Homogeneous versus Inhomogeneous Polarization Switching in PZT Thin Films: Impact of the Structural Quality and Correlation to the Negative Capacitance Effect

Abstract

:1. Introduction

2. Materials and Methods

3. Results

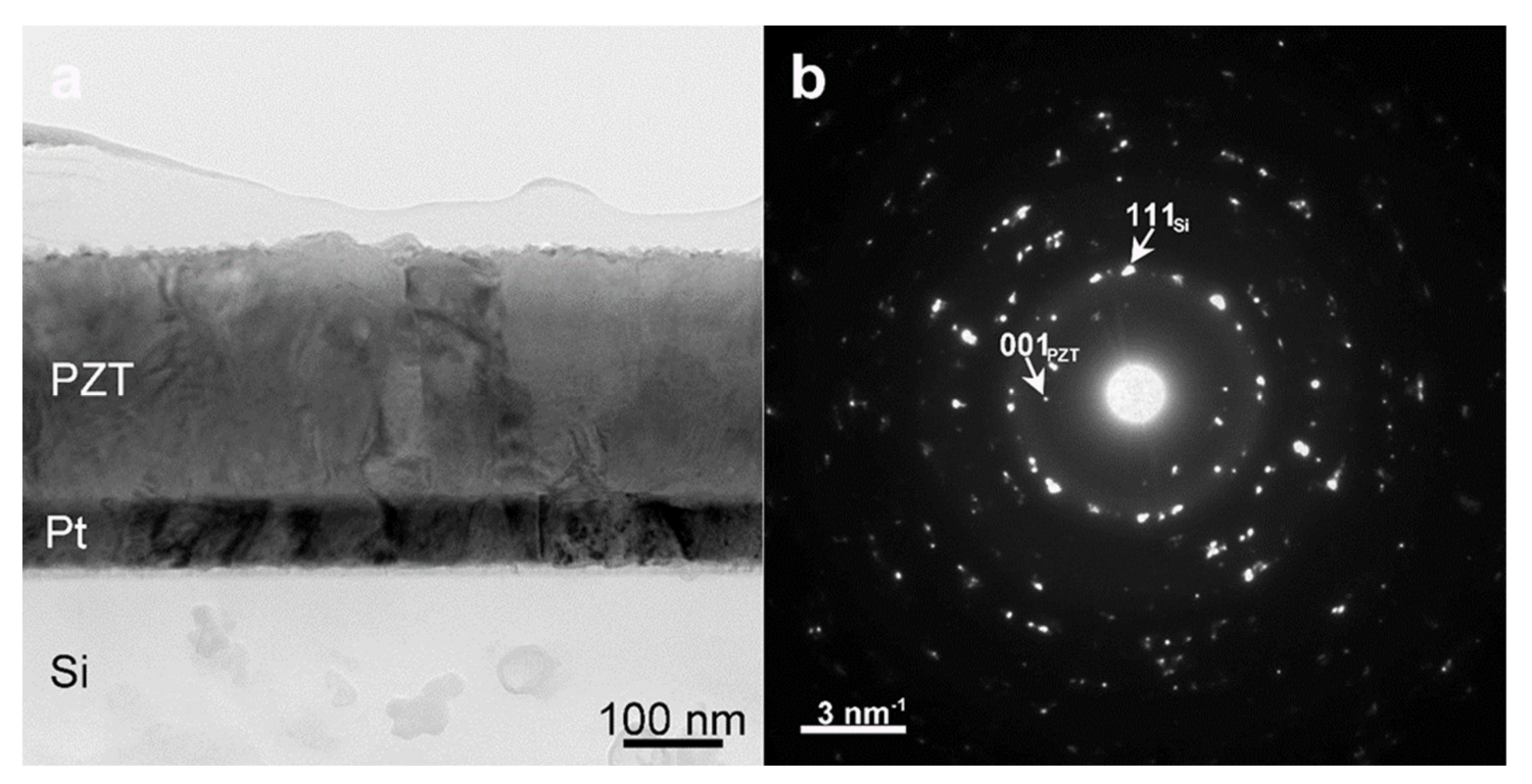

3.1. Structural Quality

3.2. Hysteresis and Derivative

3.3. Dynamic Dielectric Method to Extract Rp, Cp and Ctotal

- Sample prepoled by applying a trapezoidal pulse of maximum amplitude then trapezoidal pulses of increasing amplitude and of opposite polarity were successively applied on the sample and the current response was recorded. Polarization switching takes place in this case. The values of Rp, Cp and Ctotal were then estimated using the procedure presented elsewhere [37] and the obtained results were presented as function of the amplitude of the applied trapezoidal voltage pulse.

