3D Laser Nanoprinting of Optically Functionalized Structures with Effective-Refractive-Index Tailorable TiO2 Nanoparticle-Doped Photoresin

Abstract

:1. Introduction

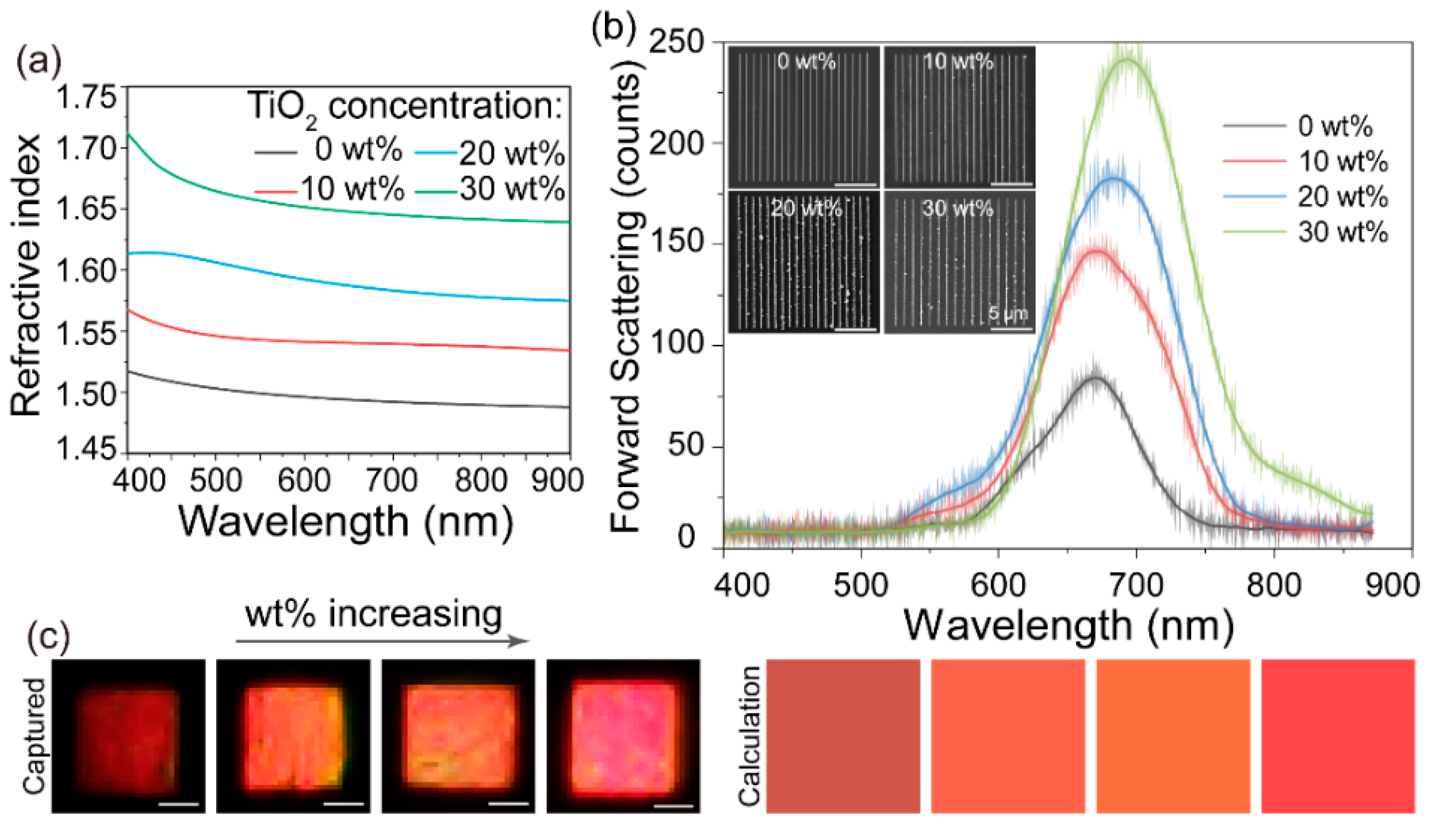

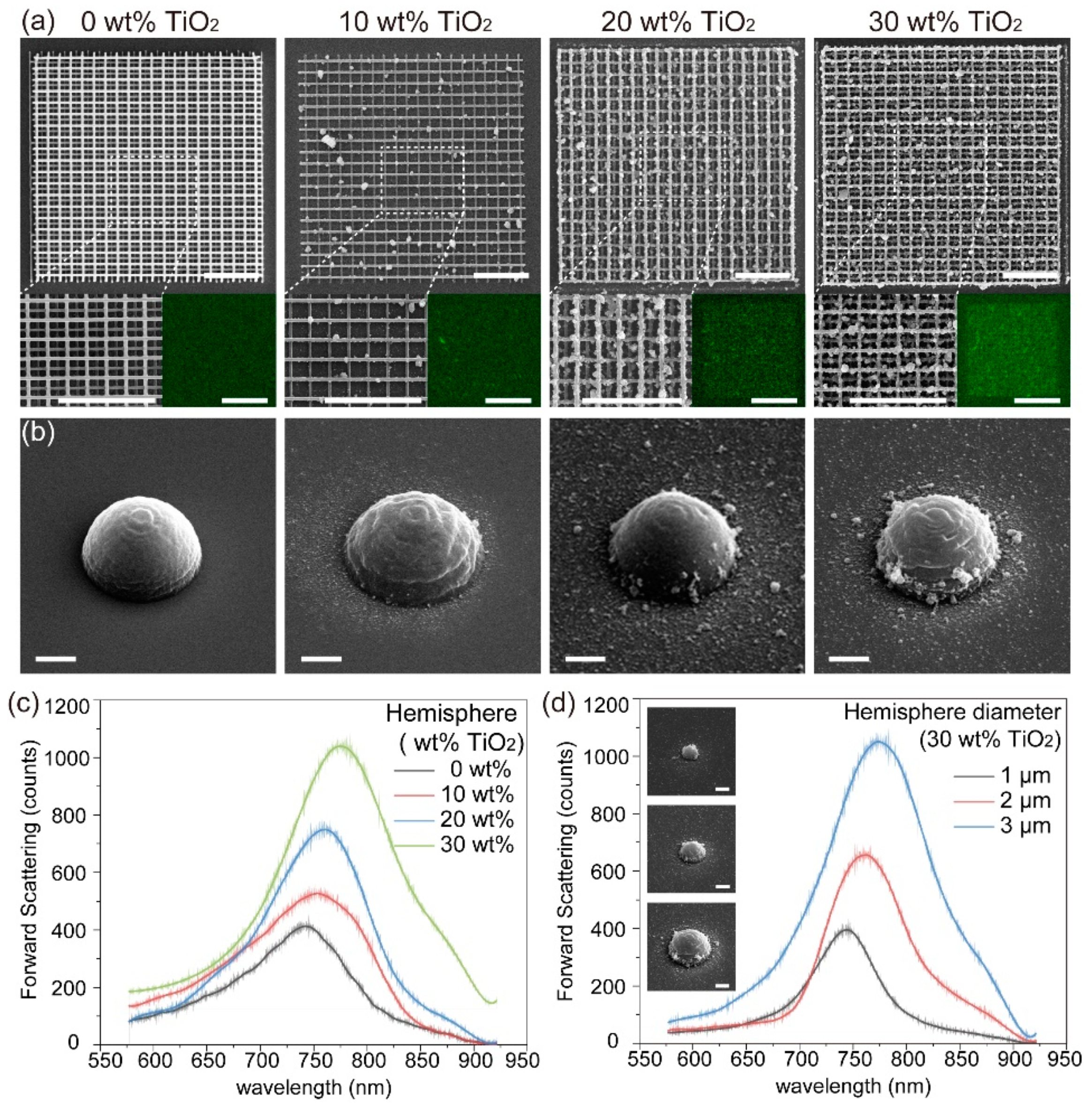

2. Materials and Methods

2.1. Synthesis of the Titanium Dioxide-Based Photosensitized Nanocomposites

2.2. Synthesis of the Photosensitized Nanocomposite Photoresin

2.3. 3D Laser Nanoprinting

2.4. Optical Properties of the Photosensitized Nanocomposites

2.5. Measurements of Dark-Field Forward Scattering Spectrum

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Capel, A.J.; Rimington, R.P.; Lewis, M.P.; Christie, S.D.R. 3D printing for chemical, pharmaceutical and biological applications. Nat. Rev. Chem. 2018, 2, 422. [Google Scholar] [CrossRef]

- Kiefer, P.; Hahn, V.; Nardi, M.; Yang, L.; Blasco, E.; Barner-Kowollik, C.; Wegener, M. Sensitive Photoresists for Rapid Multiphoton 3D Laser Micro- and Nanoprinting. Adv. Opt. Mater. 2020, 8, 2000895. [Google Scholar] [CrossRef]

