Effect of Graphene Sheets Embedded Carbon Films on the Fretting Wear Behaviors of Orthodontic Archwire–Bracket Contacts

Abstract

:1. Introduction

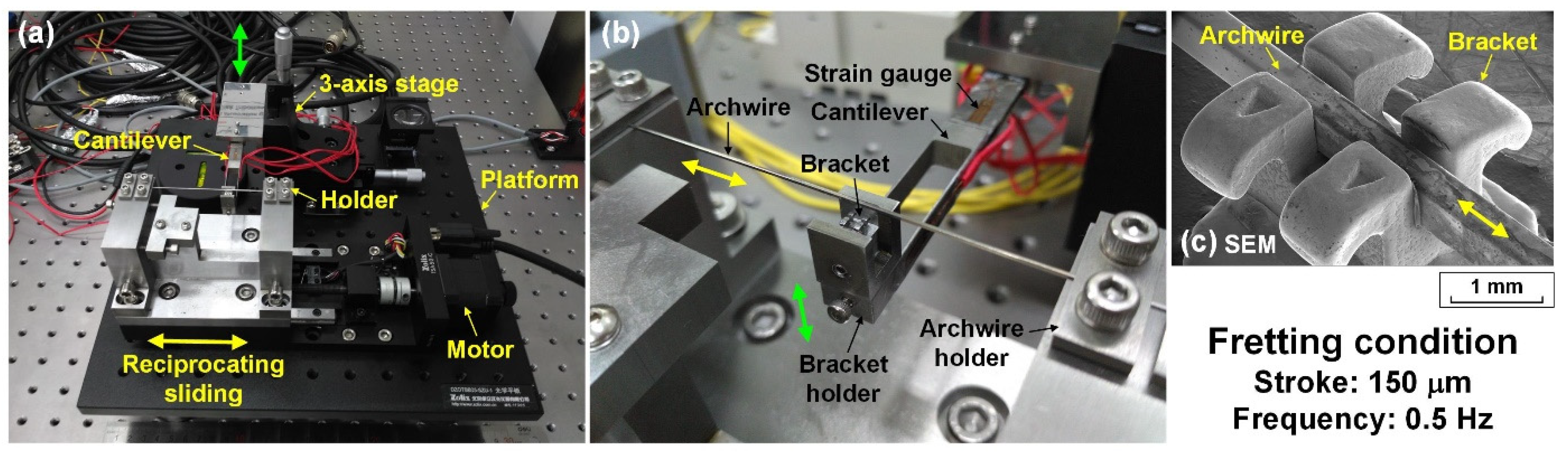

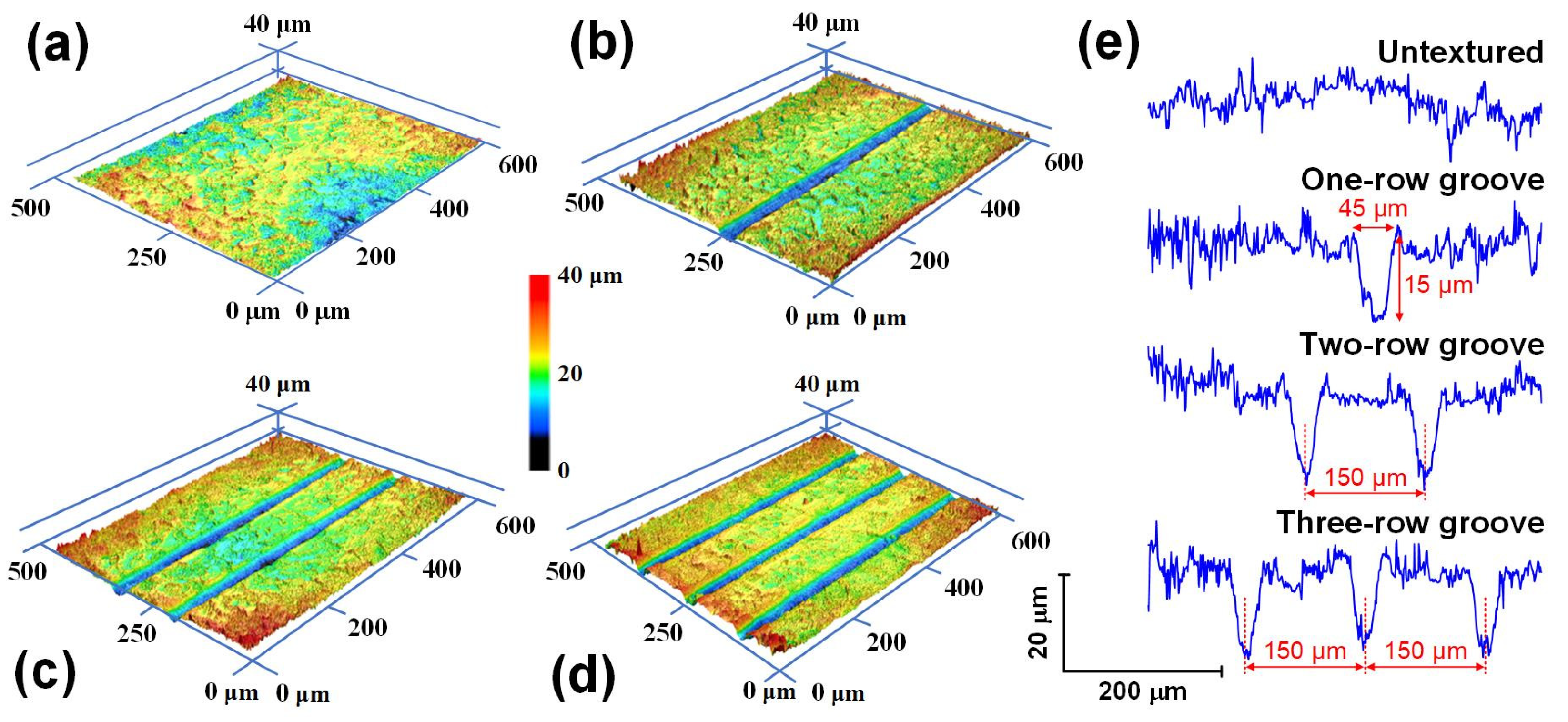

2. Materials and Methods

