Investigation of Morphological, Optical, and Dielectric Properties of RF Sputtered WOx Thin Films for Optoelectronic Applications

Abstract

:1. Introduction

2. Methodology

2.1. Deposition of WOx Thin Film

2.2. Characterization

3. Results and Discussions

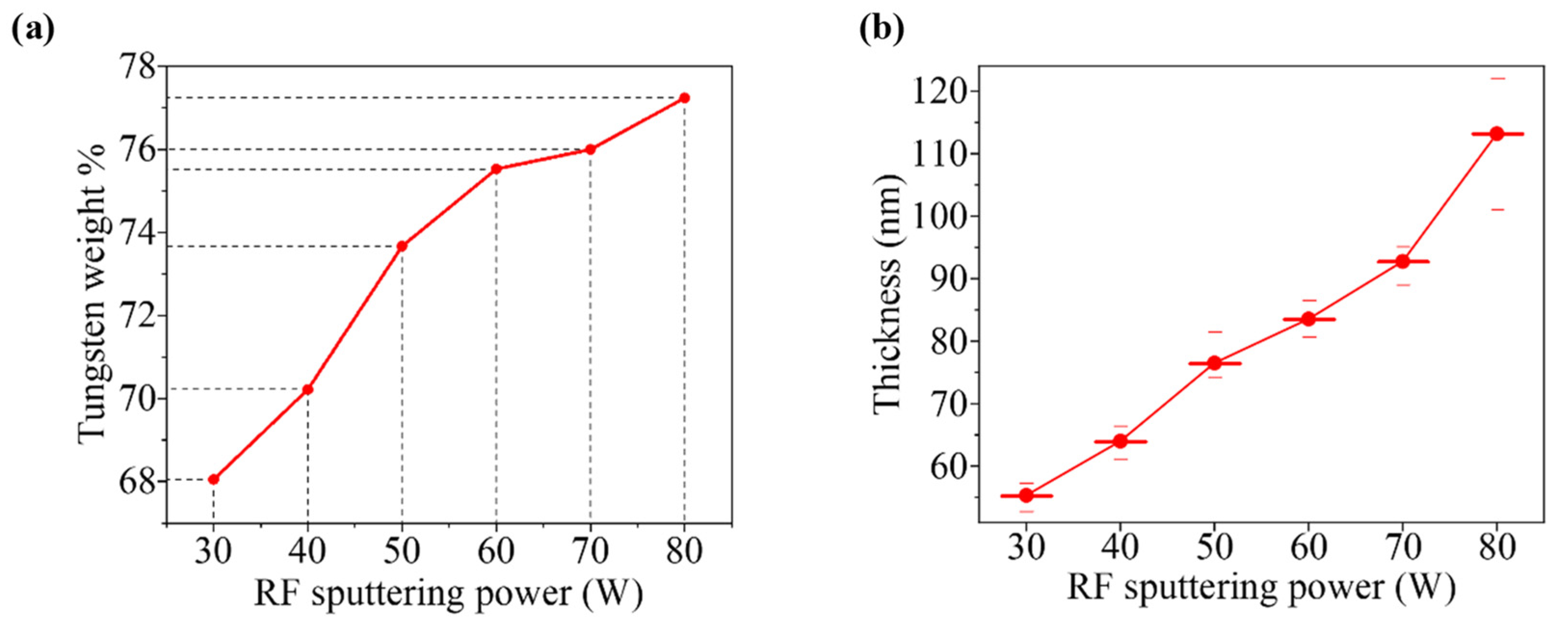

3.1. Morphological Characterization

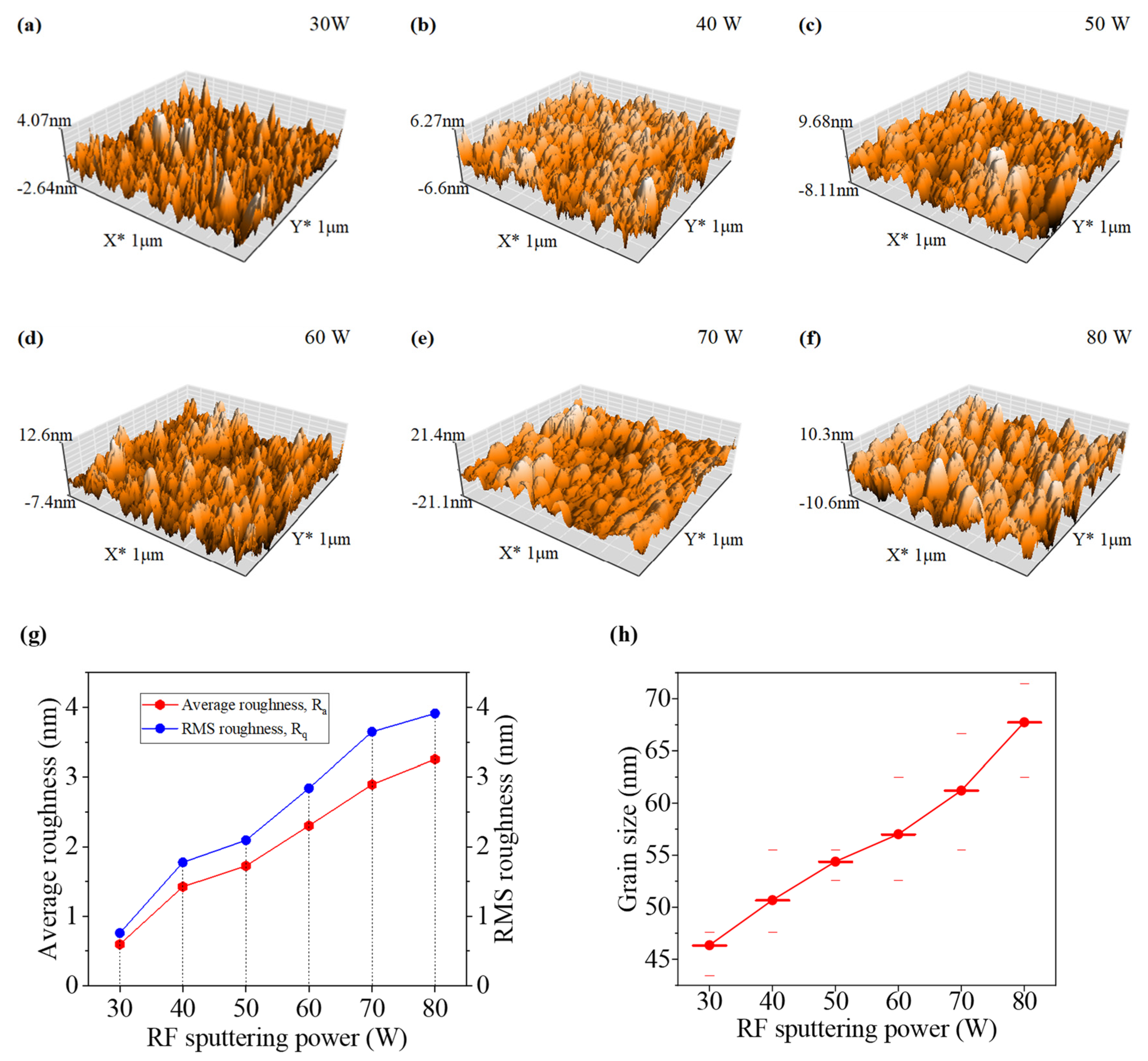

3.2. Structural Characterization

3.3. Optical Properties

3.3.1. Optical Transmittance, Reflectance, Absorbance, and Absorption Coefficient

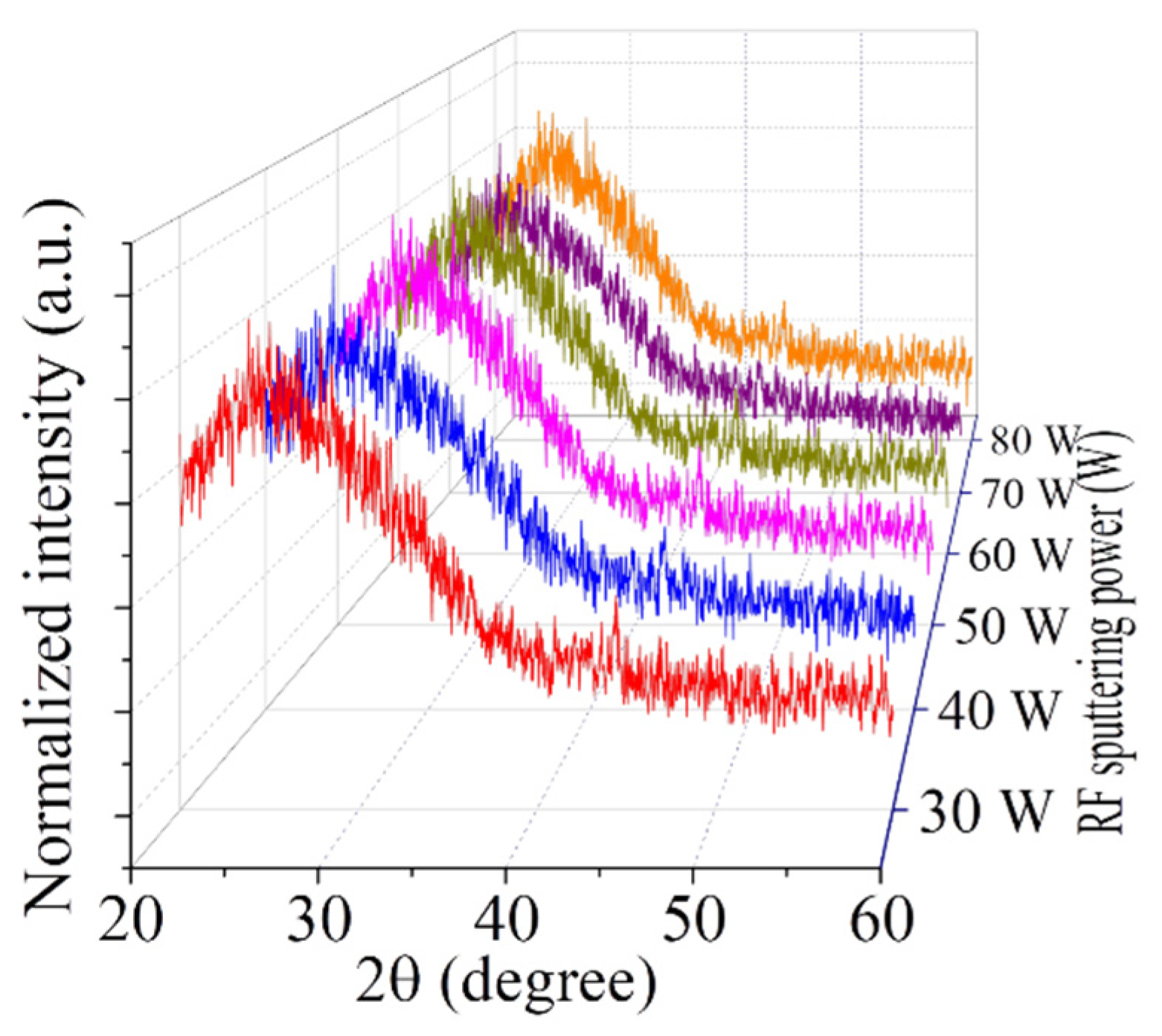

3.3.2. Penetration Depth

3.3.3. Energy Bandgap

3.3.4. Urbach Energy

3.3.5. Refractive Index and Extinction Coefficient

3.3.6. Optical Conductivity

3.3.7. Dielectric Constant

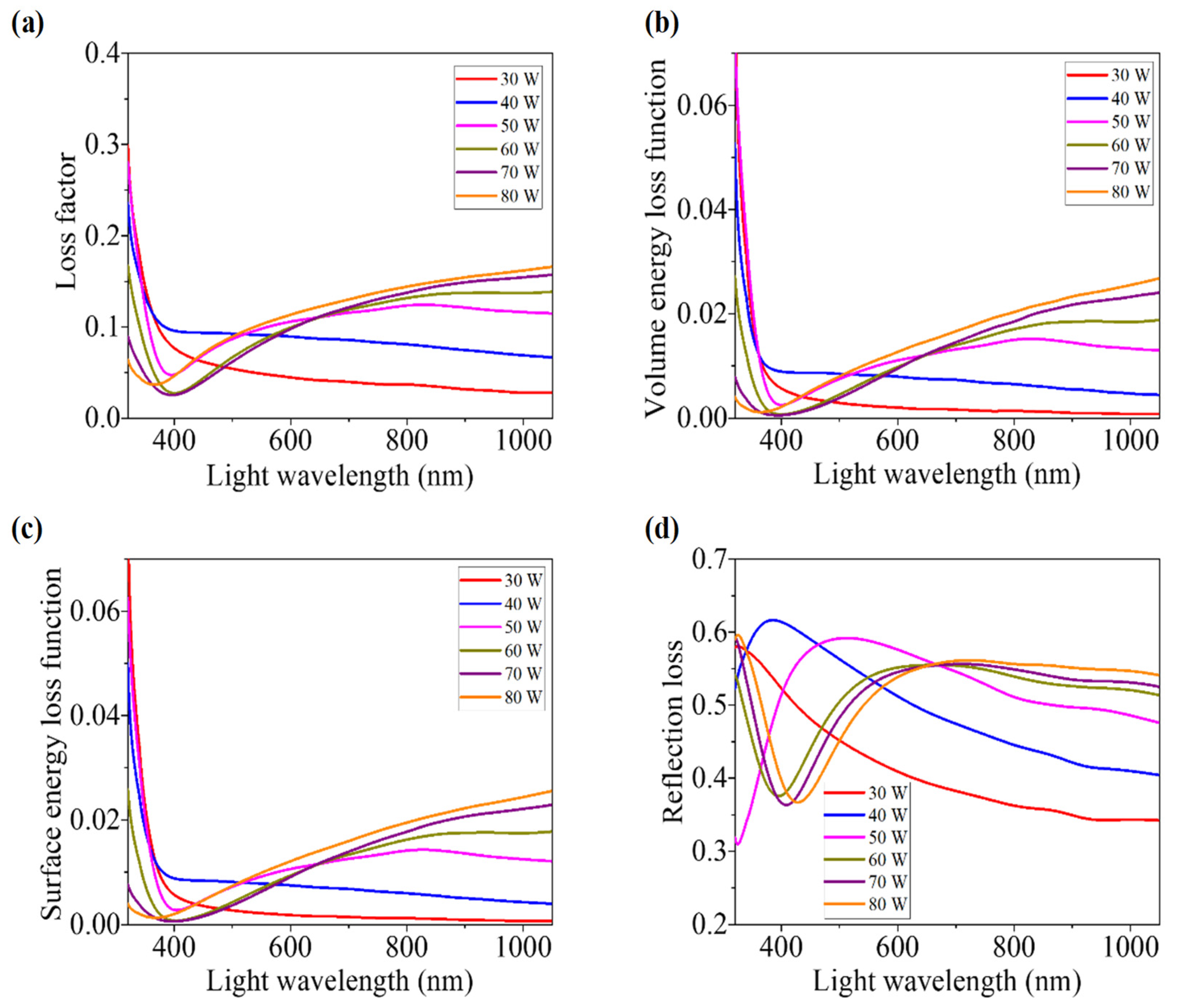

3.4. Loss Parameters

