Co-W Barrier Layers for Metallization of Copper Interconnects: Thermal Performance Analysis

Abstract

:1. Introduction

2. Materials and Methods

2.1. PVD Film Deposition

2.2. Vacuum Annealing

2.3. Film Characterization

3. Results and Discussion

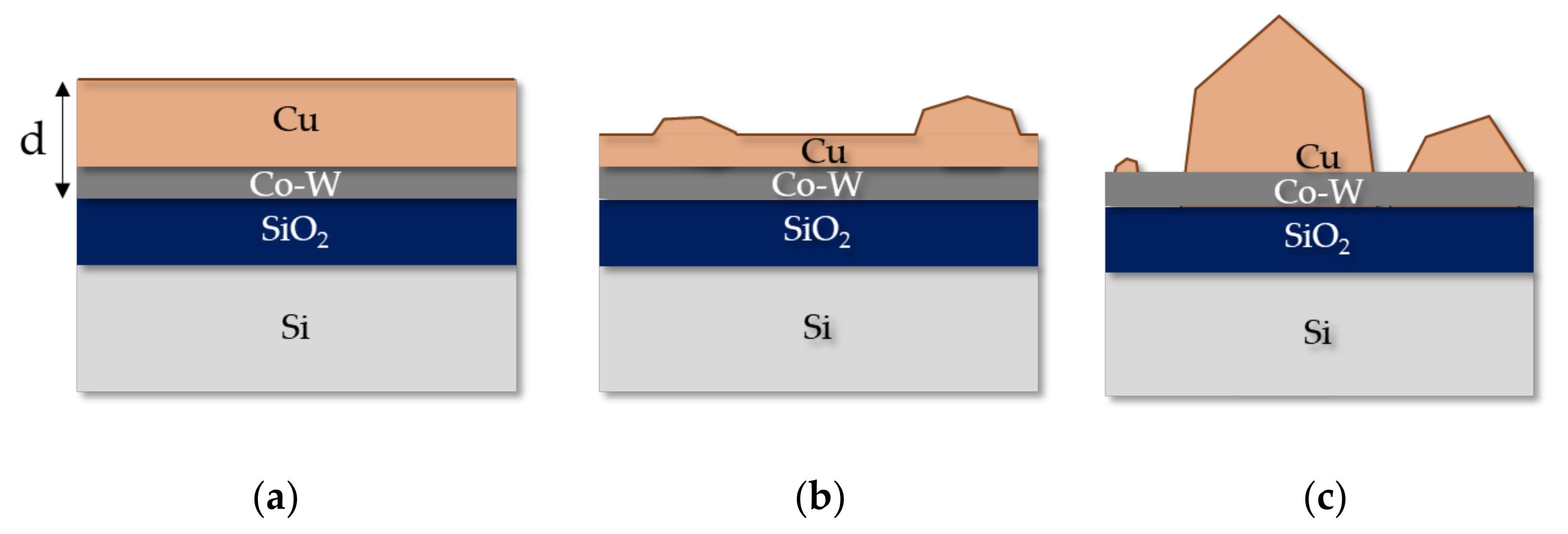

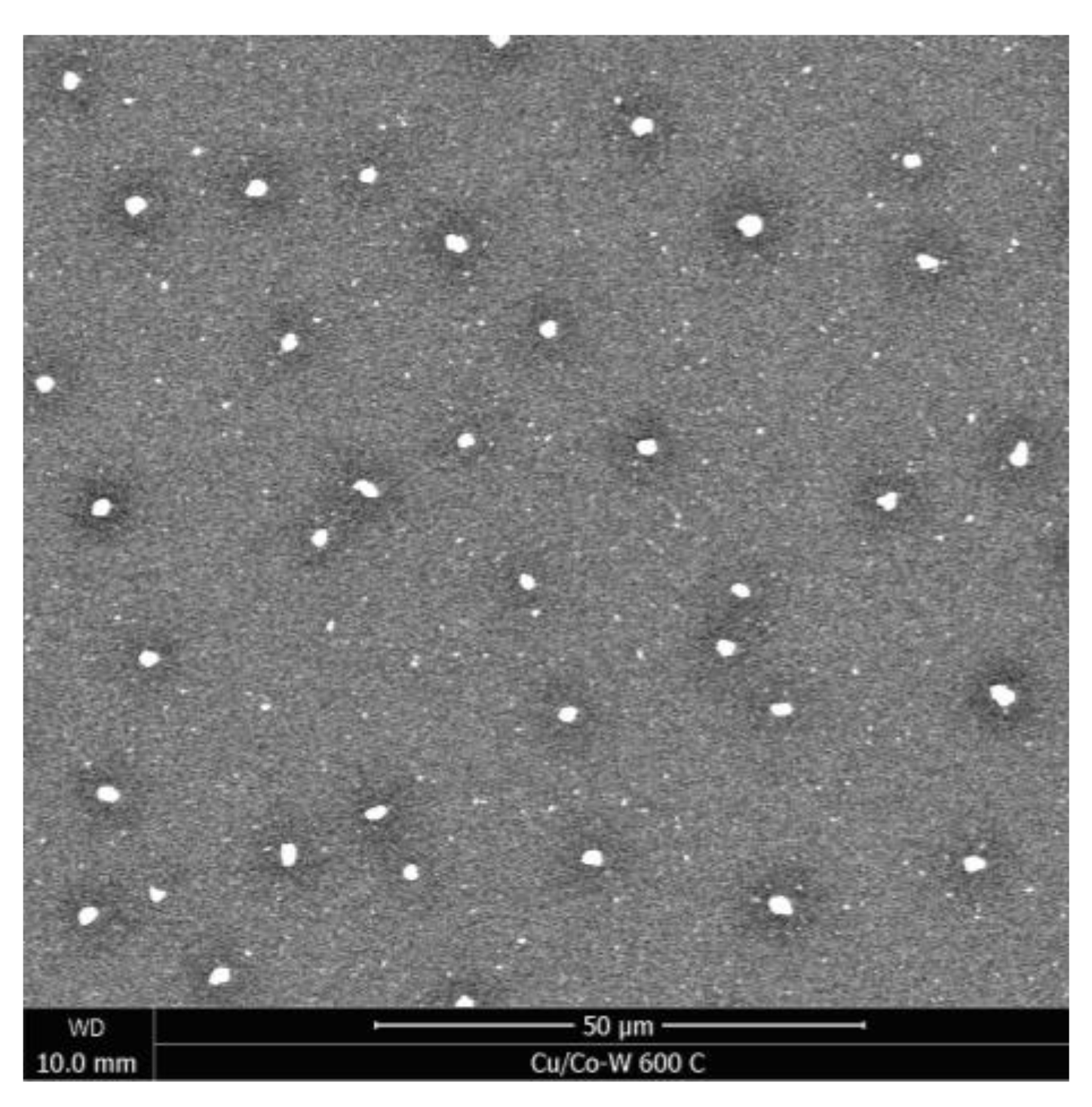

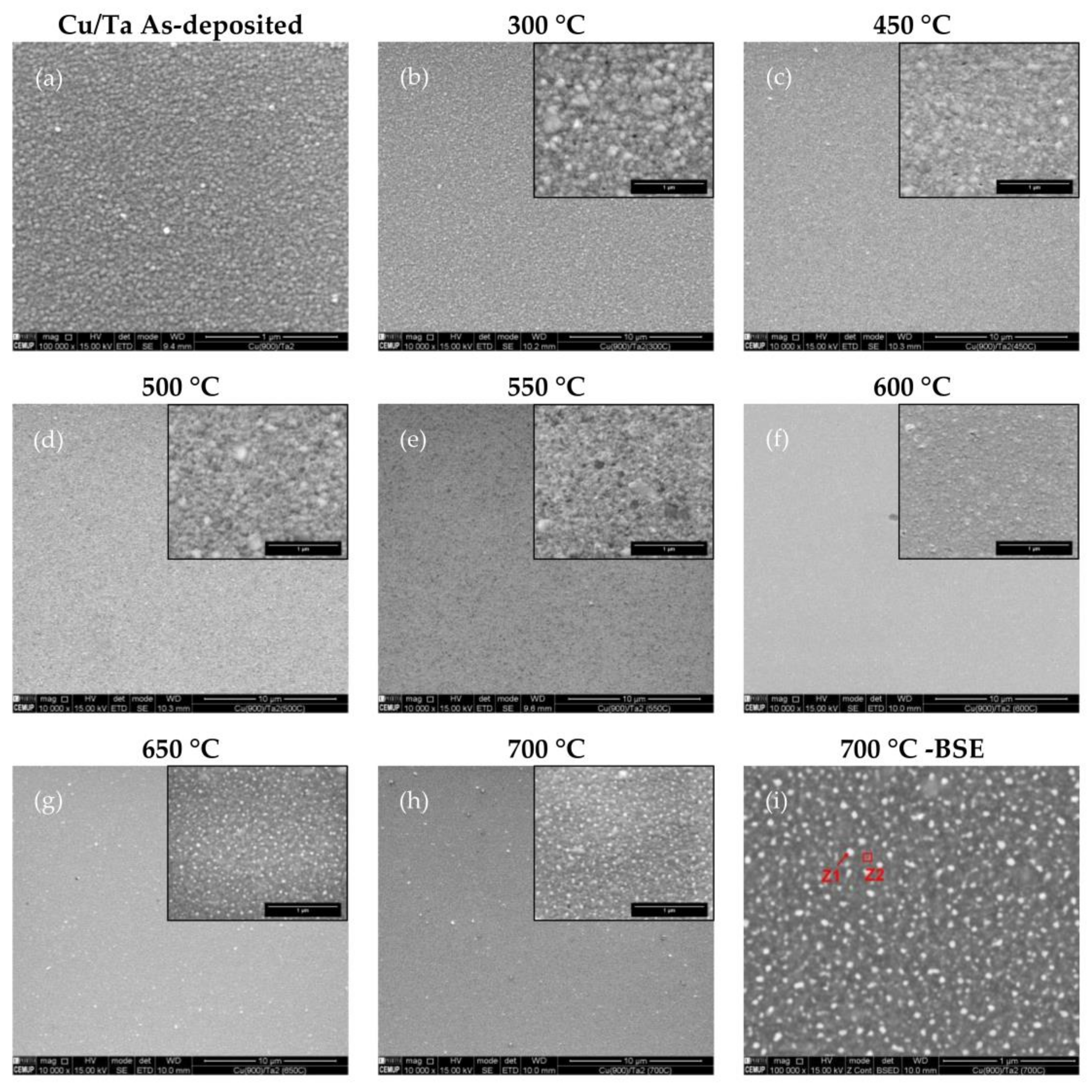

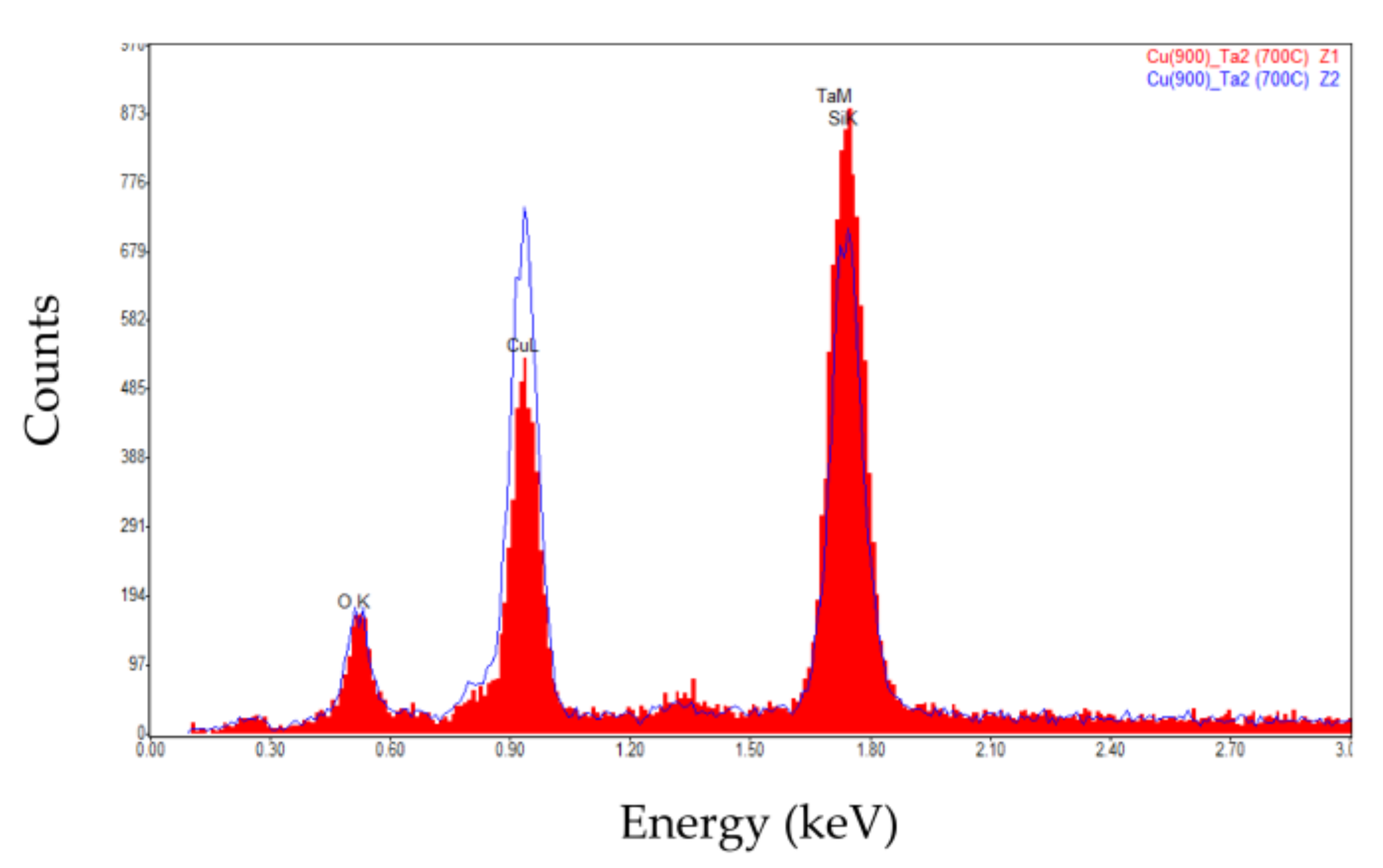

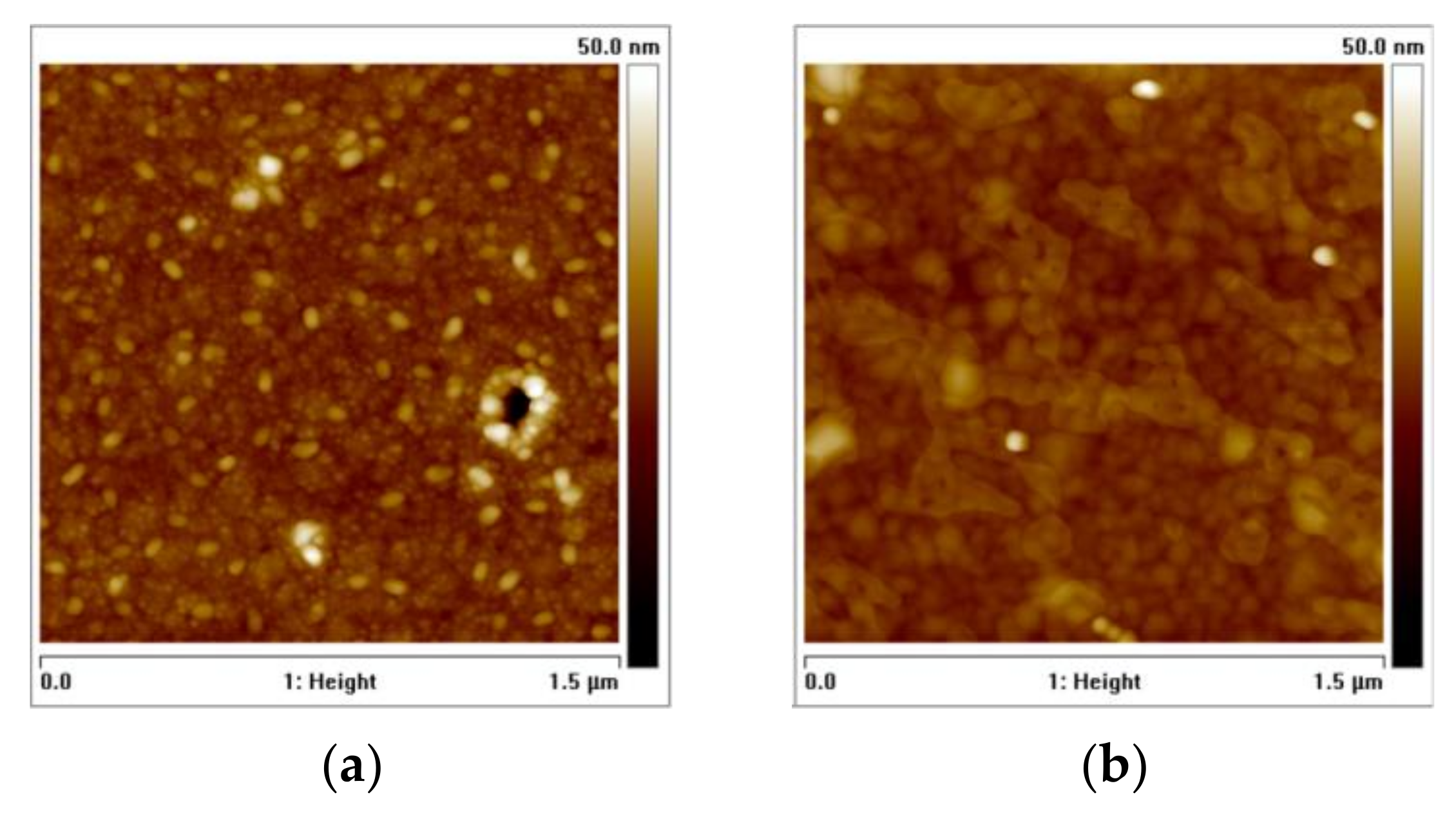

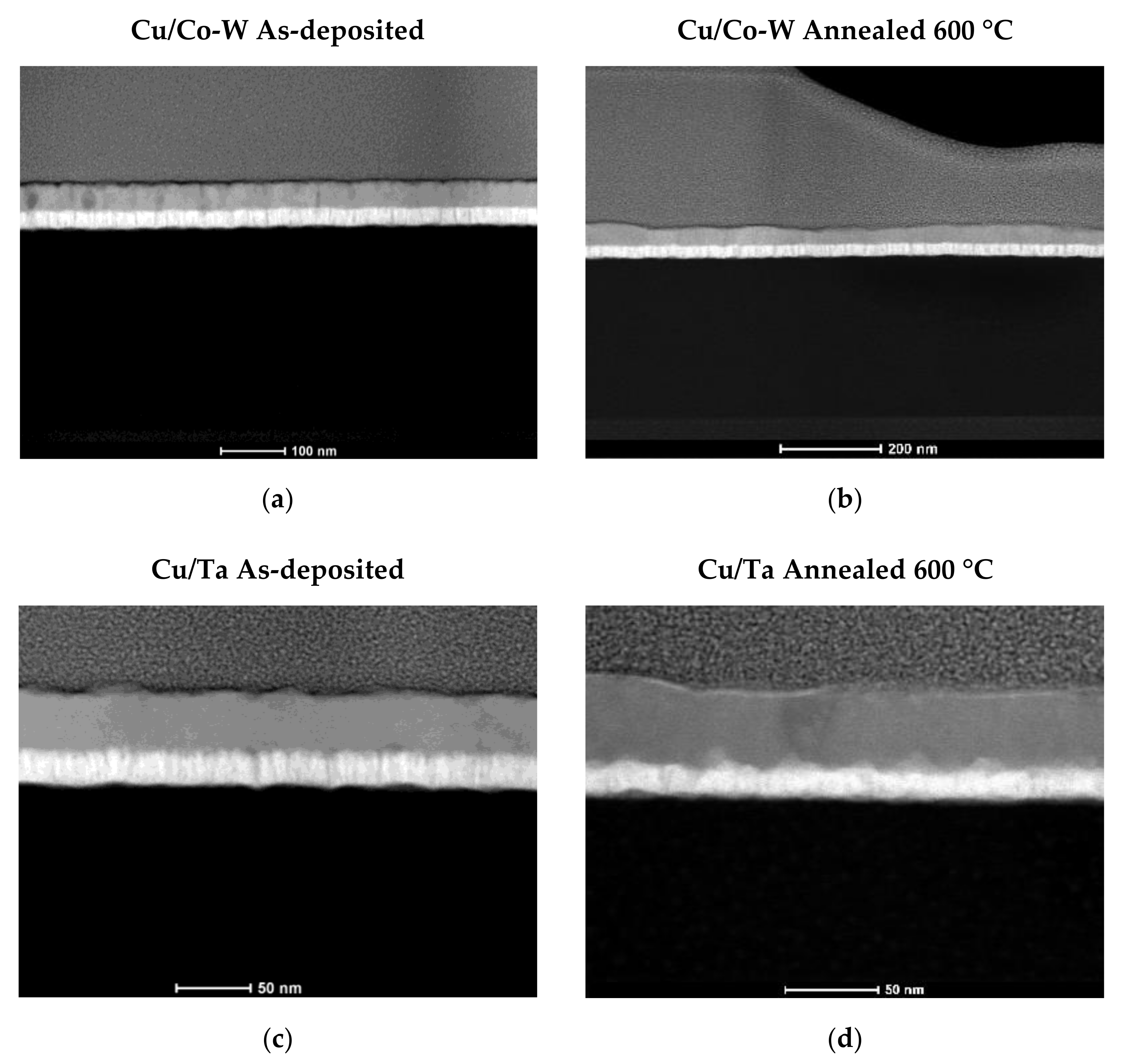

3.1. Scanning Electron Microscopy

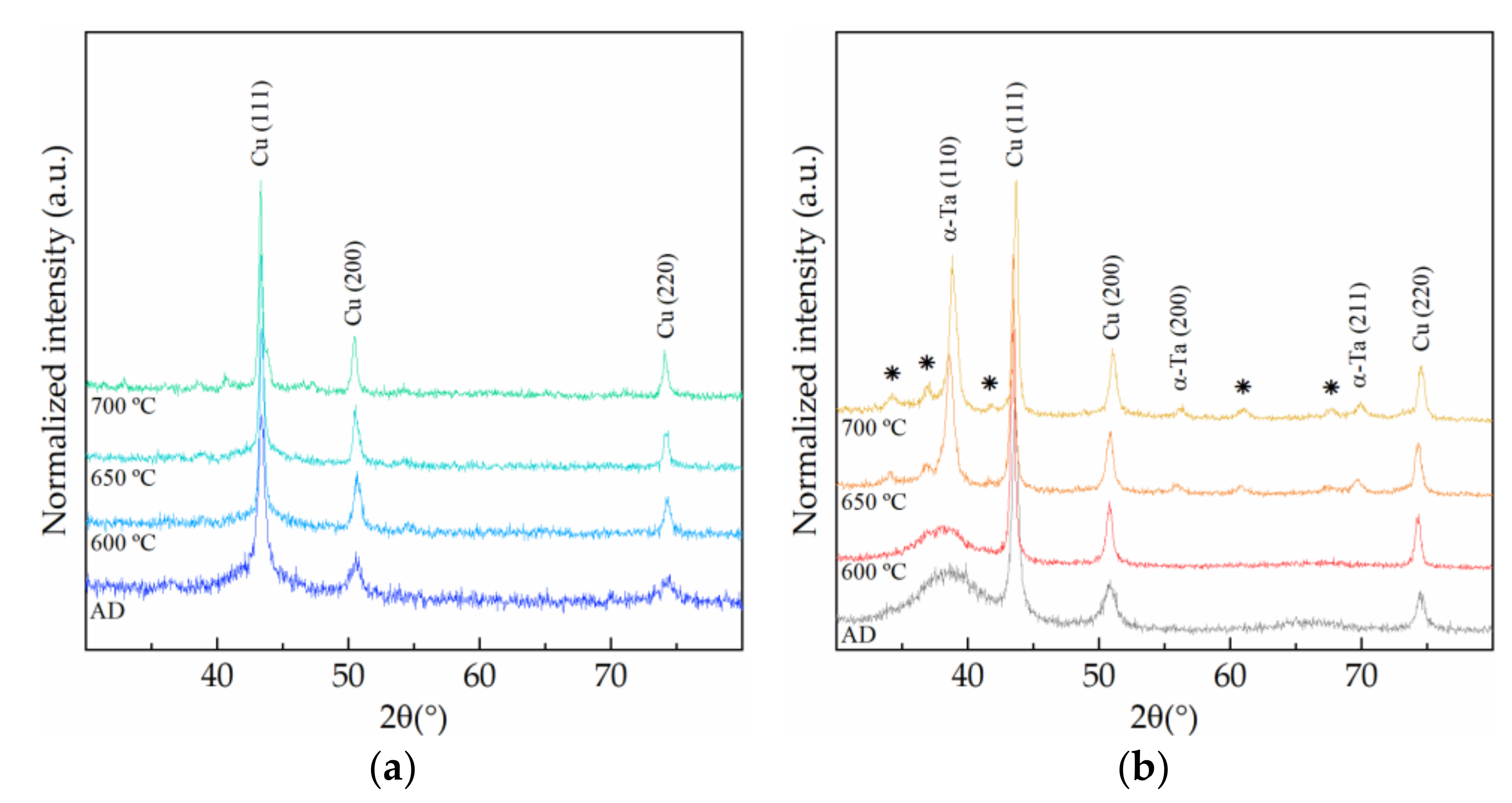

3.2. X-ray Diffraction

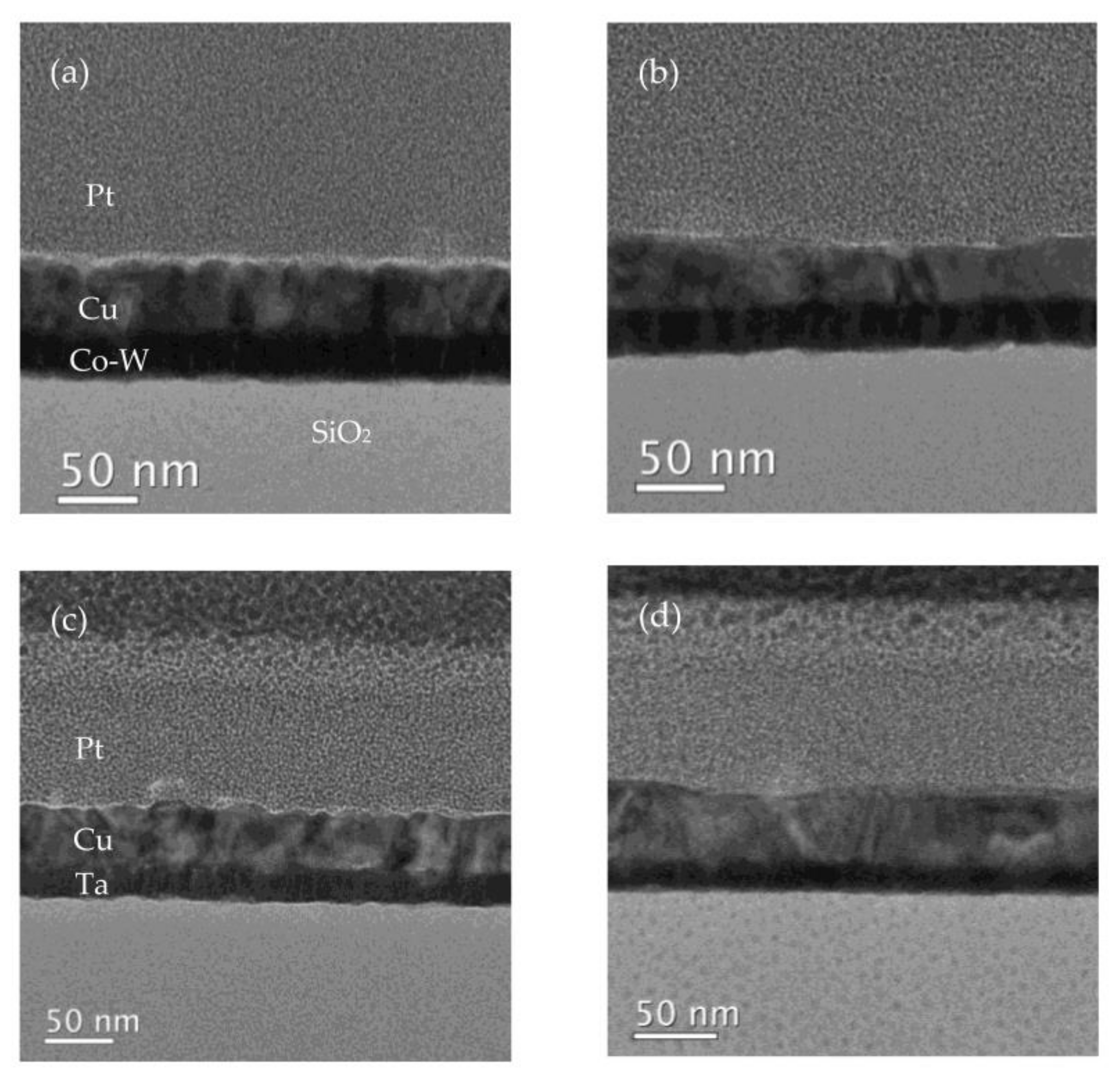

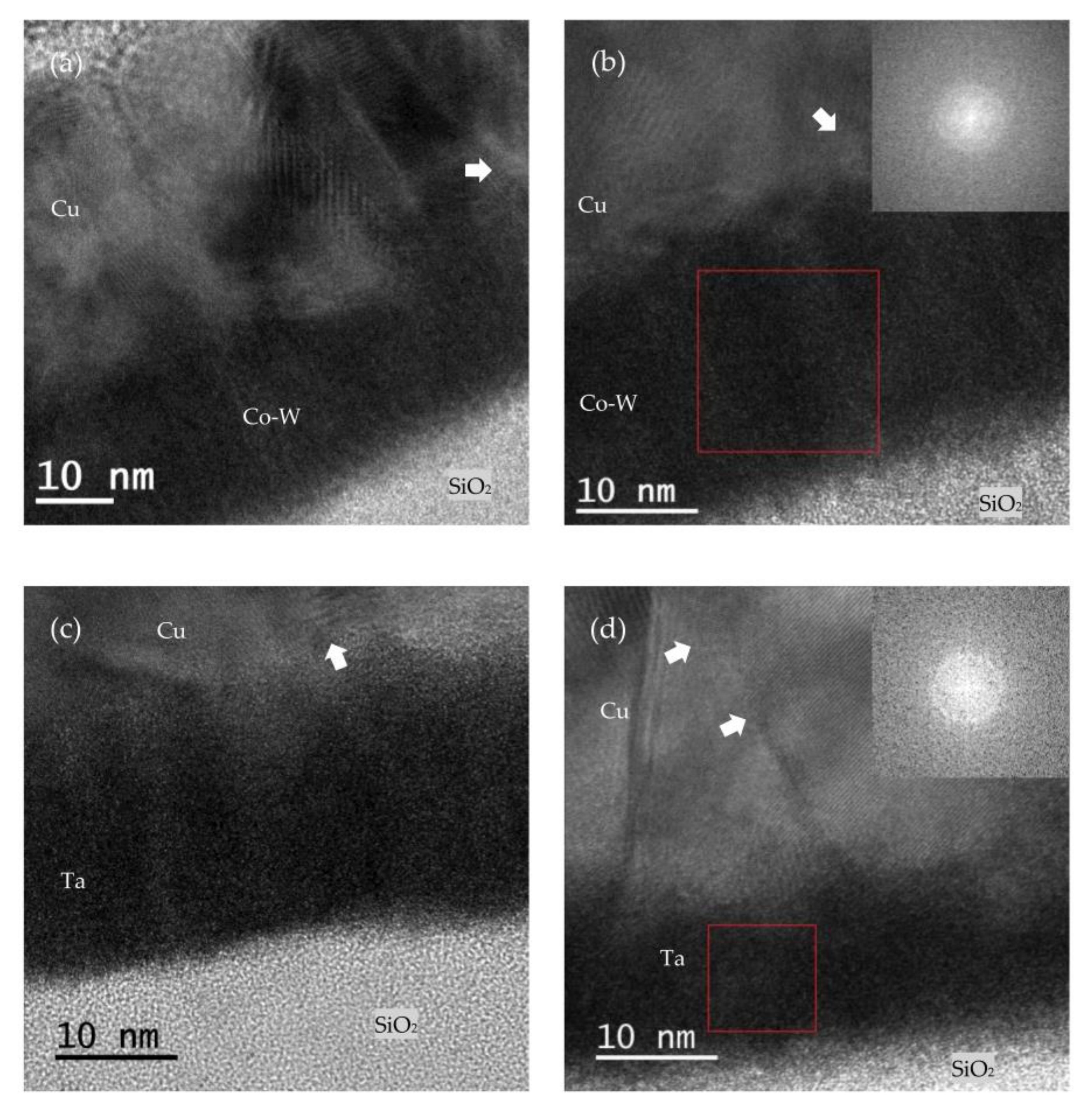

