Numerical Analysis of the Effect of Nanoparticles Size and Shape on the Efficiency of a Micro Heatsink

Abstract

:1. Introduction

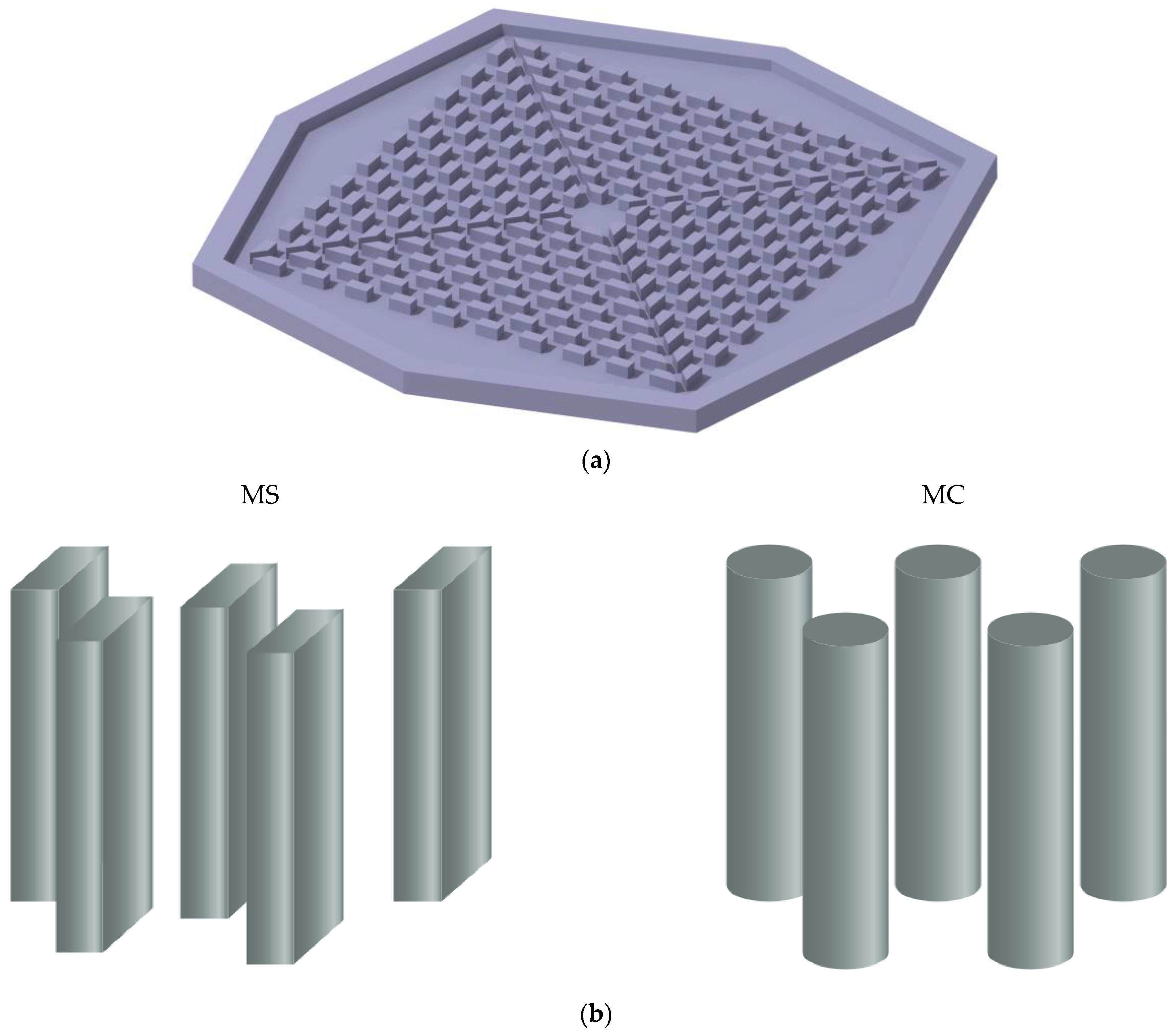

2. Problem Statement

3. Governing Equations

3.1. Thermal Efficiency

3.2. NFs Properties

3.3. Boundary Conditions

4. The Numerical Solution, Validation, and Mesh-Independence of the Solution

5. Results and Discussion

6. Conclusions

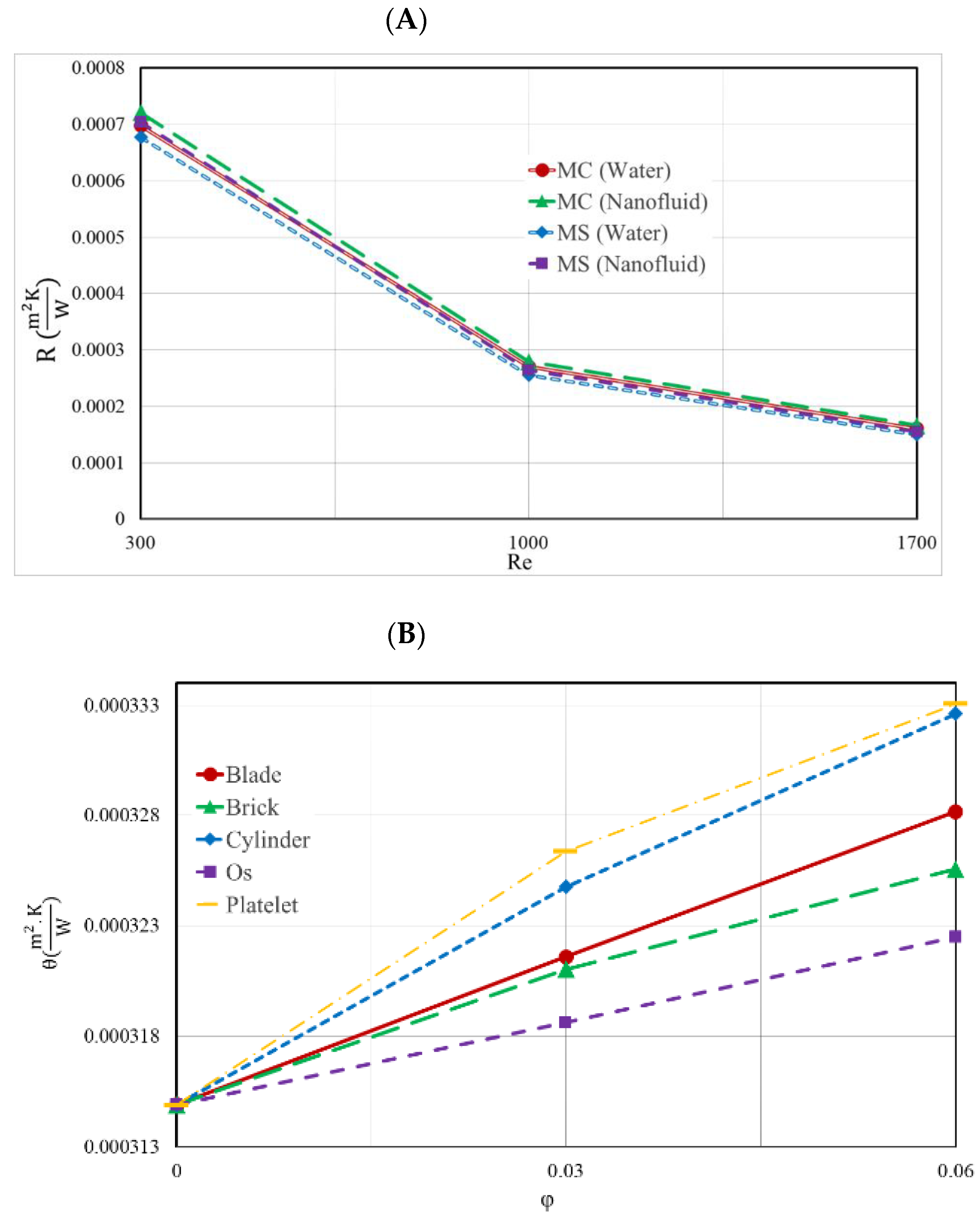

- The MS heat sink, in comparison to the other heat sink, generally had superior thermal qualities. It had a lower T-MAX, a smaller TH-R, and greater temperature uniformity. Adding nanoparticles to the heatsink with circular and square pin-fins reduced the average temperature of the heatsink by 2.8 and 2.9 K, respectively when Re = 300.

- An increase in Re further cooled down the HS and reduced its TH-R, leading to better temperature uniformity in the HSs.

- In thermal terms, the addition of NPs with a variety of forms is inappropriate for a HS. This is particularly true for large VOFs. The addition of nanoparticles in the heatsink with circular and square pin-fins enhanced the pressure drop by 13.5% and 13.3%, respectively, when the Re = 1700.

- The platelet NPs had the worst performance in terms of heat transfer when compared to the other NPs shapes. The Os form achieved the greatest levels of performance across the board, with regard to these criteria.

