Mid-Infrared Response from Cr/n-Si Schottky Junction with an Ultra-Thin Cr Metal

Abstract

:1. Introduction

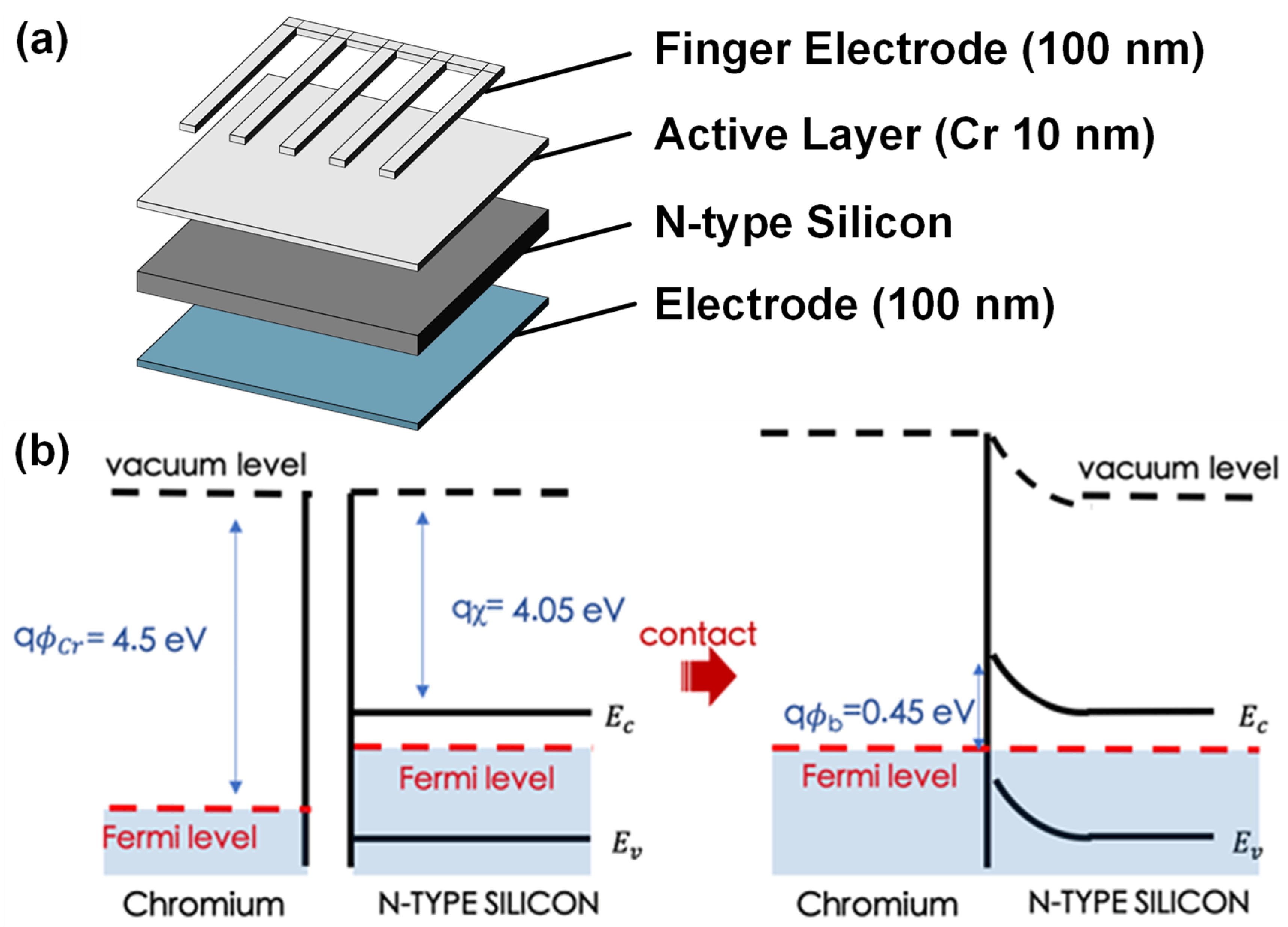

2. Materials and Methods

3. Results

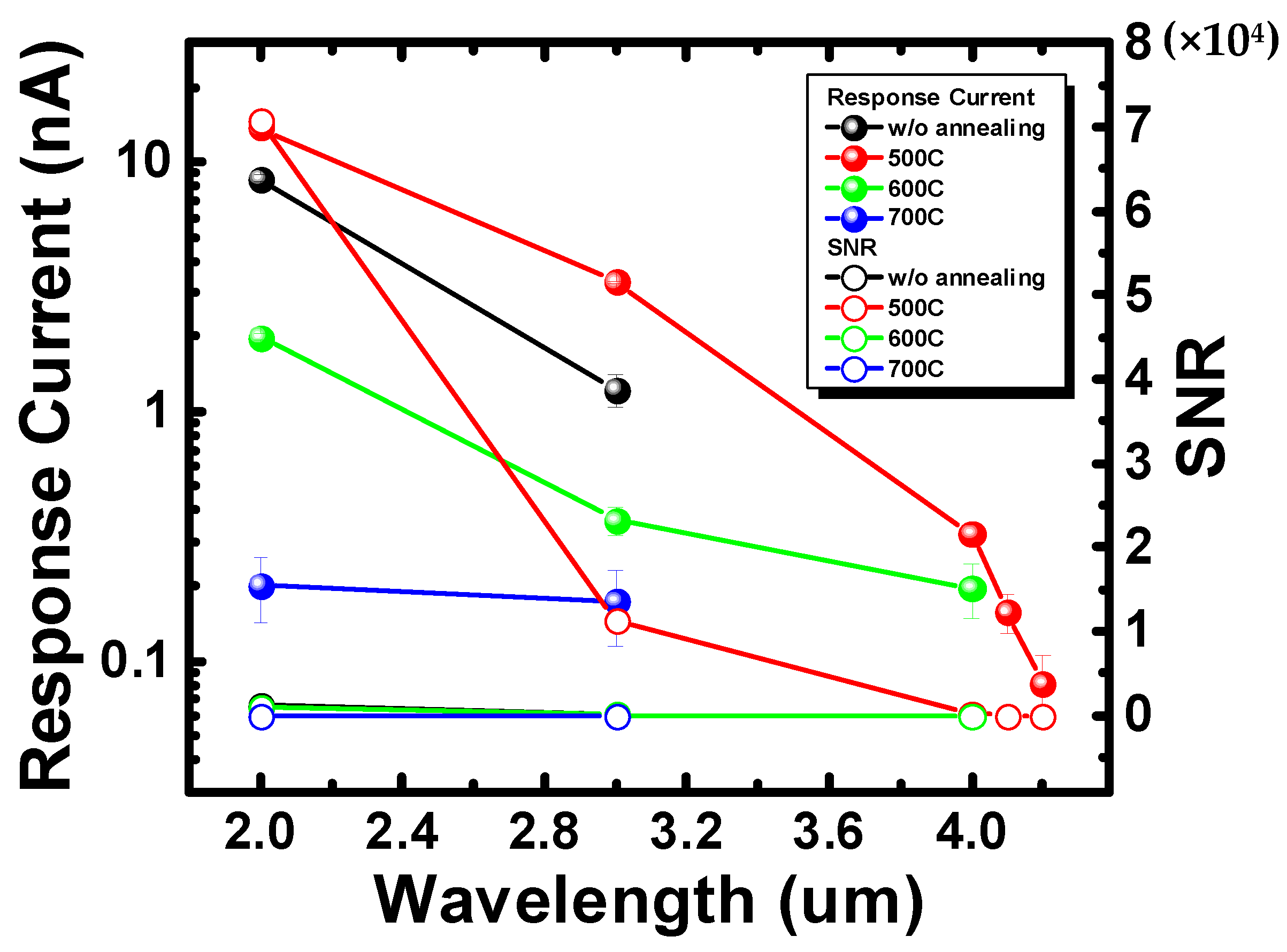

3.1. Response Current Measurement

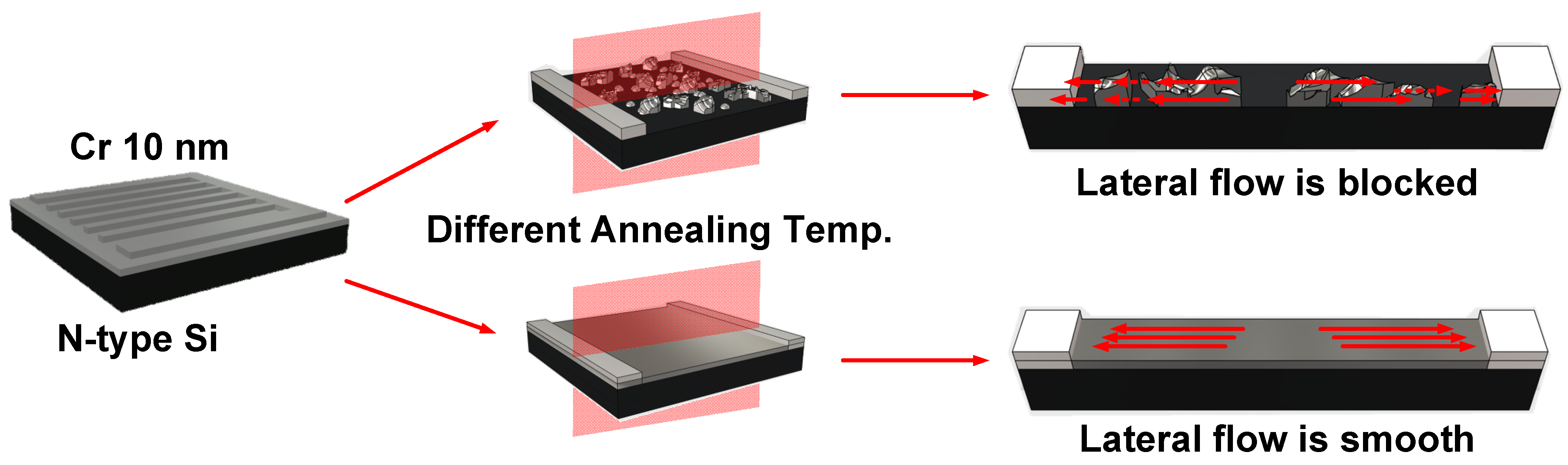

3.2. Scanning Electron Microscope Images

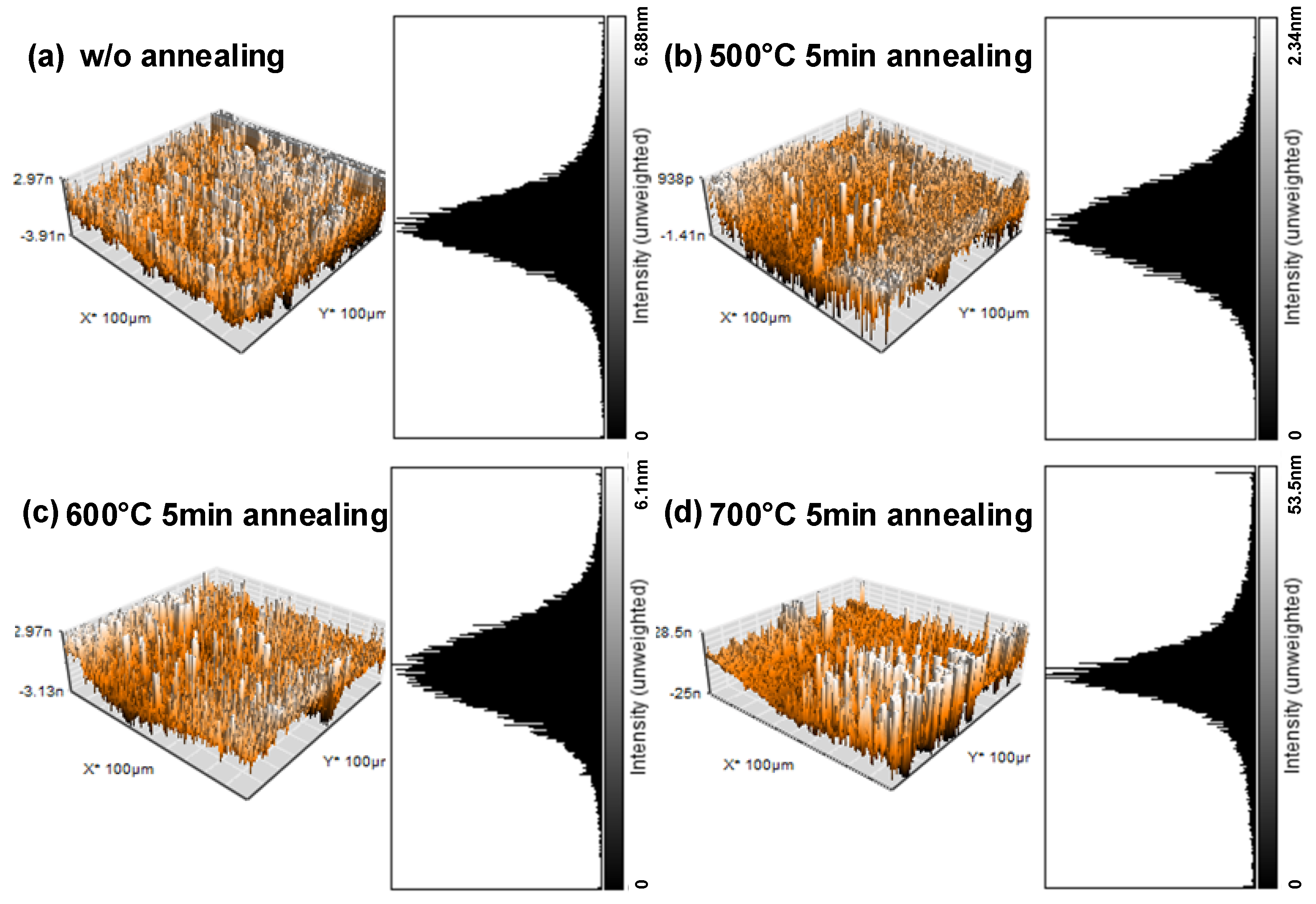

3.3. Atomic Force Microscopy Images

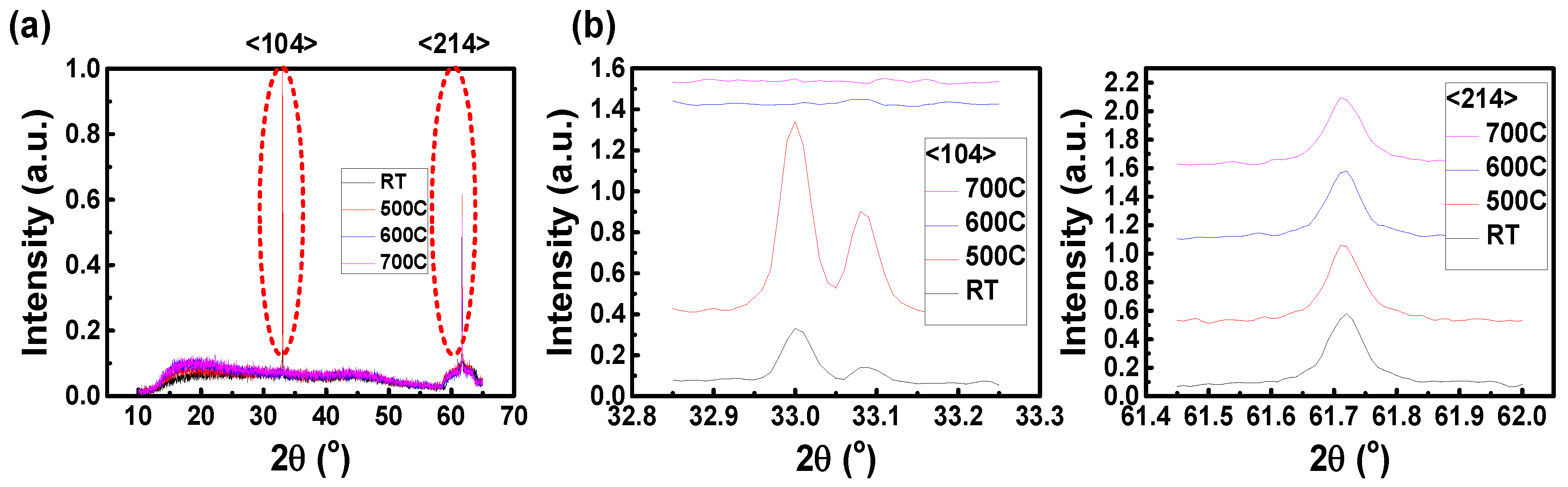

3.4. X-ray Diffraction Measurements

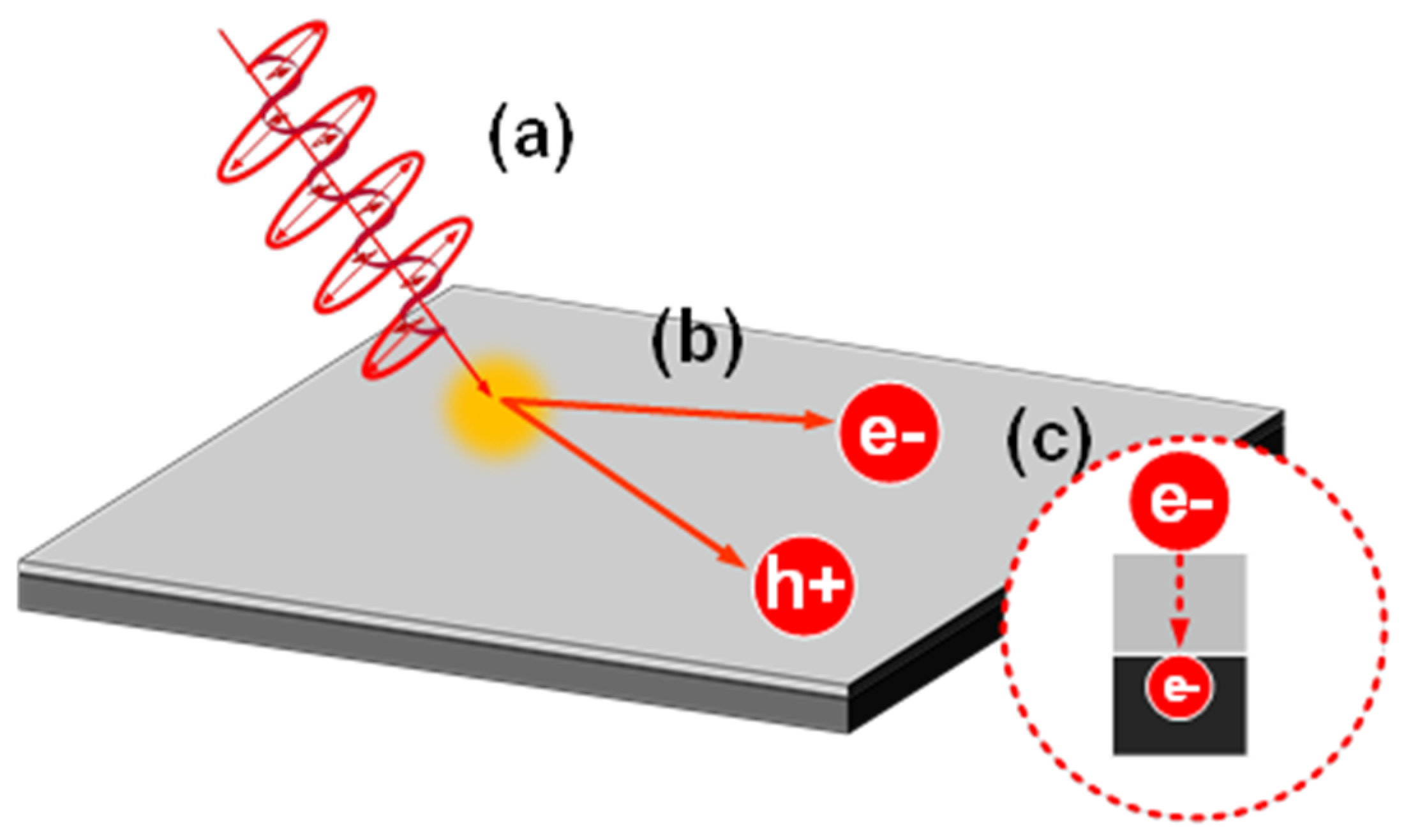

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hong, S.; Shin, J.; Hong, Y.; Wu, M.; Jang, D.; Jeong, Y.; Jung, G.; Bae, J.