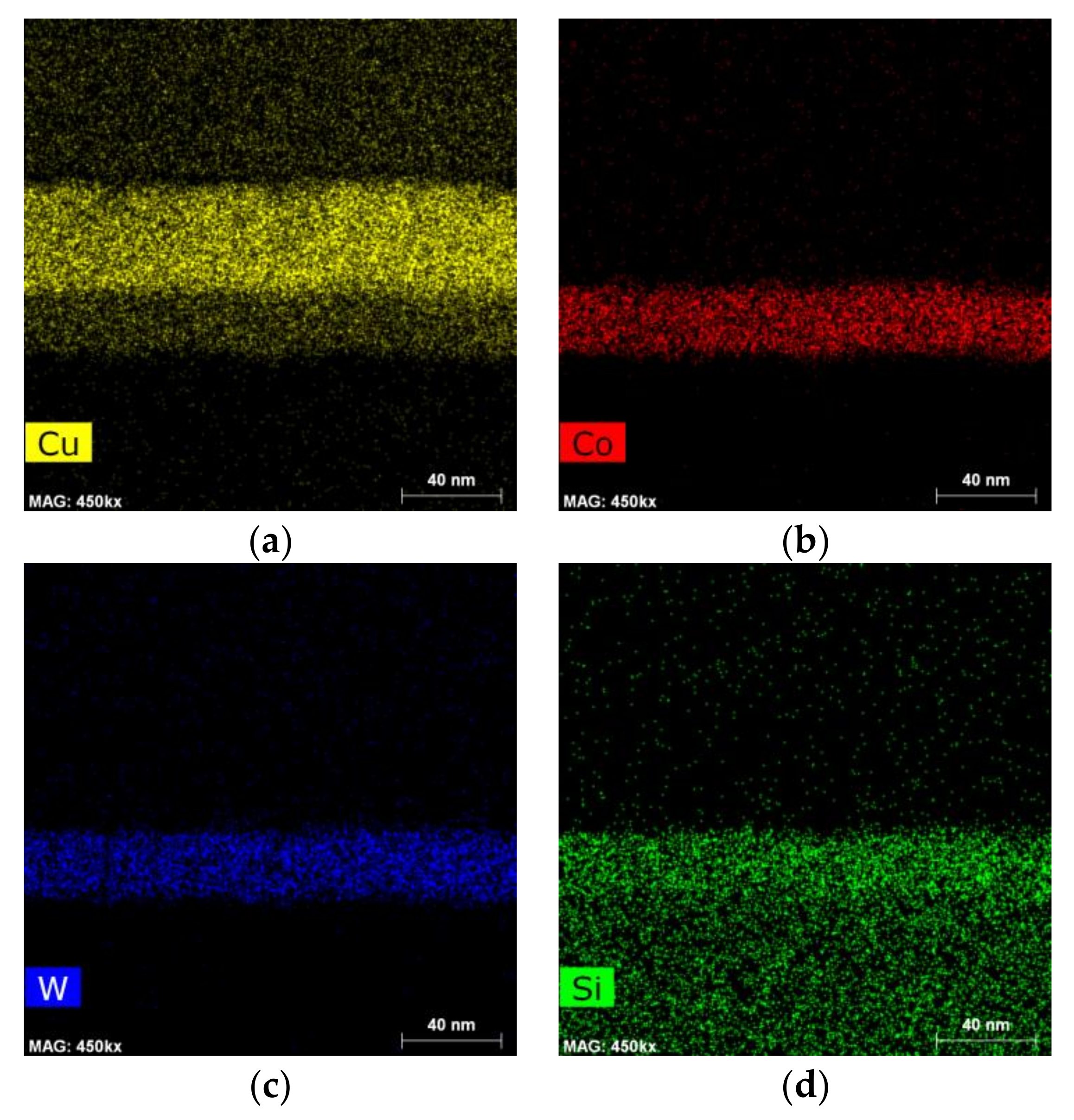

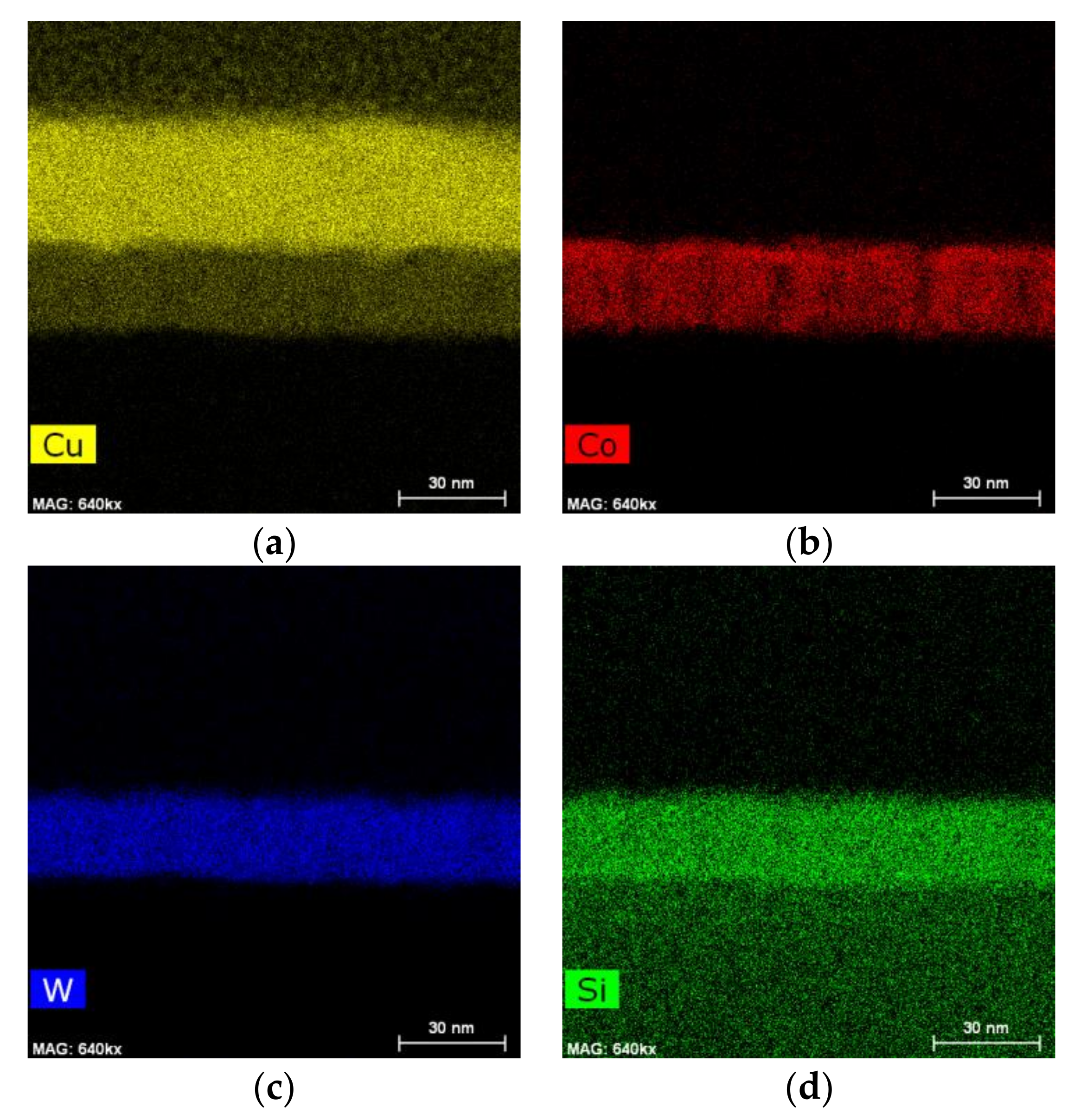

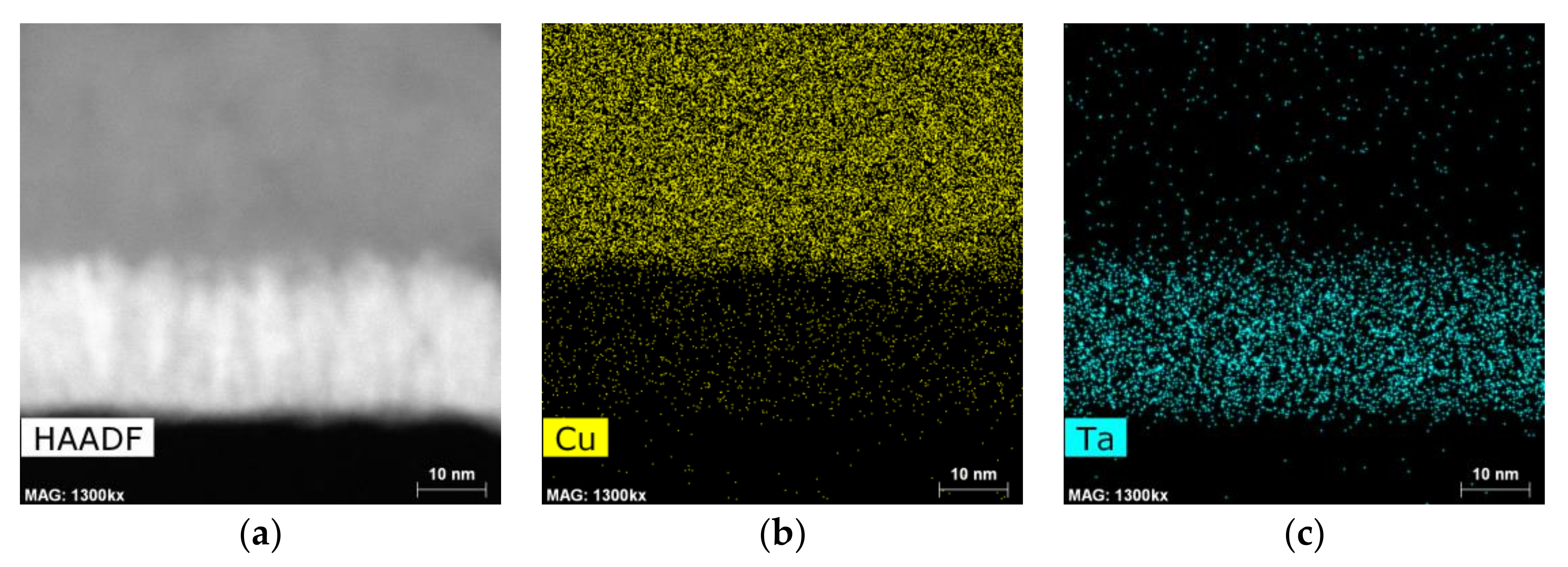

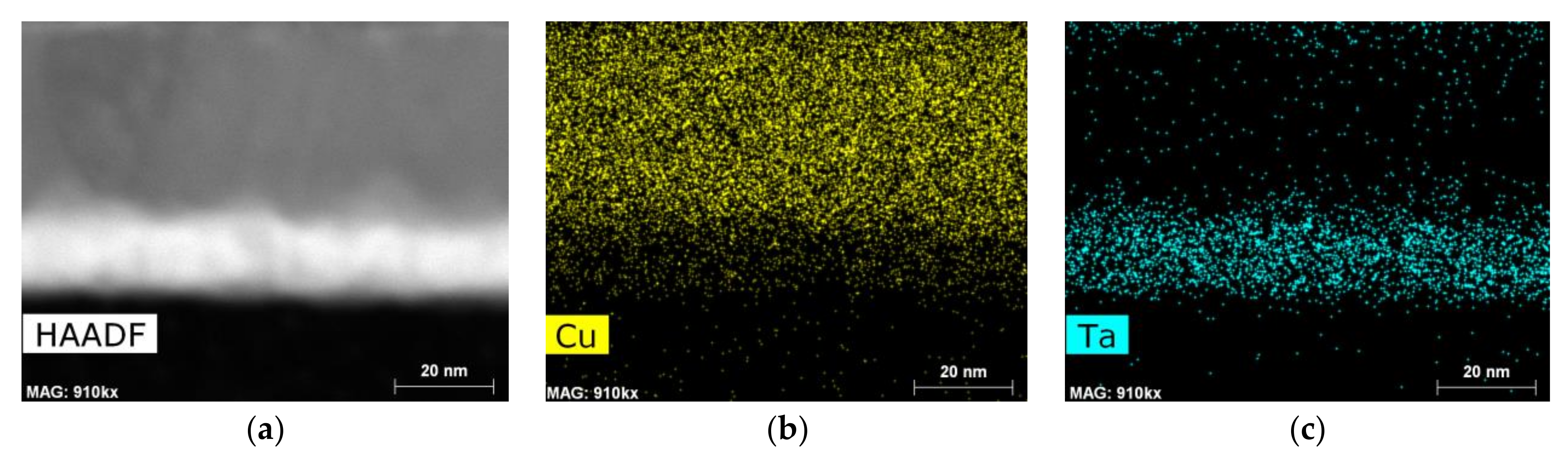

3.3. Transmission Electron Microscopy

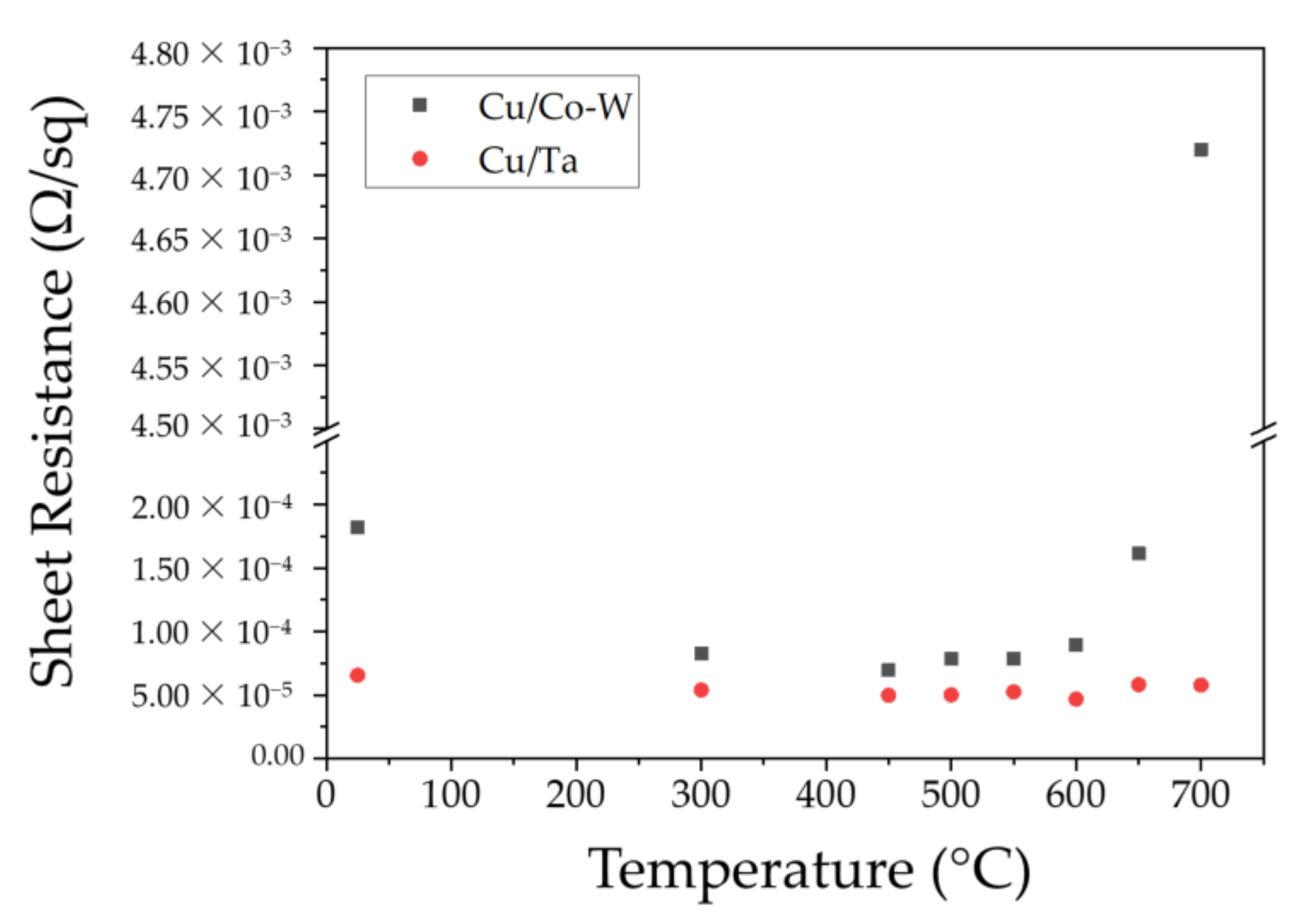

3.4. Electrical Characterization

4. Conclusions

- From a Cu surface stability perspective, the Co-W system performed worse than the Ta film, with dewetting of the Cu layer in the 300–450 °C range;

- The Ta film revealed superior Cu dewetting resistance, with no discernible agglomeration at the surface after annealing for the studied temperature ranges;

- The Cu/Co-W system exhibited diffusion resistance up to 700 °C, whereas the Cu/Ta system failed in the 600–650 °C range, with Ta diffusion through the Cu layer;

