A Study on the Dynamic Tunning Range of CVD Graphene at Microwave Frequency: Determination, Prediction and Application

Abstract

:1. Introduction

2. Materials and Methods

3. Results

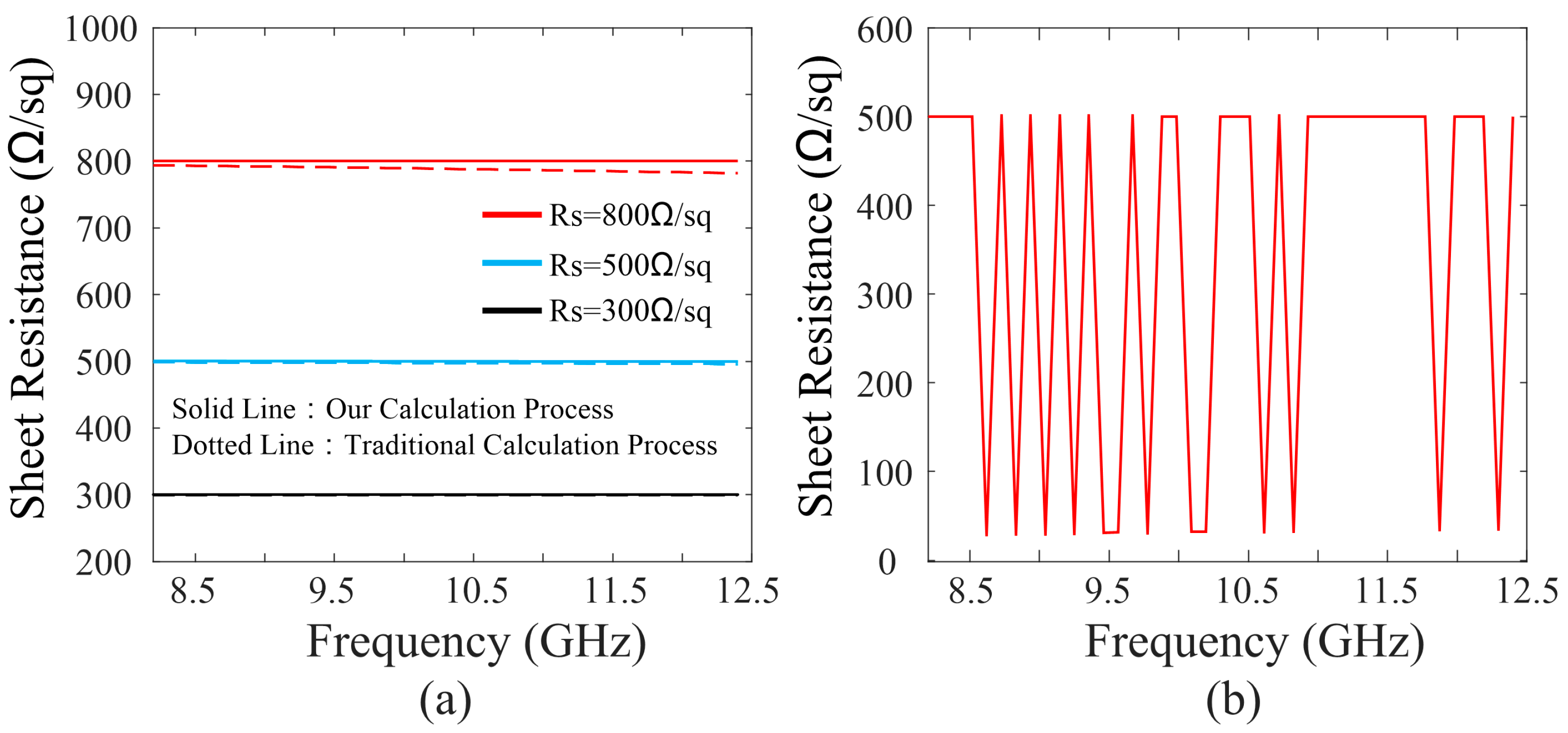

3.1. Improvement of Waveguide Method

