Microstructure and Mechanical Properties of Unidirectional, Laminated Cf/SiC Composites with α-Al2O3 Nanoparticles as Filler

Abstract

:1. Introduction

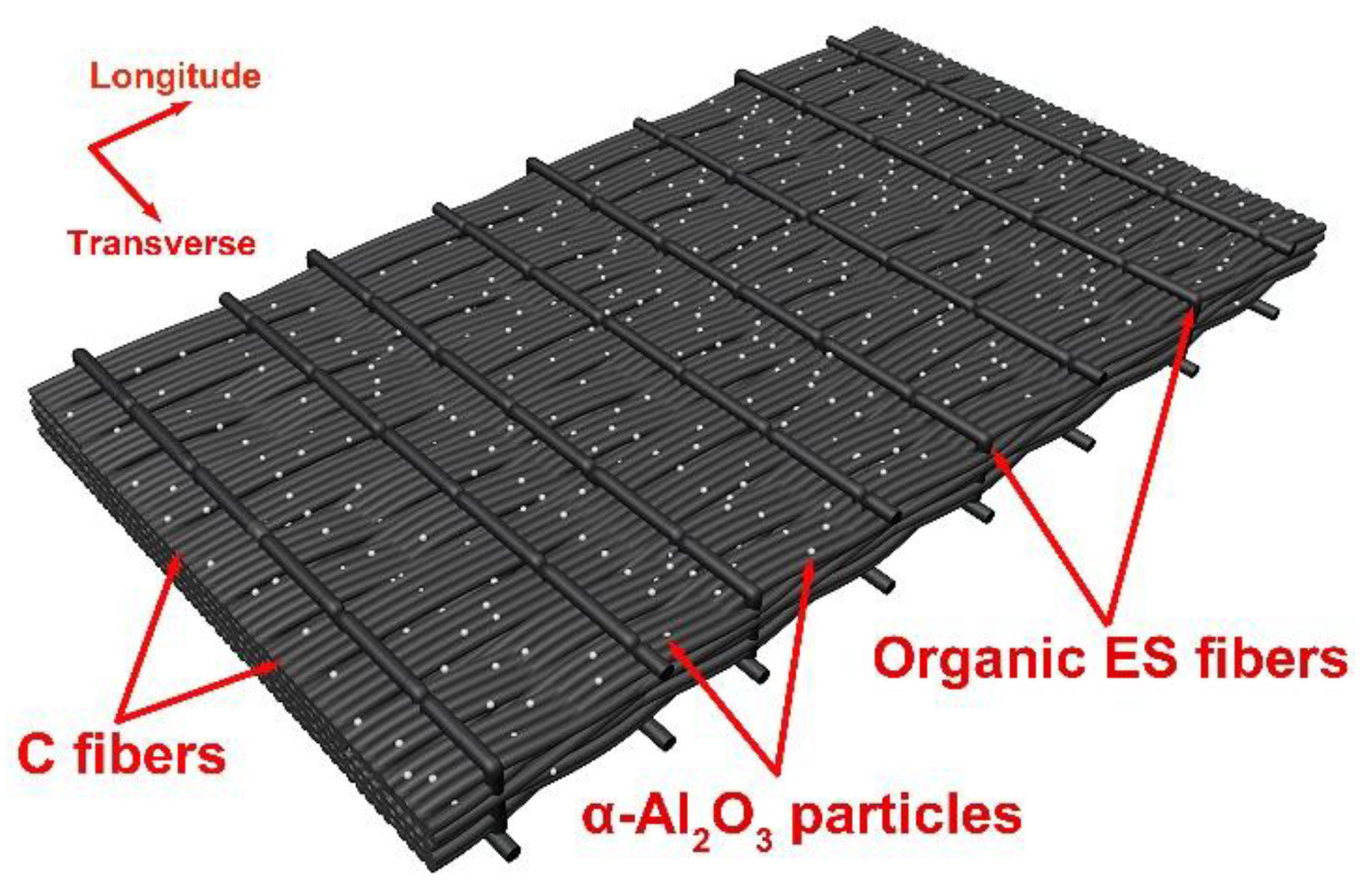

2. Materials and Methods

2.1. Preparation of Materials

2.2. Phase and Microstructure Characterization

2.3. Mechanical Property Tests

2.4. Residual Stress Measurement Using Photoluminescence Piezospectroscopy