-H.; Jang, H.W.; Lee, J.-H. Observation of physisorption in a high-performance FET-type oxygen gas sensor operating at room temperature. Nanoscale 2018, 10, 18019–18027. [Google Scholar] [CrossRef]

- Rae, S.I.; Khan, I. Surface enhanced Raman spectroscopy (SERS) sensors for gas analysis. Analyst 2010, 135, 1365–1369. [Google Scholar] [CrossRef]

- Tan, X.; Zhang, H.; Li, J.; Wan, H.; Guo, Q.; Zhu, H.; Liu, H.; Yi, F. Non-dispersive infrared multi-gas sensing via nanoantenna integrated narrowband detectors. Nat. Commun. 2020, 11, 1–9. [Google Scholar] [CrossRef]

- Okechukwu, V.O.; Mavumengwana, V.; Hümmelgen, I.A.; Mamo, M.A. Concomitant in Situ FTIR and Impedance Measurements to Address the 2-Methylcyclopentanone Vapor-Sensing Mechanism in MnO2–Polymer Nanocomposites. ACS Omega 2019, 4, 8324–8333. [Google Scholar] [CrossRef] [Green Version]

- Menendez-Delmestre, K.; Blain, A.W.; Smail, I.; Alexander, D.; Chapman, S.C.; Armus, L.; Frayer, D.; Ivison, R.; Teplitz, H. Mid-infrared spectroscopy of submillimeter galaxies: Extended star formation in massive high-redshift galaxies. Astrophys. J. Lett. 2009, 699, 667–685. [Google Scholar] [CrossRef]

- Avetisov, V.; Bjoroey, O.; Wang, J.; Geiser, P.; Paulsen, K.G. Hydrogen Sensor Based on Tunable Diode Laser Absorption Spectroscopy. Sensors 2019, 19, 5313. [Google Scholar] [CrossRef] [Green Version]