3.4.1. Loss Factor

3.4.2. Volume Energy Loss Function and Surface Energy Loss Function

3.4.3. Reflection Loss

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mardare, C.C.; Hassel, A.W. Review on the Versatility of Tungsten Oxide Coatings. Phys. Status Solidi 2019, 216, 1900047. [Google Scholar] [CrossRef] [Green Version]

- Huang, K.; Pan, Q.; Yang, F.; Ni, S.; Wei, X.; He, D. Controllable synthesis of hexagonal WO3 nanostructures and their application in lithium batteries. J. Phys. D Appl. Phys. 2008, 41, 155417. [Google Scholar] [CrossRef]

- Zheng, H.; Tachibana, Y.; Kalantar-Zadeh, K. Dye-sensitized solar cells based on WO3. Langmuir 2010, 26, 19148–19152. [Google Scholar] [CrossRef] [PubMed]

- Fang, L.; Baik, S.J.; Kim, J.W.; Kang, S.J.; Seo, J.W.; Jeon, J.W.; Kim, Y.H.; Lim, K.S. Tunable work function of a WOx buffer layer for enhanced photocarrier collection of pin-type amorphous silicon solar cells. J. Appl. Phys. 2011, 109, 104501. [Google Scholar] [CrossRef]

- Chen, C.; Jiang, Y.; Wu, Y.; Guo, J.; Kong, X.; Wu, X.; Li, Y.; Zheng, D.; Wu, S.; Gao, X.; et al. Low-Temperature-Processed WOx as Electron Transfer Layer for Planar Perovskite Solar Cells Exceeding 20% Efficiency. Solar RRL 2020, 4, 1900499. [Google Scholar] [CrossRef]

- Wu, T.; Qin, Z.; Wang, Y.; Wu, Y.; Chen, W.; Zhang, S.; Cai, M.; Dai, S.; Zhang, J.; Liu, J.; et al. The Main Progress of Perovskite Solar Cells in 2020–2021. Nano-Micro Lett. 2021, 13, 152. [Google Scholar] [CrossRef]

- Hossain, M.I.; Shahiduzzaman, M.; Ahmed, S.; Huqe, M.R.; Qarony, W.; Saleque, A.M.; Akhtaruzzaman, M.; Knipp, D.; Tsang, Y.H.; Taima, T.; et al. Near field control for enhanced photovoltaic performance and photostability in perovskite solar cells. Nano Energy 2021, 89, 106388. [Google Scholar] [CrossRef]

- Shahiduzzaman, M.; Visal, S.; Kuniyoshi, M.; Kaneko, T.; Umezu, S.; Katsumata, T.; Iwamori, S.; Kakihana, M.; Taima, T.; Isomura, M.; et al. Low-temperature-processed brookite-based TiO2 heterophase junction enhances performance of planar perovskite solar cells. Nano Lett. 2018, 19, 598–604. [Google Scholar]

- Shahiduzzaman, M.; Hossain, M.I.; Visal, S.; Kaneko, T.; Qarony, W.; Umezu, S.; Tomita, K.; Iwamori, S.; Knipp, D.; Tsang, Y.H.; et al. Spray pyrolyzed TiO2 embedded multi-layer front contact design for high-efficiency perovskite solar cells. Nano-Micro Lett. 2021, 13, 36. [Google Scholar] [CrossRef]