2.5. Young’s Modulus and Hardness of the Matrix Using Nano-Indentation

3. Results

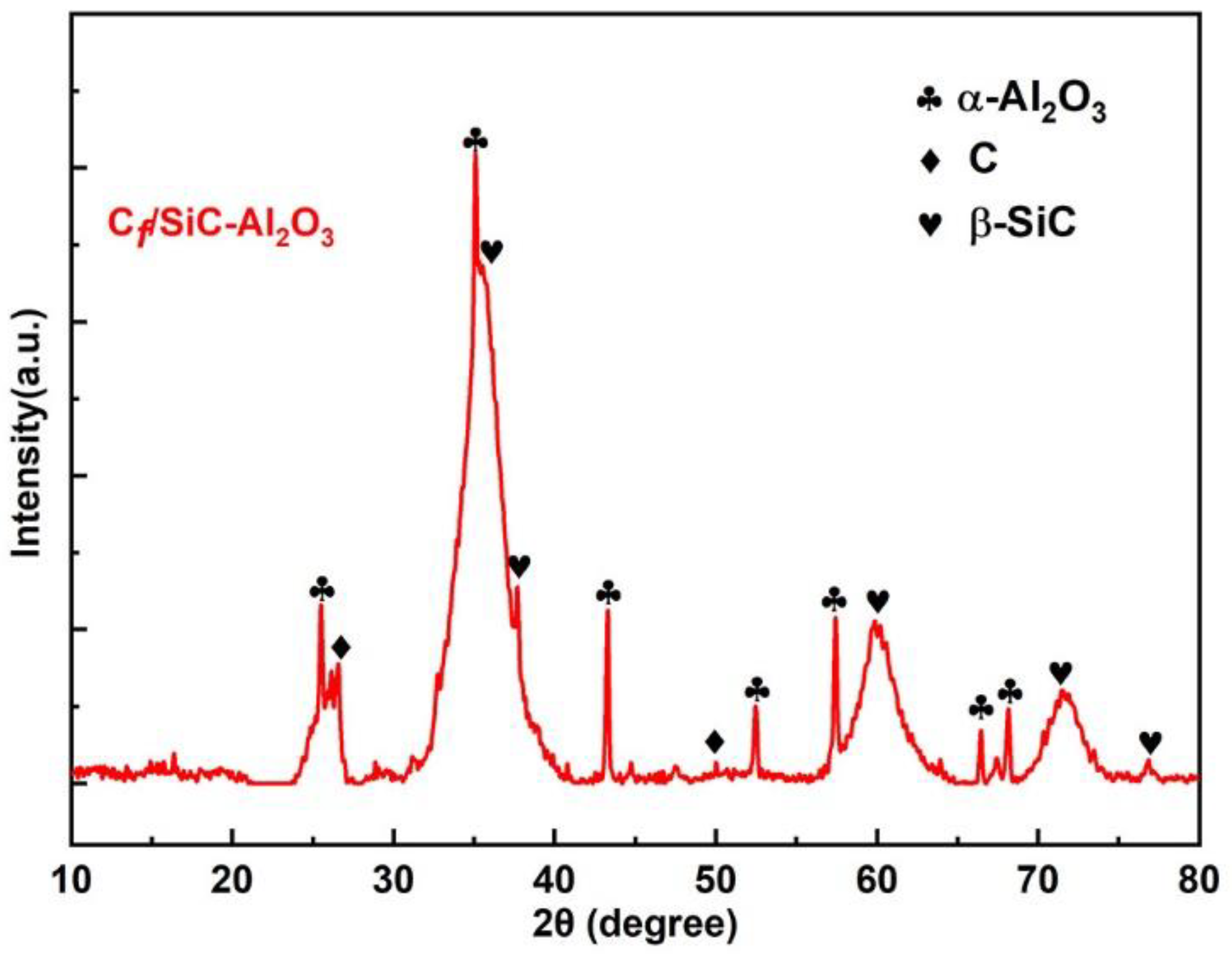

3.1. Phase Characterization of the Matrix

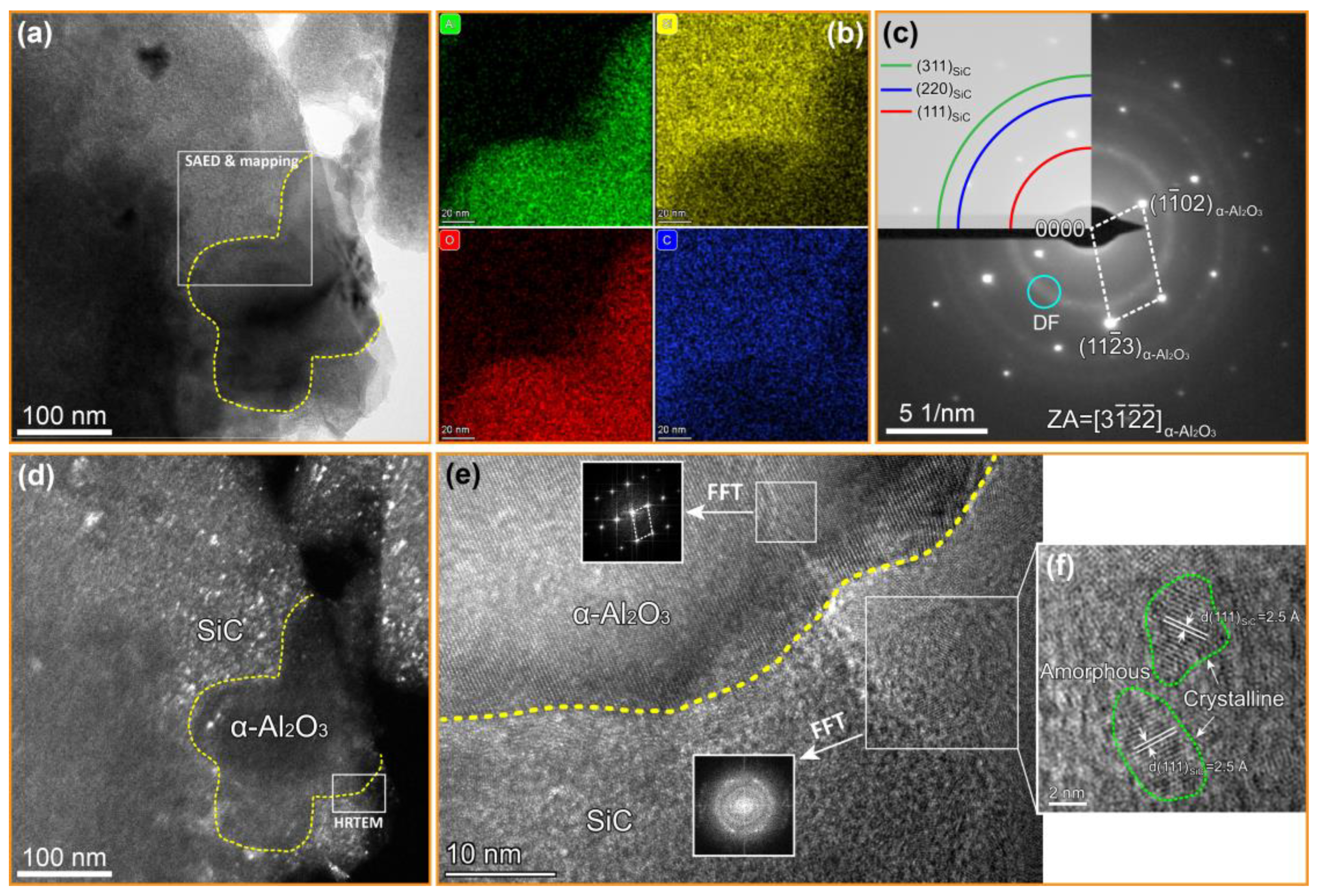

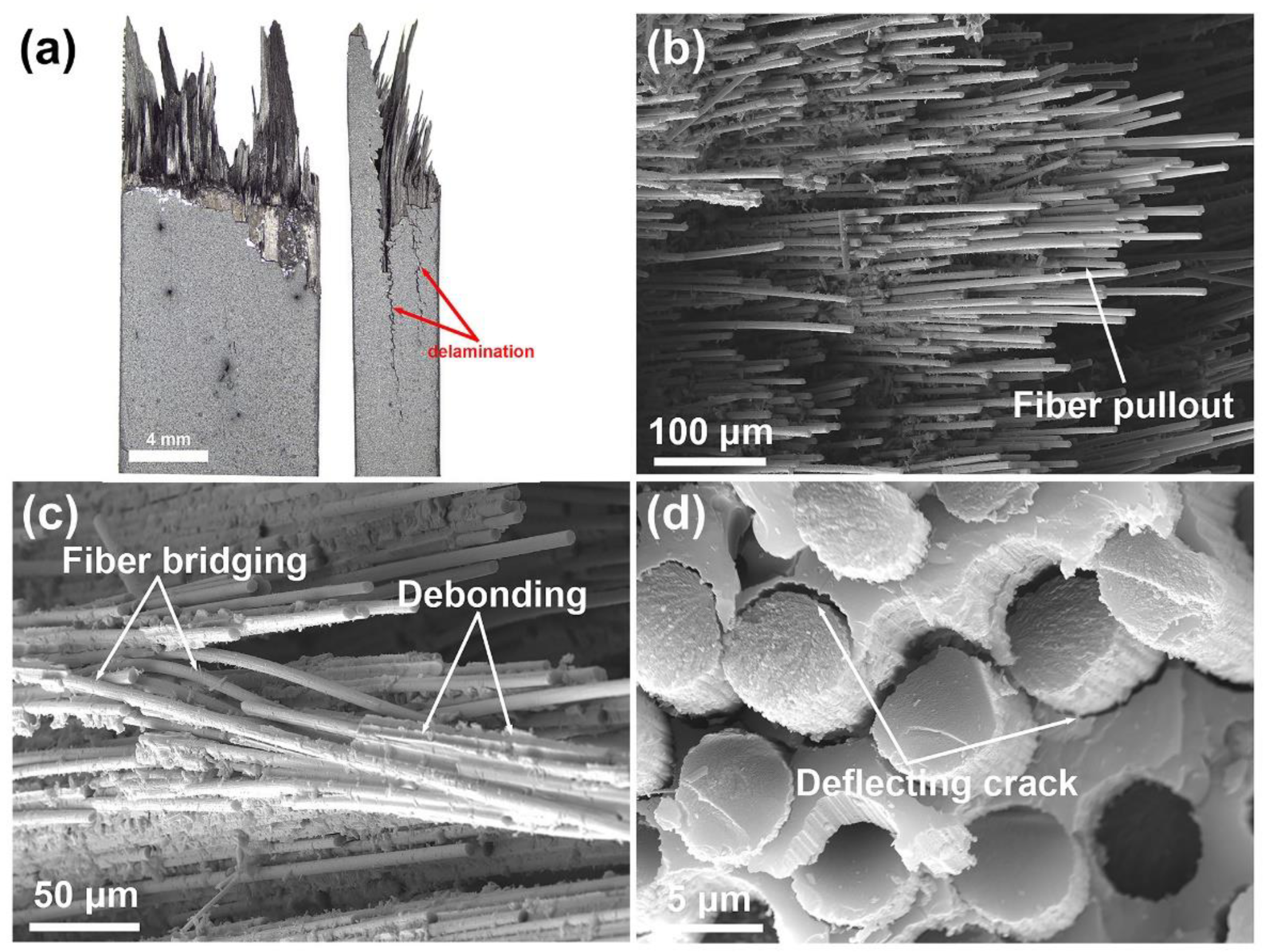

3.2. Microstructure Characterization

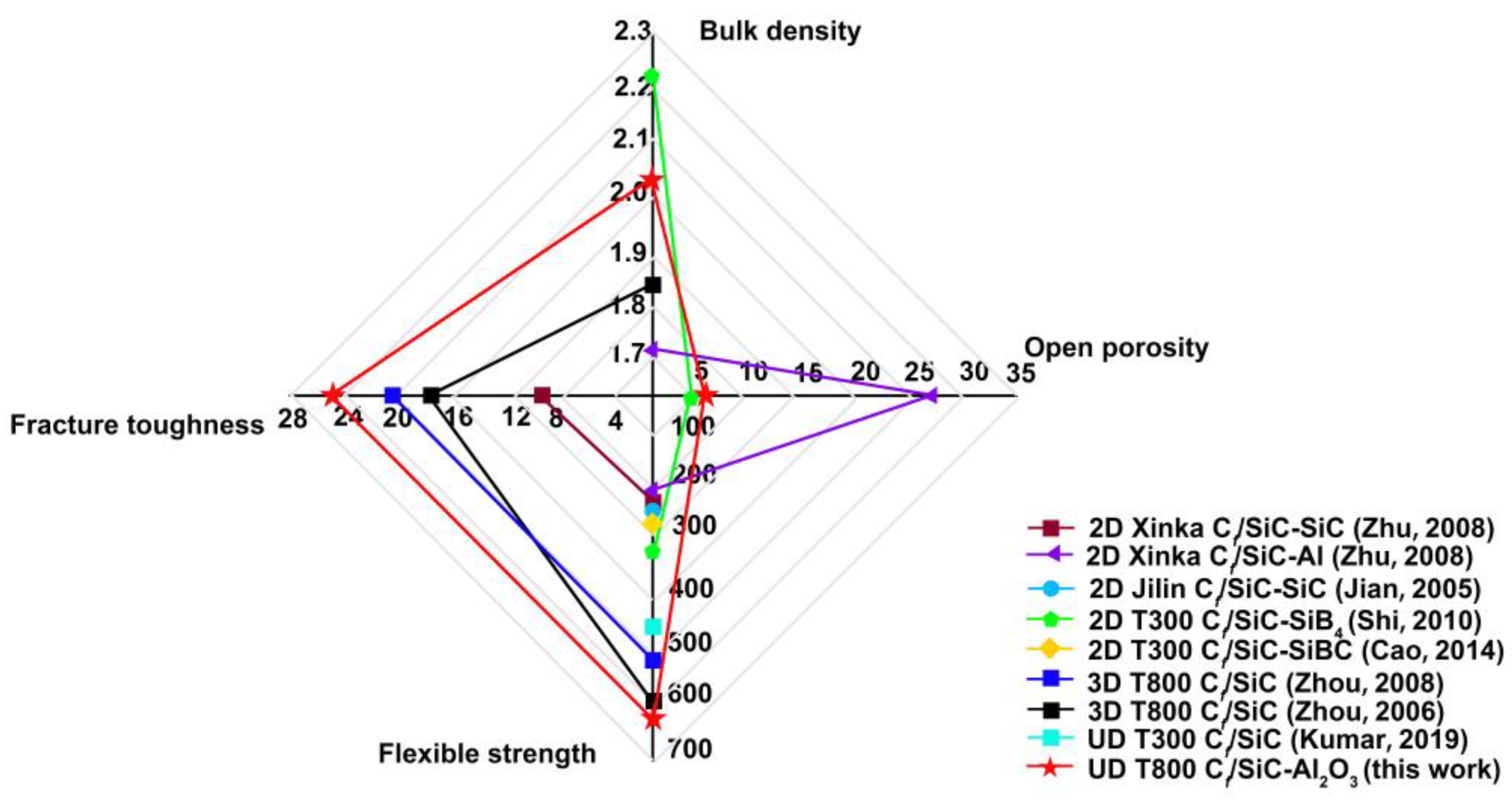

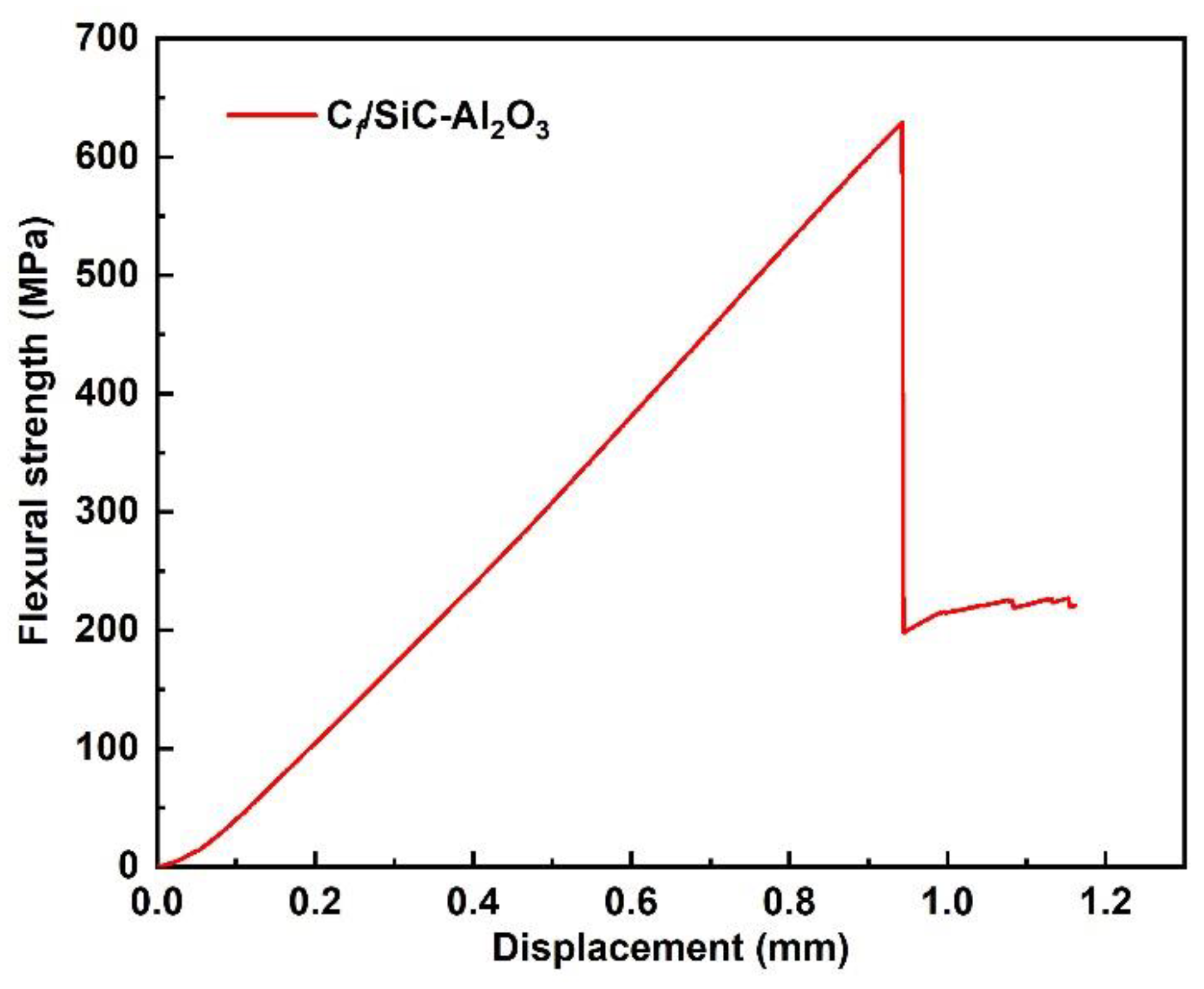

3.3. General Properties and Mechanical Properties