- A decrease in the FOM may be achieved by including NPs of varying shapes into the MHS in large VOFs.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviation

| Nomenclature | |

| Cp | Specific heat |

| FOM | Figure of Merit |

| h | Heat transfer coefficient |

| HS | Heat sink |

| k | Thermal conductivity |

| MHS | Micro heat sink |

| NF | Nanofluid |

| NP | Nanoparticle |

| Pressure | |

| PP | pumping power (W) |

| Heat flux (W/m2) | |

| volumetric flow (m3/s) | |

| R | Thermal resistance (m2.K/W) |

| T | Temperature (K) |

| v | Velocity (m/s) |

| Greek symbols | |

| φ | Solid volume fraction |

| θ | Temperature uniformity (m2.K/W) |

| μ | Dynamic viscosity |

| ρ | Density ( |

| ∆P | pressure difference |

| Subscripts | |

| Ave | Average |

| eff | Effective |

| f | Pure fluid |

| in | Inlet |

| m | Average fluid temperature |

| Max | maximum temperatures on the MHS |

| Mid | Average temperature of the MHS |

| Min | Minimum temperatures on the MHS |

| nf | Nanofluid |

| out | Outlet |

| P | Solid nanoparticle |

References

- Murshed, S.S.; de Castro, C.N. A critical review of traditional and emerging techniques and fluids for electronics cooling. Renew. Sustain. Energy Rev. 2017, 78, 821–833. [Google Scholar] [CrossRef]

- Park, S.-J.; Jang, D.; Yook, S.-J.; Lee, K.-S. Optimization of a chimney design for cooling efficiency of a radial heat sink in a LED downlight. Energy Convers. Manag. 2016, 114, 180–187. [Google Scholar] [CrossRef]

- Sun, L.; Zhu, J.; Wong, H. Simulation and evaluation of the peak temperature in LED light bulb heatsink. Microelectron. Reliab. 2016, 61, 140–144. [Google Scholar] [CrossRef]

- Alqaed, S.; Mustafa, J.; Aybar, H.; Jamil, B.; Alharthi, M.A. Investigation of thermal entropy generation and nanofluid flow in a new heatsink with effect of nanoparticles shape. Case Stud. Therm. Eng. 2022, 36, 102198. [Google Scholar] [CrossRef]

- Mustafa, J.; Alqaed, S.; Sharifpur, M. Evaluation of energy efficiency, visualized energy, and production of environmental pol-lutants of a solar flat plate collector containing hybrid nanofluid. Sustain. Energy Technol. Assess. 2022, 53, 102399. [Google Scholar]

- Tan, W.-C.; Chong, K.-K.; Tan, M.-H. Performance study of water-cooled multiple-channel heat sinks in the application of ultra-high concentrator photovoltaic system. Sol. Energy 2017, 147, 314–327. [Google Scholar] [CrossRef]

- Parsa, S.M.J.D. Reliability of thermal desalination (solar stills) for water/wastewater treatment in light of COVID-19 (novel coronavirus “SARS-CoV-2”) pandemic: What should consider? Desalination 2021, 512, 115106. [Google Scholar] [CrossRef]

- Parsa, S.M.; Y, D.J.; Rahbar, A.; Majidniya, M.; Salimi, M.; Amidpour, Y.; Amidpour, M. Experimental investigation at a summit above 13,000 ft on active solar still water purification powered by photovoltaic: A comparative study. Desalination 2020, 476. [Google Scholar] [CrossRef]

- Parsa, S.M.; Y, D.J.; Rahbar, A.; Majidniya, M.; Aberoumand, S.; Amidpour, Y.; Amidpour, M. Experimental assessment on passive solar distillation system on Mount Tochal at the height of 3964 m: Study at high altitude. Desalination 2019, 466, 77–88. [Google Scholar] [CrossRef]

- Mustafa, J.; Alqaed, S.; Sharifpur, M. Investigation into the use of phase change materials in thermal management of a solar panel in the vicinity of tubes with slotted rectangular fins. Appl. Therm. Eng. 2022, 215, 118905. [Google Scholar] [CrossRef]

- Mustafa, J.; Husain, S.; Alqaed, S.; Khan, U.A.; Jamil, B. Performance of Two Variable Machine Learning Models to Forecast Monthly Mean Diffuse Solar Radiation across India under Various Climate Zones. Energies 2022, 15, 7851. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, K.; Cui, Z.; Wei, J. Effects of the location of the inlet and outlet on heat transfer performance in pin fin CPU heat sink. Appl. Therm. Eng. 2019, 151, 506–513. [Google Scholar] [CrossRef]

- Zhao, N.; Guo, L.; Qi, C.; Chen, T.; Cui, X. Experimental study on thermo-hydraulic performance of nanofluids in CPU heat sink with rectangular grooves and cylindrical bugles based on exergy efficiency. Energy Convers. Manag. 2018, 181, 235–246. [Google Scholar] [CrossRef]

