Spacer Layer Thickness Dependence of the Giant Magnetoresistance in Electrodeposited Ni-Co/Cu Multilayers

Abstract

:1. Introduction

1.1. Giant Magnetoresistance in Multilayers

1.2. Electrodeposited Multilayers with GMR

1.3. Spacer Layer Thickness Dependence of the GMR in Electrodeposited Multilayers: Current Status and Open Questions

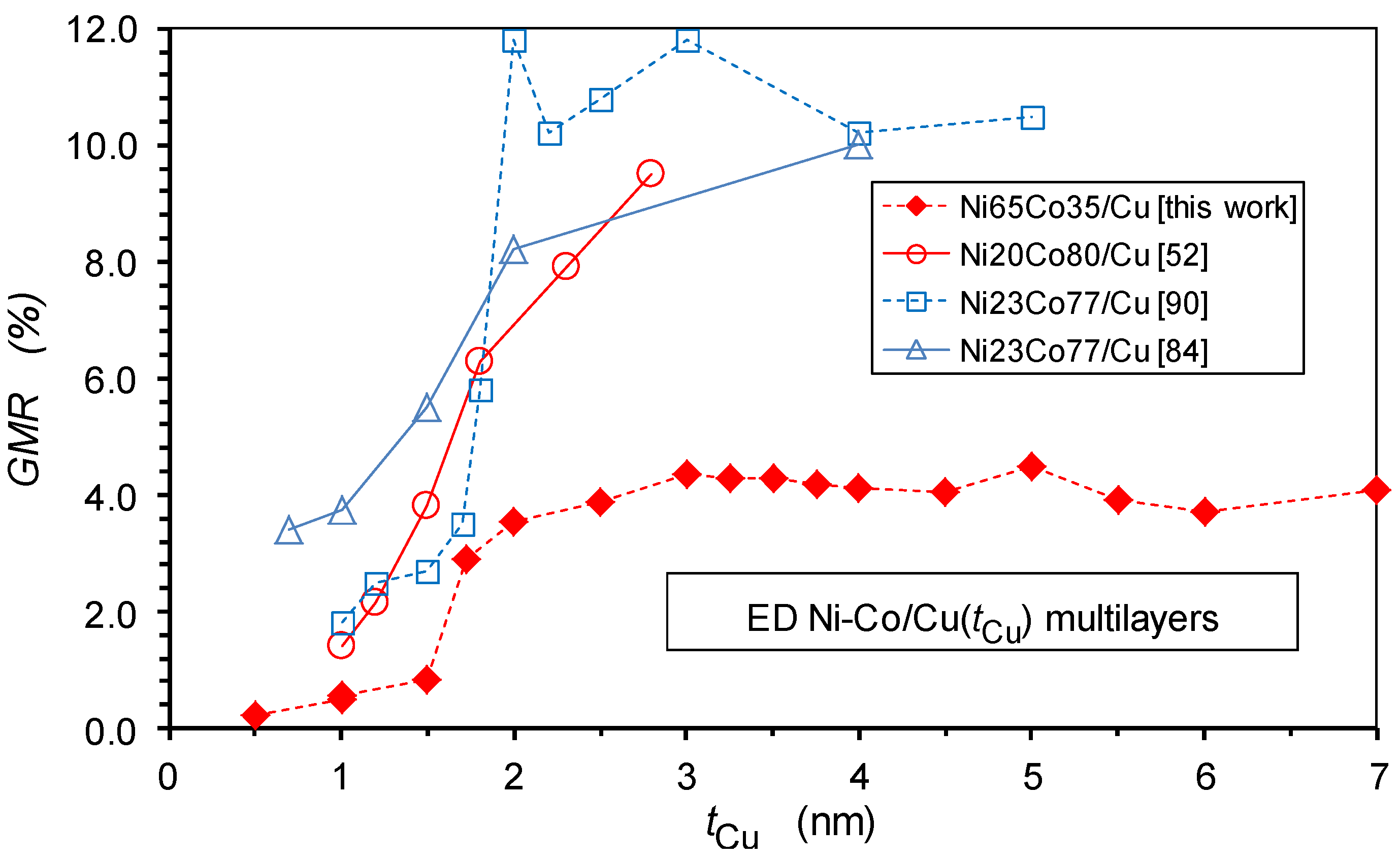

2. Experimental

2.1. Sample Preparation and Composition Analysis

2.2. XRD Studies