- Nißler, R.; Bader, O.; Dohmen, M.; Walter, S.G.; Noll, C.; Selvaggio, G.; Groß, U.; Kruss, S. Remote near infrared identification of pathogens with multiplexed nanosensors. Nat. Commun. 2020, 11, 1–12. [Google Scholar] [CrossRef]

- Mauer, L.J.; Chernyshova, A.L.; Hiatt, A.; Deering, A.; Davis, R. Melamine Detection in Infant Formula Powder Using Near- and Mid-Infrared Spectroscopy. J. Agric. Food Chem. 2009, 57, 3974–3980. [Google Scholar] [CrossRef]

- Cha, S.; Sung, J.H.; Sim, S.; Park, J.; Heo, H.; Jo, M.-H.; Choi, H. 1s-intraexcitonic dynamics in monolayer MoS2 probed by ultrafast mid-infrared spectroscopy. Nat. Commun. 2016, 7, 10768. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Pei, Y.; LaLonde, A.D.; Snyder, G.J. Weak electron–phonon coupling contributing to high thermoelectric performance in n-type PbSe. Proc. Natl. Acad. Sci. USA 2012, 109, 9705–9709. [Google Scholar] [CrossRef] [Green Version]

- Pei, Y.; LaLonde, A.; Iwanaga, S.; Snyder, G.J. High thermoelectric figure of merit in heavy hole dominated PbTe. Energy Environ. Sci. 2011, 4, 2085–2089. [Google Scholar] [CrossRef] [Green Version]

- Borri, P.; Langbein, W.; Schneider, S.; Woggon, U.; Sellin, R.L.; Ouyang, D.; Bimberg, D. Ultralong Dephasing Time in InGaAs Quantum Dots. Phys. Rev. Lett. 2001, 87, 157401. [Google Scholar] [CrossRef] [Green Version]

