Detecting Carbon Nanotube Orientation with Topological Analysis of Scanning Electron Micrographs

Abstract

:1. Introduction

2. Materials and Methods

3. Persistent Homology

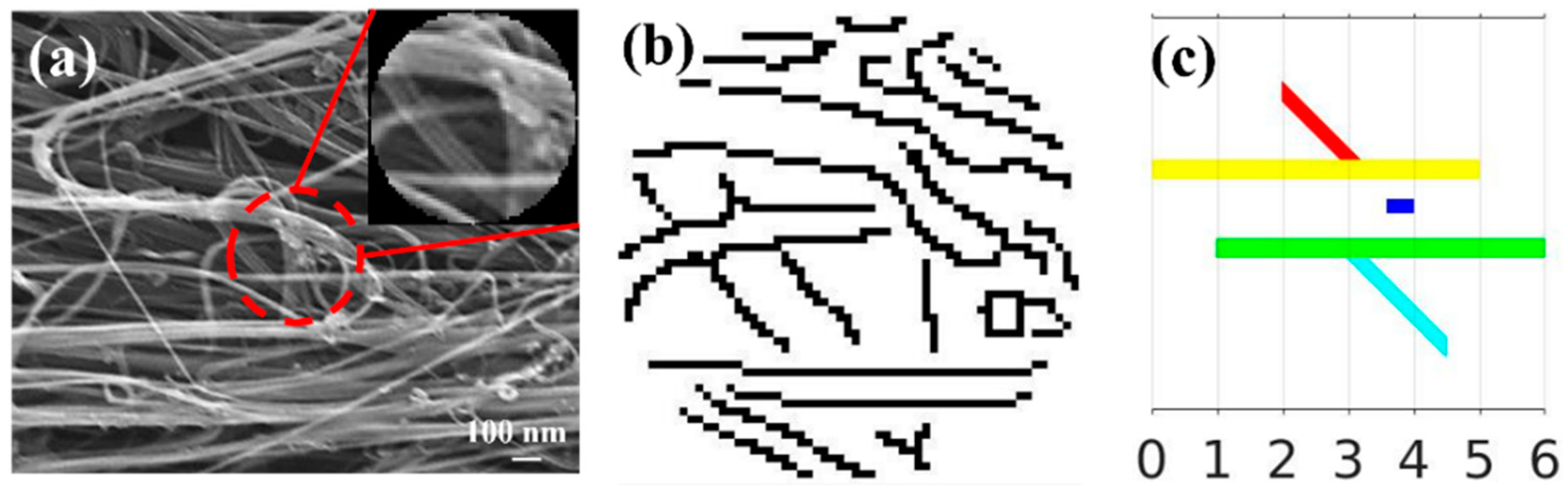

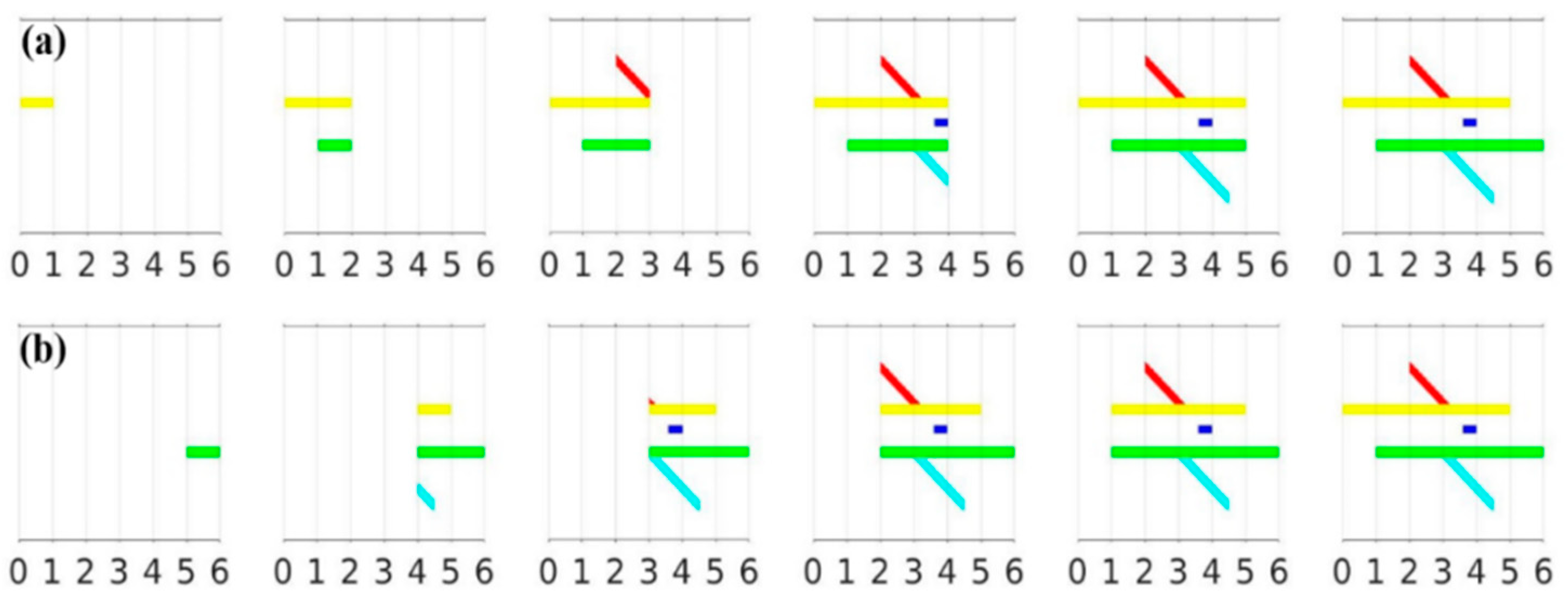

3.1. Persistent Homology Barcodes

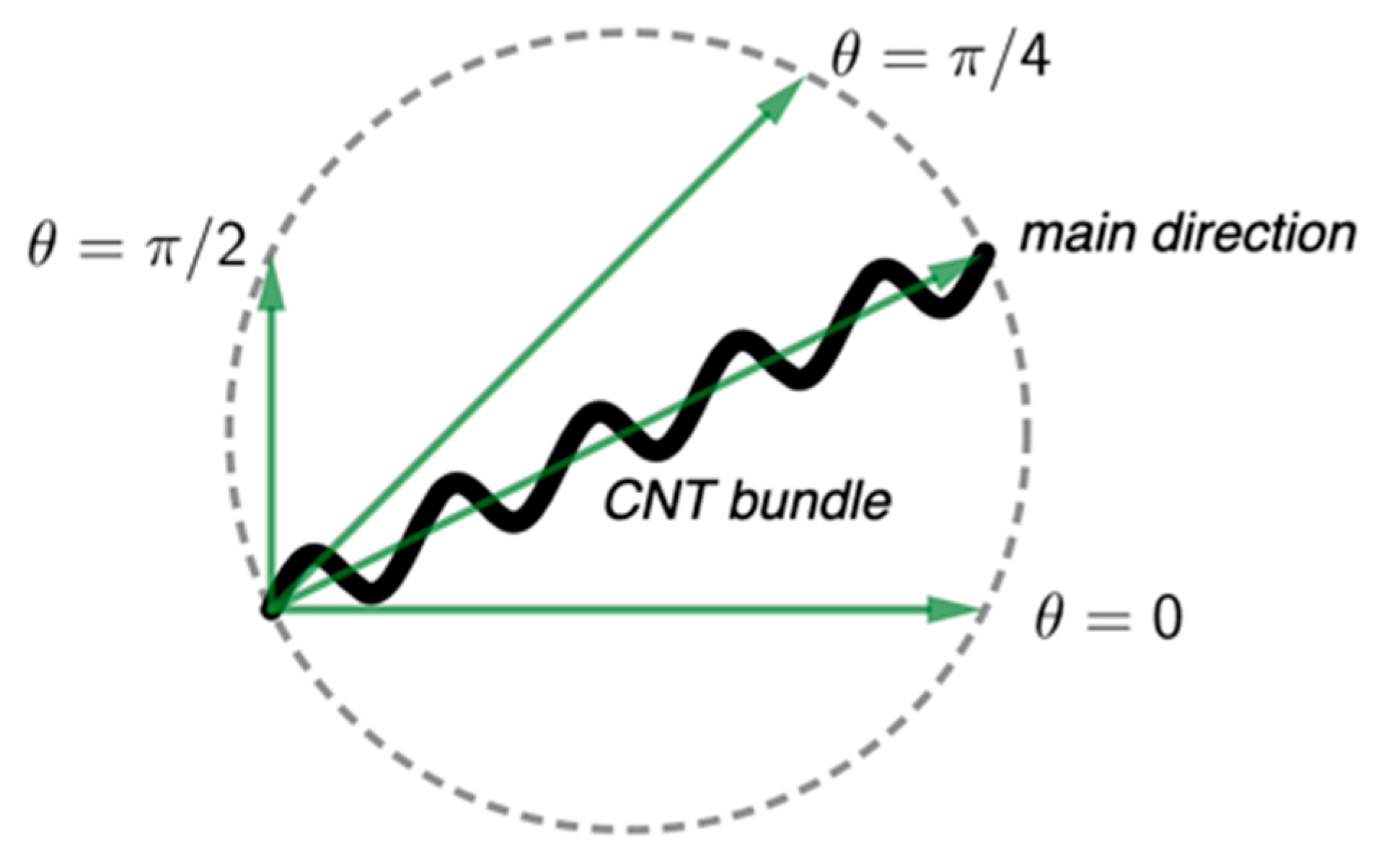

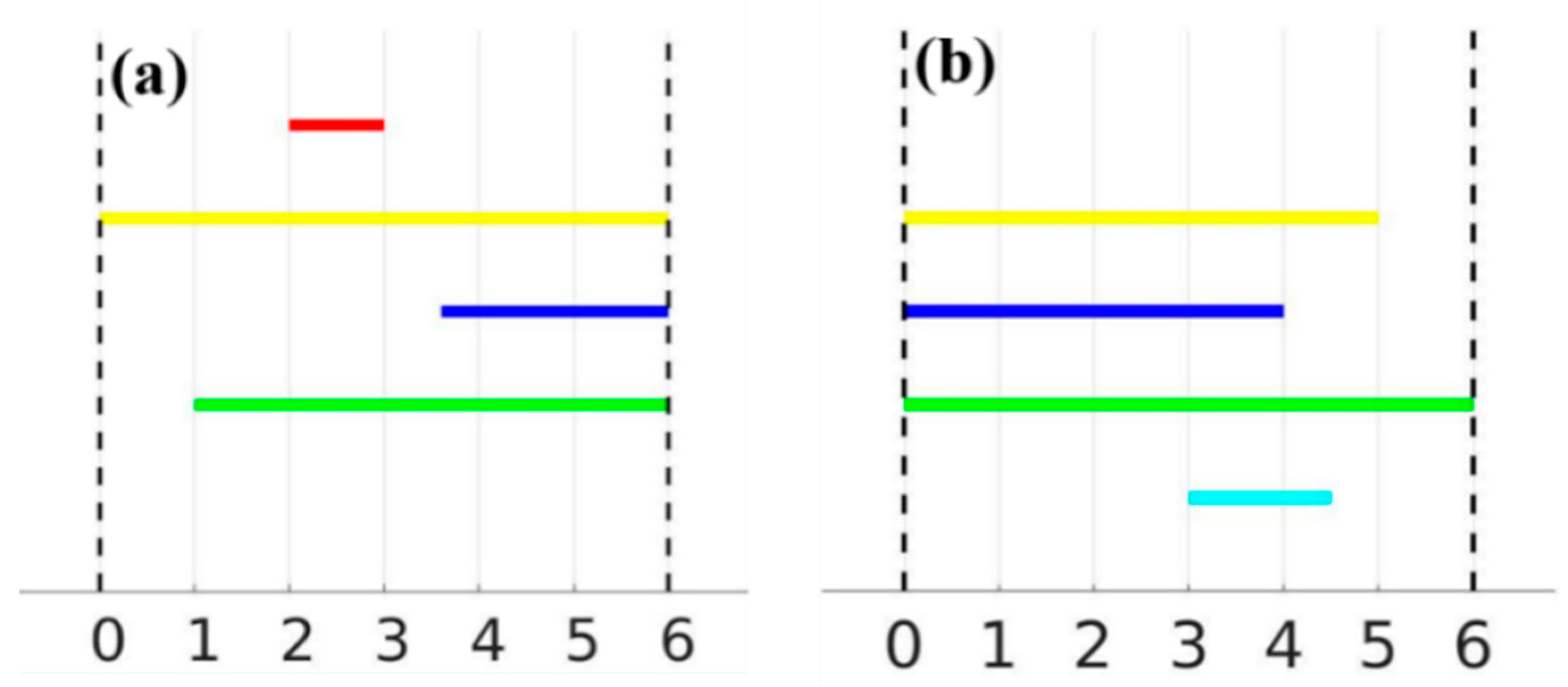

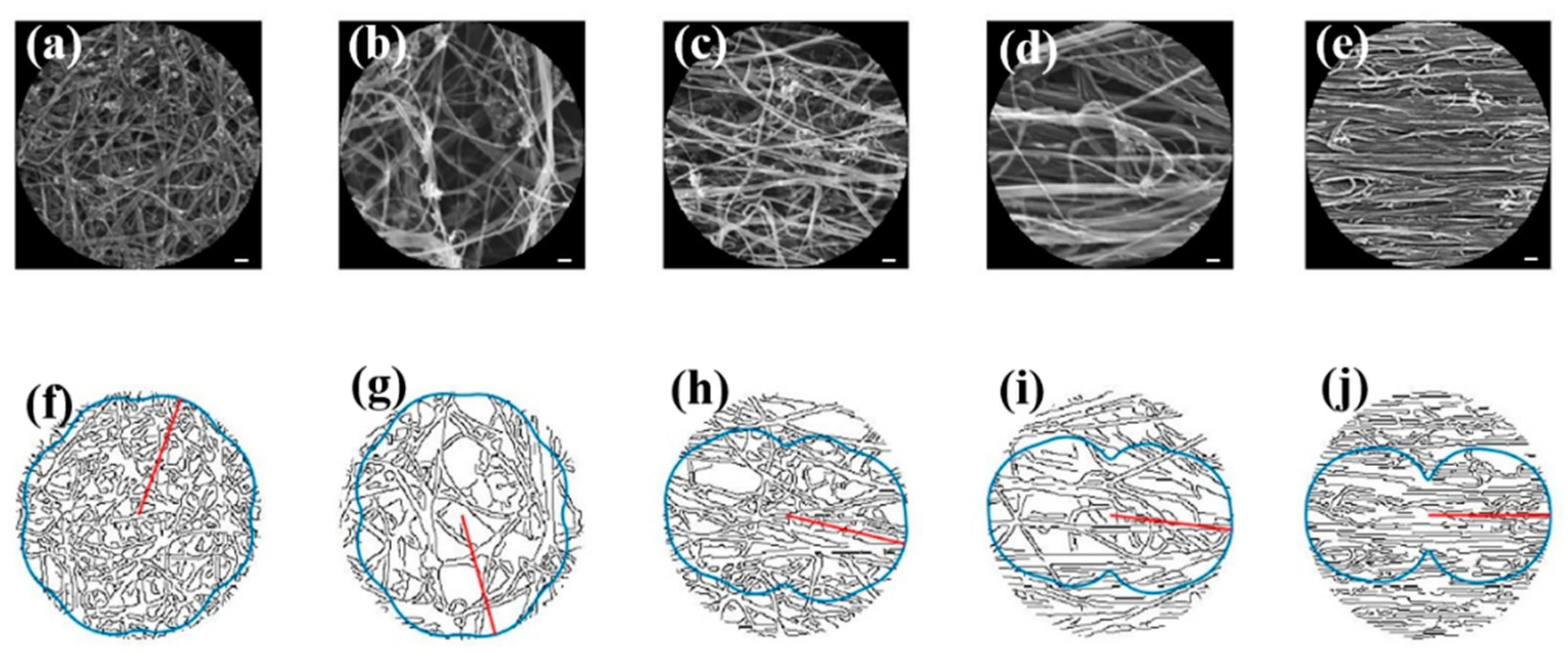

3.2. Orientation and Alignment

4. Discussion

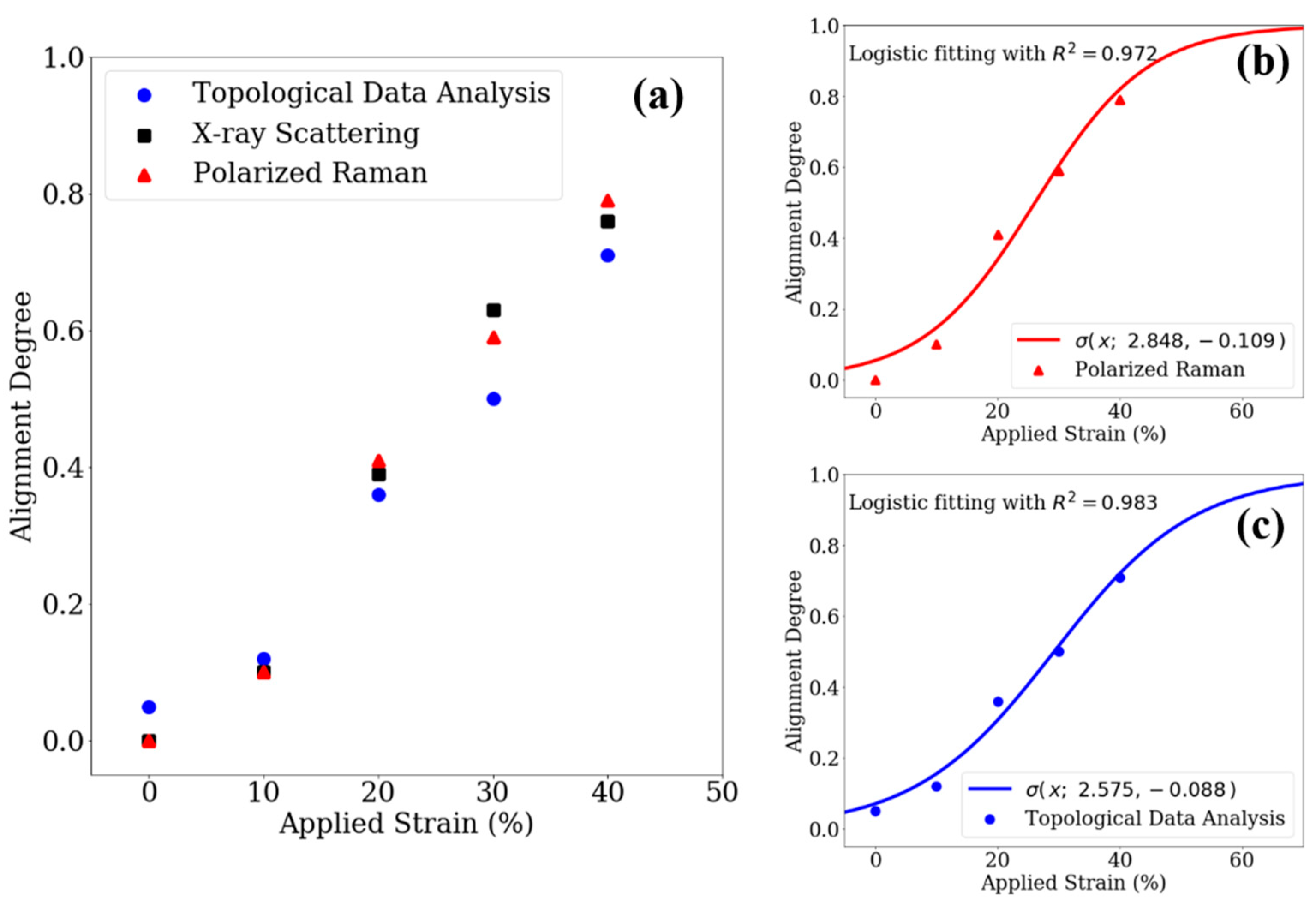