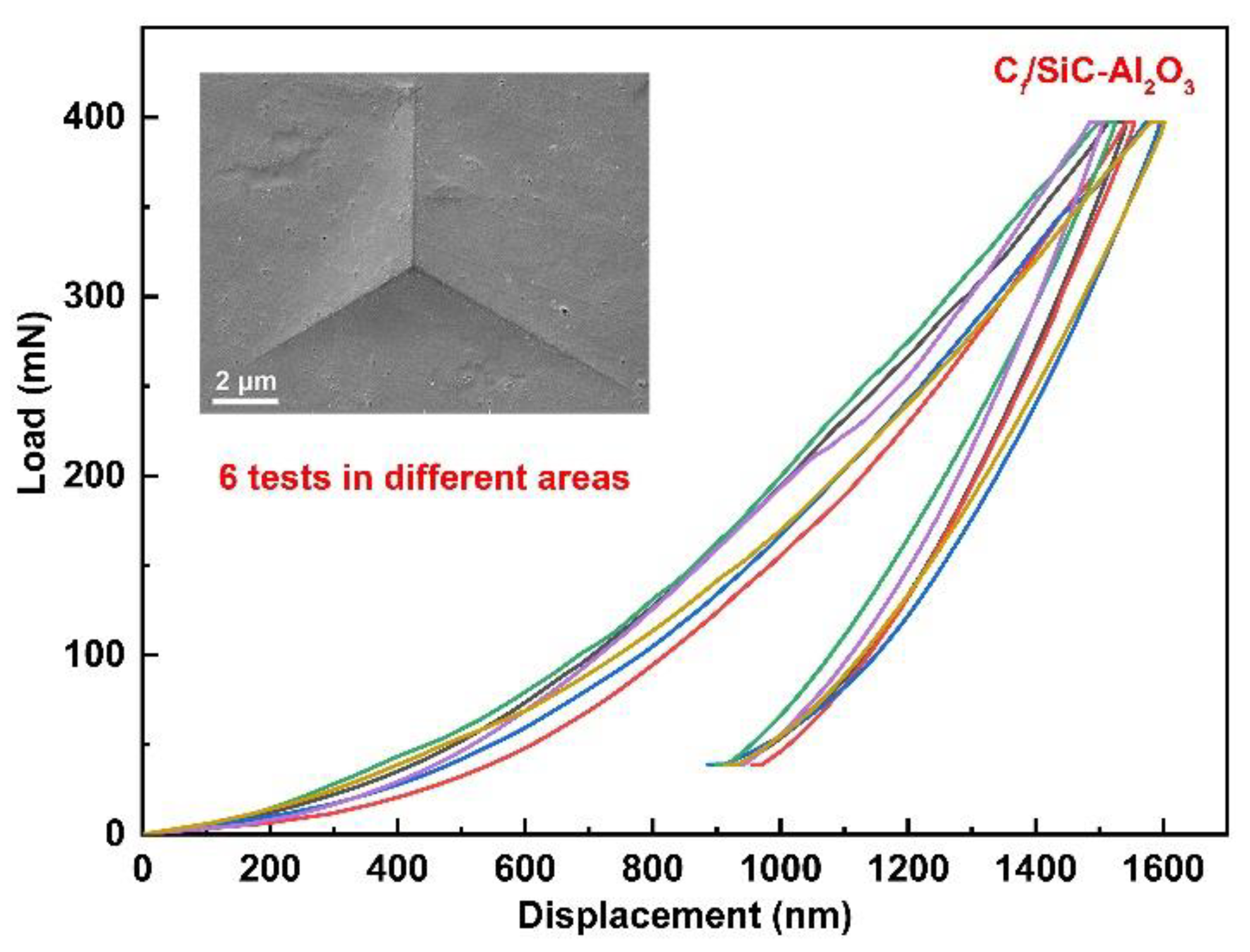

3.4. Young’s Modulus and Hardness of the Matrix

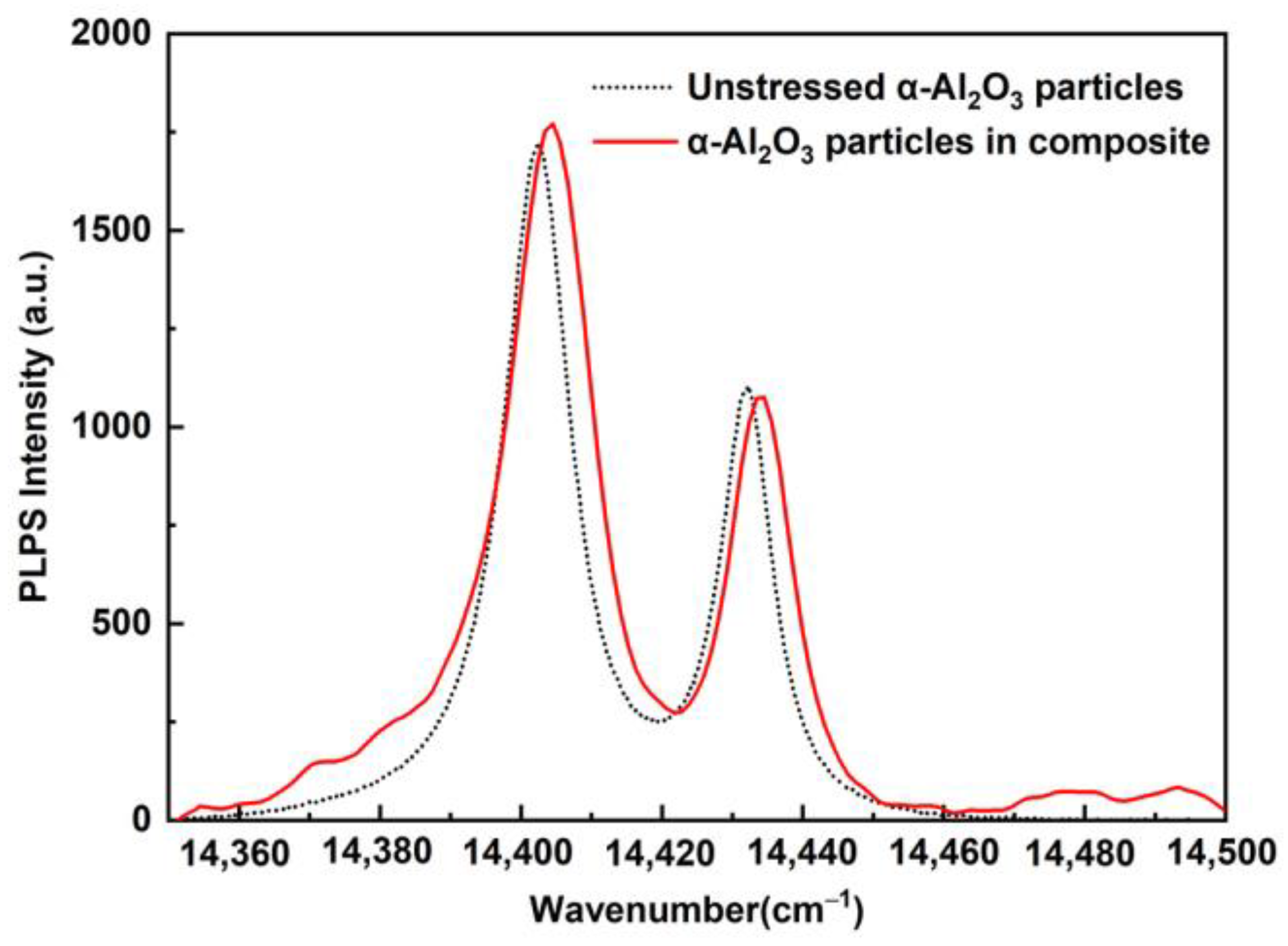

4. Discussion

5. Conclusions

- (1)

- The Cf/SiC-Al2O3 composite had a good flexural strength of 629.3 MPa and fracture toughness of 25.2 MPa·m1/2 and exhibited a nonbrittle failure behavior. The interlaminar shear strength of the Cf/SiC-Al2O3 composite was 11.7 MPa. The SiC-Al2O3 matrix also