- The sample was prepoled as previously mentioned, and then pulses of the same polarity but of increasing amplitude were applied, and the current response was recorded. In this case, there is no polarization switching. Rp, Cp and Ctotal were again estimated and the obtained results were presented as functions of the amplitude of the applied trapezoidal voltage pulse.

- Ctotal has negative values during polarization switching. The larges values are obtained for the film deposited from the commercial target, and the smallest (more than two orders of magnitude smaller) are obtained for the polycrystalline film. If there is no polarization switching, then Ctotal is positive and relatively constant with the amplitude of the applied trapezoidal voltage.

- Cp has all the time positive values and presents a butterfly shape for the case when polarization switching takes place. If there is no switching, then Cp is almost constant and of the same value with Ctotal. One has to notice that the dynamic dielectric constant gives very nice results for Cp and Ctotal when applied to epitaxial films. In the case of the polycrystalline film the values are more scattered, and the butterfly shape of Cp, associated with polarization switching, is barely visible.

- Rp value has a drop if polarization switching takes place. When there is no polarization switching then Rp has the tendency to be relatively constant, with some increase around the coercive voltage, probably due to changes in the potential barriers at the Schottky-like contacts that are present at the electrode interfaces.

- The results of the dynamic dielectric characterization method are in agreement with those obtained from hysteresis measurements. NC effect is more pronounced in the epitaxial films than in polycrystalline ones. PFM investigations were further performed to see how domain configuration relates to NC.

3.4. PFM Results

- For the film obtained from the commercial target the well-known grid of 90° domain walls is obtained [36]. As the dc voltage applied on the tip increases from zero to the maximum value (from the left to the right in the PFM phase and PFM amplitude images), the polarization suddenly changes its orientation from upward (towards the surface, on the left side) to downward (towards the bottom electrode, on the right side). Notably, the grown film has a dominant upward orientation of polarization [38,39]. No mixture of domains with upward and downward directions of polarization is visible during switching. One can presume that the switching time is so fast that it is not possible to visualize this mixture of domains with almost zero value of the total polarization.

- For the films obtained from the pure target, the situation is significantly different. One can see that the domain structure is much more complicated than in the case of the film deposited from the commercial target. Outside the central square, where the dc voltage was gradually increased from the maximum negative voltage to the maximum positive voltage, there is a mixture of domains with upward and downward polarization directions, in contrast with a dominant upward direction evidenced in the film deposited from the commercial target. Additionally, looking to the central square one can see that the switching is not sharp and that there is a voltage range (a region) in which mixture of domains with upward and downward polarization directions are present. This region is flanked by a region of upward polarization to the left and one of downward polarization to the right. One can also notice that the grid of 90° domain walls becomes visible only after poling the film upward or downward, while on the grown surface outside the central square, this grid is hardly visible.

- As expected, the polycrystalline films are rougher than the epitaxial ones, with RMS values in between 5 and 15 nm, compared to 0.5 nm for epitaxial ones.