4.1. The CNT Alignment Validation

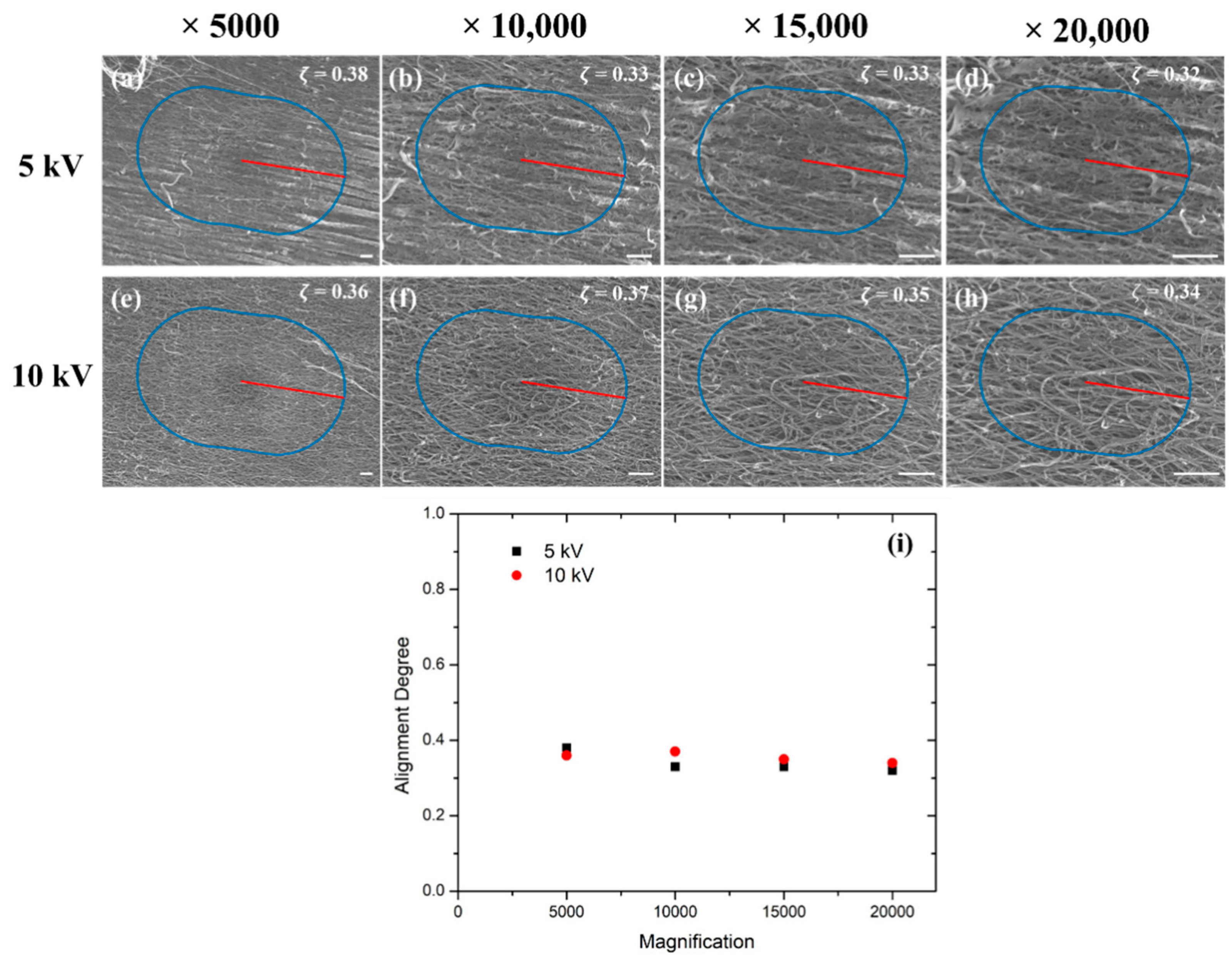

4.2. Effects of Accelerating Voltages and Magnifications

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Motta, M.; Li, Y.-L.; Kinloch, I.; Windle, A. Mechanical Properties of Continuously Spun Fibers of Carbon Nanotubes. Nano Lett. 2005, 5, 1529–1533. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.W.; Li, Y.; Zhang, X.F.; Chikkannanavar, S.B.; Zhao, Y.H.; Dangelewicz, A.M.; Zheng, L.; Doorn, S.K.; Jia, Q.; Peterson, D.E.; et