Light Trapping of Inclined Si Nanowires for Efficient Inorganic/Organic Hybrid Solar Cells

Abstract

:1. Introduction

2. Materials and Methods

2.1. Substrate Preparation

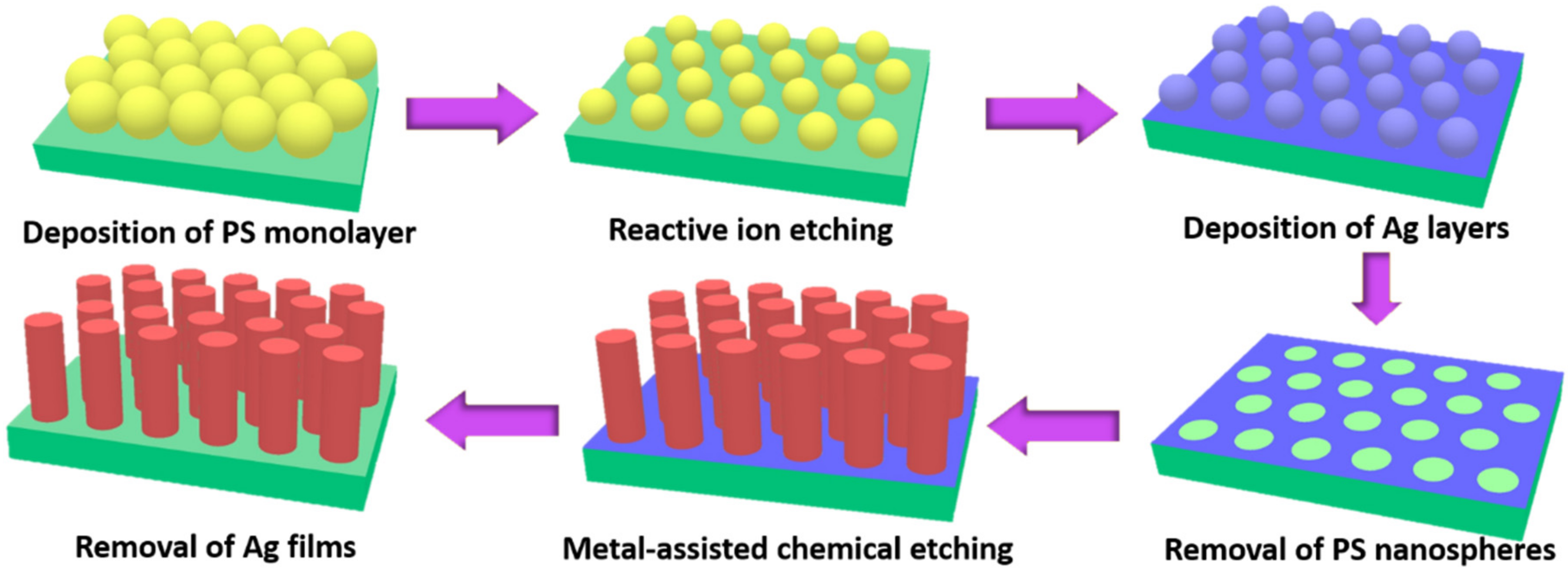

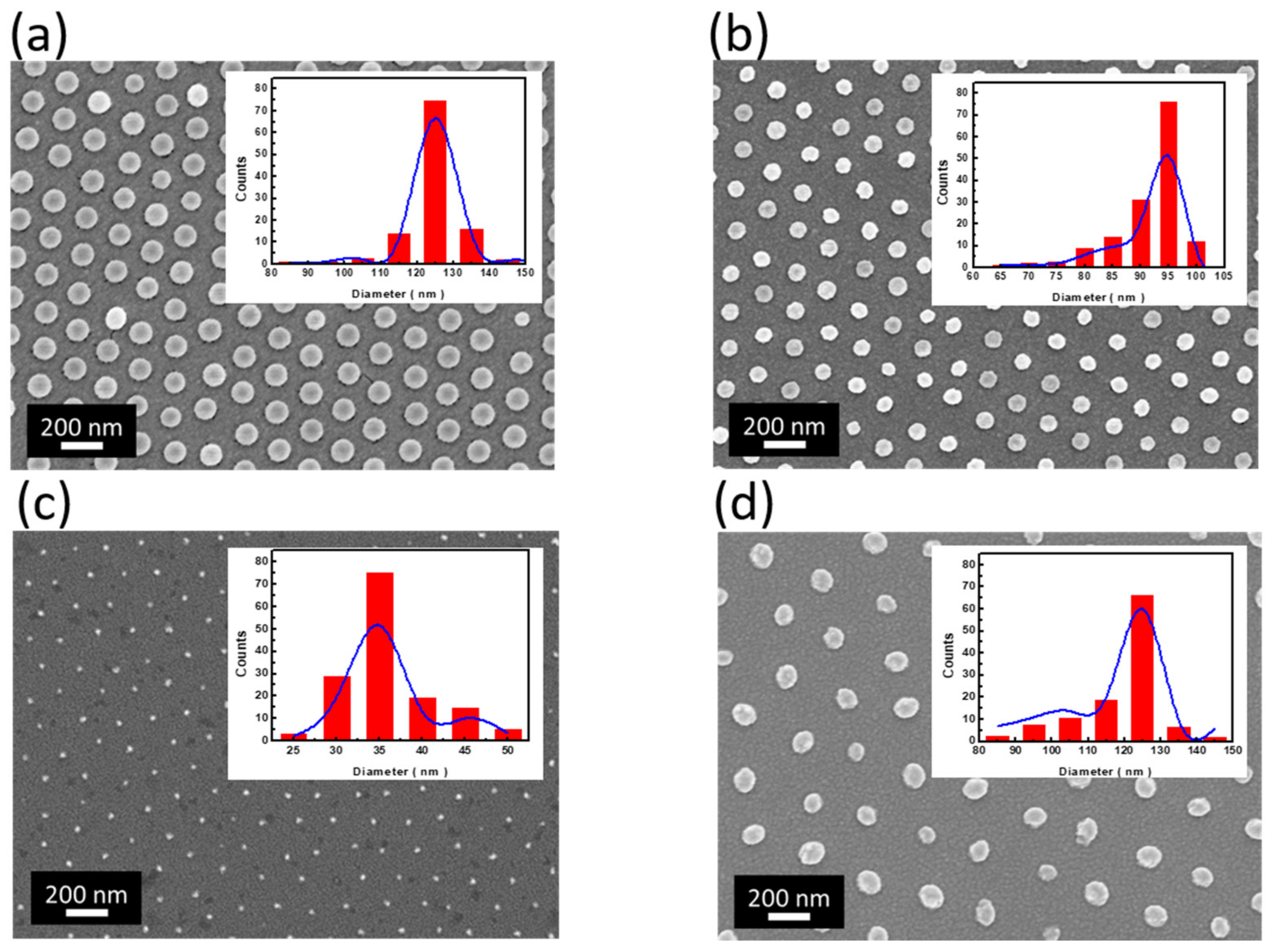

2.2. Nanosphere Lithography

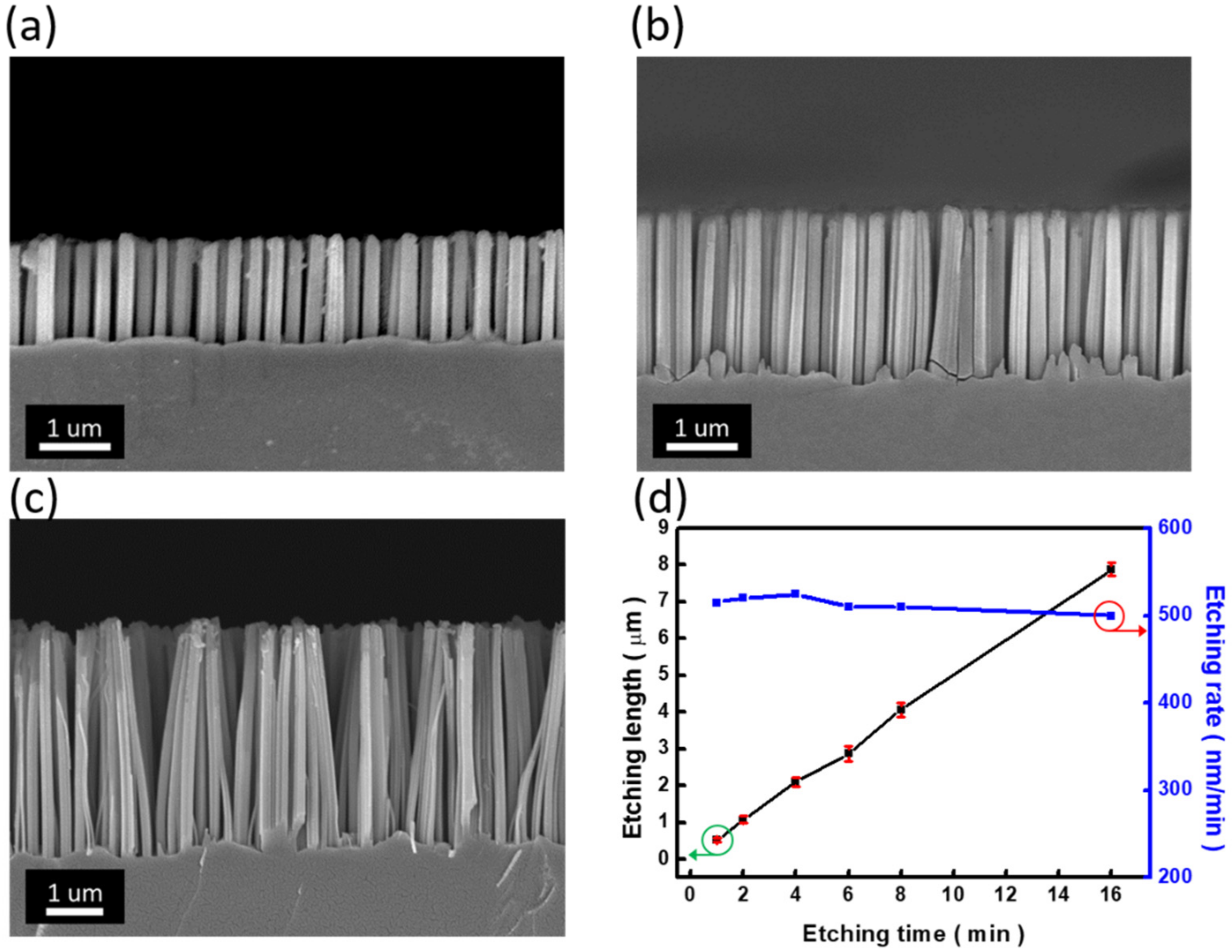