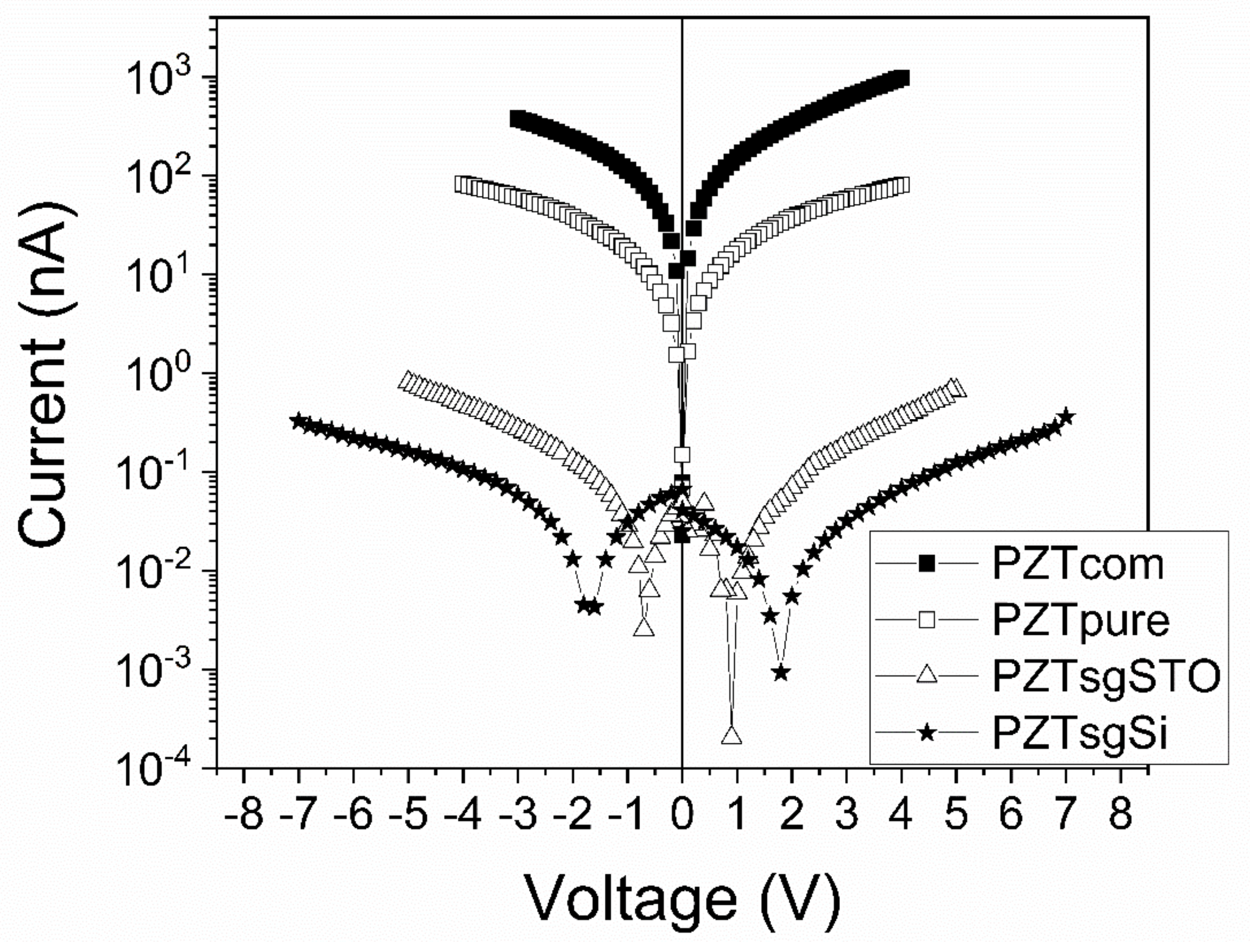

3.5. Leakage Current

- In the case of epitaxial films deposited from targets of different purities, the larger leakage current for the film deposited from the commercial target can be explained by the larger number of hetero-valent impurities found in this target compared to the pure one. These impurities can act as donors and acceptors and can affect the density of the free carriers on one hand and the height of the potential barriers at the electrode interfaces on the other hand, not mentioning the impact they can have on domain wall movement, reflected in the shape of the hysteresis loop [40,41,42,43,44,45,46,47,48]. It is known that acceptor and donor impurities can introduce energy levels in the gap, with impacts upon the position of the Fermi level position and the band alignment at the electrode interfaces [49,50,51,52]. Depending on the position of the Fermi level, the height of the potential barriers at electrodes, for the majority of carriers, can be larger or lower (in between 0.1 and 0.3 eV [36]), with impacts upon the magnitude of the leakage current.

- In the case of the polycrystalline films, the even lower leakage current can be caused by the grain barriers, acting both as trapping and scattering centers for the charge carriers.

4. Discussion

- A larger time constant for the ferroelectric layer in the case of the polycrystalline films compared to the epitaxial ones;

- A lower leakage current in polycrystalline films compared to epitaxial ones.

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Scott, J.F. Ferroelectric Memories; Springer Series in Advanced Microelectronics; Springer: Berlin/Heidelberg, Germany, 2000; Volume 3, ISBN 978-3-642-08565-9. [Google Scholar]

- Chanthbouala, A.; Garcia, V.; Cherifi, R.O.; Bouzehouane, K.; Fusil, S.; Moya, X.; Xavier, S.; Yamada, H.; Deranlot, C.; Mathur, N.D.; et al. A Ferroelectric Memristor. Nat. Mater. 2012, 11, 860–864. [Google Scholar] [CrossRef] [PubMed]

- Ishibashi, Y.; Takagi, Y. Note on Ferroelectric Domain Switching. J. Phys. Soc. Jpn. 1971, 31, 506–510. [Google Scholar] [CrossRef]

- Tagantsev, A.K.; Stolichnov, I.; Setter, N.; Cross, J.S.; Tsukada, M. Non-Kolmogorov-Avrami Switching Kinetics in Ferroelectric thin Films. Phys. Rev. B 2002, 66, 214109. [Google Scholar] [CrossRef]

- Kim, Y.; Han, H.; Lee, W.; Baik, S.; Hesse, D.; Alexe, M. Non-Kolmogorov−Avrami−Ishibashi Switching Dynamics in Nanoscale Ferroelectric Capacitors. Nano Lett. 2010, 10, 1266–1270. [Google Scholar] [CrossRef] [PubMed]

