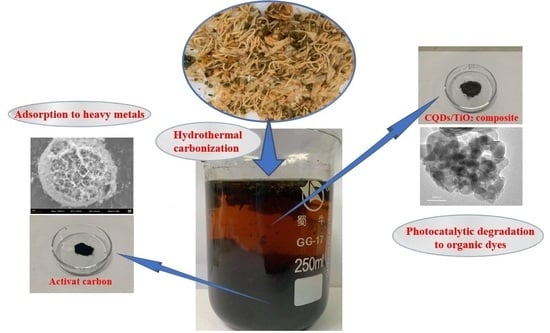

3.1. Structural Characterization of AC Based on WRN

As shown in

Table 1, the HTC powder was a partially carbonized intermediate product with about 51 wt% carbon content. Due to the high starch content of WRN, the majority of the particles of HTC showed a spherical morphology with a smooth surface (

Figure S2 in Supplementary Materials). Thus, the HTC displayed a very low surface area and could not be used for heavy metal adsorption directly. However, the HTC could generate thermal decomposition over 400 °C (

Figure S3 in Supplementary Materials). Thus, by activation at 800 °C with KOH, AC for heavy metal adsorption could be obtained. Compared with HTC, the resulting AC based on WRN showed a higher graphitization degree, in which the broad peaks at about 25 and 43° represented the (002) and (100) crystal planes of graphite, respectively. The AC based on WRN showed the morphology of porous sphere with a dimension of 10–20 μm (see

Figure 2b), which displayed a high BET-specific surface area of 1250.4 m

2·g

−1 and an average pore size of 2.48 nm, as well as a high adsorption value to methylene blue of 321 mg·g

−1 and an iodine value of 961 mg·g

−1. In addition, the AC net exhibited a type II isotherm in nitrogen adsorption and an H

2/H

4 hysteresis loop, which was a complex product composed of microporous and mesoporous structures (

Table 1,

Figure 2c,d). The IR spectrum revealed that there was a hydroxyl group in the surface of the resultant AC, in which the vibrations of σ

O-H and σ

C-O were located at 3441 cm

−1 and 1039 cm

−1, respectively, while the stretch of C=C in aromatic rings was located at 1636 cm

−1 (

Figure 2e). The XPS spectra showed the existence of C and O elements in the resulting AC (see

Figure 2f). In the high-resolution spectrum of C 1 s, the characteristic peak at 284.28 eV, 286.01 eV, and 288.37 eV could be attributed to C–C bond, C–O bond, and C=C bond, respectively (see

Figure 2g). The high-resolution spectrum of O 1 s showed the existence of C–O and O–H bonds, whose characteristic signals were located at 531.49 eV and 532.76 eV, respectively (see

Figure 2h and

Table 2).

3.2. Adsorption Performance to Heavy Metals of AC Based on WRN

Figure 3a,d shows the experimental adsorption isotherms according to the equilibrium Pb(Ⅱ) and Cr(VI) concentrations at room temperature, respectively. To gain some insight into the adsorption, the batch adsorption process was fitted using the two classical empirical models of Langmuir and Freundlich. Regression analysis of the linearized isotherms of Langmuir (

Ce/

qe versus

Ce) and Freundlich (log

qe versus log

Ce), using the slope and the intercept, gave the sorption constants(

qm,

b and

Kf, 1/

n) and correlation coefficients (R

2). The linear forms of the Langmuir and Freundlich equations are shown in

Figure 3b,c,e,f. The

qm,

b,

Kf, 1/

n values and the linear regression correlations for Langmuir and Freundlich modes are listed in

Table 3. It could be observed that the AC based on WRN displayed good adsorption performance on heavy metal ions. The adsorption of Pb(Ⅱ) and Cr(VI) on the AC could follow both Freundlich and Langmuir type adsorption isotherms. However, based on the regression coefficients, the Langmuir isotherm fitted the experimental data slightly better than the Freundlich model, which indicates that there was a homogenous distribution of active sites on the surface of AC. Based on Langmuir isotherm, the AC based on WRN showed the highest metal uptake of 0.0583 mmol·g

−1 (or 12.08 mg·g

−1) for Pb(Ⅱ) and 0.180 mmol·g

−1 (or 9.36 mg·g

−1) for Cr(VI) (come from q

m data in

Table 3). Compared with other AC adsorbents for the elimination of heavy metal ions (

Table 4), the AC based on WRN show similar Cr(VI) adsorption capacity to some low-cost AC adsorbents produced from coconut shell [

21] or peanut shell [

23], as well as similar Pb(Ⅱ) adsorption capacity to the hazelnut-husk-based AC [

25]. Combined with the low cost of WRN, the AC based on WRN had potential application in the treatment of heavy metal water pollution.

