Observation and Analysis of Staircase Response of Single Palladium Nanoparticle Collision on Gold Ultramicroelectrodes

Abstract

1. Introduction

2. Materials and Methods

2.1. Reagent

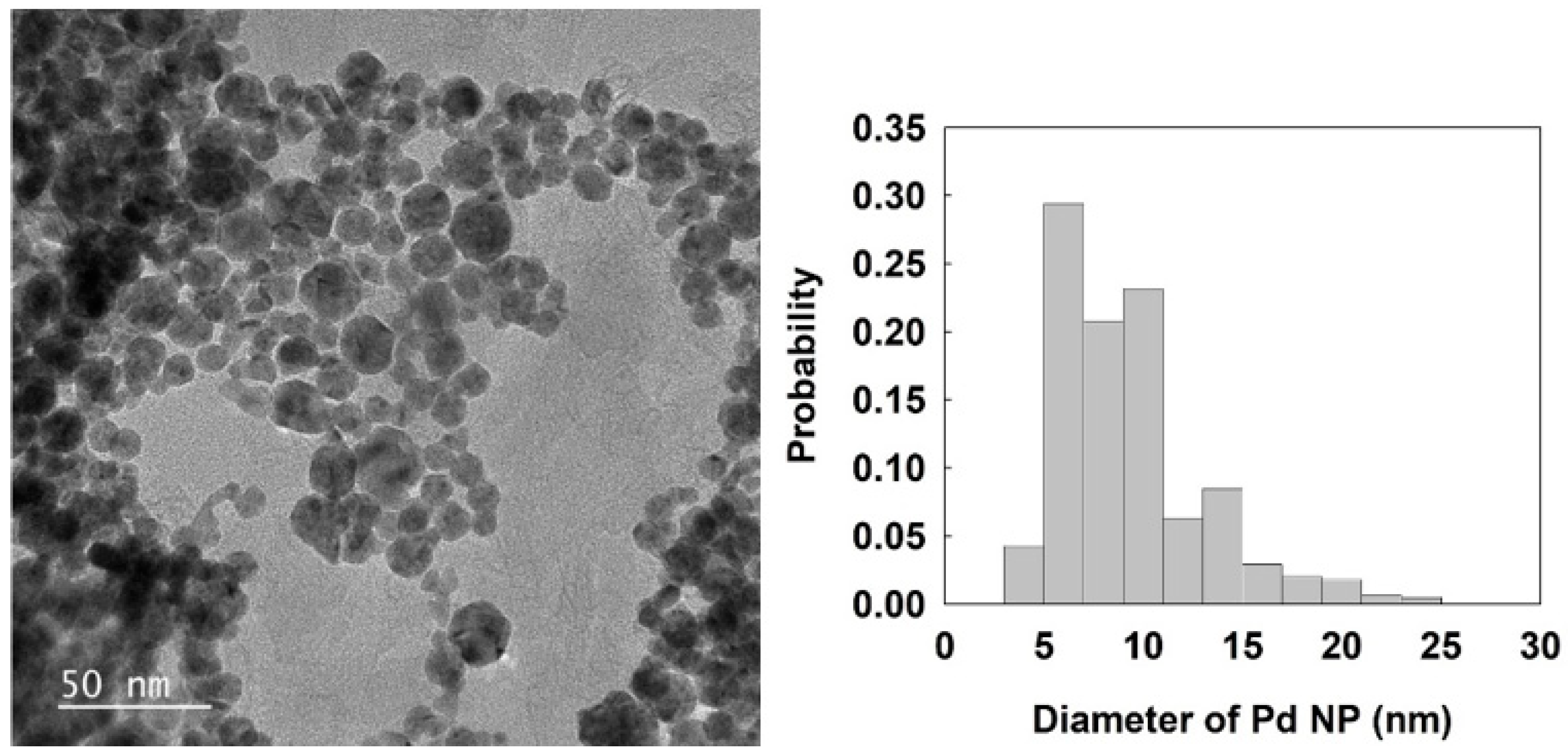

2.2. Preparation of Pd NP

2.3. Preparation of UME

2.4. Instrumentation

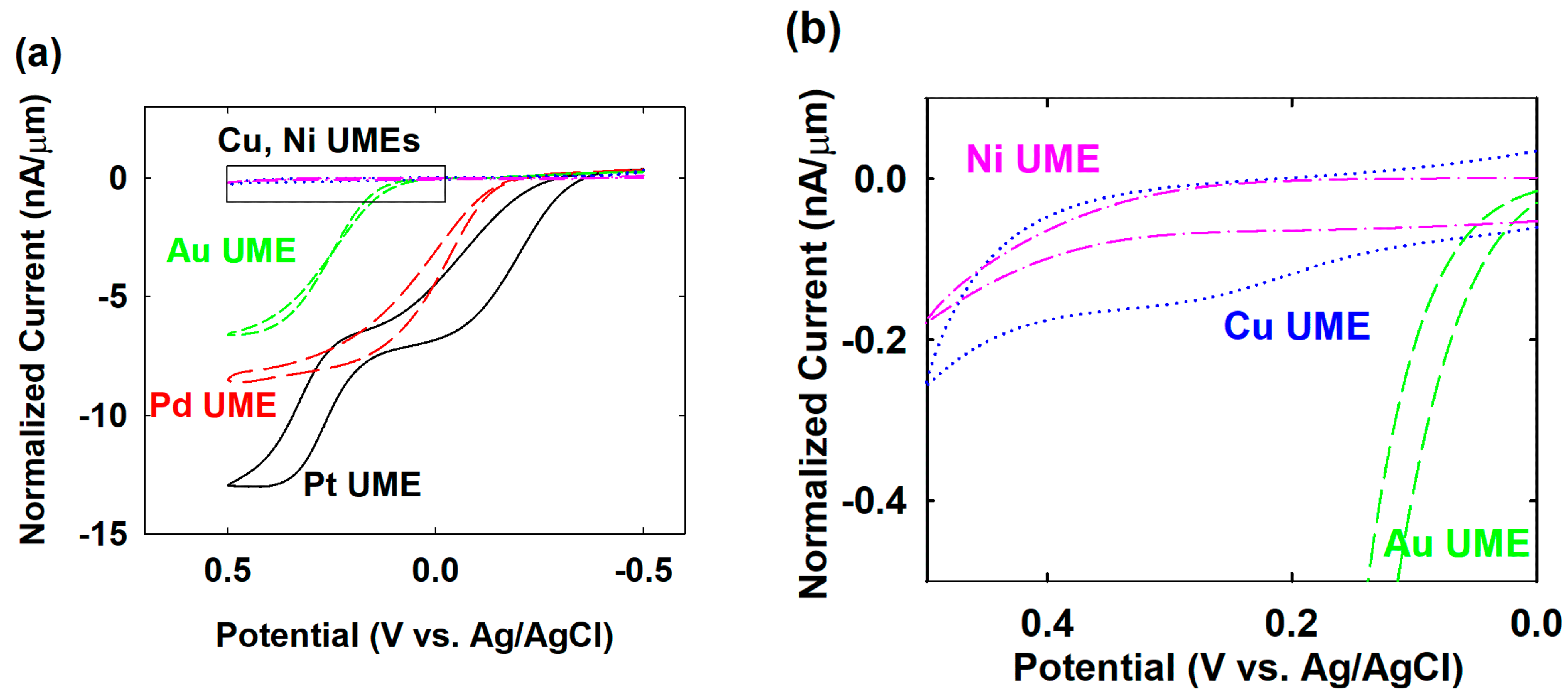

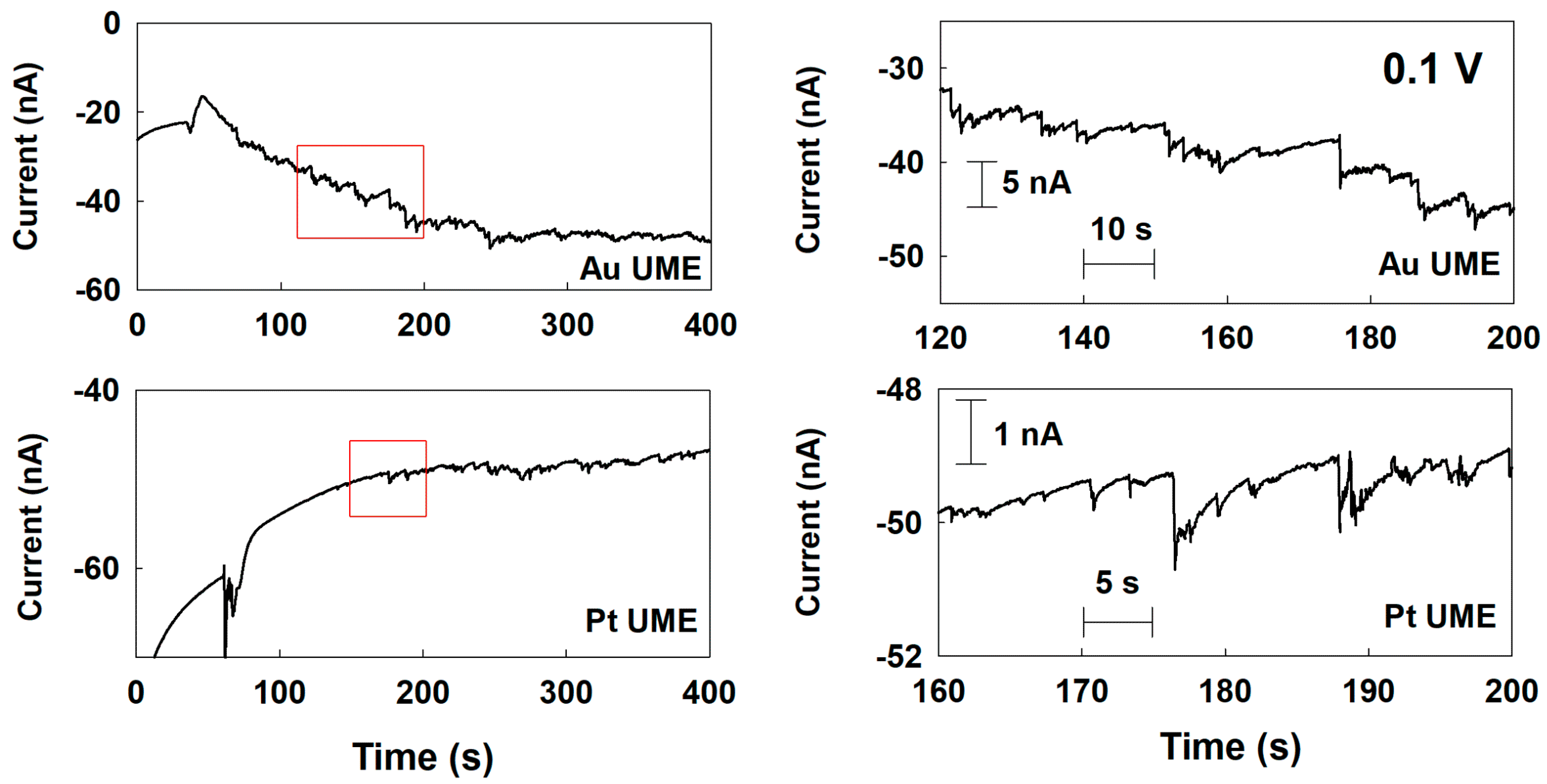

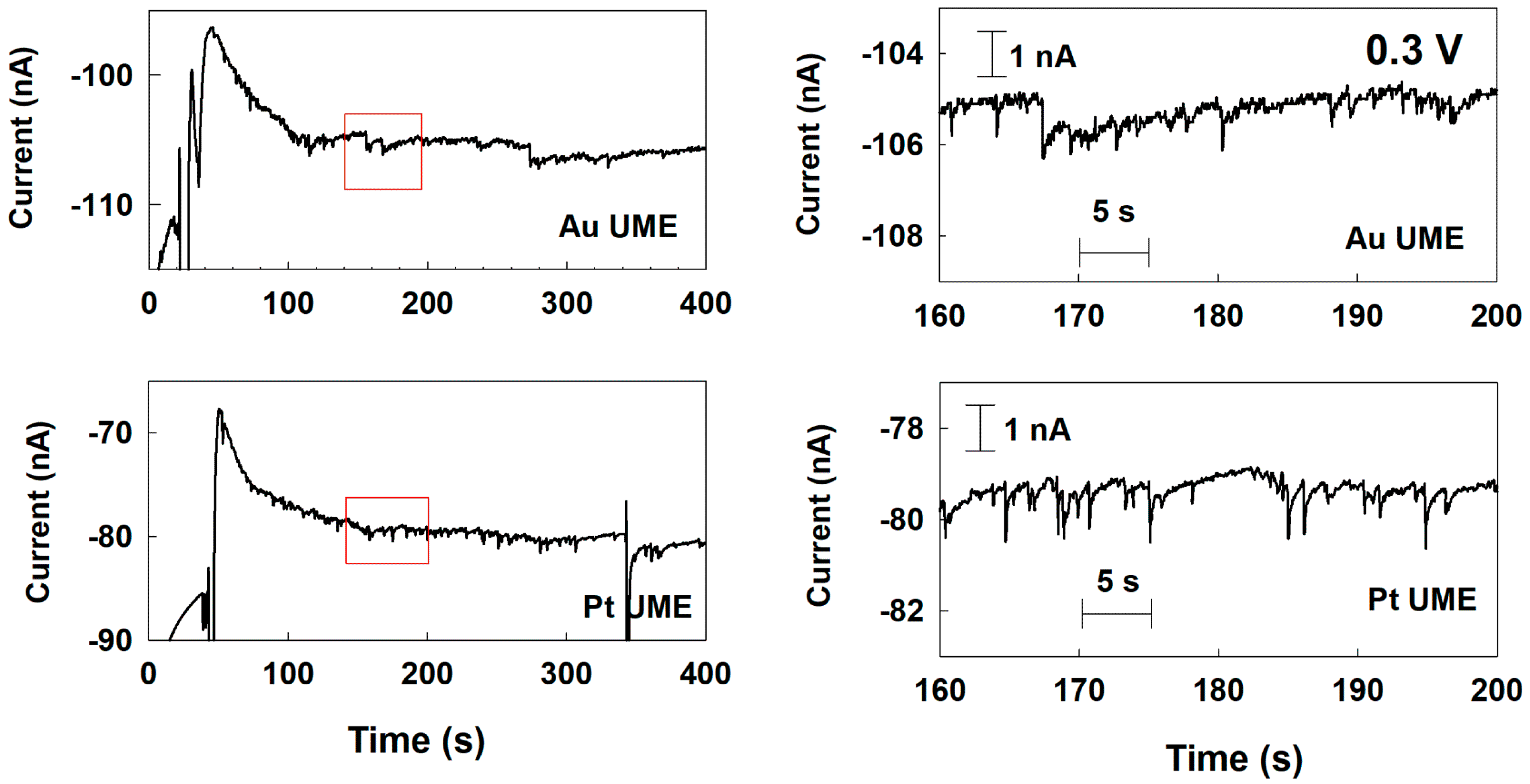

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, A.; Ostrom, C. Palladium-based nanomaterials: Synthesis and electrochemical