- Mwema, F.M.; Akinlabi, E.T.; Oladijo, O.P.; Fatoba, O.S.; Akinlabi, S.A.; Tălu, S. Chapter two—Advances in manufacturing analysis: Fractal theory in modern manufacturing. In Modern Manufacturing Processes; Kumar, K., Davim, J.P., Eds.; Woodhead Publishing Reviews: Mechanical Engineering Series; Woodhead Publishing: Cambridge, UK, 2020; pp. 13–39. ISBN 978-0-12-819496-6. [Google Scholar]

- Highland, M.J.; Fister, T.T.; Richard, M.-I.; Fong, D.D.; Fuoss, P.H.; Thompson, C.; Eastman, J.A.; Streiffer, S.K.; Stephenson, G.B. Polarization Switching without Domain Formation at the Intrinsic Coercive Field in Ultrathin Ferroelectric PbTiO3. Phys. Rev. Lett. 2010, 105, 167601. [Google Scholar] [CrossRef]

- Yukalov, V.I.; Yukalova, E.P. Ultrafast Polarization Switching in Ferroelectrics. Phys. Rev. Res. 2019, 1, 033136. [Google Scholar] [CrossRef] [Green Version]

- Subedi, A. Proposal for Ultrafast Switching of Ferroelectrics Using Midinfrared Pulses. Phys. Rev. B 2015, 92, 214303. [Google Scholar] [CrossRef] [Green Version]

- Bartic, A.T.; Wouters, D.J.; Maes, H.E.; Rickes, J.T.; Waser, R.M. Preisach Model for the Simulation of Ferroelectric Capacitors. J. Appl. Phys. 2001, 89, 3420–3425. [Google Scholar] [CrossRef] [Green Version]

- Pešić, M.; Künneth, C.; Hoffmann, M.; Mulaosmanovic, H.; Müller, S.; Breyer, E.T.; Schroeder, U.; Kersch, A.; Mikolajick, T.; Slesazeck, S. A Computational Study of Hafnia-Based Ferroelectric Memories: From ab initio via Physical Modeling to Circuit Models of Ferroelectric Device. J. Comput. Electron. 2017, 16, 1236–1256. [Google Scholar] [CrossRef] [Green Version]

- Zhao, D.; Lenz, T.; Gelinck, G.H.; Groen, P.; Damjanovic, D.; de Leeuw, D.M.; Katsouras, I. Depolarization of Multidomain Ferroelectric Materials. Nat. Commun. 2019, 10, 2547. [Google Scholar] [CrossRef] [PubMed]

- Mai, M.; Ke, S.; Lin, P.; Zeng, X. Intrinsic and Extrinsic Effects on the Ferroelectric Switching of Thin Poly(Vinylidene Fluoride/Trifluoroethylene) Copolymer Films. APL Mater. 2016, 4, 46107. [Google Scholar] [CrossRef] [Green Version]

- Hauf, C.; Hernandez Salvador, A.-A.; Holtz, M.; Woerner, M.; Elsaesser, T. Soft-Mode Driven Polarity Reversal in Ferroelectrics Mapped by Ultrafast x-Ray Diffraction. Struct. Dyn. 2018, 5, 024501. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Takahashi, K.; Kida, N.; Tonouchi, M. Terahertz Radiation by an Ultrafast Spontaneous Polarization Modulation of Multiferroic BiFeO3 Thin Films. Phys. Rev. Lett. 2006, 96, 117402. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khan, A.I.; Chatterjee, K.; Wang, B.; Drapcho, S.; You, L.; Serrao, C.; Bakaul, S.R.; Ramesh, R.; Salahuddin, S. Negative Capacitance in a Ferroelectric Capacitor. Nat. Mater. 2015, 14, 182–186. [Google Scholar] [CrossRef] [PubMed]

- Hoffmann, M.; Pešić, M.; Chatterjee, K.; Khan, A.I.; Salahuddin, S.; Slesazeck, S.; Schroeder, U.; Mikolajick, T. Direct Observation of Negative Capacitance in Polycrystalline Ferroelectric HfO2. Adv. Funct. Mater. 2016, 26, 8643–8649. [Google Scholar] [CrossRef]

- Hoffmann, M.; Pešić, M.; Slesazeck, S.; Schroeder, U.; Mikolajick, T. On the Stabilization of Ferroelectric Negative Capacitance in Nanoscale Devices. Nanoscale 2018, 10, 10891–10899. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gao, W.; Khan, A.; Marti, X.; Nelson, C.; Serrao, C.; Ravichandran, J.; Ramesh, R.; Salahuddin, S. Room-Temperature Negative Capacitance in a Ferroelectric–Dielectric Superlattice Heterostructure. Nano Lett. 2014, 14, 5814–5819. [Google Scholar] [CrossRef]

