Thermal Conductivity of 3C/4H-SiC Nanowires by Molecular Dynamics Simulation

Abstract

:1. Introduction

2. Computation Details and Methods

2.1. Crystal Structural and Modeling Details

2.2. Molecular Dynamics Simulations

3. Results and Discussion

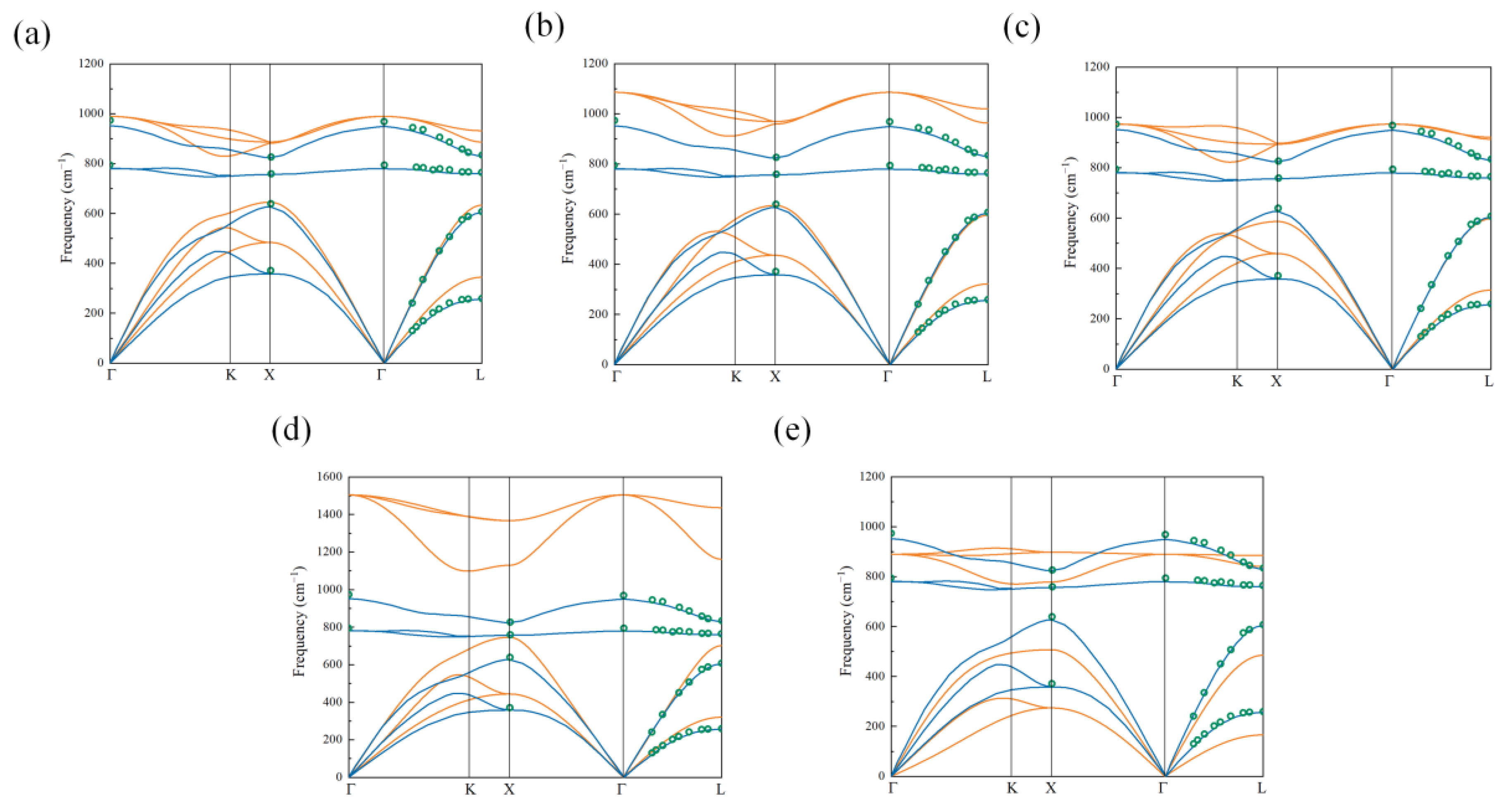

3.1. Empirical Potential Selection

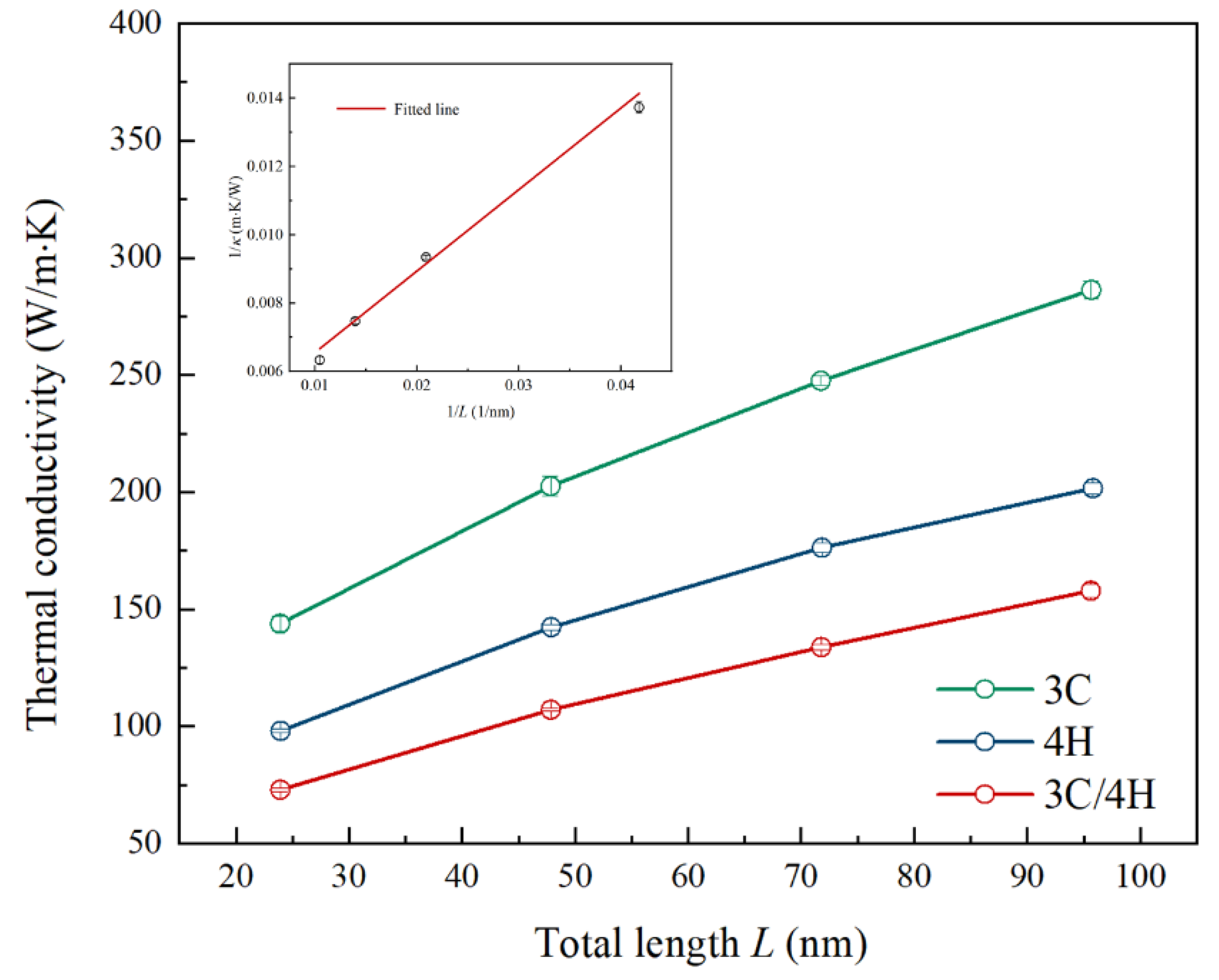

3.2. Effect of the Sample’s Total Length

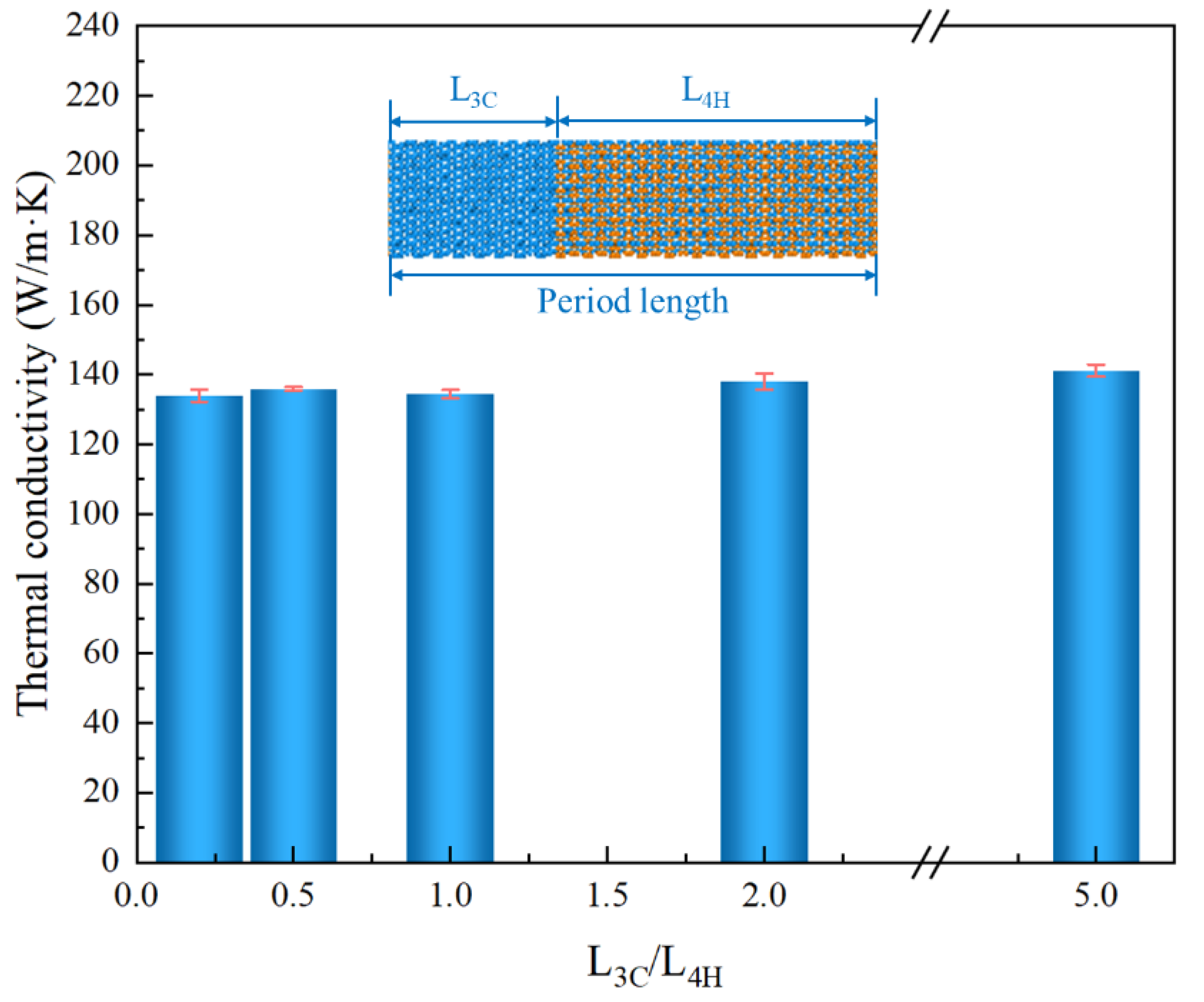

3.3. Effect of Period Length

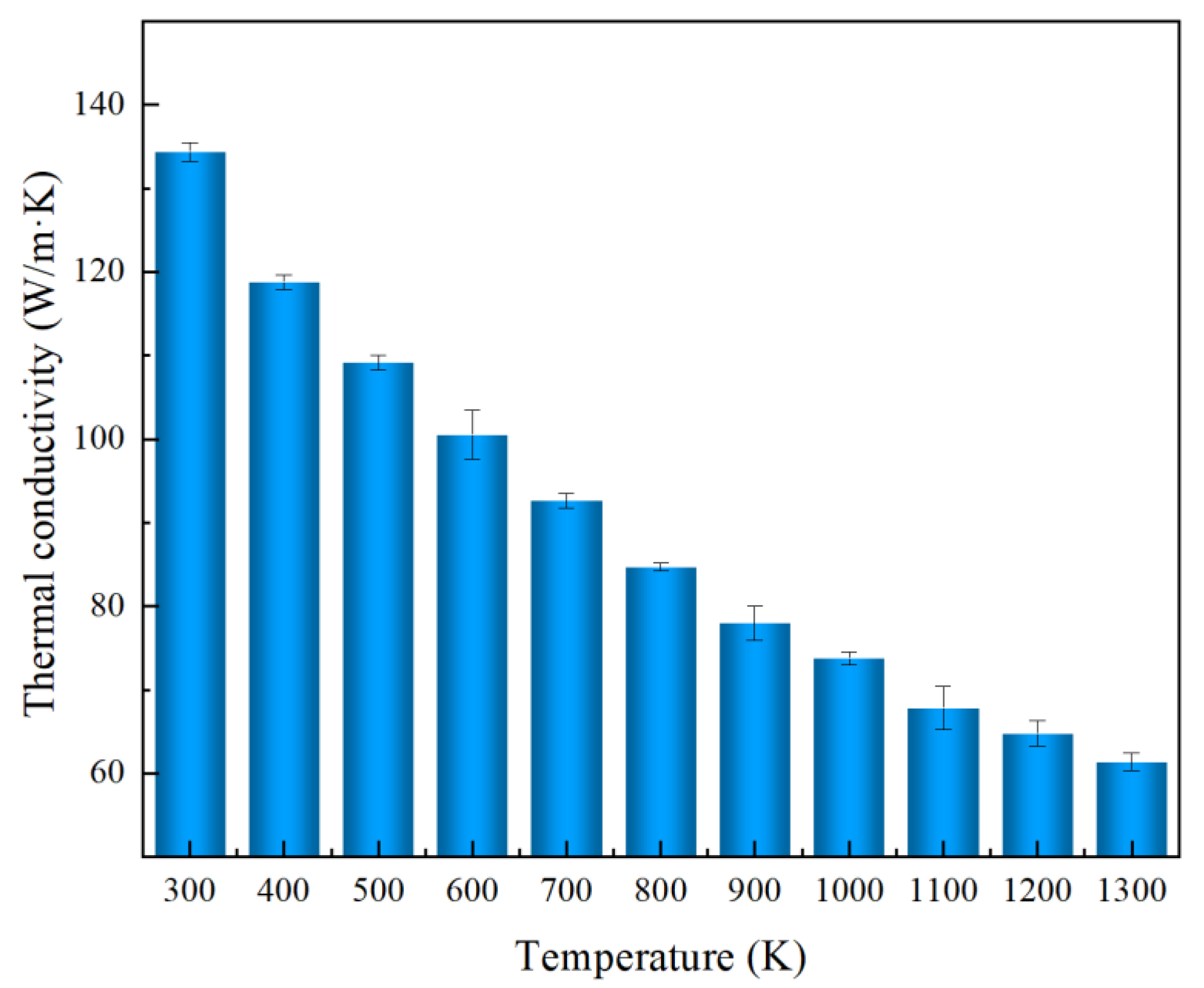

