Weft-Knitted Spacer Fabric for Highly Stretchable–Compressible Strain Sensor, Supercapacitor, and Joule Heater

Abstract

1. Introduction

2. Experimental

2.1. Materials

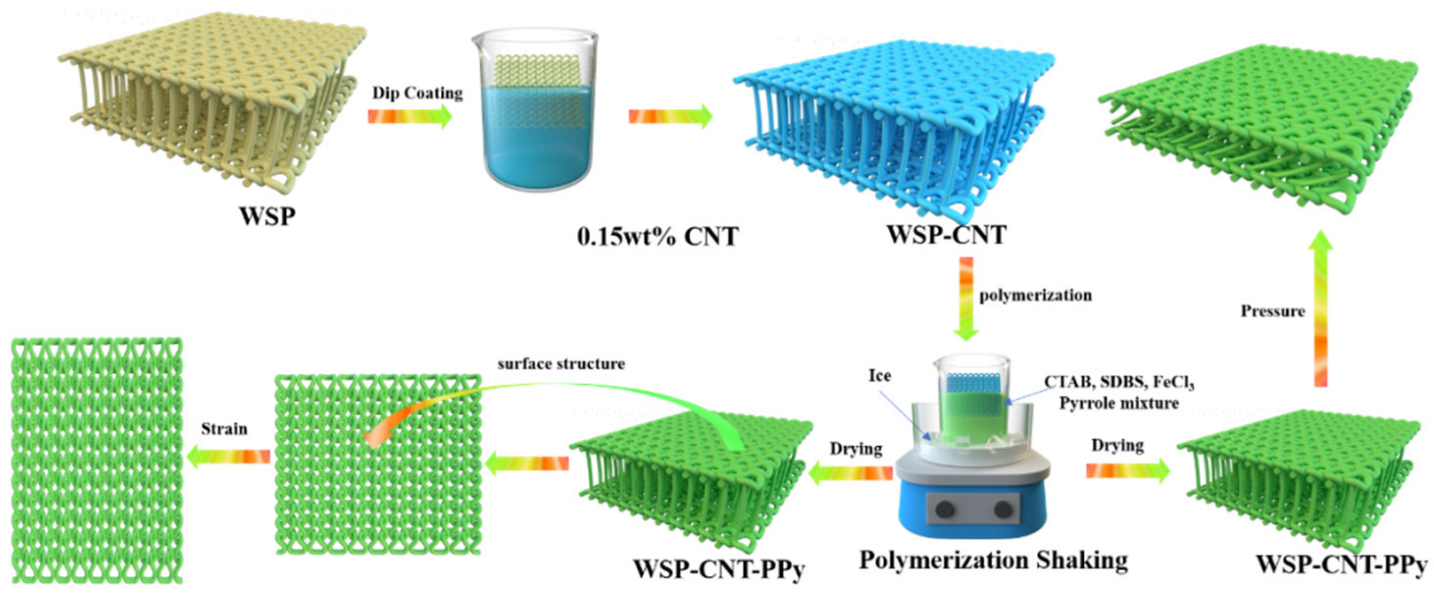

2.2. Preparation of Weft-Knitted Spacer Fabric Sensor

2.3. Measurements and Characterization

3. Results

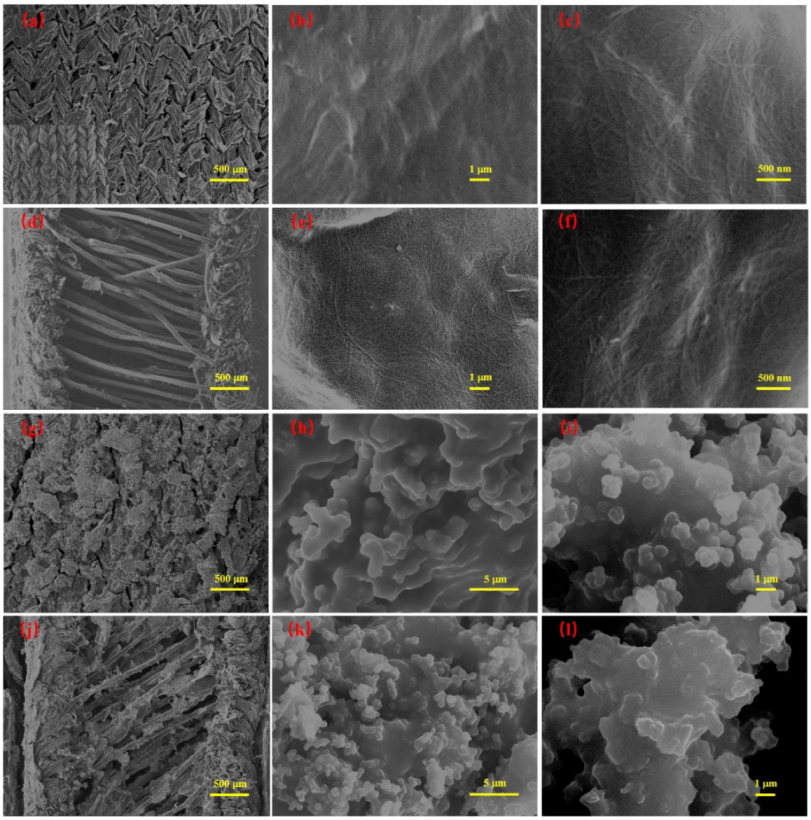

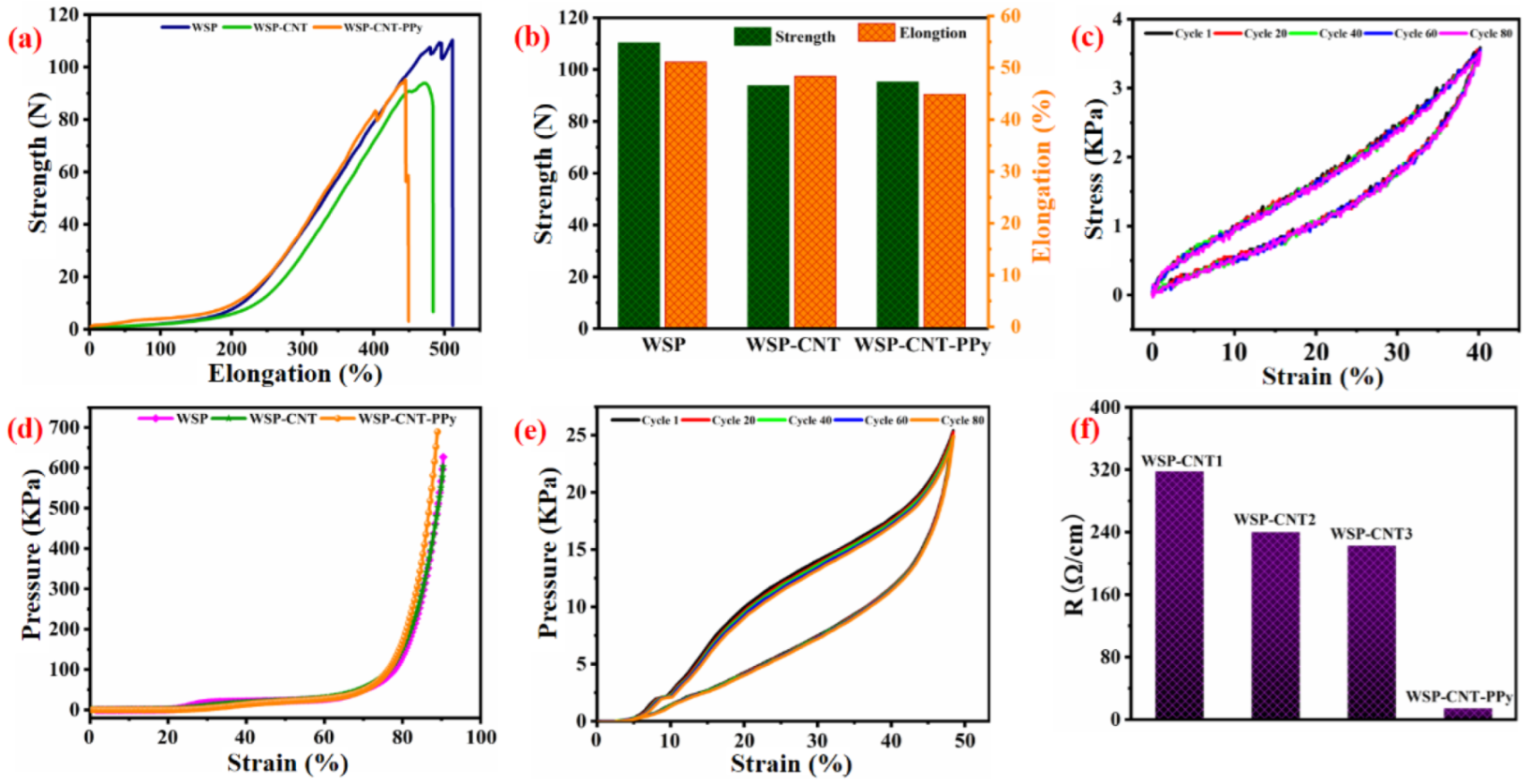

3.1. Surface Morphologies, Microstructures, and Mechanical Properties

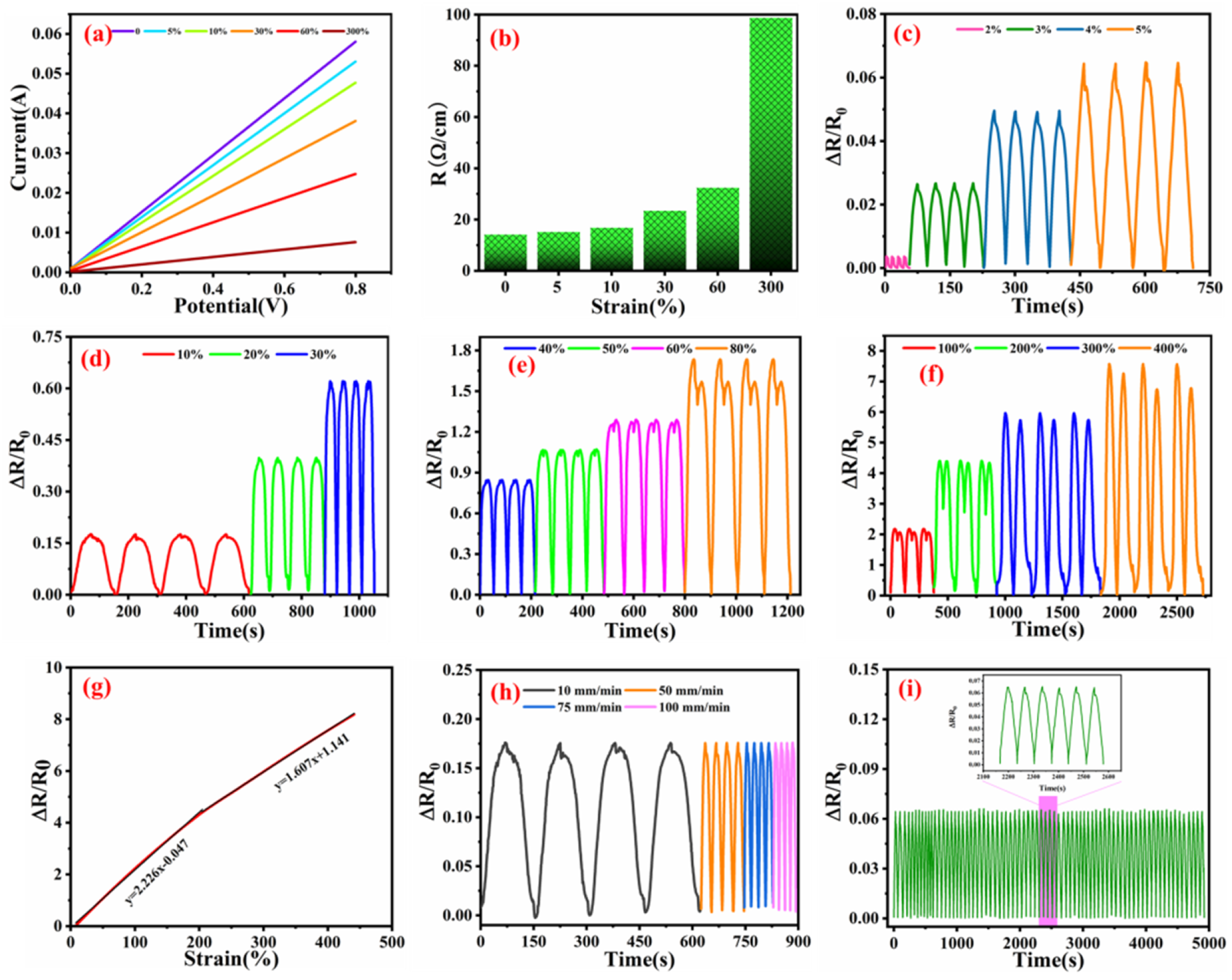

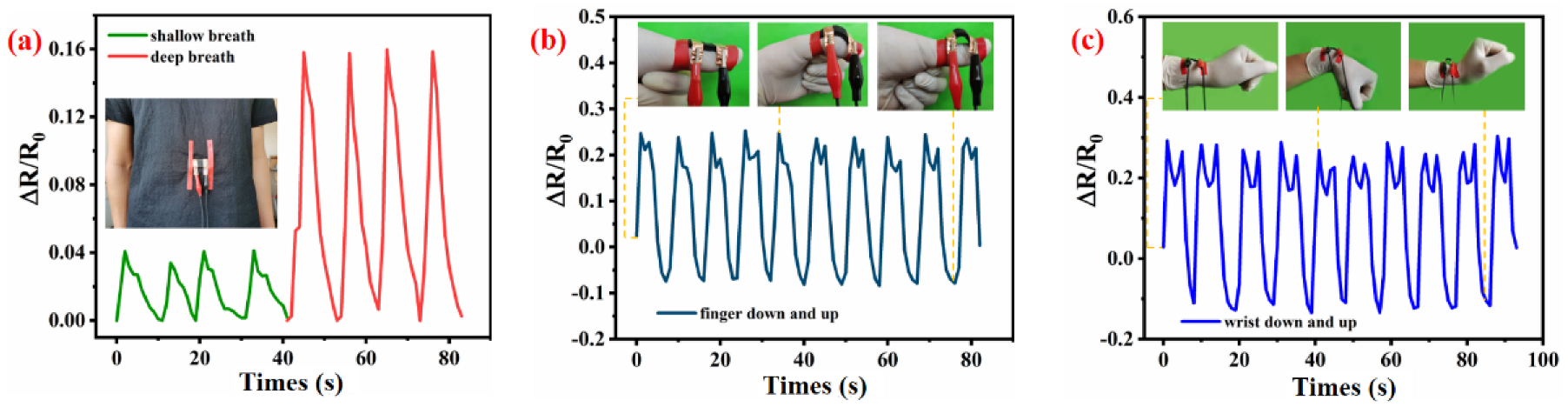

