One-Step Synergistic Treatment Approach for High Performance Amorphous InGaZnO Thin-Film Transistors Fabricated at Room Temperature

Abstract

:1. Introduction

2. Experimental Method and Characterization

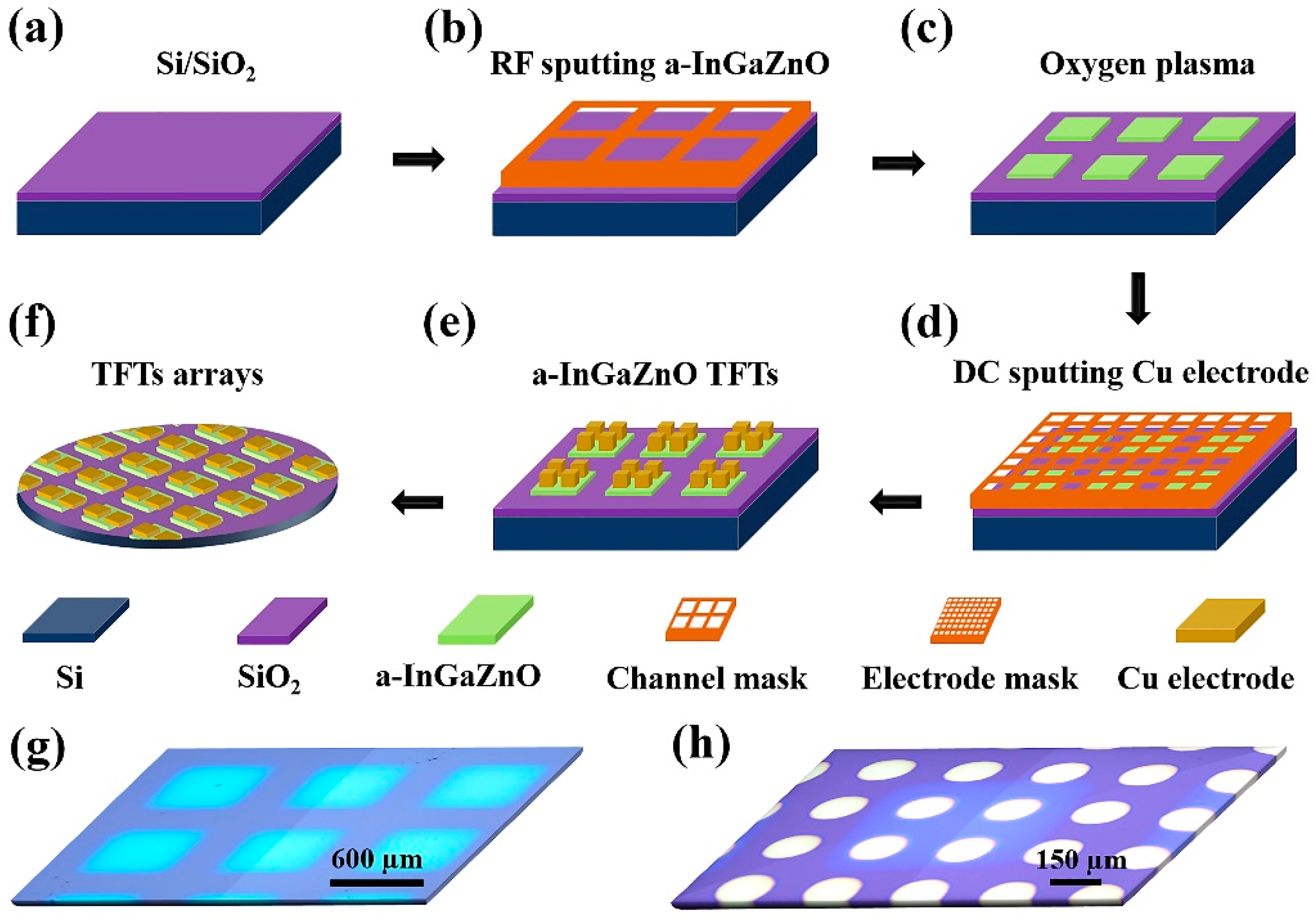

2.1. Device Preparation

2.2. Device Characterization

3. Results and Discussion

3.1. Different Sputtering Power

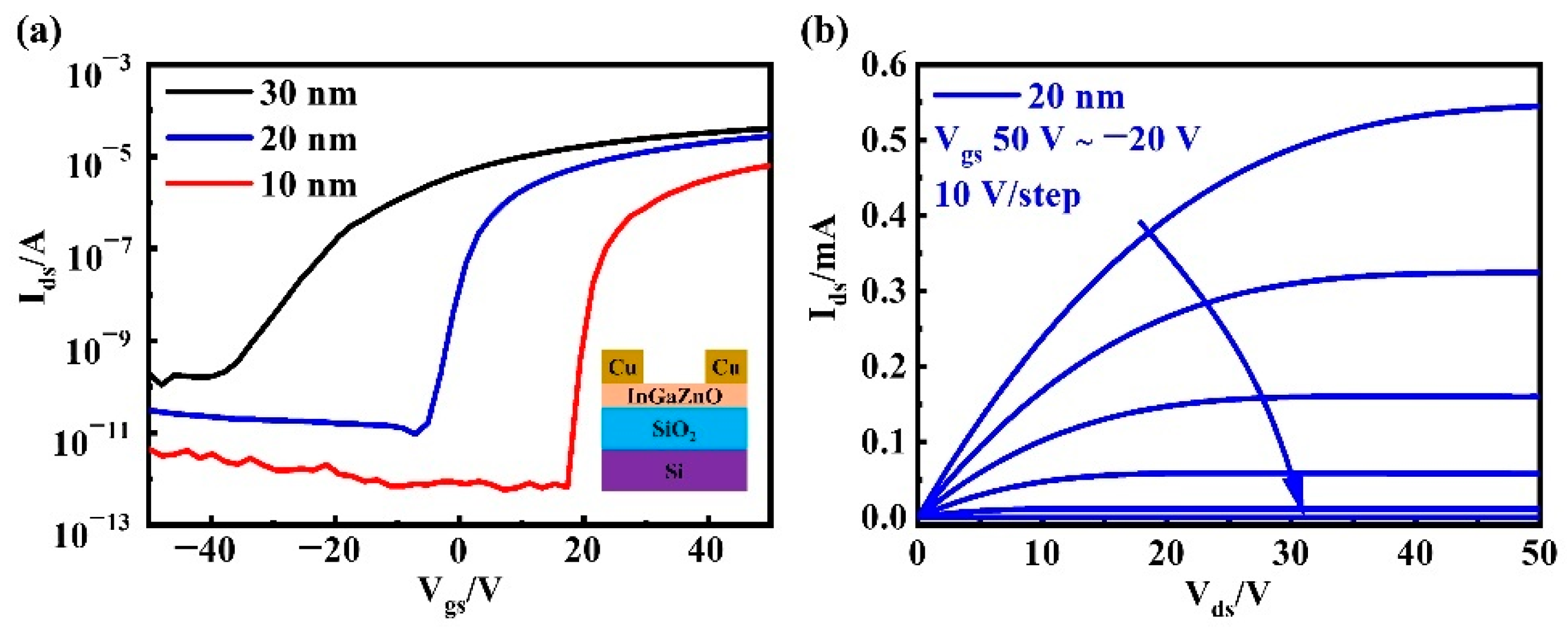

3.2. Different Thickness

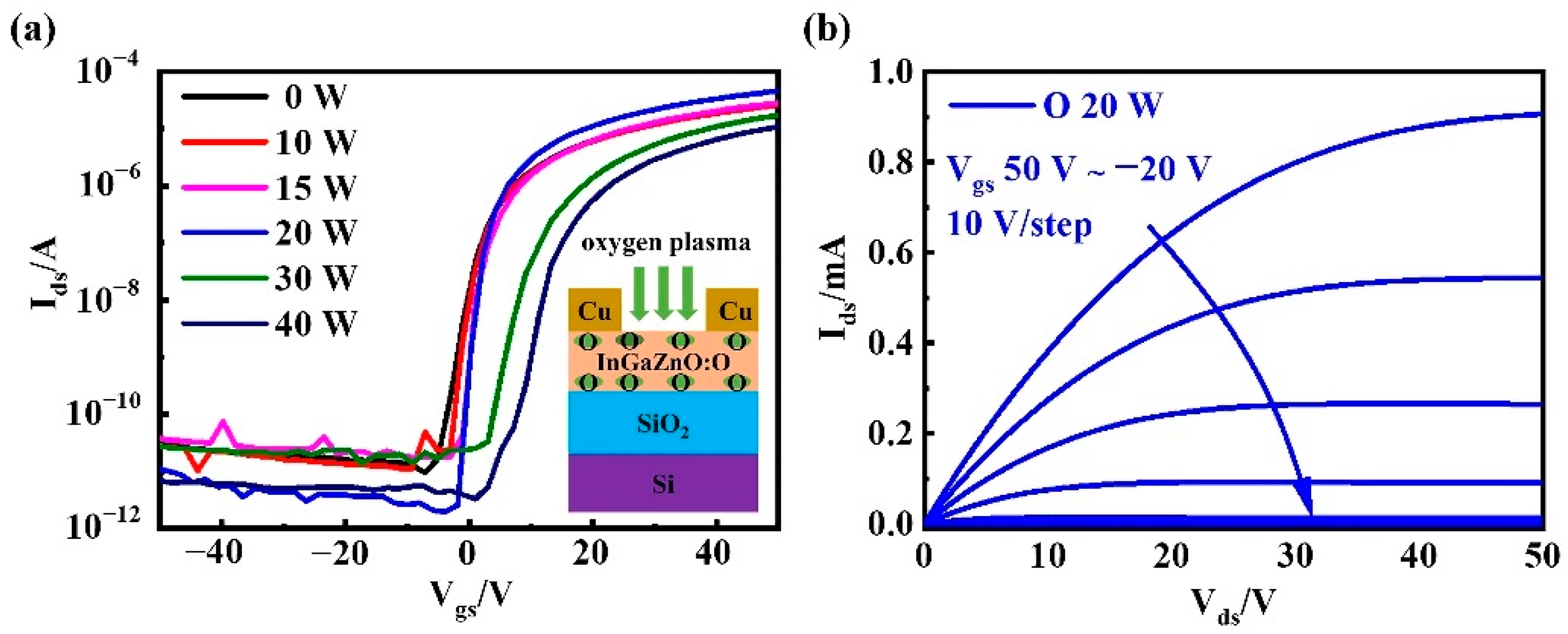

3.3. Oxygen Plasma Treatment

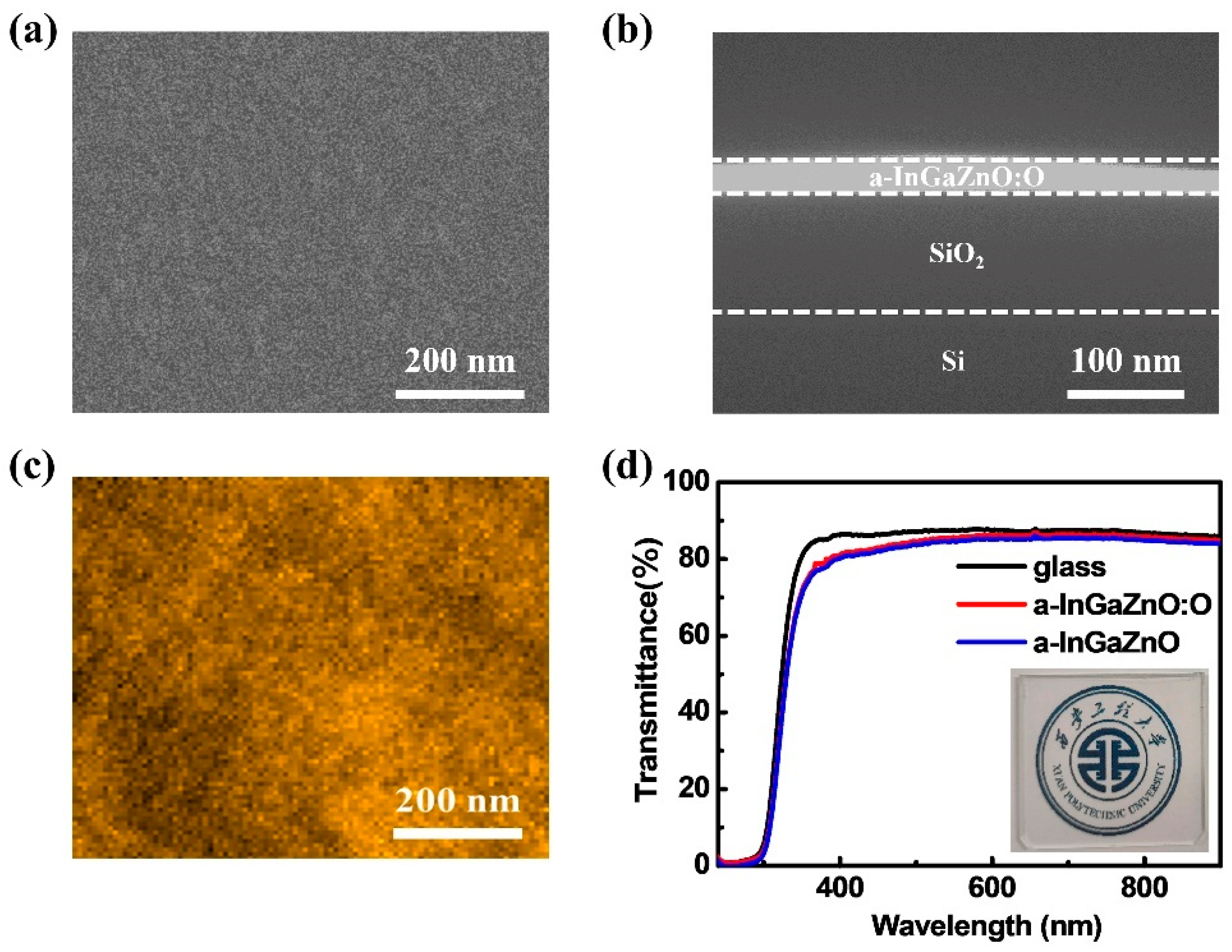

