Toward the Industrial Application of Aluminum-Based Nanocomposite Material: A Study of Zn-Plating Process in Circuit Breaker Application

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Nanocomposites

2.2. Mechanical Plating of Zinc

2.3. Surface Morphological Characterization

2.4. Microindentation Hardness Tests

2.5. Tribological Characterization

2.6. Electrical Conductivity of the Zn-Plated Nanocomposites

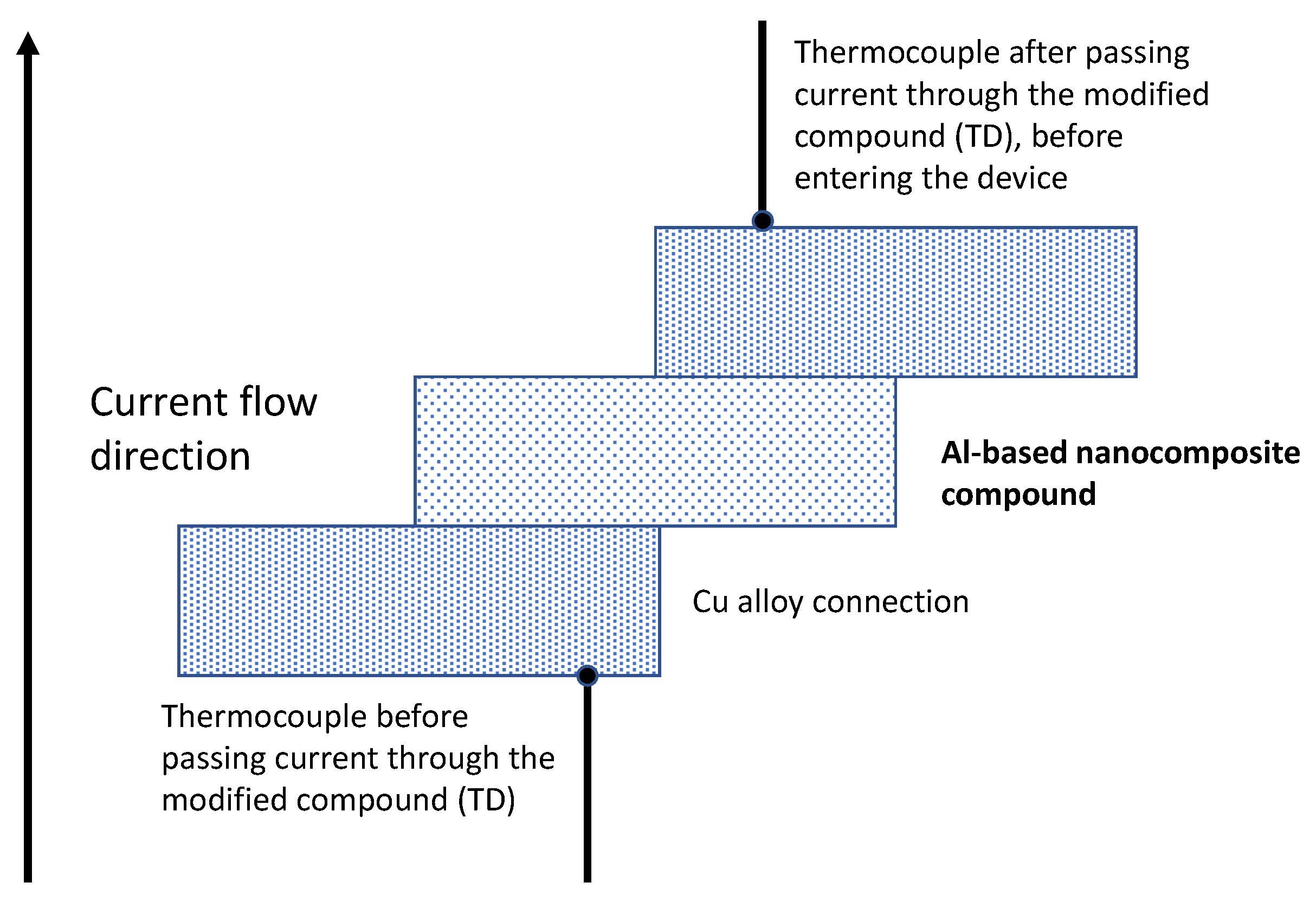

2.7. Electrical and Thermal Test Configuration of the Zn-Plated Parts Adapted to a Molded Case Circuit Breaker

3. Results and Discussion

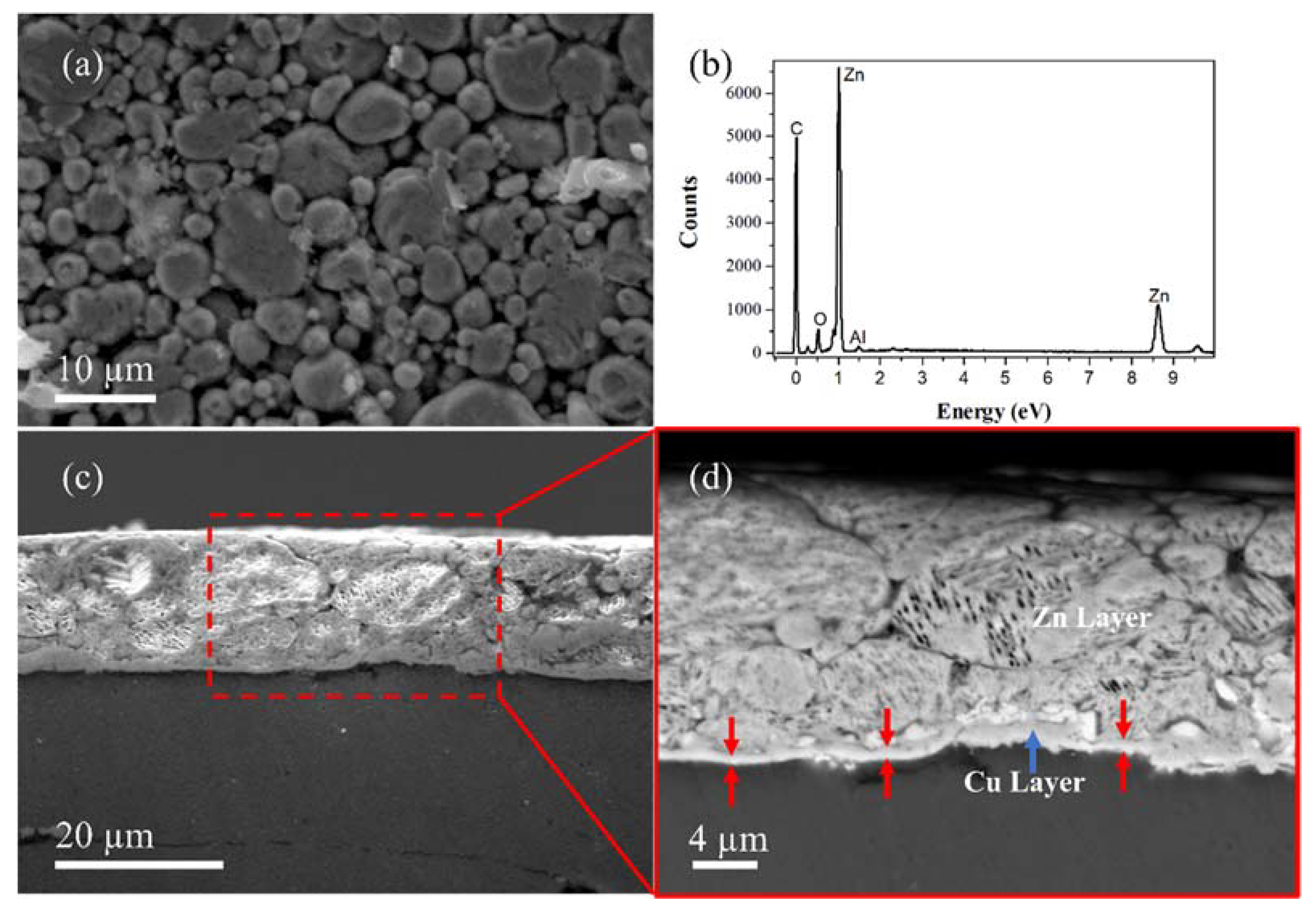

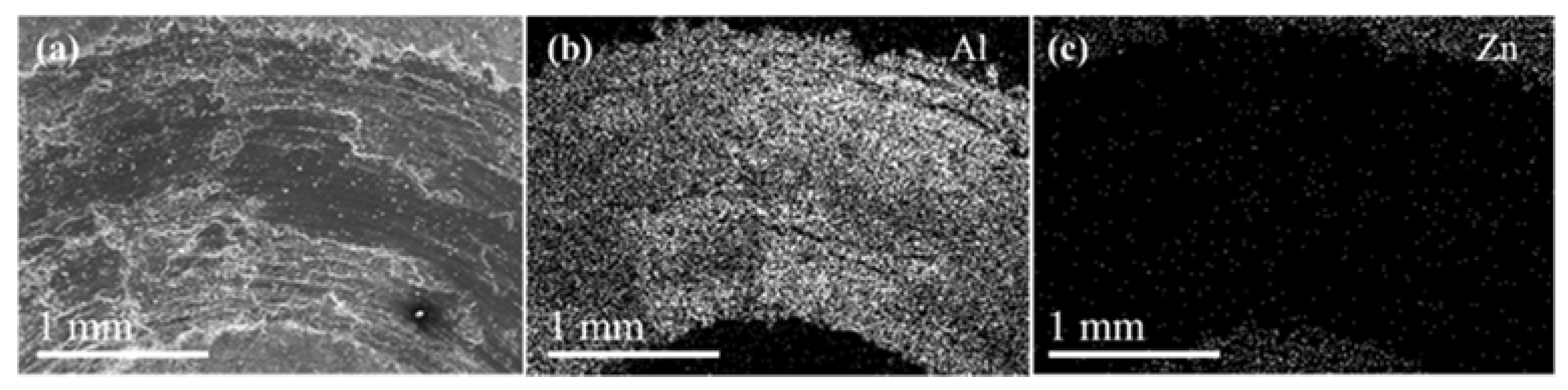

3.1. Morphological Zinc Coating Samples

