Properties of CrSi2 Layers Obtained by Rapid Heat Treatment of Cr Film on Silicon

Abstract

:1. Introduction

2. Materials and Methods

2.1. Coating Deposition

2.2. Coating Characterization

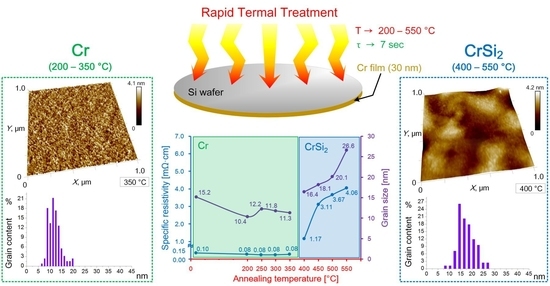

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rawal, S.K.; Kumar, A.; Jayaganthan, R.; Chandra, R. Applied Surface Science Optical and hydrophobic properties of co-sputtered chromium and titanium oxynitride films. Appl. Surf. Sci. 2011, 257, 8755–8761. [Google Scholar] [CrossRef]

- Yate, A.L.; Mart, L.; Esteve, J.; Lousa, A. Ultra Low Nanowear in Novel Chromium/Amorphous Chromium Carbide. Appl. Surf. Sci. 2017. [Google Scholar] [CrossRef]

- Danilov, F.I.; Protsenko, V.S.; Gordiienko, V.O.; Kwon, S.C.; Lee, J.Y.; Kim, M. Applied Surface Science Nanocrystalline hard chromium electrodeposition from trivalent chromium bath containing carbamide and formic acid: Structure, composition, electrochemical corrosion behavior, hardness and wear characteristics of deposits. Appl. Surf. Sci. 2011, 257, 8048–8053. [Google Scholar] [CrossRef]

- Santoni, F.; Giovine, E.; Torrioli, G.; Chiarello, F.; Castellano, M.G. Study of the Fabrication Process for a Dual Mass Tuning Fork Gyro. Procedia Eng. 2014, 87, 991–994. [Google Scholar] [CrossRef] [Green Version]

- Ghoranneviss, M.; Sari, A.H.; Esmaeelpour, M. Nitrogen implantation and heat treatment effect on the hardness improvement of the chromium film surface deposited on Si (1 1 1) substrate. Appl. Surf. Sci. 2004, 237, 326–331. [Google Scholar] [CrossRef]

- Lin, Y.C.; Hsu, C.Y.; Hung, S.K.; Chang, C.H.; Wen, D.C. The structural and optoelectronic properties of Ti-doped ZnO thin films prepared by introducing a Cr buffer layer and post-annealing. Appl. Surf. Sci. 2012, 258, 9891–9895. [Google Scholar] [CrossRef]

- Wang, X.; Chen, F.; Liu, H.; Liang, W.; Yang, Q.; Si, J.; Hou, X. Fabrication of micro-gratings on Au-Cr thin film by femtosecond laser interference with different pulse durations. Appl. Surf. Sci. 2009, 255, 8483–8487. [Google Scholar] [CrossRef]

- Shi, F.; Wang, Z.; Xue, C. Synthesis and characterization of GaN nanowires by ammoniating Ga2O3/Cr thin films deposited on Si(1 1 1) substrates. Appl. Surf. Sci. 2010, 256, 4883–4887. [Google Scholar] [CrossRef]

- Balu, R.; Raju, A.R.; Lakshminarayanan, V.; Mohan, S. Investigations on the influence of process parameters on the structural evolution of ion beam sputter deposited chromium thin films. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2005, 123, 7–12. [Google Scholar] [CrossRef] [Green Version]

- Martinez, A.; Esteve, D.; Guivarc’h, A.; Auvray, P.; Henoc, P.; Pelous, G. Metallurgical and electrical properties of chromium silicon interfaces. Solid State Electron. 1980, 23, 55–64. [Google Scholar] [CrossRef]

- Deneb Menda, U.; Özdemir, O.; Tatar, B.; Ürgen, M.; Kutlu, K. Transport and storage properties of CrSi2/Si junctions made using the CAPVD technique. Mater. Sci. Semicond. Process. 2010, 13, 257–266. [Google Scholar] [CrossRef]