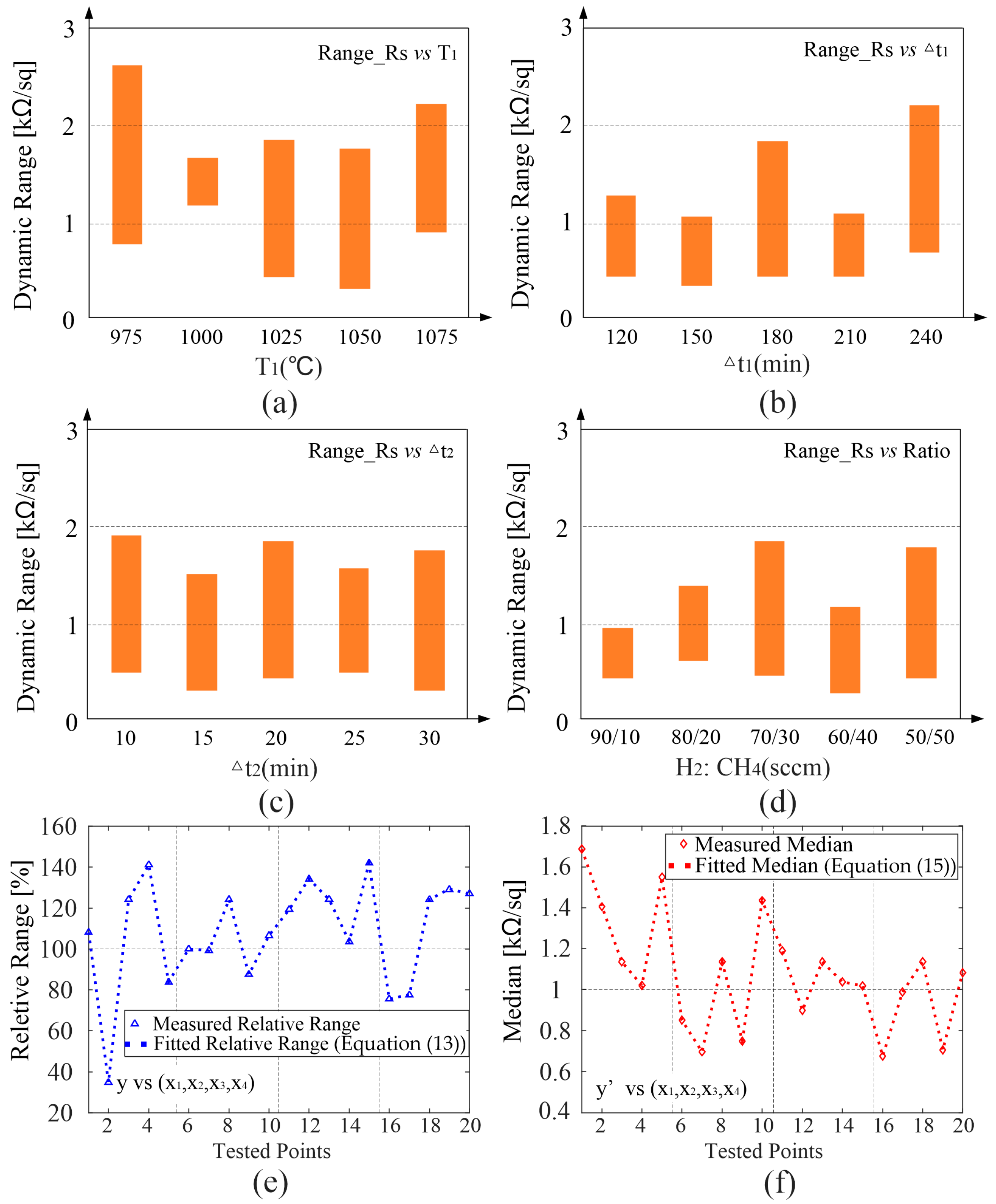

3.2. Impact of Growth Parameters

3.3. Mathematic Model

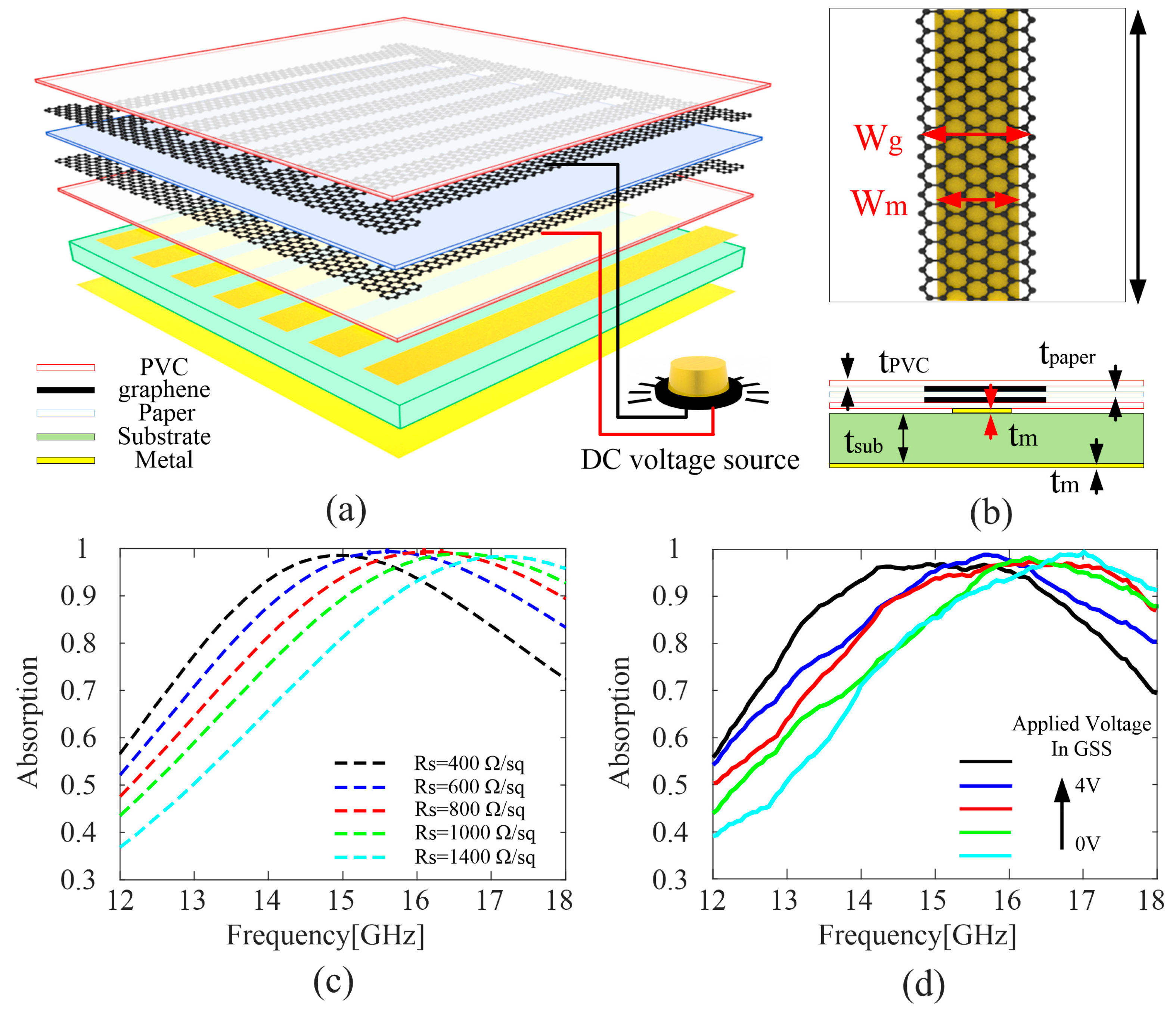

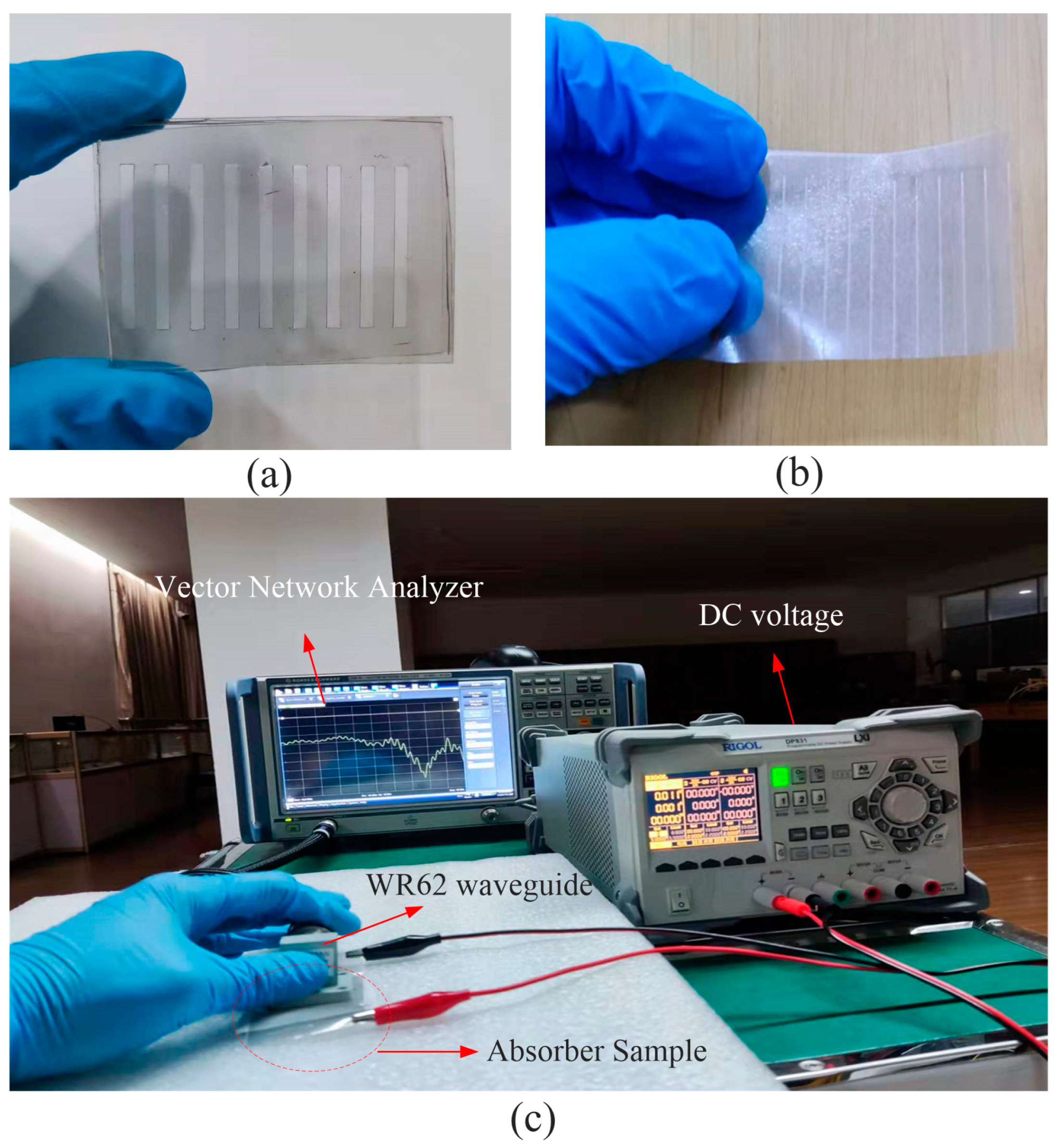

3.4. Application of the Model

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, S.H.; Choi, M.; Kim, T.-T.; Lee, S.; Liu, M.; Yin, X.; Choi, H.; Choi, C.-G.; Choi, S.-Y.; Zhang, X.; et al. Switching terahertz waves with gate-controlled active graphene metamaterials. Nat. Mater. 2012, 11, 936–941. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, J.; Wei, X.; Rukhlenko, I.D.; Chen, H.-T.; Zhu, W. Electrically Tunable Metasurface with Independent Frequency and Amplitude Modulations. ACS Photon. 2019, 7, 265–271. [Google Scholar] [CrossRef]