applications. Chem. Rev. 2015, 115, 11999–12044. [Google Scholar] [CrossRef] [PubMed]

- Yaqoob, S.B.; Adnan, R.; Rameez Khan, R.M.; Rashid, M. Gold, silver, and palladium nanoparticles: A chemical tool for biomedical applications. Front. Chem. 2020, 8, 376. [Google Scholar] [CrossRef] [PubMed]

- Stephen, A.J.; Rees, N.V.; Mikheenko, I.; Macaskie, L.E. Platinum and palladium bio-synthesized nanoparticles as sustainable fuel cell catalysts. Front. Energy 2019, 7, 66. [Google Scholar] [CrossRef]

- Jiang, K.; Zhang, H.X.; Zou, S.; Cai, W.B. Electrocatalysis of formic acid on palladium and platinum surfaces: From fundamental mechanisms to fuel cell applications. Phys. Chem. Chem. Phys. 2014, 16, 20360–20376. [Google Scholar] [CrossRef]

- Dang, S.; Zhu, Q.L.; Xu, Q. Nanomaterials derived from metal–organic frameworks. Nat. Rev. Mater. 2017, 3, 17075. [Google Scholar] [CrossRef]

- Ni, B.; Wang, X. Face the edges: Catalytic active sites of nanomaterials. Adv. Sci. 2015, 2, 1500085. [Google Scholar] [CrossRef]

- Kwon, S.J.; Fan, F.-R.F.; Bard, A.J. Observing Iridium Oxide (IrOx) Single Nanoparticle Collisions at Ultramicroelectrodes. J. Am. Chem. Soc. 2010, 132, 13165–13167. [Google Scholar] [CrossRef]

- Xiao, X.; Bard, A.J. Observing single nanoparticle collisions at an ultramicroelectrode by electrocatalytic amplification. J. Am. Chem. Soc. 2007, 129, 9610–9612. [Google Scholar] [CrossRef]

- Jung, A.R.; Lee, S.; Joo, J.W.; Shin, C.; Bae, H.; Moon, S.G.; Kwon, S.J. Potential-controlled current responses from staircase to blip in single Pt nanoparticle collisions on a Ni ultamicroelectrode. J. Am. Chem. Soc. 2015, 137, 1762–1765. [Google Scholar] [CrossRef]