The AC showed a decreased BET surface areas after Cr(VI) and Pb(II) adsorption but maintained a similar type of isotherm and pore size distribution (see

Table 1 and

Figure S4 in Supplementary Materials). The slight reduction of carbon content from the ultimate analysis could be attributed to the incidental adsorption of heavy metal elements and other counter ions. As shown in

Figure 4a,b, after the adsorption of heavy metals, the AC based on WRN could maintain its porous spherical structure, and heavy metal elements generated a homogenous distribution. The PXRD patterns of AC before and after Cr(VI) and Pb(II) adsorption revealed that the angle of graphite diffraction peaks of AC moved to lower angles after heavy metal adsorption (

Figure 4c). Moreover, from the IR spectra of AC before and after heavy metal adsorption, the C–O vibration peak located at 1039 cm

−1 red shift and the vibration peak of Pb–O and Cr–O were observed at 660 and 629 cm

−1, respectively, which indicated that chemical action of AC and heavy metal ions occurred in the adsorption process (

Figure 4d).

The AC based on WRN also shows good adsorption speed to heavy metal ions. As shown in

Figure 5a,d, the AC could approach the adsorption equilibrium of both Pb(II) and Cr(VI) after 90 min adsorption in 25 mg·L

−1 heavy metal solution. Furthermore, the pseudo-first-order and the pseudo-second-order kinetics models were employed to test of the experimental data of adsorption speed. The

qe1,

qe2,

K1,

K2 values were determined experimentally from the slope and intercept of straight-line adsorption kinetic plot. The linear forms of the pseudo-first-order and pseudo-second-order kinetic fitting are shown in

Figure 5b,c,e,f. The values and regression coefficient are presented in

Table 5. It could be observed that the adsorption process of Pb(II) and Cr(VI) by AC both accorded with the pseudo-second-order kinetic model better, which suggested that the heavy metal adsorption process of the AC was controlled by the chemisorption mechanism.

3.3. Structural Characterization of CQDs and CQDs/TiO2 Composite Based on WRN

As shown in

Figure 6a–c, CQDs synthesized by WRN showed an oval or spherical morphology, whose (020) crystal plane with a lattice spacing of about 0.283 nm could be observed. Its particle size was mainly distributed between 1.5–2.5 nm, which was well dispersed and barely reunited. The IR spectrum indicated that there were carboxyl groups in the CQDs with an absorption peak at 1709 cm

−1, which might play an important role in the combination of TiO

2. The hydroxyl and alkyl groups also existed in the resulting CQDs. The vibration of the hydroxyl group was located at about 3424 cm

−1. The stretch of C=C in aromatic rings was located at 1629 cm

−1. The absorption peaks of 2926, 1384, and 669 cm

−1 could be assigned to the stretching and bending vibration of alkyl groups (see

Figure 6d).

As shown in

Figure 7a, the CQDs/TiO

2 composite presented a nearly square or egg-shaped nanostructure with a diameter range of 10–70 nm, and spherical particles of CQDs were evenly dispersed on the surface of TiO

2. HRTEM image showed both the lattice interleaving of nano TiO

2 and CQDs, in which the lattice stripes with a spacing of 0.149 nm and 0.114 nm belonged to (213) and (004) crystal planes of anatase TiO

2, respectively, while the crystal plane spacing of 0.169 nm was highly matched with the (220) plane of rutile TiO

2. In addition, a crystal plane with a lattice spacing of about 0.283 nm could be observed, which corresponded to the (020) crystal plane of CQDs (see