- Deng, M.T.; Yu, C.L.; Huang, G.Y.; Larsson, M.; Caroff, P.; Xu, H.Q. Anomalous zero-bias conductance peak in a Nb–InSb nanowire–Nb hybrid device. Nano Lett. 2012, 12, 6414–6419. [Google Scholar] [CrossRef] [Green Version]

- Rodrigo, D.; Limaj, O.; Janner, D.; Etezadi, D.; García de Abajo, F.J.; Pruneri, V.; Altug, H. Mid-infrared plasmonic biosensing with graphene. Science 2015, 349, 165–168. [Google Scholar] [CrossRef] [Green Version]

- Rezaeifar, F.; Ahsan, R.; Lin, Q.; Chae, H.U.; Kapadia, R. Hot-electron emission processes in waveguide-integrated graphene. Nat. Photonics 2019, 13, 843–848. [Google Scholar] [CrossRef]

- Bullock, J.; Amani, M.; Cho, J.; Chen, Y.-Z.; Ahn, G.H.; Adinolfi, V.; Shrestha, V.R.; Gao, Y.; Crozier, K.B.; Chueh, Y.-L.; et al. Polarization-resolved black phosphorus/molybdenum disulfide mid-wave infrared photodiodes with high detectivity at room temperature. Nat. Photonics 2018, 12, 601–607. [Google Scholar] [CrossRef]

- Kim, H.; Uddin, S.Z.; Lien, D.-H.; Yeh, M.; Azar, N.S.; Balendhran, S.; Kim, T.; Gupta, N.; Rho, Y.; Grigoropoulos, C.P.; et al. Actively variable-spectrum optoelectronics with black phosphorus. Nature 2021, 596, 232–237. [Google Scholar] [CrossRef]

- Atabaki, A.H.; Moazeni, S.; Pavanello, F.; Gevorgyan, H.; Notaros, J.; Alloatti, L.; Wade, M.T.; Sun, C.; Kruger, S.A.; Meng, H.; et al. Integrating photonics with silicon nanoelectronics for the next generation of systems on a chip. Nature 2018, 556, 349–354. [Google Scholar] [CrossRef]

- Sun, C.; Wade, M.T.; Lee, Y.; Orcutt, J.S.; Alloatti, L.; Georgas, M.S.; Waterman, A.S.; Shainline, J.M.; Avizienis, R.R.; Lin, S.; et al. Single-chip microprocessor that communicates directly using light. Nature 2015, 528, 534–538. [Google Scholar] [CrossRef] [Green Version]

- Rahim, A.; Spuesens, T.; Baets, R.; Bogaerts, W. Open-Access Silicon Photonics: Current Status and Emerging Initiatives. Proc. IEEE 2018, 106, 2313–2330. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.-C.; Parimi, V.; Chang, W.-C.; Syu, H.-J.; Su, Z.-C.; Lin, C.-F. Silicon-Based Photodetector for Infrared Telecommunication Applications. IEEE Photonics J. 2021, 13, 1–7. [Google Scholar] [CrossRef]

- Dalal, V.L. Simple Model for Internal Photoemission. J. Appl. Phys. 1971, 42, 2274–2279. [Google Scholar] [CrossRef]

- Casalino, M.; Sirleto, L.; Iodice, M.; Saffioti, N.; Gioffrè, M.; Rendina, I.; Coppola, G. Cu/p-Si Schottky barrier-based near infrared photodetector integrated with a silicon-on-insulator waveguide. Appl. Phys. Lett. 2010, 96, 241112. [Google Scholar] [CrossRef]

- Helman, J.S.; Sánchez-Sinencio, F. Theory of Internal Photoemission. Phys. Rev. B 1973, 7, 3702–3706. [Google Scholar] [CrossRef]

- Casalino, M. Internal Photoemission Theory: Comments and Theoretical Limitations on the Performance of Near-Infrared Silicon Schottky Photodetectors. IEEE J. Quantum Electron. 2016, 52, 1–10. [Google Scholar] [CrossRef]

- Alireza, E.; Mehrara, H.; Raissi, F.; Khaje, M. Coulomb blockade in PtSi/porous Si Schottky barrier as a two-dimensional multi-tunnelling junction. IET Circuits, Devices Syst. 2015, 9, 81–86. [Google Scholar]

- Ozerden, E.; Ocak, Y.S.; Tombak, A.; Kilicoglu, T.; Turut, A. Electrical and photoelectrical properties of Ag/n-type Si metal/semiconductor contact with organic interlayer. Thin Solid Film. 2015, 597, 14–18. [Google Scholar] [CrossRef]

- Syu, H.-J.; Huang, Y.-C.; Su, Z.-C.; Sun, R.-L.; Lin, C.-F. An Alternative to Compound Semiconductors Using a Si-Based IR Detector. IEEE Trans. Electron Devices 2021, 69, 205–211. [Google Scholar] [CrossRef]

- Zhang, H.; Govorov, A.O. Optical Generation of Hot Plasmonic Carriers in Metal Nanocrystals: The Effects of Shape and Field Enhancement. J. Phys. Chem. C 2014, 118, 7606–7614. [Google Scholar] [CrossRef]