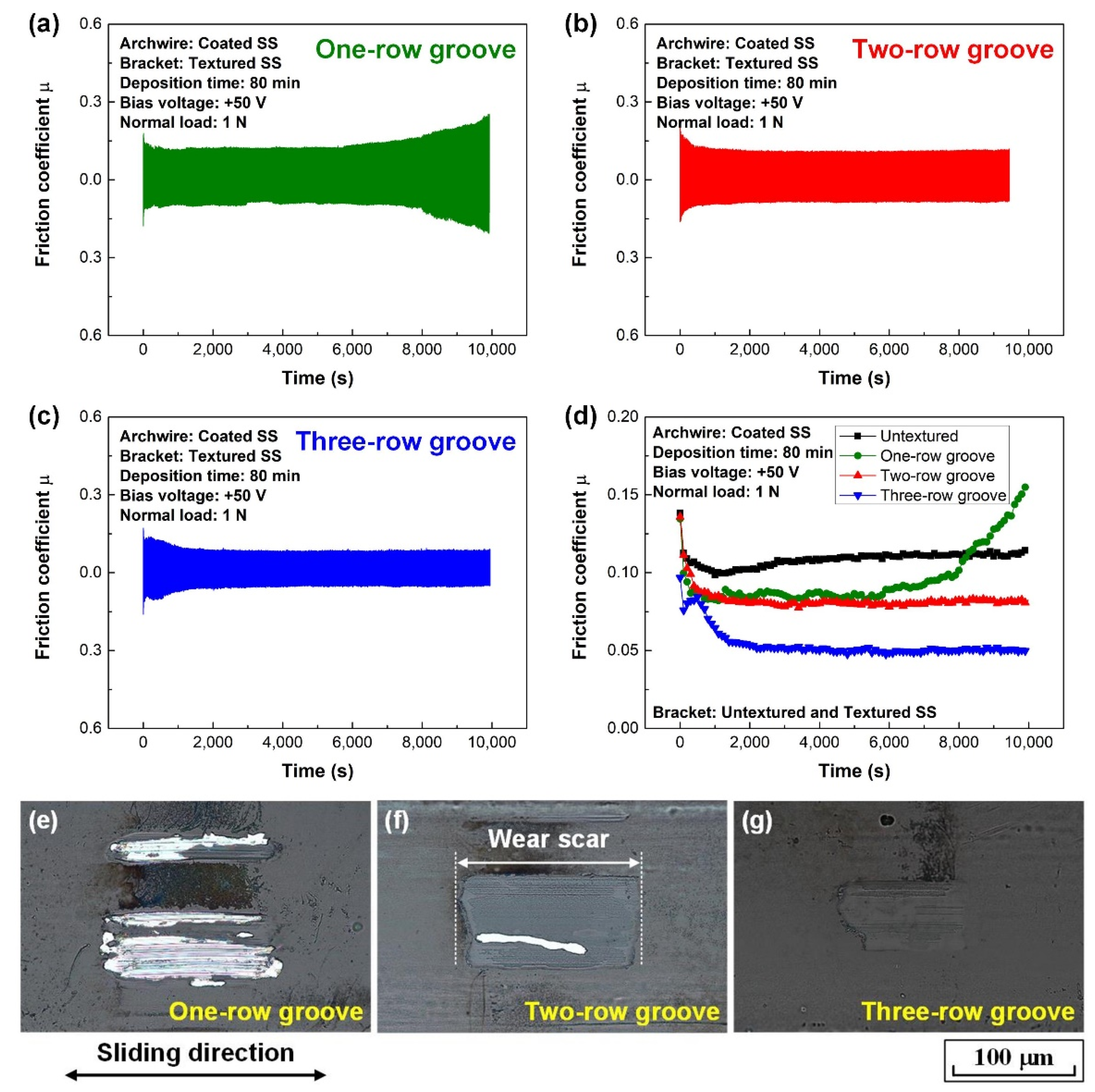

3. Results

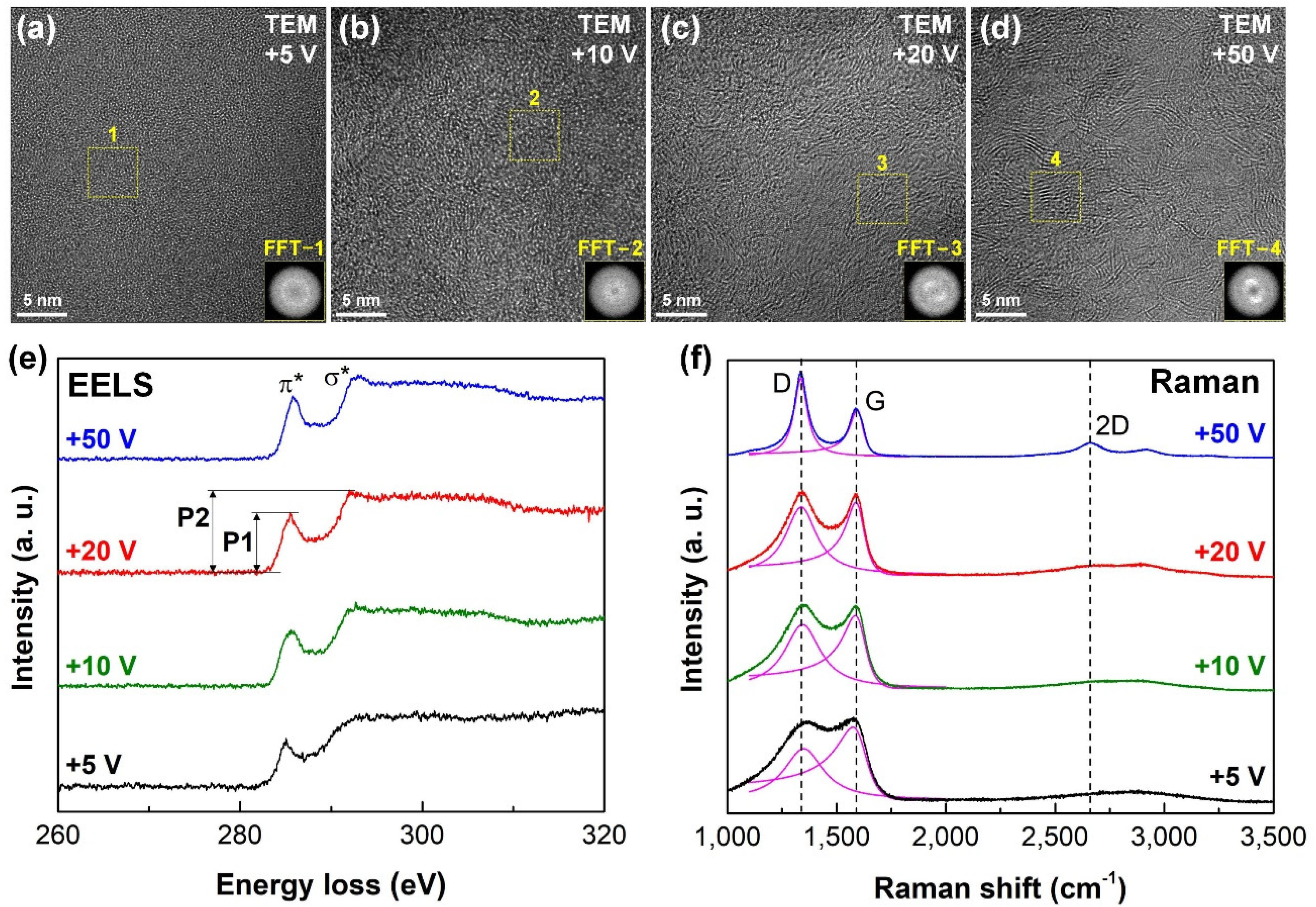

3.1. Compositon and Structure Analysis of Carbon Films

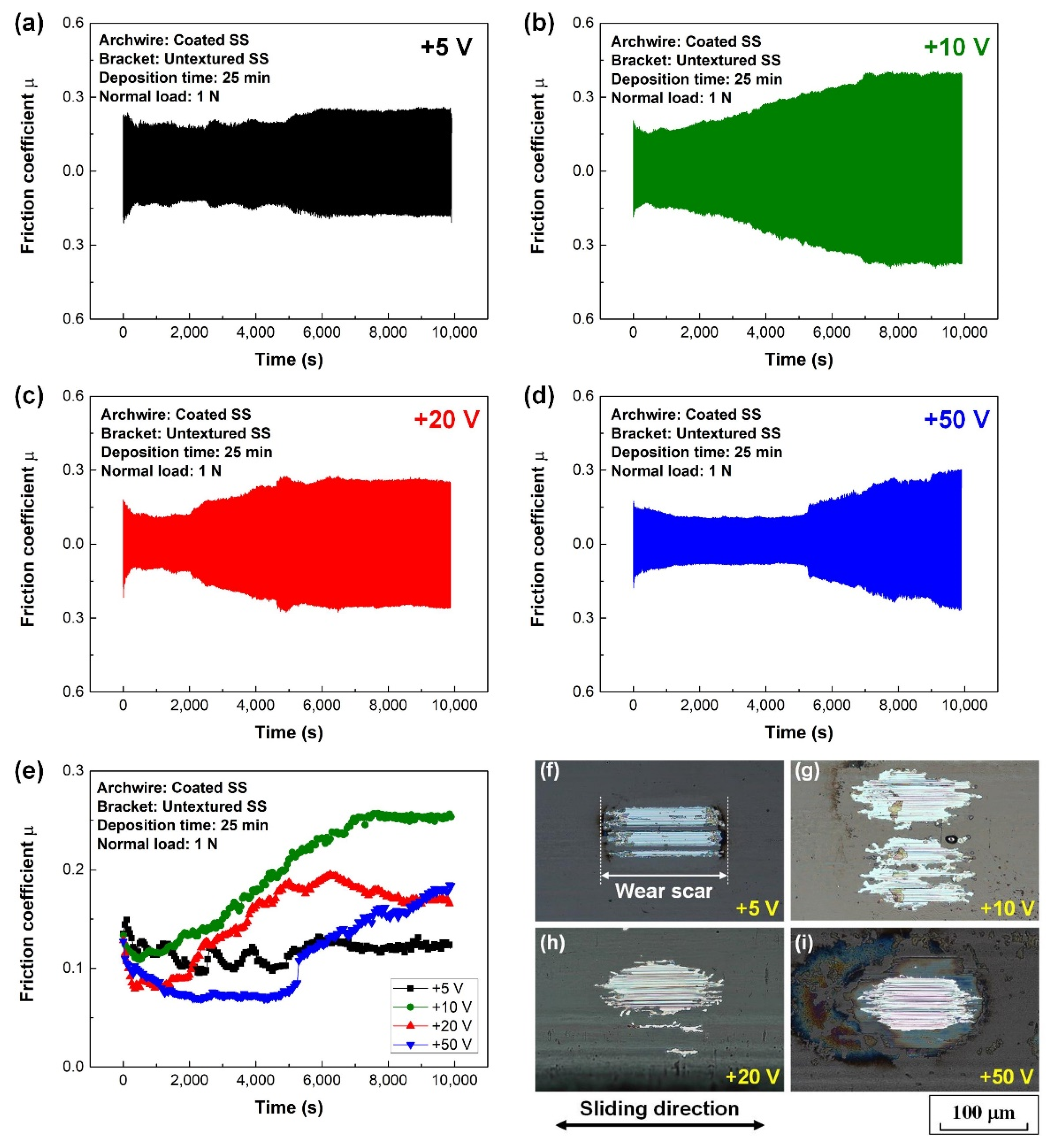

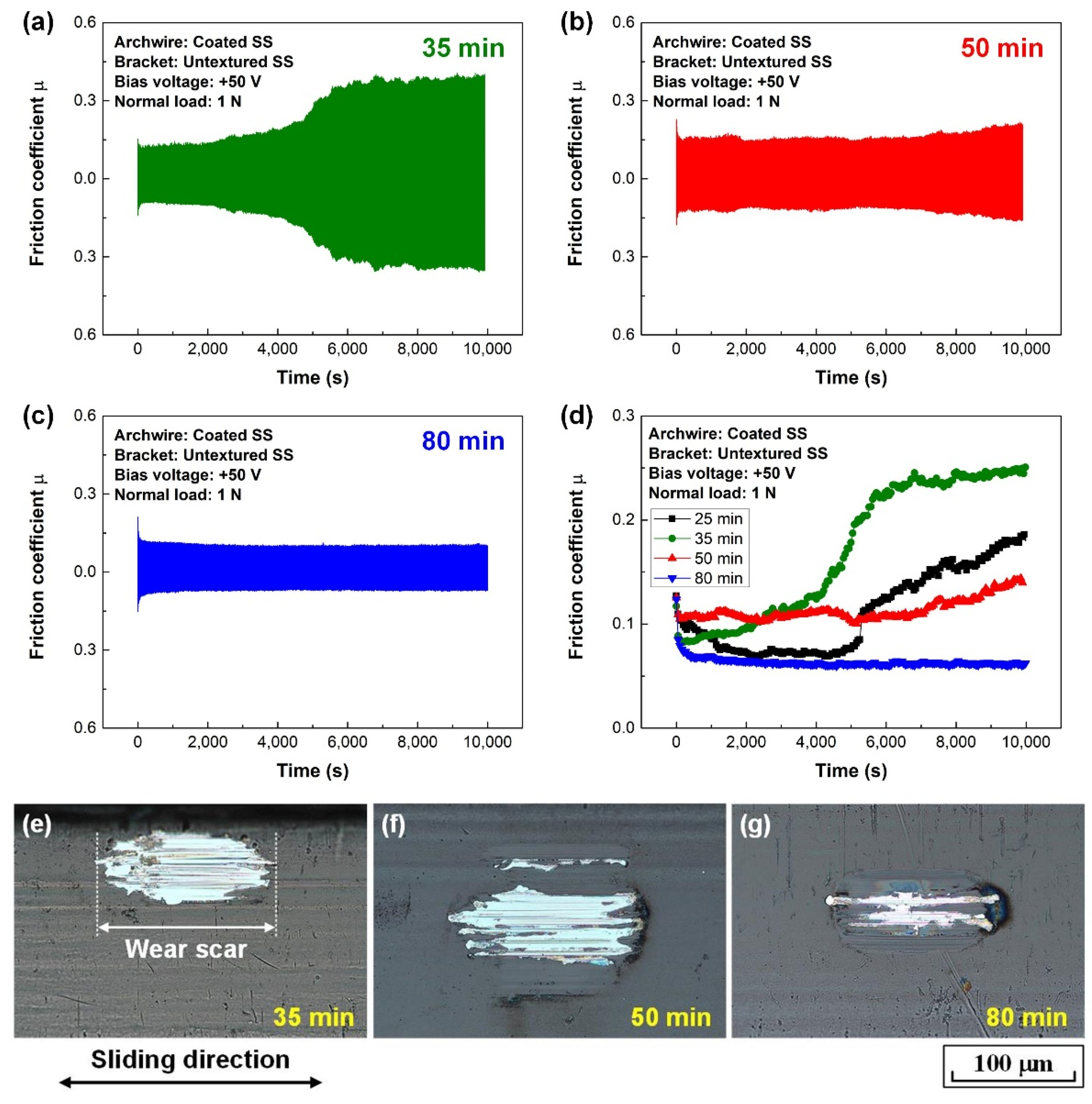

3.2. Fretting Wear Behaviors of Carbon Film-Coated Archwires

