Top-Down Production of Nano-Seeds from Activated Fly Ash Tuned for Enhancing the Early Strength in Blended Cements

Abstract

:1. Introduction

2. Experimental

2.1. Materials and Precursors

| Compounds | Chemical Composition, % by Mass | |||

|---|---|---|---|---|

| Class F | Class C | ASTM C 618 [28] Limits | ||

| Class F | Class C | |||

| SiO2 | 46.9 | 32.7 | - | - |

| Al2O3 | 22.9 | 17.6 | - | - |

| Fe2O3 | 19.2 | 5.9 | - | - |

| Total, SiO2 + Al3 + Fe2O3 | 89.0 | 56.2 | >70 | >50 |

| SO3 | 0.3 | 2.0 | <5.0 | <5.0 |

| CaO | 3.8 | 27.3 | - | - |

| MgO | 0.8 | 6.6 | - | - |

| K2O | 1.7 | 0.4 | - | - |

| Na2O | 0.6 | 2.2 | - | - |

| Moisture Content | 0.1 | 0.8 | <3.0 | <3.0 |

| Loss on Ignition (Unburnt Carbon) | 2.3 | 0.3 | <6.0 | <6.0 |

| Physical Properties | Class F | Class C | ASTM C 618 [28] Limits | |

| Class F | Class C | |||

| Specific Gravity | 2.50 | 2.83 | - | - |

| 7-day Strength Activity Index, % of control | 77.5 | 82.9 | >75 | >75 |

| Water Requirement, % of control | 102 | 91 | <105 | <105 |

| Characteristics | Cembinder Type | |

|---|---|---|

| CB50 | CB8 | |

| Density, kg/cm3 | 1.1 | 1.4 |

