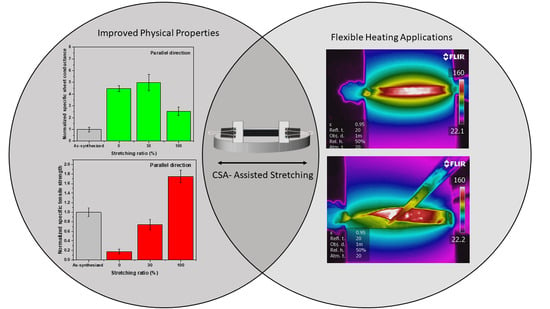

Chlorosulfonic Acid Stretched Carbon Nanotube Sheet for Flexible and Low-Voltage Heating Applications

Abstract

:1. Introduction

2. Experimental Section

2.1. CNT Sheet Fabrication

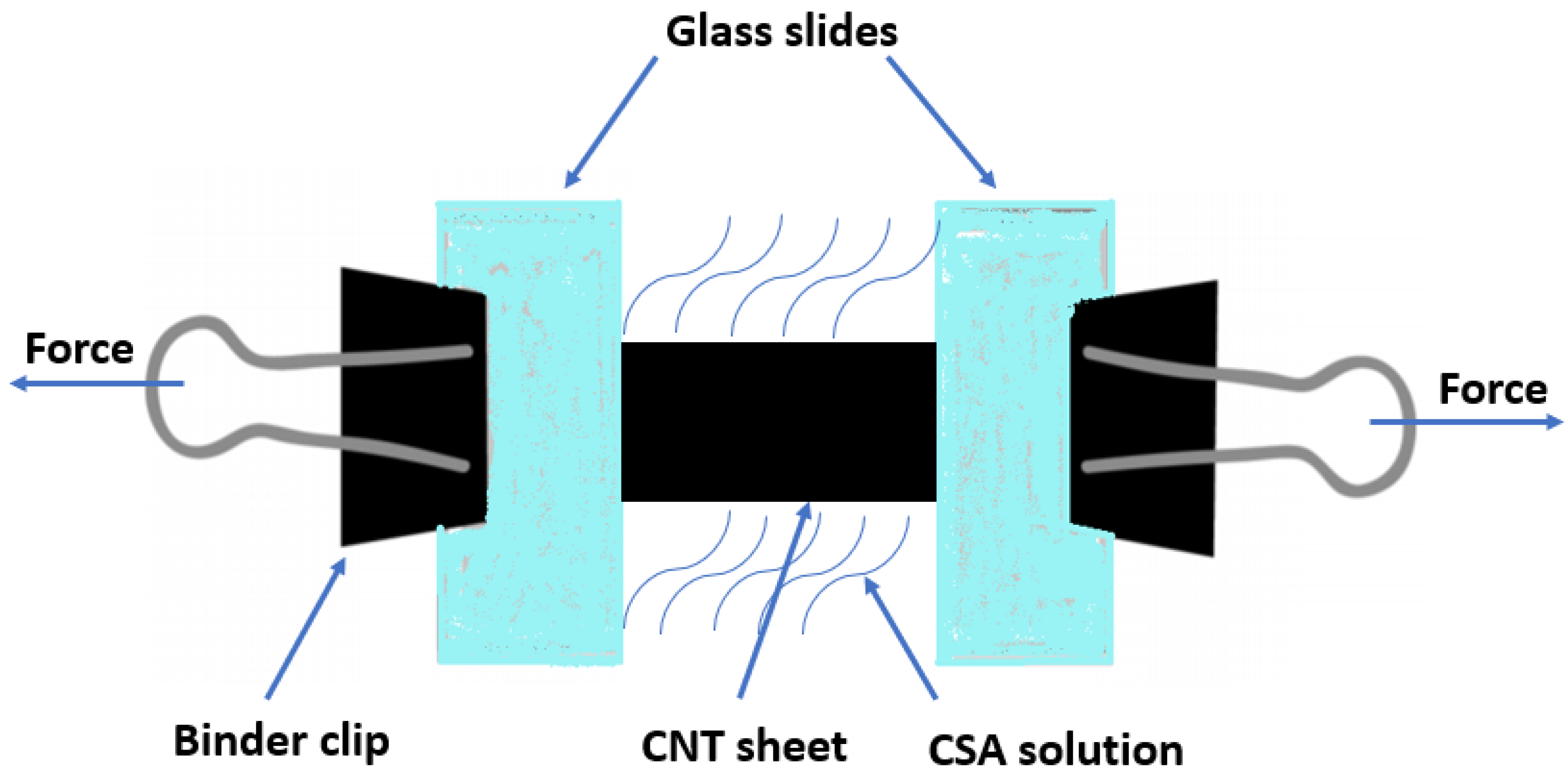

2.2. CSA-Assisted Stretching

2.3. Material Characterization

2.4. Heating Performance Measurement

3. Results and Discussion

3.1. The Effect of CSA-Stretching

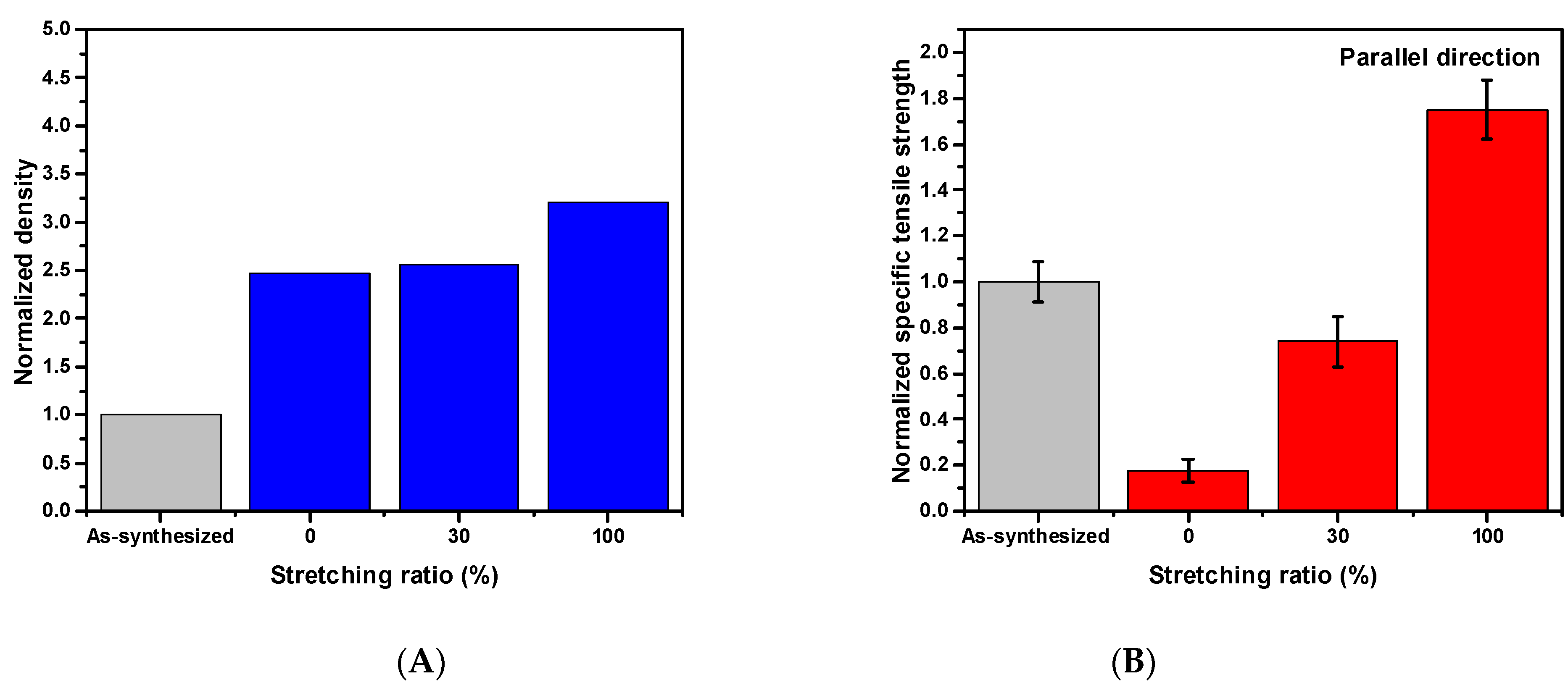

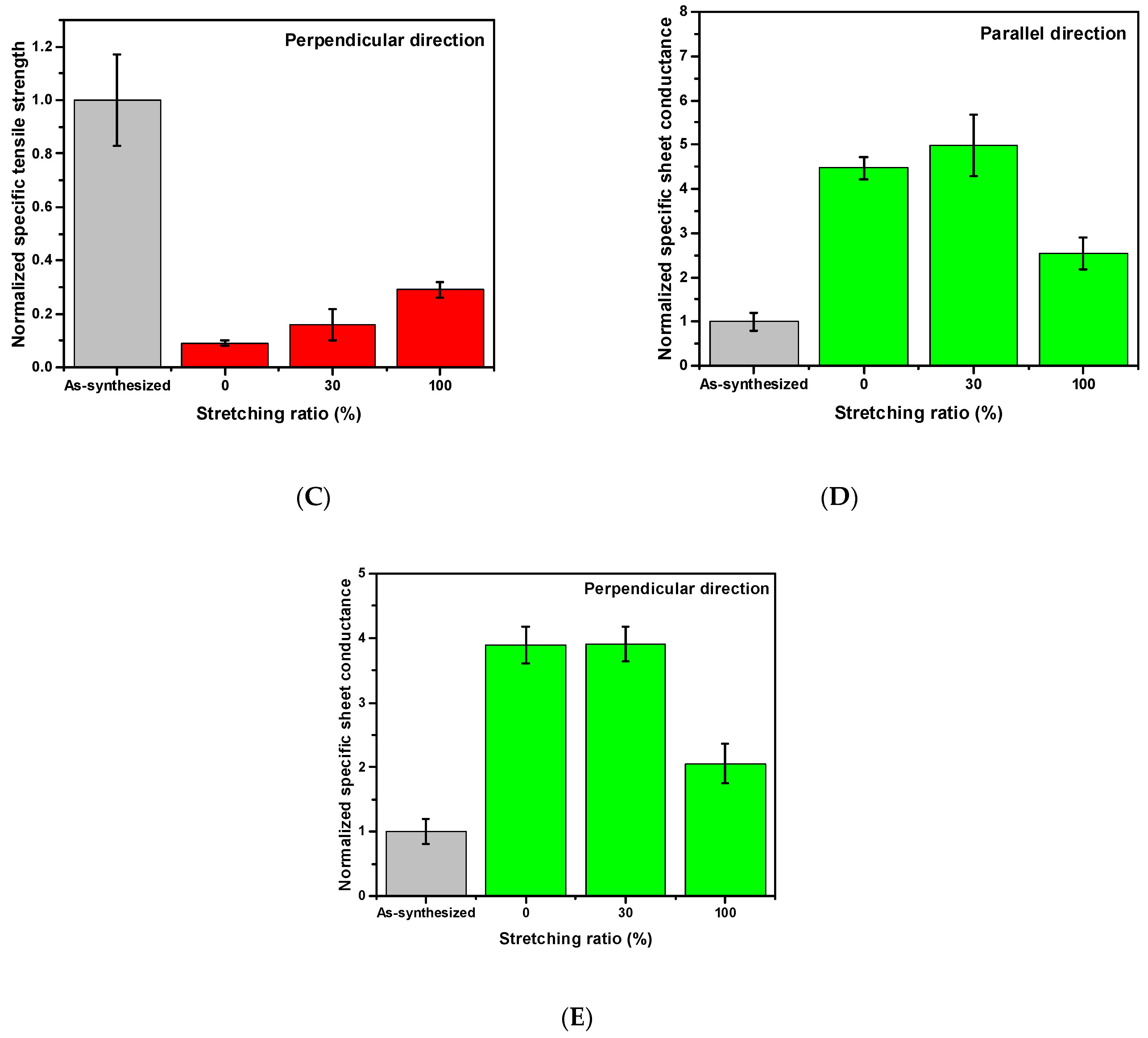

3.2. The Improvement of Mechanical and Electrical Properties

3.3. The Analysis of Alignment

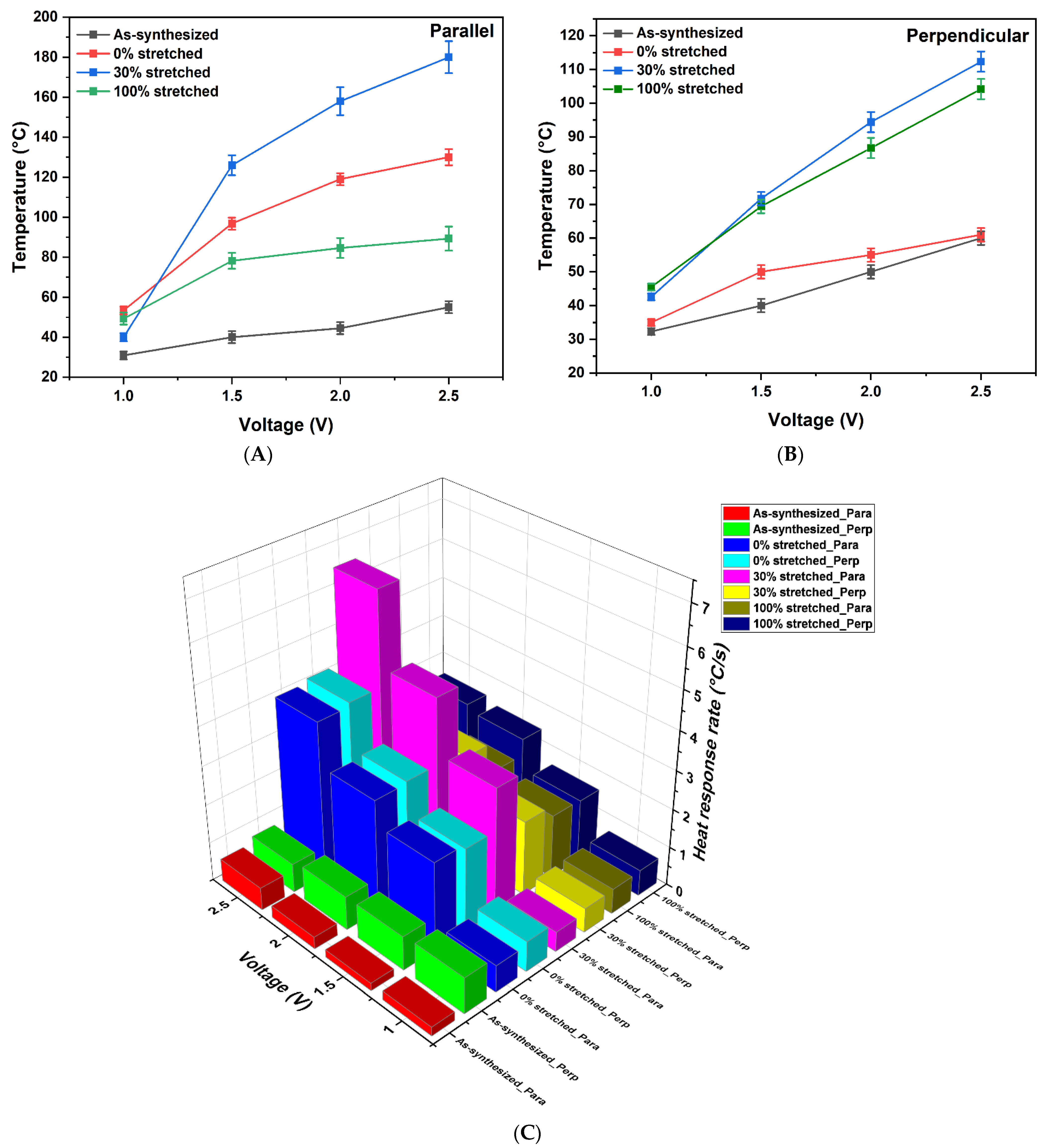

3.4. Heating Performance of CSA-Stretched CNTs

