High Critical Current Density of Nanostructured MgB2 Bulk Superconductor Densified by Spark Plasma Sintering

Abstract

:1. Introduction

2. Experimental Section

- (i)

- 500 °C + 260 MPa/15 min (Powder compaction);

- (ii)

- 650 °C + 280 MPa/20 min (Synthesis);

- (iii)

- 750 °C + 300 MPa/30 min (Sintering/Densification).

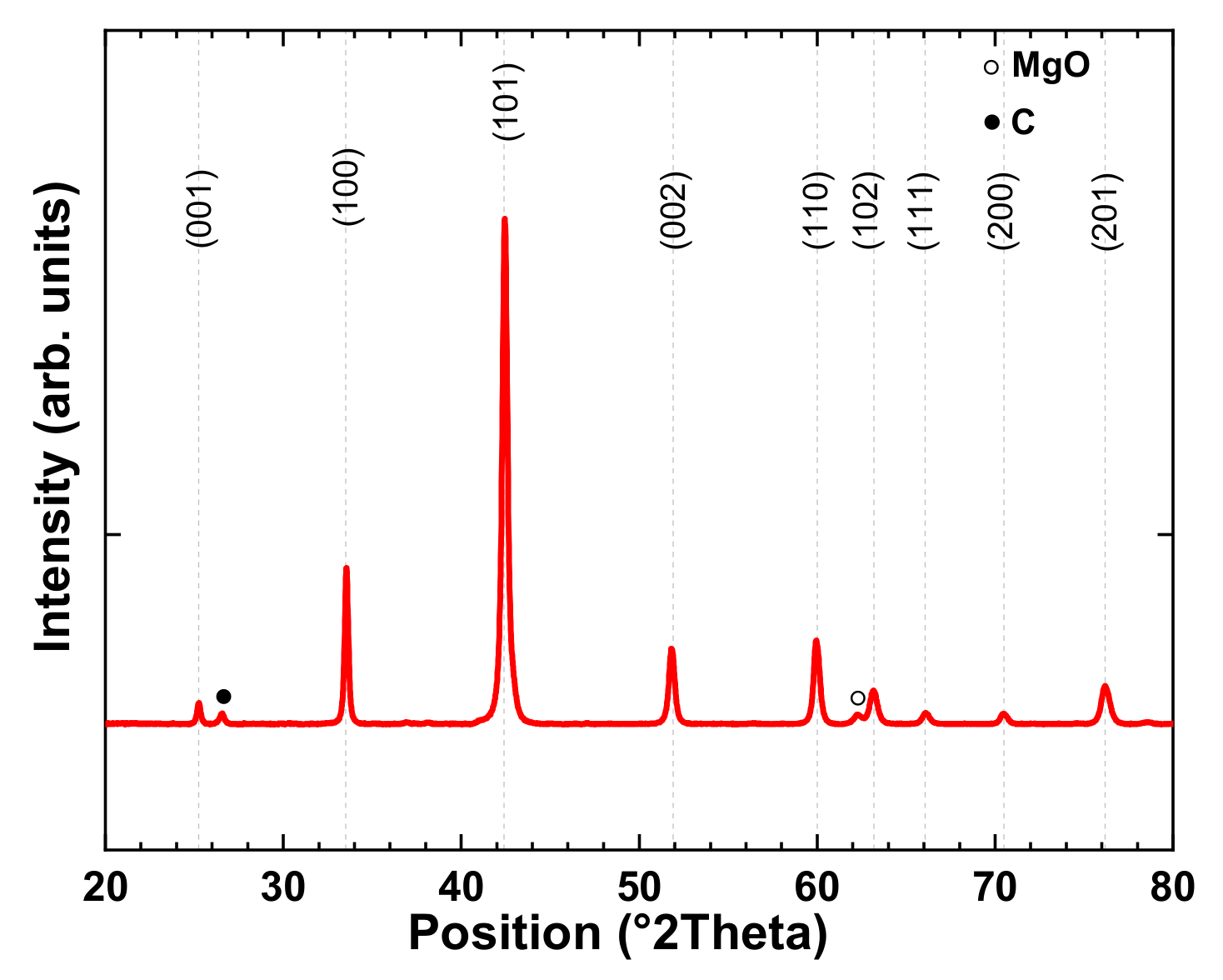

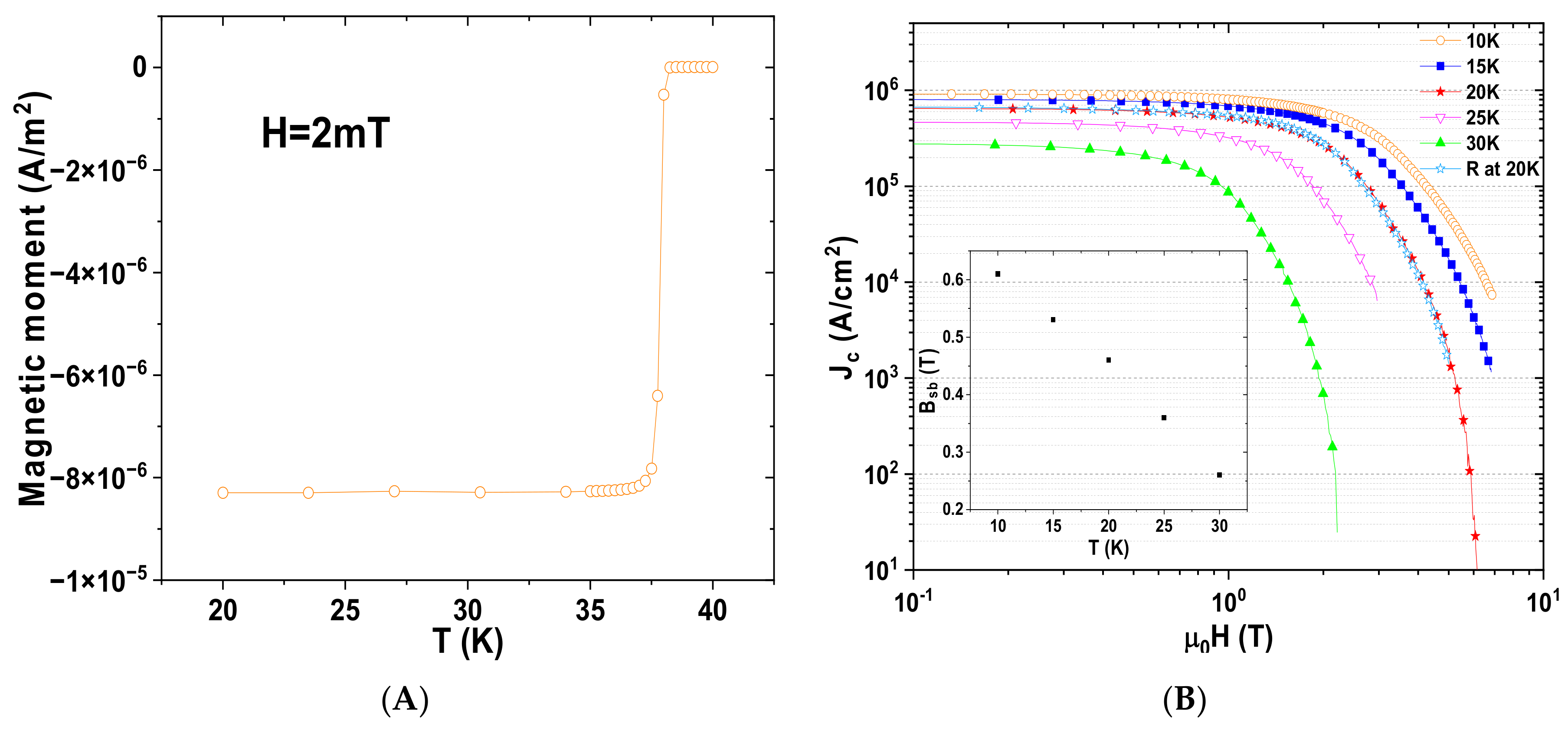

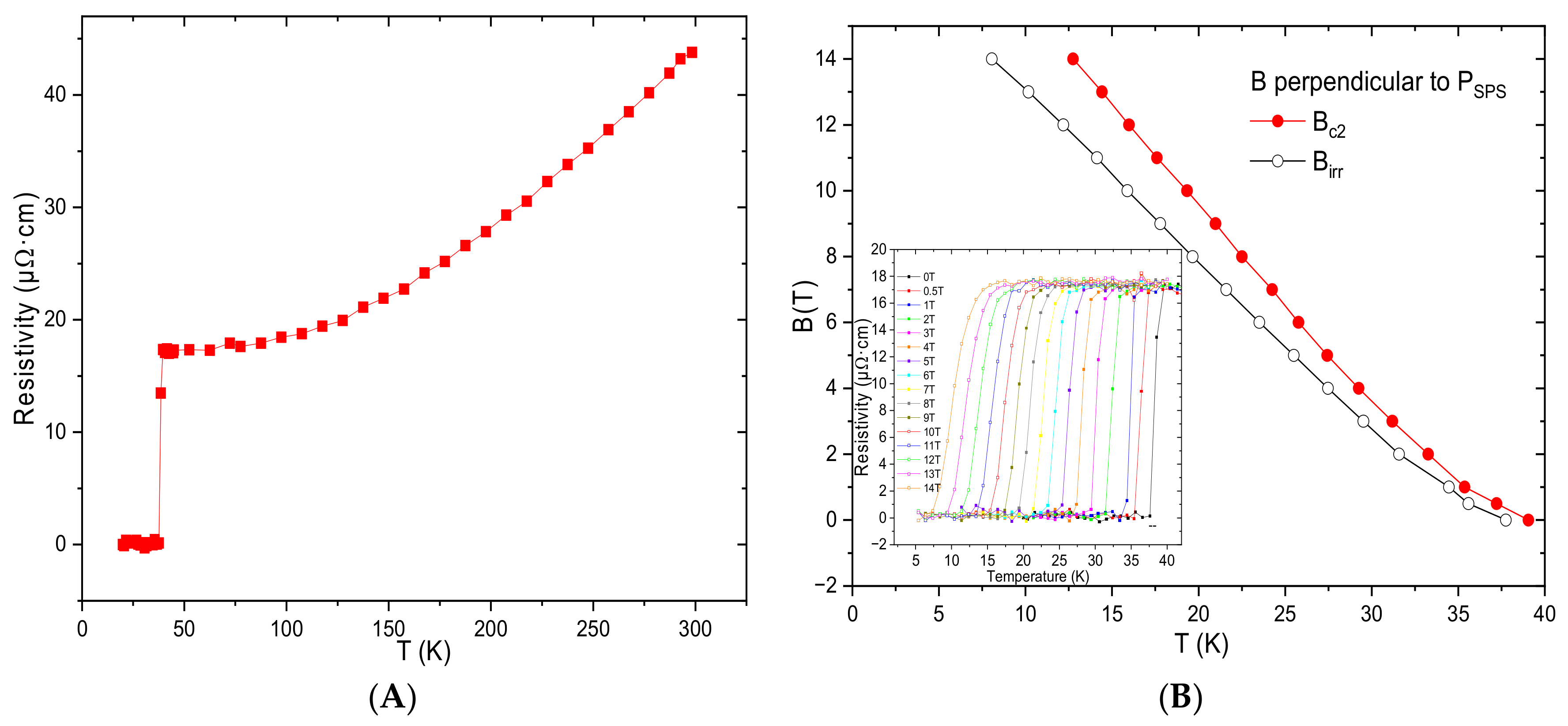

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Buzea, C.; Yamashita, T. Review of the Superconducting Properties of MgB2. Supercond. Sci. Technol. 2001, 14, R115. [Google Scholar] [CrossRef] [Green Version]

- Nagamatsu, J.; Nakagawa, N.; Muranaka, T.; Zenitani, Y.; Akimitsu, J. Akimitsu Superconductivity at 39 K in Magnesium Diboride. Nature 2001, 410, 63–64. [Google Scholar] [CrossRef] [PubMed]

- Muralidhar, M.; Kenta, N.; Koblischka, M.R.; Murakami, M. High Critical Current Densities in Bulk MgB2 Fabricated Using Amorphous Boron. Phys. Status Solidi (A) 2015, 212, 2141–2145. [Google Scholar] [CrossRef]

- Li, W.; Dou, S.-X. High Critical Current Density MgB2. In Superconductors-New Developments; IntechOpen: London, UK, 2015. [Google Scholar] [CrossRef] [Green Version]

- Yamamoto, A.; Ishihara, A.; Tomita, M.; Kishio, K. Permanent Magnet with MgB2 Bulk Superconductor. Appl. Phys. Lett. 2014, 105, 032601. [Google Scholar] [CrossRef] [Green Version]