3.4. Effect of Temperature

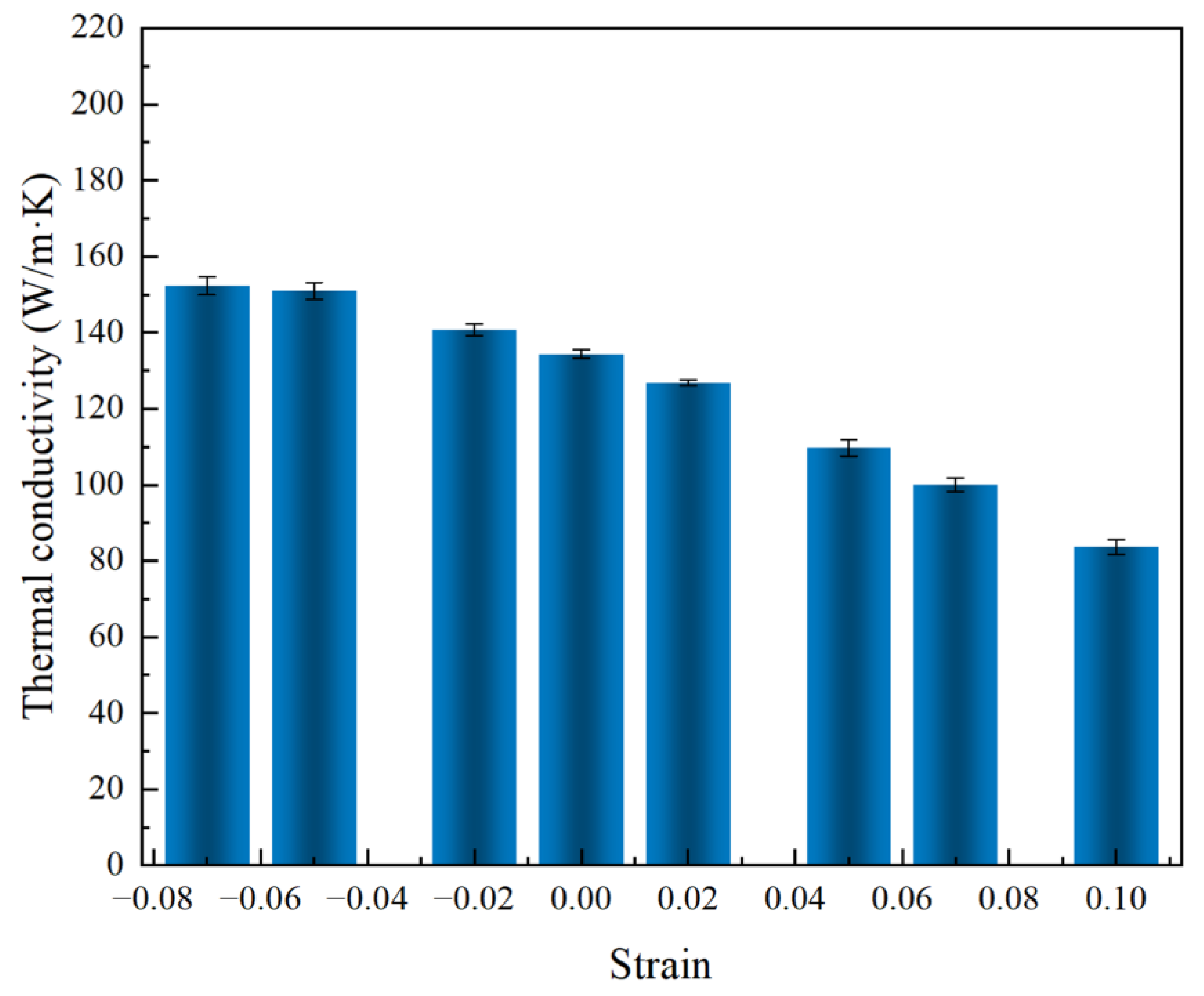

3.5. Effect of Strain

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, Z.; Zheng, Q.; Su, G. Thermoelectric properties of silicon carbide nanowires with nitride dopants and vacancies. Phys. Rev. B Condens. Matter Mater. Phys. 2011, 84, 245451. [Google Scholar] [CrossRef] [Green Version]

- Hong, M.H.; Samant, A.V.; Pirouz, P. Stacking fault energy of 6H SiC and 4H SiC single crystals. Philos. Mag. A 2000, 80, 919–935. [Google Scholar] [CrossRef]