- Co-W displayed structural continuity and integrity throughout the temperature range used;

- The sheet resistance of the Cu/Co-W was minimized after annealing at 450 °C, at 7.07 × 10−6 Ω/sq;

- The Cu/Ta system showed a minimum sheet resistance value of 6.03 × 10−6 Ω/sq after annealing at 450 °C. However, the need for the inclusion of a high resistance diffusion barrier layer such as TaN suggests an overall inferior electrical performance of the Cu/Ta/TaN system in comparison to the Cu/Co-W system.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Markov, I.L. Limits on fundamental limits to computation. Nature 2014, 512, 147–154. [Google Scholar] [CrossRef] [Green Version]

- Ganesh, K.J.; Darbal, A.D.; Rajasekhara, S.; Rohrer, G.S.; Barmak, K.; Ferreira, P.J. Effect of downscaling nano-copper interconnects on the microstructure revealed by high resolution TEM-orientation-mapping. Nanotechnology 2012, 23, 135702. [Google Scholar] [CrossRef] [PubMed]

- Shauly, E.N. Physical, Electrical, and Reliability Considerations for Copper BEOL Layout Design Rules. J. Low Power Electron. Appl. 2018, 8, 20. [Google Scholar] [CrossRef] [Green Version]

- Shen, T.; Rajagopalan, B.; Silvestre, M.C.; Ramanathan, E.; Mahalingam, A.S.K.M.; Zhang, W.; Yeap, K.B.; Justison, P. Optimizing Cu barrier thickness for interconnects