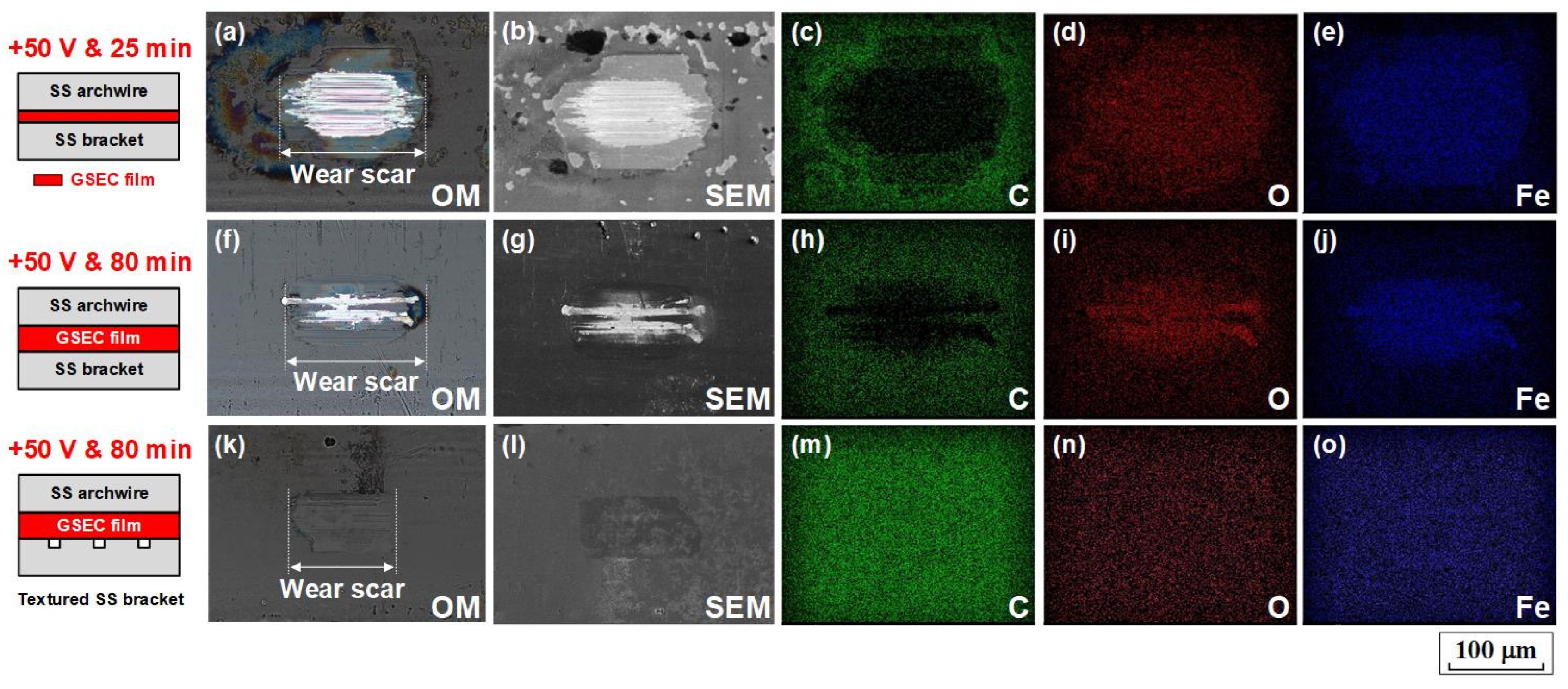

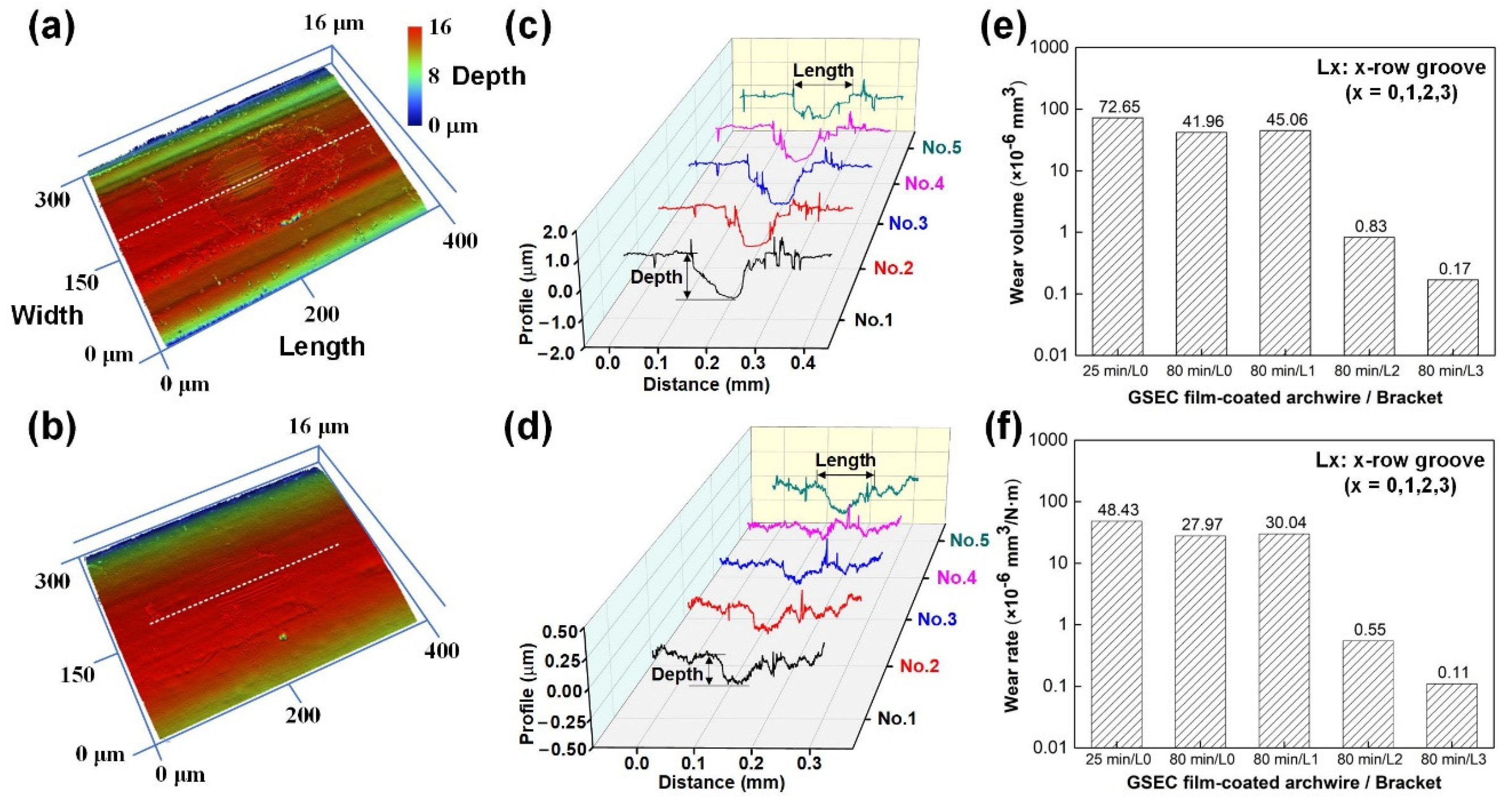

4. Discussion

4.1. SEM–EDX Mapping Analysis of the Wear Scars

4.2. Specific Wear Rate of the GSEC Film-Coated Archwires

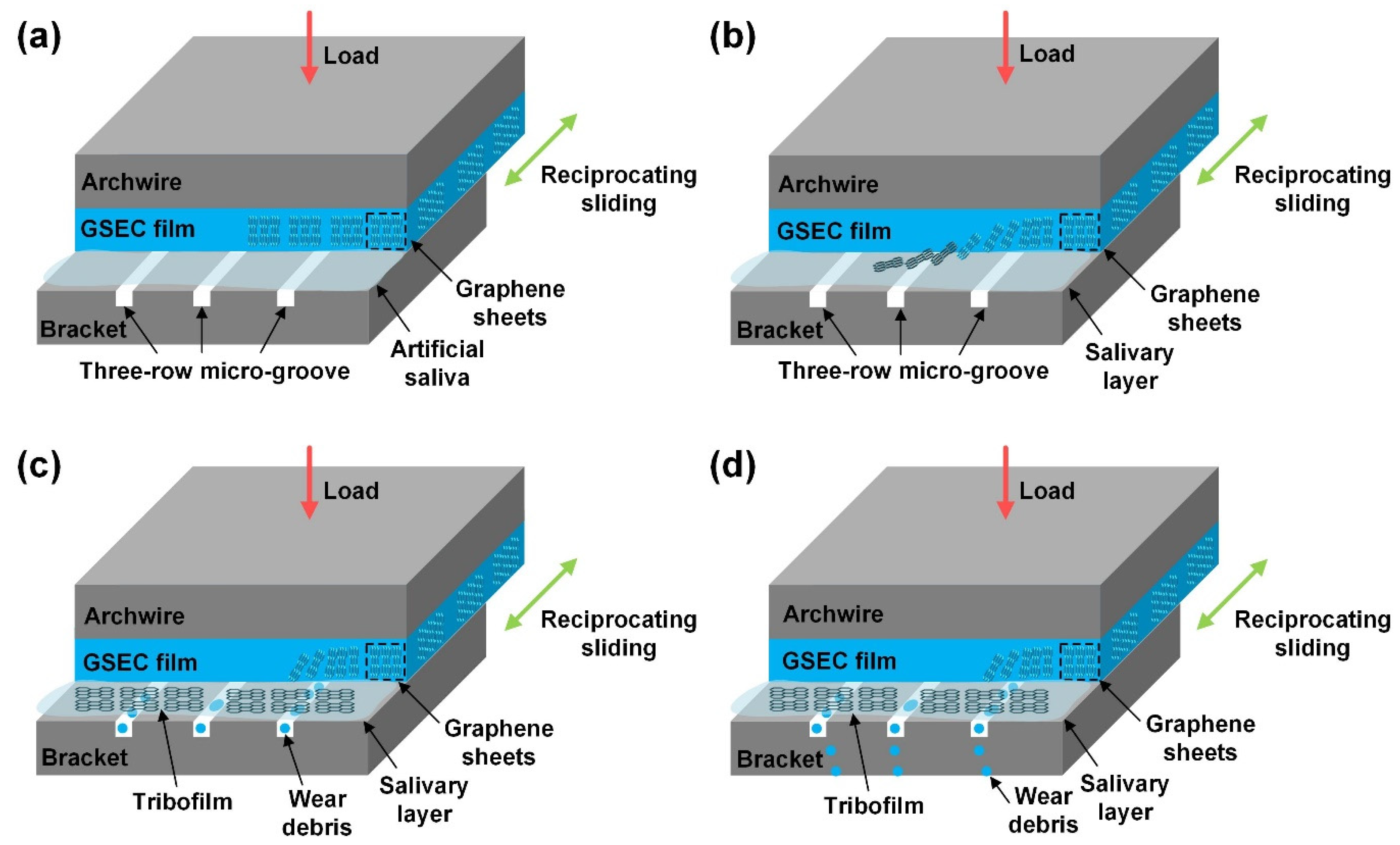

4.3. Friction and Wear Mechanisms of the GSEC Film-Coated Archwires

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Javidi, H.; Vettore, M.; Benson, P.E. Does orthodontic treatment before the age of 18 years improve oral health-related quality of life? A systematic review and meta-analysis. Am. J. Orthod. Dentofac. Orthop. 2017, 151, 644–655. [Google Scholar] [CrossRef] [PubMed]

- Yi, J.; Lu, W.; Xiao, J.; Li, X.; Li, Y.; Zhao, Z. Effect of conventional combined orthodontic-surgical treatment on oral health-related quality of life: A systematic review and meta-analysis. Am. J. Orthod. Dentofac. Orthop. 2019, 156, 29–43. [Google Scholar] [CrossRef] [PubMed]

- Kusy, R.P. A review of contemporary archwires: Their properties and characteristics. Angle Orthod. 1997, 67, 197–207. [Google Scholar] [CrossRef] [PubMed]