| SiO2, % | 15 | 50 |

| pH | 10.0 | 9.5 |

| Viscosity, mPas | <10 | <10 |

| Concentration, % | 15 | 51.5 |

| BET Surface Area, m2/g | 179.4 | 61.2 |

2.2. Methods Used for Mechano-Chemical Activation and Nano-Seed Preparation

2.3. Characterization of Activated Fly Ash Product

2.4. Design of Experiment

2.5. Methods of Mortar Specimen Preparation and Testing

3. Experimental Results and Discussion

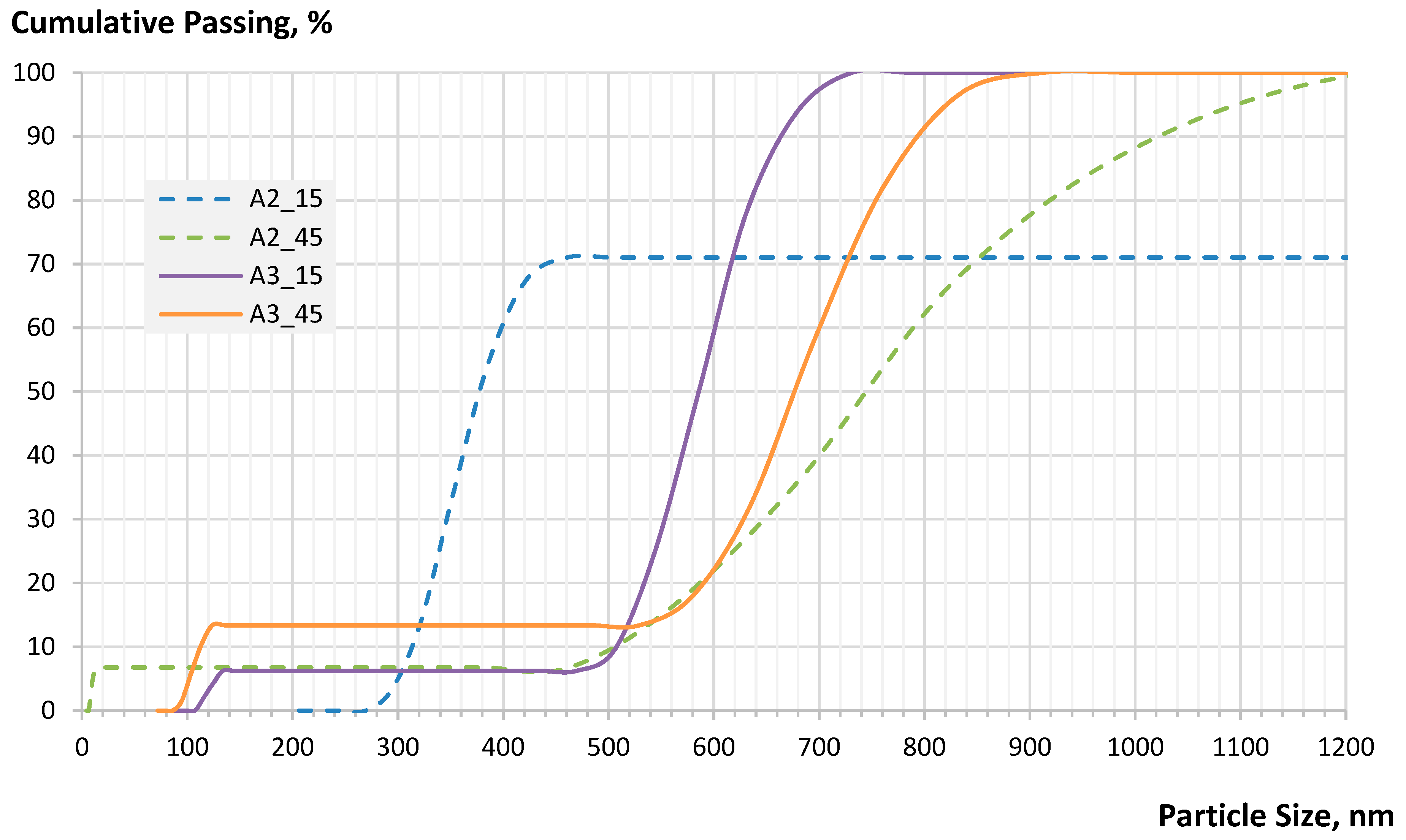

3.1. Transformations of Fly Ash Induced by Mechano-Chemical Activation

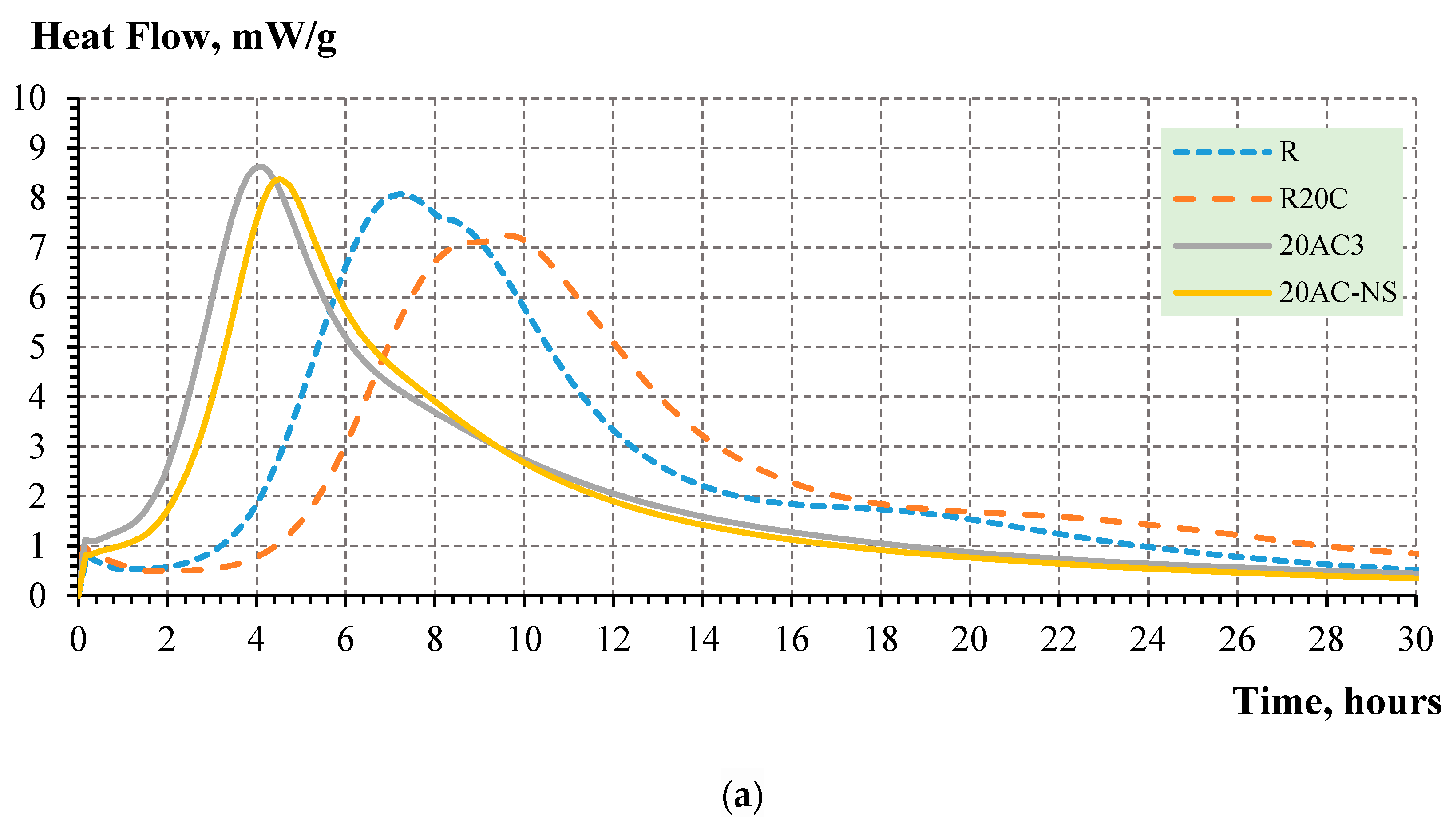

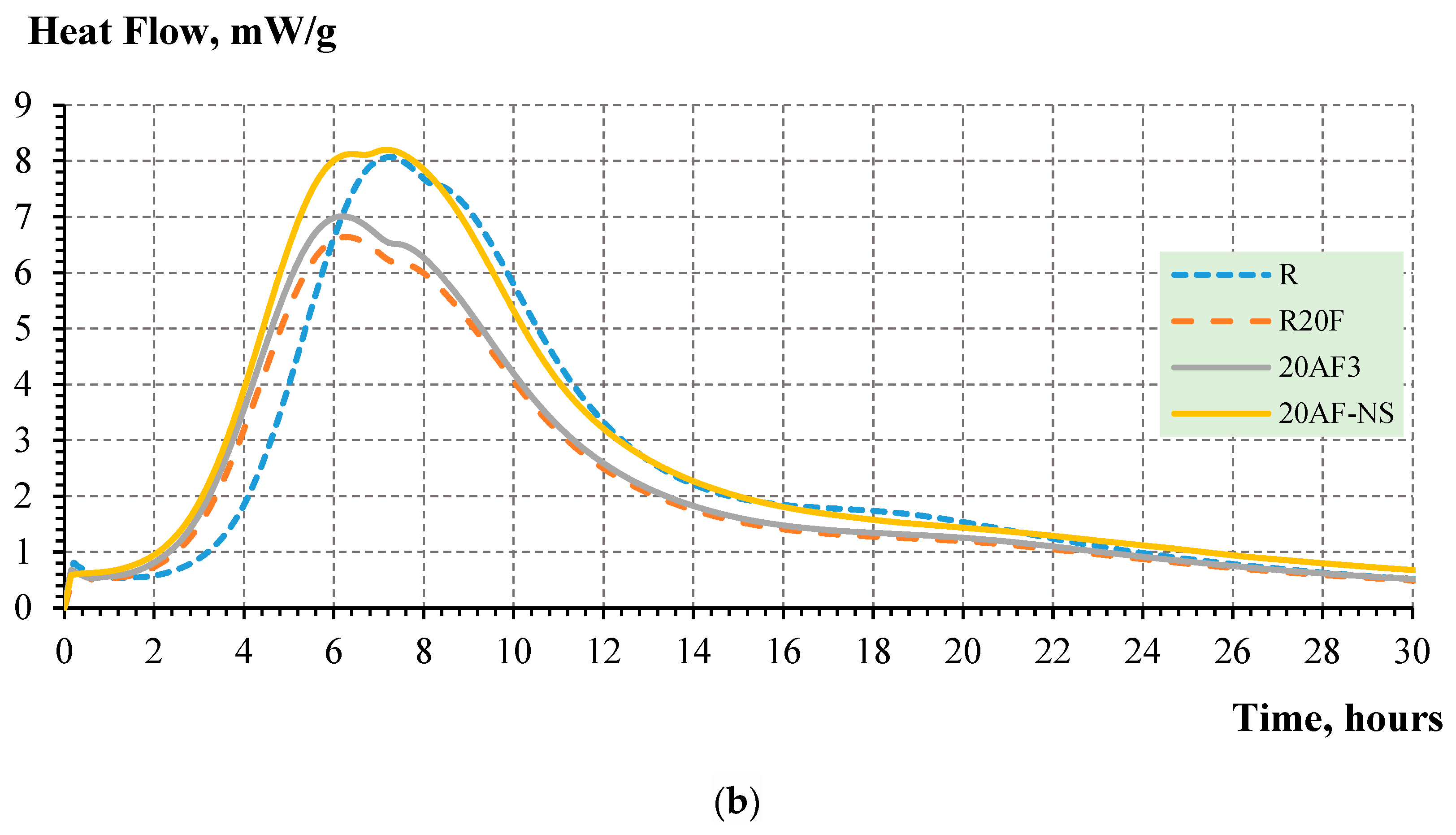

3.2. Hydration Process

3.3. Properties of Mortars

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sobolev, K. The development of a new method for the proportioning of high-performance concrete mixtures. Cem. Concr. Compos. 2004, 26, 901–907. [Google Scholar] [CrossRef]

- Sobolev, K. Mechano-chemical modification of cement with high volumes of blast furnace slag. Cem. Concr. Compos. 2005, 27, 848–853. [Google Scholar] [CrossRef]

- Sobolev, K. Sustainable Development of the Cement Industry and Blended Cements to Meet Ecological Challenges. Sci. World J. 2003, 3, 308–318. [Google Scholar] [CrossRef] [PubMed]