performance, reliability and yield. In Proceedings of the IEEE International Reliability Physics Symposium (IRPS), Pasadena, CA, USA, 17–21 April 2016. [Google Scholar]

- Yang, C.; Cohen, S.; Shaw, T.; Wang, P.; Nogami, T.; Edelstein, D. Characterization of “Ultrathin-Cu”/Ru(Ta)/TaN Liner Stack for Copper Interconnects. IEEE Electron Device Lett. 2010, 31, 722–724. [Google Scholar] [CrossRef]

- Shimizu, H.; Sakoda, K.; Shimogaki, Y. CVD of cobalt–tungsten alloy film as a novel copper diffusion barrier. Microelectron. Eng. 2013, 106, 91–95. [Google Scholar] [CrossRef]

- Su, Y.-H.; Kuo, T.-C.; Lee, W.-H.; Wang, Y.-S.; Hung, C.-C.; Tseng, W.-H.; Wei, K.-H.; Wang, Y.-L. Effect of tungsten incorporation in cobalt tungsten alloys as seedless diffusion barrier materials. Microelectron. Eng. 2017, 171, 25–30. [Google Scholar] [CrossRef]

- Kuo, T.-C.; Su, Y.-H.; Lee, W.-H.; Liao, W.H.; Wang, Y.-S.; Hung, C.-C.; Wang, Y.-L. A study on the plating and wetting ability of ruthenium-tungsten multi-layers for advanced Cu metallization. Microelectron. Eng. 2016, 162, 27–33. [Google Scholar] [CrossRef]

- Volders, H.; Carbonell, L.; Heylen, N.; Kellens, K.; Zhao, C.; Marrant, K.; Faelens, G.; Conard, T.; Parmentier, B.; Steenbergen, J.; et al. Barrier and seed repair performance of thin RuTa films for Cu interconnects. Microelectron. Eng. 2011, 88, 690–693. [Google Scholar] [CrossRef]

- Budhiman, N.; Schurmann, U.; Jensen, B.; Chemnitz, S.; Kienle, L.; Wagner, B. Transmission electron microscopy study for investigating high-temperature reliability of Ti-10 W-90-based and Ta-based diffusion barriers up to 600 degrees C. Phys. Status Solidi A-Appl. Mater. Sci. 2016, 213, 1055–1062. [Google Scholar] [CrossRef]

- Li, Z.; Tian, Y.; Teng, C.; Cao, H. Recent Advances in Barrier Layer of Cu Interconnects. Materials 2020, 13, 5049. [Google Scholar] [CrossRef]

- Wislicenus, M.; Liske, R.; Gerlich, L.; Vasilev, B.; Preusse, A. Cobalt advanced barrier metallization: A resistivity composition analysis. Microelectron. Eng. 2015, 137, 11–15. [Google Scholar] [CrossRef]