- Baghdadi, R.; Arpaia, R.; Stepantsov, E.; Arzeo, M.; Golubev, D.; Montemurro, D.; Andersson, E.; Bauch, T.; Lombardi, F. Study of In-Plane Electrical Transport Anisotropy of a-Axis Oriented YBa2Cu3O7−δ Nanodevices. Phys. Rev. B 2017, 95, 184505. [Google Scholar] [CrossRef] [Green Version]

- Namburi, D.K.; Takahashi, K.; Hirano, T.; Kamada, T.; Fujishiro, H.; Shi, Y.-H.; Cardwell, D.A.; Durrell, J.H.; Ainslie, M.D. Pulsed-Field Magnetisation of Y-Ba-Cu-O Bulk Superconductors Fabricated by the Infiltration Growth Technique. Supercond. Sci. Technol. 2020, 33, 115012. [Google Scholar] [CrossRef]

- Kumakura, H.; Takano, Y.; Fujii, H.; Togano, K.; Kito, H.; Ihara, H. Critical Current Densities and Irreversibility Fields of MgB2 Bulks. Phys. C 2001, 363, 179–183. [Google Scholar] [CrossRef]

- Jung, S.-G.; Seong, W.K.; Kang, W.N. Effect of Columnar Grain Boundaries on Flux Pinning in MgB2 Films. J. Appl. Phys. 2012, 111, 053906. [Google Scholar] [CrossRef]

- Dezhin, D.; Ilyasov, R.; Dezhina, I. Development of Superconducting Propulsion System with Liquid Hydrogen Cooling for Future Electric Aircraft. In Proceedings of the 2020 International Conference on Electrotechnical Complexes and Systems (ICOECS), Ufa, Russia, 27–30 October 2020; pp. 1–3. [Google Scholar]

- Tokita, M. Development of Large-Size Ceramic/Metal Bulk FGM Fabricated by Spark Plasma Sintering. In Materials Science Forum; Trans Tech Publications Ltd.: Zürich, Switzerland, 1999; Volume 308, pp. 83–88. [Google Scholar] [CrossRef]

- Orrù, R.; Licheri, R.; Locci, A.M.; Cincotti, A.; Cao, G. Consolidation/Synthesis of Materials by Electric Current Activated/Assisted Sintering. Mater. Sci. Eng. R Rep. 2009, 63, 127–287. [Google Scholar] [CrossRef]

- Chaim, R.; Shen, Z. Grain Size Control by Pressure Application Regime during Spark Plasma Sintering of Nd-YAG Nanopowders. J. Mater. Sci. 2008, 43, 5023–5027. [Google Scholar] [CrossRef]

- Häßler, W.; Scheiter, J.; Hädrich, P.; Kauffmann-Weiß, S.; Holzapfel, B.; Oomen, M.; Nielsch, K. Properties of Ex-Situ MgB2 Bulk Samples Prepared by Uniaxial Hot Pressing and Spark Plasma SINTERING. Phys. C Supercond. Its Appl. 2018, 551, 48–54. [Google Scholar] [CrossRef]

- Shimada, Y.; Hata, S.; Ikeda, K.; Nakashima, H.; Matsumura, S.; Tanaka, H.; Yamamoto, A.; Shimoyama, J.; Kishio, K. Microstructural Connectivity in Sintered Ex-Situ MgB2 Bulk Superconductors. J. Alloys Compd. 2016, 656, 172–180. [Google Scholar] [CrossRef] [Green Version]

- Noudem, J.G.; Xing, Y.; Bernstein, P.; Retoux, R.; Higuchi, M.; Arvapalli, S.S.; Muralidhar, M.; Murakami, M. Improvement of Critical Current Density of MgB2 Bulk Superconductor Processed by Spark Plasma Sintering. J. Am. Ceram. Soc. 2020, 103, 6169–6175. [Google Scholar] [CrossRef]

- Noudem, J.; Dupont, L.; Bernstein, P.; Retoux, R.; Chevallier, G.; Estournès, C.; Berger, K.; Higuchi, M.; Muralidhar, M.; Murakami, M. Chapter 8—Superconducting Cryo-Magnets Processed by Spark Plasma Sintering and Texturing. In Spark Plasma Sintering; Cao, G., Estournès, C., Garay, J., Orrù, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 185–199. ISBN 978-0-12-817744-0. [Google Scholar]