- Islam, M.A.; Rahman, K.S.; Misran, H.; Asim, N.; Hossain, M.S.; Akhtaruzzaman, M.; Amin, N. High mobility and transparent ZTO ETM prepared by RF reactive co-sputtering for perovskite solar cell application. Results Phys. 2019, 14, 102518. [Google Scholar] [CrossRef]

- Mahjabin, S.; Hossain, M.I.; Haque, M.; Bashar, M.S.; Jamal, M.S.; Shahiduzzaman, M.; Muhammad, G.; Sopian, K.; Akhtaruzzaman, M. Sputtered WOx thin film as the electron transport layer for efficient perovskite solar cells. Appl. Phys. A 2022, 128, 358. [Google Scholar] [CrossRef]

- Sobayel, K.; Akhtaruzzaman, M.; Rahman, K.S.; Ferdaous, M.T.; Al-Mutairi, Z.A.; Alharbi, H.F.; Alharthi, N.H.; Karim, M.R.; Hasmady, S.; Amin, N. A comprehensive defect study of tungsten disulfide (WS2) as electron transport layer in perovskite solar cells by numerical simulation. Results Phys. 2019, 12, 1097–1103. [Google Scholar] [CrossRef]

- Chen, C.M.; Lin, Z.K.; Huang, W.J.; Yang, S.H. WO3 nanoparticles or nanorods incorporating Cs2Co3/PCBM buffer bilayer as carriers transporting materials for perovskite solar cells. Nanoscale Res. Lett. 2016, 11, 464. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ali, F.; Pham, N.D.; Fan, L.; Tiong, V.; Ostrikov, K.; Bell, J.M.; Wang, H.; Tesfamichael, T. Low hysteresis perovskite solar cells using an electron-beam evaporated WO3–x thin film as the electron transport layer. ACS Appl. Energy Mater. 2019, 2, 5456–5464. [Google Scholar] [CrossRef]

- Wang, K.; Shi, Y.; Dong, Q.; Li, Y.; Wang, S.; Yu, X.; Wu, M.; Ma, T. Low-temperature and solution-processed amorphous WOX as electron-selective layer for perovskite solar cells. J. Phys. Chem. Lett. 2015, 6, 755–759. [Google Scholar] [CrossRef]

- Cheng, Y.; Yang, Q.D.; Xiao, J.; Xue, Q.; Li, H.W.; Guan, Z.; Yip, H.L.; Tsang, S.W. Decomposition of organometal halide perovskite films on zinc oxide nanoparticles. ACS Appl. Mater. Interfaces 2015, 7, 19986–19993. [Google Scholar] [CrossRef]

- Mahjabin, S.; Haque, M.M.; Sobayel, K.; Jamal, M.S.; Islam, M.A.; Selvanathan, V.; Assaifan, A.K.; Alharbi, H.F.; Sopian, K.; Amin, N.; et al. Perceiving of defect tolerance in perovskite absorber layer for efficient perovskite solar cell. IEEE Access 2020, 8, 106346–106353. [Google Scholar] [CrossRef]

- Madhuri, K.; Babu, M.B. Studies on electron beam evaporated WO3 thin films. Mater. Today Proc. 2016, 3, 84–89. [Google Scholar] [CrossRef]

- Mahjabin, S.; Haque, M.M.; Khan, S.; Selvanathan, V.; Jamal, M.S.; Bashar, M.S.; Alkhammash, H.I.; Hossain, M.I.; Shahiduzzaman, M.; Amin, N.; et al. Effects of oxygen concentration variation on the structural and optical properties of reactive sputtered WOx thin film. Sol. Energy 2021, 222, 202–211. [Google Scholar] [CrossRef]

- Badilescu, S.; Ashrit, P. Study of sol–gel prepared nanostructured WO3 thin films and composites for electrochromic applications. Solid State Ion. 2003, 158, 187–197. [Google Scholar] [CrossRef]

- Blackman, C.S.; Parkin, I.P. Atmospheric pressure chemical vapor deposition of crystalline monoclinic WO3 and WO3-x thin films from reaction of WCl6 with O-containing solvents and their photochromic and electrochromic properties. Chem. Mater. 2005, 17, 1583–1590. [Google Scholar] [CrossRef]

- Sakthivel, P.; Murugan, R.; Asaithambi, S.; Karuppaiah, M.; Rajendran, S.; Ravi, G. Influence of radiofrequency power on structural, morphological, optical and electrical properties of magnetron sputtered CdO: Sm thin films as alternative TCO for optoelectronic applications. J. Alloy. Compd. 2018, 765, 146–157. [Google Scholar] [CrossRef]