Figure 7b). Thus, it was clear that the CQDs and nano TiO

2 were successfully combined in the resulting composite. The formation of CQDs/TiO

2 composite was further proved by IR characterization (see

Figure 7c). Among them, the stretching vibration of the carboxyl group in original CQDs vanished after combination with TiO

2, and the wide absorption band of pure TiO

2 below 1000 cm

−1 had an obvious red shift and narrowing after combination, which might be due to the reaction between carboxyl group in CQDs and hydroxyl group on the surface of TiO

2. The XPS spectra showed the existence of C, O, and Ti elements in the resulting CQDs/TiO

2 composite (see

Figure 7d and

Table 6). In the high-resolution spectrum of C 1 s, the characteristic peak at 284.71 eV could be attributed to C–C bond in CQDs, while the characteristic signals centered at 285.83 and 289.20 eV were related to the C–O bond and C=C bond, respectively (See

Figure 7e). The high-resolution spectrum of O 1 s showed the existence of Ti–O, C–O, and O–H bonds, whose characteristic signals were located at 529.79, 531.30, and 532.64 eV, respectively. The characteristic peaks in Ti 2p spectrum at 458.50 and 464.20 eV belonged to the signals of Ti (2p

3/2) and Ti (2p

1/2). In addition, due to organic groups in CQDs, the point of zero charge (PZC) value of CQDs/TiO

2 composite (6.77) is higher than that of pure TiO

2 (6.03, see

Figure 7h)

3.4. Photocatalytic Performance of CQDs/TiO2 Composite

The resulting CQDs/TiO

2 composite displayed a high efficient photocatalytic degradation effect to various water-soluble dyes. The methylene blue [

49,

50] was one of the most common pollutants in dyeing waste water with considerable toxicity. As shown in

Figure 8a, this methylene blue was difficult to degrade under 405 nm visible purple light. After 80 min of illumination, the degradation rate was only 3.32%. The pure nano TiO

2 had a catalytic effect on methylene blue but a complete degradation could not be achieved, with a degradation rate of 3.18% within 10 min and 59.85% within 80 min. By contrast, the CQDs/TiO

2 composite based on WRN had much better photocatalytic performance, whose degradation rate could be as high as 81.84% within 10 min and 99.87% within 80 min. Moreover, the CQDs/TiO

2 composite could be recycled and reused without any appreciable decrease in degradation rate, which could maintain a degradation rate of more than 96.5% after seven photocatalytic cycles (See

Figure 8b). In addition, the degradation rate of CQDs/TiO

2 composite could be affected by the loading dosage of CQD

S. For example, the degradation rate of the CQD

S/TiO

2 sample with a carbon content of 4.96 wt% (CQD

S/TiO

2–4) showed a degradation rate of 93.3% within 80 min, which was slightly lower than other CQDs/TiO

2 composite with higher carbon content (see

Figure S7 in Supplementary Materials).

Under natural light (simulated by a xenon lamp), CQDs/TiO

2 based on WRN also showed better photocatalytic performance than that of pure TiO

2. The degradation rate of pure TiO

2 within 10 and 80 min was 46.71 and 49.12%, respectively, which could not achieve complete degradation. By contrast, the degradation rate of CQDs/TiO

2 could be up to 95.95% within 10 min and 99.54% within 80 min, which was even better than that under 405 nm purple light (see

Figure 8c).

As shown in

Figure 9, the resulting CQDs/TiO

2 composite displayed a high efficient photocatalytic degradation effect on other common water-soluble dyes such as malachite green, methyl violet, basic fuchsin, and rhodamine B under visible light irradiation and showed better photocatalytic performance than that of commercial TiO

2. Among them, the degradation rate of CQDs/TiO

2 composite of malachite green and methyl violet could reach up to 99% within 10 min, which indicated that this composite displayed a very high photocatalytic degradation effect on triphenylmethane dye (See

Figure 9a,b). It was also observed that the CQDs/TiO

2 composite could be used against some dyes with good photobleaching resistance. For example, rhodamine B was almost undegradable under 405 nm purple light with the existence of pure TiO

2, but the CQDs/TiO

2 composite could degrade 99% rhodamine B within 30 min (see

Figure 9d). Furthermore, due to the very low cost of CQDs based on WRN, the CQDs/TiO

2 composite based on WRN could also achieve a lower cost than that of commercial TiO

2, which could be a good substitute for commercial TiO

2 and had good application in organic water pollution control. In addition, the photocatalytic degradation processes of the dyes by CQDs/TiO

2 composite all accorded with the Langmuir Hinshelwood kinetic model, whose apparent constant (K

app) values and regression coefficients are presented in

Table 7. The K

app values displayed a range of methyl violet > malachite green > rhodamine B > methylene blue > basic fuchsin.