- Sarafraz, M.M.; Arya, A.; Hormozi, F.; Nikkhah, V. On the convective thermal performance of a CPU cooler working with liquid gallium and CuO/water nanofluid: A comparative study. Appl. Therm. Eng. 2017, 112, 1373–1381. [Google Scholar] [CrossRef]

- Zhang, X.; Tang, Y.; Zhang, F.; Lee, C.-S. A Novel Aluminum-Graphite Dual-Ion Battery. Adv. Energy Mater. 2016, 6. [Google Scholar] [CrossRef]

- Lu, S.; Guo, J.; Liu, S.; Yang, B.; Liu, M.; Yin, L.; Zheng, W. An Improved Algorithm of Drift Compensation for Olfactory Sensors. Appl. Sci. 2022, 12, 9529. [Google Scholar] [CrossRef]

- Huang, K.; Su, B.; Li, T.; Ke, H.; Lin, M.; Wang, Q. Numerical simulation of the mixing behaviour of hot and cold fluids in the rectangular T-junction with/without an impeller. Appl. Therm. Eng. 2021, 204, 117942. [Google Scholar] [CrossRef]

- Ahmed, H.E.; Salman, B.; Kherbeet, A.; Ahmed, M. Optimization of thermal design of heat sinks: A review. Int. J. Heat Mass Transf. 2018, 118, 129–153. [Google Scholar] [CrossRef]

- Freitas, R.R.Q.; Gueorguiev, G.K.; de Brito Mota, F.; de Castilho, C.M.C.; Stafström, S.; Kakanakova-Georgieva, A. Reactivity of adducts relevant to the deposition of hexagonal BN from first-principles calculations. Chem. Phys. Lett. 2013, 583, 119–124. [Google Scholar] [CrossRef]

- Mustafa, J.; Alqaed, S.; Sharifpur, M. Enhancing the energy and exergy performance of a photovoltaic thermal system with∇-shape collector using porous metal foam. J. Clean. Prod. 2022, 368, 133121. [Google Scholar] [CrossRef]

- Mustafa, J.; Alqaed, S.; Sharifpur, M. Loading phase change material in a concrete based wall to enhance concrete thermal properties. J. Build. Eng. 2022, 56, 104765. [Google Scholar] [CrossRef]

- Alqaed, S.; Mustafa, J.; Sharifpur, M. Numerical investigation and optimization of natural convection and entropy generation of alumina/H2O nanofluid in a rectangular cavity in the presence of a magnetic field with artificial neural networks. Eng. Anal. Bound. Elements 2022, 140, 507–518. [Google Scholar] [CrossRef]

- Feng, S.; Shi, M.; Yan, H.; Sun, S.; Li, F.; Lu, T.J. Natural convection in a cross-fin heat sink. Appl. Therm. Eng. 2018, 132, 30–37. [Google Scholar] [CrossRef]

- Meng, X.; Zhu, J.; Wei, X.; Yan, Y. Natural convection heat transfer of a straight-fin heat sink. Int. J. Heat Mass Transf. 2018, 123, 561–568. [Google Scholar] [CrossRef]

- Alqaed, S.; Mustafa, J.; Sharifpur, M.; Cheraghian, G. The effect of graphene nano-powder on the viscosity of water: An exper-imental study and artificial neural network modeling. Nanotechnol. Rev. 2022, 11, 2768–2785. [Google Scholar] [CrossRef]

- Deng, D.; Chen, L.; Chen, X.; Pi, G. Heat transfer and pressure drop of a periodic expanded-constrained microchannels heat sink. Int. J. Heat Mass Transf. 2019, 140, 678–690. [Google Scholar] [CrossRef]

- Ho, C.J.; Chen, W.C. An experimental study on thermal performance of Al2O3/water nanofluid in a minichannel heat sink. Appl. Therm. Eng. 2013, 50, 516–522. [Google Scholar] [CrossRef]

- Guo, Z.; Yang, J.; Tan, Z.; Tian, X.; Wang, Q. Numerical study on gravity-driven granular flow around tube out-wall: Effect of tube inclination on the heat transfer. Int. J. Heat Mass Transf. 2021, 174, 121296. [Google Scholar] [CrossRef]

- Yang, M.; Li, C.; Zhang, Y.; Wang, Y.; Li, B.; Jia, D.; Hou, Y.; Li, R. Research on microscale skull grinding temperature field under different cooling conditions. Appl. Therm. Eng. 2017, 126, 525–537. [Google Scholar] [CrossRef]

