

- Abot, J.L.; Yasmin, A.; Jacobsen, A.J. In-plane mechanical, thermal and viscoelastic properties of a satin fabric carbon/epoxy composite. Compos. Sci. Technol. 2004, 64, 263–268. [Google Scholar] [CrossRef]

- Jang, J.U.; Park, H.C.; Lee, H.S.; Khil, M.S.; Kim, S.Y. Electrically and thermally conductive carbon fibre fabric reinforced polymer composites based on nanocarbons and an in-situ polymerizable cyclic oligoester. Sci. Rep. 2018, 8, 7659. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Shi, Z.; Li, A.; Zhang, Y.F. Rgo-coated polyurethane foam/segmented polyurethane composites as solid–solid phase change thermal interface material. Polymers 2020, 12, 3004. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.Y.; Xia, K.L.; Zhang, J.; Zhang, Y.Y.; Li, Q.Y.; Takahashi, K.; Zhang, X. Measurement of specific heat and thermal conductivity of supported and suspended graphene by a comprehensive Raman optothermal method. Nanoscale 2017, 9, 10784–10793. [Google Scholar] [CrossRef] [PubMed]

| Sample | Thickness (mm) | Tensile Modulus (MPa) | Tensile Strength (MPa) |

|---|---|---|---|

| SPU | 0.52 | 609 | 10.3 |

| G/SPU | 0.30 | 1297 | 8.3 |

| CFF/SPU | 0.78 | 2100 | 44.6 |

| CFF-G/SPU | 0.76 | 2317 | 66.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Z.; Zhang, C.; Chen, X.-G.; Li, A.; Zhang, Y.-F. Thermal, Mechanical and Electrical Properties of Carbon Fiber Fabric and Graphene Reinforced Segmented Polyurethane Composites. Nanomaterials 2021, 11, 1289. https://doi.org/10.3390/nano11051289

Shi Z, Zhang C, Chen X-G, Li A, Zhang Y-F. Thermal, Mechanical and Electrical Properties of Carbon Fiber Fabric and Graphene Reinforced Segmented Polyurethane Composites. Nanomaterials. 2021; 11(5):1289. https://doi.org/10.3390/nano11051289

Chicago/Turabian StyleShi, Zhe, Cong Zhang, Xin-Gang Chen, Ang Li, and Yang-Fei Zhang. 2021. "Thermal, Mechanical and Electrical Properties of Carbon Fiber Fabric and Graphene Reinforced Segmented Polyurethane Composites" Nanomaterials 11, no. 5: 1289. https://doi.org/10.3390/nano11051289

APA StyleShi, Z., Zhang, C., Chen, X.-G., Li, A., & Zhang, Y.-F. (2021). Thermal, Mechanical and Electrical Properties of Carbon Fiber Fabric and Graphene Reinforced Segmented Polyurethane Composites. Nanomaterials, 11(5), 1289. https://doi.org/10.3390/nano11051289