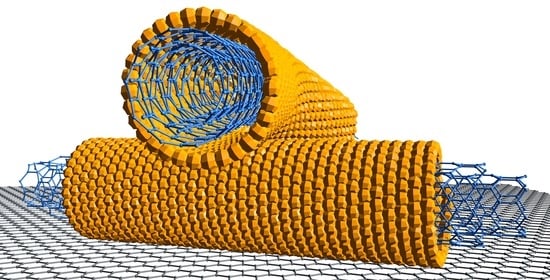

A New Method for Dispersing Pristine Carbon Nanotubes Using Regularly Arranged S-Layer Proteins

Abstract

:1. Introduction

2. Materials and Methods

2.1. Production of Wild-Type and Recombinant S-Layer Protein Solutions

2.2. Coating of Pristine and Oxidized Multi-Walled Carbon Nanotubes (MWNTs)

2.3. Coating of Graphene Sheets with S-Layer Protein SbpA

2.4. Silicification of SbpA-Coated MWNTs

2.5. Transmission Electron Microscopy (TEM)

2.6. Atomic Force Microscopy (AFM)

2.7. Zeta-Potential Measurements of rSbpA-Coated MWNTs

3. Results and Discussion

3.1. Reassembly of SbpA and SbsB S-Layer Protein on Pristine MWNTs

3.2. Reassembly of SbpA S-Layer Protein on Graphene

3.3. Zeta-Potential Measurements of SbpA S-Layer Protein-Coated MWNTs

3.4. Silicification of SbpA S-Layer Protein-Coated MWNTs

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mann, S. Life as a Nanoscale Phenomenon. Angew. Chem. Int. Ed. 2008, 47, 5306–5320. [Google Scholar] [CrossRef]

- Limo, M.J.; Rabada, A.S.; Boix, E.; Thota, V.; Westcott, Z.C.; Puddu, V.; Perry, C.C. Interactions between Metal Oxides and Biomolecules: From Fundamental Understanding to Applications. Chem. Rev. 2018, 118, 11118–11193. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- De Volder, M.F.L.; Tawfick, S.H.; Baughman, R.H.; Hart, A.J. Carbon Nanotubes: Present and Future Commercial Applications. Science 2013, 339, 535–539. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sireesha, M.; Babu, V.J.; Kiran, A.S.K.; Ramakrishna, S. A review on carbon nanotubes in biosensor devices and their applications in medicine. Nanocomposites 2018, 4, 36–57. [Google Scholar] [CrossRef]

- Chakrabarti, M.; Kiseleva, R.; Vertegel, A.; Ray, S.K. Carbon Nanomaterials for Drug Delivery and Cancer Therapy. J. Nanosci. Nanotechnol. 2015, 15, 5501–5511. [Google Scholar] [CrossRef] [PubMed]

- Rahmati, M.; Mozafari, M. Biological Response to Carbon-Family Nanomaterials: Interactions at the Nano-Bio Interface. Front. Bioeng. Biotechnol. 2019, 7, 7. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Bukkitgar, S.D.; Singh, S.; Pratibha; Singh, V.; Reddy, K.R.; Shetti, N.P.; Reddy, C.V.; Sadhu, V.; Naveen, S. Electrochemical Sensors and Biosensors Based on Graphene Functionalized with Metal Oxide Nanostructures for Healthcare Applications. Chemistryselect 2019, 4, 5322–5337. [Google Scholar] [CrossRef]

- Kharissova, O.V.; Kharisov, B.I.; Ortiz, E.G.D.C. Dispersion of carbon nanotubes in water and non-aqueous solvents. RSC Adv. 2013, 3, 24812–24852. [Google Scholar] [CrossRef]

- Dai, J.; Fernandes, R.M.F.; Regev, O.; Marques, E.F.; Furo, I. Dispersing Carbon Nanotubes in Water with Amphiphiles: Dispersant Adsorption, Kinetics, and Bundle Size Distribution as Defining Factors. J. Phys. Chem. C 2018, 122, 24386–24393. [Google Scholar] [CrossRef] [Green Version]