- Kharangate, C.R.; Libeer, W.; Palko, J.; Lee, H.; Shi, J.; Asheghi, M.; Goodson, K.E. Investigation of 3D manifold architecture heat sinks in air-cooled condensers. Appl. Therm. Eng. 2020, 167, 114700. [Google Scholar] [CrossRef]

- Chu, W.-X.; Tsai, M.-K.; Jan, S.-Y.; Huang, H.-H.; Wang, C.-C. CFD analysis and experimental verification on a new type of air-cooled heat sink for reducing maximum junction temperature. Int. J. Heat Mass Transf. 2019, 148, 119094. [Google Scholar] [CrossRef]

- Li, Y.; Gong, L.; Xu, M.; Joshi, Y. Enhancing the performance of aluminum foam heat sinks through integrated pin fins. Int. J. Heat Mass Transf. 2020, 151, 119376. [Google Scholar] [CrossRef]

- Zimmermann, S.; Tiwari, M.K.; Meijer, I.; Paredes, S.; Michel, B.; Poulikakos, D. Hot water cooled electronics: Exergy analysis and waste heat reuse feasibility. Int. J. Heat Mass Transf. 2012, 55, 6391–6399. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.; Zhang, Y.; Yang, M.; Li, B.; Dong, L.; Wang, J. Processing Characteristics of Vegetable Oil-based Nanofluid MQL for Grinding Different Workpiece Materials. Int. J. Precis. Eng. Manuf. Technol. 2018, 5, 327–339. [Google Scholar] [CrossRef]

- Yang, M.; Li, C.; Zhang, Y.; Jia, D.; Zhang, X.; Hou, Y.; Li, R.; Wang, J. Maximum undeformed equivalent chip thickness for duc-tile-brittle transition of zirconia ceramics under different lubrication conditions. Int. J. Mach. Tools Manuf. 2017, 122, 55–65. [Google Scholar] [CrossRef]

- Li, B.; Li, C.; Zhang, Y.; Wang, Y.; Jia, D.; Yang, M. Grinding temperature and energy ratio coefficient in MQL grinding of high-temperature nickel-base alloy by using different vegetable oils as base oil. Chin. J. Aeronaut. 2016, 29, 1084–1095. [Google Scholar] [CrossRef] [Green Version]

- Yang, M.; Li, C.; Zhang, Y.; Jia, D.; Li, R.; Hou, Y.; Cao, H.; Wang, J. Predictive model for minimum chip thickness and size effect in single diamond grain grinding of zirconia ceramics under different lubricating conditions. Ceram. Int. 2019, 45, 14908–14920. [Google Scholar] [CrossRef]

- Bahiraei, M.; Heshmatian, S. Electronics cooling with nanofluids: A critical review. Energy Convers. Manag. 2018, 172, 438–456. [Google Scholar] [CrossRef]

- Vinodhan, V.L.; Rajan, K. Computational analysis of new microchannel heat sink configurations. Energy Convers. Manag. 2014, 86, 595–604. [Google Scholar] [CrossRef]

- Hernandez-Perez, J.G.; Carrillo, J.G.; Bassam, A.; Flota-Banuelos, M.; Patino-Lopez, L.D. Thermal performance of a discontinu-ous finned heatsink profile for PV passive cooling. Appl. Therm. Eng. 2021, 184, 116238. [Google Scholar] [CrossRef]

- Ibrahim, M.; Saeed, T.; Chu, Y.-M.; Ali, H.M.; Cheraghian, G.; Kalbasi, R. Comprehensive study concerned graphene nano-sheets dispersed in ethylene glycol: Experimental study and theoretical prediction of thermal conductivity. Powder Technol. 2021, 386, 51–59. [Google Scholar] [CrossRef]

- Chu, Y.-M.; Ibrahim, M.; Saeed, T.; Berrouk, A.S.; Algehyne, E.A.; Kalbasi, R. Examining rheological behavior of MWCNT-TiO2/5W40 hybrid nanofluid based on experiments and RSM/ANN modeling. J. Mol. Liq. 2021, 333, 115969. [Google Scholar] [CrossRef]

- Hussein, O.A.; Habib, K.; Muhsan, A.S.; Saidur, R.; Alawi, O.A.; Ibrahim, T.K. Thermal performance enhancement of a flat plate solar collector using hybrid nanofluid. Sol. Energy 2020, 204, 208–222. [Google Scholar] [CrossRef]

- Pordanjani, A.H.; Aghakhani, S. Numerical Investigation of Natural Convection and Irreversibilities between Two Inclined Concentric Cylinders in Presence of Uniform Magnetic Field and Radiation. Heat Transf. Eng. 2021, 43, 937–957. [Google Scholar] [CrossRef]