- Pirouz, P.; Cockayne, D.J.H.; Sumida, N.S.; Hissch, P.; Lang, A.R. Dissociation of Dislocations in Diamond. Proc. R. Soc. London Ser. A 1983, 386, 241–249. [Google Scholar]

- Hassan, J.; Henry, A.; Ivanov, I.G.; Bergman, J.P. In-grown stacking faults in 4H-SiC epilayers grown on off-cut substrates. J. Appl. Phys. 2009, 105, 123513. [Google Scholar] [CrossRef]

- Skowronski, M.; Ha, S. Degradation of hexagonal silicon-carbide-based bipolar devices. J. Appl. Phys. 2006, 99, 11101. [Google Scholar] [CrossRef]

- Chung, H.J.; Liu, J.Q.; Skowronski, M. Stacking fault formation in highly doped 4H-SiC epilayers during annealing. Appl. Phys. Lett. 2002, 81, 3759–3761. [Google Scholar] [CrossRef]

- Hallin, C.; Konstantinov, A.O.; Pecz, B.; Kordina, O.; Janzen, E. The origin of 3C polytype inclusions in epitaxial layers of silicon carbide grown by chemical vapour deposition. Diam. Relat. Mater. 1997, 6, 1297–1300. [Google Scholar] [CrossRef]

- Si, W.; Dudley, M.; Kong, H.; Sumakeris, J.; Carter, C. Investigations of 3C-SiC Inclusions in 4H-SiC Epilayers on 4H-SiC Single Crystal Substrates. J. Electron. Mater. 