- Malhotra, V.M.; Mehta, P.K. Pozzolanic cementitious materials. Adv. Concr. Technol. 1996, 1, 11. [Google Scholar]

- Sobolev, K.; Ferrada-Gutiérrez, M. How nanotechnology can change the concrete world: Part 2. Am. Ceram. Soc. Bull. 2005, 84, 16–19. [Google Scholar]

- Scrivener, K.; Van Damme, H. Construction Materials: From Innovation to Conservation. MRS Bull. 2004, 29, 308–313. [Google Scholar] [CrossRef] [Green Version]

- Sobolev, K.; Lin, Z.; Flores-Vivian, I.; Pradoto, R. Nano-Engineered Cements with Enhanced Mechanical Performance. J. Am. Ceram. Soc. 2015, 99, 564–572. [Google Scholar] [CrossRef]

- Zhang, M.-H.; Islam, J.; Peethamparan, S. Use of nano-silica to increase early strength and reduce setting time of concretes with high volumes of slag. Cem. Concr. Compos. 2012, 34, 650–662. [Google Scholar] [CrossRef]

- Thongsanitgarn, P.; Wongkeo, W.; Chaipanich, A.; Poon, C.S. Heat of hydration of portland–high-calcium fly ash cement incorporating limestone powder: Effect of limestone particle size. Constr. Build. Mater. 2014, 66, 410–417. [Google Scholar] [CrossRef]