3.2. Microindentation Analysis

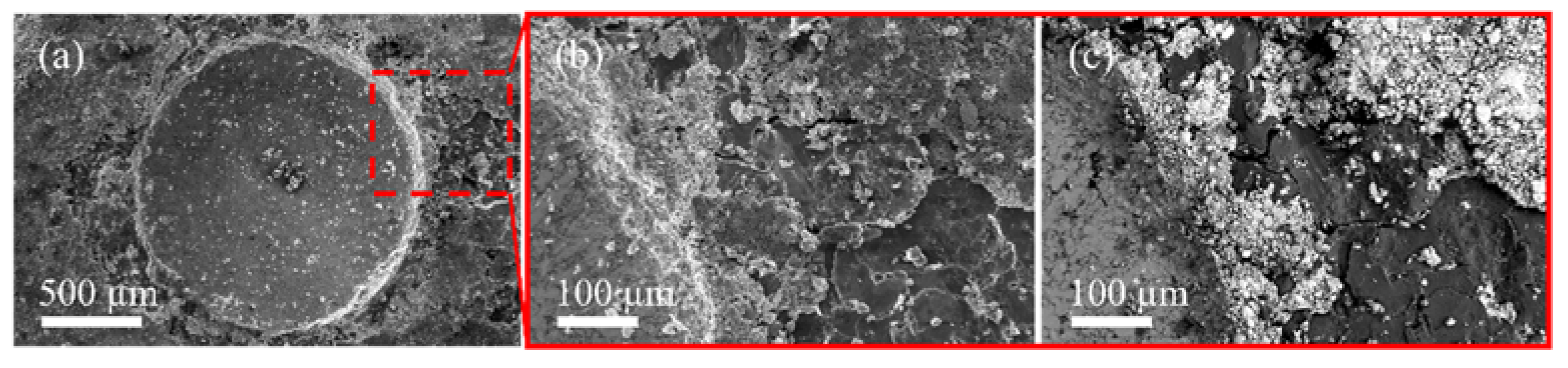

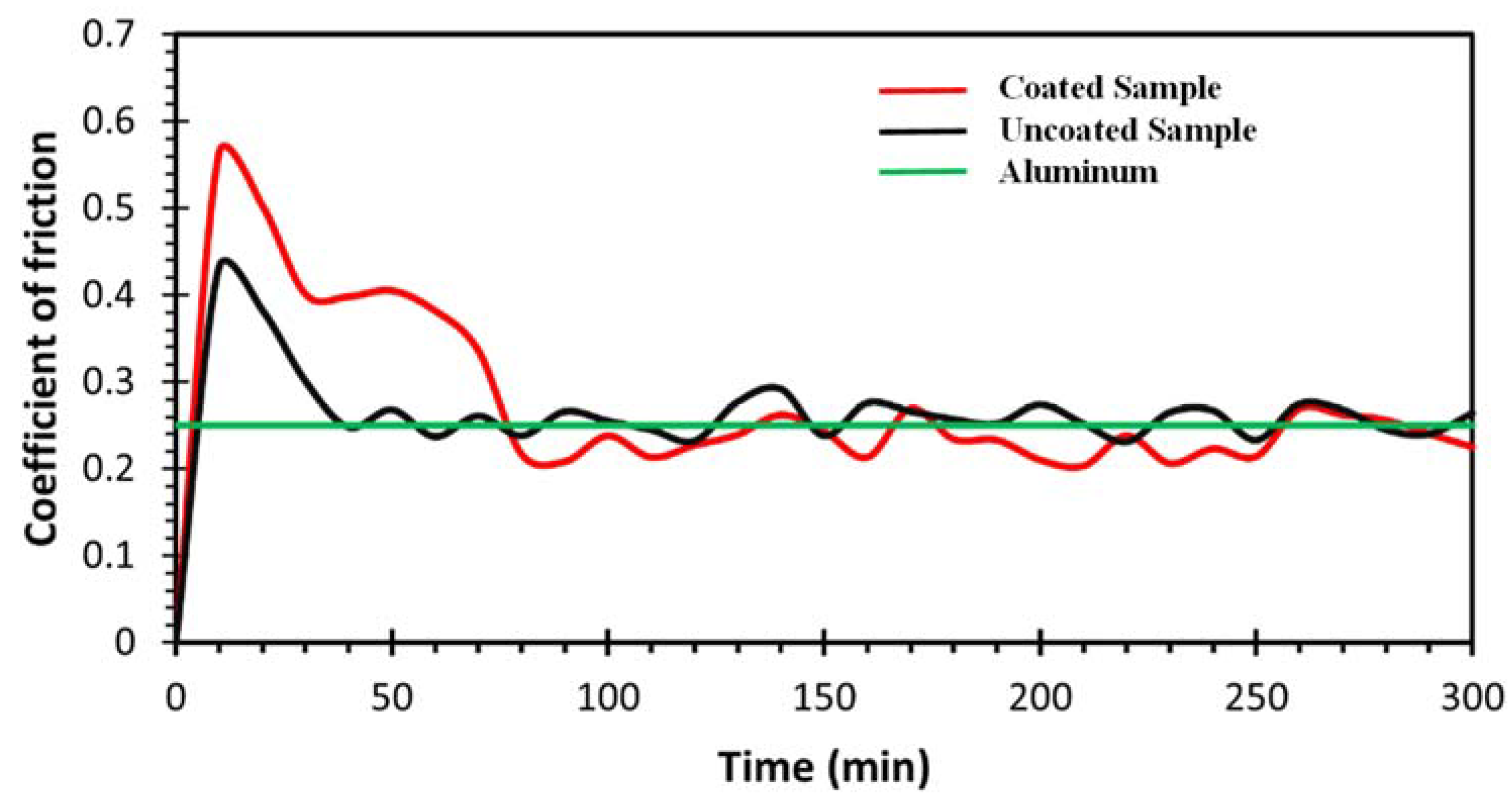

3.3. Tribology Analysis

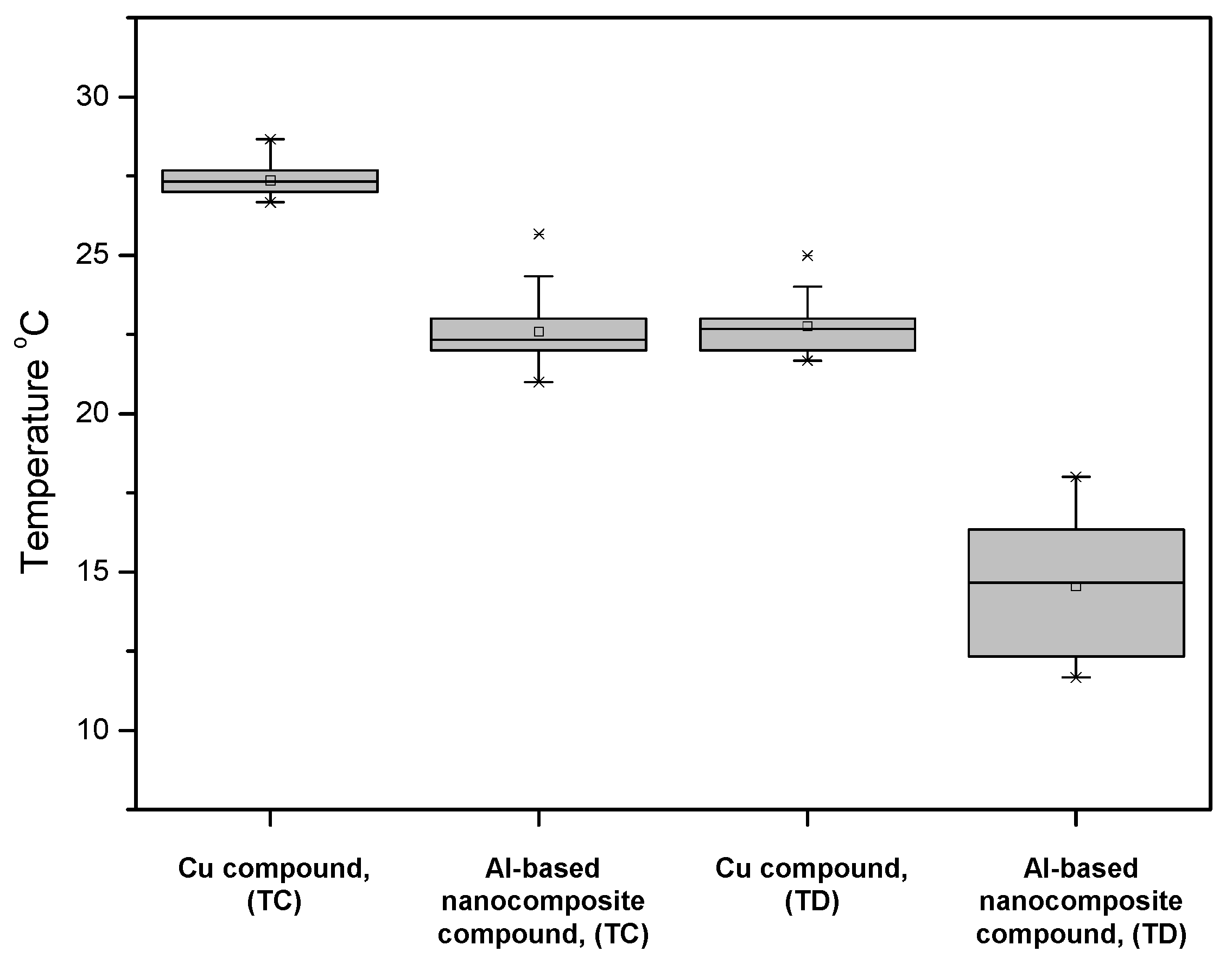

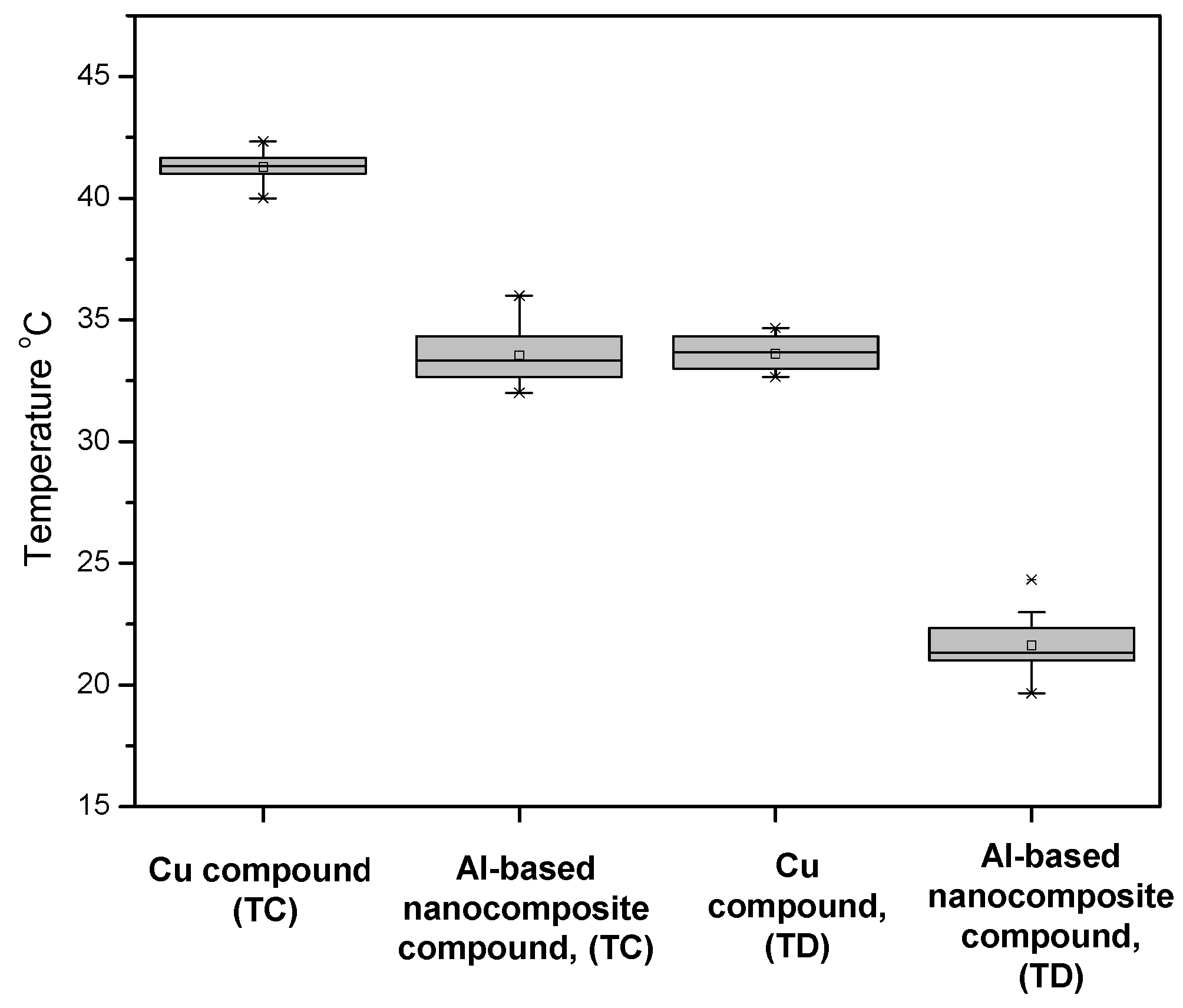

3.4. Electrical Performance of Al-Based Nanocomposite in a Molded Case Circuit Breaker

4. Conclusions

- The Cu pre-plating layer showed good homogeneous distribution on the surface of the aluminum nanocomposite, indicating an excellent interface between the nanocomposite materials and copper. However, the interface between Cu and the Zn coating had weak interaction between the materials due to the presence of semi-molten particles that caused pores formation in the coating layer.