- Sobe, G.; Schreiber, H.; Weise, G.; Voigtmann, R.; Zies, G.; Sonntag, J.; Grotzschel, R. Deposition Of Cr-Si Thin Films By Reactive Plasmatron-Magnetron Sputtering. Thin Solid Film 1985, 128, 149–159. [Google Scholar] [CrossRef]

- Tam, P.L.; Cao, Y.; Nyborg, L. Thin film characterisation of chromium disilicide. Surf. Sci. 2013, 609, 152–156. [Google Scholar] [CrossRef]

- Galkin, N.G.; Dózsa, L.; Chusovitin, E.A.; Dotsenko, S.A.; Pécz, B.; Dobos, L. Influence of CrSi2 nanocrystals on the electrical properties of Au/Si-p/CrSi2 NCs/Si(111)-n mesa-diodes. Phys. Procedia 2011, 11, 35–38. [Google Scholar] [CrossRef] [Green Version]

- Gül, F. Addressing the sneak-path problem in crossbar RRAM devices using memristor-based one Schottky diode-one resistor array. Results Phys. 2019, 12, 1091–1096. [Google Scholar] [CrossRef]

- Henrion, W.; Lange, H.; Jahne, E.; Giehler, M. Optical properties of chromium and iron disilicide layers. Appl. Surf. Sci. 1993, 70–71, 569–572. [Google Scholar] [CrossRef]

- Galkin, N.G.; Konchenko, A.V.; Vavanova, S.V.; Maslov, A.M.; Talanov, A.O. Transport, optical and thermoelectrical properties of Cr and Fe disilicides and their alloys on Si(1 1 1). Appl. Surf. Sci. 2001, 175–176, 299–305. [Google Scholar] [CrossRef]

- Kovsarian, A.; Shannon, J.M.; Cristiano, F. Comparison of amorphous Mo and Cr disilicides in hydrogenated amorphous silicon. J. Non. Cryst. Solids 2000, 276, 40–45. [Google Scholar] [CrossRef]

- Zhu, J.; Barbier, D.; Mayet, L.; Gavand, M.; Chaussemy, G. Interstitial chromium behaviour in silicon during rapid thermal annealing. Appl. Surf. Sci. 1989, 36, 413–420. [Google Scholar] [CrossRef]

- D’Anna, E.; Leggieri, G.; Luches, A.; Majni, G.; Ottaviani, G. Chromium silicide formation under pulsed heat flow. Thin Solid Films 1986, 136, 93–104. [Google Scholar] [CrossRef]

- Solovjov, J.A.; Pilipenko, V.A. Effect of rapid thermal treatment conditions on electrophysical properties of chromium thin films on silicon. Doklady Bguir. 2019, 7–8, 157–164. [Google Scholar] [CrossRef]

- Filonenko, O.; Mogilatenko, A.; Hortenbach, H.; Allenstein, F.; Beddies, G.; Hinneberg, H.J. Influence of ultrathin templates on the epitaxial growth of CrSi 2 on Si(0 0 1). Microelectron. Eng. 2004, 76, 324–330. [Google Scholar] [CrossRef]

- Newton, P.; Houzé, F.; Guessab, S.; Noël, S.; Boyer, L.; Lécayon, G.; Viel, P. Atomic force microscopy study of the topographic evolution of polyacrylonitrile thin films submitted to a rapid thermal treatment. Thin Solid Films 1997, 303, 200–206. [Google Scholar] [CrossRef]

- Lamprou, D.A.; Smith, J.R.; Nevell, T.G.; Barbu, E.; Stone, C.; Willis, C.R.; Tsibouklis, J. A comparative study of surface energy data from atomic force microscopy and from contact angle goniometry. Appl. Surf. Sci. 2010, 256, 5082–5087. [Google Scholar] [CrossRef] [Green Version]

- Galkin, N.G.; Astashynski, V.M.; Chusovitin, E.A.; Galkin, K.N.; Dergacheva, T.A.; Kuzmitski, A.M.; Kostyukevich, E.A. Ultra high vacuum growth of CrSi2 and β-FeSi2 nanoislands and Si top layers on the plasma modified monocrystalline silicon surfaces. Phys. Procedia. 2011, 11, 39–42. [Google Scholar] [CrossRef] [Green Version]