- Collepardi, M.; Skarp, U.; Troli, R. Optimization of silica fume, fly ash and amorphous nano-silica in superplasticized high-performance concretes. In Proceedings of the 8th CANMET/ACI International Conference on Fly Ash, Silica Fume, Slag, SP-221, Las Vegas, NV, USA, 23–29 May 2004. [Google Scholar]

- Björnström, J.; Martinelli, A.; Matic, A.; Borjesson, L.; Panas, I. Accelarating effects of colloidal nano-silica for beneficial calsium-silicate-hydrate formation in cement. Chem. Phys. Lett. 2004, 392, 242–248. [Google Scholar] [CrossRef]

- Björnström, J.; Panas, I. Antagonistic effect of superplasticizer and colloidal nano-silica in the hydration of Alite and Belite pastes. J. Mater. Sci. 2007, 11, 3901–3907. [Google Scholar] [CrossRef]

- Li, G. Properties of high-volume fly ash concrete incorporating nano-SiO2. Cem. Concr. Res. 2004, 34, 1043–1049. [Google Scholar] [CrossRef]

- Qing, Y.; Zenan, Z.; Deyu, K.; Rongshen, C. Influence of nano-SiO2 addition on properties of hardened cement paste as compared with silica fume. Constr. Build. Mater. 2007, 21, 539–545. [Google Scholar] [CrossRef]

