Monolayer Graphene Radiation Sensor with Backend RF Ring Oscillator Transducer

Abstract

:1. Introduction

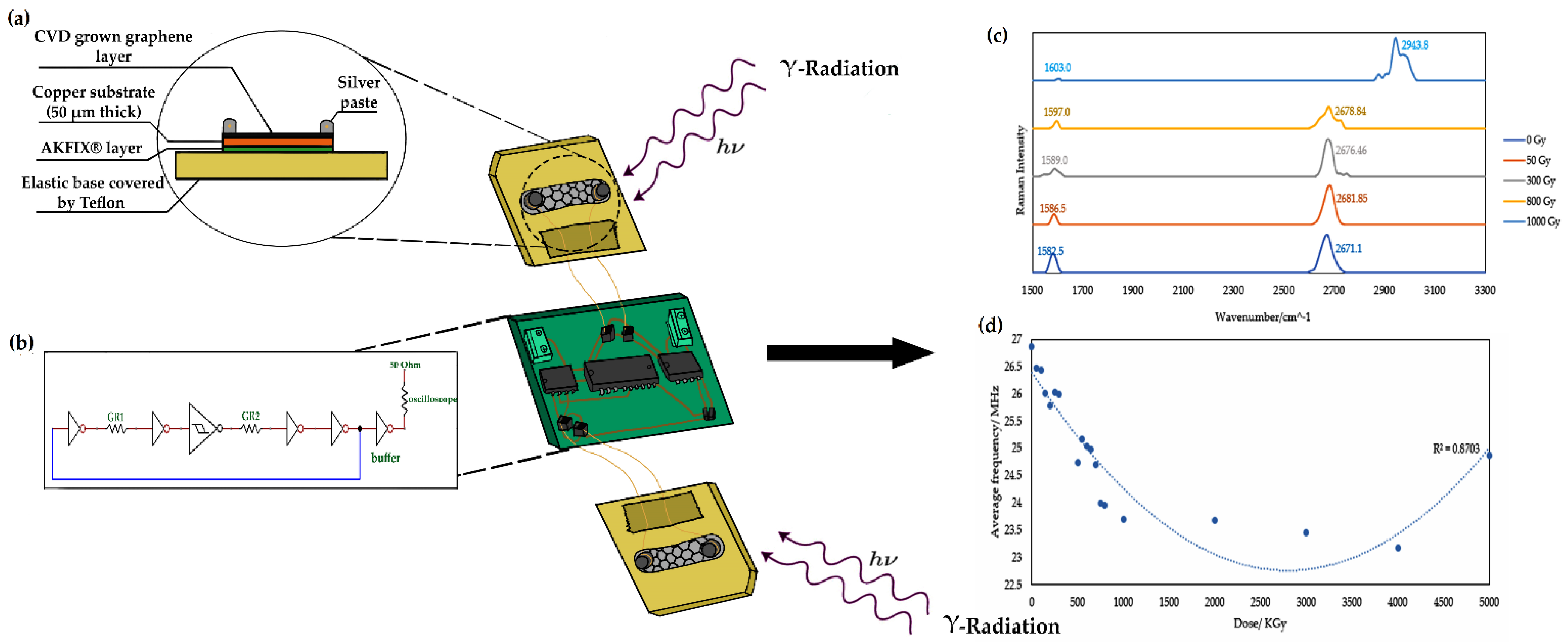

2. Working Principle

3. Materials and Methods

3.1. Materials

3.2. Device Fabrication

3.3. Gamma and Beta Irradiation

3.4. Raman Spectroscopy

3.5. SEM Characterization

4. Results and Discussion

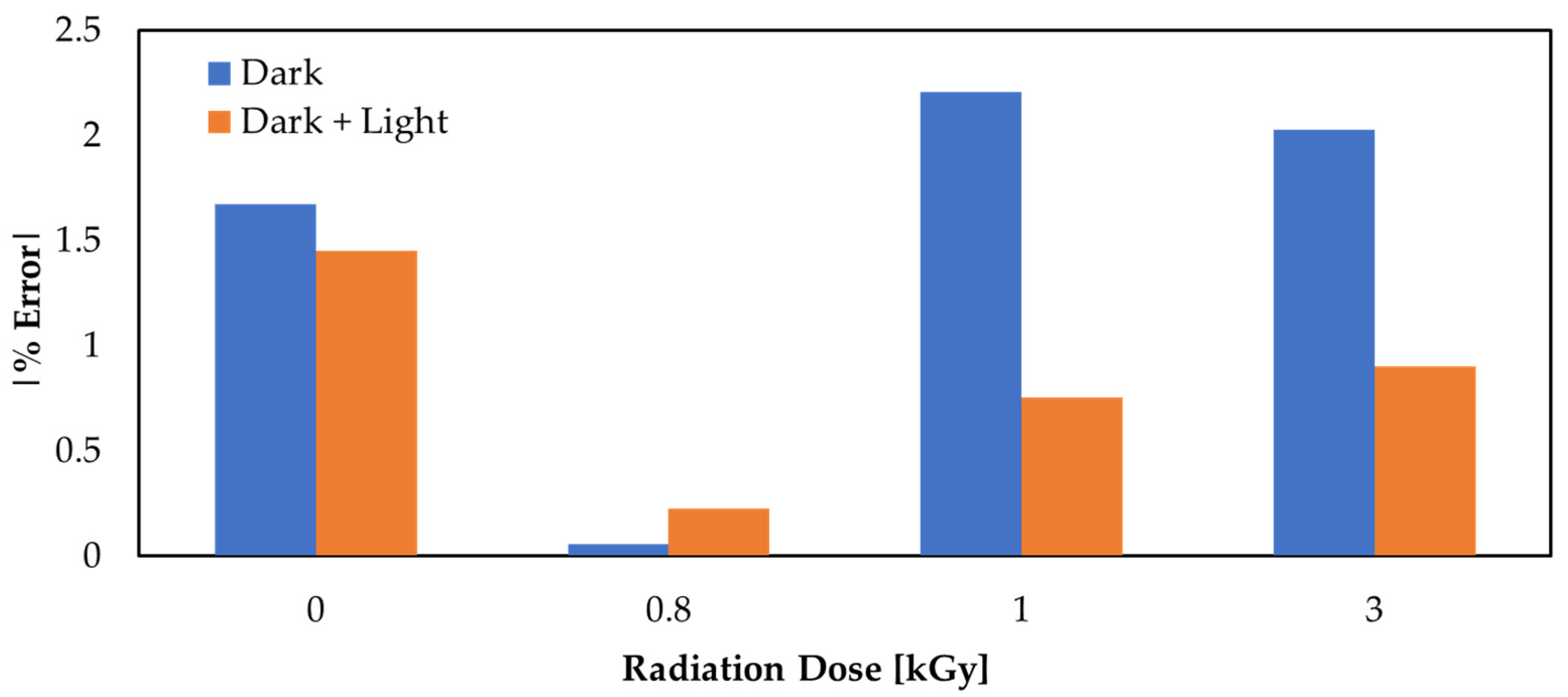

4.1. Study of Ambient Light Effects

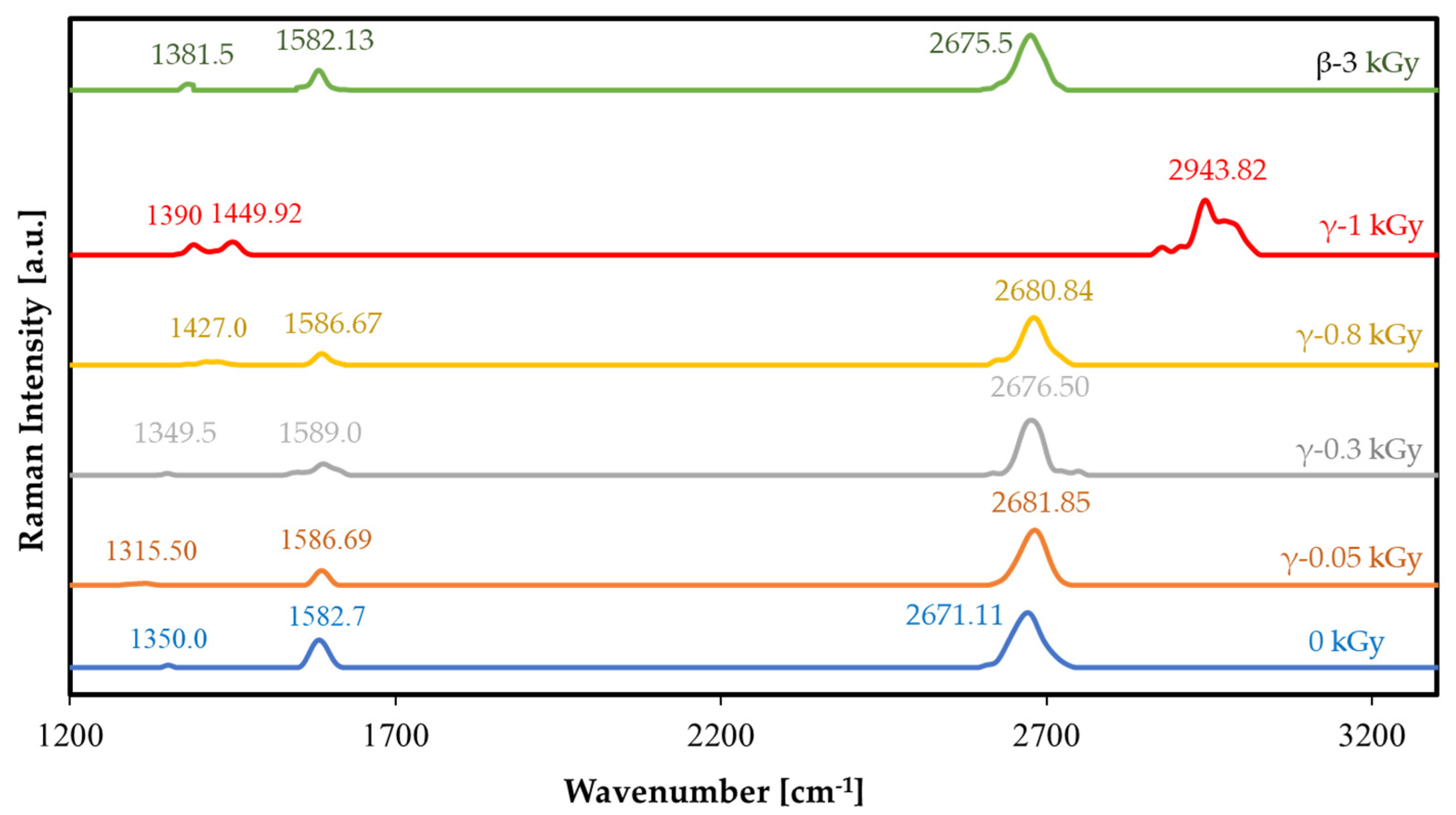

4.2. Raman Characterization