- Mukherjee, S.; Zhou, L.; Goodman, A.M.; Large, N.; Ayala-Orozco, C.; Zhang, Y.; Halas, N.J. Hot-electron-induced dissociation of H2 on gold nanoparticles supported on SiO2. J. Am. Chem. Soc. 2014, 136, 64–67. [Google Scholar] [CrossRef]

- Mukherjee, S.; Libisch, F.; Large, N.; Neumann, O.; Brown, L.V.; Cheng, J.; Lassiter, J.B.; Carter, E.A.; Nordlander, P.; Halas, N.J. Hot Electrons Do the Impossible: Plasmon-Induced Dissociation of H2 on Au. Nano Lett. 2012, 13, 240–247. [Google Scholar] [CrossRef]

- Watanabe, K.; Menzel, D.; Nilius, N.; Freund, H.-J. Photochemistry on Metal Nanoparticles. Chem. Rev. 2006, 106, 4301–4320. [Google Scholar] [CrossRef]

- Sun, Q.; Chen, J.; Zheng, J.; Qu, T.; Jin, T.; Li, Y.; Tang, J. Surface Plasmon-Assisted Transparent Conductive Electrode for Flexible Perovskite Solar Cells. Adv. Opt. Mater. 2019, 7, 1900847. [Google Scholar] [CrossRef]

- Ding, B.; Lee, B.J.; Yang, M.; Jung, H.S.; Lee, J.-K. Surface-Plasmon Assisted Energy Conversion in Dye-Sensitized Solar Cells. Adv. Energy Mater. 2011, 1, 415–421. [Google Scholar] [CrossRef]

- Manjavacas, A.; Liu, J.G.; Kulkarni, V.; Nordlander, P. Plasmon-Induced Hot Carriers in Metallic Nanoparticles. ACS Nano 2014, 8, 7630–7638. [Google Scholar] [CrossRef]

- Edappadikkunnummal, S.; Nherakkayyil, S.N.; Kuttippurath, V.; Chalil, D.M.; Desai, N.R.; Keloth, C. Surface Plasmon Assisted Enhancement in the Nonlinear Optical Properties of Phenothiazine by Gold Nanoparticle. J. Phys. Chem. C 2017, 121, 26976–26986. [Google Scholar] [CrossRef]

- Chou, J.B.; Li, X.-H.; Wang, Y.; Fenning, D.P.; Elfaer, A.; Viegas, J.; Jouiad, M.; Shao-Horn, Y.; Kim, S.-G. Surface plasmon assisted hot electron collection in wafer-scale metallic-semiconductor photonic crystals. Opt. Express 2016, 24, A1234–A1244. [Google Scholar] [CrossRef]

- Govorov, A.O.; Zhang, H.; Gun’Ko, Y.K. Theory of Photoinjection of Hot Plasmonic Carriers from Metal Nanostructures into Semiconductors and Surface Molecules. J. Phys. Chem. C 2013, 117, 16616–16631. [Google Scholar] [CrossRef]

- Syu, H.-J.; Chuang, H.-C.; Lin, M.-J.; Cheng, C.-C.; Huang, P.-J.; Lin, C.-F. Ultra-broadband photoresponse of localized surface plasmon resonance from Si-based pyramid structures. Photon Res. 2019, 7, 1119–1126. [Google Scholar] [CrossRef]

- Tielrooij, K.-J.; Song, J.; Jensen, S.; Centeno, A.; Pesquera, A.; Elorza, A.Z.; Bonn, M.; Levitov, L.; Koppens, F. Photoexcitation cascade and multiple hot-carrier generation in graphene. Nat. Phys. 2013, 9, 248–252. [Google Scholar] [CrossRef]

- Zheng, F.; Zhang, P.; Wang, X.; Huang, W.; Zhang, J.; Shen, M.; Dong, W.; Fang, L.; Bai, Y.; Shen, X.; et al. Photovoltaic enhancement due to surface-plasmon assisted visible-light absorption at the inartificial surface of lead zirconate–titanate film. Nanoscale 2014, 6, 2915–2921. [Google Scholar] [CrossRef]

- Atar, F.B.; Battal, E.; Aygun, E.L.; Daglar, B.; Bayindir, M.; Okyay, A.K. Plasmonically enhanced hot electron based photovoltaic device. Opt. Express 2013, 21, 7196–7201. [Google Scholar] [CrossRef]

- Memarzadeh, S.; Kim, J.; Aytac, Y.; Murphy, T.E.; Munday, J.N. Surface plasmon assisted control of hot-electron relaxation time. Optica 2020, 7, 608. [Google Scholar] [CrossRef]

- Lisowski, M.; Loukakos, P.; Bovensiepen, U.; Gahl, C.; Wolf, M. Ultra-fast dynamics of electron thermalization, cooling and transport effects in Ru(001). Appl. Phys. A 2003, 78, 165–176. [Google Scholar] [CrossRef]