- Aliaga-Del Castillo, A.; Pinzan, A.; Sakoda, K.L.; Bellini-Pereira, S.A.; Janson, G. Orthodontic brackets friction changes after clinical use: A systematic review. J. Clin. Exp. Dent. 2019, 11, e482. [Google Scholar] [CrossRef]

- Zakrzewski, W.; Dobrzynski, M.; Dobrzynski, W.; Zawadzka-Knefel, A.; Janecki, M.; Kurek, K.; Lubojanski, A.; Szymonowicz, M.; Rybak, Z.; Wiglusz, R.J. Nanomaterials application in orthodontics. Nanomaterials 2021, 11, 337. [Google Scholar] [CrossRef]

- Kusy, R.P.; Whitley, J.Q. Friction between different wire-bracket configurations and materials. Semin. Orthod. 1997, 3, 166–177. [Google Scholar] [CrossRef]

- Burrow, S.J. Friction and resistance to sliding in orthodontics: A critical review. Am. J. Orthod. Dentofac. Orthop. 2009, 135, 442–447. [Google Scholar] [CrossRef]

- Almeida, F.A.C.; Almeida, A.P.C.P.S.C.; Amaral, F.L.B.; Basting, R.T.; França, F.M.G.; Turssi, C.P. Lubricating conditions: Effects on friction between orthodontic brackets and archwires with different cross-sections. Dental Press J. Orthod. 2019, 24, 66–72. [Google Scholar] [CrossRef]

- Schmeidl, K.; Wieczorowski, M.; Grocholewicz, K.; Mendak, M.; Janiszewska-Olszowska, J. Frictional properties of the TiNbTaZrO orthodontic wire—A laboratory comparison to popular archwires. Materials 2021, 14, 6233. [Google Scholar] [CrossRef]

- Akaike, S.; Kobayashi, D.; Aono, Y.; Hiratsuka, M.; Hirata, A.; Hayakawa, T.; Nakamura, Y. Relationship between static friction and surface wettability of orthodontic brackets coated with diamond-like carbon (DLC), fluorine-or silicone-doped DLC coatings. Diam. Relat. Mater. 2016, 61, 109–114. [Google Scholar] [CrossRef]

- Zhang, H.; Guo, S.; Wang, D.; Zhou, T.; Wang, L.; Ma, J. Effects of nanostructured, diamondlike, carbon coating and nitrocarburizing on the frictional properties and biocompatibility of orthodontic stainless steel wires. Angle Orthod. 2016, 86, 782–788. [Google Scholar] [CrossRef]

- Bącela, J.; Łabowska, M.B.; Detyna, J.; Zięty, A.; Michalak, I. Functional coatings for orthodontic archwires—A review. Materials 2020, 13, 3257. [Google Scholar] [CrossRef] [PubMed]

- Fróis, A.; Aleixo, A.S.; Evaristo, M.; Santos, A.C.; Louro, C.S. Can a-C:H-sputtered coatings be extended to orthodontics? Coatings 2021, 11, 832. [Google Scholar] [CrossRef]

- da Silveira, R.E.; Elias, C.N.; do Amaral, F.L.B. Assessment of frictional resistance and surface roughness in orthodontic wires coated with two different nanoparticles. Microsc. Res. Tech. 2022, 85, 1884–1890. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.Y.; Huang, J.J.; Kang, T.; Diao, D.F.; Duan, Y.Z. Coating NiTi archwires with diamond-like carbon films: Reducing fluoride-induced corrosion and improving frictional properties. J. Mater. Sci.-Mater. M. 2013, 24, 2287–2292. [Google Scholar] [CrossRef] [PubMed]

- Wei, S.; Shao, T.; Ding, P. Study of CNx films on 316L stainless steel for orthodontic application. Diam. Relat. Mater. 2010, 19, 648–653. [Google Scholar] [CrossRef]

- Wei, S.; Shao, T.; Ding, P. Improvement of orthodontic friction by coating archwire with carbon nitride film. Appl. Surf. Sci. 2011, 257, 10333–10337. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, X.; Shang, H.; Lin, J. Comparison of TiN and CNx coatings on orthodontic stainless steel: Tribological and biological evaluation. Surf. Coat. Technol. 2019, 362, 381–387. [Google Scholar] [CrossRef]

- Elhelbawy, N.; Ellaithy, M. Comparative evaluation of stainless-steel wires and brackets coated with nanoparticles of Chitosan or Zinc oxide upon friction: An in vitro study. Int. Orthod. 2021, 19, 274–280. [Google Scholar] [CrossRef]

- Arici, N.; Akdeniz, B.S.; Oz, A.A.; Gencer, Y.; Tarakci, M.; Arici, S. Effectiveness of medical coating materials in decreasing friction between orthodontic brackets and archwires. Korean J. Orthod. 2021, 51, 270–281. [Google Scholar] [CrossRef]

- Barbosa, L.M.; da Silva, W.M., Jr.; de Mello, J.D.B. Orthomicrotribometer. Wear 2019, 426–427, 1729–1739. [Google Scholar] [CrossRef]

- Kang, T.; Huang, S.Y.; Huang, J.J.; Li, Q.H.; Diao, D.F.; Duan, Y.Z. The effects of diamond-like carbon films on fretting wear behavior of orthodontic archwire-bracket contacts. J. Nanosci. Nanotechnol. 2015, 15, 4641–4647. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Zhang, W.; Diao, D. Low friction of graphene nanocrystallite embedded carbon nitride coatings prepared with MCECR plasma sputtering. Surf. Coat. Technol. 2017, 332, 153–160. [Google Scholar] [CrossRef]

- Zhang, W.Q.; Diao, D.F.; Sun, K.; Fan, X.; Wang, P. Study on friction-electrification coupling in sliding-mode triboelectric nanogenerator. Nano Energy 2018, 48, 456–463. [Google Scholar] [CrossRef]