- Tamagnone, M.; Fallahi, A.; Mosig, J.R.; Perruisseau-Carrier, J. Fundamental limits and near-optimal design of graphene modulators and non-reciprocal devices. Nat. Photon. 2014, 8, 556–563. [Google Scholar] [CrossRef] [Green Version]

- Sensale-Rodriguez, B.; Yan, R.; Kelly, M.M.; Fang, T.; Tahy, K.; Hwang, W.S.; Jena, D.; Liu, L.; Xing, H.G. Broadband graphene terahertz modulators enabled by intraband transitions. Nat. Commun. 2012, 3, 780. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Long, J.; Baisong, G.; Jason, H.; Caglar, G. Graphene plasmonics for tunable terahertz metamaterials. Nat. Nanotechnol. 2011, 6, 630–634. [Google Scholar] [CrossRef]

- Gomez-Diaz, J.; Moldovan, C.; Capdevila, S.; Romeu, J.; Bernard, L.; Magrez, A.; Ionescu, A.; Perruisseau-Carrier, J. Self-biased reconfigurable graphene stacks for terahertz plasmonics. Nat. Commun. 2015, 6, 6334. [Google Scholar] [CrossRef]

- Chen, P.-Y.; Soric, J.; Padooru, Y.R.; Bernety, H.M.; Yakovlev, A.B.; Alù, A. Nanostructured graphene metasurface for tunable terahertz cloaking. New J. Phys. 2013, 15, 123029. [Google Scholar] [CrossRef]

- Chen, P.-Y.; Alù, A. Atomically Thin Surface Cloak Using Graphene Monolayers. ACS Nano 2011, 5, 5855–5863. [Google Scholar] [CrossRef]

- Lu, F.; Liu, B.; Shen, S. Infrared Wavefront Control Based on Graphene Metasurfaces. Adv. Opt. Mater. 2014, 2, 794–799. [Google Scholar] [CrossRef]

- Yatooshi, T.; Ishikawa, A.; Tsuruta, K. Terahertz wavefront control by tunable metasurface made of graphene ribbons. Appl. Phys. Lett. 2015, 107, 053105. [Google Scholar] [CrossRef]

- Wang, J.; Lu, W.B.; Li, X.B.; Liu, J.L. Terahertz Wavefront Control Based on Graphene Manipulated Fabry-Pérot Cavities. IEEE Photon. Technol. Lett. 2016, 28, 971–997. [Google Scholar] [CrossRef]

- Zhang, Z.; Yan, X.; Liang, L.; Wei, D.; Wang, M.; Wang, Y.; Yao, J. The novel hybrid metal-graphene metasurfaces for broadband focusing and beam-steering in farfield at the terahertz frequencies. Carbon 2018, 132, 529–538. [Google Scholar] [CrossRef]

- Chen, H.; Liu, Z.-G.; Lu, W.-B.; Zhang, A.-Q.; Li, X.-B.; Zhang, J. Microwave Beam Reconfiguration Based on Graphene Ribbon. IEEE Trans. Antennas Propag. 2018, 66, 6049–6056. [Google Scholar] [CrossRef]

- Chen, H.; Lu, W.-B.; Liu, Z.-G.; Geng, M.-Y. Microwave Programmable Graphene Metasurface. ACS Photon. 2020, 7, 1425–1435. [Google Scholar] [CrossRef]

- Yi, D.; Wei, X.C.; Xu, Y.L. A transparent microwave absorber based on patterned graphene: Design measurement and en-hancement. IEEE Trans. Nanotechnol. 2017, 16, 484–490. [Google Scholar] [CrossRef]

- Chen, H.; Lu, W.-B.; Liu, Z.-G.; Zhang, J.; Zhang, A.-Q.; Wu, B. Experimental Demonstration of Microwave Absorber Using Large-Area Multilayer Graphene-Based Frequency Selective Surface. IEEE Trans. Microw. Theory Tech. 2018, 66, 3807–3816. [Google Scholar] [CrossRef]