had a considerable Young’s modulus of 138.2 ± 8.66 GPa and hardness of 10.3 ± 1.03 GPa.

- (2)

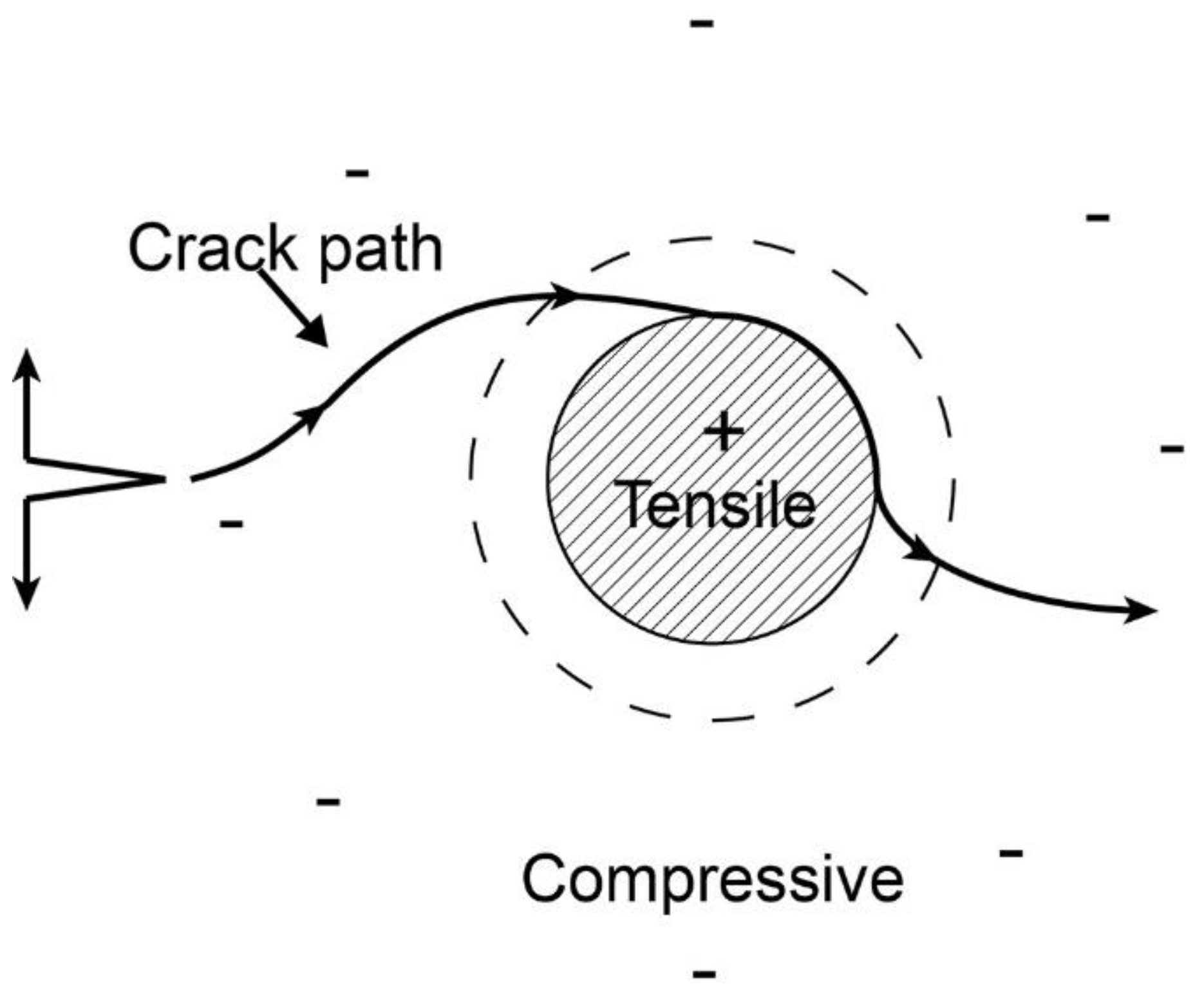

- The good mechanical properties of the Cf/SiC-Al2O3 composites are related to its lower porosity (~6.67%), the good mechanical properties of the SiC-Al2O3 matrix and the thermal residual compressive stress in the matrix which can deflect or close cracks to improve the toughness and strength of the composite.

- (3)

- The Cf/SiC-Al2O3 composite showed excellent mechanical properties (flexural strength and fracture toughness) compared with conventional Cf/SiC composites in previous works. This means the Cf/SiC-Al2O3 composite could be used as an ideal high temperature structural material for advanced engines, gas turbines, spacecraft thermal protection systems, scramjets and ramjet components.