3.2. Stretchable Strain Sensing and Wearable Applications

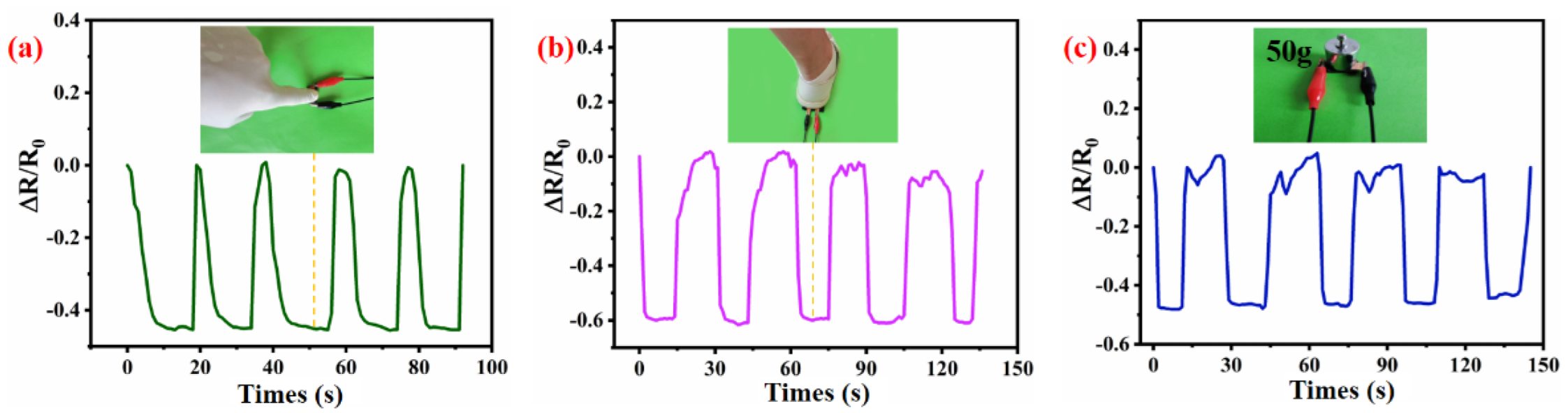

3.3. Compressive Strain Sensing and Wearable Applications

3.4. Electrochemical Performance of WSP-CNT-PPy

3.5. Electro-Heating Performance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Afroj, S.; Tan, S.; Abdelkader, A.M.; Novoselov, K.S.; Karim, N. Highly conductive, scalable, and machine washable graphene-based e-textiles for multifunctional wearable electronic applications. Adv. Funct. Mater. 2020, 30, 2000293. [Google Scholar] [CrossRef]