- Chen, H.; Lu, W.-B.; Liu, Z.-G.; Jiang, Z.H. Flexible Rasorber Based on Graphene With Energy Manipulation Function. IEEE Trans. Antennas Propag. 2019, 68, 351–359. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Z.; Shao, L.; Zhu, W. Dynamical absorption manipulation in a graphene-based optically transparent and flexible metasurface. Carbon 2021, 176, 374–382. [Google Scholar] [CrossRef]

- Hanson, G.W. Dyadic Green’s functions and guided surface waves for a surface conductivity model of graphene. J. Appl. Phys. 2008, 103, 064302. [Google Scholar] [CrossRef]

- Bae, S.; Kim, H.; Lee, Y.; Xu, X.; Park, J.-S.; Zheng, Y.; Balakrishnan, J.; Lei, T.; Kim, H.R.; Song, Y.I.; et al. Roll-to-roll production of 30-inch graphene films for transparent electrodes. Nat. Nanotechnol. 2010, 5, 574–578. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Balci, O.; Polat, E.O.; Kakenov, N.; Kocabas, C. Graphene-enabled electrically switchable radar-absorbing surfaces. Nat. Commun. 2015, 6, 6628. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, C.; Zhao, J.; Zhang, B.H.; Song, R.G.; Wang, Y.C.; He, D.P.; Cheng, Q. Multilayered Graphene-Assisted Broadband Scattering Suppression through an Ultrathin and Ultralight Metasurface. ACS Appl. Mater. Interfaces 2021, 13, 7698–7704. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Long, C.; Yin, S.; Song, R.G.; Zhang, B.H.; Zhang, J.W.; He, D.P.; Cheng, Q. Graphene-based anisotropic polarization meta-filter. Mater. Des. 2021, 206, 109768. [Google Scholar] [CrossRef]

- Zhang, A.-Q.; Liu, Z.-G.; Wei-Bing, L.; Chen, H. Graphene-Based Dynamically Tunable Attenuator on a Coplanar Waveguide or a Slotline. IEEE Trans. Microw. Theory Tech. 2018, 67, 70–77. [Google Scholar] [CrossRef]

- Chen, H.; Geng, M.Y.; Liu, Z.G.; Lu, W.B. A quantitative study of CVD graphene on synthesis parameters and sheet resistance. In Proceedings of the 2021 IEEE 4th International Conference on Electronic Information and Communication Technology (ICEICT), Xi’an, China, 18–20 August 2021; pp. 836–839. [Google Scholar]

- Pekdemir, S.; Onses, M.S.; Hancer, M. Low temperature growth of graphene using inductively-coupled plasma chemical vapor deposition. Surf. Coatings Technol. 2017, 309, 814–819. [Google Scholar] [CrossRef]

- Terasawa, T.-O.; Saiki, K. Effect of vapor-phase oxygen on chemical vapor deposition growth of graphene. Appl. Phys. Express 2015, 8, 35101. [Google Scholar] [CrossRef]

- Pallavi; Joshi, S.; Singh, D.; Kaur, M.; Lee, H.-N. Comprehensive Review of Orthogonal Regression and its Applications in Different Domains. Arch. Comput. Methods Eng. 2022, 1209, 1–21. [Google Scholar] [CrossRef]

- Li, X.; Hao, J. Orthogonal test design for optimization of synthesis of super early strength anchoring material. Constr. Build. Mater. 2018, 181, 42–48. [Google Scholar] [CrossRef]

- Wang, P.; Tian, C.; Liu, R.; Wang, J. Mathematical model for multivariate nonlinear prediction of SMD of X-type swirl pressure nozzles. Process Saf. Environ. Prot. 2019, 125, 228–237. [Google Scholar] [CrossRef]

- Konishi, S. Introduction to Multivariate Analysis: Linear and Nonlinear Modeling; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Zhang, J.; Liu, Z.; Lu, W.; Chen, H.; Wu, B.; Liu, Q. A low profile tunable microwave absorber based on graphene sandwich structure and high impedance surface. Int. J. RF Microw. Comput. Eng. 2019, 30, e22022. [Google Scholar] [CrossRef] [Green Version]