- Wang, P.; Xue, P.; Chen, C.; Diao, D. Structural and tribological behaviors of graphene nanocrystallited carbon nitride films. Appl. Surf. Sci. 2019, 495, 143591. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Raman spectroscopy of amorphous, nanostructured, diamond–like carbon, and nanodiamond. Phil. Trans. R. Soc. Lond. A 2004, 362, 2477–2512. [Google Scholar] [CrossRef]

- Chen, C.; Diao, D.; Fan, X.; Yang, L.; Wang, C. Frictional behavior of carbon film embedded with controlling-sized graphene nanocrystallites. Tribol. Lett. 2014, 55, 429–435. [Google Scholar] [CrossRef]

- Wang, X.; Kato, K.; Adachi, K.; Aizawa, K. The effect of laser texturing of SiC surface on the critical load for the transition of water lubrication mode from hydrodynamic to mixed. Tribol. Int. 2001, 34, 703–711. [Google Scholar] [CrossRef]

- Pettersson, U.; Jacobson, S. Influence of surface texture on boundary lubricated sliding contacts. Tribol. Int. 2003, 36, 857–864. [Google Scholar] [CrossRef]

- Etsion, I. State of the art in laser surface texturing. J. Tribol. 2005, 127, 248–253. [Google Scholar] [CrossRef]

- Bonse, J.; Kirner, S.V.; Griepentrog, M.; Spaltmann, D.; Krüger, J. Femtosecond laser texturing of surfaces for tribological applications. Materials 2018, 11, 801. [Google Scholar] [CrossRef]

- Grützmacher, P.G.; Profito, F.J.; Rosenkranz, A. Multi-scale surface texturing in tribology—Current knowledge and future perspectives. Lubricants 2019, 7, 95. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R.; Wieczorowski, M. Functional importance of surface texture parameters. Materials 2021, 14, 5326. [Google Scholar] [CrossRef] [PubMed]

- Zhou, K. Study on Effect of Surface Microtexture on Friction and Wear Behaviors of Orthodontic Brackets. Master’s Thesis, Shenzhen University, Shenzhen, China, 2020. [Google Scholar]

- Archard, J. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Pan, Z.; Zhou, Q.; Wang, P.; Diao, D. Robust low friction performance of graphene sheets embedded carbon films coated orthodontic stainless steel archwires. Friction 2022, 10, 142–158. [Google Scholar] [CrossRef]

- Pettersson, U.; Jacobson, S. Friction and wear properties of micro textured DLC coated surfaces in boundary lubricated sliding. Tribol. Lett. 2004, 17, 553–559. [Google Scholar] [CrossRef]

- Rapoport, L.; Moshkovich, A.; Perfilyev, V.; Lapsker, I.; Halperin, G.; Itovich, Y.; Etsion, I. Friction and wear of MoS2 films on laser textured steel surfaces. Surf. Coat. Technol. 2008, 202, 3332–3340. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Marian, M. Combining surface textures and MXene coatings–towards enhanced wear-resistance and durability. Surf. Topogr. Metrol. Prop. 2022, 10, 033001. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Xue, Q.; Yuan, N.; Ding, J. A facile method to improve tribological properties of silicon surface by combining nanogrooves patterning and thin film lubrication. Colloids Surf. A Physicochem. Eng. Aspects 2010, 372, 139–145. [Google Scholar] [CrossRef]

- Xue, Y.; Wu, C.; Shi, X.; Huang, Q.; Ibrahim, A.M.M. Effects of groove-textured surfaces filled with Sn-Ag-Cu and MXene-Ti3C2 composite lubricants on tribological properties of CSS-42L bearing steel. Friction 2022, 10, 1091–1113. [Google Scholar] [CrossRef]

| Substrate Bias Voltage (V) | EELS P1/P2 | D Peak Position (cm−1) | G Peak Position (cm−1) | ID/IG | Lα (nm) | Hardness(GPa) | Young’s Modulus (GPa) |

|---|---|---|---|---|---|---|---|

| +5 | 0.66 | 1349 | 1574 | 0.70 | 1.13 | 12.1 | 123.0 |

| +10 | 0.67 | 1344 | 1586 | 0.88 | 1.26 | 4.6 | 35.4 |

| +20 | 0.72 | 1338 | 1589 | 0.94 | 1.31 | 4.0 | 31.5 |

| +50 | 0.75 | 1336 | 1594 | 1.66 | 1.74 | 0.8 | 7.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, P.; Luo, X.; Qin, J.; Pan, Z.; Zhou, K. Effect of Graphene Sheets Embedded Carbon Films on the Fretting Wear Behaviors of Orthodontic Archwire–Bracket Contacts. Nanomaterials 2022, 12, 3430. https://doi.org/10.3390/nano12193430

Wang P, Luo X, Qin J, Pan Z, Zhou K. Effect of Graphene Sheets Embedded Carbon Films on the Fretting Wear Behaviors of Orthodontic Archwire–Bracket Contacts. Nanomaterials. 2022; 12(19):3430. https://doi.org/10.3390/nano12193430

Chicago/Turabian StyleWang, Pengfei, Xin Luo, Jiajie Qin, Zonglin Pan, and Kai Zhou. 2022. "Effect of Graphene Sheets Embedded Carbon Films on the Fretting Wear Behaviors of Orthodontic Archwire–Bracket Contacts" Nanomaterials 12, no. 19: 3430. https://doi.org/10.3390/nano12193430

APA StyleWang, P., Luo, X., Qin, J., Pan, Z., & Zhou, K. (2022). Effect of Graphene Sheets Embedded Carbon Films on the Fretting Wear Behaviors of Orthodontic Archwire–Bracket Contacts. Nanomaterials, 12(19), 3430. https://doi.org/10.3390/nano12193430