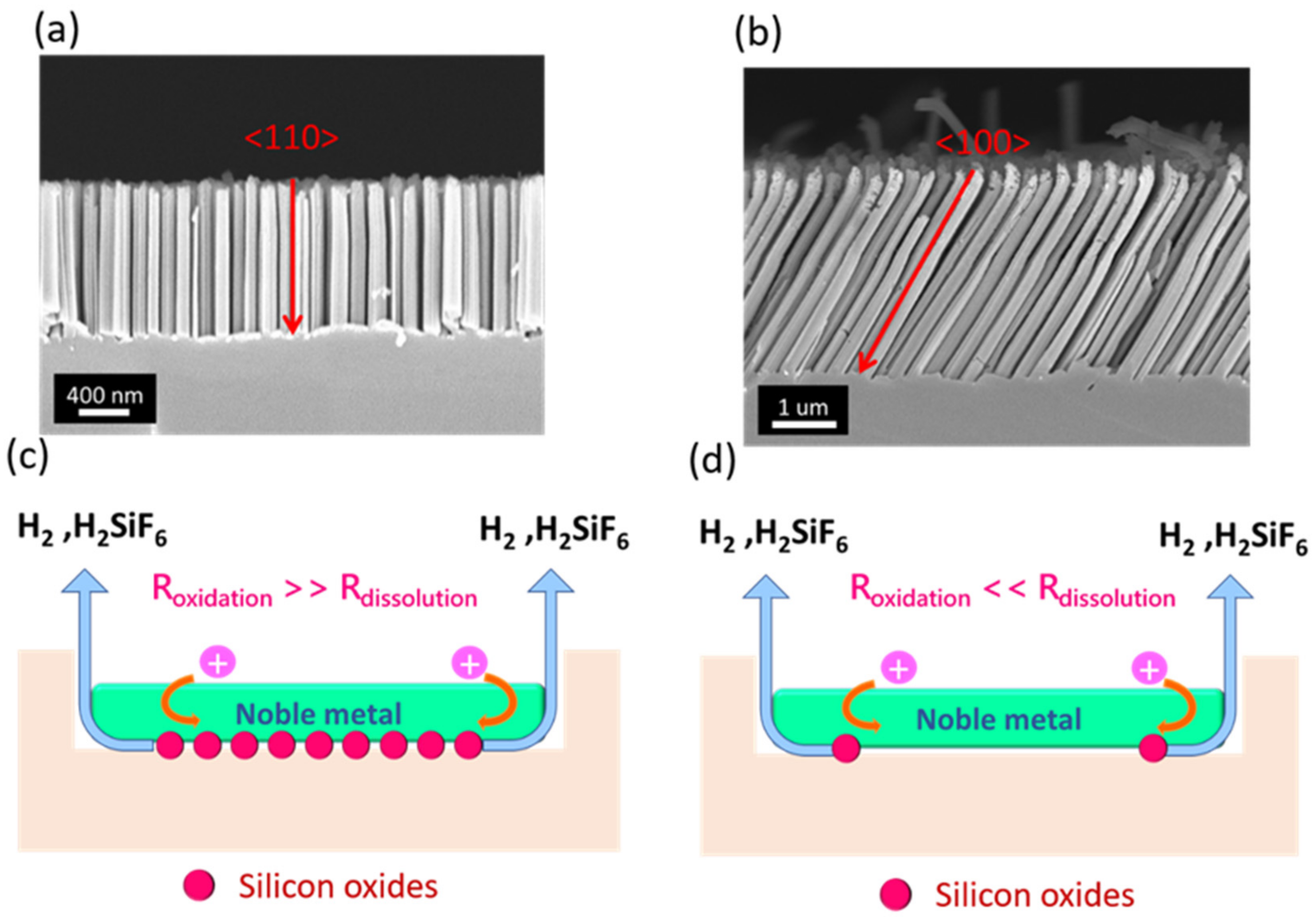

2.3. Fabrication of Si Nanowires

2.4. Device Fabrication

2.5. Characterizations

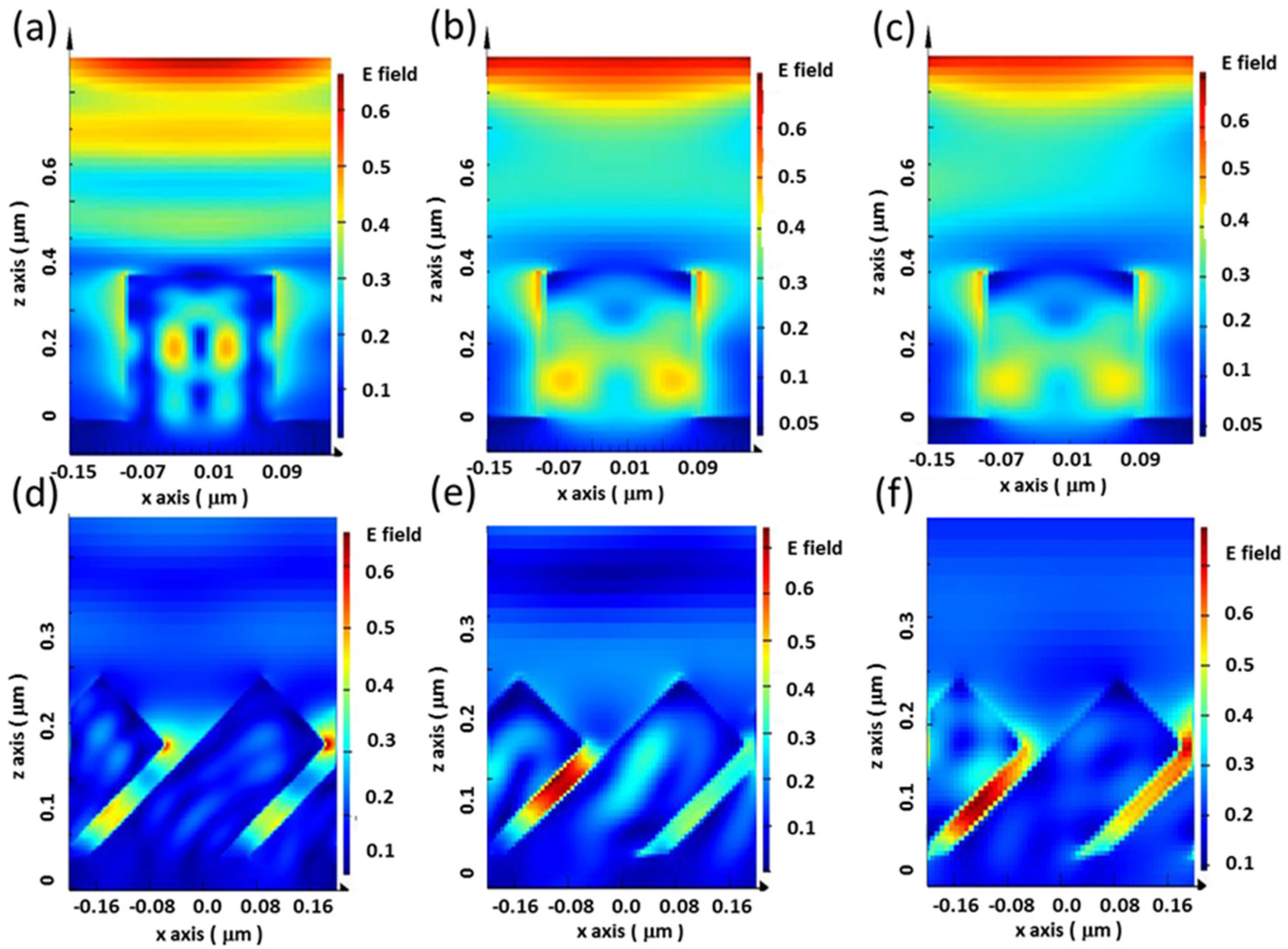

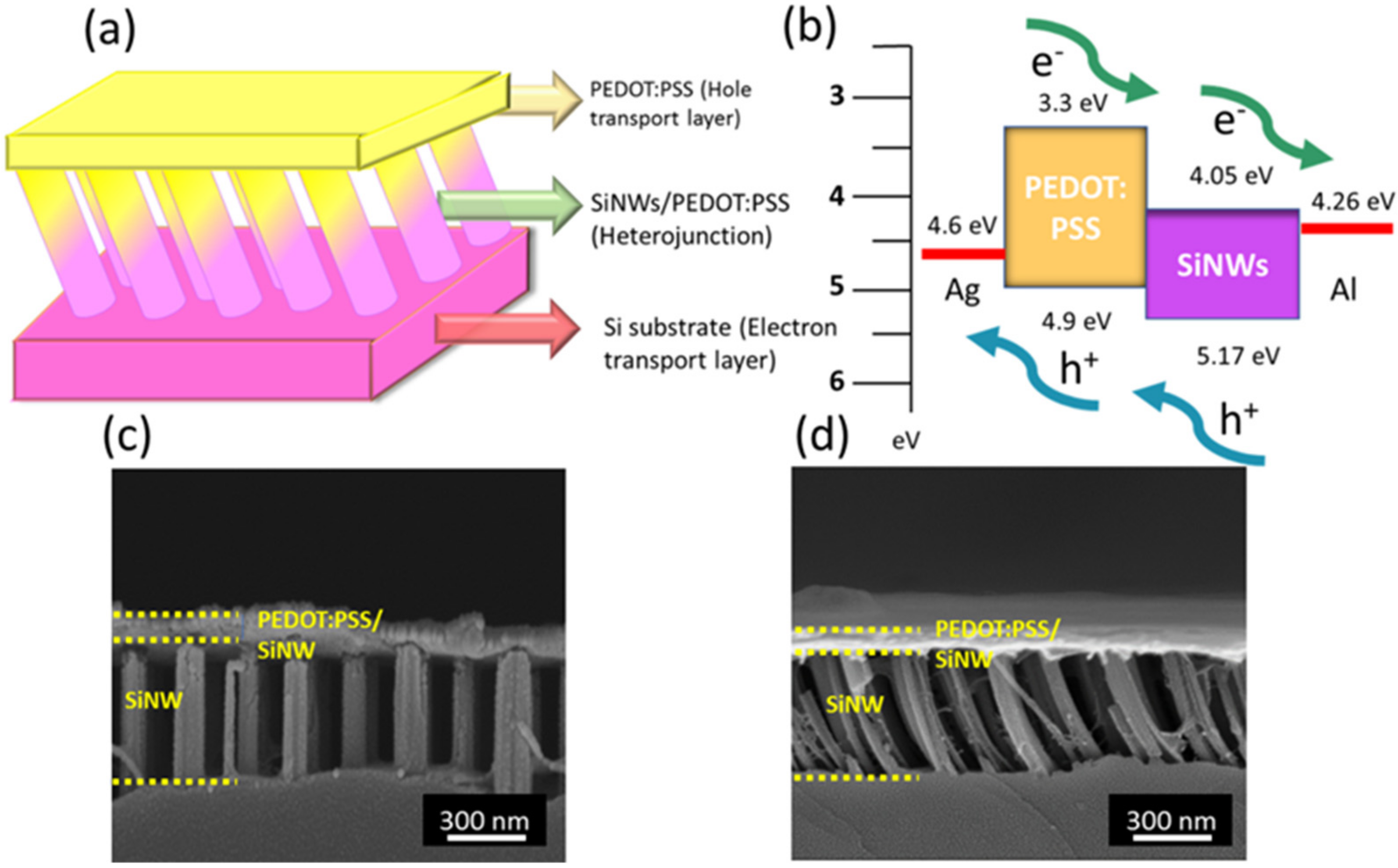

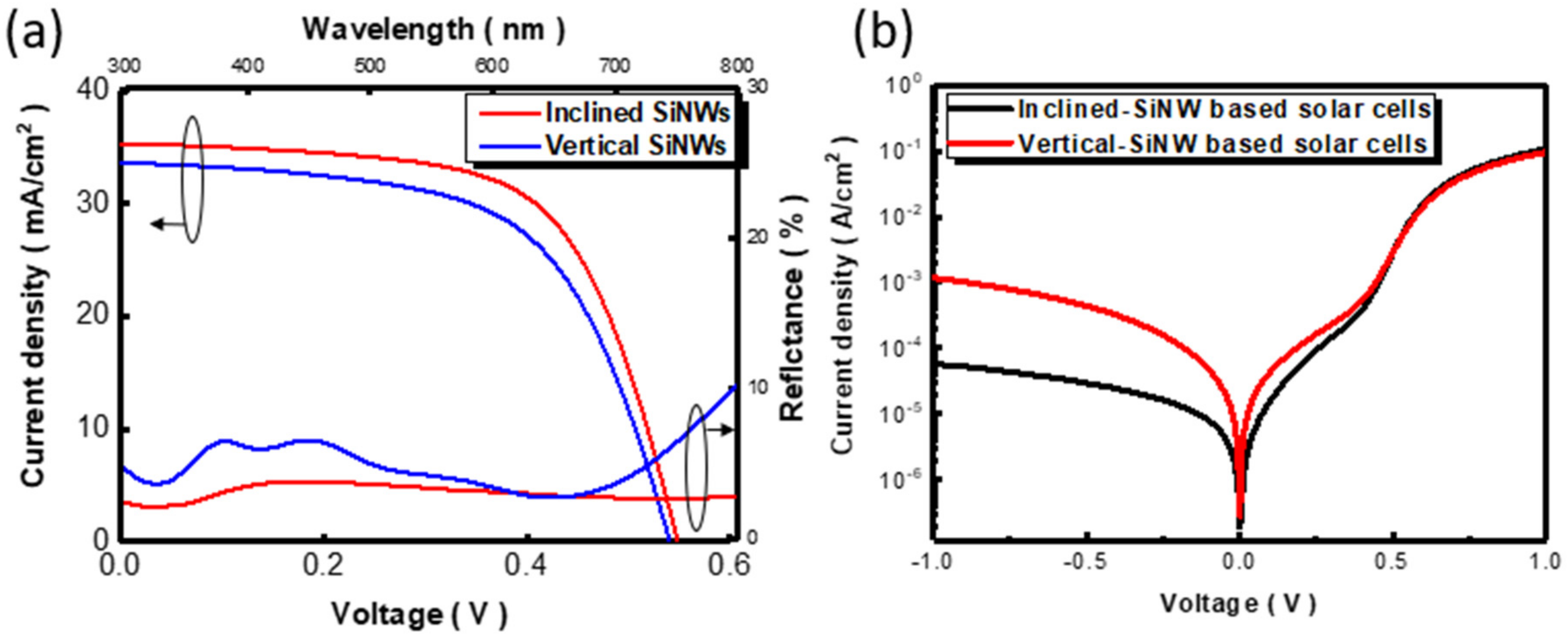

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, Y. Nanofabrication