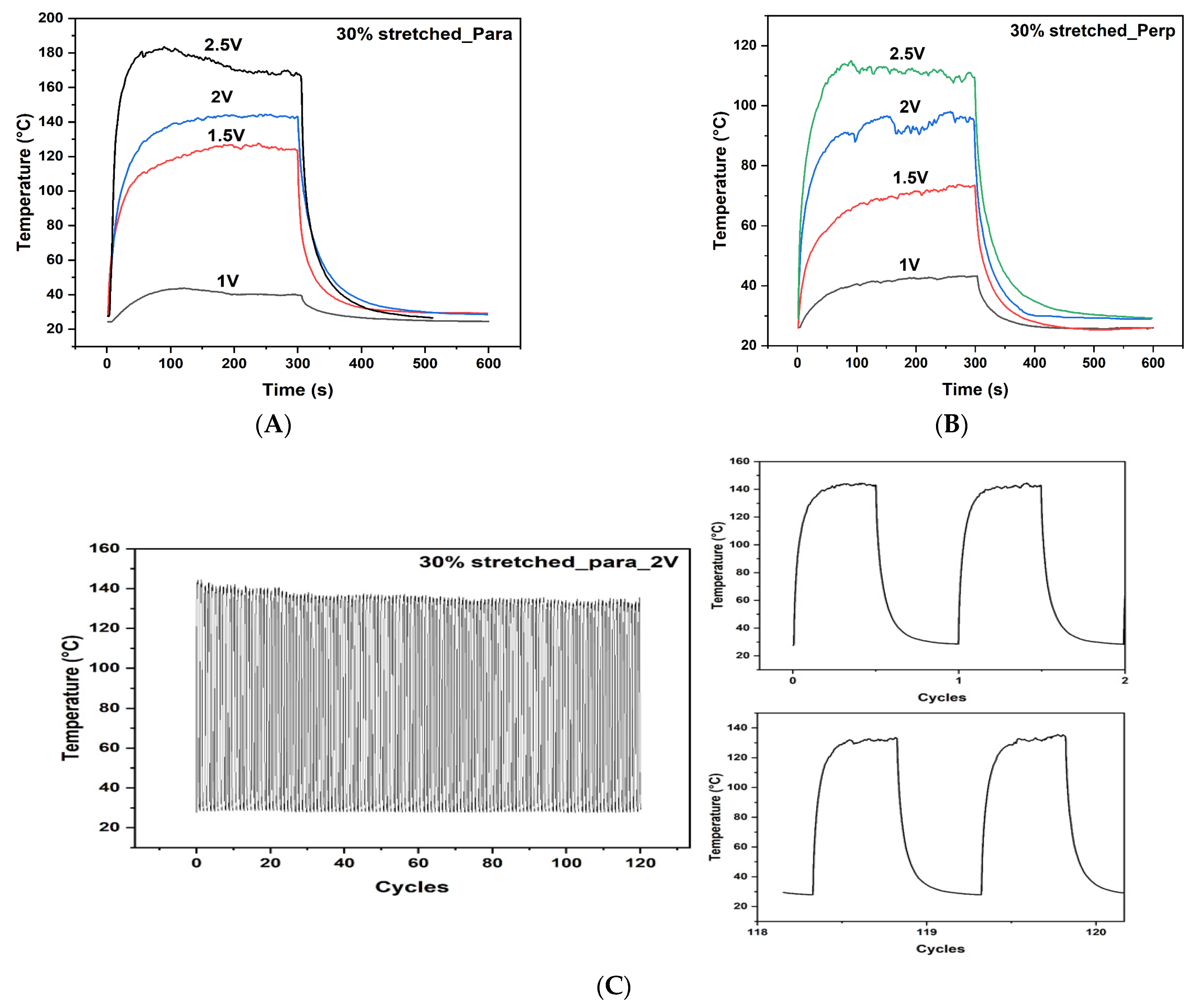

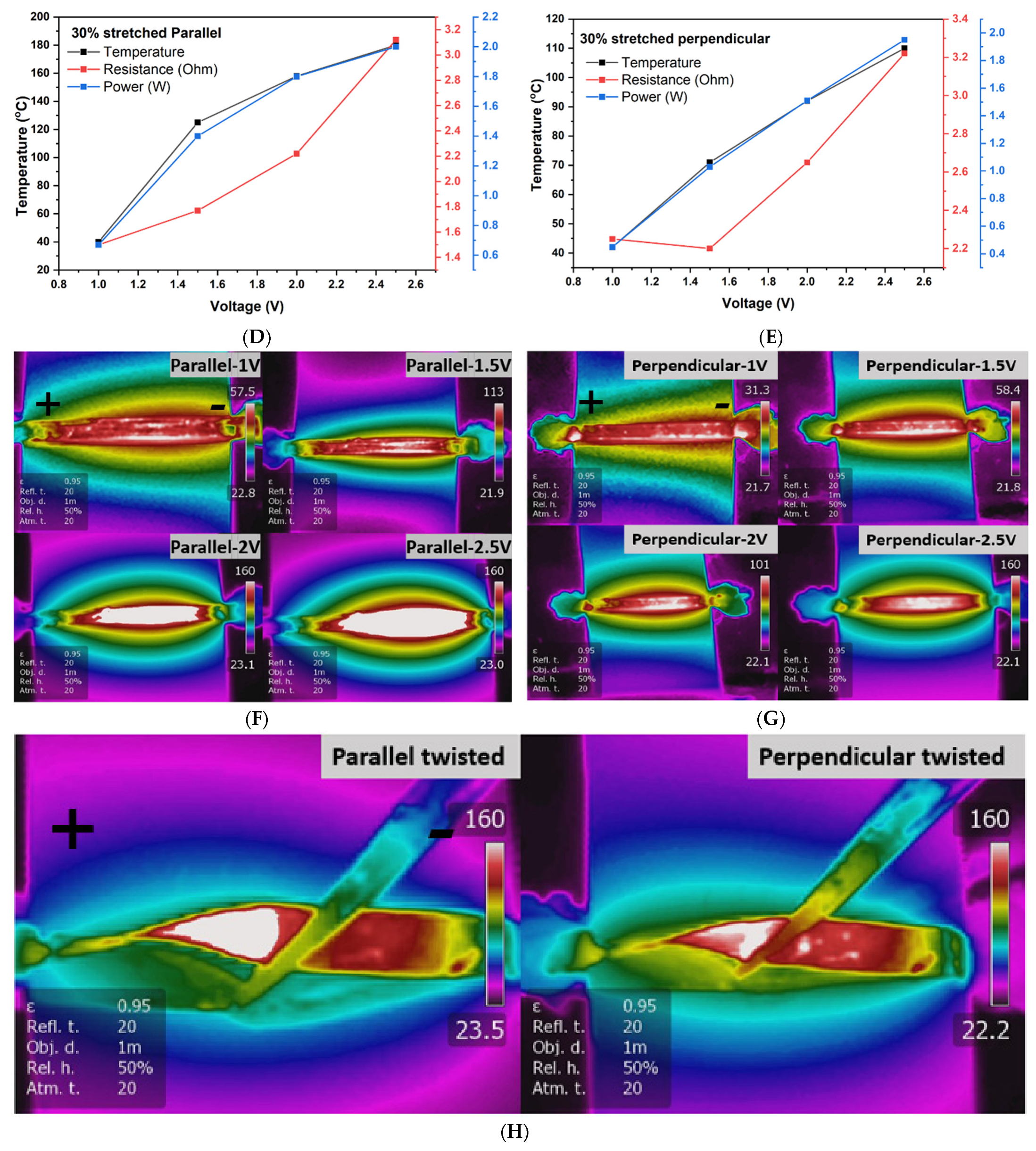

3.5. Heating Performance of 30% Stretched CNT

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Zhou, C.; Kong, J.; Dai, H. Intrinsic electrical properties of individual single-walled carbon nanotubes with small band gaps. Phys. Rev. Lett. 2000, 84, 5604–5607. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Charlier, J.C.; Blase, X.; Roche, S. Electronic and transport properties of nanotubes. Rev. Mod. Phys. 2007, 79, 677–732. [Google Scholar] [CrossRef] [Green Version]

- Hong, S.; Myung, S. Nanotube electronics: A flexible approach to mobility. Nat. Nanotechnol. 2007, 2, 207–208. [Google Scholar] [CrossRef]