- Khodadadi, H.; Aghakhani, S.; Majd, H.; Kalbasi, R.; Wongwises, S.; Afrand, M. A comprehensive review on rheological behav-ior of mono and hybrid nanofluids: Effective parameters and predictive correlations. Int. J. Heat Mass Transfer. 2018, 127, 997–1012. [Google Scholar] [CrossRef]

- Dogonchi, A.S.; Seyyedi, S.M.; Hashemi-Tilehnoee, M.; Chamkha, A.J.; Ganji, D.D. Investigation of natural convection of mag-netic nanofluid in an enclosure with a porous medium considering Brownian motion. Case Stud. Therm. Eng. 2019, 14, 100502. [Google Scholar] [CrossRef]

- Shaw, S.; Nayak, M.K.; Dogonchi, A.S.; Chamkha, A.J.; Elmasry, Y.; Alsulami, R. Hydrothermal and entropy production anal-yses of magneto-cross nanoliquid under rectified Fourier viewpoint: A robust approach to industrial applications. Case Stud. Therm. Eng. 2021, 26, 100974. [Google Scholar]

- Ganesh, N.V.; Chamkha, A.J.; Al-Mdallal, Q.M.; Kameswaran, P. Magneto-Marangoni nano-boundary layer flow of water and ethylene glycol based γ Al2O3 nanofluids with non-linear thermal radiation effects. Case Stud. Therm. Eng. 2018, 12, 340–348. [Google Scholar] [CrossRef]

- Tian, M.-W.; Rostami, S.; Aghakhani, S.; Goldanlou, A.S.; Qi, C. A techno-economic investigation of 2D and 3D configurations of fins and their effects on heat sink efficiency of MHD hybrid nanofluid with slip and non-slip flow. Int. J. Mech. Sci. 2021, 189. [Google Scholar] [CrossRef]

- Kolsi, L.; Selimefendigil, F.; Öztop, H.F.; Hassen, W.; Aich, W. Impacts of double rotating cylinders on the forced convection of hybrid nanofluid in a bifurcating channel with partly porous layers. Case Stud. Therm. Eng. 2021, 26, 101020. [Google Scholar] [CrossRef]

- Selimefendigil, F.; Öztop, H.F. Corrugated conductive partition effects on MHD free convection of CNT-water nanofluid in a cavity. Int. J. Heat Mass Transf. 2018, 129, 265–277. [Google Scholar] [CrossRef]

- Miroshnichenko, I.V.; Sheremet, M.A.; Oztop, H.F.; Abu-Hamdeh, N. Natural convection of Al2O3/H2O nanofluid in an open inclined cavity with a heat-generating element. Int. J. Heat Mass Transfer. 2018, 126, 184–191. [Google Scholar] [CrossRef]

- Parsa, S.M.; Majidniya, M.; Alawee, W.; Dhahad, H.A.; Ali, H.M.; Afrand, M.; Amidpour, M. Thermodynamic, economic, and sensitivity analysis of salt gradient solar pond (SGSP) integrated with a low-temperature multi effect desalination (MED): Case study, Iran. Sustainable Energy Technol. Assessments. 2021, 47, 101478. [Google Scholar] [CrossRef]

- Parsa, S.M.; Rahbar, A.; Koleini, M.; Javadi, Y.D.; Afrand, M.; Rostami, S.; Amidpour, M. First approach on nanofluid-based solar still in high altitude for water desalination and solar water disinfection (SODIS). Desalination 2020, 491, 114592. [Google Scholar] [CrossRef]

- Parsa, S.M.; Rahbar, A.; Koleini, M.; Aberoumand, S.; Afrand, M.; Amidpour, M. A renewable energy-driven thermoelectric-utilized solar still with external condenser loaded by silver/nanofluid for simultaneously water disinfection and desalination. Desalination 2020, 480, 114354. [Google Scholar] [CrossRef]

- Mustafa, J.; Siddiqui, M.A.; Anwer, S.F. Experimental and Numerical Analysis of Heat Transfer in a Tall Vertical Concentric Annular Thermo-siphon at Constant heat Flux Condition. Heat Transf. Eng. 2019, 40, 896–913. [Google Scholar] [CrossRef]

- Pordanjani, A.H.; Aghakhani, S.; Karimipour, A.; Afrand, M.; Goodarzi, M. Investigation of free convection heat transfer and entropy generation of nanofluid flow inside a cavity affected by magnetic field and thermal radiation. J. Therm. Anal. 2019, 137, 997–1019. [Google Scholar] [CrossRef]

