Direct Laser Writing of SERS Hollow Fibers

Abstract

:1. Introduction

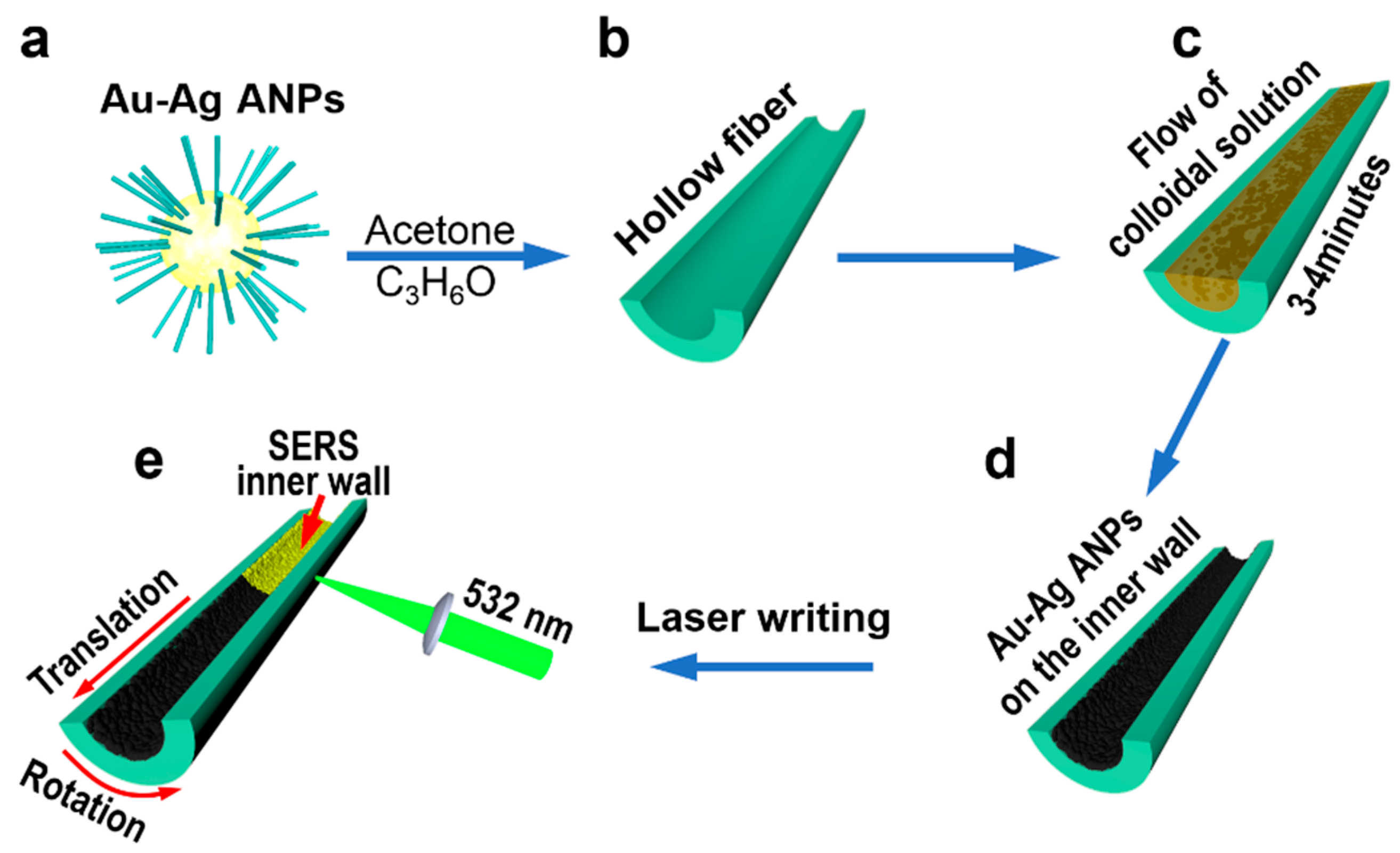

2. Direct Laser Writing (DLW) of SERS Structures on the Inner Wall of a Hollow Fiber