- Maruyama, H.; Kariya, R.; Arai, F. Evaluation of thermal conductivity of single carbon nanotubes in air and liquid using a fluorescence temperature sensor. Appl. Phys. Lett. 2013, 103, 161905. [Google Scholar] [CrossRef]

- Pop, E.; Mann, D.; Wang, Q.; Goodson, K.; Dai, H. Thermal conductance of an individual single-wall carbon nanotube above room temperature. Nano Lett. 2006, 6, 96–100. [Google Scholar] [CrossRef] [Green Version]

- Treacy, M.M.J.; Ebbesen, T.W.; Gibson, J.M. Exceptionally high Young’s modulus observed for individual carbon nanotubes. Nature 1996, 381, 678–680. [Google Scholar] [CrossRef]

- Yu, M.F.; Files, B.S.; Arepalli, S.; Ruoff, R.S. Tensile loading of ropes of single wall carbon nanotubes and their mechanical properties. Phys. Rev. Lett. 2000, 84, 5552–5555. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Takei, K.; Takahashi, T.; Javey, A. Carbon nanotube electronics–moving forward. Chem. Soc. Rev. 2012, 42, 2592–2609. [Google Scholar] [CrossRef]

- Karimov, K.S.; Khalid, F.A.; Chani, M.T.S. Carbon nanotubes based strain sensors. Meas. J. Int. Meas. Confed. 2012, 45, 918–921. [Google Scholar] [CrossRef]

- Yamada, T.; Hayamizu, Y.; Yamamoto, Y.; Yomogida, Y.; Izadi-Najafabadi, A.; Futaba, D.N.; Hata, K. A stretchable carbon nanotube strain sensor for human-motion detection. Nat. Nanotechnol. 2011, 6, 296–301. [Google Scholar] [CrossRef]