- Cerpa, A.; Lado, I.; Quiroga, O.; Moreno, R.; García, R.; Cerdán, S.; Abu-Lail, N.I. Colloidal and rheological characterization of SWCNT in biological media. Int. J. Smart Nano Mater. 2019, 10, 300–315. [Google Scholar] [CrossRef]

- Youssry, M.; Al-Ruwaidhi, M.; Zakeri, M.; Zakeri, M. Physical functionalization of multi-walled carbon nanotubes for enhanced dispersibility in aqueous medium. Emergent Mater. 2020, 3, 25–32. [Google Scholar] [CrossRef] [Green Version]

- Wallace, A.F.; DeYoreo, J.J.; Dove, P.M. Kinetics of Silica Nucleation on Carboxyl- and Amine-Terminated Surfaces: Insights for Biomineralization. J. Am. Chem. Soc. 2009, 131, 5244–5250. [Google Scholar] [CrossRef] [PubMed]

- Ilk, N.; Völlenkle, C.; Egelseer, E.M.; Breitwieser, A.; Sleytr, U.B.; Sára, M. Molecular Characterization of the S-Layer Gene, sbpA, of Bacillus sphaericus CCM 2177 and Production of a Functional S-Layer Fusion Protein with the Ability to Recrystallize in a Defined Orientation while Presenting the Fused Allergen. Appl. Environ. Microbiol. 2002, 68, 3251–3260. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pavkov-Keller, T.; Howorka, S.; Keller, W. The Structure of Bacterial S-Layer Proteins. Prog. Mol. Biol. Transl. Sci. 2011, 103, 73–130. [Google Scholar] [CrossRef]

- Breitwieser, A.; Siedlaczek, P.; Lichtenegger, H.; Sleytr, U.B.; Pum, D. S-Layer Protein Coated Carbon Nanotubes. Coatings 2019, 9, 492. [Google Scholar] [CrossRef] [Green Version]

- Saeed, K.; Khan, I. Carbon nanotubes-properties and applications: A review. Carbon Lett. 2013, 14, 131–144. [Google Scholar] [CrossRef] [Green Version]

- Sleytr, U.B.; Schuster, B.; Egelseer, E.-M.; Pum, D. S-layers: Principles and applications. FEMS Microbiol. Rev. 2014, 38, 823–864. [Google Scholar] [CrossRef]

- Sleytr, U. Self-assembly of the hexagonally and tetragonally arranged subunits of bacterial surface layers and their reattachment to cell walls. J. Ultrastruct. Res. 1976, 55, 360–377. [Google Scholar] [CrossRef]

- Pum, D.; Sleytr, U.B. Reassembly of S-layer proteins. Nanotechnology 2014, 25, 312001. [Google Scholar] [CrossRef]

- Schuster, B.; Sleytr, U. S-Layer Ultrafiltration Membranes. Membranes 2021, 11, 275. [Google Scholar] [CrossRef]

- Egelseer, E.M.; Ilk, N.; Pum, D.; Messner, P.; Schäffer, C.; Schuster, B.; Sleytr, U.B. S-Layers, microbial, biotechnological applications. In Encyclopedia of Industrial Biotechnology: Bioprocess, Bioseparation, and Cell Technology; Flickinger, M.C., Ed.; John Wiley and Sons: Hoboken, NJ, USA, 2010; Volume 7, pp. 4424–4448. [Google Scholar]

- Ilk, N.; Egelseer, E.M.; Sleytr, U.B. S-layer fusion proteins—Construction principles and applications. Curr. Opin. Biotechnol. 2011, 22, 824–831. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Göbel, C.; Schuster, B.; Baurecht, D.; Sleytr, U.B.; Pum, D. S-layer templated bioinspired synthesis of silica. Colloids Surf. B Biointerfaces 2010, 75, 565–572. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schuster, D.; Küpcü, S.; Belton, D.; Perry, C.; Stöger-Pollach, M.; Sleytr, U.; Pum, D. Construction of silica-enhanced S-layer protein cages. Acta Biomater. 2013, 9, 5689–5697. [Google Scholar] [CrossRef] [PubMed]