2.3. Measurement of Magnetoresistance and Magnetic Properties

3. Structural Studies by XRD

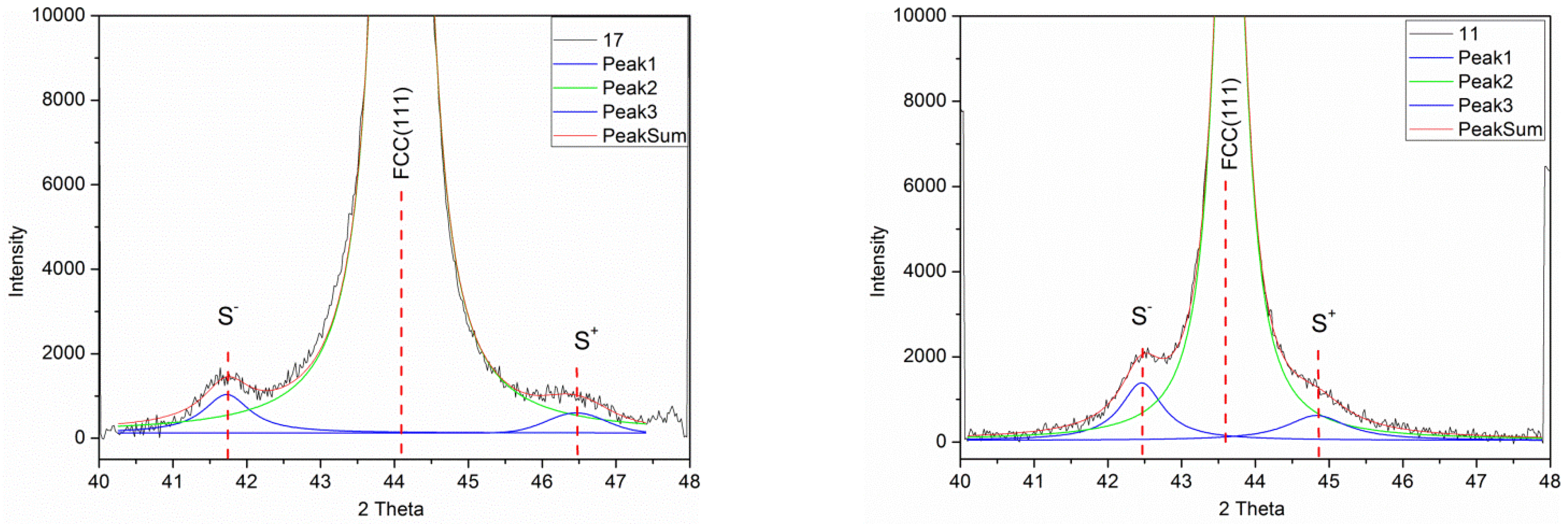

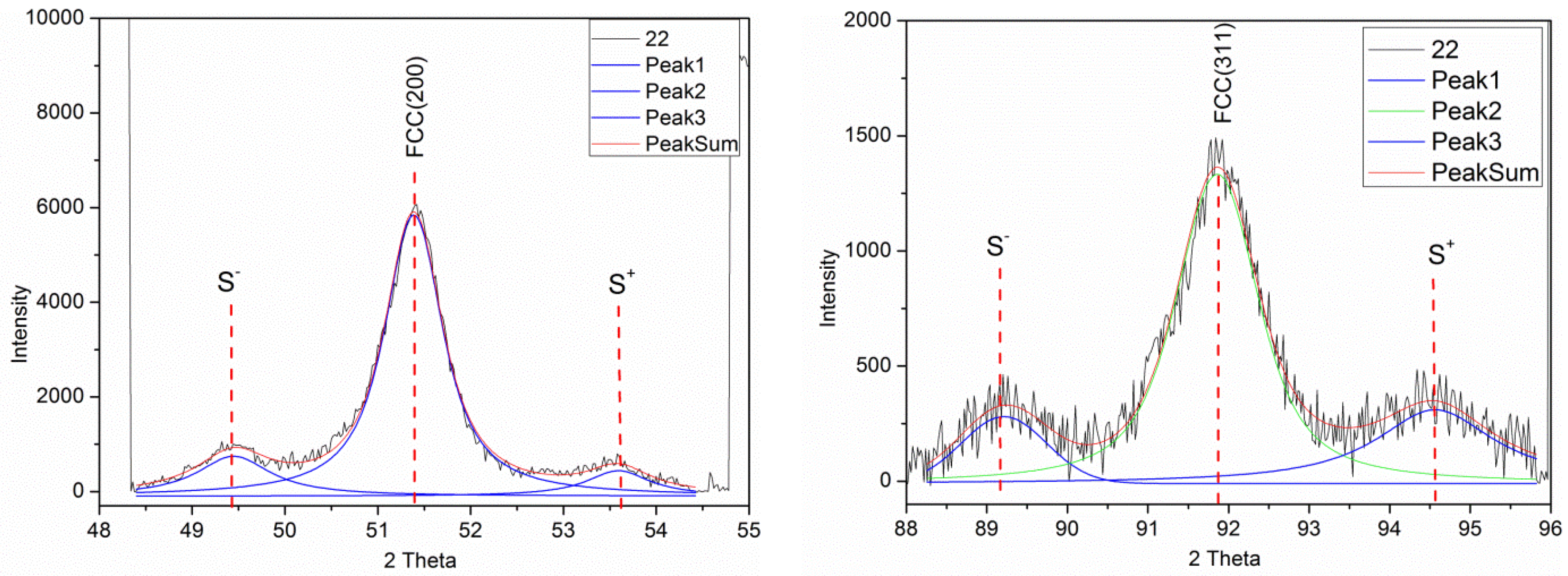

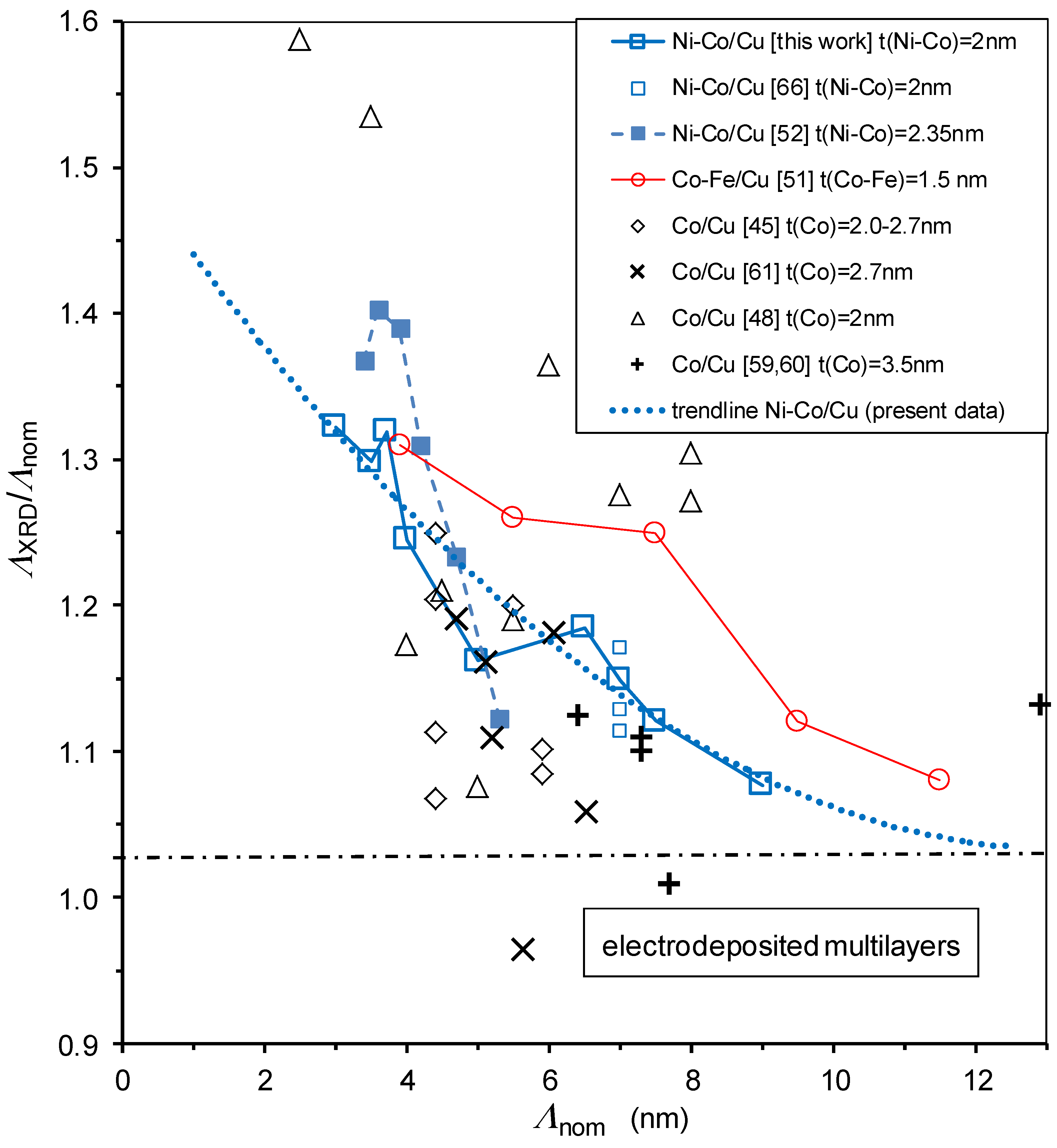

3.1. XRD Patterns and Satellite Reflections

3.2. Lattice Parameters and Interplanar Distances

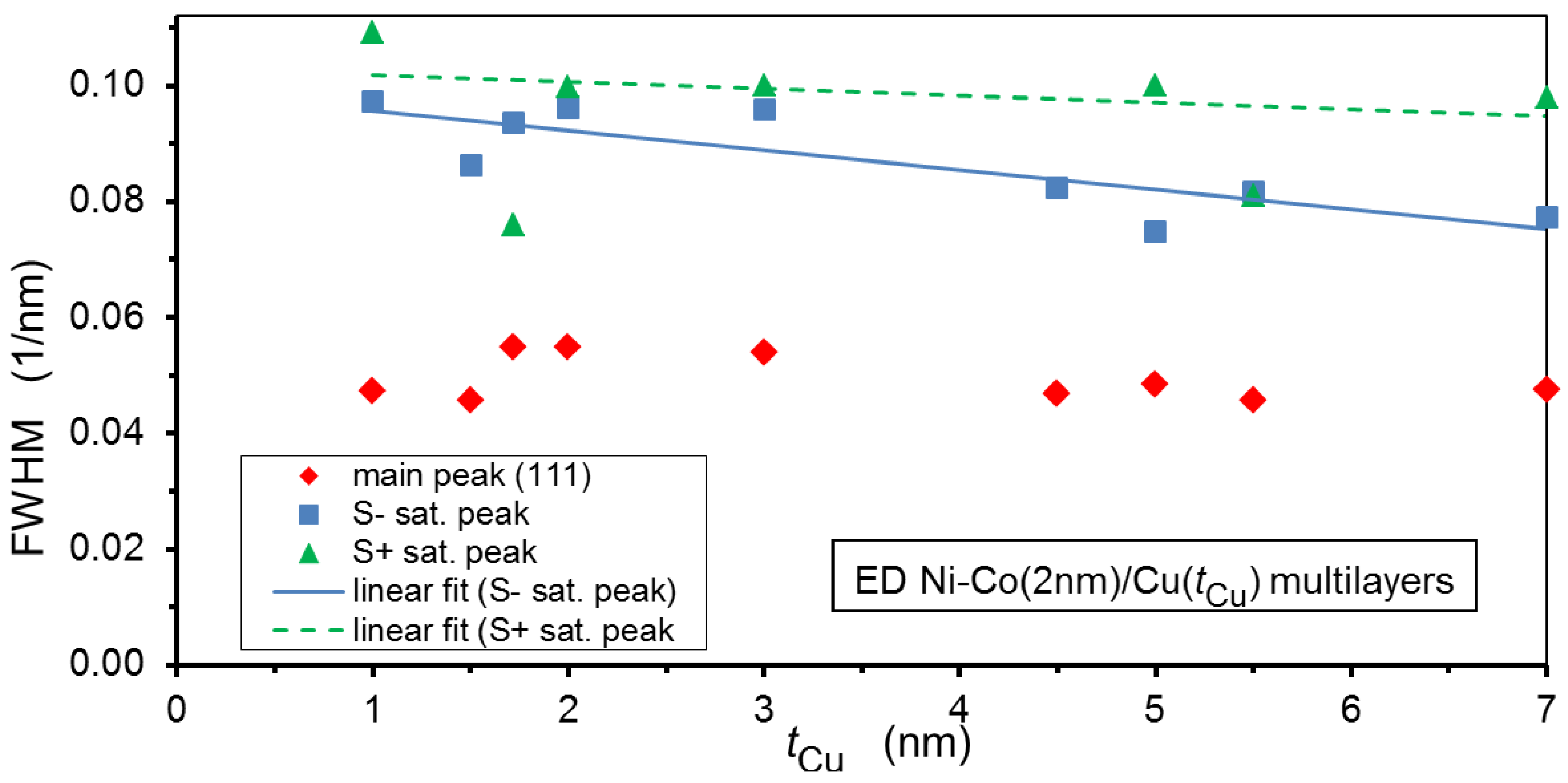

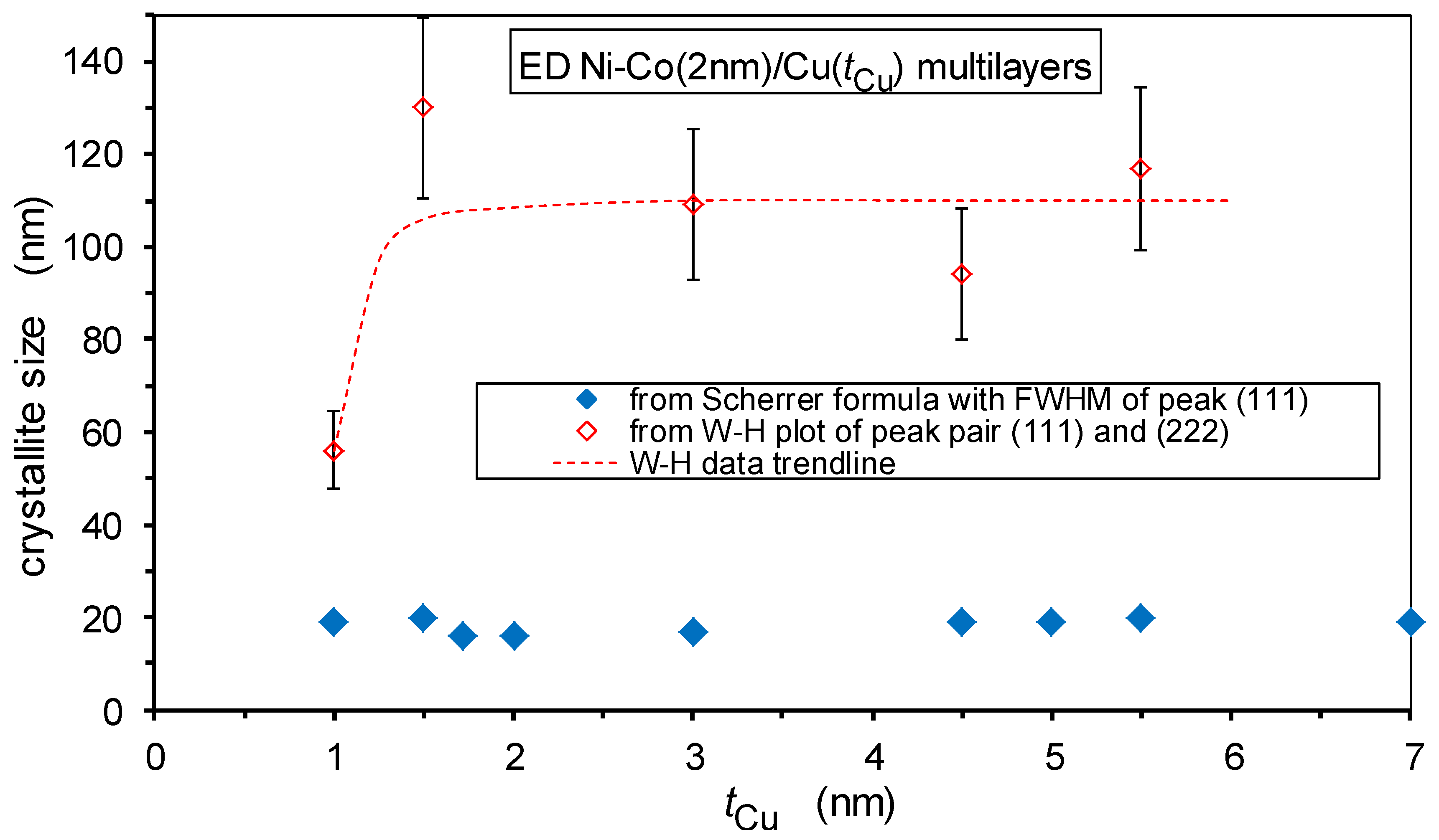

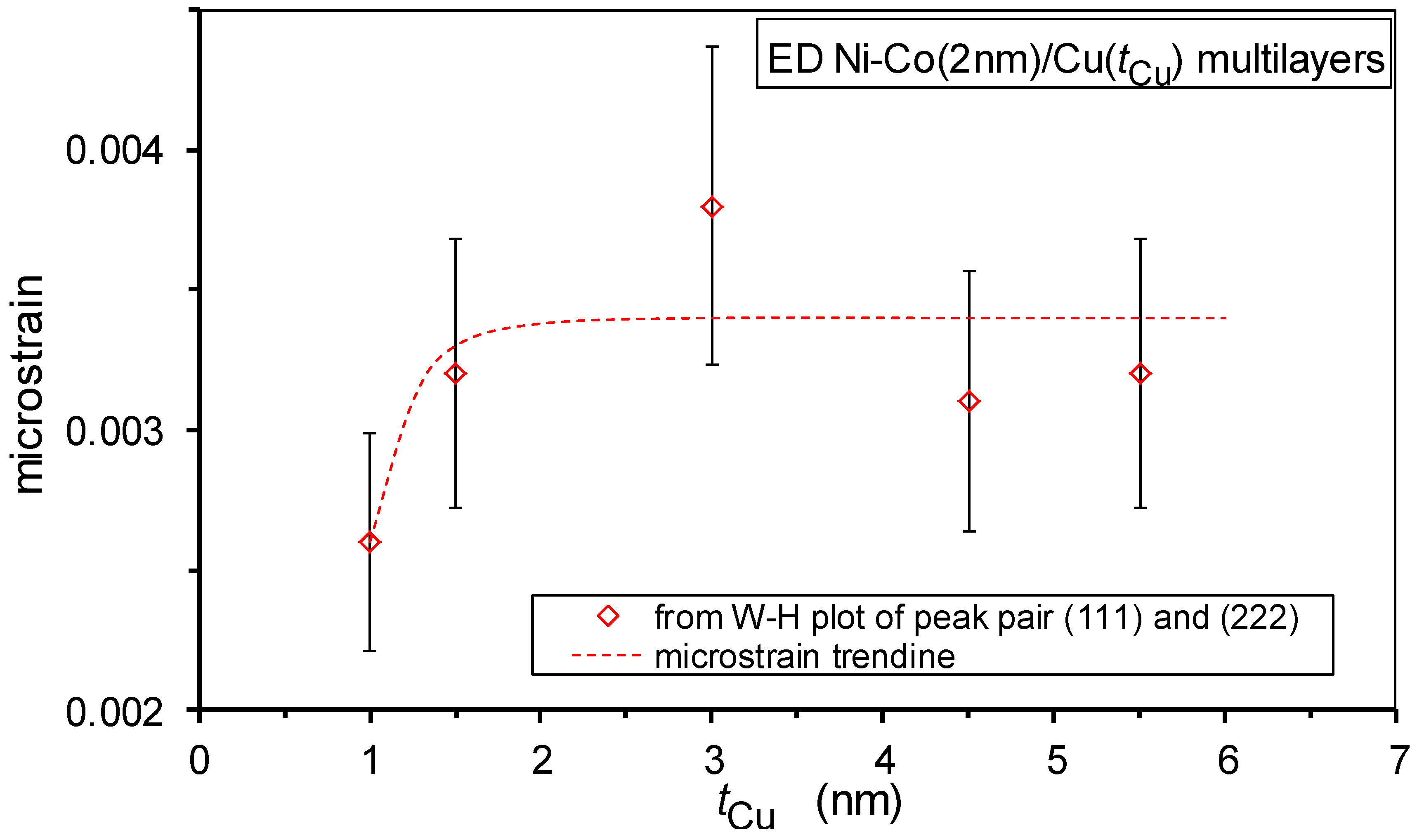

3.3. Crystallite Size and Microstrain

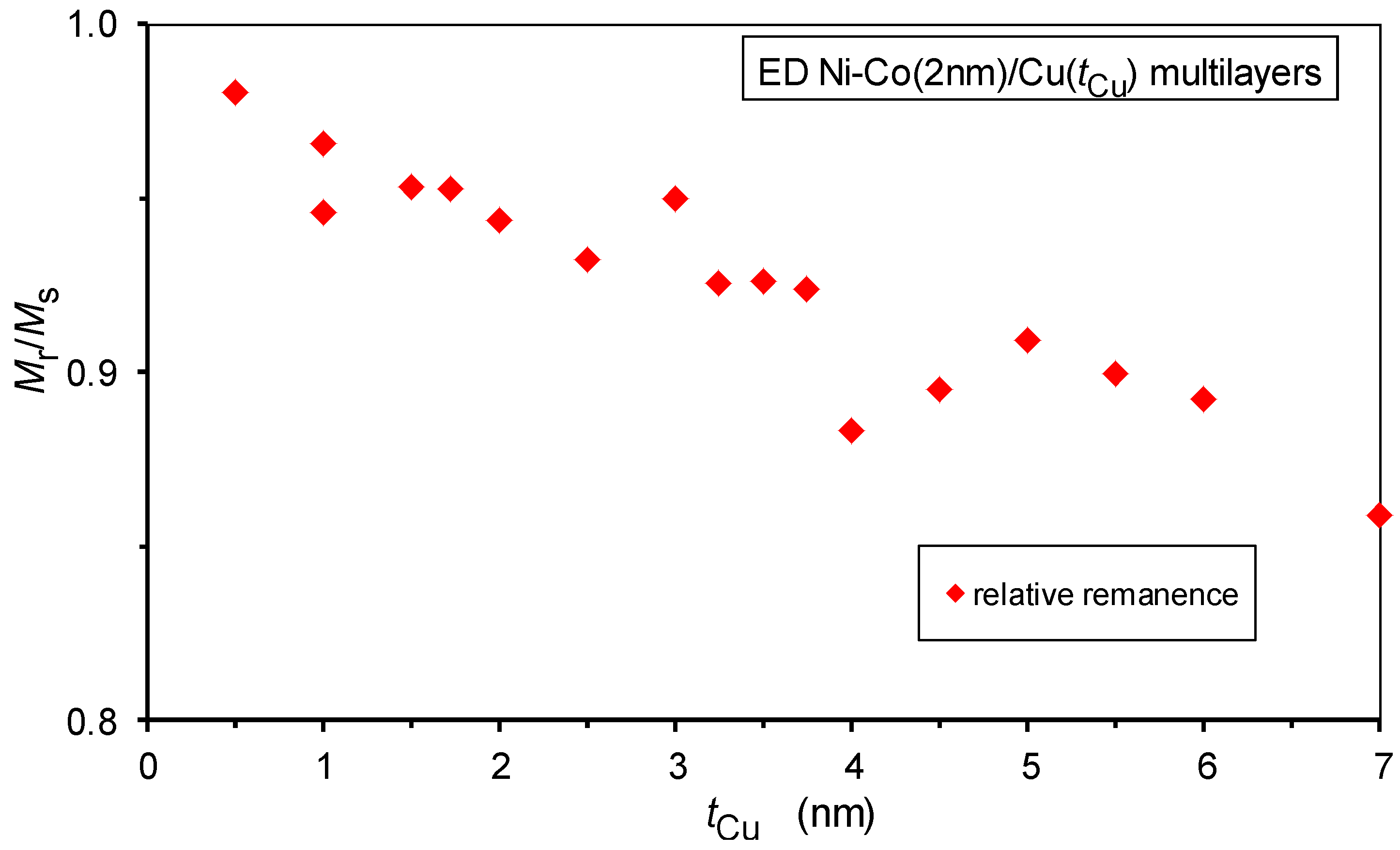