- Marszalek, K. Magnetron-sputtered WO3 films for electrochromic devices. Thin Solid Film. 1989, 175, 227–233. [Google Scholar] [CrossRef]

- Srinivasa Rao, K.; Rajini Kanth, B.; Srujana Devi, G.; Mukhopadhyay, P.K. Structural and optical properties of nanocrystalline WO3 thin films. J. Mater. Sci. Mater. Electron. 2011, 22, 1466–1472. [Google Scholar] [CrossRef]

- Madhavi, V.; Kondaiah, P.; Hussain, O.M.; Uthanna, S. Structural, optical and electrochromic properties of RF magnetron sputtered WO3 thin films. Phys. B Condens. Matter 2014, 454, 141–147. [Google Scholar] [CrossRef]

- Madhavi, V.; Kondaiah, P.; Hussain, O.M.; Uthanna, S. Electrochemical properties of magnetron sputtered WO3 thin films. InAIP Conf. Proc. 2013, 1512, 758–759. [Google Scholar]

- Lemire, C.; Lollman, D.B.; Al Mohammad, A.; Gillet, E.; Aguir, K. Reactive RF magnetron sputtering deposition of WO3 thin films. Sens. Actuators B Chem. 2002, 84, 43–48. [Google Scholar] [CrossRef]

- Feng, W.; Wang, X.; Zhou, H.; Chen, F. Effects of sputtering power on properties of PbSe nanocrystalline thin films deposited by RF magnetron sputtering. Vacuum 2014, 109, 108–111. [Google Scholar] [CrossRef]

- Yu, X.; Ma, J.; Ji, F.; Wang, Y.; Zhang, X.; Cheng, C.; Ma, H. Effects of sputtering power on the properties of ZnO: Ga films deposited by rf magnetron-sputtering at low temperature. J. Cryst. Growth 2005, 274, 474–479. [Google Scholar] [CrossRef]

- Raja, M.; Chandrasekaran, J.; Balaji, M. The structural, optical and electrical properties of spin coated WO3 thin films using organic acids. Silicon 2017, 9, 201–210. [Google Scholar] [CrossRef]

- Ozkan, E.; Lee, S.H.; Tracy, C.E.; Pitts, J.R.; Deb, S.K. Comparison of electrochromic amorphous and crystalline tungsten oxide films. Sol. Energy Mater. Sol. Cells 2003, 79, 439–448. [Google Scholar] [CrossRef]

- Alfonso, E.; Olaya, J.; Cubillos, G. Thin film growth through sputtering technique and its applications. Cryst.-Sci. Technol. 2012, 23, 11–12. [Google Scholar]

- Koo, J.B.; Hong, K.J.; Park, J.S.; Shin, D.C. Effect of grain size on transmittance and mechanical strength of sintered alumina. Mater. Sci. Eng. A 2004, 374, 191–195. [Google Scholar]

- Subrahmanyam, A.; Karuppasamy, A. Optical and electrochromic properties of oxygen sputtered tungsten oxide (WO3) thin films. Sol. Energy Mater. Sol. Cells 2007, 91, 266–274. [Google Scholar] [CrossRef]

- Hameed, T.A.; Wassel, A.R.; El Radaf, I. Investigating the effect of thickness on the structural, morphological, optical and electrical properties of AgBiSe2 thin films. J. Alloy. Compd. 2019, 805, 1–11. [Google Scholar] [CrossRef]

- Manthiram, K.; Alivisatos, A.P. Tunable localized surface plasmon resonances in tungsten oxide nanocrystals. J. Am. Chem. Soc. 2012, 134, 3995–3998. [Google Scholar] [CrossRef] [PubMed]

- Bashar, M.S.; Yusoff, Y.; Abdullah, S.F.; Rahaman, M.; Chelvanathan, P.; Gafur, A.; Ahmed, F.; Akhtaruzzaman, M.; Amin, N. An Investigation on Structural and Optical Properties of Zn1− xMgxS Thin Films Deposited by RF Magnetron Co-Sputtering Technique. Coatings 2020, 10, 766. [Google Scholar] [CrossRef]

- Anwar, M.; Siddiqi, S.; Ghauri, I. Optical Absorption in Amorphous Thin Films of SnO2 Deposited by Thermal Evaporation. Int. J. Mod. Phys. B 2007, 21, 2017–2032. [Google Scholar] [CrossRef]

- Hassanien, A.S.; Sharma, I. Band-gap engineering, conduction and valence band positions of thermally evaporated amorphous Ge15-x Sbx Se50 Te35 thin films: Influences of Sb upon some optical characterizations and physical parameters. J. Alloy. Compd. 2019, 798, 750–763. [Google Scholar] [CrossRef]