- Shenton, W.; Pum, D.; Sleytr, U.B.; Mann, S. Biocrystal templating of CdS superlattices using self-assembled bacterial S-layers. Nature 1997, 389, 585–587. [Google Scholar] [CrossRef]

- Winningham, T.A.; Gillis, H.P.; Choutov, D.A.; Martin, K.P.; Moore, J.T.; Douglas, K. Formation of ordered nanocluster arrays by self-assembly on nanopatterned Si(100) surfaces. Surf. Sci. 1998, 406, 221–228. [Google Scholar] [CrossRef]

- Mertig, M.; Wahl, R.; Lehmann, M.; Simon, P.; Pompe, W. Formation and manipulation of regular metallic nanoparticle arrays on bacterial surface layers: An advanced TEM study. Eur. Phys. J. D 2001, 16, 317–320. [Google Scholar] [CrossRef]

- Hall, S.R.; Shenton, W.; Engelhardt, H.; Mann, S. Site-specific organization of gold nanoparticles by biomolecular templating. Chemphyschem 2001, 2, 184–186. [Google Scholar] [CrossRef]

- Suhr, M.; Unger, N.; Viacava, K.E.; Günther, T.J.; Raff, J.; Pollmann, K. Investigation of metal sorption behavior of Slp1 from Lysinibacillus sphaericus JG-B53: A combined study using QCM-D, ICP-MS and AFM. BioMetals 2014, 27, 1337–1349. [Google Scholar] [CrossRef] [PubMed]

- Sára, M.; Kuen, B.; Mayer, H.F.; Mandl, F.; Schuster, K.C.; Sleytr, U.B. Dynamics in oxygen-induced changes in S-layer protein synthesis from Bacillus stearothermophilus PV72 and the S-layer-deficient variant T5 in continuous culture and studies of the cell wall composition. J. Bacteriol. 1996, 178, 2108–2117. [Google Scholar] [CrossRef] [Green Version]

- Weigert, S.; Sára, M. Surface modification of an ultrafiltration membrane with crystalline structure and studies on interactions with selected protein molecules. J. Membr. Sci. 1995, 106, 147–159. [Google Scholar] [CrossRef]

- Egelseer, E.M.; Leitner, K.; Jarosch, M.; Hotzy, C.; Zayni, S.; Sleytr, U.B.; Sára, M. The S-Layer Proteins of Two Bacillus stearothermophilus Wild-Type Strains Are Bound via Their N-Terminal Region to a Secondary Cell Wall Polymer of Identical Chemical Composition. J. Bacteriol. 1998, 180, 1488–1495. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sleytr, U.B. Heterologous reattachment of regular arrays of glycoproteins on bacterial surfaces. Nat. Cell Biol. 1975, 257, 400–402. [Google Scholar] [CrossRef] [PubMed]

- Comolli, L.R.; Siegerist, C.E.; Shin, S.-H.; Bertozzi, C.; Regan, W.; Zettl, A.; De Yoreo, J. Conformational Transitions at an S-Layer Growing Boundary Resolved by Cryo-TEM. Angew. Chem. Int. Ed. 2013, 52, 4829–4832. [Google Scholar] [CrossRef]

- Messner, P.; Pum, D.; Sleytr, U.B. Characterization of the ultrastructure and the self-assembly of the surface layer of Bacillus stearothermophilus strain NRS 2004/3a. J. Ultrastruct. Mol. Struct. Res. 1986, 97, 73–88. [Google Scholar] [CrossRef]