- Aghakhani, S.; Ghasemi, B.; Pordanjani, A.H.; Wongwises, S.; Afrand, M. Effect of replacing nanofluid instead of wa-ter on heat transfer in a channel with extended surfaces under a magnetic field. Int. J. Numer. Methods Heat Fluid Flow. 2019, 29, 1249–1271. [Google Scholar] [CrossRef]

- Zheng, Y.; Yaghoubi, S.; Dezfulizadeh, A.; Aghakhani, S.; Karimipour, A.; Tlili, I. Free convection/radiation and entropy genera-tion analyses for nanofluid of inclined square enclosure with uniform magnetic field. J. Therm. Anal. Calorim. 2020, 141, 635–648. [Google Scholar] [CrossRef]

- Zhang, J.; Li, C.; Zhang, Y.; Yang, M.; Jia, D.; Liu, G.; Hou, Y.; Li, R.; Zhang, N.; Wu, Q.; et al. Experimental assessment of an environmentally friendly grinding process using nanofluid minimum quantity lubrication with cryogenic air. J. Clean. Prod. 2018, 193, 236–248. [Google Scholar] [CrossRef]

- Pordanjani, A.H.; Aghakhani, S.; Alnaqi, A.A.; Afrand, M. Effect of alumina nano-powder on the convection and the entropy generation of water inside an inclined square cavity subjected to a magnetic field: Uniform and non-uniform temperature bounda-ry conditions. Int. J. Mech. Sci. 2019, 152, 99–117. [Google Scholar] [CrossRef]

- Mahian, O.; Kianifar, A.; Heris, S.Z.; Wongwises, S. First and second laws analysis of a minichannel-based solar collector using boehmite alumina nanofluids: Effects of nanoparticle shape and tube materials. Int. J. Heat Mass Transf. 2014, 78, 1166–1176. [Google Scholar] [CrossRef]

- Dix, J.; Jokar, A.; Martinsen, R. A Microchannel Heat Exchanger for Electronics Cooling Applications. In Proceedings of the ASME 2008 6th International Conference on Nanochannels, Microchannels, and Minichannels, Darmstadt, Germany, 23–25 June 2008; pp. 1935–1936. [Google Scholar] [CrossRef]

- Chang, H.; Han, Z.; Li, X.; Ma, T.; Wang, Q. Experimental study on heat transfer performance of sCO2 near pseudo-critical point in airfoil-fin PCHE from viewpoint of average thermal-resistance ratio. Int. J. Heat Mass Transf. 2022, 196, 123257. [Google Scholar] [CrossRef]

- Guo, Z.; Tian, X.; Wu, Z.; Yang, J.; Wang, Q. Heat transfer of granular flow around aligned tube bank in moving bed: Experi-mental study and theoretical prediction by thermal resistance mode. Energy Convers. Manag. 2022, 257, 115435. [Google Scholar] [CrossRef]

- Huo, J.; Wei, H.; Fu, L.; Zhao, C.; He, C. Highly active Fe36Co44 bimetallic nanoclusters catalysts for hydrolysis of ammonia borane: The first-principles study. Chin. Chem. Lett. 2022. [Google Scholar] [CrossRef]

- Jilte, R.; Ahmadi, M.H.; Kumar, R.; Kalamkar, V.; Mosavi, A. Cooling Performance of a Novel Circulatory Flow Concentric Mul-ti-Channel Heat Sink with Nanofluids. Nanomaterials 2020, 10, 647. [Google Scholar] [CrossRef] [Green Version]

- Alfaryjat, A.A.; Dobrovicescu, A.; Stanciu, D. Influence of heat flux and Reynolds number on the entropy generation for differ-ent types of nanofluids in a hexagon microchannel heat sink. Chin. J. Chem. Eng. 2019, 27, 501–513. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, S.; Wang, R.; Wang, Y.; Feng, X. A design methodology for wind farm layout considering cable routing and eco-nomic benefit based on genetic algorithm and GeoSteiner. Renew. Energy 2020, 146, 687–698. [Google Scholar] [CrossRef]

- Al-Rashed, A.A.; Ranjbarzadeh, R.; Aghakhani, S.; Soltanimehr, M.; Afrand, M.; Nguyen, T.K. Entropy generation of boehmite alumina nanofluid flow through a minichannel heat exchanger considering nanoparticle shape effect. Phys. A Stat. Mech. Its Appl. 2019, 521, 724–736. [Google Scholar] [CrossRef]

- Bahiraei, M.; Monavari, A.; Naseri, M.; Moayedi, H. Transfer, Irreversibility characteristics of a modified micro-channel heat sink operated with nanofluid considering different shapes of nanoparticles. Int. J. Heat Mass Transfer. 2020, 151, 119359. [Google Scholar] [CrossRef]