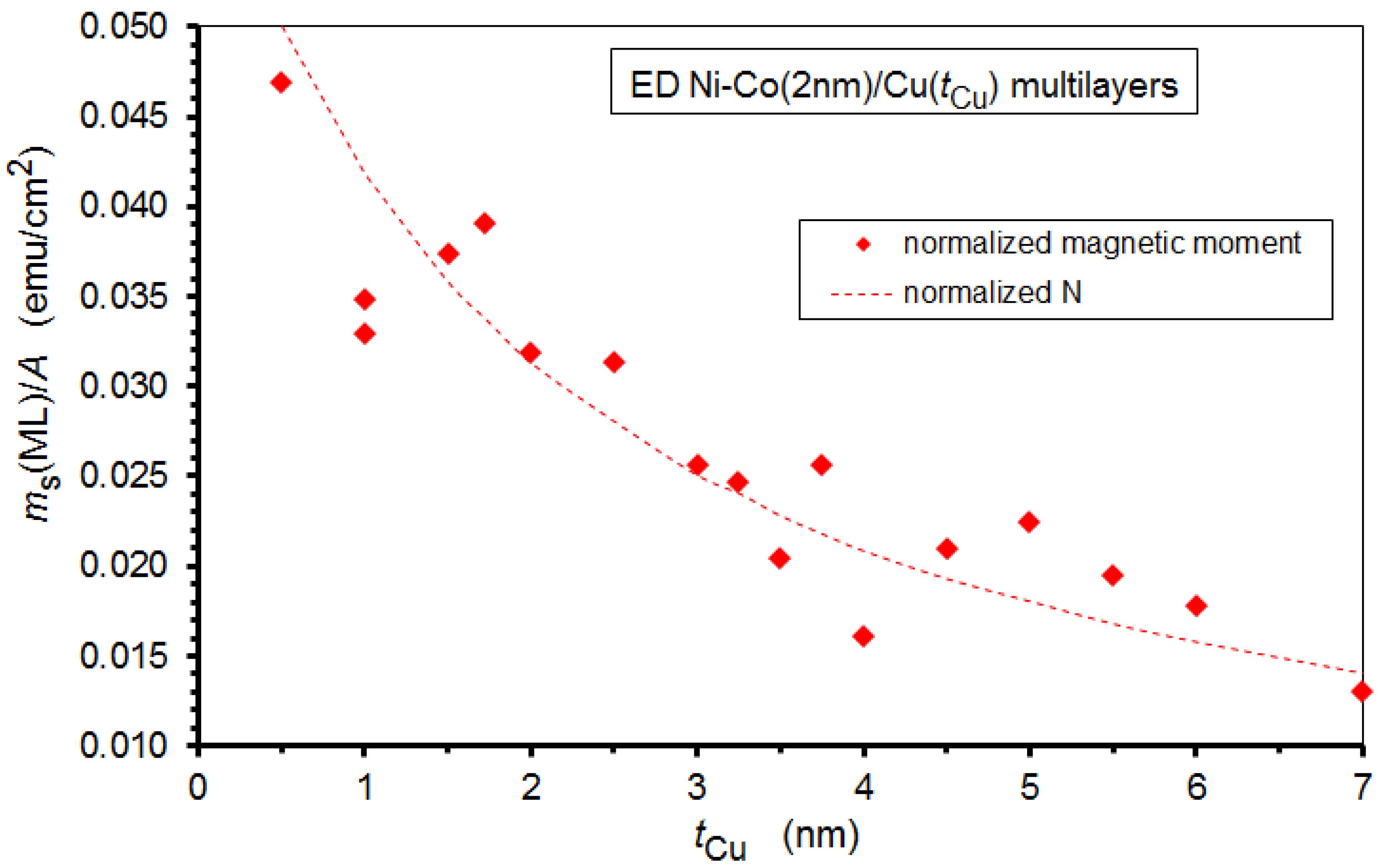

4. Magnetic Properties

5. Magnetoresistance Results

5.1. MR(H) Curves

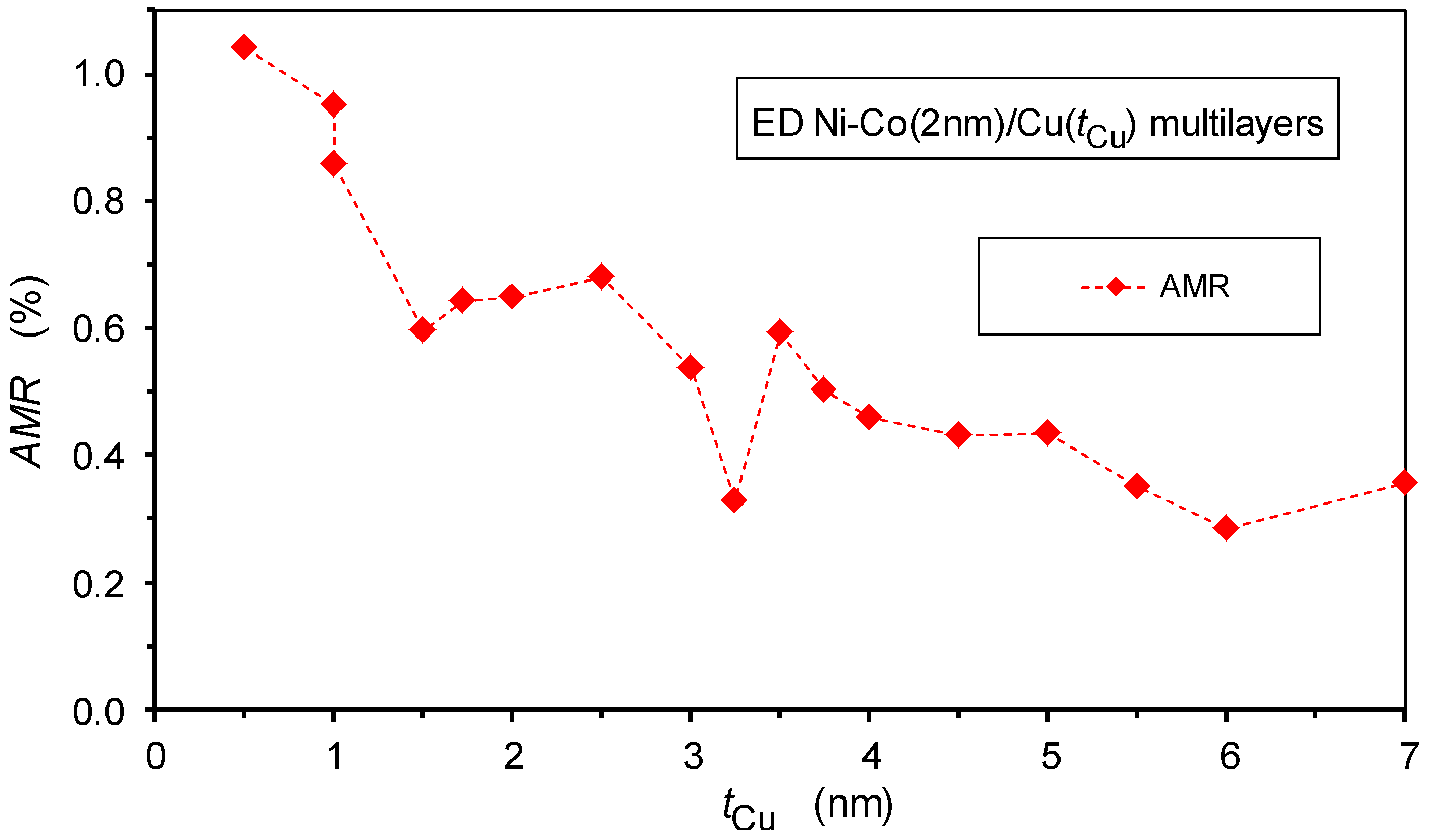

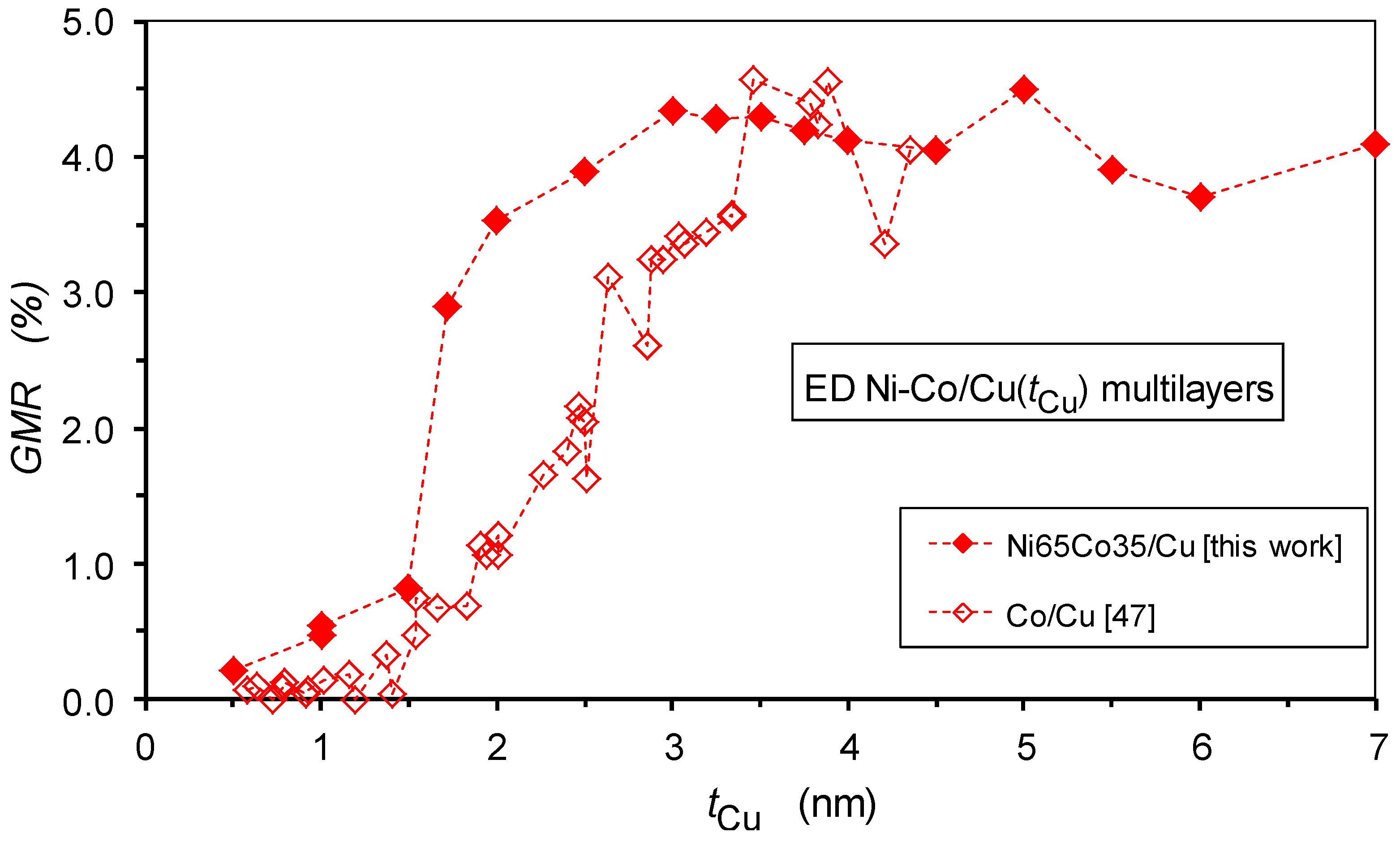

5.2. Spacer Layer Thickness Dependence of the GMR and AMR

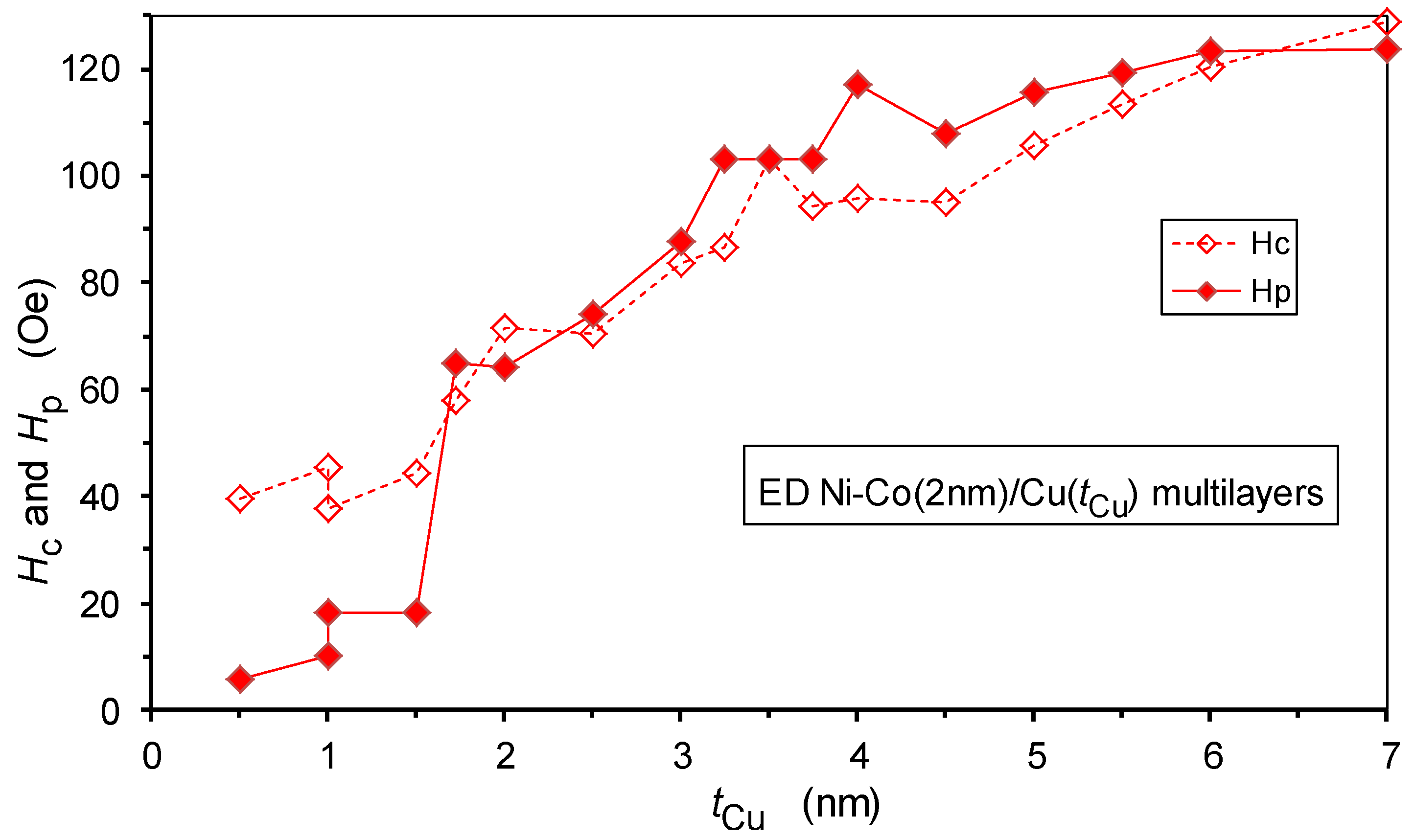

5.3. Spacer Layer Thickness Dependence of the Hysteresis Parameters Hc and Hp

6. Discussion: Critical Evaluation of the GMR vs. Spacer Thickness Behavior Reported for Ni-Co/Cu Multilayers

6.1. Decreasing GMR with Increasing Spacer Thickness

6.2. Critical Assessment of Previous Papers Claiming to Have Observed Oscillatory GMR

6.3. Increasing GMR with Increasing Spacer Thickness

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Baibich, M.N.; Broto, J.M.; Fert, A.; van Dau, F.N.; Petroff, F.; Etienne, P.; Creuzet, G.; Friederich, A.; Chazelas, J. Giant magnetoresistance of (001) Fe/(001) Cr magnetic superlattices. Phys. Rev. Lett. 1988, 61, 2472. [Google Scholar] [CrossRef] [Green Version]

- Binasch, G.; Grünberg, P.; Saurenbach, F.; Zinn, W. Enhanced magnetoresistance in layered magnetic structures with antiferromagnetic interlayer exchange. Phys. Rev. B 1989, 39, 4828. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mosca, D.H.; Petroff, F.; Fert, A.; Schroeder, P.A.; Pratt, W.P., Jr.; Laloee, R. Oscillatory interlayer coupling and giant magnetoresistance in Co/Cu multilayers. J. Magn. Magn. Mater. 1991, 94, L1. [Google Scholar] [CrossRef]