al. Structure-Dependent Electrical Properties of Carbon Nanotube Fibers. Adv. Mater. 2007, 19, 3358–3363. [Google Scholar] [CrossRef]

- Dong, L.; Park, J.G.; Leonhardt, B.E.; Zhang, S.; Liang, R. Continuous Synthesis of Double-Walled Carbon Nanotubes with Water-Assisted Floating Catalyst Chemical Vapor Deposition. Nanomaterials 2020, 10, 365. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Han, Y.; Zhang, X.; Yu, X.; Zhao, J.; Li, S.; Liu, F.; Gao, P.; Zhang, Y.; Zhao, T.; Li, Q. Bio-Inspired Aggregation Control of Carbon Nanotubes for Ultra-Strong Composites. Sci. Rep. 2015, 5, 11533. [Google Scholar] [CrossRef] [Green Version]

- Gorrasi, G.; Bugatti, V.; Milone, C.; Mastronardo, E.; Piperopoulos, E.; Iemmo, L.; Di Bartolomeo, A. Effect of temperature and morphology on the electrical properties of PET/conductive nanofillers composites. Compos. Part B Eng. 2018, 135, 149–154. [Google Scholar] [CrossRef]

- Iakoubovskii, K. Techniques of aligning carbon nanotubes. Cent. Eur. J. Phys. 2009, 7, 645–653. [Google Scholar] [CrossRef] [Green Version]

- Fischer, J.E.; Zhou, W.; Vavro, J.; Llaguno, M.C.; Guthy, C.; Haggenmueller, R.; Casavant, M.J.; Walters, D.E.; Smalley, R.E. Magnetically aligned single wall carbon nanotube films: Preferred orientation and anisotropic transport properties. J. Appl. Phys. 2003, 93, 2157–2163. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.; Song, P.; Liu, C.; Wu, W.; Fan, S. Highly oriented carbon nanotube papers made of aligned carbon nanotubes. Nanotechnology 2008, 19, 075609. [Google Scholar] [CrossRef]

- Tran, T.; Fan, Z.; Liu, P.; Myint, S.M.; Duong, H. Super-strong and highly conductive carbon nanotube ribbons from post-treatment methods. Carbon 2016, 99, 407–415. [Google Scholar] [CrossRef]

- Sedelnikova, O.; Kanygin, M.; Korovin, E.; Bulusheva, L.; Suslyaev, V.; Okotrub, A. Effect of fabrication method on the structure and electromagnetic response of carbon nanotube/polystyrene composites in low-frequency and Ka bands. Compos. Sci. Technol. 2014, 102, 59–64. [Google Scholar] [CrossRef]