- Arani, A.A.A.; Sadripour, S.; Kermani, S. Nanoparticle shape effects on thermal-hydraulic performance of boehmite alumina nanofluids in a sinusoidal–wavy mini-channel with phase shift and variable wavelength. Int. J. Mech. Sci. 2017, 128–129, 550–563. [Google Scholar] [CrossRef]

- Bahiraei, M.; Heshmatian, S. Application of a novel biological nanofluid in a liquid block heat sink for cooling of an electronic processor: Thermal performance and irreversibility considerations. Energy Convers. Manag. 2017, 149, 155–167. [Google Scholar] [CrossRef]

- Timofeeva, E.V.; Routbort, J.L.; Singh, D. Particle shape effects on thermophysical properties of alumina nanofluids. J. Appl. Phys. 2009, 106, 014304. [Google Scholar] [CrossRef]

- Hamilton, R.L.; Crosser, O.K. Thermal Conductivity of Heterogeneous Two-Component Systems. Ind. Eng. Chem. Fundam. 1962, 1, 187–191. [Google Scholar] [CrossRef]

- Ooi, E.H.; Popov, V. Numerical study of influence of nanoparticle shape on the natural convection in Cu-water nanofluid. Int. J. Therm. Sci. 2013, 65, 178–188. [Google Scholar] [CrossRef]

- Mueller, S.; Llewellin, E.; Mader, H.M. The rheology of suspensions of solid particles. Proc. R. Soc. A Math. Phys. Eng. Sci. 2009, 466, 1201–1228. [Google Scholar] [CrossRef] [Green Version]

- Mustafa, J.; Alqaed, S.; Kalbasi, R. Challenging of using CuO nanoparticles in a flat plate solar collector-Energy saving in a solar-assisted hot process stream. J. Taiwan Inst. Chem. Eng. 2021, 124, 258–265. [Google Scholar] [CrossRef]

- Hasan, M.I. Investigation of flow and heat transfer characteristics in micro pin fin heat sink with nanofluid. Appl. Therm. Eng. 2014, 63, 598–607. [Google Scholar] [CrossRef]

Platelets  | 2.61 | 37.1 | 612.6 |

Blades  | 2.74 | 14.6 | 123.3 |

Cylinders  | 3.95 | 13.5 | 904.4 |

Bricks  | 3.37 | 1.9 | 471.4 |

| Case | |||

|---|---|---|---|

Os nanoparticles |

| Properties | ||||

|---|---|---|---|---|

| H2O (water) | ||||

| (Boehmite alumina) | 30 | - |

| Mesh | Number of Meshes | ||

|---|---|---|---|

| M 1 | 1,014,534 | ||

| M 2 | 1,367,912 | ||

| M 3 | 1,791,400 | ||

| M 4 | 2,159,241 | ||

| M 5 | 2,455,901 | ||

| M 6 | 2,835,401 |

| Shape NP | k (W/m K) | %Inc |

|---|---|---|

Platelets  | 0.7089958 | 15.66 |

Blades | 0.7137772 | 16.44 |

Cylinders | 0.758281 | 23.70 |

Bricks | 0.7369486 | 20.22 |

OS | 0.823751621 | 34.99 |

| Shape NP | %Inc | |

|---|---|---|

Platelets  | 0.005448 | 443.14 |

Blades  | 0.002327 | 132.00 |

Cylinders  | 0.005081 | 406.58 |

Bricks  | 0.002819 | 181.05 |

OS  | 0.00125 | 24.62 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alqaed, S.; Mustafa, J.; Almehmadi, F.A.; Alharthi, M.A.; Sharifpur, M.; Cheraghian, G. Numerical Analysis of the Effect of Nanoparticles Size and Shape on the Efficiency of a Micro Heatsink. Nanomaterials 2022, 12, 3836. https://doi.org/10.3390/nano12213836

Alqaed S, Mustafa J, Almehmadi FA, Alharthi MA, Sharifpur M, Cheraghian G. Numerical Analysis of the Effect of Nanoparticles Size and Shape on the Efficiency of a Micro Heatsink. Nanomaterials. 2022; 12(21):3836. https://doi.org/10.3390/nano12213836

Chicago/Turabian StyleAlqaed, Saeed, Jawed Mustafa, Fahad Awjah Almehmadi, Mathkar A. Alharthi, Mohsen Sharifpur, and Goshtasp Cheraghian. 2022. "Numerical Analysis of the Effect of Nanoparticles Size and Shape on the Efficiency of a Micro Heatsink" Nanomaterials 12, no. 21: 3836. https://doi.org/10.3390/nano12213836