- Parkin, S.S.P.; Bhadra, R.; Roche, K.P. Oscillatory magnetic exchange coupling through thin copper layers. Phys. Rev. Lett. 1991, 66, 2152. [Google Scholar] [CrossRef] [PubMed]

- McGuire, T.R.; Potter, R.I. Anisotropic magnetoresistance in ferromagnetic 3d alloys. IEEE Trans. Magn. 1975, 11, 1018. [Google Scholar] [CrossRef]

- Daughton, J.M. GMR applications. J. Magn. Magn. Mater. 1999, 192, 334–342. [Google Scholar] [CrossRef]

- Fu, P.; Zheng, F. A new GMR sensor based on gradient magnetic field detection for DC and wide-band current measurement. In Proceedings of the 2022 IEEE Region 10 Symposium (TENSYMP), Mumbai, India, 1–3 July 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Mabarroh, N.M.; Alfansuri, T.; Aji Wibowo, N.; Imani Istiqomah, N.; Marsel Tumbelaka, R.; Suharyadi, E. Detection of green-synthesized magnetite nanoparticles using spin-valve GMR-based sensor and their potential as magnetic labels. J. Magn. Magn. Mater. 2022, 560, 169645. [Google Scholar] [CrossRef]

- Wu, K.; Su, D.; Saha, R.; Wang, J.P. Giant Magnetoresistance (GMR) Materials and Devices for Biomedical and Industrial Applications. In Spintronics: Materials, Devices and Applications; Wang, K., Yang, M., Luo, J., Eds.; Wiley: Hoboken, NJ, USA, 2022; pp. 3–49. [Google Scholar] [CrossRef]

- Hassan, M.; Laureti, S.; Rinaldi, C.; Fagiani, F.; Barucca, G.; Casoli, F.; Mezzi, A.; Bolli, E.; Kaciulis, S.; Fix, M.; et al. Thin-Film Heterostructures Based on Co/Ni Synthetic Antiferromagnets on Polymer Tapes: Toward Sustainable Flexible Spintronics. ACS Appl. Mater. Interfaces 2022, article in press. [Google Scholar] [CrossRef]

- Reig, C.; Cubells-Beltrán, M.D. Giant Magnetoresistance (GMR) Magnetometers. In High Sensitivity Magnetometers; Grosz, A., Haji-Sheikh, M., Mukhopadhyay, S., Eds.; Part of the book series Smart Sensors, Measurement and Instrumentation; Springer: Cham, Switzerland, 2017; Volume 19, pp. 225–252. [Google Scholar] [CrossRef]

- Kondalkar, V.V.; Li, X.; Yang, S.S.; Lee, K. Highly efficient current sensor built on a chip based on nanocrystalline NiFe/Cu/NiFe thin film. J. Ind. Eng. Chem. 2017, 53, 416–424. [Google Scholar] [CrossRef]

- Han, X.F.; Wan, C.H.; Wu, H.; Guo, C.Y.; Tang, P.; Yan, Z.R.; Xing, Y.W.; He, W.Q.; Yu, G.Q. From Microelectronics to Spintronics and Magnonics—A Topical Review. Chin. Phys. B 2022, 31, 117504. [Google Scholar] [CrossRef]

- Cubells-Beltrán, M.D.; Reig, C.; Madrenas, J.; De Marcellis, A.; Santos, J.; Cardoso, S.; Freitas, P.P. Integration of GMR sensors with different technologies. Sensors 2016, 16, 939. [Google Scholar] [CrossRef] [PubMed]

- Moser, A.; Takano, K.; Margulies, D.T.; Albrecht, M.; Sonobe, Y.; Ikeda, Y.; Sun, S.; Fullerton, E.E. Magnetic recording: Advancing into the future. J. Phys. D 2002, 35, R157. [Google Scholar] [CrossRef]

- Kulkarni, P.D.; Nakatani, T.; Li, Z.; Sasaki, T.; Sakuraba, Y. The effect of NiFeCr seed layer composition on the giant magnetoresistance properties of [FeCoNi/Cu] multilayers. J. Magn. Magn. Mater. 2022, 560, 169562. [Google Scholar] [CrossRef]

- Milyaev, M.A.; Naumova, L.I.; Proglyado, V.V.; Pavlova, A.Y.; Makarova, M.V.; Patrakov, E.I.; Glazunov, N.P.; Ustinov, V.V. Advantages of using Cu1-xInx alloys as spacers in GMR multilayers. J. Alloys Compd. 2022, 917, 165512. [Google Scholar] [CrossRef]

- Kac, M.; Dobrowolska, A.; Polit, A.; Żukrowski, J.; Marszalek, M. The influence of the atomic scale interface roughness on the GMR effect in Fe/Cr multilayers. J. Alloys Compd. 2020, 824, 153877. [Google Scholar] [CrossRef]

- Parkin, S.S.P. Systematic variation of the strength and oscillation period of indirect magnetic exchange coupling through the 3d, 4d, and 5d transition metals. Phys. Rev. Lett. 1991, 67, 3598. [Google Scholar] [CrossRef]

- Parkin, S.S.P.; Chappert, C.; Herman, F. Oscillatory exchange coupling and giant magnetoresistance via Cu-X alloys (X= Au, Fe, Ni). Europhys. Lett. 1993, 24, 71. [Google Scholar] [CrossRef]

- Bayreuther, G.; Bensch, F.; Kottler, V. Quantum oscillations of properties in magnetic multilayers. J. Appl. Phys. 1996, 79, 4509. [Google Scholar] [CrossRef] [Green Version]

- Szász, K.; Bakonyi, I. Modeling the Magnetoresistance versus Field Curves of GMR Multilayers with Antiferromagnetic and/or Orthogonal Coupling by Assuming Single-Domain State and Coherent Rotations. J. Spintr. Magn. Nanomater. 2012, 1, 159. [Google Scholar] [CrossRef]

- Marrows, C.H.; Hickey, B.J. Bilinear and biquadratic interlayer exchange coupling in sputtered Co/Cu multilayers damaged with residual gas impurities. Phys. Rev. B 1999, 59, 463. [Google Scholar] [CrossRef]

- Parkin, S.S.P. Giant magnetoresistance in magnetic nanostructures. Ann. Rev. Mater. Sci. 1995, 25, 357. [Google Scholar] [CrossRef]

- Alper, M.; Attenborough, K.; Hart, R.; Lane, S.J.; Lashmore, D.S.; Younes, C.; Schwarzacher, W. Giant magnetoresistance in electrodeposited superlattices. Appl. Phys. Lett. 1993, 63, 2144–2146. [Google Scholar] [CrossRef]

- Alper, M.; Attenborough, K.; Baryshev, V.; Hart, R.; Lashmore, D.S.; Schwarzacher, W. Giant magnetoresistance in electrodeposited Co–Ni–Cu/Cu superlattices. J. Appl. Phys. 1994, 75, 6543–6545. [Google Scholar] [CrossRef]

- Schwarzacher, W.; Lashmore, D.S. Giant magnetoresistance in electrodeposited films. IEEE Trans. Magn. 1996, 32, 3133–3153. [Google Scholar] [CrossRef]

- Bakonyi, I.; Péter, L. Electrodeposited multilayer films with giant magnetoresistance (GMR): Progress and problems. Progr. Mater. Sci. 2010, 55, 107. [Google Scholar] [CrossRef]

- Aliofkhazraei, M.; Walsh, F.C.; Zangari, G.; Köçkar, H.; Alper, M.; Rizal, C.; Magagnin, L.; Protsenko, V.; Arunachalam, R.; Rezvanian, A.; et al. Development of electrodeposited multilayer coatings: A review of fabrication, microstructure, properties and applications. Appl. Surf. Sci. Adv. 2021, 6, 100141. [Google Scholar] [CrossRef]

- Rizal, C.; Niraula, B.B. Ferromagnetic Alloys: Magnetoresistance, Microstructure, Magnetism, and Beyond. J. Nano Electron. Phys. 2015, 7, 04068. [Google Scholar]

- Péter, L. Compositionally Modulated and Multilayered Deposits. In Electrochemical Methods of Nanostructure Preparation; Springer: Cham, Switzerland, 2021; pp. 133–181. [Google Scholar]

- Walsh, F.C. The continued development of multilayered and compositionally modulated electrodeposits. Trans. IMF 2022, 100, 233–244. [Google Scholar] [CrossRef]

- Bakonyi, I.; Hansal, W.E.G. Development of pulse-plating technology for the preparation of coatings with varying composition along their thickness: A historical overview. Trans. IMF 2018, 96, 237–243. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Dogra, A.; Chowdhury, P.; Rajak, S.; Srivastava, C. Low temperature effect on magnetic conversion and giant magnetoresistance in electrodeposited CoCu/Cu multilayers. J. Alloys Compd. 2015, 647, 1098–1103. [Google Scholar] [CrossRef]

- Sahin, T.; Kockar, H.; Alper, M. Properties of electrodeposited CoFe/Cu multilayers: The effect of Cu layer thickness. J. Magn. Magn. Mater. 2015, 373, 128–131. [Google Scholar] [CrossRef]