- Lee, J.; Llerena Zambrano, B.; Woo, J.; Yoon, K.; Lee, T. Recent advances in 1d stretchable electrodes and devices for textile and wearable electronics: Materials, fabrications, and applications. Adv. Mater. 2020, 32, e1902532. [Google Scholar] [CrossRef] [PubMed]

- Yang, K.; Isaia, B.; Brown, L.J.E.; Beeby, S. E-textiles for healthy ageing. Sensors 2019, 19, 4463. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, X.; Zhang, X. Ultrarobust, tough and highly stretchable self-healing materials based on cartilage-inspired noncovalent assembly nanostructure. Nat. Commun. 2021, 12, 1291. [Google Scholar] [CrossRef] [PubMed]

- Cheng, D.S.; Bai, X.; Pan, J.J.; Wu, J.H.; Ran, J.H.; Cai, G.M.; Wang, X. In situ hydrothermal growth of cu nps on knitted fabrics through polydopamine templates for heating and sensing. Chem. Eng. J. 2020, 382, 123036. [Google Scholar] [CrossRef]

- Li, X.; Koh, K.H.; Farhan, M.; Lai, K.W.C. An ultraflexible polyurethane yarn-based wearable strain sensor with a polydimethylsiloxane infiltrated multilayer sheath for smart textiles. Nanoscale 2020, 12, 4110–4118. [Google Scholar] [CrossRef] [PubMed]

- Tang, X.; Yan, X. Dip-coating for fibrous materials: Mechanism, methods and applications. J. Sol-Gel Sci. Technol. 2017, 81, 378–404. [Google Scholar] [CrossRef]

- Chai, Z.; Zhang, N.; Sun, P.; Huang, Y.; Zhao, C.; Fan, H.J.; Fan, X.; Mai, W. Tailorable and wearable textile devices for solar energy harvesting and simultaneous storage. ACS Nano 2016, 10, 9201–9207. [Google Scholar] [CrossRef]

- Lee, J.; Kim, D.; Chun, S.; Song, J.H.; Yoo, E.S.; Kim, J.K.; Pang, C. Intrinsically strain-insensitive, hyperelastic temperature-sensing fiber with compressed micro-wrinkles for integrated textronics. Adv. Mater. Technol. 2020, 5, 10. [Google Scholar] [CrossRef]