2.1. Basic Principles for the DLW Technique

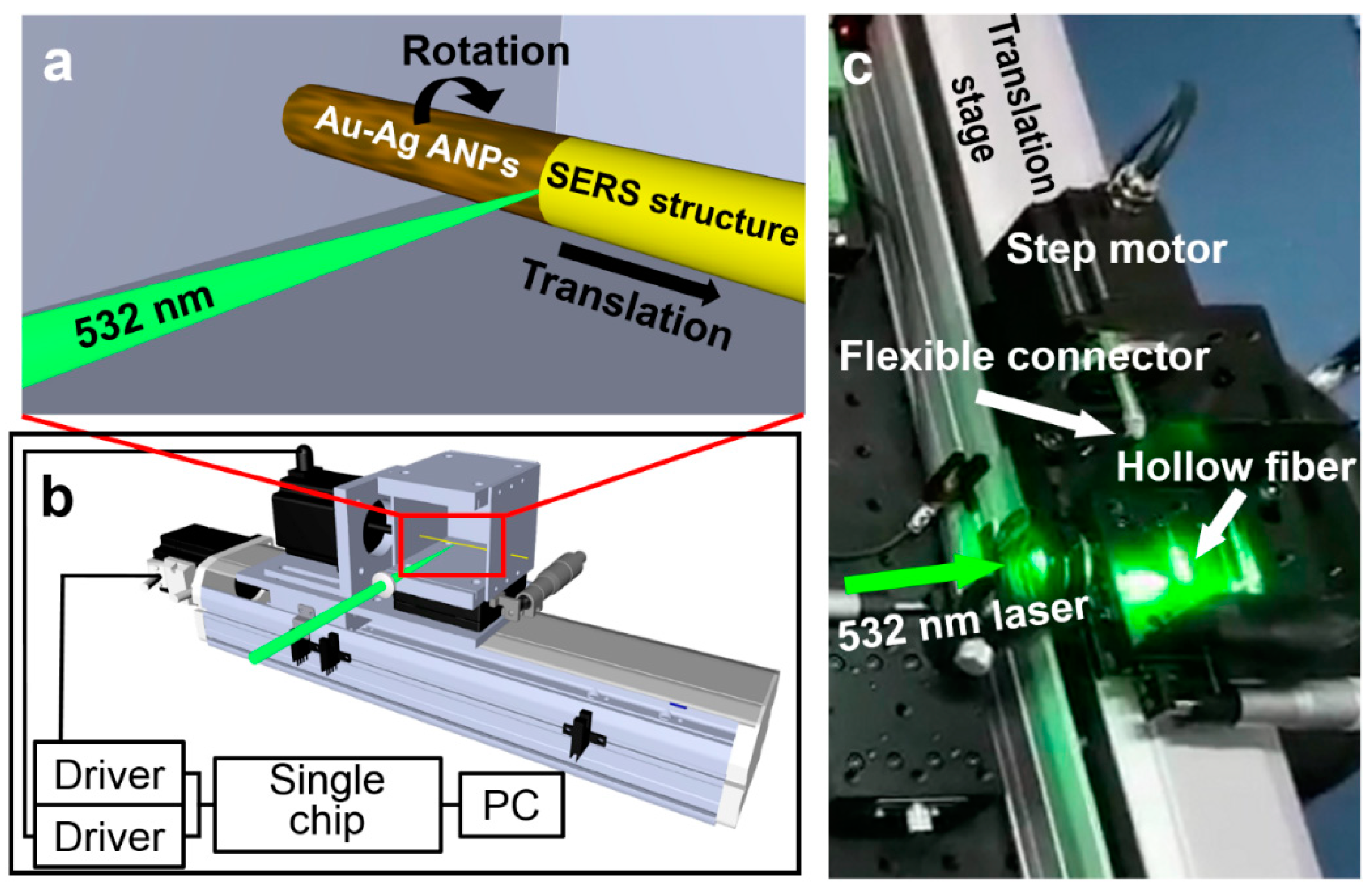

2.2. Program-Controlled DLW System

3. 3D SERS Microcavity by the Curved Inner Wall of the Hollow Fiber