- Flores, I.; Sobolev, K.; Torres-Martinez, L.M.; Cuellar, E.L.; Valdez, P.L.; Zarazua, E. Performance of cement systems with nano- SiO2 particles produced using sol-gel method. J. Transp. Res. Board 2010, 1, 10–14. [Google Scholar] [CrossRef]

- Gaitero, J.; Campillo, I.; Guerrero, A. Reduction of the calcium leaching rate of cement paste by addition of silica nanoparticles. Cem. Concr. Res. 2008, 38, 1112–1118. [Google Scholar] [CrossRef] [Green Version]

- Jansson, I.; Skarp, U.; Bigley, C. The value of colloidal silica for enhanced durability in high fluidity cement based mixes. In Proceedings of the 5th International RILEM Simposium on Self-Compacting Concrete, Ghent, Belgium, 3–5 September 2007. [Google Scholar]

- Green, B.H. Development of a high-density cementitious rock-matching grout using nanoparticles. In Proceedings of the ACI Session on “Nanotechnology of Concrete: Recent Developments and Future Perspectives, SP-254, Denver, CO, USA, 7 November 2008. [Google Scholar]

- Kawashima, S.; Hou, P.; Wang, K.; Corr, D.J.; Shah, S.P. Activation of Fly Ash through Nanomodification; American Concrete Institute: Indianapolis, IN, USA; ACI Special Publication: Dallas, CO, USA, 2012. [Google Scholar]

- Felekoğlu, B.; Türkel, S.; Kalyoncu, H. Optimization of fineness to maximize the strength activity of high-calcium ground fly ash–portland cement composites. Constr. Build. Mater. 2009, 23, 2053–2061. [Google Scholar] [CrossRef]

- Hela, R.; Orsáková, D. The mechanical activation of fly ash. In Proceedings of the Concrete and Concrete Structures 2013—6th International Conference, Terchova, Slovakia, 23–25 October 2013. [Google Scholar]

- Sobolev, K. High-Strength Concrete with Low Cement Factor. Ph.D. Dissertation, Chemical Admixtures Lab, Scientific and Research Institute of Concrete and Reinforced Concrete, Moscow, Russia, 1993. [Google Scholar]

- Sobolev, K.; Lin, Z.; Cao, Y.; Sun, H.; Flores-Vivian, I.; Rushing, T.; Cummins, T.; Weiss, W.J. The influence of mechanical activation by vibro-milling on the early-age hydration and strength development of cement. Cem. Concr. Compos. 2016, 71, 53–62. [Google Scholar] [CrossRef]

- Krishnaraj, L.; Ravichandran, P. Investigation on grinding impact of fly ash particles and its characterization analysis in cement mortar composites. Ain Shams Eng. J. 2019, 10, 267–274. [Google Scholar] [CrossRef]

- Moini, M.; Sobolev, K.; Flores-Vivian, I.; Muzenski, S.; Pham, L.T.; Cramer, S.; Beyene, M. Durability of Concrete Mixtures Containing Supplementary Cementitious Materials in Rapid Chloride Permeability Test. ACI Mater. J. 2019, 116, 67–76. [Google Scholar] [CrossRef]

- ASTM C150-21; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C778-21; Standard Specification for Standard Sand. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C618-19; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C109; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or 50-mm Cube Specimens). ASTM International: West Conshohocken, PA, USA, 1994.

- ASTM C230-97; Standard Specification for Flow Table for Use in Tests of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 1997.

- ASTM C305-20; Standard Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C1437-20; Standard Test Method for Flow of Hydraulic Cement Mortar. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C138-01; Standard Test Method for Unit Weight, Yield, and Air Content (Gravimetric) of Concrete. ASTM International: West Conshohocken, PA, USA, 2001.