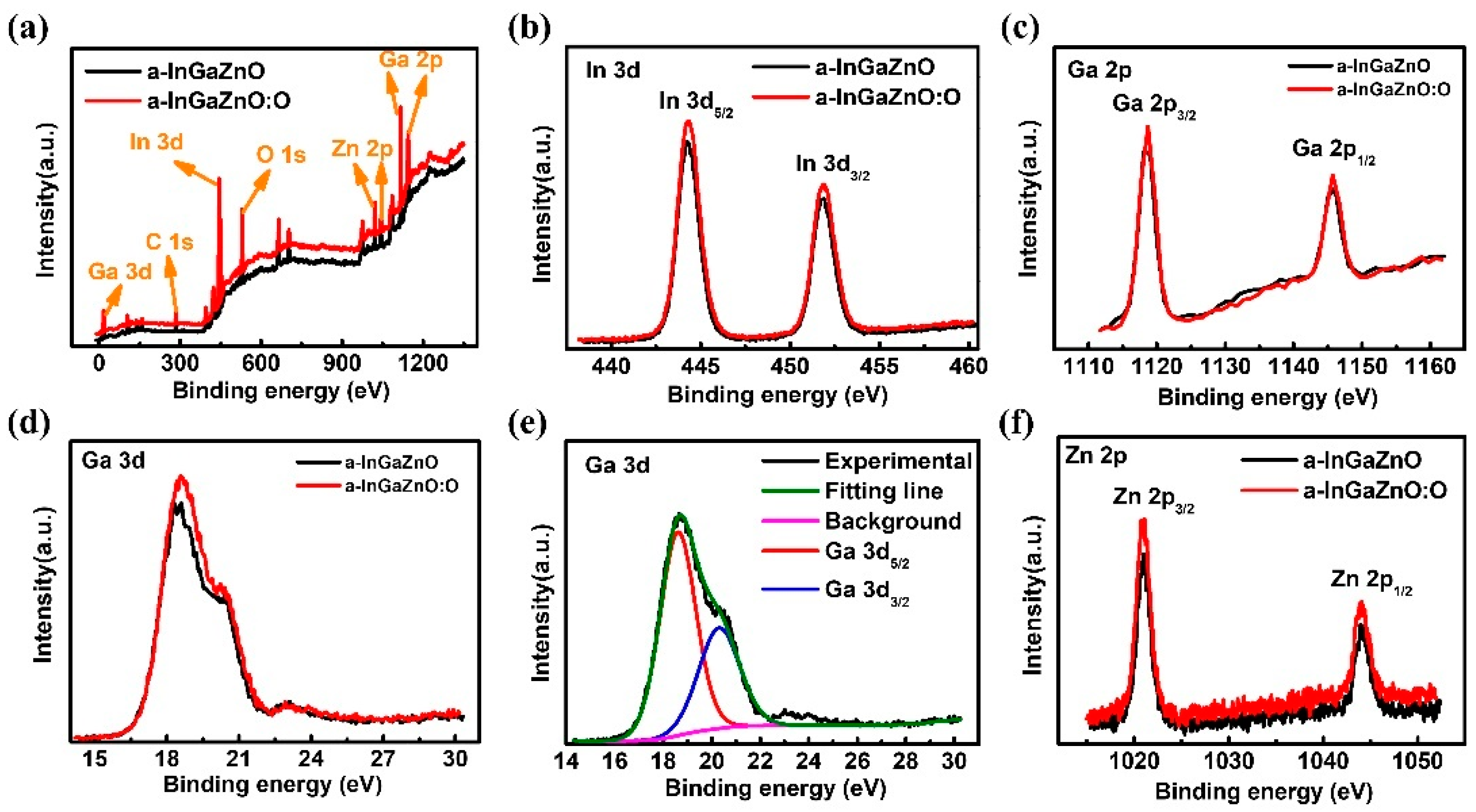

3.4. Characterization Analysis of a-InGaZnO Based Channel

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Oh, H.; Oh, J.-Y.; Park, C.W.; Pi, J.-E.; Yang, J.-H.; Hwang, C.-S. High density integration of stretchable inorganic thin film transistors with excellent performance and reliability. Nat. Commun. 2022, 13, 4963. [Google Scholar] [CrossRef] [PubMed]

- Myny, K. The development of flexible integrated circuits based on thin-film transistors. Nat. Electron. 2018, 1, 30–39. [Google Scholar] [CrossRef]