- Wang, C.; Hwang, D.; Yu, Z.; Takei, K.; Park, J.; Chen, T.; Ma, B.; Javey, A. User-interactive electronic skin for instantaneous pressure visualization. Nat. Mater. 2013, 12, 899–904. [Google Scholar] [CrossRef] [PubMed]

- Xiang, L.; Zhang, H.; Hu, Y.; Peng, L.M. Carbon nanotube-based flexible electronics. J. Mater. Chem. C 2018, 6, 7714–7727. [Google Scholar] [CrossRef]

- Gbordzoe, S.; Malik, R.; Alvarez, N.; Wolf, R.; Shanov, V. Flexible low-voltage carbon nanotube heaters and their applications. In Advances in Carbon Nanostructures; InTech: London, UK, 2016. [Google Scholar] [CrossRef] [Green Version]

- Jiang, J.W.; Wang, J.S. Joule heating and thermoelectric properties in short single-walled carbon nanotubes: Electron-phonon interaction effect. J. Appl. Phys. 2011, 110, 124319. [Google Scholar] [CrossRef] [Green Version]

- Sinha, M.K.; Mukherjee, S.K.; Pathak, B.; Paul, R.K.; Barhai, P.K. Effect of deposition process parameters on resistivity of metal and alloy films deposited using anodic vacuum arc technique. Thin Solid Film. 2006, 515, 1753–1757. [Google Scholar] [CrossRef]

- Janas, D.; Koziol, K.K. A review of production methods of carbon nanotube and graphene thin films for electrothermal applications. Nanoscale 2014, 6, 3037–3045. [Google Scholar] [CrossRef]