- The indentations of the tribological tests showed that the Zn coatings for the metallic nanocomposites should be considered as smooth coatings since the collected coefficient of friction values for both the coated and uncoated samples were similar.

- The identification of plating process parameters plays a key role in obtaining good quality coating. Zn coatings can be used on Al nanocomposite materials to mitigate corrosion deterioration without hindering heat dissipation, while maintaining a stable electrical resistance in the MCCB, contrary to what happens with Cu, which in-creases its electrical resistance as the temperature in the device increases.

- The developed aluminum-based nanocomposite compounds follow the RoHS compliance guide, showing good performance under the MCCB device operation conditions.

- The aluminum-based nanocomposite material with Zn as coating exhibited improved properties in the home-made engineered test that was based on the UL 489 standard for electrical devices, against the typical used material, with a final cost reduction in the manufacturing process for the MCCB process.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lei, L.; Shen, Y.; Chen, X.; Qian, L.; Lu, K. Ultrahigh Strength and High Electrical Conductivity in Copper. Science 2004, 304, 422–426. [Google Scholar]

- Valiev, R.Z.; Murashkin, M.Y.; Sabirov, I. A nanostructural design to produce high-strength Al alloys with enhanced electrical conductivity. Scr. Mater. 2014, 76, 13–16. [Google Scholar] [CrossRef]