- Kuru, H.; Kockar, H.; Alper, M. Giant magnetoresistance (GMR) behavior of electrodeposited NiFe/Cu multilayers: Dependence of non-magnetic and magnetic layer thicknesses. J. Magn. Magn. Mater. 2017, 444, 132–139. [Google Scholar] [CrossRef]

- Tekgül, A.; Alper, M.; Kockar, H. Simple electrodepositing of CoFe/Cu multilayers: Effect of ferromagnetic layer thicknesses. J. Magn. Magn. Mater. 2017, 421, 472–476. [Google Scholar] [CrossRef]

- Zsurzsa, S.; Péter, L.; Kiss, L.F.; Bakonyi, I. Magnetic and magnetoresistance studies of nanometric electrodeposited Co films and Co/Cu layered structures: Influence of magnetic layer thickness. J. Magn. Magn. Mater. 2017, 421, 194. [Google Scholar] [CrossRef] [Green Version]

- Kumaraguru, S.; Pavulraj, R.; Vijayakumar, J.; Mohan, S. Electrodeposition of cobalt/silver multilayers from deep eutectic solvent and their giant magnetoresistance. J. Alloy. Compd. 2017, 693, 1143–1149. [Google Scholar] [CrossRef]

- Jiang, W.; Shen, L.; Xu, M.; Zhu, J.; Tian, Z. Roughness, hardness and giant magneto resistance of Cu/Co multilayers prepared by jet electrochemical deposition. Int. J. Electrochem. Sci. 2018, 13, 9669–9680. [Google Scholar] [CrossRef]

- Zalka, D.; Péter, L.; El-Tahawy, M.; Gubicza, J.; Molnár, G.; Bakonyi, I. Structure and giant magnetoresistance of Co-Fe/Cu multilayer films electrodeposited from various bath formulations. J. Electrochem. Soc. 2019, 166, D923. [Google Scholar] [CrossRef]

- Tekgül, A.; Şahin, T.; Köçkar, H.; Alper, M. Structural, magnetic and GMR properties of FeCo (Cu)/Cu magnetic multilayers electrodeposited at high cathode potentials of the magnetic layer. Optoelectron. Adv. Mater.-Rapid Commun. 2020, 14, 189–195. [Google Scholar]

- Péter, L.; Liu, Q.X.; Kerner, Z.; Bakonyi, I. Relevance of the potentiodynamic method in parameter selection for pulse-plating of Co-Cu/Cu multilayers. Electrochim. Acta 2004, 49, 1513. [Google Scholar]

- Weihnacht, V.; Péter, L.; Tóth, J.; Pádár, J.; Kerner, Z.; Schneider, C.M.; Bakonyi, I. Giant magnetoresistance in Co-Cu/Cu multilayers prepared by various electrodeposition control modes. J. Electrochem. Soc. 2003, 150, C507. [Google Scholar]

- Cziráki, Á.; Péter, L.; Weihnacht, V.; Tóth, J.; Simon, E.; Pádár, J.; Pogány, L.; Schneider, C.M.; Gemming, T.; Wetzig, K.; et al. Structure and giant magnetoresistance behaviour of Co–Cu/Cu multilayers electrodeposited under various deposition conditions. Nanosci. Nanotechnol. 2006, 6, 2000–2012. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.X.; Péter, L.; Pádár, J.; Bakonyi, I. Ferromagnetic and superparamagnetic contributions in the magnetoresistance of electrodeposited Co-Cu/Cu multilayers. J. Electrochem. Soc. 2005, 152, C316–C323. [Google Scholar] [CrossRef]

- Bakonyi, I.; Simon, E.; Tóth, B.G.; Péter, L.; Kiss, L.F. Giant magnetoresistance in electrodeposited Co-Cu/Cu multilayers: Origin of the absence of oscillatory behavior. Phys. Rev. B 2009, 79, 174421. [Google Scholar] [CrossRef] [Green Version]

- Rajasekaran, N.; Pogány, L.; Révész, Á.; Tóth, B.G.; Mohan, S.; Péter, L.; Bakonyi, I. Structure and giant magnetoresistance of electrodeposited Co/Cu multilayers prepared by two-pulse (G/P) and three-pulse (G/P/G) plating. J. Electrochem. Soc. 2014, 161, D339. [Google Scholar] [CrossRef] [Green Version]

- Rajasekaran, N.; Mani, J.; Tóth, B.G.; Molnár, G.; Mohan, S.; Péter, L.; Bakonyi, I. Giant magnetoresistance and structure of electrodeposited Co/Cu multilayers: The influence of layer thicknesses and Cu deposition potential. J. Electrochem. Soc. 2015, 162, D204–D212. [Google Scholar] [CrossRef] [Green Version]

- Lenczowski, S.K.J.; Schönenberger, C.; Gijs, M.A.M.; de Jonge, W.J.M. Giant magnetoresistance of electrodeposited Co/Cu multilayers. J. Magn. Magn. Mater. 1995, 148, 455–465. [Google Scholar] [CrossRef]

- Tóth, B.G.; Péter, L.; Pogány, L.; Révész, Á.; Bakonyi, I. Preparation, structure and giant magnetoresistance of electrodeposited Fe-Co/Cu multilayers. J. Electrochem. Soc. 2014, 161, D154. [Google Scholar] [CrossRef] [Green Version]

- Péter, L.; Pádár, J.; Tóth-Kádár, E.; Cziráki, Á.; Sóki, P.; Pogány, L.; Bakonyi, I. Electrodeposition of Co–Ni–Cu/Cu multilayers: 1. Composition, structure and magnetotransport properties. Electrochim. Acta 2007, 52, 3813. [Google Scholar] [CrossRef]

- Bakonyi, I.; Péter, L.; Rolik, Z.; Kiss-Szabó, K.; Kupay, Z.; Tóth, J.; Kiss, L.F.; Pádár, J. Decomposition of the magnetoresistance of multilayers into ferromagnetic and superparamagnetic contributions. Phys. Rev. B 2004, 70, 054427. [Google Scholar] [CrossRef] [Green Version]

- Ishiji, K.; Hashizume, H. Interface structures and magnetic properties of exchanged-coupled Co/Cu multilayers sputter-grown on Ta buffers. Jpn. J. Appl. Phys. A 2006, 45, 4187. [Google Scholar] [CrossRef]

- Bian, Y.; Ström-Olsen, J.O.; Altounian, Z.; Huai, Y.; Cochrane, R.W. Giant magnetoresistance with low saturation field in (NixCo100−x/Cu) multilayers. J. Appl. Phys. 1994, 75, 7064. [Google Scholar] [CrossRef]

- Zsurzsa, S.; Pellicer, E.; Sort, J.; Péter, L.; Bakonyi, I. Electron microscopy characterization of electrodeposited homogeneous and multilayered nanowires in the Ni-Co-Cu system. J. Electrochem. Soc. 2018, 165, D536. [Google Scholar] [CrossRef]

- Tóth, B.G.; Péter, L.; Bakonyi, I. Magnetoresistance and surface roughness study of the initial growth of electrodeposited Co/Cu multilayers. J. Electrochem. Soc. 2011, 158, D671. [Google Scholar] [CrossRef]

- Tóth, B.G.; Péter, L.; Révész, Á.; Pádár, J.; Bakonyi, I. Temperature dependence of the electrical resistivity and the anisotropic magnetoresistance (AMR) of electrodeposited Ni-Co alloys. Eur. Phys. J. B 2010, 75, 167. [Google Scholar] [CrossRef] [Green Version]

- Rafaja, D.; Schimpf, C.; Klemm, V.; Schreiber, G.; Bakonyi, I.; Péter, L. Formation of microstructural defects in electrodeposited Co/Cu multilayers. Acta Mater. 2009, 57, 3211. [Google Scholar] [CrossRef]

- Rafaja, D.; Schimpf, C.; Schucknecht, T.; Klemm, V.; Péter, L.; Bakonyi, I. Microstructure formation in electrodeposited Co–Cu/Cu multilayers with GMR effect: Influence of current density during magnetic layer deposition. Acta Mater. 2011, 59, 2992. [Google Scholar] [CrossRef] [Green Version]

- Bakonyi, I.; Péter, L.; Horváth, Z.E.; Pádár, J.; Pogány, L.; Molnár, G. Evolution of Structure with Spacer Layer Thickness in Electrodeposited Co/Cu Multilayers. J. Electrochem. Soc. 2008, 155, D688. [Google Scholar] [CrossRef]

- Cullity, B.D.; Stock, S.R. Elements of X-ray Diffraction, 3rd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2001. [Google Scholar]

- Gubicza, J. X-ray Line Profile Analysis in Materials Science; IGI-Global: Hershey, PA, USA, 2014; ISBN 978-1-4666-5852-3. [Google Scholar]

- Fullerton, E.E.; Schuller, I.K.; Vanderstraeten, H.; Bruynserade, Y. Structural refinement of superlattices from x-ray diffraction. Phys. Rev. B 1992, 45, 9292. [Google Scholar] [CrossRef]

- Michaelsen, C. On the structure and homogeneity of solid solutions: The limits of conventional X-ray diffraction. Philos. Magaz. A 1995, 72, 813. [Google Scholar] [CrossRef]

- Tóth, B.G.; Péter, L.; Dégi, J.; Révész, Á.; Oszetzky, D.; Molnár, G.; Bakonyi, I. Influence of Cu deposition potential on the giant magnetoresistance and surface roughness of electrodeposited Ni–Co/Cu multilayers. Electrochim. Acta 2013, 91, 122. [Google Scholar] [CrossRef] [Green Version]

- Bödeker, P.; Abromeit, A.; Bröhl, K.; Sonntag, P.; Metoki, N.; Zabel, H. Growth and x-ray characterization of Co/Cu (111) superlattices. Phys. Rev. B 1993, 47, 2353. [Google Scholar] [CrossRef] [PubMed]

- ASTM Powder Diffraction File PDF-00-004-0836 (fcc-Cu). Available online: https://www.icdd.com (accessed on 26 October 2022).