- Chitranshi, M.; Pujari, A.; Ng, V.; Chen, D.; Chauhan, D.; Hudepohl, R.; Saleminik, M.; Kim, S.Y.; Kubley, A.; Shanov, V.; et al. Carbon nanotube sheet-synthesis and applications. Nanomaterials 2020, 10, 2023. [Google Scholar] [CrossRef]

- Chen, D.R.; Chitranshi, M.; Schulz, M.; Shanov, V. A review of three major factors controlling carbon nanotubes synthesis from the floating catalyst chemical vapor deposition. Nano LIFE 2019, 9. [Google Scholar] [CrossRef]

- Chen, R.; Chauhan, D.; Xu, C.; Ng, V.; Hou, G.; Shanov, V.; Mast, D.; Fialkova, S.; Schulz, M.J. Floating catalyst reactor design and safety features for carbon nanotube synthesis. In Nanotube Superfiber Materials; Elsevier: Amsterdam, The Netherlands, 2019; pp. 851–866. [Google Scholar] [CrossRef]

- Schulz, M.J.; Chitranshi, M.; Chauhan, D.; Kubley, A.; Pujari, A.; Xu, C.; Chen, D.; Chaudhary, S.; Hou, G.; Bell, G.; et al. Pioneering carbon nanotube textile engineering & fashion technology. J. Text. Eng. Fash. Technol. 2019, 5. [Google Scholar] [CrossRef]

- Chen, D.R.; Adusei, P.K.; Chitranshi, M.; Fang, Y.; Johnson, K.; Schulz, M.; Shanov, V. Electrochemical activation to enhance the volumetric performance of carbon nanotube electrodes. Appl. Surf. Sci. 2020, 541, 148448. [Google Scholar] [CrossRef]

- Schulz, M.J.; Shanov, V.; Yin, Z.; Cahay, M. Nanotube Superfiber Materials: Science, Manufacturing, Commercialization; William Andrew: Norwich, CT, USA, 2019. [Google Scholar] [CrossRef]

- Nicholas, A.; Parra-Vasquez, G.; Behabtu, N.; Green, M.J.; Pint, C.L.; Young, C.C.; Schmidt, J.; Kesselman, E.; Goyal, A.; Ajayan, P.M.; et al. Spontaneous dissolution of ultralong single-and multiwalled carbon nanotubes. ACS Nano 2010, 4, 3969–3978. [Google Scholar] [CrossRef]

- Lee, D.M.; Park, J.; Lee, J.; Lee, S.H.; Kim, S.H.; Kim, S.M.; Jeong, H.S. Improving mechanical and physical properties of ultra-thick carbon nanotube fiber by fast swelling and stretching process. Carbon 2021, 172, 733–741. [Google Scholar] [CrossRef]

- Bulmer, J.S.; Mizen, J.E.; Gspann, T.S.; Kaniyoor, A.; Ryley, J.B.; Kiley, P.J.; Sparkes, M.R.; O’Neill, B.; Elliott, J.A. Extreme stretching of high G:D ratio carbon nanotube fibers using super-acid. Carbon 2019, 153, 725–736. [Google Scholar] [CrossRef]

- Datsyuk, V.; Kalyva, M.; Papagelis, K.; Parthenios, J.; Tasis, D.; Siokou, A.; Kallitsis, I.; Galiotis, C. Chemical oxidation of multiwalled carbon nanotubes. Carbon 2008, 46, 833–840. [Google Scholar] [CrossRef]

- Lee, J.; Lee, D.M.; Jung, Y.; Park, J.; Lee, H.S.; Kim, Y.K.; Park, C.R.; Jeong, H.S.; Kim, S.M. Direct spinning and densification method for high-performance carbon nanotube fibers. Nat. Commun. 2019, 10, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Jung, D.; Han, M.; Lee, G.S. Flexible transparent conductive heater using multiwalled carbon nanotube sheet. J. Vac. Sci. Technol. B 2014, 32, 04E105. [Google Scholar] [CrossRef] [Green Version]

- Jang, H.S.; Jeon, S.K.; Nahm, S.H. The manufacture of a transparent film heater by spinning multi-walled carbon nanotubes. Carbon 2011, 49, 111–116. [Google Scholar] [CrossRef]

- Yoon, Y.H.; Song, J.W.; Kim, D.; Kim, J.; Park, J.K.; Oh, S.K.; Han, C.S. Transparent film heater using single-walled carbon nanotubes. Adv. Mater. 2007, 19, 4284–4287. [Google Scholar] [CrossRef]