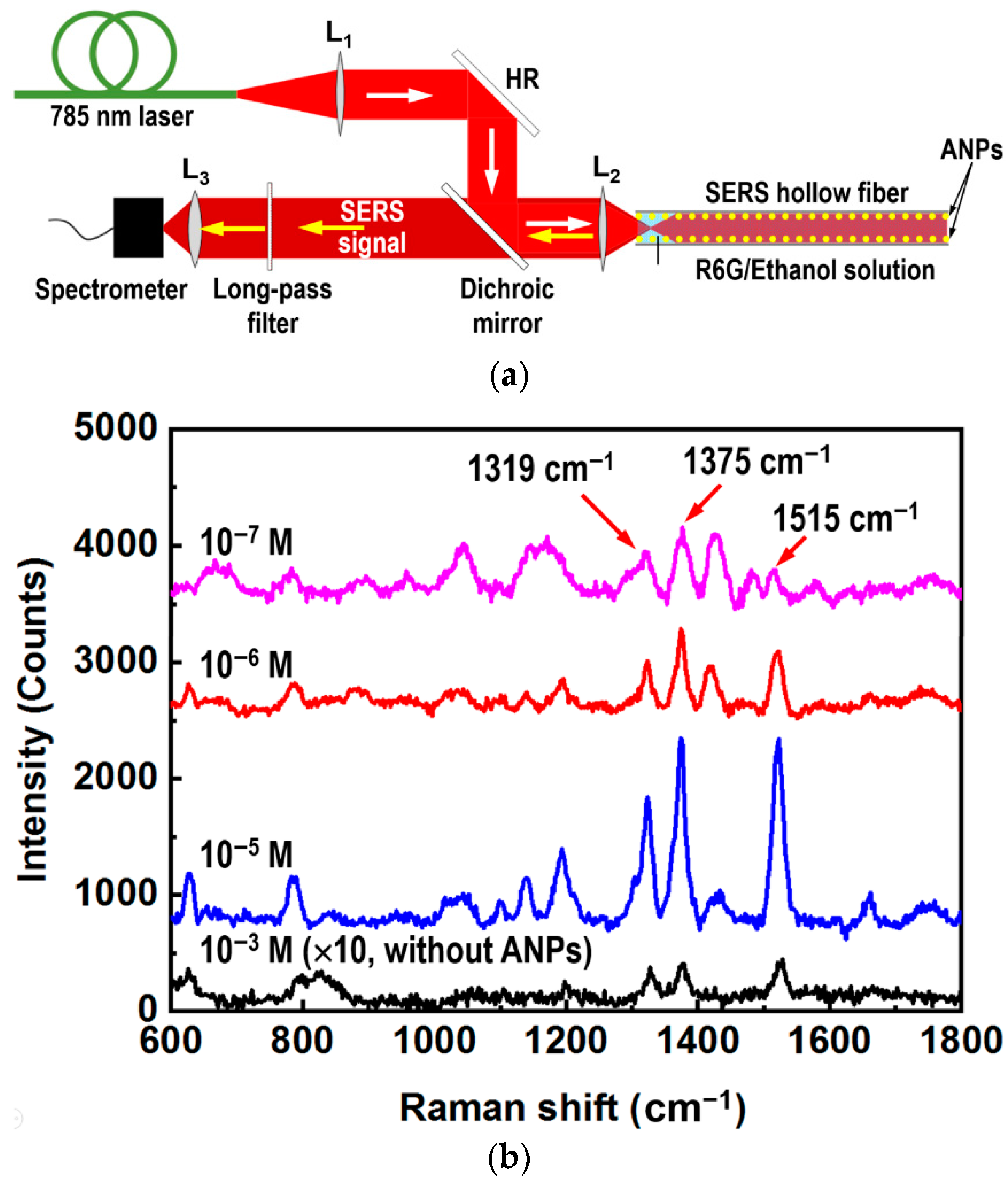

4. Sensing of Low-Concentration R6G Molecules in Ethanol

5. Conclusions

6. Experimental Methods

6.1. Synthesis of Au–Ag Alloy Nanoparticles (Au–Ag ANPs)

- (1)