- ASTM Powder Diffraction File PDF-00-004-0850 (fcc-Ni). Available online: https://www.icdd.com (accessed on 26 October 2022).

- ASTM Powder Diffraction File PDF-00-015-0806 (fcc-Co). Available online: https://www.icdd.com (accessed on 26 October 2022).

- Rafaja, D.; Klemm, V.; Schreiber, G.; Knapp, M.; Kužel, R. Interference phenomena observed by X-ray diffraction in nanocrystalline thin films. J. Appl. Cryst. 2004, 37, 613. [Google Scholar] [CrossRef]

- Cyrille, M.C.; Kim, S.; Gomez, M.E.; Santamaria, J.; Krishnan, K.M.; Schuller, I.K. Enhancement of perpendicular and parallel giant magnetoresistance with the number of bilayers in Fe/Cr superlattices. Phys. Rev. B 2000, 62, 3361. [Google Scholar] [CrossRef] [Green Version]

- Bozorth, R.M. Ferromagnetism; Van Nostrand: New York, NY, USA, 1951. [Google Scholar]

- Campbell, I.A.; Fert, A. Transport Properties of Ferromagnets. In Ferromagnetic Materials; Wohlfarth, E.P., Ed.; North-Holland: Amsterdam, The Netherlands, 1982; Volume 3, Chapter 9. [Google Scholar]

- Raquet, B.; Viret, M.; Sondergard, E.; Cespedes, O.; Mamy, R. Electron-magnon scattering and magnetic resistivity in ferromagnets. Phys. Rev. B 2002, 66, 024433. [Google Scholar] [CrossRef]

- Madduri, P.V.P.; Kaul, S.N. Magnon-induced interband spin-flip scattering contribution to resistivity and magnetoresistance in a nanocrystalline itinerant-electron ferromagnet: Effect of crystallite size. Phys. Rev. B 2017, 95, 184402. [Google Scholar] [CrossRef]

- Bakonyi, I.; Czeschka, F.D.; Kiss, L.F.; Isnaini, V.A.; Krupp, A.T.; Palotás, K.; Zsurzsa, S.; Péter, L. High-field magnetoresistance of microcrystalline and nanocrystalline Ni metalat 3 K and 300 K. Eur. Phys. J. Plus 2022, 137, 871. [Google Scholar] [CrossRef]

- Bakonyi, I. Guidelines for the evaluation of magnetotransport parameters from measurements on thin strip-shaped samples of bulk metallic ferromagnets with finite residual resistivity. Eur. Phys. J Plus 2018, 133, 521. [Google Scholar] [CrossRef]

- Munford, M.L.; Sartorelli, M.L.; Seligman, L.; Pasa, A.A. Morphology and magnetic properties of Co thin films electrodeposited on Si. J. Electrochem. Soc. 2002, 149, C274. [Google Scholar] [CrossRef]

- Prutton, M. Thin Ferromagnetic Films; Butterworths: London, UK, 1964. [Google Scholar]

- Soohoo, R.F. Magnetic Thin Films; Harper & Row: New York, NY, USA, 1965. [Google Scholar]

- Liu, Q.X.; Péter, L.; Tóth, J.; Kiss, L.F.; Cziráki, Á.; Bakonyi, I. The role of nucleation in the evolution of giant magnetoresistance with layer thicknesses in electrodeposited Co–Cu/Cu multilayers. J. Magn. Magn. Mater. 2004, 280, 60. [Google Scholar] [CrossRef]

- Nabiyouni, G.; Schwarzacher, W. Dependence of GMR on crystal orientation in electrodeposited Co Ni Cu/Cu superlattices. J. Magn. Magn. Mater. 1996, 156, 355. [Google Scholar] [CrossRef]

- O’Keeffe, A.P.; Kasyutich, O.I.; Schwarzacher, W.; de Oliveira, L.S.; Pasa, A.A. Giant magnetoresistance in multilayers electrodeposited on n-Si. Appl. Phys. Lett. 1998, 73, 1002. [Google Scholar] [CrossRef]

- Kainuma, S.; Ishikura, S.; Hisatake, K.; Watanabe, T.; Fukumuro, N. Dependence of GMR on copper layer thickness in electrodeposited CoNiCu/Cu multilayers. J. Magn. Soc. Japan 1998, 22, 224. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cavallotti, P.L.; Manara, D.; Vallauri, R.; Vicenzo, A.; da Silva, J.M.; Sa, M.A. GMR effect in electrodeposited Cu/CoNi(Cu) multilayers. In Magnetic Materials, Processes, and Devices V.; Romankiw, L.T., Krongelb, S., Ahn, C.H., Eds.; The Electrochemical Society Proceedings Series: Pennington, NJ, USA, 1999; PV 98–20; p. 156. [Google Scholar]

- Hua, S.Z.; Lashmore, D.S.; Salamanca-Riba, L.; Schwarzacher, W.; Swartzendruber, L.J.; McMichael, R.D.; Bennett, L.H.; Hart, R. Giant magnetoresistance peaks in CoNiCu/Cu multilayers grown by electrodeposition. J. Appl. Phys. 1994, 76, 6519. [Google Scholar] [CrossRef]

- Hua, S.Z.; Salamanca-Riba, L.; Bennett, L.H.; Swartzendruber, L.J.; McMichael, R.D.; Lashmore, D.S.; Schlesinger, M. Giant magnetoresistance of electrodeposited CoNiCu/Cu multilayers. Scripta Met. Mater. 1995, 33, 1643. [Google Scholar] [CrossRef]

- Kubota, H.; Ishio, S.; Miyazaki, T.; Stadnik, Z.M. Giant magnetoresistance and interlayer exchange coupling in Ni-Co/Cu multilayer films. J. Magn. Magn. Mater. 1994, 129, 383. [Google Scholar] [CrossRef]

- Kasyutich, O.I.; Schwarzacher, W.; Fedosyuk, V.M.; Laskarzhevskiy, P.A.; Masliy, A.I. Comparison of the Structure and Magnetotransport Properties of Co-Ni-Cu/Cu Multilayers Electrodeposited on n-GaAs (001) and (111). J. Electrochem. Soc. 2000, 147, 2964. [Google Scholar] [CrossRef]

- Gilmer, G.H.; Grabow, M.H.; Bakker, A.F. Modelling of epitaxial growth. Mater. Sci. Eng. B 1990, 6, 101. [Google Scholar] [CrossRef]

- Bobo, J.F.; Kikuchi, H.; Redon, O.; Snoeck, E.; Piecuch, M.; White, R.L. Pinholes in antiferromagnetically coupled multilayers: Effects on hysteresis loops and relation to biquadratic exchange. Phys. Rev. B 1999, 60, 4131. [Google Scholar] [CrossRef]

- Bian, Y.; Ström-Olsen, J.O.; Altounian, Z.; Huai, Y.; Cochrane, R.W. (Ni80Co20/Cu) multilayers: Giant magnetoresistance with low saturation field. Appl. Phys. Lett. 1993, 62, 3525. [Google Scholar] [CrossRef]

- Bian, Y.; Altounian, Z.; Ström-Olsen, J.O.; Sutton, M.; Cochrane, R.W. Structural Studies of Sputtered Ni80Co20/Cu Multilayers. MRS Symp. Proc. 1995, 382, 197. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zsurzsa, S.; El-Tahawy, M.; Péter, L.; Kiss, L.F.; Gubicza, J.; Molnár, G.; Bakonyi, I. Spacer Layer Thickness Dependence of the Giant Magnetoresistance in Electrodeposited Ni-Co/Cu Multilayers. Nanomaterials 2022, 12, 4276. https://doi.org/10.3390/nano12234276

Zsurzsa S, El-Tahawy M, Péter L, Kiss LF, Gubicza J, Molnár G, Bakonyi I. Spacer Layer Thickness Dependence of the Giant Magnetoresistance in Electrodeposited Ni-Co/Cu Multilayers. Nanomaterials. 2022; 12(23):4276. https://doi.org/10.3390/nano12234276

Chicago/Turabian StyleZsurzsa, Sándor, Moustafa El-Tahawy, László Péter, László Ferenc Kiss, Jenő Gubicza, György Molnár, and Imre Bakonyi. 2022. "Spacer Layer Thickness Dependence of the Giant Magnetoresistance in Electrodeposited Ni-Co/Cu Multilayers" Nanomaterials 12, no. 23: 4276. https://doi.org/10.3390/nano12234276