- (4)

- Future work should be focused on the comparison of the mechanical and oxidation resistance properties of Cf/SiC composites with and without Al2O3. In addition, the relationship between the mechanical properties and the volume fraction of the Al2O3 filler should be comprehensively investigated.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Naslain, R. Design, preparation and properties of non-oxide CMCs for application in engines and nuclear reactors: An overview. Compos. Sci. Technol. 2004, 64, 155–170. [Google Scholar] [CrossRef]

- Christin, F. Design, fabrication, and application of thermostructural composites (TSC) like C/C, C/SiC, and SiC/SiC composites. Adv. Eng. Mater. 2002, 4, 903–912. [Google Scholar] [CrossRef]

- de Omena Pina, S.R.; Pardini, L.C.; Yoshida, I.V.P. Carbon fiber/ceramic matrix composites: Processing, oxidation and mechanical properties. J. Mater. Sci. 2007, 42, 4245–4253. [Google Scholar] [CrossRef]

- Donald, I.; McMillan, P. Ceramic-matrix composites. J. Mater. Sci. 1976, 11, 949–972. [Google Scholar] [CrossRef]

- Ahmad, I.; Islam, M.; Subhani, T.; Zhu, Y. Toughness enhancement in graphene nanoplatelet/SiC reinforced Al2O3 ceramic hybrid nanocomposites. Nanotechnology 2016, 27, 425704. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Huang, Z.; Dong, S.; Yuan, M.; Jiang, D. Manufacturing 2D carbon-fiber-reinforced SiC matrix composites by slurry infiltration and PIP process. Ceram. Int. 2008, 34, 1201–1205. [Google Scholar] [CrossRef]

- Zhu, Y.; Huang, Z.; Dong, S.; Yuan, M.; Jiang, D. The fabrication of 2D Cf/SiC composite by a modified PIP process using active Al powders as active filler. Mater. Charact. 2008, 59, 975–978. [Google Scholar] [CrossRef]

- Jian, K.; Chen, Z.-H.; Ma, Q.-S.; Hu, H.-F.; Zheng, W.-W. Processing and properties of 2D-Cf/SiC composites incorporating SiC fillers. Mater. Sci. Eng. A 2005, 408, 330–335. [Google Scholar] [CrossRef]

- Shi, F.; Yin, X.; Fan, X.; Cheng, L.; Zhang, L. A new route to fabricate SiB4 modified C/SiC composites. J. Eur. Ceram. Soc. 2010, 30, 1955–1962. [Google Scholar] [CrossRef]

- Cao, X.; Yin, X.; Fan, X.; Zhao, K.; Luo, H.; Cheng, L.; Zhang, L. High-temperature flexural properties of SiBC modified C/SiC composites. Ceram. Int. 2014, 40, 6185–6190. [Google Scholar] [CrossRef]

- Zhou, X.G.; Yu, H.J.; Huang, B.Y.; Yang, J.G.; Huang, Z.L. Effect of Silicon Carbide Interlayers on the Mechanical Behavior of T800-HB-Fiber-Reinforced Silicon Carbide-Matrix Composites. Key Eng. Mater. 2008, 368, 1844–1846. [Google Scholar]

- Xingui, Z.; Yu, Y.; Changrui, Z.; Boyun, H.; Xueye, L. Effect of carbon fiber pre-heat-treatment on the microstructure and properties of Cf/SiC composites. Mater. Sci. Eng. A 2006, 433, 104–107. [Google Scholar] [CrossRef]

- Kumar, S.; Mishra, R.; Ranjan, A.; Manocha, L.; Prasad, N.E. Synthesis of Polycarbosilane, Polymer Impregnation Pyrolysis-based C/SiC Composites and Prototype Development. Def. Sci. J. 2019, 69, 599–606. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, W.; Cheng, L.; Zhang, L. Preparation and properties of 2D C/ZrB2-SiC ultra high temperature ceramic composites. Mater. Sci. Eng. A 2009, 524, 129–133. [Google Scholar] [CrossRef]

- Li, L.; Wang, Y.; Cheng, L.; Zhang, L. Preparation and properties of 2D C/SiC–ZrB2–TaC composites. Ceram. Int. 2011, 37, 891–896. [Google Scholar] [CrossRef]

- Pi, H.; Fan, S.; Wang, Y. C/SiC–ZrB2–ZrC composites fabricated by reactive melt infiltration with ZrSi2 alloy. Ceram. Int. 2012, 38, 6541–6548. [Google Scholar] [CrossRef]

- Galizia, P.; Sciti, D.; Jain, N. Insight into microstructure and flexural strength of ultra-high temperature ceramics enriched SICARBON™ composite. Mater. Des. 2021, 208, 109888. [Google Scholar] [CrossRef]

- Jian, K.; Chen, Z.-H.; Ma, Q.-S.; Zheng, W.-W. Effects of pyrolysis processes on the microstructures and mechanical properties of Cf/SiC composites using polycarbosilane. Mater. Sci. Eng. A 2005, 390, 154–158. [Google Scholar] [CrossRef]

- Unlu, M.D.; Goller, G.; Yucel, O.; Sahin, F.C. The spark plasma sintering of silicon carbide ceramics using alumina. Acta Phys. Pol. A 2014, 125, 257–259. [Google Scholar] [CrossRef]

- Gomez, E.; Echeberria, J.; Iturriza, I.; Castro, F. Liquid phase sintering of SiC with additions of Y2O3, Al2O3 and SiO2. J. Eur. Ceram. Soc. 2004, 24, 2895–2903. [Google Scholar] [CrossRef]

- Heuer, A. Oxygen and aluminum diffusion in α-Al2O3: How much do we really understand? J. Eur. Ceram. Soc. 2008, 28, 1495–1507. [Google Scholar] [CrossRef]

- Luo, L.R.; Zou, Z.H.; Shan, X.; Cai, H.Y.; Yang, L.X.; Jin, H.Y.; Zhao, X.F. Introducing segmentation cracks in air plasma-sprayed thermal barrier coatings by controlling residual stress. J. Am. Ceram. Soc. 2021, 105, 1286–1299. [Google Scholar] [CrossRef]

- Jang, B.K. Microstructure of nano SiC dispersed Al2O3-ZrO2 composites. Mater. Chem. Phys. 2005, 93, 337–341. [Google Scholar] [CrossRef]

- Li, X.; Fan, X.; Ni, N.; Zhao, X.; Li, C.; Xiao, P. Continuous alumina fiber-reinforced yttria-stabilized zirconia composites with high density and toughness. J. Eur. Ceram. Soc. 2020, 40, 1539–1548. [Google Scholar] [CrossRef]

- Yang, L.; Zhong, B.; Liao, J.; Ouyang, P.; Chen, Z.; Wang, F.; Luo, L.; Kou, Z. Mechanical properties of unidirectional laminated hybrid SiC–Nextel™ 720 fiber-reinforced oxide matrix composites fabricated by a novel precursor infiltration and pyrolysis method. Mater. Sci. Eng. A 2022, 832, 142375. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Z.; Yang, L.; Liao, J.; Guan, T.; Xiao, Q. Mechanical properties and failure mechanism of 3D needle-punched Cf/SiC–Al composites. Ceram. Int. 2021, 47, 33509–33514. [Google Scholar] [CrossRef]

- Liu, H.; Cheng, H.; Wang, J.; Tang, G. Effects of the single layer CVD SiC interphases on the mechanical properties of the SiCf/SiC composites fabricated by PIP process. Ceram. Int. 2010, 36, 2033–2037. [Google Scholar] [CrossRef]