- Hatamie, A.; Angizi, S.; Kumar, S.; Pandey, C.M.; Simchi, A.; Willander, M.; Malhotra, B.D. Review—Textile based chemical and physical sensors for healthcare monitoring. J. Electrochem. Soc. 2020, 167, 037546. [Google Scholar] [CrossRef]

- Xu, X.; Luo, M.; He, P.; Yang, J. Washable and flexible screen printed graphene electrode on textiles for wearable healthcare monitoring. J. Phys. D: Appl. Phys. 2020, 53, 125402. [Google Scholar] [CrossRef]

- Mishra, R.K.; Martín, A.; Nakagawa, T.; Barfidokht, A.; Lu, X.; Sempionatto, J.R.; Lyu, K.M.; Karajic, A.; Musameh, M.M.; Kyratzis, I.L.; et al. Detection of vapor-phase organophosphate threats using wearable conformable integrated epidermal and textile wireless biosensor systems. Biosens. Bioelectron. 2018, 101, 227–234. [Google Scholar] [CrossRef]

- An, J.; Ma, Y.; He, M.; Yan, J.; Zhang, C.; Li, X.; Shen, P.; Luo, S.; Gao, Y. A wearable and highly sensitive textile-based pressure sensor with Ti3C2Tx nanosheets. Sens. Actuators A: Phys. 2020, 311, 112081. [Google Scholar] [CrossRef]

- Hassan, Z.; Kalaoglu, F.; Atalay, O. Development and characterization of conductive textile (cotton) for wearable electronics and soft robotic applications. Tex. Res. J. 2020, 90, 1792–1804. [Google Scholar] [CrossRef]

- Pyka, W.; Jedrzejowski, M.; Chudy, M.; Krafczyk, W.; Tokarczyk, O.; Dziezok, M.; Bzymek, A.; Bysko, S.; Blachowicz, T.; Ehrmann, A. On the use of textile materials in robotics. J. Eng. Fibers Fabr. 2020, 15, 1558925020910725. [Google Scholar] [CrossRef]

- Liao, X.; Song, W.; Zhang, X.; Huang, H.; Wang, Y.; Zheng, Y. Directly printed wearable electronic sensing textiles towards human-machine interfaces. J. Mater. Chem. C 2018, 6, 12841–12848. [Google Scholar] [CrossRef]

- He, Q.; Wu, Y.; Feng, Z.; Fan, W.; Lin, Z.; Sun, C.; Zhou, Z.; Meng, K.; Wu, W.; Yang, J. An all-textile triboelectric sensor for wearable teleoperated human-machine interaction. J. Mater. Chem. A 2019, 7, 26804–26811. [Google Scholar] [CrossRef]

- Zhang, L.; Liang, Y.; Xiao, P.; Chen, T.; Zhang, L.; He, J.; Liang, Y.; Chen, T.; He, J.; Liao, Y.; et al. A self-protective, reproducible textile sensor with high performance towards human-machine interactions. J. Mater. Chem. A 2019, 7, 26631–26640. [Google Scholar] [CrossRef]

- Liu, M.; Pu, X.; Jiang, C.; Liu, T.; Huang, X.; Chen, L.; Du, C.; Sun, J.; Hu, W.; Wang, Z.L. Large-area all-textile pressure sensors for monitoring human motion and physiological signals. Adv. Mater. 2017, 29, 1703700. [Google Scholar] [CrossRef] [PubMed]

- Eguchi, K.; Nambu, M.; Kamikawa, T.; Ueshima, K.; Kuroda, T. Smart textile device with embedded fabric electrodes targeting periodic limb movements monitoring at home: A case report. J. Fiber Sci. Technol. 2019, 75, 164–180. [Google Scholar] [CrossRef]

- Eizentals, P.; Katashev, A.; Oks, A.; Semjonova, G. Smart shirt system for compensatory movement retraining assistance: Feasibility study. Health Technol. 2020, 10, 861–874. [Google Scholar] [CrossRef]