by electron beam lithography and its applications: A review. Microelectron. Eng. 2015, 135, 57–72. [Google Scholar] [CrossRef]

- Zhang, A.; Lieber, C.M. Nano-bioelectronics. Chem. Rev. 2016, 116, 215–257. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Boukai, A.I.; Bunimovich, Y.; Tahir-Kheli, J.; Yu, J.K.; Goddard, W.A., III; Health, J.R. Silicon nanowires as efficient thermo-electric materials. Nature 2008, 451, 168–171. [Google Scholar] [CrossRef] [PubMed]

- Elyamny, S.; Dimaggio, E.; Magagna, S.; Narducci, D.; Pennelli, G. High power thermoelectric generator based on vertical silicon nanowires. Nano Lett. 2020, 20, 4748–4753. [Google Scholar] [CrossRef]

- Li, Y.; Qian, F.; Xiang, J.; Lieber, C.M. Nanowire electronic and optoelectronic devices. Mater. Today 2016, 9, 18–27. [Google Scholar] [CrossRef]

- Ilham, R.P.; Wei, T.C.; Hsiao, P.H.; Chen, C.Y. Simple cosolvent-treated PEDOT:PSS films on hybrid solar cells with improved efficiency. IEEE J. Photovolt. 2020, 10, 771–776. [Google Scholar]

- Patolsky, F.; Zheng, G.; Lieber, C.M. Fabrication of silicon nanowire devices for ultrasensitive, label-free, real-time detection of biological and chemical species. Nat. Protoc. 2006, 1, 1711. [Google Scholar] [CrossRef]