- Cui, X.; Wu, Y.; Zhang, G.; Liu, Y.; Liu, X. Study on the improvement of electrical conductivity and mechanical properties of low alloying electrical aluminum alloys. Compos. Part B Eng. 2017, 110, 381–387. [Google Scholar] [CrossRef]

- Editor, S.; Davim, J.P. Lecture Notes on Multidisciplinary Industrial Engineering Optimization Methods in Engineering; Springer: Berlin/Heidelberg, Germany, 2019; Volume 49. [Google Scholar]

- Shin, S.E.; Choi, H.J.; Hwang, J.Y.; Bae, D.H. Strengthening behavior of carbon/metal nanocomposites. Sci. Rep. 2015, 5, 16114. [Google Scholar] [CrossRef] [Green Version]

- Aborkin, A.; Khorkov, K.; Prusov, E.; Ob’Edkov, A.; Kremlev, K.; Perezhogin, I.; Alymov, M. Effect of Increasing the Strength of Aluminum Matrix Nanocomposites Reinforced with Microadditions of Multiwalled Carbon Nanotubes Coated with TiC Nanoparticles. Nanomaterials 2019, 9, 1596. [Google Scholar] [CrossRef] [Green Version]

- Mohammed, S.M.A.K.; Chen, D.L. Carbon Nanotube-Reinforced Aluminum Matrix Composites. Adv. Eng. Mater. 2020, 22, 1901176. [Google Scholar] [CrossRef] [Green Version]

- Ajayan, P.M.; Ebbesen, T.W. Nanometre-size tubes of carbon. Rep. Prog. Phys. 1997, 60, 1025–1062. [Google Scholar] [CrossRef]

- Dai, H. Carbon nanotubes: Opportunities and challenges. Surf. Sci. 2002, 500, 218–241. [Google Scholar] [CrossRef]