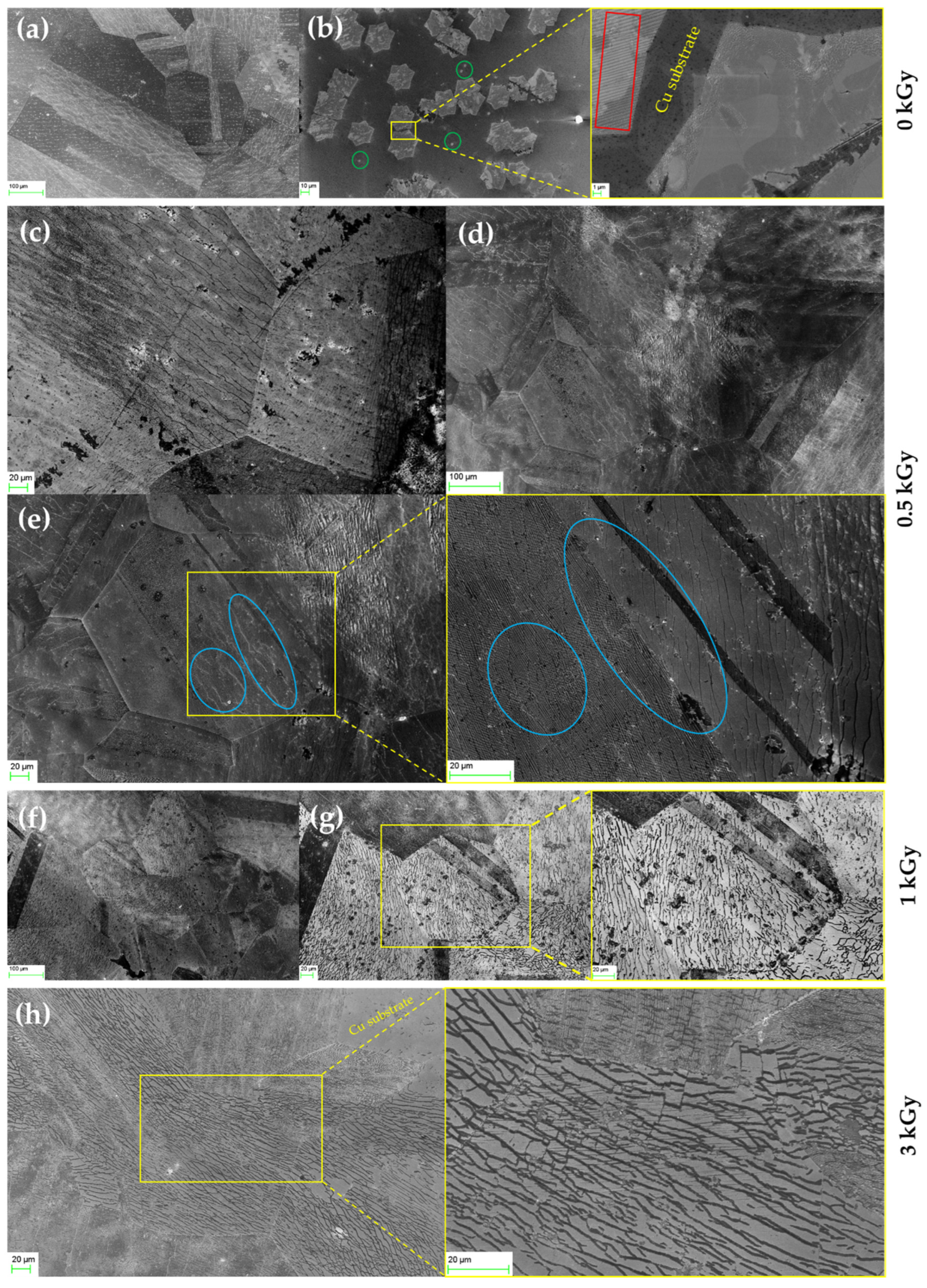

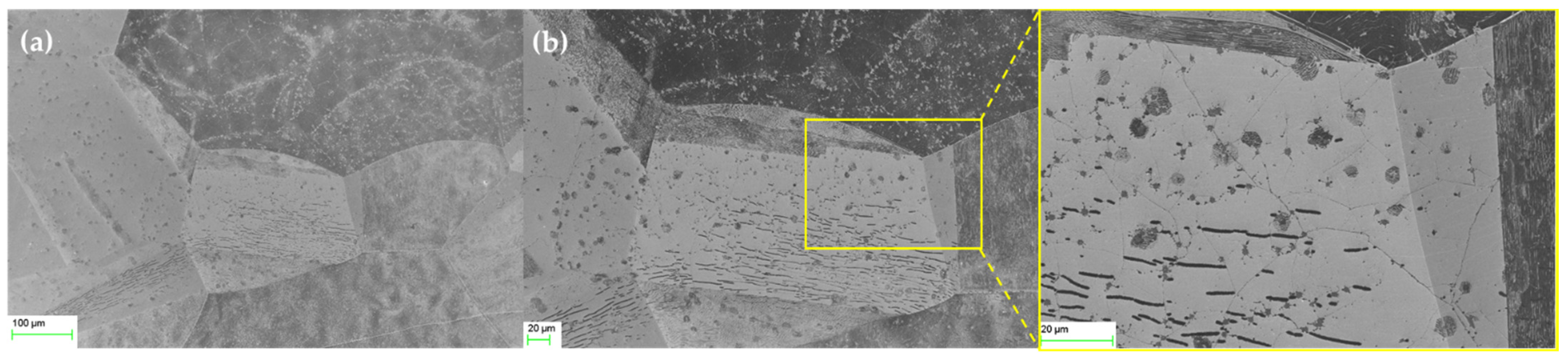

4.3. Morphological Characterization

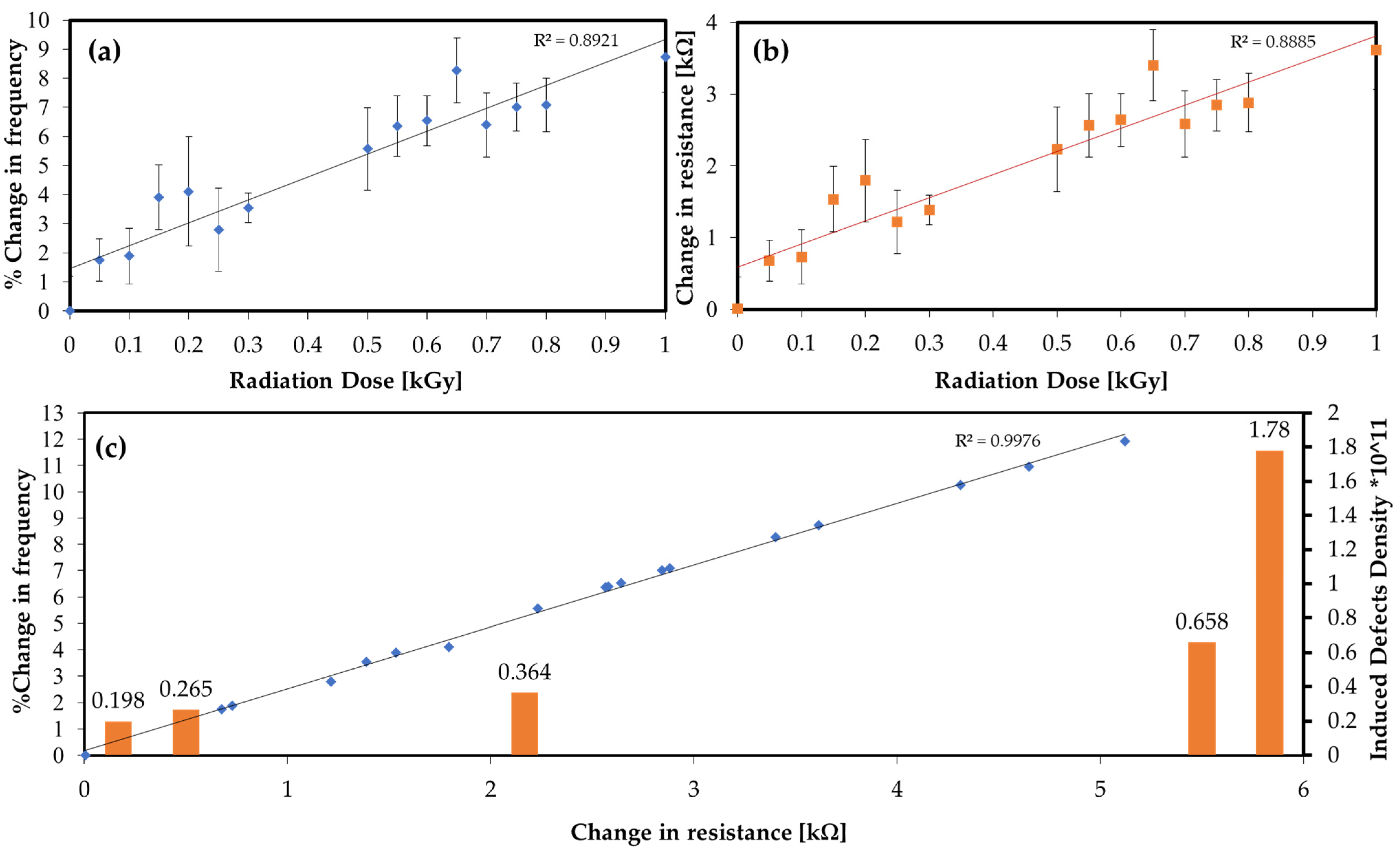

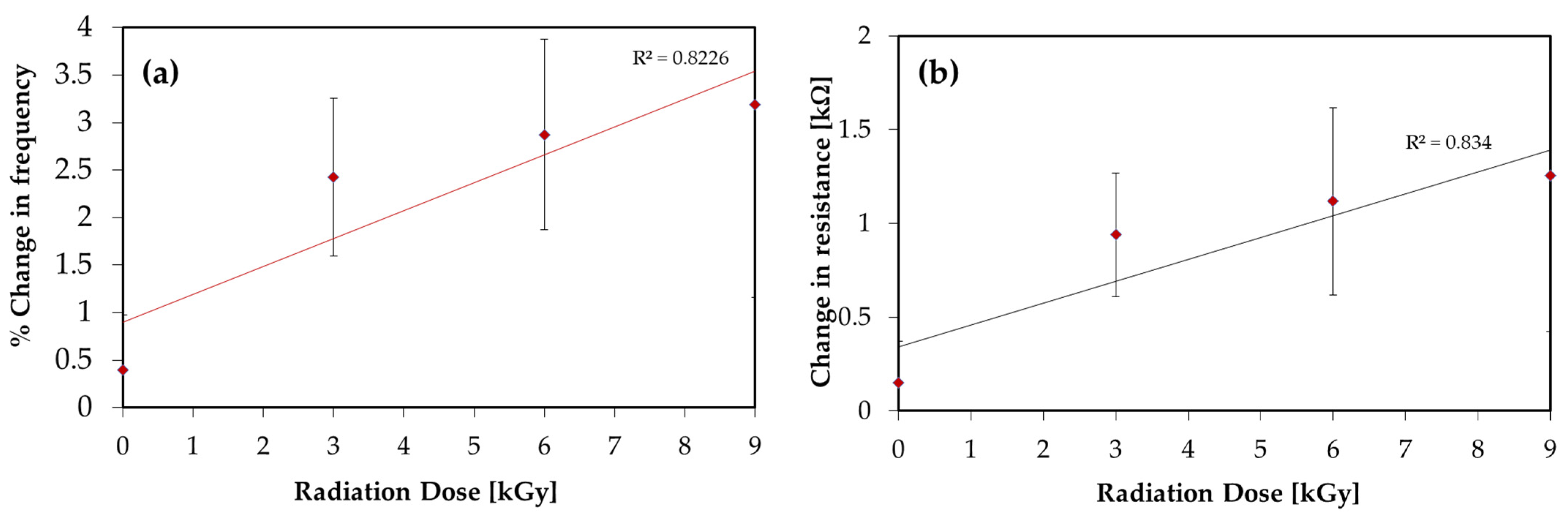

4.4. Backend RF Ring Oscillator Characterization

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sizov, F. THz radiation sensors. Opto-Electronics Rev. 2010, 18, 10–36. [Google Scholar] [CrossRef] [Green Version]