- de Terris, T.; Andreau, O.; Peyre, P.; Adamski, F.; Koutiri, I.; Gorny, C.; Dupuy, C. Optimization and Comparison of Porosity Rate Measurement Methods of Selective Laser Melted Metallic Parts. Addit. Manuf. 2019, 28, 802–813. [Google Scholar] [CrossRef]

- Sauerzopf, F.M.; Wiesinger, H.P.; Weber, H.W. Anisotropic Current Flow and Demagnetization Corrections in the Bean Model. Cryogenics 1990, 30, 650–655. [Google Scholar] [CrossRef]

- Lutterotti, L.; Matthies, S.; Wenk, H. MAUD (material analysis using diffraction): A user friendly Java program for Rietveld texture analysis and more. In Proceedings of the Twelfth International Conference on Textures of Materials (ICOTOM-12), Montreal, QC, Canada, 9–13 August 1999; NRC Research Press: Ottawa, ON, Canada, 1999; Volume 1. [Google Scholar]

- Kim, J.H.; Dou, S.X.; Shi, D.Q.; Rindfleisch, M.; Tomsic, M. Study of MgO Formation and Structural Defects in In Situ Processed MgB2 /Fe Wires. Supercond. Sci. Technol. 2007, 20, 1026–1031. [Google Scholar] [CrossRef]

- Sahu, P. Lattice Imperfections in Intermetallic Ti–Al Alloys: An X-Ray Diffraction Study of the Microstructure by the Rietveld Method. Intermetallics 2006, 14, 180–188. [Google Scholar] [CrossRef]

- Yamamoto, A.; Shimoyama, J.; Kishio, K.; Matsushita, T. Limiting Factors of Normal-State Conductivity in Superconducting MgB2: An Application of Mean-Field Theory for a Site Percolation Problem. Supercond. Sci. Technol. 2007, 20, 658–666. [Google Scholar] [CrossRef]

- Blatter, G.; Feigel’man, M.V.; Geshkenbein, V.B.; Larkin, A.I.; Vinokur, V.M. Vortices in High-Temperature Superconductors. Rev. Mod. Phys. 1994, 66, 1125–1388. [Google Scholar] [CrossRef]

- Xu, X.; Dou, S.X.; Wang, X.L.; Kim, J.H.; Stride, J.A.; Choucair, M.; Yeoh, W.K.; Zheng, R.K.; Ringer, S.P. Graphene Doping to Enhance the Flux Pinning and Supercurrent Carrying Ability of a Magnesium Diboride Superconductor. Supercond. Sci. Technol. 2010, 23, 085003. [Google Scholar] [CrossRef] [Green Version]

- Matsushita, T. MgB2. In Flux Pinning in Superconductors; Matsushita, T., Ed.; Springer Series in Solid-State Sciences; Springer: Berlin/Heidelberg, Germany, 2014; pp. 377–403. ISBN 978-3-642-45312-0. [Google Scholar]

- Prikhna, T.; Eisterer, M.; Gawalek, W.; Kozyrev, A.; Weber, H.W.; Sokolovsky, V.; Chaud, X.; Noudem, J.; Habisreuther, T.; Moshchil, V.; et al. Synthesis Pressure–Temperature Effect on Pinning in MgB2-Based Superconductors. J. Supercond. Nov. Magn. 2013, 26, 1569–1576. [Google Scholar] [CrossRef]

- Prikhna, T.; Eisterer, M.; Gawalek, W.; Mamalis, A.G.; Kozyrev, A.; Kovylaev, V.; Hristoforou, E.; Weber, H.W.; Noudem, J.G.; Goldacker, W.; et al. Structure and Functional Properties of Bulk MgB2 Superconductors Synthesized and Sintered under Pressure. In Materials Science Forum; Trans Tech Publications Ltd.: Zürich, Switzerland, 2014; Volume 792, pp. 21–26. [Google Scholar] [CrossRef]

- Mustapić, M.; Horvat, J.; Hossain, M.S.; Skoko, Ž.; Dou, S. Enhancing Superconducting Properties of MgB2 Pellets by Addition of Amorphous Magnetic Ni–Co–B Nanoparticles. Supercond. Sci. Technol. 2013, 26, 075013. [Google Scholar] [CrossRef] [Green Version]

- Muralidhar, M.; Nozaki, K.; Kobayashi, H.; Zeng, X.L.; Koblischka-Veneva, A.; Koblischka, M.R.; Inoue, K.; Murakami, M. Optimization of Sintering Conditions in Bulk MgB2 Material for Improvement of Critical Current Density. J. Alloys Compd. 2015, 649, 833–842. [Google Scholar] [CrossRef]