- Cheng, Q.; Bao, J.; Park, J.G.; Liang, Z.; Zhang, C.; Wang, B. High Mechanical Performance Composite Conductor: Multi-Walled Carbon Nanotube Sheet/Bismaleimide Nanocomposites. Adv. Funct. Mater. 2009, 19, 3219–3225. [Google Scholar] [CrossRef]

- Cheng, Q.; Wang, B.; Zhang, C.; Liang, Z. Functionalized Carbon-Nanotube Sheet/Bismaleimide Nanocomposites: Mechanical and Electrical Performance Beyond Carbon-Fiber Composites. Small 2010, 6, 763–767. [Google Scholar] [CrossRef] [PubMed]

- Arutyunyan, N.R.; A Kanygin, M.; Pozharov, A.; Kubarev, V.; Bulusheva, L.G.; Okotrub, A.V.; Obraztsova, E. Light polarizer in visible and THz range based on single-wall carbon nanotubes embedded into poly(methyl methacrylate) film. Laser Phys. Lett. 2016, 13, 065901. [Google Scholar] [CrossRef]

- Han, Y.; Li, S.; Chen, F.; Zhao, T. Multi-scale alignment construction for strong and conductive carbon nanotube/carbon composites. Mater. Today Commun. 2016, 6, 56–68. [Google Scholar] [CrossRef]

- Han, B.; Xue, X.; Xu, Y.; Zhao, Z.; Guo, E.; Liu, C.; Luo, L.; Hou, H. Preparation of carbon nanotube film with high alignment and elevated density. Carbon 2017, 122, 496–503. [Google Scholar] [CrossRef]

- Li, S.; Park, J.G.; Liang, Z.; Siegrist, T.; Liu, T.; Zhang, M.; Cheng, Q.; Wang, B.; Zhang, C. In situ characterization of structural changes and the fraction of aligned carbon nanotube networks produced by stretching. Carbon 2012, 50, 3859–3867. [Google Scholar] [CrossRef]

- Wang, B.N.; Bennett, R.D.; Verploegen, E.; Hart, A.J.; Cohen, R.E. Quantitative Characterization of the Morphology of Multiwall Carbon Nanotube Films by Small-Angle X-ray Scattering. J. Phys. Chem. C 2007, 111, 5859–5865. [Google Scholar] [CrossRef]

- Li, W.; Zhang, H.; Wang, C.; Zhang, Y.; Xu, L.; Zhu, K.; Xie, S. Raman characterization of aligned carbon nanotubes produced by thermal decomposition of hydrocarbon vapor. Appl. Phys. Lett. 1997, 70, 2684–2686. [Google Scholar] [CrossRef]

- Brandley, E.; Greenhalgh, E.S.; Shaffer, M.S.; Li, Q. Mapping carbon nanotube orientation by fast fourier transform of scanning electron micrographs. Carbon 2018, 137, 78–87. [Google Scholar] [CrossRef]

- Carlsson, G. Topology and Data. Bull. Am. Math. Soc. 2009, 46, 255–308. [Google Scholar] [CrossRef] [Green Version]

- Wasserman, L. Topological Data Analysis. Annu. Rev. Stat. Its Appl. 2018, 5, 501–532. [Google Scholar] [CrossRef] [Green Version]

- Cohen-Steiner, D.; Edelsbrunner, H.; Harer, J. Stability of Persistence Diagrams. Discret. Comput. Geom. 2006, 7, 103–120. [Google Scholar]

- Nielson, J.; Paquette, J.; Liu, A.W.; Guandique, C.F.; Tovar, C.A.; Inoue, T.; Irvine, K.-A.; Gensel, J.C.; Kloke, J.; Petrossian, T.; et al. Topological data analysis for discovery in preclinical spinal cord injury and traumatic brain injury. Nat. Commun. 2015, 6, 8581. [Google Scholar] [CrossRef]

- Taylor, D.; Klimm, F.; Harrington, H.A.; Kramar, M.; Mischaikow, K.; Porter, M.A.; Mucha, P.J. Topological data analysis of contagion maps for examining spreading processes on networks. Nat. Commun. 2015, 6, 7723. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Saadatfar, M.; Takeuchi, H.; Robins, V.; Francois, N.; Hiraoka, Y. Pore configuration landscape of granular crystallization. Nat. Commun. 2017, 8, 15082. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Frank, M.H.; Coneva, V.; Mio, W.; Chitwood, D.H.; Topp, C.N. The Persistent Homology Mathematical Framework Provides Enhanced Genotype-to-Phenotype Associations for Plant Morphology. Plant Physiol. 2018, 177, 1382–1395. [Google Scholar] [CrossRef] [Green Version]