- First, 1.143 g tetrabutylammonium bromide (TOAB) was added into 60 mL toluene to fully dissolve; then, 2.44 mL aqueous sulfuric acid solution with a concentration of 1.5 mol/L was added to the solution;

- (2)

- Next, 0.173 g silver nitrate was added into the above-prepared solution with sufficient stirring, until the solution became clarified;

- (3)

- Then, 0.11 g H[AuCl₄]·4H₂O was added into the above-prepared solution. Thus, the water-insoluble TOAB formed ionic conjugates with Au3+ and Ag+, which were transferred to the toluene phase, preventing Ag+ and [AuCl4]- from forming AgCl and Au(OH)3 precipitate in the aqueous phase. The toluene phase became red–brown in color;

- (4)

- After the aqueous phase was clarified and transparent, it was separated and the organic phase was retained. Then, 0.371 g hexanethiol was added to the solution of the organic phase before the solution was heated to 40 °C in a water bath;

- (5)

- Next, 15 mL aqueous sodium borohydride solution with a mass concentration of 1.8% was added to the solution prepared in (4), and was heated and stirred for 12 h. Thus, hexanethiol-protected gold–silver alloy nanoparticle colloids were prepared;

- (6)

- The aqueous phase was separated and the organic phase was distilled under reduced pressure at 50 °C in water bath, so that a black oily viscous liquid was obtained;

- (7)

- The product in (6) was then washed with methanol under centrifugation. The washing of the black precipitate was repeated 4 to 5 times. Gold and silver alloy nanoparticles were thus produced after being dried by blowing with nitrogen. The transmission electron microscope (TEM) image and the energy-dispersion X-ray spectrum (EDS) measured on the synthesized Ag–Au ANPs are given in Figure S4 and Figure S5, respectively. The TEM image in Figure S4 shows a diameter of roughly 3–8 nm for the Ag–Au ANPs and the EDS data determine a weight ratio of 3:5 or an atomic ratio of roughly 1:1 between the Ag and Au elements. The photographs of the as-prepared powder sample of the ANPs and the colloidal solution of the ANPs in acetone with a concentration of 100 mg/mL are shown in Figure S6.

6.2. Microscopic and Spectroscopic Measurements

6.3. The Optical and Electromechanical Design

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fleischmann, M.; Hendra, P.J.; McQuillan, A.J. Raman spectra of pyridine adsorbed at a silver electrode. Chem. Phys. Lett. 1974, 26, 163–166. [Google Scholar] [CrossRef]

- Jeanmaire, D.L.; van Duyne, R.P. Surface Raman spectroelectrochemistry: Part I. Heterocyclic, aromatic, and aliphatic amines adsorbed on the anodized silver electrode. J. Electroanal. Chem. Interfacial Electrochem. 1977, 84, 1–20. [Google Scholar] [CrossRef]

- Shi, Y.; Chen, N.; Su, Y.; Wang, H.; He, Y. Silicon nanohybrid-based SERS chips armed with an internal standard for broad-range, sensitive and reproducible simultaneous quantification of lead(II) and mercury(II) in real systems. Nanoscale 2018, 10, 4010–4018. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Yu, L.; Li, J.; Wang, L.; Lu, R. Polyamide@Ag coralloid nanoarrays with 3D high-density hot spots for ultrasensitive SERS sensing. Chem. Eng. J. 2020, 397, 125434. [Google Scholar] [CrossRef]

- Ren, X.; Cheshari, E.C.; Qi, J.; Li, X. Silver microspheres coated with a molecularly imprinted polymer as a SERS substrate for sensitive detection of bisphenol A. Microchim. Acta 2018, 185, 242. [Google Scholar] [CrossRef]

- Sánchez-Gil, J.A.; García-Ramos, J.V.; Méndez, E.R. Electromagnetic mechanism in surface-enhanced Raman scattering from Gaussian-correlated randomly rough metal substrates. Opt. Express 2002, 10, 879–886. [Google Scholar] [CrossRef]