- Speller, R.; Olivo, A.; Pani, S.; Royle, G. Biomedical sensors of ionizing radiation. Biomed. Sens. 2010, 129–239. [Google Scholar]

- Flakus, F.N. Detecting and Measuring Ionizing Radiation—A Short History. IAEA Bull. 1982, 23, 31–36. [Google Scholar]

- Welsh, J.S. Beta radiation. Oncol. 2006, 11, 181–183. [Google Scholar] [CrossRef] [PubMed]

- Barabanova, A.V. Significance of beta-radiation skin burns in Chernobyl patients for the theory and practice of radiopathology. Vojn. Pregl. 2006, 63, 477–480. [Google Scholar] [CrossRef]

- Kent, E.M.; Moses, C.; Ford, W.B.; Kutz, E.R.; George, R.S. Radioactive isotopes in management of carcinomatosis of serous body cavities. Arch. Intern. Med. 1954, 94, 334–340. [Google Scholar] [CrossRef]

- Stalter, R.; Dianella, H. Gamma Radiation; IntechOpen: Vienna, Austria, 2012. [Google Scholar]

- Zamanian, A.; Hardiman, C. Electromagnetic radiation and human health: A review of sources and effects. High Freq. Electron. 2005, 4, 16–26. [Google Scholar]

- Leroy, C. Review of radiation detectors. In Proceedings of the AIP Conference, Greensboro, NC, USA, 1–2 August 2007; American Institute of Physics: College Park, MD, USA, 2007; Volume 958, pp. 92–100. [Google Scholar]

- Zaidi, M.K.; Naeem, S. Gas-Filled and Plastic Scintillation Detectors: Advantages and Disadvantages. In New Techniques for the Detection of Nuclear and Radioactive Agents; Springer: Dordrecht, Switzerland, 2009; pp. 181–192. [Google Scholar]

- Nielsen, C.J. Radiation Safety Certification: A Review. J. Nucl. Med. Technol. 2018, 46, 321–325. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Chen, J.; Bakr, O.M.; Mohammed, O.F. Metal Halide Perovskites for X-ray Imaging Scintillators and Detectors. ACS Energy Lett. 2021, 6, 739–768. [Google Scholar] [CrossRef]

- Tarancón, A.; Bagán, H.; García, J.F. Plastic scintillators and related analytical procedures for radionuclide analysis. J. Radioanal. Nucl. Chem. 2017, 314, 555–572. [Google Scholar] [CrossRef]