- Tauc, J.; Grigorovici, R.; Vancu, A. Optical properties and electronic structure of amorphous germanium. Phys. Status Solidi 1966, 15, 627–637. [Google Scholar] [CrossRef]

- Rafiq, M.K.; Ayoba, A.; Baisa, B.; Akhtaruzzamanb, M.; Aminc, N. Investigating the impact of growth temperature on WS2 thin film. J. Kejuruter. 2020, 3, 23–28. [Google Scholar]

- Gaury, J.F.M.M.; Kelder, E.M.; Bychkov, E.; Biskos, G. Characterization of Nb-doped WO3 thin films produced by Electrostatic Spray Deposition. Thin Solid Film. 2013, 534, 32–39. [Google Scholar] [CrossRef]

- Ramana, C.; Smith, R.; Hussain, O. Grain size effects on the optical characteristics of pulsed-laser deposited vanadium oxide thin films. Phys. Status Solidi 2003, 199, R4–R6. [Google Scholar] [CrossRef]

- Mahmood, K.; Sarwar, S.; Mehran, M.T. Current status of electron transport layers in perovskite solar cells: Materials and properties. Rsc Adv. 2017, 7, 17044–17062. [Google Scholar] [CrossRef] [Green Version]

- Cody, G.D.; Tiedje, T.; Abeles, B.; Brooks, B.; Goldstein, Y. Disorder and the optical-absorption edge of hydrogenated amorphous silicon. Phys. Rev. Lett. 1981, 47, 1480. [Google Scholar] [CrossRef]

- Singh, S.; Li, C.; Panzer, F.; Narasimhan, K.L.; Graeser, A.; Gujar, T.P.; Köhler, A.; Thelakkat, M.; Huettner, S.; Kabra, D. Effect of thermal and structural disorder on the electronic structure of hybrid perovskite semiconductor CH3NH3PbI3. J. Phys. Chem. Lett. 2016, 7, 3014–3021. [Google Scholar] [CrossRef]

- Rai, R. Analysis of the Urbach tails in absorption spectra of undoped ZnO thin films. J. Appl. Phys. 2013, 113, 153508. [Google Scholar] [CrossRef]

- Li, W.; Zhao, K.; Zhou, H.; Yu, W.; Zhu, J.; Hu, Z.; Chu, J. Precursor solution temperature dependence of the optical constants, band gap and Urbach tail in organic–inorganic hybrid halide perovskite films. J. Phys. D Appl. Phys. 2018, 52, 045103. [Google Scholar] [CrossRef]

- Hassanien, A.S. Studies on dielectric properties, opto-electrical parameters and electronic polarizability of thermally evaporated amorphous Cd50S50− xSex thin films. J. Alloy. Compd. 2016, 671, 566–578. [Google Scholar] [CrossRef]

- Yadav, P. Linear and nonlinear optical properties of Ternary and quaternary chalcogenide thin films. Ph.D. Thesis, The Northcap University, Gurugram, India, 2015. [Google Scholar]

- He, G.; Liu, J.; Chen, H.; Liu, Y.; Sun, Z.; Chen, X.; Liu, M.; Zhang, L. Interface control and modification of band alignment and electrical properties of HfTiO/GaAs gate stacks by nitrogen incorporation. J. Mater. Chem. C 2014, 2, 5299–5308. [Google Scholar] [CrossRef]

- He, G.; Zhang, L.D.; Li, G.H.; Liu, M.; Zhu, L.Q.; Pan, S.S.; Fang, Q. Spectroscopic ellipsometry characterization of nitrogen-incorporated HfO2 gate dielectrics grown by radio-frequency reactive sputtering. Appl. Phys. Lett. 2005, 86, 232901. [Google Scholar] [CrossRef]

- Mohamed, S.H.; El-Hossary, F.M.; Gamal, G.A.; Kahlid, M.M. Properties of indium tin oxide thin films deposited on polymer substrates. Acta Phys. Pol. A 2009, 115, 704–708. [Google Scholar] [CrossRef]

- Hossain, M.I.; Saleque, A.M.; Ahmed, S.; Saidjafarzoda, I.; Shahiduzzaman, M.; Qarony, W.; Knipp, D.; Biyikli, N.; Tsang, Y.H. Perovskite/perovskite planar tandem solar cells: A comprehensive guideline for reaching energy conversion efficiency beyond 30%. Nano Energy 2021, 79, 105400. [Google Scholar] [CrossRef]

- Elsaeedy, H. Growth, structure, optical and optoelectrical characterizations of the Cu2NiSnS4 thin films synthesized by spray pyrolysis technique. J. Mater. Sci. Mater. Electron. 2019, 30, 12545–12554. [Google Scholar] [CrossRef]