- Zhou, X.; Xu, W.; Liu, G.; Panda, D.; Chen, P. Size-dependent catalytic activity and dynamics of gold nanoparticles at the single-molecule level. J. Am. Chem. Soc. 2010, 132, 138–146. [Google Scholar] [CrossRef]

- Zhou, H.; Fan, F.R.F.; Bard, A.J. Observation of discrete Au nanoparticle collisions by electrocatalytic amplification using Pt ultramicroelectrode surface modification. J. Phys. Chem. Lett. 2010, 1, 2671–2674. [Google Scholar] [CrossRef]

- Zhou, Y.-G.; Rees, N.V.; Compton, R.G. The electrochemical detection and characterization of silver nanoparticles in aqueous solution. Angew. Chem. Int. Ed. 2011, 50, 4219–4221. [Google Scholar] [CrossRef] [PubMed]

- Ustarroz, J.; Kang, M.; Bullions, E.; Unwin, P.R. Impact and oxidation of single silver nanoparticles at electrode surface: One shot versus multiple events. Chem. Sci. 2017, 8, 1841–1853. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Yang, C.; Tang, H.; Li, Y. Stochastic collision electrochemistry from single G-quadruplex/hemin: Electrochemical amplification and microRNA sensing. Anal. Chem. 2021, 93, 4593–4600. [Google Scholar] [CrossRef]

- Hao, R.; Fan, Y.; Zhang, B. Electrochemical detection of nanoparticle collision by reduction of silver chloride. J. Electrochem. Soc. 2016, 163, H3145–H3151. [Google Scholar] [CrossRef]

- Wang, H.; Tang, H.; Li, Y. Intrinsic Electrocatalytic Activity of Single MoS2 Quantum Dot Collision on Ag Ultramicroelectrodes. J. Phys. Chem. C 2021, 125, 3337–3345. [Google Scholar] [CrossRef]

- Daryanavard, N.; Zare, H.R. Single palladium nanoparticle collisions detection through chronopotentiometric method: Introducing a new approach to improve the analytical signals. Anal. Chem. 2017, 89, 8901–8907. [Google Scholar] [CrossRef]

- Park, J.Y.; Kim, K.J.; Son, H.; Kwon, S.J. Chronoamperometric Observation and Analysis of Electrocatalytic Ability of Single Pd Nanoparticle for Hydrogen Peroxide Reduction Reaction. Nanomaterials 2018, 8, 879. [Google Scholar] [CrossRef]

- Dasari, R.; Tai, K.; Robinson, D.A.; Stevenson, K.J. Electrochemical monitoring of single nanoparticle collisions at mercury-modified platinum ultramicroelectrodes. ACS Nano 2014, 8, 4539–4546. [Google Scholar] [CrossRef] [PubMed]

- Jung, S.Y.; Joo, J.W.; Kwon, S.J. Observation of Blip Response in a Single Pt Nanoparticle Collision on a Cu Ultramicroelectrode. Bull. Korean Chem. Soc. 2016, 37, 349–354. [Google Scholar] [CrossRef]

- Guo, Y.; Xu, Y.-T.; Gao, G.-H.; Wang, T.; Zhao, B.; Fu, X.-Z.; Sung, R.; Wong, C.-P. Electro-oxidation of formaldehyde and methanol over hollow porous palladium nanoparticles with enhanced catalytic activity. Catal. Commun. 2015, 58, 40–45. [Google Scholar] [CrossRef]

- Shin, C.; Park, T.E.; Park, C.; Kwon, S.J. Observation of single Pt nanoparticle collisions: Enhanced electrocatalytic activity on a Pd ultramicroelectrode. ChemPhysChem 2016, 17, 1637–1641. [Google Scholar] [CrossRef] [PubMed]

- Choi, Y.S.; Jung, S.Y.; Joo, J.W.; Kwon, S.J. Observation of Electrocatalytic Amplification of Iridium Oxide (IrOx) Single Nanoparticle Collision on Copper Ultramicroelectrodes. Bull. Korean Chem. Soc. 2014, 35, 2519–2522. [Google Scholar] [CrossRef][Green Version]

- Huang, L.-F.; Hutchison, M.J.; Santucci, R.J.; Scully, J.R.; Rondinelli, J.M. Improved Electrochemical Phase Diagrams from Theory and Experiment: The Ni-Water System and Its Complex Compounds. J. Phys. Chem. C 2017, 121, 9782–9789. [Google Scholar] [CrossRef]