- Fabjan, C.W. Particle Physics Reference Library: Volume 2: Detectors for Particles and Radiation; Springer Nature: London, UK, 2020; Volume 2. [Google Scholar]

- Karmakar, A.; Wang, J.; Prinzie, J.; De Smedt, V.; Leroux, P. A Review of Semiconductor Based Ionising Radiation Sensors Used in Harsh Radiation Environments and Their Applications. Radiation 2021, 1, 194–217. [Google Scholar] [CrossRef]

- Mirzaei, A.; Huh, J.-S.; Kim, S.S.; Kim, H.W. Room Temperature Hard Radiation Detectors Based on Solid State Compound Semiconductors: An Overview. Electron. Mater. Lett. 2018, 14, 261–287. [Google Scholar] [CrossRef]

- Johns, P.M.; Nino, J.C. Room temperature semiconductor detectors for nuclear security. J. Appl. Phys. 2019, 126, 040902. [Google Scholar] [CrossRef] [Green Version]

- Sharaf, A.H.; Gamal, A.; Serry, M. High performance NEMS ultrahigh sensitive radiation sensor based on platinum nanorods capacitor. In Proceedings of the 2013 IEEE SENSORS, Baltimore, MD, USA, 3–6 November 2013; IEEE: New York, NY, USA, 2013; pp. 1–4. [Google Scholar]

- Nag, A.; Mitra, A.; Mukhopadhyay, S. Graphene and its sensor-based applications: A review. Sens. Actuators A Phys. 2018, 270, 177–194. [Google Scholar] [CrossRef]

- Serry, M.; Sharaf, A.; Emira, A.; Abdul-Wahed, A.; Gamal, A. Nanostructured graphene–Schottky junction low-bias radiation sensors. Sens. Actuators A Phys. 2015, 232, 329–340. [Google Scholar] [CrossRef] [Green Version]

- Alexandrou, K.; Masurkar, A.; Edrees, H.; Wishart, J.F.; Hao, Y.; Petrone, N.; Hone, J.; Kymissis, I. Improving the radiation hardness of graphene field effect transistors. Appl. Phys. Lett. 2016, 109, 153108. [Google Scholar] [CrossRef] [Green Version]

- Jain, S.; Gupta, A.; Shinde, V.; Rao, V.R.; Gajarushi, A. Application of Mono Layered Graphene Field Effect Transistors for Gamma Radiation Detection. In Proceedings of the 2018 IEEE 13th Nanotechnology Materials and Devices Conference (NMDC), Portland, OR, USA, 14–17 October 2018; IEEE: New York, NY, USA, 2018; pp. 1–4. [Google Scholar]

- Patil, A.; Koybasi, O.; Lopez, G.; Foxe, M.; Childres, I.; Roecker, C.; Boguski, J.; Gu, J.; Bolen, M.L.; Capano, M.A.; et al. Graphene field effect transistor as radiation sensor. In Proceedings of the 2011 IEEE Nuclear Science Symposium Conference Record, Valencia, Spain, 23–29 October 2011; IEEE: New York, NY, USA, 2011; pp. 455–459. [Google Scholar]

- Jain, S.; Gajarushi, A.S.; Gupta, A.; Rao, V.R. A Passive Gamma Radiation Dosimeter Using Graphene Field Effect Transistor. IEEE Sen. J. 2020, 20, 2938–2944. [Google Scholar] [CrossRef]

- Everard, J. Fundamentals of RF Circuit Design: With Low Noise Oscillators; John Wiley& Sons, Ltd.: Chichester, UK, 2001. [Google Scholar] [CrossRef]

- Chiu, Y.; Hong, H.-C.; Wu, P.-C. Development and Characterization of a CMOS-MEMS Accelerometer with Differential LC-Tank Oscillators. J. Microelectromechanical Syst. 2013, 22, 1285–1295. [Google Scholar] [CrossRef] [Green Version]

- Weng, C.-H.; Pillai, G.; Li, S.-S. A Thin-Film Piezoelectric-on-Silicon MEMS Oscillator for Mass Sensing Applications. IEEE Sens. J. 2020, 20, 7001–7009. [Google Scholar] [CrossRef]

- Zanjani, S.M.M.; Holt, M.; Sadeghi, M.M.; Rahimi, S.; Akinwande, D. 3D integrated monolayer graphene–Si CMOS RF gas sensor platform. NPJ 2D Mater. Appl. 2017, 1, 1–9. [Google Scholar] [CrossRef]