- Hsiao, P.H.; Li, T.C.; Chen, C.Y. ZnO/Cu2O/Si Nanowire Arrays as Ternary Heterostructure-Based Photocatalysts with Enhanced Photodegradation Performances. Nanoscale Res. Lett. 2019, 14, 244. [Google Scholar] [CrossRef] [Green Version]

- Huang, Z.; Geyer, N.; Werner, P.; De Boor, J.; Gösele, U. Metal-assisted chemical etching of silicon: A review: In memory of Prof. Ulrich Gösele. Adv. Mater. 2010, 23, 285–308. [Google Scholar] [CrossRef]

- Garnett, E.; Yang, P. Light trapping in silicon nanowire solar cells. Nano Lett. 2010, 10, 1082–1087. [Google Scholar] [CrossRef]

- Chen, C.Y.; Wei, T.C.; Lai, Y.C.; Lee, T.C. Passivating silicon-based hybrid solar cells through tuning PbI2 content of perovskite coatings. Appl. Surf. Sci. 2020, 511, 145541. [Google Scholar] [CrossRef]

- Chen, C.Y.; Wei, T.C.; Hsiao, P.H.; Hung, C.H. Vanadium Oxide as Transparent Carrier-Selective Layer in Silicon Hybrid Solar Cells Promoting Photovoltaic Performances. ACS Appl. Energy Mater. 2019, 2, 4873–4881. [Google Scholar] [CrossRef]

- Mallorquí, A.D.; Alarcón-Lladó, E.; Mundet, I.C.; Kiani, A.; Demaurex, B.; DeWolf, S.; Menzel, A.; Zacharias, M.; Fontcuberta i Morral, A. Field-effect passivation on silicon nanowire solar cells. Nano Res. 2015, 8, 673–681. [Google Scholar] [CrossRef]

- Trinh, P.V.; Anh, N.N.; Cham, N.T.; Tu, L.T.; Hao, N.V.; Thang, B.H.; Chuc, N.V.; Thanh, C.T.; Minh, P.N.; Fukata, N. Enhanced power conversion efficiency of an n-Si/PEDOT:PSS hybrid solar cell using nanostructured silicon and gold nanoparticles. RSC Adv. 2022, 12, 10514–10521. [Google Scholar] [CrossRef]

- Hayden, O.; Greytak, A.B.; Bell, D.C. Core-shell nanowire light-emitting diodes. Adv. Mater. 2005, 17, 701–704. [Google Scholar] [CrossRef]

- Huang, Z.; Fang, H.; Zhu, J. Fabrication of silicon nanowire arrays with controlled diameter, length, and density. Adv. Mater. 2007, 19, 744–748. [Google Scholar] [CrossRef]

- Zhu, J.; Yu, Z.; Burkhart, G.F.; Hsu, C.M.; Connor, S.T.; Xu, Y.; Wang, Q.; McGehee, M.; Fan, S.; Cui, Y. Optical absorption enhancement in amorphous silicon nanowire and nanocone arrays. Nano Lett. 2009, 9, 279–282. [Google Scholar] [CrossRef] [Green Version]

- Osminkina, L.A.; Gonchar, K.A.; Marshov, V.S.; Bunkov, K.V.; Petrov, D.V.; Golovan, L.A.; Talkenberg, F.; Sivakov, V.A.; Timoshenko, V.Y. Optical properties of silicon nanowire arrays formed by metal-assisted chemical etching: Evidences for light localization effect. Nanoscale Res. Lett. 2012, 7, 524. [Google Scholar] [CrossRef] [Green Version]

- Sato, K.; Dutta, M.; Fukata, N. Inorganic/organic hybrid solar cells: Optimal carrier transport in vertically aligned silicon nanowire arrays. Nanoscale 2014, 6, 6092–6101. [Google Scholar] [CrossRef]

- Khaled, A.; Hameed, M.F.O.; Rahman, B.M.A.; Grattan, K.T.V.; Obayya, S.S.A.; Hussein, M. Characteristics of silicon nanowire solar cells with a crescent nanohole. Opt. Express 2020, 28, 31020–31033. [Google Scholar] [CrossRef]

- Chen, S.-H.; Wei, T.-C.; Wu, T.-Y.; Chen, C.-Y. Interface management of silicon-nanowire based hybrid solar cells through facile solution-processed oxidation. Mater. Lett. 2022, 307, 130967. [Google Scholar] [CrossRef]

- Khang, D.-Y. Recent progress in Si-PEDOT: PSS inorganic–organic hybrid solar cells. J. Phys. D 2019, 52, 503002. [Google Scholar] [CrossRef]

- Wei, T.-C.; Chen, S.-H.; Chen, C.-Y. Highly conductive PEDOT: PSS film made with ethylene-glycol addition and heated-stir treatment for enhanced photovoltaic performances. Mater. Chem. Front. 2020, 4, 3302–3309. [Google Scholar] [CrossRef]