- Xing, B.B.; Liu, Z.G.; Lu, W.B.; Chen, H. Wideband microwave absorber with dynamically tunable absorption based on gra-phene and random metasurface. IEEE Antennas Wirel. Propag. Lett. 2019, 18, 2602–2606. [Google Scholar] [CrossRef]

- Pozar, D. Microwave Engineering, 3rd ed.; Wiley: Hoboken, NJ, USA, 2005. [Google Scholar]

- Gómez-Díaz, J.S.; Perruisseau-Carrier, J.; Sharma, P.; Ionescu, A. Non-contact characterization of graphene surface impedance at micro and millimeter waves. J. Appl. Phys. 2012, 111, 114908. [Google Scholar] [CrossRef]

- Sun, F.T.; Feng, A.H.; Chen, B.B. Effect of Copper Pretreatment on Growth of Graphene Films by Chemical Vapor Deposition. J. Inorg. Mater. 2020, 35, 1177–1182. [Google Scholar] [CrossRef]

- Costa, F.; Monorchio, A.; Manara, G. Analysis and design of ultrathin electromagnetic absorbers comprising resistively loaded high impedance surfaces. IEEE Trans. Antennas Propag. 2010, 58, 1551–1555. [Google Scholar] [CrossRef] [Green Version]

- Lookman, T.; Balachandran, P.V.; Xue, D.; Yuan, R. Active learning in materials science with emphasis on adaptive sampling using uncertainties for targeted design. NPJ Comput. Mater. 2019, 5, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Fan, X.; Forsberg, F.; Smith, A.D.; Schröder, S.; Wagner, S.; Rödjegård, H.; Fischer, A.C.; Östling, M.; Lemme, M.C.; Niklaus, F. Graphene ribbons with suspended masses as transducers in ultra-small nanoelectro-mechanical accelerometers. Nat. Electron. 2019, 2, 394–404. [Google Scholar] [CrossRef] [Green Version]

- Aamir, M.A.; Moore, J.N.; Lu, X.; Seifert, P.; Englund, D.; Fong, K.C.; Efetov, D.K. Ultra-fast calorimetric measurements of the electronic heat capacity of graphene. arXiv 2020, arXiv:2020.14280. [Google Scholar] [CrossRef]

| Sequence | T1 (°C) | Δt1 (min) | Δt2 (min) | Ratio (sccm) | Tunning Range (kΩ/sq) |

|---|---|---|---|---|---|

| 1 | 1050 | 120 | 30 | 70:30 | [0.43, 1.43] |

| 2 | 1050 | 180 | 10 | 60:40 | [0.54, 1.76] |

| 3 | 1025 | 60 | 30 | 60:40 | [0.77, 1.43] |

| 4 | 1025 | 180 | 20 | 70:30 | [0.43, 1.84] |

| 5 | 1025 | 120 | 10 | 50:50 | [0.62, 1.14] |

| 6 | 1025 | 180 | 30 | 50:50 | [0.60, 1.38] |

| 7 | 1000 | 60 | 10 | 70:30 | [0.67, 1.51] |

| 8 | 1050 | 60 | 20 | 50:50 | [0.44, 1.08] |

| 9 | 1000 | 120 | 20 | 60:40 | [0.49, 1.08] |

| Sequence | T1 (°C) | Δt1 (min) | Δt2 (min) | Ratio (sccm) | Tunning Range (kΩ/sq) |