- Mayer, F.; Ryklin, D.; Wacker, I.; Curticean, R.; Calkovsky, M.; Niemeyer, A.; Dong, Z.Q.; Levkin, P.A.; Gerthsen, D.; Schroder, R.R.; et al. 3D Two-Photon Microprinting of Nanoporous Architectures. Adv. Mater. 2020, 32, 2002044. [Google Scholar] [CrossRef] [PubMed]

- Kawata, S.; Sun, H.B.; Tanaka, T.; Takada, K. Finer features for functional microdevices—Micromachines can be created with higher resolution using two-photon absorption. Nature 2001, 412, 697. [Google Scholar] [CrossRef]

- Lay, C.L.; Koh, C.S.L.; Lee, Y.H.; Phan-Quang, G.C.; Sim, H.Y.F.; Leong, S.X.; Han, X.; Phang, I.Y.; Ling, X.Y. Two-photon-assisted polymerization and reduction: Emerging formulations and applications. ACS Appl. Mater. Interfaces 2020, 12, 10061. [Google Scholar] [CrossRef] [PubMed]

- Gan, Z.S.; Cao, Y.Y.; Evans, R.A.; Gu, M. Three-dimensional deep sub-diffraction optical beam lithography with 9 nm feature size. Nat. Commun. 2013, 4, 2061. [Google Scholar] [CrossRef] [Green Version]

- Gansel, J.K.; Thiel, M.; Rill, M.S.; Decker, M.; Bade, K.; Saile, V.; von Freymann, G.; Linden, S.; Wegener, M. Gold helix photonic metamaterial as broadband circular polarizer. Science 2009, 325, 1513. [Google Scholar] [CrossRef]

- Jiang, M.L.; Song, S.C.; Li, Y.J.; Zeng, X.Z.; Zhu, L.W.; Zhang, M.S.; Wang, S.; Li, X.P.; Cao, Y.Y. 3D high precision laser printing of a flat nanofocalizer for subwavelength light spot array. Opt. Lett. 2021, 46, 356. [Google Scholar] [CrossRef]

- Turner, M.D.; Schroder-Turk, G.E.; Gu, M. Fabrication and characterization of three-dimensional biomimetic chiral composites. Opt. Express 2011, 19, 10001. [Google Scholar] [CrossRef]

- Yee, D.W.; Lifson, M.L.; Edwards, B.W.; Greer, J.R. Additive manufacturing of 3D-architected multifunctional metal oxides. Adv. Mater. 2019, 31, 1901345. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.J.; Wang, H.; Ho, J.F.; Ng, R.C.; Ng, R.J.H.; Hall-Chen, V.H.; Koay, E.H.H.; Dong, Z.G.; Liu, H.L.; Qiu, C.W.; et al. Structural color three-dimensional printing by shrinking photonic crystals. Nat. Commun. 2019, 10, 4340. [Google Scholar] [CrossRef] [Green Version]

- Saha, S.K.; Wang, D.; Nguyen, V.H.; Chang, Y.N.; Oakdale, J.S.; Chen, S.C. Scalable submicrometer additive manufacturing. Science 2019, 366, 105. [Google Scholar] [CrossRef] [PubMed]

- Kelly, B.E.; Bhattacharya, I.; Heidari, H.; Shusteff, M.; Spadaccini, C.M.; Taylor, H.K. Volumetric additive manufacturing via tomographic reconstruction. Science 2019, 363, 1075. [Google Scholar] [CrossRef] [PubMed]

- Jia, Y.C.; Wang, S.X.; Chen, F. Femtosecond laser direct writing of flexibly configured waveguide geometries in optical crystals: Fabrication and application. Opto-Electron. Adv. 2020, 3, 190042. [Google Scholar] [CrossRef]

- Vyatskikh, A.; Ng, R.C.; Edwards, B.; Briggs, R.M.; Greer, J.R. Additive Manufacturing of High-Refractive-Index, Nanoarchitected Titanium Dioxide for 3D Dielectric Photonic Crystals. Nano Lett. 2020, 20, 3513. [Google Scholar] [CrossRef] [PubMed]

- Frolich, A.; Fischer, J.; Zebrowski, T.; Busch, K.; Wegener, M. Titania Woodpiles with Complete Three-Dimensional Photonic Bandgaps in the Visible. Adv. Mater. 2013, 25, 3588. [Google Scholar] [CrossRef] [PubMed]

- Hossain, M.M.; Gu, M. Broadband optical absorptions in inversed woodpile metallic photonic crystals. Opt. Mater. Express 2012, 2, 996. [Google Scholar] [CrossRef]