- Jia, S.L.; Geng, H.Z.; Wang, L.; Tian, Y.; Xu, C.X.; Shi, P.P.; Gu, Z.Z.; Yuan, X.S.; Jing, L.C.; Guo, Z.Y.; et al. Carbon nanotube-based flexible electrothermal film heaters with a high heating rate. R. Soc. Open Sci. 2018, 5, 172072. [Google Scholar] [CrossRef] [Green Version]

- Im, H.; Jang, E.Y.; Choi, A.; Kim, W.J.; Kang, T.J.; Park, Y.W.; Kim, Y.H. Enhancement of heating performance of carbon nanotube sheet with granular metal. ACS Appl. Mater. Interfaces 2012, 4. [Google Scholar] [CrossRef]

- Rashid, T.; Liang, H.L.; Taimur, M.; Chiodarelli, N.; Khawaja, H.A.; Edvardsen, K.; de Volder, M. Roll to roll coating of carbon nanotube films for electro thermal heating. Cold Reg. Sci. Technol. 2020, 182, 103210. [Google Scholar] [CrossRef]

- Ryu, Y.; Yin, L.; Yu, C. Dramatic electrical conductivity improvement of carbon nanotube networks by simultaneous de-bundling and hole-doping with chlorosulfonic acid. J. Mater. Chem. 2012, 22, 6959–6964. [Google Scholar] [CrossRef]

- Gbordzoe, S.; Yarmolenko, S.; Kanakaraj, S.; Haase, M.R.; Alvarez, N.T.; Borgemenke, R.; Adusei, P.K.; Shanov, V. Effects of laser cutting on the structural and mechanical properties of carbon nanotube assemblages. Mater. Sci. Eng. B 2017, 223, 143–152. [Google Scholar] [CrossRef]

- Hecht, D.S.; Heintz, A.M.; Lee, R.; Hu, L.; Moore, B.; Cucksey, C.; Risser, S. High conductivity transparent carbon nanotube films deposited from superacid. Nanotechnology 2011, 22, 075201. [Google Scholar] [CrossRef]

- Aouraghe, M.A.; Xu, F.; Liu, X.; Qiu, Y. Flexible, quickly responsive and highly efficient E-heating carbon nanotube film. Compos. Sci. Technol. 2019, 183, 107824. [Google Scholar] [CrossRef]

- Bae, J.J.; Lim, S.C.; Han, G.H.; Jo, Y.W.; Doung, D.L.; Kim, E.S.; Chae, S.J.; Huy, T.Q.; van Luan, N.; Lee, Y.H. Heat dissipation of transparent graphene defoggers. Adv. Funct. Mater. 2012, 22, 4819–4826. [Google Scholar] [CrossRef]

| Material | Size (cm × cm) | Voltage (V) | Temperature (°C) | Reference |

|---|---|---|---|---|

| CSA-stretched CNT | 2 × 0.2 | 2.5 | >180 | This work |

| MWCNT on Glass | 1 × 1.5 | 40 | 80 | [29] |

| MWCNT on PET | 0.65 × 0.85 | 15 | 77 | [30] |

| SWCNT on PET | 4 × 4 | 12 | 95 | [31] |

| SWCNT on PET | 5 × 5 | 35 | 75.5 | [32] |

| CNT/Pd | 0.5 × 0.5 | 5.5 | 105 | [33] |

| CNT ink on PET substrate | 8.5 × 3 | 35 | 50 ± 3.8 | [34] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, D.R.; Chitranshi, M.; Adusei, P.K.; Schulz, M.; Shanov, V.; Cahay, M.M. Chlorosulfonic Acid Stretched Carbon Nanotube Sheet for Flexible and Low-Voltage Heating Applications. Nanomaterials 2021, 11, 2132. https://doi.org/10.3390/nano11082132

Chen DR, Chitranshi M, Adusei PK, Schulz M, Shanov V, Cahay MM. Chlorosulfonic Acid Stretched Carbon Nanotube Sheet for Flexible and Low-Voltage Heating Applications. Nanomaterials. 2021; 11(8):2132. https://doi.org/10.3390/nano11082132

Chicago/Turabian StyleChen, Daniel Rui, Megha Chitranshi, Paa Kwasi Adusei, Mark Schulz, Vesselin Shanov, and Marc M. Cahay. 2021. "Chlorosulfonic Acid Stretched Carbon Nanotube Sheet for Flexible and Low-Voltage Heating Applications" Nanomaterials 11, no. 8: 2132. https://doi.org/10.3390/nano11082132

APA StyleChen, D. R., Chitranshi, M., Adusei, P. K., Schulz, M., Shanov, V., & Cahay, M. M. (2021). Chlorosulfonic Acid Stretched Carbon Nanotube Sheet for Flexible and Low-Voltage Heating Applications. Nanomaterials, 11(8), 2132. https://doi.org/10.3390/nano11082132