- Bhagurkar, A.G.; Yamamoto, A.; Babu, N.H.; Durrell, J.H.; Dennis, A.R.; Cardwell, D.A. Synthesis of Dense Bulk MgB2 by an Infiltration and Growth Process. Supercond. Sci. Technol. 2015, 28, 015012. [Google Scholar] [CrossRef] [Green Version]

- Zou, J.; Ainslie, M.D.; Fujishiro, H.; Bhagurkar, A.G.; Naito, T.; Babu, N.H.; Fagnard, J.-F.; Vanderbemden, P.; Yamamoto, A. Numerical Modelling and Comparison of MgB2 Bulks Fabricated by HIP and Infiltration Growth. Supercond. Sci. Technol. 2015, 28, 075009. [Google Scholar] [CrossRef]

- Dadiel, J.L.; Naik, S.P.K.; Pęczkowski, P.; Sugiyama, J.; Ogino, H.; Sakai, N.; Kazuya, Y.; Warski, T.; Wojcik, A.; Oka, T.; et al. Synthesis of Dense MgB2 Superconductor via In Situ and Ex Situ Spark Plasma Sintering Method. Materials 2021, 14, 7395. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Kim, J.H.; Hossain, M.S.A.; Park, J.S.; Zhao, Y.; Dou, S.X.; Yeoh, W.K.; Rindfleisch, M.; Tomsic, M. Phase Transformation and Superconducting Properties of MgB2 Using Ball-Milled Low Purity Boron. J. Appl. Phys. 2008, 103, 023912. [Google Scholar] [CrossRef] [Green Version]

- Kang, Won Nam Single-Crystal like MgB2 Thin Films Grown on c-Cut Sapphire Substrates. Prog. Supercond. Cryog. 2014, 16, 7–9. [CrossRef] [Green Version]

- Shigeta, I.; Abiru, T.; Abe, K.; Nishida, A.; Matsumoto, Y. Temperature and Field Dependence of Magnetization of MgB2 Polycrystals. Phys. C Supercond. 2003, 392, 359–363. [Google Scholar] [CrossRef]

| Method | Sintering/ Densification | Density | Grain Size (nm) | Jc-0T (A/cm2) | Jc-4T (A/cm2) | Reference |

|---|---|---|---|---|---|---|

| Conventional sintering (CC) | 775–800 °C 3 h | 50–60% | ~100 | 2–3 × 105 | 102–103 | [29,30] |

| Infiltration and growth process (IG) | 750 °C 2 h | ~90% | 500 | 2 × 105 | 102 | [31,32] |

| Hot-pressing or high-pressure processing (HP) | 1050 °C 2 GPa 1 h | 99% | 17–37 | 5–9 × 105 | 1–2 × 104 | [27,28] |

| Spark plasma sintering (SPS) | 750–850 °C 50 MPa 20 min | 75–88% | ~132 | 5 × 105 | 4 × 103 | [17,33] |

| In this work | 750 °C 300 MPa 30 min | 95% | ~58 | 7 × 105 | 104 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, Y.; Bernstein, P.; Miryala, M.; Noudem, J.G. High Critical Current Density of Nanostructured MgB2 Bulk Superconductor Densified by Spark Plasma Sintering. Nanomaterials 2022, 12, 2583. https://doi.org/10.3390/nano12152583

Xing Y, Bernstein P, Miryala M, Noudem JG. High Critical Current Density of Nanostructured MgB2 Bulk Superconductor Densified by Spark Plasma Sintering. Nanomaterials. 2022; 12(15):2583. https://doi.org/10.3390/nano12152583

Chicago/Turabian StyleXing, Yiteng, Pierre Bernstein, Muralidhar Miryala, and Jacques G. Noudem. 2022. "High Critical Current Density of Nanostructured MgB2 Bulk Superconductor Densified by Spark Plasma Sintering" Nanomaterials 12, no. 15: 2583. https://doi.org/10.3390/nano12152583

APA StyleXing, Y., Bernstein, P., Miryala, M., & Noudem, J. G. (2022). High Critical Current Density of Nanostructured MgB2 Bulk Superconductor Densified by Spark Plasma Sintering. Nanomaterials, 12(15), 2583. https://doi.org/10.3390/nano12152583