- Hao, J.; Li, J.; Shi, W.; Wang, B.; Tan, Y. The novel effect mechanism of Al2O3 nano-powder in the pack cementation process to prepare SiC coating on C/C composites. J. Eur. Ceram. Soc. 2021, 41, 1107–1113. [Google Scholar] [CrossRef]

- Hall, C.; Hamilton, A. Porosity–density relations in stone and brick materials. Mater. Struct. 2015, 48, 1265–1271. [Google Scholar] [CrossRef]

- Liu, H.; Ma, Q.; Liu, W. Mechanical and oxidation resistance properties of 3D carbon fiber-reinforced mullite matrix composites prepared by sol–gel process. Ceram. Int. 2014, 40, 7203–7212. [Google Scholar] [CrossRef]

- He, J.; Beyerlein, I.J.; Clarke, D.R. Load transfer from broken fibers in continuous fiber Al2O3-Al composites and dependence on local volume fraction. J. Mech. Phys. Solids 1999, 47, 465–502. [Google Scholar] [CrossRef]

- Thimmappa, S.K.; Golla, B.R.; Pitchuka, S.B. Nanoindentation and high temperature oxidation behavior of ZrB2–20SiC-(0–10 wt.%) ta UHTCs. Ceram. Int. 2021, 47, 22184–22190. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Van Landingham, M.R. Review of instrumented indentation. J. Res. Natl. Inst. Stand. Technol. 2003, 108, 249. [Google Scholar] [CrossRef] [PubMed]

- Hardiman, M.; Vaughan, T.J.; McCarthy, C.T. A review of key developments and pertinent issues in nanoindentation testing of fibre reinforced plastic microstructures. Compos. Struct. 2017, 180, 782–798. [Google Scholar] [CrossRef]

- Cho, K.-S.; Kim, Y.-W.; Choi, H.-J.; Lee, J.-G. SiC-TiC and SiC-TiB2 composites densified by liquid-phase sintering. J. Mater. Sci. 1996, 31, 6223–6228. [Google Scholar] [CrossRef]

- Sudre, O.; Lange, F.F. Effect of inclusions on densification: I, microstructural development in an Al2O3 matrix containing a high volume fraction of ZrO2 inclusions. J. Am. Ceram. Soc. 1992, 75, 519–524. [Google Scholar] [CrossRef]

- Zok, F.; Lange, F.F.; Porter, J.R. Packing density of composite powder mixtures. J. Am. Ceram. Soc. 1991, 74, 1880–1885. [Google Scholar] [CrossRef]

- Liao, J.; Chen, Z.; Li, B.; Liu, J.; Guan, T.; Yu, S.; Tang, K.; Wu, Q.; Wang, Y. Microstructure and mechanical properties of Cf/SiC–Al composites fabricated by PIP and vacuum pressure infiltration processes. J. Alloys Compd. 2019, 803, 934–941. [Google Scholar] [CrossRef]

- Yan, C.; Liu, R.; Zhang, C.; Cao, Y. Ablation and mechanical properties of 3D braided C/ZrC–SiC composites with various SiC/ZrC ratios. Ceram. Int. 2016, 42, 19019–19026. [Google Scholar] [CrossRef]

- Yan, C.; Liu, R.; Cao, Y.; Zhang, C. Fabrication and properties of PIP 3D Cf/ZrC–SiC composites. Mater. Sci. Eng. A 2014, 591, 105–110. [Google Scholar] [CrossRef]

- Yang, B.; Zhou, X.; Yu, J. The properties of Cf/SiC composites prepared from different precursors. Ceram. Int. 2015, 41, 4207–4213. [Google Scholar] [CrossRef]

- Liang, J.; Xiao, H.; Gao, P.; Guo, W.; Liu, J. Microstructure and properties of 2D-Cf/SiC composite fabricated by combination of CVI and PIP process with SiC particle as inert fillers. Ceram. Int. 2017, 43, 1788–1794. [Google Scholar] [CrossRef]

- Luo, X.; He, J.; Liu, X.; Xu, Y.; Li, J.; Guo, X.; Wang, Q.; Li, L. Design, Fabrication, and Mechanical Properties of T-700TM Multiaxial-Warp-Knitting–Needled–C/SiC Composite and Pin. Materials 2022, 15, 2338. [Google Scholar] [CrossRef]

- Krenkel, W. Carbon fibre reinforced silicon carbide composites (C/SiC, C/C-SiC). In Handbook of Ceramic Composites; Springer: Berlin/Heidelberg, Germany, 2005; pp. 117–148. [Google Scholar]

- Tan, J.; Meadows, P.; Zhang, D.; Chen, X.; López-Honorato, E.; Zhao, X.; Yang, F.; Abram, T.; Xiao, P. Young’s modulus measurements of SiC coatings on spherical particles by using nanoindentation. J. Nucl. Mater. 2009, 393, 22–29. [Google Scholar] [CrossRef]

- Evans, A.; Zok, F.; Davis, J. The role of interfaces in fiber-reinforced brittle matrix composites. Compos. Sci. Technol. 1991, 42, 3–24. [Google Scholar] [CrossRef]

- Kushvaha, V.; Tippur, H. Effect of filler shape, volume fraction and loading rate on dynamic fracture behavior of glass-filled epoxy. Compos. Part B Eng. 2014, 64, 126–137. [Google Scholar] [CrossRef]

- Sharma, A.; Kumar, S.A.; Kushvaha, V. Effect of aspect ratio on dynamic fracture toughness of particulate polymer composite using artificial neural network. Eng. Fract. Mech. 2020, 228, 106907. [Google Scholar] [CrossRef]

- Fu, S.-Y.; Feng, X.-Q.; Lauke, B.; Mai, Y.-W. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate–polymer composites. Compos. Part B Eng. 2008, 39, 933–961. [Google Scholar] [CrossRef]

- Asl, M.S.; Nayebi, B.; Motallebzadeh, A.; Shokouhimehr, M. Nanoindentation and nanostructural characterization of ZrB2–SiC composite doped with graphite nano-flakes. Compos. Part B Eng. 2019, 175, 107153. [Google Scholar]

- Clark, M.D.; Walker, L.S.; Hadjiev, V.G.; Khabashesku, V.; Corral, E.L.; Krishnamoorti, R. Polymer Precursor-Based Preparation of Carbon Nanotube-Silicon Carbide Nanocomposites. J. Am. Ceram. Soc. 2012, 95, 328–337. [Google Scholar] [CrossRef]

- An, L.; Xu, W.; Rajagopalan, S.; Wang, C.; Wang, H.; Fan, Y.; Zhang, L.; Jiang, D.; Kapat, J.; Chow, L. Carbon-Nanotube-Reinforced Polymer-Derived Ceramic Composites. Adv. Mater. 2004, 16, 2036–2040. [Google Scholar] [CrossRef]

- Zhao, S.; Zhou, X.; Yu, J.; Mummery, P. Effect of heat treatment on microstructure and mechanical properties of PIP-SiC/SiC composites. Mater. Sci. Eng. A 2013, 559, 808–811. [Google Scholar] [CrossRef]

- Cui, Y.; Bai, R.C.; Li, A.; Ren, M.; Sun, J. Microstructure and Micromechanical Property of C/C-SiC Composites. Adv. Mater. Res. 2011, 16, 238–241. [Google Scholar]

- Sakai, T.; Watanabe, H.; Aikawa, T. Effects of carbon on phase transformation of β-SiC with Al2O3. J. Mater. Sci. Lett. 1987, 6, 865–866. [Google Scholar] [CrossRef]