- Vyatskikh, A.; Delalande, S.; Kudo, A.; Zhang, X.; Portela, C.M.; Greer, J.R. Additive manufacturing of 3D nano-architected metals. Nat. Commun. 2018, 9, 593. [Google Scholar] [CrossRef] [Green Version]

- Wen, H.J.; Song, S.C.; Xie, F.; Wang, B.; Xu, J.; Feng, Z.W.; Wu, S.Y.; Han, J.; Guan, B.O.; Xu, X.X.; et al. Great chiral fluorescence from the optical duality of silver nanostructures enabled by 3D laser printing. Mater. Horiz. 2020, 7, 3201. [Google Scholar] [CrossRef]

- Xu, B.B.; Xia, H.; Niu, L.G.; Zhang, Y.L.; Sun, K.; Chen, Q.D.; Xu, Y.; Lv, Z.Q.; Li, Z.H.; Misawa, H.; et al. Flexible Nanowiring of Metal on Nonplanar Substrates by Femtosecond-Laser-Induced Electroless Plating. Small 2010, 6, 1762. [Google Scholar] [CrossRef]

- Xiong, W.; Liu, Y.; Jiang, L.J.; Zhou, Y.S.; Li, D.W.; Jiang, L.; Silvain, J.F.; Lu, Y.F. Laser-Directed Assembly of Aligned Carbon Nanotubes in Three Dimensions for Multifunctional Device Fabrication. Adv. Mater. 2016, 28, 2002. [Google Scholar] [CrossRef] [PubMed]

- Long, J.; Xiong, W.; Wei, C.Y.R.; Lu, C.C.F.; Wang, R.Q.; Deng, C.S.; Liu, H.; Fan, X.H.; Jiao, B.Z.; Gao, S.; et al. Directional Assembly of ZnO Nanowires via Three-Dimensional Laser Direct Writing. Nano Lett. 2020, 20, 5159. [Google Scholar] [CrossRef]

- Xia, H.; Wang, J.A.; Tian, Y.; Chen, Q.D.; Du, X.B.; Zhang, Y.L.; He, Y.; Sun, H.B. Ferrofluids for fabrication of remotely controllable micro-nanomachines by two-photon polymerization. Adv. Mater. 2010, 22, 3204. [Google Scholar] [CrossRef] [PubMed]

- Lu, C.L.; Yang, B. High refractive index organic-inorganic nanocomposites: Design, synthesis and application. J. Mater. Chem. 2009, 19, 2884. [Google Scholar] [CrossRef]

- Duan, X.M.; Sun, H.B.; Kaneko, K.; Kawata, S. Two-photon polymerization of metal ions doped acrylate monomers and oligomers for three-dimensional structure fabrication. Thin Solid Films 2004, 453, 518. [Google Scholar] [CrossRef]

- Duoss, E.B.; Twardowski, M.; Lewis, J.A. Sol-gel inks for direct-write assembly of functional oxides. Adv. Mater. 2007, 19, 3485. [Google Scholar] [CrossRef]

- Sakellari, I.; Gaidukeviciute, A.; Giakoumaki, A.; Gray, D.; Fotakis, C.; Farsari, M.; Vamvakaki, M.; Reinhardt, C.; Ovsianikov, A.; Chichkov, B.N. Two-photon polymerization of titanium-containing sol-gel composites for three-dimensional structure fabrication. Appl. Phys. A 2010, 100, 359. [Google Scholar] [CrossRef]

- Gorbovyi, P.; Uklein, A.; Tieng, S.; Brinza, O.; Traore, M.; Chhor, K.; Museur, L.; Kanaev, A. Novel nanostructured pHEMA-TiO2 hybrid materials with efficient light-induced charge separation. Nanoscale 2011, 3, 1807–1812. [Google Scholar] [CrossRef] [PubMed]

- Gorbovyi, P.; Diaz-Gomez, A.P.; Traore, M.; Museur, L.; Rozes, L.; Ribot, F.; Sanchez, C.; Kuznetsov, A.I.; Chichkov, B.N.; Kanaev, A. Alkoxysilane effect in hybrid material: A comparison of pHEMA-TiO2 and pMAPTMS-TiO2 nanoparticulate hybrids. Mater. Res. Bull. 2019, 114, 130. [Google Scholar] [CrossRef]

- Gailevicius, D.; Padolskyte, V.; Mikoliunaite, L.; Sakirzanovas, S.; Juodkazis, S.; Malinauskas, M. Additive-manufacturing of 3D glass-ceramics down to nanoscale resolution. Nanoscale Horiz. 2019, 4, 647. [Google Scholar] [CrossRef]