- Petrashin, P.; Lancioni, W.; Laprovitta, A.; Castagnola, J. Embedded Radiation sensor with OBIST structure for applications in mixed signal systems. JAREE J. Adv. Res. Electr. Eng. 2021, 5. [Google Scholar] [CrossRef]

- Yang, P.; Xia, T.; Li, H.; Wang, X. A Temperature Insensitive Ring Oscillator for Low Power RF Communications. In Proceedings of the 2013 IEEE International Conference on Green Computing and Communications and IEEE Internet of Things and IEEE Cyber, Physical and Social Computing, Beijing, China, 20–23 August 2013; IEEE: New York, NY, USA, 2013; pp. 1804–1809. [Google Scholar]

- Ansón-Casaos, A.; Puértolas, J.; Pascual, F.; Ferrer, J.H.; Castell, P.; Benito, A.; Maser, W.K.; Martínez, M. The effect of gamma-irradiation on few-layered graphene materials. Appl. Surf. Sci. 2014, 301, 264–272. [Google Scholar] [CrossRef] [Green Version]

- Cazalas, E.; Hogsed, M.R.; Vangala, S.; Snure, M.R.; McClory, J.W. Gamma-ray radiation effects in graphene-based transistors with h-BN nanometer film substrates. Appl. Phys. Lett. 2019, 115, 223504. [Google Scholar] [CrossRef]

- Schmitz, M.; Ouaj, T.; Winter, Z.; Rubi, K.; Watanabe, K.; Taniguchi, T.; Zeitler, U.; Beschoten, B.; Stampfer, C. Fractional quantum Hall effect in CVD-grown graphene. 2D Mater. 2020, 7, 041007. [Google Scholar] [CrossRef]

- Fang, Z.; Lin, Z.; Zhang, P. Preparation and characterization of low temperature curing conductive silver paste for screen printing. AIP Conf. Proc. 2018, 1995, 020020. [Google Scholar] [CrossRef]

- Frank, O.; Vejpravova, J.; Holy, V.; Kavan, L.; Kalbac, M. Interaction between graphene and copper substrate: The role of lattice orientation. Carbon 2014, 68, 440–451. [Google Scholar] [CrossRef] [Green Version]

- Cançado, L.G.; Jorio, A.; Ferreira, E.; Stavale, F.; Achete, C.A.; Capaz, R.B.; Moutinho, M.; Lombardo, A.; Kulmala, T.S.; Ferrari, A.C. Quantifying Defects in Graphene via Raman Spectroscopy at Different Excitation Energies. Nano Lett. 2011, 11, 3190–3196. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shlimak, I.; Butenko, A.; Kogan, E.; Kaveh, M. Irradiation-induced broadening of the Raman spectra in monolayer graphene. J. Appl. Phys. 2019, 126, 194302. [Google Scholar] [CrossRef]

| Type | Irradiation Dose [kGy] | D-Band Shift | G-Band Shift | 2D-Band Shift | ||

|---|---|---|---|---|---|---|

| Gamma Irradiation | 0 | 0.088 | - | - | - | 0.198 |

| 0.05 | 0.118 | −34.5 | +3.99 | +10.74 | 0.265 | |

| 0.3 | 0.162 | −0.5 | +6.30 | +5.39 | 0.364 | |

| 0.8 | 0.293 | +77 | +3.97 | +9.73 | 0.658 | |

| 1 | 0.792 | +40 | −132.8 | +252.71 | 1.780 | |

| Beta Irradiation | 3 | 0.304 | +31.5 | −0.57 | +4.39 | 0.683 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tawfik, M.W.; Sharaf, A.; Serry, M. Monolayer Graphene Radiation Sensor with Backend RF Ring Oscillator Transducer. Nanomaterials 2022, 12, 305. https://doi.org/10.3390/nano12030305

Tawfik MW, Sharaf A, Serry M. Monolayer Graphene Radiation Sensor with Backend RF Ring Oscillator Transducer. Nanomaterials. 2022; 12(3):305. https://doi.org/10.3390/nano12030305

Chicago/Turabian StyleTawfik, Mohamed W., Abdelhameed Sharaf, and Mohamed Serry. 2022. "Monolayer Graphene Radiation Sensor with Backend RF Ring Oscillator Transducer" Nanomaterials 12, no. 3: 305. https://doi.org/10.3390/nano12030305