- Chang, S.W.; Chuang, V.P.; Boles, S.T.; Thompson, C.V. Metal-catalyzed etching of vertically aligned polysilicon and amorphous silicon nanowire arrays by etching direction confinement. Adv. Funct. Mater. 2010, 20, 4364. [Google Scholar] [CrossRef]

- Li, J.Y.; Hung, C.H.; Chen, C.Y. Hybrid black silicon solar cells textured with the interplay of copper-induced galvanic displacement. Sci. Rep. 2017, 7, 17177. [Google Scholar] [CrossRef]

- Li, X.; Bonn, P.W. Metal-assisted chemical etching in HF/H2O2 produces porous silicon. Appl. Phys. Lett. 2000, 77, 2572–2574. [Google Scholar] [CrossRef]

- Chen, C.Y.; Hsiao, P.H.; Wei, T.C.; Chen, T.C.; Tang, C.H. Well incorporation of carbon nanodots with silicon nanowire arrays featuring excellent photocatalytic performances. Phys. Chem. Chem. Phys. 2017, 19, 11786–11792. [Google Scholar] [CrossRef]

- Singh, N.; Sahoo, M.K.; Kale, P.G. Effect of MACE parameters on length of porous silicon nanowires (PSiNWs). J. Cryst. Growth 2018, 496, 10–14. [Google Scholar] [CrossRef]

- Putra, I.R.; Li, J.Y.; Chen, C.Y. 18.78% hierarchical black silicon solar cells achieved with the balance of light-trapping and interfacial contact. Appl. Surf. Sci. 2019, 478, 725–732. [Google Scholar] [CrossRef]

- Chen, C.Y.; Liu, Y.R. Exploring the kinetics of ordered silicon nanowires with the formation of nanogaps using metal-assisted chemical etching. Phys. Chem. Chem. Phys. 2014, 14, 26711–26714. [Google Scholar] [CrossRef]

- Naffeti, M.; Postigo, P.A.; Chtourou, R.; Zaïbi, M.A. Elucidating the effect of etching time key-parameter toward optically and electrically-active silicon nanowires. Nanomaterials 2020, 10, 404. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Samajdar, D.P. Light-trapping strategy for PEDOT: PSS/c-Si nanopyramid based hybrid solar cells embedded with metallic nanoparticles. Sol. Energy 2019, 190, 278–285. [Google Scholar]

- Thomas, J.P.; Leung, K.T. Defect-minimized PEDOT: PSS/planar-Si solar cell with very high efficiency. Adv. Funct. Mater. 2014, 24, 4978–4985. [Google Scholar] [CrossRef]

- Zhang, F.; Song, T.; Sun, B. Conjugated polymer–silicon nanowire array hybrid Schottky diode for solar cell application. Nanotechnology 2012, 23, 194006. [Google Scholar] [CrossRef]

| Structure | Efficiency (%) | FF (%) | n | |||||

|---|---|---|---|---|---|---|---|---|

| Inclined SiNWs | 12.23 | 35.24 | 0.548 | 63.40 | 1.43 | 163.22 | 1.51 | |

| Vertical SiNWs | 10.91 | 33.60 | 0.540 | 60.12 | 1.66 | 123.32 | 1.67 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.-H.; Kuo, K.-Y.; Tsai, K.-H.; Chen, C.-Y. Light Trapping of Inclined Si Nanowires for Efficient Inorganic/Organic Hybrid Solar Cells. Nanomaterials 2022, 12, 1821. https://doi.org/10.3390/nano12111821

Chen S-H, Kuo K-Y, Tsai K-H, Chen C-Y. Light Trapping of Inclined Si Nanowires for Efficient Inorganic/Organic Hybrid Solar Cells. Nanomaterials. 2022; 12(11):1821. https://doi.org/10.3390/nano12111821

Chicago/Turabian StyleChen, Shih-Hsiu, Kuan-Yi Kuo, Kun-Hung Tsai, and Chia-Yun Chen. 2022. "Light Trapping of Inclined Si Nanowires for Efficient Inorganic/Organic Hybrid Solar Cells" Nanomaterials 12, no. 11: 1821. https://doi.org/10.3390/nano12111821

APA StyleChen, S.-H., Kuo, K.-Y., Tsai, K.-H., & Chen, C.-Y. (2022). Light Trapping of Inclined Si Nanowires for Efficient Inorganic/Organic Hybrid Solar Cells. Nanomaterials, 12(11), 1821. https://doi.org/10.3390/nano12111821