- Celante, V.G.; Freitas, M.B.J.G. Electrodeposition of copper from spent Li-ion batteries by electrochemical quartz crystal microbalance and impedance spectroscopy techniques. J. Appl. Electrochem. 2010, 40, 233–239. [Google Scholar] [CrossRef]

- Chen, Q.; Liu, Y.; Edwards, M.A.; Liu, Y.; White, H.S. Nitrogen bubbles at Pt nanoelectrodes in a nonaqueous medium: Oscillating behavior and geometry of critical nuclei. Anal. Chem. 2020, 92, 6408–6414. [Google Scholar] [CrossRef]

- Chen, Q.; Zhao, J.; Deng, X.; Shan, Y.; Peng, Y. Single-Entity Electrochemistry of Nano-and Microbubbles in Electrolytic Gas Evolution. J. Phys. Chem. Lett. 2022, 13, 6153–6163. [Google Scholar] [CrossRef]

- Mun, S.K.; Lee, S.; Kim, D.Y.; Kwon, S.J. Various Current Responses of Single Silver Nanoparticle Collisions on a Gold Ultramicroelectrode Depending on the Collision Conditions. Chem. Asian J. 2017, 12, 2434–2440. [Google Scholar] [CrossRef]

- Bard, A.J.; Faulkner, L.R. Electrochemical Methods, Fundamentals and Applications, 2nd ed.; John Wiley & Sons: New York, NY, USA, 2001. [Google Scholar]

- Kwon, S.J.; Zhou, H.; Fan, F.-R.F.; Vorobyev, V.; Zhang, B.; Bard, A.J. Stochastic electrochemistry with electrocatalytic nanoparticles at inert ultramicroelectrodes—Theory and experiments. Phys. Chem. Chem. Phys. 2011, 13, 5394–5402. [Google Scholar] [CrossRef]

- Joo, S.; Baldwin, D.F. Adhesion mechanisms of nanoparticle silver to substrate materials: Identification. Nanotechnology 2010, 21, 055204. [Google Scholar] [CrossRef] [PubMed]

- Hemmingson, S.L.; Campbell, C.T. Trends in adhesion energies of metal nanoparticles on oxide surfaces: Understanding support effects in catalysis and nanotechnology. ACS Nano 2017, 11, 1196–1203. [Google Scholar] [CrossRef] [PubMed]

- Kleijn, S.E.; Serrano-Bou, B.; Yanson, A.I.; Koper, M.T. Influence of hydrazine-induced aggregation on the electrochemical detection of platinum nanoparticles. Langmuir 2013, 29, 2054–2064. [Google Scholar] [CrossRef] [PubMed]

| UME | Response Type at 0.1 V | Response Type at 0.3 V | Peak Height [a] (pA) at 0.1 V | Frequency [b] (s−1 μm−1) at 0.1 V | Peak height [a] (pA) at 0.3 V | Frequency [b] (s−1 μm−1) at 0.3 V |

|---|---|---|---|---|---|---|

| Au | Staircase | Blip | 700 | 0.051 | 625 | 0.050 |

| Pt | Blip | Blip | 325 | 0.028 | 416 | 0.071 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rudakemwa, H.; Kim, K.J.; Park, T.E.; Son, H.; Na, J.; Kwon, S.J. Observation and Analysis of Staircase Response of Single Palladium Nanoparticle Collision on Gold Ultramicroelectrodes. Nanomaterials 2022, 12, 3095. https://doi.org/10.3390/nano12183095

Rudakemwa H, Kim KJ, Park TE, Son H, Na J, Kwon SJ. Observation and Analysis of Staircase Response of Single Palladium Nanoparticle Collision on Gold Ultramicroelectrodes. Nanomaterials. 2022; 12(18):3095. https://doi.org/10.3390/nano12183095

Chicago/Turabian StyleRudakemwa, Hubert, Ki Jun Kim, Tae Eun Park, Hyeryeon Son, Jaedo Na, and Seong Jung Kwon. 2022. "Observation and Analysis of Staircase Response of Single Palladium Nanoparticle Collision on Gold Ultramicroelectrodes" Nanomaterials 12, no. 18: 3095. https://doi.org/10.3390/nano12183095

APA StyleRudakemwa, H., Kim, K. J., Park, T. E., Son, H., Na, J., & Kwon, S. J. (2022). Observation and Analysis of Staircase Response of Single Palladium Nanoparticle Collision on Gold Ultramicroelectrodes. Nanomaterials, 12(18), 3095. https://doi.org/10.3390/nano12183095

_Hui.png)