- Zhao, Z.; Huang, Q.; Yan, C.; Liu, Y.; Zeng, X.; Wei, X.; Hu, Y.; Zheng, Z. Machine-washable and breathable pressure sensors based on triboelectric nanogenerators enabled by textile technologies. Nano Energy 2020, 70, 104528. [Google Scholar] [CrossRef]

- Lan, L.; Zhao, F.; Yao, Y.; Ping, J.; Ying, Y. One-step and spontaneous in-situ growth of popcorn-like nanostructures on stretchable double-twisted fiber for ultra-sensitive textile pressure sensor. ACS Appl. Mater. Interfaces 2020, 12, 10689–10696. [Google Scholar] [CrossRef]

- Qi, K.; Zhou, Y.; Ou, K.; Dai, Y.; You, X.; Wang, H.; He, J.; Qin, X.; Wang, R. Weavable and stretchable piezoresistive carbon nanotubes-embedded nanofiber sensing yarns for highly sensitive and multimodal wearable textile sensor. Carbon 2020, 170, 464–476. [Google Scholar] [CrossRef]

- Guo, Q.; Huang, B.; Lu, C.; Zhou, T.; Su, G.; Jia, L.; Zhang, X. A cephalopod-inspired mechanoluminescence material with skin-like self-healing and sensing properties. Mater. Horiz. 2019, 6, 996–1004. [Google Scholar]

- Ma, P.B.; Chang, Y.P.; Jiang, G.M. Design and fabrication of auxetic warp-knitted structures with a rotational hexagonal loop. Text. Res. J. 2016, 86, 2151–2157. [Google Scholar] [CrossRef]

- Foroughi, J.; Spinks, G.M.; Aziz, S.; Mirabedini, A.; Jeiranikhameneh, A.; Wallace, G.G.; Kozlov, M.E.; Baughman, R.H. Knitted carbon-nanotube-sheath/spandex-core elastomeric yarns for artificial muscles and strain sensing. ACS Nano 2016, 10, 9129–9135. [Google Scholar] [CrossRef]

- Zhang, H.; Dias, T.K. Electromechanical properties of knitted fabric integrated with laser engraved carbon-loaded fiber. J. Text. Inst. 2016, 107, 733–742. [Google Scholar] [CrossRef]

- Tokarska, M.; Orpel, M. Study of anisotropic electrical resistance of knitted fabrics. Text. Res. J. 2019, 89, 1073–1083. [Google Scholar] [CrossRef]

- Cai, G.; Yang, M.; Pan, J.; Cheng, D.; Xia, Z.; Wang, X.; Tang, B. Large-scale production of highly stretchable cnt/cotton/spandex composite yarn for wearable applications. ACS Appl. Mater. Interfaces 2018, 10, 32726–32735. [Google Scholar] [CrossRef]

- Xu, L.; Liu, Z.; Zhai, H.; Chen, X.; Sun, R.; Lyu, S.; Fan, Y.; Yi, Y.; Chen, Z.; Jin, L.; et al. Moisture-resilient graphene-dyed wool fabric for strain sensing. ACS Appl. Mater. Interfaces 2020, 12, 13265–13274. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.T.; Miao, X.H.; Raji, R.K. Flexible knitted sensing device for identifying knee joint motion patterns. Smart Mater. Struct. 2019, 28, 9. [Google Scholar] [CrossRef]

- Liu, X.; Su, G.; Guo, Q.; Lu, C.; Zhou, T.; Zhou, C.; Zhang, X. Hierarchically structured self-healing sensors with tunable positive/negative piezoresistivity. Adv. Funct. Mater. 2018, 28, 1706658. [Google Scholar] [CrossRef]

- Ryu, H.; Park, S.; Park, J.J.; Bae, J. A knitted glove sensing system with compression strain for finger movements. Smart Mater. Struct. 2018, 27, 7. [Google Scholar] [CrossRef]