- He, J.; Clarke, D.R. Determination of the Piezospectroscopic Coefficients for Chromium-Doped Sapphire. J. Am. Ceram. Soc. 1995, 78, 1347–1353. [Google Scholar] [CrossRef]

- Gupta, Y.M.; Shen, X.A. Potential use of the ruby R2 line shift for static high-pressure calibration. Appl. Phys. Lett. 1991, 58, 583–585. [Google Scholar] [CrossRef]

- Shetty, D.K. Shear-lag analysis of fiber push-out (indentation) tests for estimating interfacial friction stress in ceramic-matrix composites. J. Am. Ceram. Soc. 1988, 71, C107–C109. [Google Scholar] [CrossRef]

- Magdy, M.; Hu, Y.-B.; Zhao, J. A study of the morphological effect of an α-Al2O3 layer on the creep life for nickel-based superalloys using microstructure-based geometrical models. Vacuum 2022, 202, 111174. [Google Scholar] [CrossRef]

- Mei, H. Measurement and calculation of thermal residual stress in fiber reinforced ceramic matrix composites. Compos. Sci. Technol. 2008, 68, 3285–3292. [Google Scholar] [CrossRef]

- Bansal, N.P.; Lamon, J. Ceramic Matrix Composites: Materials, Modeling and Technology; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Xu, C. Effects of particle size and matrix grain size and volume fraction of particles on the toughening of ceramic composite by thermal residual stress. Ceram. Int. 2005, 31, 537–542. [Google Scholar] [CrossRef]

- Wei, G.; Becher, P. Improvements in mechanical properties in SiC by the addition of TiC particles. J. Am. Ceram. Soc. 1984, 67, 571–574. [Google Scholar] [CrossRef]

- Taya, M.; Hayashi, S.; Kobayashi, A.S.; Yoon, H. Toughening of a particulate-reinforced ceramic-matrix composite by thermal residual stress. J. Am. Ceram. Soc. 1990, 73, 1382–1391. [Google Scholar] [CrossRef]

- Fahmy, A.; Ragai, A. Thermal-expansion behavior of two-phase solids. J. Appl. Phys. 1970, 41, 5108–5111. [Google Scholar] [CrossRef]

- Ke, L.-L.; Yang, J.; Kitipornchai, S. Nonlinear free vibration of functionally graded carbon nanotube-reinforced composite beams. Compos. Struct. 2010, 92, 676–683. [Google Scholar] [CrossRef]

| Sample | Fiber Diameter (μm) | Density (g·cm−3) | Tensile Strength (GPa) | Elastic Modulus (GPa) | Elongation (%) |

|---|---|---|---|---|---|

| T800 carbon fibers | 5 | 1.81 | 5.5 | 294 | 1.9 |

| Trademark | Purity (%) | Density (g·cm−3) | Specific Surface Area (m2·g−1) | Average Particle Size (nm) | Crystal Structure |

|---|---|---|---|---|---|

| α-Al2O3-W01 | 99.9 | 3.9 | 45.45 | 30 | α-Al2O3 |

| Sample | Bulk Density (g·cm−3) | Open Porosity (%) | Flexible Strength (MPa) | Fracture Toughness (MPa·m1/2) | Interlaminar Shear Strength (MPa) |

|---|---|---|---|---|---|

| Cf/SiC-Al2O3 | 2.03 | 6.67 | 629.3 | 25.2 | 11.7 |

| Materials | Structure | Bulk Density (g·cm−3) | Open Porosity (%) | Flexible Strength (MPa) | Fracture Toughness (MPa·m1/2) | Reference |

|---|---|---|---|---|---|---|

| Xinka Cf/SiC-SiC | 2D | - | - | 232 | 10 | [6] |

| Xinka Cf/SiC-Al | 2D | 1.72 ± 0.03 | 27 | 211 ± 13 | - | [7] |

| Jilin Cf/SiC-SiC | 2D | - | - | 246.4 | - | [8] |

| T300 Cf/SiC-SiB4 | 2D | 2.23 | 6 | 330 | - | [9] |

| T300 Cf/SiC-SiBC | 2D | - | - | 276 | - | [10] |

| T800 Cf/SiC | 3D | - | - | 511.5 | 20.8 | [11] |

| T800 Cf/SiC | 3D | 1.86 | - | 600.8 | 18.5 | [12] |

| T300 Cf/SiC | UD | - | - | 400–450 | - | [13] |

| Property | Gasphase Infiltration (CVI) Process | Liquid Infiltration Process | Polymer Infiltration and Pyrolysis (PIP) | Polymer Infiltration and Pyrolysis (PIP) | ||||

|---|---|---|---|---|---|---|---|---|

| CVI (Isothermal) | CVI (p, T-Gradient) | Liquid Polymer Infiltration (LPI) | Infiltration (LSI) | |||||

| Cf/SiC | Cf/SiC | Cf/SiC | Cf/SiC | Cf/SiC | Cf/C-SiC | Cf/SiC | Cf/SiC-Al2O3 | |

| Interlaminar shear strength (MPa) | 26.1–46.8 | 35 | 45–48 | 10 | 35 | 28–33 | 10–12 | 11.7 |

| Porosity (%) | 10–15 | 10 | 10-15 | 10 | 15–20 | 2–5 | 10–25 | 6.67 |

| Density (g/cm3) | 2.0 | 2.1 | 2.1–2.2 | 1.8 | 1.7–1.8 | 1.9–2.0 | 1.6–1.8 | 2.03 |

| Fiber preform | MWK-N | (0°/90°) PW | (0°/90°) PW | (0°/90°) PW | (0°/90°) PW | (0°/90°) PW | UD | UD |

| Manufacturer | NWPU | SNECMA | MAN | Dornier | MAN | DLR | - | - |

| Reference | [44] | [44] | [44] | [44] | [44] | [44] | [45] | This work |

| Sample | Young’s Modulus (GPa) | Hardness (GPa) |

|---|---|---|

| Cf/SiC–Al2O3 | 138.2 ± 8.66 | 10.3 ± 1.03 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, L.; Wang, F.; Liao, J.; Chen, Z.; Kou, Z. Microstructure and Mechanical Properties of Unidirectional, Laminated Cf/SiC Composites with α-Al2O3 Nanoparticles as Filler. Nanomaterials 2022, 12, 3406. https://doi.org/10.3390/nano12193406

Yang L, Wang F, Liao J, Chen Z, Kou Z. Microstructure and Mechanical Properties of Unidirectional, Laminated Cf/SiC Composites with α-Al2O3 Nanoparticles as Filler. Nanomaterials. 2022; 12(19):3406. https://doi.org/10.3390/nano12193406

Chicago/Turabian StyleYang, Lixia, Fei Wang, Jiahao Liao, Zhaofeng Chen, and Zongde Kou. 2022. "Microstructure and Mechanical Properties of Unidirectional, Laminated Cf/SiC Composites with α-Al2O3 Nanoparticles as Filler" Nanomaterials 12, no. 19: 3406. https://doi.org/10.3390/nano12193406

APA StyleYang, L., Wang, F., Liao, J., Chen, Z., & Kou, Z. (2022). Microstructure and Mechanical Properties of Unidirectional, Laminated Cf/SiC Composites with α-Al2O3 Nanoparticles as Filler. Nanomaterials, 12(19), 3406. https://doi.org/10.3390/nano12193406