- Zukauskas, A.; Matulaitiene, I.; Paipulas, D.; Niaura, G.; Malinauskas, M.; Gadonas, R. Tuning the refractive index in 3D direct laser writing lithography: Towards GRIN microoptics. Laser Photon. Rev. 2015, 9, 706. [Google Scholar] [CrossRef]

- Skliutas, E.; Lebedevaite, M.; Kabouraki, E.; Baldacchini, T.; Ostrauskaite, J.; Vamvakaki, M.; Farsari, M.; Juodkazis, S.; Malinauskas, M. Polymerization mechanisms initiated by spatio-temporally confined light. Nanophotonics 2021, 10, 1211. [Google Scholar] [CrossRef]

- Werdehausen, D.; Staude, I.; Burger, S.; Petschulat, J.; Scharf, T.; Pertsch, T.; Decker, M. Design rules for customizable optical materials based on nanocomposites. Opt. Mater. Express 2018, 8, 3456. [Google Scholar] [CrossRef] [Green Version]

- Markel, V.A. Introduction to the Maxwell Garnett approximation: Tutorial. J. Opt. Soc. Am. A 2016, 33, 1244. [Google Scholar] [CrossRef] [Green Version]

- Mallet, P.; Guerin, C.A.; Sentenac, A. Maxwell-Garnett mixing rule in the presence of multiple scattering: Derivation and accuracy. Phys. Rev. B 2005, 72, 014205. [Google Scholar] [CrossRef] [Green Version]

- Doyle, W.T. Optical properties of a suspension of metal spheres. Phys. Rev. B 1989, 39, 9852. [Google Scholar] [CrossRef]

- Glass, S.; Trinklein, B.; Abel, B.; Schulze, A. TiO2 as Photosensitizer and Photoinitiator for Synthesis of Photoactive TiO2-PEGDA Hydrogel Without Organic Photoinitiator. Front. Chem. 2018, 6, 340. [Google Scholar] [CrossRef] [PubMed]

- Yoon, G.; Kim, K.; Huh, D.; Lee, H.; Rho, J. Single-step manufacturing of hierarchical dielectric metalens in the visible. Nat. Commun. 2020, 11, 2268. [Google Scholar] [CrossRef] [PubMed]

- Niklasson, G.A.; Granqvist, C.G.; Hunderi, O. Effective medium models for the optical properties of inhomogeneous materials. Appl. Optics 1981, 20, 26. [Google Scholar] [CrossRef]

- Smith, T.; Guild, J. The C.I.E. colorimetric standards and their use. Trans. Opt. Soc. 1931, 33, 73. [Google Scholar] [CrossRef]

- Song, S.C.; Ma, X.L.; Pu, M.B.; Li, X.; Liu, K.P.; Gao, P.; Zhao, Z.Y.; Wang, Y.Q.; Wang, C.T.; Luo, X.G. Actively Tunable Structural Color Rendering with Tensile Substrate. Adv. Opt. Mater. 2017, 5, 1600829. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, S.; Li, Y.; Yao, Z.; Li, J.; Li, X.; Cao, Y. 3D Laser Nanoprinting of Optically Functionalized Structures with Effective-Refractive-Index Tailorable TiO2 Nanoparticle-Doped Photoresin. Nanomaterials 2022, 12, 55. https://doi.org/10.3390/nano12010055

Song S, Li Y, Yao Z, Li J, Li X, Cao Y. 3D Laser Nanoprinting of Optically Functionalized Structures with Effective-Refractive-Index Tailorable TiO2 Nanoparticle-Doped Photoresin. Nanomaterials. 2022; 12(1):55. https://doi.org/10.3390/nano12010055

Chicago/Turabian StyleSong, Shichao, Yijie Li, Zhuofan Yao, Jie Li, Xiangping Li, and Yaoyu Cao. 2022. "3D Laser Nanoprinting of Optically Functionalized Structures with Effective-Refractive-Index Tailorable TiO2 Nanoparticle-Doped Photoresin" Nanomaterials 12, no. 1: 55. https://doi.org/10.3390/nano12010055

APA StyleSong, S., Li, Y., Yao, Z., Li, J., Li, X., & Cao, Y. (2022). 3D Laser Nanoprinting of Optically Functionalized Structures with Effective-Refractive-Index Tailorable TiO2 Nanoparticle-Doped Photoresin. Nanomaterials, 12(1), 55. https://doi.org/10.3390/nano12010055