- Kim, Y.J.; Park, M.H.; Lee, Y.H.; Kim, H.J.; Jeon, W.; Moon, T.; Do Kim, K.; Jeong, D.S.; Yamada, H.; Hwang, C.S. Frustration of Negative Capacitance in AlO3/BaTiO3 Bilayer Structure. Sci. Rep. 2016, 6, 19039. [Google Scholar] [CrossRef] [PubMed]

- Íñiguez, J.; Zubko, P.; Luk’yanchuk, I.; Cano, A. Ferroelectric Negative Capacitance. Nat. Rev. Mater. 2019, 4, 243–256. [Google Scholar] [CrossRef] [Green Version]

- Salahuddin, S.; Datta, S. Use of Negative Capacitance to Provide Voltage Amplification for Low Power Nanoscale Devices. Nano Lett. 2008, 8, 405–410. [Google Scholar] [CrossRef] [PubMed]

- Cavin, R.K.; Zhirnov, V.V.; Hutchby, J.A.; Bourianoff, G.I. Energy Barriers, Demons, and Minimum Energy Operation of Electronic Devices. Fluct. Noise Lett. 2005, 05, C29–C38. [Google Scholar] [CrossRef]

- Cao, W.; Banerjee, K. Is Negative Capacitance FET a Steep-Slope Logic Switch? Nat. Commun. 2020, 11, 196. [Google Scholar] [CrossRef] [PubMed]

- Hoffmann, M.; Fengler, F.P.G.; Herzig, M.; Mittmann, T.; Max, B.; Schroeder, U.; Negrea, R.; Lucian, P.; Slesazeck, S.; Mikolajick, T. Unveiling the Double-Well Energy Landscape in a Ferroelectric Layer. Nature 2019, 565, 464–467. [Google Scholar] [CrossRef] [PubMed]

- Pintilie, L.; Boni, G.A.; Chirila, C.; Hrib, L.; Trupina, L.; Filip, L.D.; Pintilie, I. Polarization Switching and Negative Capacitance in Epitaxial PbZr0.2Ti0.8O3 Thin Films. Phys. Rev. Appl. 2020, 14, 014080. [Google Scholar] [CrossRef]

- Saha, A.K.; Datta, S.; Gupta, S.K. “Negative capacitance” in resistor-ferroelectric and ferroelectric-dielectric networks: Apparent or intrinsic? J. Appl. Phys. 2018, 123, 105102. [Google Scholar] [CrossRef]

- Chang, S.-C.; Avci, U.E.; Nikonov, D.E.; Manipatruni, S.; Young, I.A. Physical Origin of Transient Negative Capacitance in a Ferroelectric Capacitor. Phys. Rev. Appl. 2018, 9, 014010. [Google Scholar] [CrossRef] [Green Version]

- Song, S.J.; Kim, Y.J.; Park, M.H.; Lee, Y.H.; Kim, H.J.; Moon, T.; Do Kim, K.; Choi, J.-H.; Chen, Z.; Jiang, A.; et al. Alternative Interpretations for Decreasing Voltage with Increasing Charge in Ferroelectric Capacitors. Sci. Rep. 2016, 6, 20825. [Google Scholar] [CrossRef]

- Cheng, P.-H.; Yin, Y.-T.; Tsai, I.-N.; Lu, C.-H.; Li, L.-J.; Pan, S.C.; Shieh, J.; Shiojiri, M.; Chen, M.-J. Negative Capacitance from the Inductance of Ferroelectric Switching. Commun. Phys. 2019, 2, 32. [Google Scholar] [CrossRef] [Green Version]

- Yadav, A.K.; Nguyen, K.X.; Hong, Z.; García-Fernández, P.; Aguado-Puente, P.; Nelson, C.T.; Das, S.; Prasad, B.; Kwon, D.; Cheema, S.; et al. Spatially Resolved Steady-State Negative Capacitance. Nature 2019, 565, 468–471. [Google Scholar] [CrossRef] [Green Version]

- Zubko, P.; Wojdeł, J.C.; Hadjimichael, M.; Fernandez-Pena, S.; Sené, A.; Luk’yanchuk, I.; Triscone, J.-M.; Íñiguez, J. Negative Capacitance in Multidomain Ferroelectric Superlattices. Nature 2016, 534, 524–528. [Google Scholar] [CrossRef] [Green Version]

- Cano, A.; Jiménez, D. Multidomain Ferroelectricity as a Limiting Factor for Voltage Amplification in Ferroelectric Field-Effect Transistors. Appl. Phys. Lett. 2010, 97, 133509. [Google Scholar] [CrossRef] [Green Version]