- De Volder, M.F.L.; Tawfick, S.H.; Baughman, R.H.; Hart, A.J. Carbon Nanotubes: Present and Future Commercial Applications. Science 2013, 339, 535–539. [Google Scholar] [CrossRef] [Green Version]

- Hjortstam, O.; Isberg, P.; Söderholm, S.; Dai, H. Can we achieve ultra-low resistivity in carbon nanotube-based metal composites? Appl. Phys. A 2004, 78, 1175–1179. [Google Scholar] [CrossRef]

- Baumli, P.; Sytchev, J.; Kaptay, G. Perfect wettability of carbon by liquid aluminum achieved by a multifunctional flux. J. Mater. Sci. 2010, 45, 5177–5190. [Google Scholar] [CrossRef]

- Juhasz, K.L.; Baumli, P.; Sytchev, J.; Kaptay, G. Wettability of graphite by liquid aluminum under molten potassium halide fluxes. J. Mater. Sci. 2013, 48, 7679–7685. [Google Scholar] [CrossRef]

- Veillère, A.; Kurita, H.; Kawasaki, A.; Lu, Y.; Heintz, J.-M.; Silvain, J.-F. Aluminum/Carbon Composites Materials Fabricated by the Powder Metallurgy Process. Materials 2019, 12, 4030. [Google Scholar] [CrossRef] [Green Version]

- Popoola, A.P.I.; Olorunniwo, O.E.; Ige, O.O. Developments in Corrosion Protection; Intech: London, UK, 2014. [Google Scholar]

- Ranganatha, S.; Venkatesha, T.V.; Vathsala, K.; Kumar, M.K.P. Electrochemical studies on Zn/nano-CeO2 electrode-posited composite coatings. Surf. Coat. Technol. 2012, 208, 64–72. [Google Scholar] [CrossRef]

- Lyons, E.H. Fundamental principles. In Modern Electroplating; Lowenheim, F.A., Ed.; Wiley: New York, NY, USA, 1974; pp. 31–36. [Google Scholar]

- Wetzel, D. Batch hot dip galvanized coatings. In ASM Handbook, Volume 5—Surface Engineering; Cotell, C.M., Sprague, J.A., Smidt, F.A., Jr., Eds.; ASM International: Geauga, OH, USA, 1994; pp. 360–371. [Google Scholar]

- Mattox, D.M. Ion plating and ion beam-assisted deposition. In Handbook of Physical Vapor Deposition (PVD) Processing, 2nd ed.; Mattox, D.M., Ed.; William Andrew Publishing: Norwich, NY, USA, 2010; pp. 301–331. [Google Scholar]

- Heilig, M.L. United States Patent Office. ACM Siggraph Comput. Graph. 1994, 28, 131–134. [Google Scholar] [CrossRef]

- Ulloa-Castillo, N.A.; Martínez-Romero, O.; Hernandez-Maya, R.; Segura-Cárdenas, E.; Elías-Zúñiga, A. Spark Plasma Sintering of Aluminum-Based Powders Reinforced with Carbon Nanotubes: Investigation of Electrical Conductivity and Hardness Properties. Materials 2021, 14, 373. [Google Scholar] [CrossRef]

- Ulloa-Castillo, N.A.; Hernández-Maya, R.; Islas-Urbano, J.; Martínez-Romero, O.; Segura-Cárdenas, E.; Elías-Zúñiga, A. Enhancement of Electrical Conductivity of Aluminum-Based Nanocomposite Produced by Spark Plasma Sintering. Nanomaterials 2021, 11, 1150. [Google Scholar] [CrossRef]

- Hernández-Maya, R.; Ulloa-Castillo, N.A.; Martínez-Romero, O.; Segura-Cárdenas, E.; Elías-Zúñiga, A. Spark Plasma Sintering of Aluminum Nanocomposite Powders: Recent Strategy to Translate from Lab-Scale to Mass Production. Nanomaterials 2021, 11, 3372. [Google Scholar] [CrossRef]

- Ramezani, M.; Neitzert, T. Mechanical milling of aluminum powder using planetary ball milling process. J. Achiev. Mater. Manuf. Eng. 2012, 55, 790–798. [Google Scholar]

- Toozandehjani, M.; Matori, K.A.; Ostovan, F.S.; Aziz, A.; Mamat, M.S. Effect of milling time on the microstructure physical and mechanical properties of Al-Al2O3 nanocomposite synthesized by ball milling and powder metallurgy. Materials 2017, 10, 1232. [Google Scholar] [CrossRef] [Green Version]