1997, 26, 151–159. [Google Scholar] [CrossRef]

- Yu, J.; Yu, Y.; Bai, Z.; Peng, Y.; Tang, X.; Hu, X.; Xie, X.; Xu, X.; Chen, X. Morphological and microstructural analysis of triangular defects in 4H-SiC homoepitaxial layers. CrystEngComm 2022, 24, 1582–1589. [Google Scholar] [CrossRef]

- Kim, H.; Kim, S.I.; Kim, S.; Lee, N.; Shin, H.; Lee, C.W. Relation between work function and structural properties of triangular defects in 4H-SiC epitaxial layer: Kelvin probe force microscopic and spectroscopic analyses. Nanoscale 2020, 12, 8216–8229. [Google Scholar] [CrossRef]

- Hu, J.; Jia, R.; Niu, Y.; Zang, Y.; Pu, H. Study of a new type nominal “washboard-like” triangular defects in 4H-SiC 4° off-axis (0001) Si-face homoepitaxial layers. J. Cryst. Growth 2019, 506, 14–18. [Google Scholar] [CrossRef]

- Guo, J.; Yang, Y.; Raghothamachar, B.; Kim, T.; Dudley, M.; Kim, J. Understanding the microstructures of triangular defects in 4H-SiC homoepitaxial. J. Cryst. Growth 2017, 480, 119–125. [Google Scholar] [CrossRef]