- Saha, A.K.; Gupta, S.K. Multi-Domain Negative Capacitance Effects in Metal-Ferroelectric-Insulator-Semiconductor/Metal Stacks: A Phase-field Simulation Based Study. Sci. Rep. 2020, 10, 10207. [Google Scholar] [CrossRef]

- Luk’yanchuk, I.; Tikhonov, Y.; Sené, A.; Razumnaya, A.; Vinokur, V.M. Harnessing Ferroelectric Domains for Negative Capacitance. Commun. Phys. 2019, 2, 22. [Google Scholar] [CrossRef]

- Boni, G.A.; Chirila, C.F.; Stancu, V.; Amarande, L.; Pasuk, I.; Trupina, L.; Istrate, C.M.; Radu, C.; Tomulescu, A.; Neatu, S.; et al. Accidental Impurities in Epitaxial Pb(Zr0.2Ti0.8)O3 Thin Films Grown by Pulsed Laser Deposition and Their Impact on the Macroscopic Electric Properties. Nanomaterials 2021, 11, 1177. [Google Scholar] [CrossRef] [PubMed]

- Boni, G.A.; Chirila, C.; Filip, L.D.; Pintilie, I.; Pintilie, L. Negative Capacitance in Epitaxial Ferroelectric Capacitors Evidenced by Dynamic Dielectric Characterization. Mater. Today Commun. 2021, 26, 102076. [Google Scholar] [CrossRef]

- Luo, Y.; Li, X.; Chang, L.; Gao, W.; Yuan, G.; Yin, J.; Liu, Z. Upward Ferroelectric Self-Poling in (001) Oriented PbZr0.2Ti0.8O3 Epitaxial Films with Compressive strain. AIP Adv. 2013, 3, 122101. [Google Scholar] [CrossRef] [Green Version]

- Arenholz, E.; van der Laan, G.; Fraile-Rodríguez, A.; Yu, P.; He, Q.; Ramesh, R. Probing Ferroelectricity in PbZr0.2Ti0.8O3 with Polarized Soft x Rays. Phys. Rev. B 2010, 82, 140103. [Google Scholar] [CrossRef] [Green Version]

- Whatmore, R. Ferroelectric Materials. In Springer Handbook of Electronic and Photonic Materials; Kasap, S., Capper, P., Eds.; Springer Handbooks; Springer International Publishing: Cham, Switzerland, 2017; p. 1. ISBN 978-3-319-48933-9. [Google Scholar]

- Maglione, M.; Philippot, G.; Levasseur, D.; Payan, S.; Aymonier, C.; Elissalde, C. Defect Chemistry in Ferroelectric Perovskites: Long Standing Issues and Recent Advances. Dalton Trans. 2015, 44, 13411–13418. [Google Scholar] [CrossRef]

- Erhart, P.; Eichel, R.-A.; Träskelin, P.; Albe, K. Association of Oxygen Vacancies with Impurity Metal Ions in Lead Titanate. Phys. Rev. B 2007, 76, 174116. [Google Scholar] [CrossRef] [Green Version]

- Veerapandiyan, V.K.; Khosravi, H.S.; Canu, G.; Feteira, A.; Buscaglia, V.; Reichmann, K.; Deluca, M. B-Site Vacancy Induced Raman Scattering in BaTiO3-Based Ferroelectric Ceramics. J. Eur. Ceram. Soc. 2020, 40, 4684–4688. [Google Scholar] [CrossRef]

- Feng, Y.; Wu, J.; Chi, Q.; Li, W.; Yu, Y.; Fei, W. Defects and Aliovalent Doping Engineering in Electroceramics. Chem. Rev. 2020, 120, 1710–1787. [Google Scholar] [CrossRef]

- Hong, S.; Nakhmanson, S.M.; Fong, D.D. Screening Mechanisms at Polar Oxide Heterointerfaces. Rep. Prog. Phys. 2016, 79, 076501. [Google Scholar] [CrossRef] [Green Version]

- Schenk, T.; Yurchuk, E.; Mueller, S.; Schroeder, U.; Starschich, S.; Böttger, U.; Mikolajick, T. About the Deformation of Ferroelectric Hystereses. Appl. Phys. Rev. 2014, 1, 041103. [Google Scholar] [CrossRef]

- Eichel, R.-A.; Kungl, H.; Jakes, P. Defect Structure of Non-Stoichiometric and Aliovalently Doped Perovskite Oxides. Mater. Technol. 2013, 28, 241–246. [Google Scholar] [CrossRef]