- Santos, R.F.; Oliveira, B.M.C.; Chícharo, A.; Alpuim, P.; Ferreira, P.J.; Simões, S.; Viana, F.; Vieira, M.F. Seedless Cu Electroplating on Co-W Thin Films in Low pH Electrolyte: Early Stages of Formation. Nanomaterials 2021, 11, 1914. [Google Scholar] [CrossRef]

- Lane, M.W.; Liniger, E.G.; Lloyd, J.R. Relationship between interfacial adhesion and electromigration in Cu metallization. J. Appl. Phys. 2003, 93, 1417–1421. [Google Scholar] [CrossRef]

- Ohring, M. 5.1 Introduction. In Materials Science of Thin Films—Deposition and Structure, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2001. [Google Scholar]

- He, C.; Zhang, J.; Wang, J.; Ma, G.; Zhao, D.; Cai, Q. Effect of structural defects on corrosion initiation of TiN nanocrystalline films. Appl. Surf. Sci. 2013, 276, 667–671. [Google Scholar] [CrossRef]

- Panjan, P.; Drnovšek, A.; Mahne, N.; Čekada, M.; Panjan, M. Surface Topography of PVD Hard Coatings. Coatings 2021, 11, 1387. [Google Scholar] [CrossRef]

- Mardani, S.; Norström, H.; Smith, U.; Zhang, S.-L. High-temperature Ta diffusion in the grain boundary of thin Cu films. J. Vac. Sci. Technol. B 2016, 34, 040606. [Google Scholar] [CrossRef]

- Holloway, K.; Fryer, P.M.; Cabral, C., Jr.; Harper, J.M.E.; Bailey, P.J.; Kelleher, K.H. Tantalum as a diffusion barrier between copper and silicon: Failure mechanism and effect of nitrogen additions. J. Appl. Phys. 1992, 71, 5433–5444. [Google Scholar] [CrossRef] [Green Version]

- Laurila, T.; Zeng, K.; Kivilahti, J.K.; Molarius, J.; Suni, I. Failure mechanism of Ta diffusion barrier between Cu and Si. J. Appl. Phys. 2000, 88, 3377–3384. [Google Scholar] [CrossRef]

- Buchin, E.Y.; Naumov, V.V.; Vasilyev, S.V. Formation of Nanoporous Copper-Silicide Films. Semiconductors 2019, 53, 395–399. [Google Scholar] [CrossRef]

- Thompson, C.V. Solid-State Dewetting of Thin Films. Annu. Rev. Mater. Res. 2012, 42, 399–434. [Google Scholar] [CrossRef]

- Gall, D. The search for the most conductive metal for narrow interconnect lines. J. Appl. Phys. 2020, 127, 050901. [Google Scholar] [CrossRef] [Green Version]

- Rossnagel, S.M.; Kuan, T.S. Alteration of Cu conductivity in the size effect regime. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Processing Meas. Phenom. 2004, 22, 240–247. [Google Scholar] [CrossRef]

- Graham, R.L.; Alers, G.B.; Mountsier, T.; Shamma, N.; Dhuey, S.; Cabrini, S.; Geiss, R.H.; Read, D.T.; Peddeti, S. Resistivity dominated by surface scattering in sub-50 nm Cu wires. Appl. Phys. Lett. 2010, 96, 042116. [Google Scholar] [CrossRef]

- Rossnagel, S.M. Characteristics of ultrathin Ta and TaN films. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Processing Meas. Phenom. 2002, 20, 2328–2336. [Google Scholar] [CrossRef]

- Hu, Y.; Rasadujjaman, M.; Wang, Y.; Zhang, J.; Yan, J.; Baklanov, M.R. Study on the Electrical, Structural, Chemical and Optical Properties of PVD Ta(N) Films Deposited with Different N2 Flow Rates. Coatings 2021, 11, 937. [Google Scholar] [CrossRef]

- Choi, D.; Liu, X.; Schelling, P.K.; Coffey, K.R.; Barmak, K. Failure of semiclassical models to describe resistivity of nanometric, polycrystalline tungsten films. J. Appl. Phys. 2014, 115, 104308. [Google Scholar] [CrossRef] [Green Version]

- Sun, T.; Yao, B.; Warren, A.P.; Barmak, K.; Toney, M.F.; Peale, R.E.; Coffey, K.R. Surface and grain-boundary scattering in nanometric Cu films. Phys. Rev. B 2010, 81, 155454. [Google Scholar] [CrossRef] [Green Version]

- Barmak, K.; Darbal, A.; Ganesh, K.J.; Ferreira, P.J.; Rickman, J.M.; Sun, T.; Yao, B.; Warren, A.P.; Coffey, K.R. Surface and grain boundary scattering in nanometric Cu thin films: A quantitative analysis including twin boundaries. J. Vac. Sci. Technol. A Vac. Surf. Film. 2014, 32, 061503. [Google Scholar] [CrossRef] [Green Version]

- Chan, K.Y.; Tou, T.Y.; Teo, B.S. Thickness dependence of the structural and electrical properties of copper films deposited by dc magnetron sputtering technique. Microelectron. J. 2006, 37, 608–612. [Google Scholar] [CrossRef]

- Smith, R.S.; Ryan, E.T.; Hu, C.-K.; Motoyama, K.; Lanzillo, N.; Metzler, D.; Jiang, L.; Demarest, J.; Quon, R.; Gignac, L.; et al. An evaluation of Fuchs-Sondheimer and Mayadas-Shatzkes models below 14nm node wide lines. AIP Adv. 2019, 9, 025015. [Google Scholar] [CrossRef] [Green Version]

- Gall, D. Electron mean free path in elemental metals. J. Appl. Phys. 2016, 119, 085101. [Google Scholar] [CrossRef] [Green Version]

- Purswani, J.M.; Gall, D. Electron scattering at single crystal Cu surfaces. Thin Solid Film. 2007, 516, 465–469. [Google Scholar] [CrossRef]

- Lim, J.-W.; Isshiki, M. Electrical resistivity of Cu films deposited by ion beam deposition: Effects of grain size, impurities, and morphological defect. J. Appl. Phys. 2006, 99, 094909. [Google Scholar] [CrossRef]

| Film | Mean Thickness (nm) | Std. Deviation |

|---|---|---|

| Co-W (as-deposited) | 26.9 | 1.8 |

| Co-W (annealed 600 °C) | 24.0 | 2.4 |

| Cu (Co-W, as-deposited) | 42.4 | 2.5 |

| Cu (Co-W, 600 °C) | 35.7 | 5.1 |

| Ta (as-deposited) | 23.0 | 1.2 |

| Ta (annealed 600 °C) | 17.8 | 2.3 |

| Cu (Ta, as-deposited) | 39.8 | 2.0 |

| Cu (Ta, 600 °C) | 41.0 | 2.6 |

| System | Electrical Resistivity (Ω∙cm) | |

|---|---|---|

| 25 °C | 600 °C | |

| Cu/Co-W | 1.09 × 10−5 | 5.01 × 10−6 |

| Cu/Ta | 4.92 × 10−6 | 3.51 × 10−6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliveira, B.M.C.; Santos, R.F.; Piedade, A.P.; Ferreira, P.J.; Vieira, M.F. Co-W Barrier Layers for Metallization of Copper Interconnects: Thermal Performance Analysis. Nanomaterials 2022, 12, 1752. https://doi.org/10.3390/nano12101752

Oliveira BMC, Santos RF, Piedade AP, Ferreira PJ, Vieira MF. Co-W Barrier Layers for Metallization of Copper Interconnects: Thermal Performance Analysis. Nanomaterials. 2022; 12(10):1752. https://doi.org/10.3390/nano12101752

Chicago/Turabian StyleOliveira, Bruno M. C., Ruben F. Santos, Ana P. Piedade, Paulo J. Ferreira, and Manuel F. Vieira. 2022. "Co-W Barrier Layers for Metallization of Copper Interconnects: Thermal Performance Analysis" Nanomaterials 12, no. 10: 1752. https://doi.org/10.3390/nano12101752