- Nishijima, Y.; Khurgin, J.B.; Rosa, L.; Fujiwara, H.; Juodkazis, S. Randomization of gold nano-brick arrays: A tool for SERS enhancement. Opt. Express 2013, 21, 13502–13514. [Google Scholar] [CrossRef]

- Liu, X.; Kitamura, K.; Yu, Q.; Xu, J.; Osada, M.; Takahiro, N.; Li, J.; Cao, G. Tunable and highly reproducible surface-enhanced Raman scattering substrates made from large-scale nanoparticle arrays based on periodically poled LiNbO3 templates. Sci. Technol. Adv. Mater. 2013, 14, 055011. [Google Scholar] [CrossRef]

- Huebner, U.; Boucher, R.; Schneidewind, H.; Cialla, D.; Popp, J. Microfabricated SERS-arrays with sharp-edged metallic nanostructures. Microelectron. Eng. 2008, 85, 1792–1794. [Google Scholar] [CrossRef]

- Aravind, P.K.; Nitzan, A.; Metiu, H. The interaction between electromagnetic resonances and its role in spectroscopic studies of molecules adsorbed on colloidal particles or metal spheres. Surf. Sci. 1981, 110, 189–204. [Google Scholar]

- Shanthil, M.; Thomas, R.; Swathi, R.S.; George Thomas, K. Ag@SiO2 core–shell nanostructures: Distance-dependent plasmon coupling and SERS investigation. J. Phys. Chem. Lett. 2012, 3, 1459–1464. [Google Scholar] [CrossRef]

- McMahon, J.M.; Li, S.; Ausman, L.K.; Schatz, G.C. Modeling the effect of small gaps in surface-enhanced Raman spectroscopy. J. Phys. Chem. C 2012, 116, 1627–1637. [Google Scholar] [CrossRef]

- Kim, D.; Kim, J.; Henzie, J.; Ko, Y.; Lim, H.; Kwon, G.; Na, J.; Kim, H.; Yamauchi, Y.; You, J. Mesoporous Au films assembled on flexible cellulose nanopaper as high-performance SERS substrates. Chem. Eng. J. 2021, 419, 129445. [Google Scholar] [CrossRef]

- Lim, H.; Kim, D.; Kwon, G.; Kim, H.-J.; You, J.; Kim, J.; Eguchi, M.; Nanjundan, A.K.; Na, J.; Yamauchi, Y. Synthesis of Uniformly Sized Mesoporous Silver Films and Their SERS Application. J. Phys. Chem. C 2020, 124, 23730–23737. [Google Scholar] [CrossRef]

- Lim, H.; Kim, J.; Kani, K.; Masud, M.K.; Park, H.; Kim, M.; Alsheri, S.M.; Ahamad, T.; Alhokbany, N.; Na, J.; et al. Designed Patterning of Mesoporous Metal Films Based on Electrochemical Micelle Assembly Combined with Lithographical Techniques. Small 2020, 16, 1902934. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, X.; Zhai, T.; Sander, T.; Chen, L.; Klar, P.J. Centimeter-scale-homogeneous SERS substrates with seven-order global enhancement through thermally controlled plasmonic nanostructures. Nanoscale 2014, 6, 5099–5105. [Google Scholar] [CrossRef]

- Liu, F.; Zhang, X.; Mu, Y.; Lin, J.; Wang, M.; Ma, H. Complementary dark and bright plasmonic nanocavities with controllable energy exchange for SERS sensing. Adv. Opt. Mater. 2020, 8, 2000544. [Google Scholar] [CrossRef]

- Choi, C.J.; Xu, Z.; Wu, H.-Y.; Liu, G.L.; Cunningham, B.T. Surface-enhanced Raman nanodomes. Nanotechnology 2010, 21, 415301. [Google Scholar] [CrossRef]

- Hao, E.; Schatz, G.C. Electromagnetic fields around silver nanoparticles and dimers. J. Chem. Phys. 2004, 120, 357–366. [Google Scholar] [CrossRef]