- Wang, C.; Cheng, R.; Liao, L.; Duan, X. High performance thin film electronics based on inorganic nanostructures and composites. Nano Today 2013, 8, 514–530. [Google Scholar] [CrossRef]

- Nomura, K.; Ohta, H.; Takagi, A.; Kamiya, T.; Hirano, M.; Hosono, H. Room-temperature fabrication of transparent flexible thin-film transistors using amorphous oxide semiconductors. Nature 2004, 432, 488–492. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Chen, X.; Liu, L.; Zeng, Z.; Chang, S.; Wang, H.; Wu, H.; Long, S.; Liu, C. Micron channel length ZnO thin film transistors using bilayer electrodes. J. Colloid Interface Sci. 2022, 622, 769–779. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Zhang, D.; Ding, Y.; Liu, G.; Shan, F. Study of oxygen plasma treatment on solution-processed SnOx thin-film transistors. J. Phys. D Appl. Phys. 2022, 55, 325102. [Google Scholar] [CrossRef]

- Li, Y.; Zeng, X.; Ye, Q.; Yao, R.; Zhong, J.; Fu, X.; Yang, Y.; Li, M.; Ning, H.; Peng, J. Effect of oxygen defect on the performance of Nd: InZnO high mobility thin-film transistors. Surf. Interfaces 2022, 33, 102184. [Google Scholar] [CrossRef]

- Eadi, S.B.; Shin, H.J.; Kumar, P.S.; Song, K.W.; Yuvakkumar, R.; Lee, H.D. Fluorine-implanted indium-gallium-zinc oxide (IGZO) chemiresistor sensor for high-response NO2 detection. Chemosphere 2021, 284, 131287. [Google Scholar] [CrossRef]

- Naqi, M.; Kwon, N.; Jung, S.H.; Pujar, P.; Cho, H.W.; Cho, Y.I.; Cho, H.K.; Lim, B.; Kim, S. High-Performance Non-Volatile InGaZnO Based Flash Memory Device Embedded with a Monolayer Au Nanoparticles. Nanomaterials 2021, 11, 1101. [Google Scholar] [CrossRef]