- Sharma, K.; Al-Kabbi, A.S.; Saini, G.S.S.; Tripathi, S.K. Determination of dispersive optical constants of nanocrystalline CdSe(nc-CdSe) thin films. Mater. Res. Bull. 2012, 47, 1400–1406. [Google Scholar] [CrossRef]

- Hssi, A.A.; Atourki, L.; Labchir, N.; Ouafi, M.; Abouabassi, K.; Elfanaoui, A.; Ihlal, A.; Bouabid, K. Optical and dielectric properties of electrochemically deposited p-Cu2O films. Mater. Res. Express 2020, 7, 016424. [Google Scholar] [CrossRef]

- Ghosh, T.; Sharma, S.K.; Pradhan, D. Giant Dielectric Constant and Superior Photovoltaic Property of the Mechanochemically Synthesized Stable CH3NH3PbBr3 in a Hole Transporter-Free Solar Cell. ACS Sustain. Chem. Eng. 2019, 8, 1445–1454. [Google Scholar] [CrossRef]

- Peláiz-Barranco, A. Advances in Ferroelectrics; BoD–Books on Demand: Vienna, Austria, 2012. [Google Scholar]

- Zaka, H.; Parditka, B.; Erdélyi, Z.; Atyia, H.E.; Sharma, P.; Fouad, S.S. Investigation of dispersion parameters, dielectric properties and opto–electrical parameters of ZnO thin film grown by ALD. Optik 2020, 203, 163933. [Google Scholar] [CrossRef]

- Musikant, S. Glass. In Encyclopedia of Physical Science and Technology, 3rd ed.; Meyers, R.A., Ed.; Academic Press: New York, NY, USA, 2003; pp. 781–806. [Google Scholar]

- Sharma, P.; El-Bana, M.S.; Fouad, S.S.; Sharma, V. Effect of compositional dependence on physical and optical parameters of Te17Se83−xBix glassy system. J. Alloy. Compd. 2016, 667, 204–210. [Google Scholar] [CrossRef]

- El-Bana, M.; Fouad, S. Opto-electrical characterisation of As33Se67−xSnx thin films. J. Alloy. Compd. 2017, 695, 1532–1538. [Google Scholar] [CrossRef]

| RF Sputtering Power (W) | Weight % of W | Average Thickness (nm) | Average Grain Size (nm) | Average Roughness Ra (nm) | RMS Roughness Rq (nm) |

|---|---|---|---|---|---|

| 30 | 68.05 | 55.334 | 46.36 | 0.597 | 0.758 |

| 40 | 70.22 | 64.006 | 50.685 | 1.424 | 1.775 |

| 50 | 73.76 | 76.508 | 54.386 | 1.724 | 2.093 |

| 60 | 75.53 | 83.55 | 57.013 | 2.301 | 2.839 |

| 70 | 76.01 | 92.767 | 61.21 | 2.893 | 3.648 |

| 80 | 77.24 | 113.2 | 67.74 | 3.253 | 3.913 |

| RF Sputtering Power (W) | Energy Band Gap Eg (eV) |

|---|---|

| 30 | 3.751 |

| 40 | 3.737 |

| 50 | 3.72 |

| 60 | 3.695 |

| 70 | 3.66 |

| 80 | 3.642 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahjabin, S.; Haque, M.M.; Sobayel, K.; Selvanathan, V.; Jamal, M.S.; Bashar, M.S.; Sultana, M.; Hossain, M.I.; Shahiduzzaman, M.; Algethami, M.; et al. Investigation of Morphological, Optical, and Dielectric Properties of RF Sputtered WOx Thin Films for Optoelectronic Applications. Nanomaterials 2022, 12, 3467. https://doi.org/10.3390/nano12193467

Mahjabin S, Haque MM, Sobayel K, Selvanathan V, Jamal MS, Bashar MS, Sultana M, Hossain MI, Shahiduzzaman M, Algethami M, et al. Investigation of Morphological, Optical, and Dielectric Properties of RF Sputtered WOx Thin Films for Optoelectronic Applications. Nanomaterials. 2022; 12(19):3467. https://doi.org/10.3390/nano12193467

Chicago/Turabian StyleMahjabin, Samiya, Md. Mahfuzul Haque, K. Sobayel, Vidhya Selvanathan, M. S. Jamal, M. S. Bashar, Munira Sultana, Mohammad Ismail Hossain, Md. Shahiduzzaman, Merfat Algethami, and et al. 2022. "Investigation of Morphological, Optical, and Dielectric Properties of RF Sputtered WOx Thin Films for Optoelectronic Applications" Nanomaterials 12, no. 19: 3467. https://doi.org/10.3390/nano12193467