- Vianna, P.G.; Grasseschi, D.; Domingues, S.H.; de Matos, C.J.S. Real-time optofluidic surface-enhanced Raman spectroscopy based on a graphene oxide/gold nanorod nanocomposite. Opt. Express 2018, 26, 22698–22708. [Google Scholar] [CrossRef]

- Chen, M.; Tang, J.; Luo, W.; Zhang, Z.; Zhu, Y.; Wang, R.; Yang, H.; Chen, X. Core-shell-satellite microspheres-modified glass capillary for microsampling and ultrasensitive SERS spectroscopic detection of methotrexate in serum. Sens. Actuators B Chem. 2018, 275, 267–276. [Google Scholar] [CrossRef]

- Yu, Y.; Zeng, P.; Yang, C.; Gong, J.; Liang, R.; Ou, Q.; Zhang, S. Gold-nanorod-coated capillaries for the SERS-based detection of thiram. ACS Appl. Nano Mater. 2019, 2, 598–606. [Google Scholar] [CrossRef]

- Yang, X.; Shi, C.; Wheeler, D.; Newhouse, R.; Chen, B.; Zhang, J.Z.; Gu, C. High-sensitivity molecular sensing using hollow-core photonic crystal fiber and surface-enhanced Raman scattering. J. Opt. Soc. Am. A 2010, 27, 977–984. [Google Scholar] [CrossRef]

- Han, M.; Zhu, Z.; Ouyang, M.; Liu, Y.; Shu, X. Highly efficient triplet-triplet-annihilation upconversion sensitized by a thermally activated delayed fluorescence molecule in optical microcavities. Adv. Funct. Mater. 2021, 31, 2104044. [Google Scholar] [CrossRef]

- Liao, W.; Chen, Y.; Huang, L.; Wang, Y.; Zhou, Y.; Tang, Q.; Chen, Z.; Liu, K. A capillary-based SERS sensor for ultrasensitive and selective detection of Hg2+ by amalgamation with Au@4-MBA@Ag core–shell nanoparticles. Microchim. Acta 2021, 188, 354. [Google Scholar] [CrossRef]

- Shanthil, M.; Fathima, H.; George Thomas, K. Cost-effective plasmonic platforms: Glass capillaries decorated with Ag@SiO2 nanoparticles on inner walls as SERS substrates. ACS Appl. Mater. Interfaces 2017, 9, 19470–19477. [Google Scholar] [CrossRef]

- Mu, Y.; Liu, M.; Li, J.; Zhang, X. Plasmonic hollow fibers with distributed inner-wall hotspots for direct SERS detection of flowing liquids. Opt. Lett. 2021, 46, 1369–1372. [Google Scholar] [CrossRef]

- Li, H.; Liu, H.; Qin, Y.; Mu, Y.; Fang, X.; Zhai, T.; Zhang, X. Gold-stabilized gold–silver alloy nanostructures as high-performance SERS substrate. Plasmonics 2020, 15, 2027–2032. [Google Scholar] [CrossRef]

- Kang, C.; Sun, Z.T.; Fang, X.H.; Zha, L.; Han, Y.; Liu, H.M.; Guo, J.X.; Zhang, X.P. Molecular trace detection in liquids using refocusing optical feedback by a silver coated capillary. Nanoscale Adv. 2021, 3, 6934–6939. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Mu, Y.; Liu, M.; Zhang, X. Direct Laser Writing of SERS Hollow Fibers. Nanomaterials 2022, 12, 2843. https://doi.org/10.3390/nano12162843

Li J, Mu Y, Liu M, Zhang X. Direct Laser Writing of SERS Hollow Fibers. Nanomaterials. 2022; 12(16):2843. https://doi.org/10.3390/nano12162843

Chicago/Turabian StyleLi, Jiajun, Yunyun Mu, Miao Liu, and Xinping Zhang. 2022. "Direct Laser Writing of SERS Hollow Fibers" Nanomaterials 12, no. 16: 2843. https://doi.org/10.3390/nano12162843