- Zomorodian, A.; Carlsson, G. Computing Persistent Homology. Discret. Comput. Geom. 2004, 33, 249–274. [Google Scholar] [CrossRef] [Green Version]

- Downes, R.; Wang, S.; Haldane, D.; Moench, A.; Liang, R. Strain-Induced Alignment Mechanisms of Carbon Nanotube Networks. Adv. Eng. Mater. 2014, 17, 349–358. [Google Scholar] [CrossRef]

- Downes, R.D.; Hao, A.; Park, J.G.; Su, Y.-F.; Liang, R.; Jensen, B.D.; Siochi, E.J.; Wise, K.E. Geometrically constrained self-assembly and crystal packing of flattened and aligned carbon nanotubes. Carbon 2015, 93, 953–966. [Google Scholar] [CrossRef]

- Hermans, J.J.; Hermans, P.H.; Vermaas, D.; Weidinger, A. Quantitative evaluation of orientation in cellulose fibres from the X-ray fibre diagram. Recl. Des Trav. Chim. Des Pays-Bas 1946, 65, 427–447. [Google Scholar] [CrossRef]

- Canny, J. A Computational Approach to Edge Detection. IEEE Trans. Pattern Anal. Mach. Intell. 1986, 8, 679–698. [Google Scholar] [CrossRef] [PubMed]

- Carlsson, G.; Zomorodian, A.; Collins, A.; Guibas, L. Persistence Barcodes for Shapes. Int. J. Shape Modeling 2005, 11, 149–188. [Google Scholar] [CrossRef]

- Ghrist, R. Barcodes: The Persistent Topology of Data. Bull. Am. Math. Soc. 2008, 45, 61–75. [Google Scholar] [CrossRef] [Green Version]

- Chazal, F.; Cohen-Steiner, D.; Glisse, M.; Guibas, L.J.; Oudot, S. Proximity of Persistence Modules and Their Diagrams. In Proceedings of the SCG’ 09: Proceedings of the twenty-fifth Annual Symposium on Computational Geometry, Aarhus, Denmark, 8–10 June 2009; pp. 237–246. [Google Scholar]

- Goldstein, J.I.; Newbury, D.E.; Michael, J.R.; Ritchie, N.W.M.; Scott, J.H.J.; Joy, D.C. Scanning Electron Microscopy and X-ray Microanalysis, 4th ed.; Springer: New York, NY, USA, 2018. [Google Scholar]

- Song, J.; Yang, C.; Hu, H.; Dai, X.; Wang, C.; Zhang, H. Penetration depth at various Raman excitation wavelengths and stress model for Raman spectrum in biaxially-strained Si. Sci. China Ser. G Phys. Mech. Astron. 2013, 56, 2065–2070. [Google Scholar] [CrossRef]

- Dresselhaus, M.S.; Dresselhaus, G.; Saito, R.; Jorio, A. Raman spectroscopy of carbon nanotubes. Phys. Rep. 2005, 409, 47–99. [Google Scholar] [CrossRef]

- Dresselhaus, M.S.; Jorio, A.; Filho, A.G.S.; Saito, R. Defect characterization in graphene and carbon nanotubes using Raman spectroscopy. Philos. Trans. R. Soc. London. Ser. A Math. Phys. Eng. Sci. 2010, 368, 5355–5377. [Google Scholar] [CrossRef]

- Li, Z.; Lu, C.; Xia, Z.; Zhou, Y.; Luo, Z. X-ray diffraction patterns of graphite and turbostratic carbon. Carbon 2007, 45, 1686–1695. [Google Scholar] [CrossRef]

- Fujimoto, H. Theoretical X-ray scattering intensity of carbons with turbostratic stacking and AB stacking structures. Carbon 2003, 41, 1585–1592. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, L.; Hang, H.; Park, J.G.; Mio, W.; Liang, R. Detecting Carbon Nanotube Orientation with Topological Analysis of Scanning Electron Micrographs. Nanomaterials 2022, 12, 1251. https://doi.org/10.3390/nano12081251

Dong L, Hang H, Park JG, Mio W, Liang R. Detecting Carbon Nanotube Orientation with Topological Analysis of Scanning Electron Micrographs. Nanomaterials. 2022; 12(8):1251. https://doi.org/10.3390/nano12081251

Chicago/Turabian StyleDong, Liyu, Haibin Hang, Jin Gyu Park, Washington Mio, and Richard Liang. 2022. "Detecting Carbon Nanotube Orientation with Topological Analysis of Scanning Electron Micrographs" Nanomaterials 12, no. 8: 1251. https://doi.org/10.3390/nano12081251