- Hao, D.D.; Xu, B.; Cai, Z.S. Polypyrrole coated knitted fabric for robust wearable sensor and heater. J. Mater. Sci. Mater. Electron. 2018, 29, 9218–9226. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, M.; Yang, B.; Tan, J.; Ding, X. Highly compressible, thermally stable, light-weight, and robust aramid nanofibers/ti3alc2 mxene composite aerogel for sensitive pressure sensor. ACS Nano 2020, 14, 10633–10647. [Google Scholar] [CrossRef]

- Pan, C.; Wang, J.; Ji, X.; Liu, L. Stretchable, compressible, self-healable carbon nanotube mechanically enhanced composite hydrogels with high strain sensitivity. J. Mater. Chem. C 2020, 8, 1933–1942. [Google Scholar] [CrossRef]

- Bi, L.; Yang, Z.; Chen, L.; Wu, Z.; Ye, C. Compressible agnws/ti3c2tx mxene aerogel-based highly sensitive piezoresistive pressure sensor as versatile electronic skins. J. Mater. Chem. A 2020, 8, 20030–20036. [Google Scholar] [CrossRef]

- Wang, J.-J.; Zhang, Q.; Ji, X.-X.; Liu, L.-B. Highly stretchable, compressible, adhesive, conductive self-healing composite hydrogels with sensor capacity. Chin. J. Polym. Sci. 2020, 38, 1221–1229. [Google Scholar] [CrossRef]

- Song, Y.; Chen, H.; Su, Z.; Chen, X.; Miao, L.; Zhang, J.; Cheng, X.; Zhang, H. Highly compressible integrated supercapacitor-piezoresistance-sensor system with cnt-pdms sponge for health monitoring. Small 2017, 13, 1702091. [Google Scholar] [CrossRef]

- Jiang, X.; Ren, Z.; Fu, Y.; Liu, Y.; Zou, R.; Ji, G.; Ning, H.; Li, Y.; Wen, J.; Qi, H.J.; et al. Highly compressible and sensitive pressure sensor under large strain based on 3d porous reduced graphene oxide fiber fabrics in wide compression strains. ACS Appl. Mater. Interfaces 2019, 11, 37051–37059. [Google Scholar] [CrossRef] [PubMed]

- Kurbak, A. Geometrical models for weft-knitted spacer fabrics. Text. Res. J. 2017, 87, 409–423. [Google Scholar] [CrossRef]

- Souri, H.; Bhattacharyya, D. Wearable strain sensors based on electrically conductive natural fiber yarns. Mater. Des. 2018, 154, 217–227. [Google Scholar] [CrossRef]

- Zhao, K.; Niu, W.B.; Zhang, S.F. Highly stretchable, breathable and negative resistance variation textile strain sensor with excellent mechanical stability for wearable electronics. J. Mater. Sci. 2020, 55, 2439–2453. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dou, L.; Zeng, Z.; Cheng, D.; Li, S.; Ke, W.; Cai, G. Weft-Knitted Spacer Fabric for Highly Stretchable–Compressible Strain Sensor, Supercapacitor, and Joule Heater. Nanomaterials 2022, 12, 3684. https://doi.org/10.3390/nano12203684

Dou L, Zeng Z, Cheng D, Li S, Ke W, Cai G. Weft-Knitted Spacer Fabric for Highly Stretchable–Compressible Strain Sensor, Supercapacitor, and Joule Heater. Nanomaterials. 2022; 12(20):3684. https://doi.org/10.3390/nano12203684

Chicago/Turabian StyleDou, Lu, Zhen Zeng, Deshan Cheng, Shengyu Li, Wei Ke, and Guangming Cai. 2022. "Weft-Knitted Spacer Fabric for Highly Stretchable–Compressible Strain Sensor, Supercapacitor, and Joule Heater" Nanomaterials 12, no. 20: 3684. https://doi.org/10.3390/nano12203684

APA StyleDou, L., Zeng, Z., Cheng, D., Li, S., Ke, W., & Cai, G. (2022). Weft-Knitted Spacer Fabric for Highly Stretchable–Compressible Strain Sensor, Supercapacitor, and Joule Heater. Nanomaterials, 12(20), 3684. https://doi.org/10.3390/nano12203684