In order to further export the photocatalytic mechanism of the as-prepared CQDs/TiO

2 composite based on WRN, the UV-VIS absorption spectra of the pure TiO

2 and CQDs/TiO

2 composite were tested and shown in

Figure 10a. The absorption of the pure TiO

2 was mainly in the UV region, and there was almost no absorption in the wavelength range above 430 nm. In contrast, the CQDs/TiO

2 composite exhibited a wide visible-light absorption region and enhanced light-absorption intensity. Thus, the combination of CQDs and TiO

2 could effectively enhance the energy absorption and produce more electron-hole pairs in the visible light region. Furthermore, the band gaps of the pure TiO

2 and CQDs/TiO

2 samples were calculated by means of Kubelka–Munk theory [

51] and shown in

Figure 10b. The band gap of the pure TiO

2 photocatalyst was about 3.07 eV. By comparison, the introduction of CQDs could afford a narrower band gap of 1.55 eV, which could promote the electronic transition and improve the photocatalytic degradation process. This feature of the CQDs/TiO

2 composite was also proven by photocurrent response with on/off cycles of visible light irradiation (

Figure 10c). It could be observed that the CQDs/TiO

2 electrode displayed a much higher photocurrent (more than 60 times) in comparison to the pure TiO

2 electrode upon irradiation. This means that a faster interfacial charge transfer to the electron acceptor occured in the CQDs/TiO

2 composite, which resulted in the more effective separation of electron-hole pairs. On the other hand, the steady-state PL spectra of the pure TiO

2 and CQDs/TiO

2 composite (

Figure 10d) showed that the emission intensity of the CQDs/TiO

2 composite was much lower than that of pure TiO

2 at similar emission, which suggested that the modification of CQDs could effective reduce the recombination of electron-hole pairs.

The ESR spin-trap with the DMPO technique was used to investigate the reactive oxygen species generated by the CQDs/TiO

2 composite or pure TiO

2 photocatalysts. As shown in

Figure 11a,b, obvious characteristic peaks of both superoxide radical (O

2·−) and hydroxyl radical (·OH) of DMPO was observed by using the CQDs/TiO

2 composite as a photocatalyst, which suggested that the CQDs/TiO

2 composite could reduce adsorbed O

2 to form O

2·− radical and oxidize adsorbed H

2O or OH

− to form ·OH radical under light radiation. Moreover, compared with using pure TiO

2 as a photocatalyst, signals of both O

2·− and ·OH radical of DMPO with CQDs/TiO

2 composite were evidently stronger (

Figure 11c,d). Thus the CQDs/TiO

2 composite displayed stronger abilities in producing O

2·− and ·OH radical than that of pure TiO

2 on the same test condition, which demonstrates that the introduction of CQDs could result in efficient electron-hole pair separation and enable more photogenerated electrons to reduce O

2 and more photogenerated holes to oxidize H

2O or OH

−. Based on the results of photodegradation and reactive oxygen species during the degradation process, possible photocatalytic mechanism schematics was illustrated in

Figure 11e. When the CQDs/TiO

2 composite was irradiated by visible light, the CQDs can be easily excited with photogenerated electrons on the conduction band (CB) and leave the holes on the valence band (VB). The photogenerated hole could react with H

2O or OH

− to produce more ·OH. The excited electrons could spatial transfer to the TiO

2 quickly and result in a more efficient electron-hole pair separation. After that, the separated electrons on the CQDs could react with O

2 to produce more O

2·−. The generated O

2·− and ·OH radical play the main role in the photodegradation process, causing excellent photocatalytic activity.