- Sleutel, M.; Van Driessche, A.E.S. Role of clusters in nonclassical nucleation and growth of protein crystals. Proc. Natl. Acad. Sci. USA 2014, 111, e546–e553. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chung, S.; Shin, S.-H.; Bertozzi, C.R.; De Yoreo, J.J. Self-catalyzed growth of S layers via an amorphous-to-crystalline transition limited by folding kinetics. Proc. Natl. Acad. Sci. USA 2010, 107, 16536–16541. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shin, S.-H.; Chung, S.; Sanii, B.; Comolli, L.R.; Bertozzi, C.R.; De Yoreo, J.J. Direct observation of kinetic traps associated with structural transformations leading to multiple pathways of S-layer assembly. Proc. Natl. Acad. Sci. USA 2012, 109, 12968–12973. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Breitwieser, A.; Iturri, J.; Toca-Herrera, J.-L.; Sleytr, U.B.; Pum, D. In Vitro Characterization of the Two-Stage Non-Classical Reassembly Pathway of S-Layers. Int. J. Mol. Sci. 2017, 18, 400. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moll, D.; Huber, C.; Schlegel, B.; Pum, D.; Sleytr, U.B.; Sára, M. S-layer-streptavidin fusion proteins as template for nanopatterned molecular arrays. Proc. Natl. Acad. Sci. USA 2002, 99, 14646–14651. [Google Scholar] [CrossRef] [Green Version]

- White, B.; Banerjee, S.; O’Brien, S.; Turro, N.J.; Herman, I.P. Zeta-Potential Measurements of Surfactant-Wrapped Individual Single-Walled Carbon Nanotubes. J. Phys. Chem. C 2007, 111, 13684–13690. [Google Scholar] [CrossRef]

- Skwarek, E.; Bolbukh, Y.; Tertykh, V.; Janusz, W. Electrokinetic Properties of the Pristine and Oxidized MWCNT Depending on the Electrolyte Type and Concentration. Nanoscale Res. Lett. 2016, 11, 166. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rothbauer, M.; Küpcü, S.; Sticker, D.; Sleytr, U.B.; Ertl, P. Exploitation of S-layer Anisotropy: pH-dependent Nanolayer Orientation for Cellular Micropatterning. ACS Nano 2013, 7, 8020–8030. [Google Scholar] [CrossRef]

- Busch, A.P.; Rhinow, D.; Yang, F.; Reinhardt, H.; Beyer, A.; Gölzhäuser, A.; Hampp, N. Site-selective biomineralization of native biological membranes. J. Mater. Chem. B 2014, 2, 6924–6930. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.S.; Wang, H.C.; Huang, Y.J.; Zhao, Z.X.; Qin, X.; Wang, Y.Y.; Miao, Z.Y.; Chen, Q.A.; Qiao, M.Q. Noncovalently functionalized multi-wall carbon nanotubes in aqueous solution using the hydrophobin HFBI and their electroanalytical application. Biosens. Bioelectron. 2010, 26, 1104–1108. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Ren, Q.; Wu, Y.-N.; Morris, V.K.; Rey, A.A.; Braet, F.; Kwan, A.H.; Sunde, M. Surface functionalization of carbon nanomaterials by self-assembling hydrophobin proteins. Biopolymers 2012, 99, 84–94. [Google Scholar] [CrossRef] [PubMed]

- Ostermaier, F.; Scharfenberg, L.; Schneider, K.; Hennig, S.; Ostermann, K.; Posseckardt, J.; Rödel, G.; Mertig, M. From 2D to 1D functionalization: Steps towards a carbon nanotube based biomembrane sensor for curvature sensitive proteins. Phys. Status Solidi A 2015, 212, 1389–1394. [Google Scholar] [CrossRef]

- Gomes, F.O.; Maia, L.B.; Delerue-Matos, C.; Moura, I.; Moura, J.J.; Morais, S. Third-generation electrochemical biosensor based on nitric oxide reductase immobilized in a multiwalled carbon nanotubes/1-n-butyl-3-methylimidazolium tetrafluoroborate nanocomposite for nitric oxide detection. Sens. Actuators B Chem. 2019, 285, 445–452. [Google Scholar] [CrossRef]

- Gallay, P.A.; Rubianes, M.D.; Gutierrez, F.A.; Rivas, G.A. Avidin and Glucose Oxidase-non-covalently Functionalized Multi-walled Carbon Nanotubes: A New Analytical Tool for Building a Bienzymatic Glucose Biosensor. Electroanalysis 2019, 31, 1888–1894. [Google Scholar] [CrossRef]

- Breitwieser, A.; Pum, D.; Toca-Herrera, J.L.; Sleytr, B.U. Magnetic beads functionalized with recombinant S-layer protein exhibit high human IgG-binding and anti-fouling properties. Curr. Top. Pept. Protein Res. 2016, 17, 45–55. [Google Scholar]