- Pramanick, A.; Prewitt, A.D.; Forrester, J.S.; Jones, J.L. Domains, Domain Walls and Defects in Perovskite Ferroelectric Oxides: A Review of Present Understanding and Recent Contributions. Crit. Rev. Solid State Mater. Sci. 2012, 37, 243–275. [Google Scholar] [CrossRef]

- Robertson, J. Band Offsets of Wide-Band-Gap Oxides and Implications for Future Electronic Devices. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 2000, 18, 1785–1791. [Google Scholar] [CrossRef]

- Klein, A. Energy Band Alignment at Interfaces of Semiconducting Oxides: A Review of Experimental Determination Using Photoelectron Spectroscopy and Comparison with Theoretical Predictions by the Electron Affinity Rule, Charge Neutrality Levels, and the Common Anion Rule. Thin Solid Film. 2012, 520, 3721–3728. [Google Scholar] [CrossRef]

- Zhang, W.Q.; Yang, Q.; Zhou, Y.C.; Cao, J.X. Interface Effect on Leakage Current of Ferroelectric film. Comput. Mater. Sci. 2016, 115, 120–124. [Google Scholar] [CrossRef]

- Pintilie, I.; Teodorescu, C.M.; Ghica, C.; Chirila, C.; Boni, A.G.; Hrib, L.; Pasuk, I.; Negrea, R.; Apostol, N.; Pintilie, L. Polarization-Control of the Potential Barrier at the Electrode Interfaces in Epitaxial Ferroelectric Thin Films. ACS Appl. Mater. Interfaces 2014, 6, 2929–2939. [Google Scholar] [CrossRef]

- Gruverman, A.; Rodriguez, B.J.; Dehoff, C.; Waldrep, J.D.; Kingon, A.I.; Nemanich, R.J.; Cross, J.S. Direct Studies of Domain Switching Dynamics in Thin Film Ferroelectric Capacitors. Appl. Phys. Lett. 2005, 87, 082902. [Google Scholar] [CrossRef] [Green Version]

- Chang, H.; Kalinin, S.V.; Yang, S.; Yu, P.; Bhattacharya, S.; Wu, P.P.; Balke, N.; Jesse, S.; Chen, L.Q.; Ramesh, R.; et al. Watching Domains Grow: In-Situ Studies of Polarization Switching by Combined Scanning Probe and Scanning Transmission Electron Microscopy. J. Appl. Phys. 2011, 110, 052014. [Google Scholar] [CrossRef] [Green Version]

- Winkler, C.R.; Damodaran, A.R.; Karthik, J.; Martin, L.W.; Taheri, M.L. Direct Observation of Ferroelectric Domain Switching in Varying Electric Field Regimes Using In Situ TEM. Micron 2012, 43, 1121–1126. [Google Scholar] [CrossRef] [Green Version]

- Boddu, V.; Endres, F.; Steinmann, P. Molecular Dynamics Study of Ferroelectric Domain Nucleation and Domain Switching Dynamics. Sci. Rep. 2017, 7, 806. [Google Scholar] [CrossRef] [Green Version]

- Volk, T.; Isakov, D.; Ivanov, N.; Ivleva, L.; Betzler, K.; Tunyagi, A.; Wöhlecke, M. Study of Ferroelectric Domain Switching by Domain Wall Induced Light Scattering. J. Appl. Phys. 2005, 97, 074102. [Google Scholar] [CrossRef] [Green Version]

- Shin, Y.-H.; Grinberg, I.; Chen, I.-W.; Rappe, A.M. Nucleation and Growth Mechanism of Ferroelectric Domain-Wall Motion. Nature 2007, 449, 881–884. [Google Scholar] [CrossRef] [Green Version]

- Nelson, C.T.; Gao, P.; Jokisaari, J.R.; Heikes, C.; Adamo, C.; Melville, A.; Baek, S.-H.; Folkman, C.M.; Winchester, B.; Gu, Y.; et al. Domain Dynamics During Ferroelectric Switching. Science 2011, 334, 968–971. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Xie, L.; Pan, X. Real-Time Studies of Ferroelectric Domain Switching: A Review. Rep. Prog. Phys. 2019, 82, 126502. [Google Scholar] [CrossRef]

- Yang, S.M.; Kim, Y.; Yang, S.M.; Kim, Y. Nanoscale Probing of Ferroelectric Domain Switching Using Piezoresponse Force Microscopy. J. Korean Ceram. Soc. 2019, 56, 340–349. [Google Scholar] [CrossRef] [Green Version]