- Song, J.; Schinow, V. Correlation between friction and wear properties and electrical performance of silver coated electrical conectors. Wear 2015, 330–331, 400–405. [Google Scholar] [CrossRef]

- Munoz, M.; Chen, H.; Hernandez, J. Tin plating investigation as a potential alternative to Silver plating in plug in connection for Low Voltage Low Amp Miniature Circuit Breaker. In Proceedings of the 2016 IEEE Holm Conference on Electrical Contacts, Clearwater Beach, FL, USA, 9–12 October 2016; pp. 187–191. [Google Scholar]

- Chatterjee, B. Mechanical Plating. Galvanotechnik 2005, 96, 136–146. [Google Scholar]

- Mathavan, J.J.; Patnaik, A. Analysis of wear properties of aluminium based journal bearing alloys with and without lubrication. IOP Conf. Ser. Mater. Sci. Eng. 2016, 149, 12052. [Google Scholar] [CrossRef]

- Santos, A.; Córdoba, E.; Ramírez, Z.; Sierra, C.; Ortega, Y. Determination of the coefficient of dynamic friction between coatings of alumina and metallic materials. J. Phys. Conf. Ser. 2017, 935, 12042. [Google Scholar] [CrossRef]

- Zare, Y.; Yop Rhee, K.; Park, S.-J. Modeling the roles of carbon nanotubes and interphase dimensions in the conductivity of nanocomposites. Results Phys. 2019, 15, 102562. [Google Scholar] [CrossRef]

- Deng, F.; Zheng, Q.-S. An analytical model of effective electrical conductivity of carbon nanotube composites. Appl. Phys. Lett. 2008, 92, 71902. [Google Scholar] [CrossRef]

- Bakshi, S.R.; Lahiri, D.; Agarwal, A. Carbon nanotube reinforced metal matrix composites—A review. Intern. Mater. Rev. 2010, 55, 41–64. [Google Scholar] [CrossRef]

- Zhang, G.; Jiang, S.; Zhang, H.; Yao, W.; Liu, C. Excellent heat dissipation properties of the super-aligned carbon nanotube films. RSC Adv. 2016, 6, 61686–61694. [Google Scholar] [CrossRef]

- Ujah, C.O.; Popoola, A.P.I.; Popoola, O.M.; Aigbodion, V.S. Enhanced tribology, thermal and electrical properties of Al-CNT composite processed via spark plasma sintering for transmission conductor. J. Mater. Sci. 2019, 54, 14064–14073. [Google Scholar] [CrossRef]

- Abu-Eishah, S.I. Correlations for the Thermal Conductivity of Metals as a Function of Temperature. Int. J. Thermophys. 2001, 22, 1855–1868. [Google Scholar] [CrossRef]

| Sample | Description Sample | Conductivity (MS/m) | % IACS |

|---|---|---|---|

| I1 | uncoated | 24 | 41.7 |

| I2 | uncoated | 24 | 41.7 |

| S2 | zinc coated | 24.6 | 42.57 |

| S3 | zinc coated | 24.6 | 41.57 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Segura-Cárdenas, E.; Ulloa-Castillo, N.A.; Hernández-Maya, R.; Martínez-Romero, O.; Elías-Zúñiga, A. Toward the Industrial Application of Aluminum-Based Nanocomposite Material: A Study of Zn-Plating Process in Circuit Breaker Application. Nanomaterials 2022, 12, 3535. https://doi.org/10.3390/nano12193535

Segura-Cárdenas E, Ulloa-Castillo NA, Hernández-Maya R, Martínez-Romero O, Elías-Zúñiga A. Toward the Industrial Application of Aluminum-Based Nanocomposite Material: A Study of Zn-Plating Process in Circuit Breaker Application. Nanomaterials. 2022; 12(19):3535. https://doi.org/10.3390/nano12193535

Chicago/Turabian StyleSegura-Cárdenas, Emmanuel, Nicolás A. Ulloa-Castillo, Roberto Hernández-Maya, Oscar Martínez-Romero, and Alex Elías-Zúñiga. 2022. "Toward the Industrial Application of Aluminum-Based Nanocomposite Material: A Study of Zn-Plating Process in Circuit Breaker Application" Nanomaterials 12, no. 19: 3535. https://doi.org/10.3390/nano12193535

APA StyleSegura-Cárdenas, E., Ulloa-Castillo, N. A., Hernández-Maya, R., Martínez-Romero, O., & Elías-Zúñiga, A. (2022). Toward the Industrial Application of Aluminum-Based Nanocomposite Material: A Study of Zn-Plating Process in Circuit Breaker Application. Nanomaterials, 12(19), 3535. https://doi.org/10.3390/nano12193535