- Chen, T.; Wang, C.; Yang, G.; Lou, Q.; Lin, Q.; Zhang, S.; Zhou, H. Monolithic Integration of Perovskite Photoabsorbers with IGZO Thin-Film Transistor Backplane for Phototransistor-Based Image Sensor. Adv. Mater. Technol. 2022, 2200679. [Google Scholar] [CrossRef]

- Ding, X.; Huang, F.; Li, S.; Zhang, J.; Jiang, X.; Zhang, Z. Effect of O2 plasma treatment on density-of-states in a-IGZO thin film transistors. Electron. Mater. Lett. 2016, 13, 45–50. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Tarsoly, G.; Shan, F.; Kim, S.-J. Optimizing Oxygen Plasma Treatment Time to Improve the Characteristics of a-IGZO Thin-Film Transistors and Resistive-Load Inverters. IEEE Trans. Electron. Devices 2022, 69, 1883–1888. [Google Scholar] [CrossRef]

- Lee, J.Y.; Heo, K.J.; Choi, S.G.; Ryu, H.G.; Koh, J.H.; Kim, S.J. Effects of Oxygen Injection Rates on a-IGZO Thin-film Transistors with Oxygen Plasma Treatment. J. Semicond. Technol. Sci. 2021, 21, 189–198. [Google Scholar] [CrossRef]

- Wang, C.; Lu, W.; Li, F.; Luo, Q.; Ma, F. Migration of weakly bonded oxygen atoms in a-IGZO thin films and the positive shift of threshold voltage in TFTs. Chin. Phys. B 2022, 31, 096101. [Google Scholar] [CrossRef]

- Lee, S.Y.; Kim, D.H.; Chong, E.; Jeon, Y.W.; Kim, D.H. Effect of channel thickness on density of states in amorphous InGaZnO thin film transistor. Appl. Phys. Lett. 2011, 98, 122105. [Google Scholar] [CrossRef] [Green Version]

- Kim, B.; Chong, E.; Kim, D.H.; Jeon, Y.W.; Kim, D.H.; Lee, S.Y. Origin of threshold voltage shift by interfacial trap density in amorphous InGaZnO thin film transistor under temperature induced stress. Appl. Phys. Lett. 2011, 99, 062108. [Google Scholar] [CrossRef]

- Moon, Y.-K.; Lee, S.; Kim, W.-S.; Kang, B.-W.; Jeong, C.-O.; Lee, D.-H.; Park, J.-W. Improvement in the bias stability of amorphous indium gallium zinc oxide thin-film transistors using an O2 plasma-treated insulator. Appl. Phys. Lett. 2009, 95, 013507. [Google Scholar] [CrossRef]

- Liu, W.S.; Hsu, C.H.; Jiang, Y.; Lai, Y.C.; Kuo, H.C. Improvement of device characteristics of plasma-treated indium gallium zinc oxide thin-film transistors through thermal annealing. Semicond. Sci. Technol. 2021, 36, 045007. [Google Scholar] [CrossRef]

- Kamiya, T.; Nomura, K.; Hosono, H. Present status of amorphous In-Ga-Zn-O thin-film transistors. Sci. Technol. Adv. Mater. 2010, 11, 044305. [Google Scholar] [CrossRef]

- Fortunato, E.; Barquinha, P.; Martins, R. Oxide semiconductor thin-film transistors: A review of recent advances. Adv. Mater. 2012, 24, 2945–2986. [Google Scholar] [CrossRef]

- Sanal, K.C.; Mackay, T.G.; Majeesh, M.; Jayaraj, M.K.; Lakhtakia, A.; Jen, Y.-J.; Suzuki, M. Growth of IGZO thin films and fabrication of transparent thin film transistor by RF magnetron sputtering. Proc. SPIE 2013, 8818, 199–205. [Google Scholar] [CrossRef]

- Li, Y.; Pei, Y.L.; Hu, R.Q.; Chen, Z.M.; Zhao, Y.; Shen, Z.; Fan, B.F.; Liang, J.; Wang, G. Effect of channel thickness on electrical performance of amorphous IGZO thin-film transistor with atomic layer deposited alumina oxide dielectric. Curr. Appl. Phys. 2014, 14, 941–945. [Google Scholar] [CrossRef]