- Kalinin, S.V.; Rodriguez, B.J.; Jesse, S.; Chu, Y.H.; Zhao, T.; Ramesh, R.; Choudhury, S.; Chen, L.Q.; Eliseev, E.A.; Morozovska, A.N. Intrinsic Single-Domain Switching in Ferroelectric Materials on a Nearly Ideal Surface. Proc. Natl. Acad. Sci. USA 2007, 104, 20204–20209. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kliem, H.; Kuehn, M. Modeling the Switching Kinetics in Ferroelectrics. J. Appl. Phys. 2011, 110, 114106. [Google Scholar] [CrossRef]

- Ivry, Y.; Scott, J.F.; Salje, E.K.H.; Durkan, C. Nucleation, Growth, and Control of Ferroelectric-Ferroelastic Domains in Thin Polycrystalline Films. Phys. Rev. B 2012, 86, 205428. [Google Scholar] [CrossRef] [Green Version]

- Pantel, D.; Chu, Y.-H.; Martin, L.W.; Ramesh, R.; Hesse, D.; Alexe, M. Switching Kinetics in Epitaxial BiFeO3 Thin Films. J. Appl. Phys. 2010, 107, 084111. [Google Scholar] [CrossRef]

- Bystrov, V.S.; Fridkin, V.M. Domain and Homogeneous Switching in Ferroelectrics. Ferroelectrics 2020, 569, 164–181. [Google Scholar] [CrossRef]

- Ducharme, S.; Fridkin, V.M.; Bune, A.V.; Palto, S.P.; Blinov, L.M.; Petukhova, N.N.; Yudin, S.G. Intrinsic Ferroelectric Coercive Field. Phys. Rev. Lett 2000, 84, 175–178. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ducharme, S.; Fridkin, V.; Gaynutdinov, R.; Minnekaev, M.; Tolstikhina, A.; Zenkevich, A. Homogeneous Switching in Ultrathin Ferroelectric BaTiO3 Films. arXiv 2012, arXiv:1204.4792. [Google Scholar]

- Gaynutdinov, R.; Yudin, S.; Ducharme, S.; Fridkin, V. Homogeneous Switching in Ultrathin Ferroelectric Films. J. Phys. Condens. Matter 2011, 24, 015902. [Google Scholar] [CrossRef] [PubMed]

- Tian, B.B.; Chen, L.F.; Liu, Y.; Bai, X.F.; Wang, J.L.; Sun, S.; Yuan, G.L.; Sun, J.L.; Dkhil, B.; Meng, X.J.; et al. Homogeneous Switching Mechanism in Pure Polyvinylidene Fluoride Ultrathin Films. Phys. Rev. B 2015, 92, 060102. [Google Scholar] [CrossRef]

| Sample | Pr (C/m2) | Ec (MV/m) | Ein (MV/m) |

|---|---|---|---|

| PZT—PLD grown from commercial target | 0.87 | 16.25 | 4.37 |

| PZT—PLD grown from pure target | 0.65 | 17.95 | 2.65 |

| PZT—sol-gel on SRO/STO substrate | 0.295 | 16.5 | −8 |

| PZT—sol-gel on Pt/Si substrate | 0.145 | 17.2 | −2.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pintilie, L.; Boni, G.A.; Chirila, C.F.; Stancu, V.; Trupina, L.; Istrate, C.M.; Radu, C.; Pintilie, I. Homogeneous versus Inhomogeneous Polarization Switching in PZT Thin Films: Impact of the Structural Quality and Correlation to the Negative Capacitance Effect. Nanomaterials 2021, 11, 2124. https://doi.org/10.3390/nano11082124

Pintilie L, Boni GA, Chirila CF, Stancu V, Trupina L, Istrate CM, Radu C, Pintilie I. Homogeneous versus Inhomogeneous Polarization Switching in PZT Thin Films: Impact of the Structural Quality and Correlation to the Negative Capacitance Effect. Nanomaterials. 2021; 11(8):2124. https://doi.org/10.3390/nano11082124

Chicago/Turabian StylePintilie, Lucian, Georgia Andra Boni, Cristina Florentina Chirila, Viorica Stancu, Lucian Trupina, Cosmin Marian Istrate, Cristian Radu, and Ioana Pintilie. 2021. "Homogeneous versus Inhomogeneous Polarization Switching in PZT Thin Films: Impact of the Structural Quality and Correlation to the Negative Capacitance Effect" Nanomaterials 11, no. 8: 2124. https://doi.org/10.3390/nano11082124

APA StylePintilie, L., Boni, G. A., Chirila, C. F., Stancu, V., Trupina, L., Istrate, C. M., Radu, C., & Pintilie, I. (2021). Homogeneous versus Inhomogeneous Polarization Switching in PZT Thin Films: Impact of the Structural Quality and Correlation to the Negative Capacitance Effect. Nanomaterials, 11(8), 2124. https://doi.org/10.3390/nano11082124