- Finstad, T.L.; Thomas, O.; D’heurle, F.M. Bilayers with Chromium Dishlicide: Chromium-Vanadium. Appl. Surf. Sci. 1989, 38, 106–116. [Google Scholar] [CrossRef]

- Chaplanov, A. Pulsed annealing of metal films and metal-semiconductor systems. Vacuum 1993, 44, 1085–1088. [Google Scholar] [CrossRef]

- Höflich, A.; Bradley, N.; Hall, C.; Evans, D.; Murphy, P.; Charrault, E. Packing density/surface morphology relationship in thin sputtered chromium films. Surf. Coatings Technol. 2016, 291, 286–291. [Google Scholar] [CrossRef]

- Lintymer, J.; Martin, N.; Chappe, J.M.; Takadoum, J. Glancing angle deposition to control microstructure and roughness of chromium thin films. Wear 2008, 264, 444–449. [Google Scholar] [CrossRef]

- Patnaik, L.; Maity, S.R.; Kumar, S. Comprehensive structural, nanomechanical and tribological evaluation of silver doped DLC thin film coating with chromium interlayer (Ag-DLC/Cr) for biomedical application. Ceram. Int. 2020, 46, 22805–22818. [Google Scholar] [CrossRef]

- Kuznetsova, T.; Lapitskaya, V.; Khabarava, A.; Chizhik, S.; Warcholinski, B.; Gilewicz, A. The influence of nitrogen on the morphology of ZrN coatings deposited by magnetron sputtering. Appl. Surf. Sci. 2020, 522, 146508. [Google Scholar] [CrossRef]

- Anishchik, V.M.; Uglov, V.V.; Kuleshov, A.K.; Filipp, A.R.; Rusalsky, D.P.; Astashynskaya, M.V.; Samtsov, M.P.; Kuznetsova, T.A.; Thiery, F.; Pauleau, Y. Electron field emission and surface morphology of a-C and a-C:H thin films. Thin Solid Films 2005, 482, 248–252. [Google Scholar] [CrossRef]

| Treatment | T (°C) | Time | Film Thickness (nm) | Ra (nm) | Rq (nm) | Rz (nm) | Grain Size (nm) | γ (N/m) | Specific Resistivity (10−4 Ω·cm) |

|---|---|---|---|---|---|---|---|---|---|

| RTT | 450 | 7 s | 60.0 * | 3.33 | 4.25 | 3.1 | 18.1 | 0.28 | 31.1 |

| Conventional heating | 30 min | 35.7 | 1.59 | 2.17 | 1.7 | 16.8 | 0.28 | 1.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuznetsova, T.; Lapitskaya, V.; Solovjov, J.; Chizhik, S.; Pilipenko, V.; Aizikovich, S. Properties of CrSi2 Layers Obtained by Rapid Heat Treatment of Cr Film on Silicon. Nanomaterials 2021, 11, 1734. https://doi.org/10.3390/nano11071734

Kuznetsova T, Lapitskaya V, Solovjov J, Chizhik S, Pilipenko V, Aizikovich S. Properties of CrSi2 Layers Obtained by Rapid Heat Treatment of Cr Film on Silicon. Nanomaterials. 2021; 11(7):1734. https://doi.org/10.3390/nano11071734

Chicago/Turabian StyleKuznetsova, Tatyana, Vasilina Lapitskaya, Jaroslav Solovjov, Sergei Chizhik, Vladimir Pilipenko, and Sergei Aizikovich. 2021. "Properties of CrSi2 Layers Obtained by Rapid Heat Treatment of Cr Film on Silicon" Nanomaterials 11, no. 7: 1734. https://doi.org/10.3390/nano11071734

APA StyleKuznetsova, T., Lapitskaya, V., Solovjov, J., Chizhik, S., Pilipenko, V., & Aizikovich, S. (2021). Properties of CrSi2 Layers Obtained by Rapid Heat Treatment of Cr Film on Silicon. Nanomaterials, 11(7), 1734. https://doi.org/10.3390/nano11071734