- Krausmann, J.; Sanctis, S.; Engstler, J.; Luysberg, M.; Bruns, M.; Schneider, J.J. Charge Transport in Low-Temperature Processed Thin-Film Transistors Based on Indium Oxide/Zinc Oxide Heterostructures. ACS Appl. Mater. Interfaces 2018, 10, 20661–20671. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, X.W.; Goh, G.K.L.; Demir, H.V.; Yu, H.Y. Influence of Channel Layer Thickness on the Electrical Performances of Inkjet-Printed In-Ga-Zn Oxide Thin-Film Transistors. IEEE Trans. Electron. Devices 2011, 58, 480–485. [Google Scholar] [CrossRef] [Green Version]

- Chu, M.-C.; Meena, J.S.; Liu, P.-T.; Shieh, H.-P.D.; You, H.-C.; Tu, Y.-W.; Chang, F.-C.; Ko, F.-H. Oxygen Plasma Functioning of Charge Carrier Density in Zinc Oxide Thin-Film Transistors. Appl. Phys. Express. 2013, 6, 076501. [Google Scholar] [CrossRef]

- Noh, H.-K.; Park, J.-S.; Chang, K.J. Effect of hydrogen incorporation on the negative bias illumination stress instability in amorphous In-Ga-Zn-O thin-film-transistors. J. Appl. Phys. 2013, 113, 063712. [Google Scholar] [CrossRef]

- Ryu, B.; Noh, H.-K.; Choi, E.-A.; Chang, K.J. O-vacancy as the origin of negative bias illumination stress instability in amorphous In–Ga–Zn–O thin film transistors. Appl. Phys. Lett. 2010, 97, 022108. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.-Y.; Tarsoly, G.; Choi, S.-G.; Ryu, H.-G.; Kim, S.-J. Influences of Oxygen Plasma Posttreatment on Electrical Characteristics of Amorphous Indium–Gallium–Zinc–Oxide Thin-Film Transistors. Phys. Status Solidi 2021, 218, 2100205. [Google Scholar] [CrossRef]

- Abliz, A.; Gao, Q.; Wan, D.; Liu, X.; Xu, L.; Liu, C.; Jiang, C.; Li, X.; Chen, H.; Guo, T.; et al. Effects of Nitrogen and Hydrogen Codoping on the Electrical Performance and Reliability of InGaZnO Thin-Film Transistors. ACS Appl. Mater. Interfaces 2017, 9, 10798–10804. [Google Scholar] [CrossRef]

- Abliz, A.; Xu, L.; Wan, D.; Duan, H.; Wang, J.; Wang, C.; Luo, S.; Liu, C. Effects of yttrium doping on the electrical performances and stability of ZnO thin-film transistors. Appl. Surf. Sci. 2019, 475, 565–570. [Google Scholar] [CrossRef]

- Abliz, A.; Wan, D.; Yang, L.; Mamat, M.; Chen, H.; Xu, L.; Wang, C.; Duan, H. Investigation on the electrical performances and stability of W-doped ZnO thin-film transistors. Mater. Sci. Semicond. Process. 2019, 95, 54–58. [Google Scholar] [CrossRef]

- Oh, C.; Jang, H.; Kim, H.W.; Jung, H.; Park, H.; Cho, J.; Kim, B.S. Influence of oxygen partial pressure in In-Sn-Ga-O thin-film transistors at a low temperature. J. Alloys. Compd. 2019, 805, 211–217. [Google Scholar] [CrossRef]

- Hanyu, Y.; Domen, K.; Nomura, K.; Hiramatsu, H.; Kumomi, H.; Hosono, H.; Kamiya, T. Hydrogen passivation of electron trap in amorphous In-Ga-Zn-O thin-film transistors. Appl. Phys. Lett. 2013, 103, 202114. [Google Scholar] [CrossRef]