|---|---|---|---|---|---|

| 1 | 975 | 180 | 20 | 70:30 | [0.78, 1.84] |

| 2 | 1000 | 180 | 20 | 70:30 | [1.16,1.65] |

| 3 | 1025 | 180 | 20 | 70:30 | [0.43, 1.84] |

| 4 | 1050 | 180 | 20 | 70:30 | [0.30, 1.74] |

| 5 | 1075 | 180 | 20 | 70:30 | [0.90, 2.20] |

| 6 | 1025 | 120 | 20 | 70:30 | [0.43, 1.28] |

| 7 | 1025 | 150 | 20 | 70:30 | [0.35, 1.04] |

| 8 | 1025 | 180 | 20 | 70:30 | [0.43, 1.84] |

| 9 | 1025 | 210 | 20 | 70:30 | [0.42, 1.08] |

| 10 | 1025 | 240 | 20 | 70:30 | [0.67, 2.20] |

| 11 | 1025 | 180 | 10 | 70:30 | [0.48, 1.90] |

| 12 | 1025 | 180 | 15 | 70:30 | [0.30, 1.50] |

| 13 | 1025 | 180 | 20 | 70:30 | [0.43, 1.84] |

| 14 | 1025 | 180 | 25 | 70:30 | [0.50, 1.58] |

| 15 | 1025 | 180 | 30 | 70:30 | [0.30, 1.74] |

| 16 | 1025 | 180 | 20 | 90:10 | [0.42, 0.93] |

| 17 | 1025 | 180 | 20 | 80:20 | [0.61, 1.37] |

| 18 | 1025 | 180 | 20 | 70:30 | [0.43, 1.84] |

| 19 | 1025 | 180 | 20 | 60:40 | [0.25, 1.16] |

| 20 | 1025 | 180 | 20 | 50:50 | [0.40, 1.77] |

| i | 1 | 2 | 3 | 4 | |

|---|---|---|---|---|---|

| j | |||||

| 1 | 2.4885 × 10−5 | −0.1033 | 1.6068 × 102 | −1.1102 × 105 | |

| 2 | 1.0493 × 10−5 | −0.0075 | 1.9464 | −2.2040 × 102 | |

| 3 | 0.0037 | −0.2364 | 5.1130 | −42.2300 | |

| 4 | 4.9760 × 10−4 | −0.1350 | 13.4652 | −5.8628 × 102 | |

| i | 1 | 2 | 3 | 4 | |

|---|---|---|---|---|---|

| j | |||||

| 1 | 2.4885 × 10−5 | −0.1033 | 1.6068 × 102 | −1.1102 × 105 | |

| 2 | 1.0493 × 10−5 | −0.0075 | 1.9464 | −2.2040 × 102 | |

| 3 | 0.0037 | −0.2364 | 5.1130 | −42.2300 | |

| 4 | 4.9760 × 10−4 | −0.1350 | 13.4652 | −5.8628 × 102 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.; Liu, Z.-G.; Geng, M.-Y.; Meng, X.-Y.; Fu, W.-L.; Ju, L.; Yu, B.-Y.; Yang, W.; Dai, Y.-Q.; Lu, W.-B. A Study on the Dynamic Tunning Range of CVD Graphene at Microwave Frequency: Determination, Prediction and Application. Nanomaterials 2022, 12, 4424. https://doi.org/10.3390/nano12244424

Chen H, Liu Z-G, Geng M-Y, Meng X-Y, Fu W-L, Ju L, Yu B-Y, Yang W, Dai Y-Q, Lu W-B. A Study on the Dynamic Tunning Range of CVD Graphene at Microwave Frequency: Determination, Prediction and Application. Nanomaterials. 2022; 12(24):4424. https://doi.org/10.3390/nano12244424

Chicago/Turabian StyleChen, Hao, Zhen-Guo Liu, Ming-Yang Geng, Xiang-Yu Meng, Wan-Lin Fu, Lu Ju, Bu-Yun Yu, Wu Yang, Yun-Qian Dai, and Wei-Bing Lu. 2022. "A Study on the Dynamic Tunning Range of CVD Graphene at Microwave Frequency: Determination, Prediction and Application" Nanomaterials 12, no. 24: 4424. https://doi.org/10.3390/nano12244424

APA StyleChen, H., Liu, Z. -G., Geng, M. -Y., Meng, X. -Y., Fu, W. -L., Ju, L., Yu, B. -Y., Yang, W., Dai, Y. -Q., & Lu, W. -B. (2022). A Study on the Dynamic Tunning Range of CVD Graphene at Microwave Frequency: Determination, Prediction and Application. Nanomaterials, 12(24), 4424. https://doi.org/10.3390/nano12244424