- Ucisik, M.H.; Küpcü, S.; Breitwieser, A.; Gelbmann, N.; Schuster, B.; Sleytr, U.B. S-layer fusion protein as a tool functionalizing emulsomes and CurcuEmulsomes for antibody binding and targeting. Colloids Surf. B Biointerfaces 2015, 128, 132–139. [Google Scholar] [CrossRef] [Green Version]

- Völlenkle, C.; Weigert, S.; Ilk, N.; Egelseer, E.; Weber, V.; Loth, F.; Falkenhagen, D.; Sleytr, U.B.; Sara, M. Construction of a Functional S-Layer Fusion Protein Comprising an Immunoglobulin G-Binding Domain for Development of Specific Adsorbents for Extracorporeal Blood Purification. Appl. Environ. Microbiol. 2004, 70, 1514–1521. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Breitwieser, A.; Egelseer, E.M.; Moll, D.; Ilk, N.; Hotzy, C.; Bohle, B.; Ebner, C.; Sleytr, U.B.; Sára, M. A recombinant bacterial cell surface (S-layer)-major birch pollen allergen-fusion protein (rSbsC/Bet v1) maintains the ability to self-assemble into regularly structured monomolecular lattices and the functionality of the allergen. Protein Eng. 2002, 15, 243–249. [Google Scholar] [CrossRef] [Green Version]

- Huber, C.; Liu, J.; Egelseer, E.M.; Moll, D.; Knoll, W.; Sleytr, U.B.; Sára, M. Heterotetramers Formed by an S-Layer-Streptavidin Fusion Protein and Core-Streptavidin as a Nanoarrayed Template for Biochip Development. Small 2005, 2, 142–150. [Google Scholar] [CrossRef] [PubMed]

- Neubauer, A.; Hödl, C.; Pum, D.; Sleytr, U.B. A Multistep Enzyme Sensor for Sucrose Based on S-Layer Microparticles As Immobilization Matrix. Anal. Lett. 1994, 27, 849–865. [Google Scholar] [CrossRef]

- Fiegel, V.; Harlepp, S.; Begin-Colin, S.; Bégin, D.; Mertz, D.; Bégin-Colin, S. Design of Protein-Coated Carbon Nanotubes Loaded with Hydrophobic Drugs through Sacrificial Templating of Mesoporous Silica Shells. Chem. Eur. J. 2018, 24, 4662–4670. [Google Scholar] [CrossRef] [PubMed]

| S-Layer Protein | Bacterial Strain | S-Layer Lattice Symmetry | Lattice Parameters |

|---|---|---|---|

| SbpA | L. sphaericus CCM2177 | square (p4) | a = b = 13.1 nm, d = 9 nm base angle γ = 90° |

| SbsB | G. stearothermophilus PV72/p2 | oblique (p1) | a = 10.4 nm, b = 7.9 nm, d = 4.5 nm base angle γ = 81° |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Breitwieser, A.; Sleytr, U.B.; Pum, D. A New Method for Dispersing Pristine Carbon Nanotubes Using Regularly Arranged S-Layer Proteins. Nanomaterials 2021, 11, 1346. https://doi.org/10.3390/nano11051346

Breitwieser A, Sleytr UB, Pum D. A New Method for Dispersing Pristine Carbon Nanotubes Using Regularly Arranged S-Layer Proteins. Nanomaterials. 2021; 11(5):1346. https://doi.org/10.3390/nano11051346

Chicago/Turabian StyleBreitwieser, Andreas, Uwe B. Sleytr, and Dietmar Pum. 2021. "A New Method for Dispersing Pristine Carbon Nanotubes Using Regularly Arranged S-Layer Proteins" Nanomaterials 11, no. 5: 1346. https://doi.org/10.3390/nano11051346

APA StyleBreitwieser, A., Sleytr, U. B., & Pum, D. (2021). A New Method for Dispersing Pristine Carbon Nanotubes Using Regularly Arranged S-Layer Proteins. Nanomaterials, 11(5), 1346. https://doi.org/10.3390/nano11051346