- Fan, W.T.; Liu, P.T.; Kuo, P.Y.; Chang, C.M.; Liu, I.H.; Kuo, Y. Numerical Analysis of Oxygen-Related Defects in Amorphous In-W-O Nanosheet Thin-Film Transistor. Nanomaterials 2021, 11, 3070. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.-S.; Joo, M.-K.; Xing Piao, M.; Ahn, S.-E.; Choi, Y.-H.; Jang, H.-K.; Kim, G.-T. Plasma treatment effect on charge carrier concentrations and surface traps in a-InGaZnO thin-film transistors. J. Appl. Phys. 2014, 115, 114503. [Google Scholar] [CrossRef]

| RF Power (W) | Vth (V) | µFE (cm2/V s) | Ion/Ioff | SS (V/dec) | Dit (cm−2/eV) |

|---|---|---|---|---|---|

| 50 | −10 | 18 | 105 | 2.9 | 1.1 × 1011 |

| 40 | −0.9 | 17 | 106 | 1.7 | 6.3 × 1010 |

| 30 | 5 | 14 | 106 | 1.2 | 4.5 × 1010 |

| Channel Thickness (nm) | Vth (V) | µFE (cm2/V s) | Ion/Ioff | SS (V/dec) | Dit (cm−2/eV) |

|---|---|---|---|---|---|

| 30 | −19 | 14 | 105 | 5.6 | 2.1 × 1011 |

| 20 | −0.9 | 17 | 106 | 1.7 | 6.3 × 1010 |

| 10 | 19 | 6 | 106 | 0.7 | 2.6 × 1010 |

| Oxygen Power (W) | Vth (V) | µFE (cm2/V s) | Ion/Ioff | SS (V/dec) | Dit (cm−2/eV) |

|---|---|---|---|---|---|

| 0 | −0.9 | 17 | 106 | 1.7 | 6.3 × 1010 |

| 10 | −0.8 | 18 | 106 | 1.5 | 5.7 × 1010 |

| 15 | 0.3 | 19 | 106 | 1.3 | 4.8 × 1010 |

| 20 | 0.9 | 28 | 107 | 0.9 | 3.3 × 1010 |

| 30 | 9.1 | 14 | 105 | 1.9 | 7.1 × 1010 |

| 40 | 12 | 10 | 106 | 2.2 | 8.2 × 1010 |

| RF Power (W) | Channel Thickness (nm) | Plasma | Annealing Temperature (°C) | Contact Electrode | µFE (cm2/V s) | Ion/Ioff | Vth (V) | SS (V/dec) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| 40 | 20 | – oxygen | RT | Cu | 17 28 | 106 107 | −0.9 0.9 | 1.7 0.9 | This work |

| / | 50 | – oxygen | 120 | Ti/Au | 14.4 16.9 | 106 105 | −23 4.3 | 0.6 1.3 | [35] |

| / | 15 | – oxygen | 250 | Al | 7.3 10.1 | 107 107 | 1.4 0.5 | 0.3 0.2 | [11] |

| 150 | 50 | – oxygen | 300 | Al | 8.9 14.8 | 102 108 | 5.1 0.4 | 7.3 0.6 | [28] |

| / | 50 | – | 300 | Al | 5.7 9.6 | 107 108 | 5.3 8.4 | 1.1 0.5 | [12] |

| 150 | 50 | – oxygen | 350 | Al | 10.6 14.4 | 107 108 | 2.8 4.5 | 0.9 0.7 | [13] |

| / | 30 | – | 350 | Ti/Au | 4.8 | 107 | 9.1 | 1.2 | [15] |

| 30 | 50 | – | 350 | / | 7.8 | 107 | 12.7 | 1.1 | [16] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Li, Y.; Jin, Y.; Guo, G.; Song, Y.; Huang, H.; He, H.; Wang, A. One-Step Synergistic Treatment Approach for High Performance Amorphous InGaZnO Thin-Film Transistors Fabricated at Room Temperature. Nanomaterials 2022, 12, 3481. https://doi.org/10.3390/nano12193481

Wang C, Li Y, Jin Y, Guo G, Song Y, Huang H, He H, Wang A. One-Step Synergistic Treatment Approach for High Performance Amorphous InGaZnO Thin-Film Transistors Fabricated at Room Temperature. Nanomaterials. 2022; 12(19):3481. https://doi.org/10.3390/nano12193481

Chicago/Turabian StyleWang, Chunlan, Yuqing Li, Yebo Jin, Gangying Guo, Yongle Song, Hao Huang, Han He, and Aolin Wang. 2022. "One-Step Synergistic Treatment Approach for High Performance Amorphous InGaZnO Thin-Film Transistors Fabricated at Room Temperature" Nanomaterials 12, no. 19: 3481. https://doi.org/10.3390/nano12193481