- Çankaya, G.; Ucar, N. Schottky barrier height dependence on the metal work function for p-type Si Schottky diodes. Z. Für Nat. A 2004, 59, 795–798. [Google Scholar] [CrossRef]

- Jang, M.; Lee, J. Analysis of Schottky Barrier Height in Small Contacts Using a Thermionic-Field Emission Model. ETRI J. 2002, 24, 455–461. [Google Scholar] [CrossRef] [Green Version]

- Zhang, T.; Raynaud, C.; Planson, D. Measure and analysis of 4H-SiC Schottky barrier height with Mo contacts. Eur. Phys. J. Appl. Phys. 2019, 85, 10102. [Google Scholar] [CrossRef]

- Mehrara, H.; Erfanian, A.; Khaje, M.; Zahedinejad, M.; Raissi, F.; Rezvani, F. Pore size dependence of PtSi/Porous Si Schottky barrier detectors on quantum efficiency response. Sens. Actuators A Phys. 2012, 184, 119–123. [Google Scholar] [CrossRef]

- Blaber, M.; Arnold, M.; Ford, M. A review of the optical properties of alloys and intermetallics for plasmonics. J. Physics: Condens. Matter 2010, 22, 143201. [Google Scholar] [CrossRef]

- Rakić, A.D.; Djurišić, A.B.; Elazar, J.M.; Majewski, M.L. Optical properties of metallic films for vertical-cavity optoelectronic devices. Appl. Opt. 1998, 37, 5271–5283. [Google Scholar] [CrossRef]

- Sundararaman, R.; Narang, P.; Jermyn, A.S.; Iii, W.A.G.; Atwater, H.A. Theoretical predictions for hot-carrier generation from surface plasmon decay. Nat. Commun. 2014, 5, 5788. [Google Scholar] [CrossRef]

- Ma, J.; Wang, Z.; Wang, L.W. Interplay between plasmon and single-particle excitations in a metal nanocluster. Nat. Commun. 2015, 6, 1–11. [Google Scholar] [CrossRef]

- Bauer, M.; Alexander, M.; Martin, A. Hot electron lifetimes in metals probed by time-resolved two-photon photoemission. Prog. Surf. Sci. 2015, 90, 319–376. [Google Scholar] [CrossRef]

- Brown, A.M.; Sundararaman, R.; Narang, P.; Goddard, W.A., III; Atwater, H.A. Ab initio phonon coupling and optical response of hot electrons in plasmonic metals. Phys. Rev. B 2016, 94, 075120. [Google Scholar] [CrossRef] [Green Version]

- Shalagatskyi, V. Ultrafast Acoustics in Hybrid and Magnetic Structures. Ph.D. Thesis, Université du Maine, Penobscot, ME, USA, 2015. [Google Scholar]

| Parameter | w/o Annealing | 500 °C Annealing | 600 °C Annealing | 700 °C Annealing |

|---|---|---|---|---|

| Maximum different (nm) | 6.88 | 2.34 | 6.1 | 53.5 |

| Ra (nm) | 4.468 | 0.341 | 0.998 | 8.438 |

| Annealing Temperature (°C) | Crystallite Size, Dg (nm) | d-Spacing (Å) | Bragg Angle, 2θ (°) | Microstrain, ε | Residual Stress, σX (GPa) |

|---|---|---|---|---|---|

| R.T. | 190.964 | 2.714 | 32.97 | 0.000185 | 0.077 |

| 500 | 201.559 | 2.712 | 32.99 | 0.000172 | 0.071 |

| Annealing Temperature (°C) | Crystallite Size, Dg (nm) | d-Spacing (Å) | Bragg Angle, 2θ (°) | Microstrain, ε | Residual Stress, σX (GPa) |

|---|---|---|---|---|---|

| R.T. | 104.047 | 1.5018 | 61.71 | −0.0006 | −0.25 |

| 500 | 73.2 | 1.5017 | 61.71 | −0.0009 | −0.37 |

| 600 | 95.789 | 1.502 | 61.7 | −0.0006 | −0.25 |

| 700 | 83.45 | 1.5018 | 61.71 | −0.0007 | −0.27 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, Z.-C.; Li, Y.-H.; Lin, C.-F. Mid-Infrared Response from Cr/n-Si Schottky Junction with an Ultra-Thin Cr Metal. Nanomaterials 2022, 12, 1750. https://doi.org/10.3390/nano12101750

Su Z-C, Li Y-H, Lin C-F. Mid-Infrared Response from Cr/n-Si Schottky Junction with an Ultra-Thin Cr Metal. Nanomaterials. 2022; 12(10):1750. https://doi.org/10.3390/nano12101750

Chicago/Turabian StyleSu, Zih-Chun, Yu-Hao Li, and Ching-Fuh Lin. 2022. "Mid-Infrared Response from Cr/n-Si Schottky Junction with an Ultra-Thin Cr Metal" Nanomaterials 12, no. 10: 1750. https://doi.org/10.3390/nano12101750