- Sedaghat, A.; Zayed, A.; Sandberg, P. Measurement and Prediction of Heat of Hydration of Portland Cement Using Isothermal Conduction Calorimetry. J. Test. Evaluation 2013, 41, 943–950. [Google Scholar] [CrossRef] [Green Version]

- ASTM C1702-15; Standard Test Method for Measurement of Heat of Hydration of Hydraulic Cementitious Materials Using Isothermal Conduction Calorimetry. ASTM International: West Conshohocken, PA, USA, 2015.

| Chemical Composition | ASTM C150 [26] Limit, % | Result, % by Mass | Physical Properties | ASTM C150 [26] Limit | Test Result |

|---|---|---|---|---|---|

| SiO2 | - | 19.4 | Specific gravity | - | 3.08 |

| Al2O3 | - | 5.3 | Time of setting, minutes | ||

| Fe2O3 | - | 3.0 | Initial | 45 min | 88 |

| CaO | - | 63.2 | Final | 375 max | 222 |

| MgO | 6.0 max | 2.9 | Compressive strength, MPa | ||

| SO3 | 3.0 max | 3.3 | 1 day | - | 18.1 |

| Loss on Ignition | 3.0 max | 1.1 | 3 days | 12.0 | 28.7 |

| Na2O | - | 0.3 | 7 days | 19.0 | 34.3 |

| K2O | - | 0.7 | 28 days | 28.0 | 40.4 |

| Others, % | - | 0.9 | |||

| C3S | 60.7 | ||||

| C2S | - | 9.9 | |||

| C3A | - | 8.9 | |||

| C4AF | - | 9.1 | |||

| C4AF + 2(C3A) | - | 26.9 | |||

| C3S + 4.75(C3A) | - | 102.9 | |||

| Na2Oeq | 0.6 max | 0.8 | |||

| Mix ID | Cement Replacement with Fly Ash, % by Mass | W/C | Activation Time, Hours | Composition of Activated Component, % by Mass | SP, % | Flow, % | Setting Time, Minutes | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Fly Ash | Nano Silica | Initial | Final | |||||||

| Class F | Class C | |||||||||

| R30F | 30 | 0.36 | - | - | - | - | 0.15 | 82 | 210 | 450 |

| 30AF1 | 30 | 0.36 | 1 | 20 | - | - | 0.15 | 83 | 210 | 435 |

| 30AF2 | 30 | 0.36 | 2 | 20 | - | - | 0.15 | 94 | 180 | 372 |

| 30AF3 | 30 | 0.36 | 3 | 20 | - | - | 0.15 | 108 | 165 | 332 |

| 30AF4 | 30 | 0.36 | 4 | 20 | - | - | 0.15 | >140 | 150 | 306 |

| R | - | 0.3 | - | - | - | - | 0.15 | 47 | 84 | 420 |

| R20C | 20 | 0.3 | 3 | - | - | - | 0.15 | 42 | 228 | 582 |

| 20AC | 20 | 0.3 | 3 | - | 20 | - | 0.15 | 105 | 54 | 240 |

| 20AC-NS | 20 | 0.3 | 3 | - | 20 | 0.1 | 0.15 | 90 | 60 | 258 |

| R20F | 20 | 0.3 | 3 | - | - | - | 0.15 | >140 | 108 | 324 |

| 20AF | 20 | 0.3 | 3 | 20 | - | - | 0.15 | >140 | 108 | 300 |

| 20AF-NS | 20 | 0.3 | 3 | 20 | - | 0.1 | 0.15 | 130 | 108 | 348 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sobolev, K.; Pradoto, R.; Flores-Vivian, I.; Kozhukhova, M.; Zhernovskaya, I. Top-Down Production of Nano-Seeds from Activated Fly Ash Tuned for Enhancing the Early Strength in Blended Cements. Nanomaterials 2022, 12, 2347. https://doi.org/10.3390/nano12142347

Sobolev K, Pradoto R, Flores-Vivian I, Kozhukhova M, Zhernovskaya I. Top-Down Production of Nano-Seeds from Activated Fly Ash Tuned for Enhancing the Early Strength in Blended Cements. Nanomaterials. 2022; 12(14):2347. https://doi.org/10.3390/nano12142347

Chicago/Turabian StyleSobolev, Konstantin, Rani Pradoto, Ismael Flores-Vivian, Marina Kozhukhova, and Irina Zhernovskaya. 2022. "Top-Down Production of Nano-Seeds from Activated Fly Ash Tuned for Enhancing the Early Strength in Blended Cements" Nanomaterials 12, no. 14: 2347. https://doi.org/10.3390/nano12142347

APA StyleSobolev, K., Pradoto, R., Flores-Vivian, I., Kozhukhova, M., & Zhernovskaya, I. (2022). Top-Down Production of Nano-Seeds from Activated Fly Ash Tuned for Enhancing the Early Strength in Blended Cements. Nanomaterials, 12(14), 2347. https://doi.org/10.3390/nano12142347