- Yamashita, T.; Naijo, T.; Matsuhata, H.; Momose, K.; Osawa, H.; Okumura, H. Characteristic morphologies of triangular defects on Si-face 4H-SiC epitaxial films. J. Cryst. Growth 2016, 433, 97–104. [Google Scholar] [CrossRef]

- Chen, B.; Matsuhata, H.; Sekiguchi, T.; Ichinoseki, K.; Okumura, H. Surface defects and accompanying imperfections in 4H–SiC: Optical, structural and electrical characterization. Acta Mater. 2012, 60, 51–58. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, Y.; Zhou, J.; Jiao, J.; Chen, Y.; Wang, H.; Liu, C.; Jiang, Z.; Wang, Z. Stacking fault and unoccupied densities of state dependence of electromagnetic wave absorption in SiC nanowires. J. Mater. Chem. C Mater. Opt. Electron. Devices 2015, 3, 4416–4423. [Google Scholar] [CrossRef]

- Lee, J.H.; Jeon, W.B.; Moon, J.S.; Lee, J.; Han, S.; Bodrog, Z.; Gali, A.; Lee, S.; Kim, J. Strong Zero-Phonon Transition from Point Defect-Stacking Fault Complexes in Silicon Carbide Nanowires. Nano Lett. 2021, 21, 9187–9194. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Toney, M.F.; Ko, W.; Randel, J.C.; Jung, H.J.; Munakata, K.; Lu, J.; Geballe, T.H.; Beasley, M.R.; Sinclair, R.; et al. Laser-Synthesized Epitaxial Graphene. ACS Nano 2010, 4, 7524–7530. [Google Scholar] [CrossRef]

- Lemaitre, M.G.; Tongay, S.; Wang, X.; Venkatachalam, D.K.; Fridmann, J.; Gila, B.P.; Hebard, A.F.; Ren, F.; Elliman, R.G.; Appleton, B.R. Low-temperature, site selective graphitization of SiC via ion implantation and pulsed laser annealing. Appl. Phys. Lett. 2012, 100, 193105. [Google Scholar] [CrossRef]

- Choi, I.; Jeong, H.Y.; Shin, H.; Kang, G.; Byun, M.; Kim, H.; Chitu, A.M.; Im, J.S.; Ruoff, R.S.; Choi, S.; et al. Laser-induced phase separation of silicon carbide. Nat. Commun. 2016, 7, 13562. [Google Scholar] [CrossRef] [Green Version]

- Wan, P.; Wu, Z.; Zhang, H.; Gao, L.; Wang, J. Porous Nano-SiC as Thermal Insulator: Wisdom on Balancing Thermal Stability, High Strength and Low Thermal Conductivity. Mater. Res. Lett. 2016, 4, 104–111. [Google Scholar] [CrossRef] [Green Version]

- Li, P.; Yan, X.; Chen, J.; Dong, P.; Huang, B. Electronic and doping properties of hexagonal silicon carbide with stacking faults induced cubic inclusions. J. Appl. Phys. 2021, 129, 235703. [Google Scholar] [CrossRef]

- Li, D.; Li, H.; Li, B. A novelty design for radiation resistance of SiC by recrystallization-induced stacking faults. J. Mater. Res. Technol. 2022, 19, 3852–3856. [Google Scholar] [CrossRef]

- Barbisan, L.; Sarikov, A.; Marzegalli, A.; Montalenti, F.; Miglio, L. Nature and Shape of Stacking Faults in 3C-SiC by Molecular Dynamics Simulations. Phys. Status Solidi (b) 2021, 258, 2000598. [Google Scholar] [CrossRef]

- Scalise, E.; Barbisan, L.; Sarikov, A.; Montalenti, F.; Miglio, L.; Marzegalli, A. The origin and nature of killer defects in 3C-SiC for power electronic applications by a multiscale atomistic approach. J. Mater. Chem. C 2020, 8, 8380–8392. [Google Scholar] [CrossRef]

- Yan, X.; Liu, C.; Gadre, C.A.; Gu, L.; Aoki, T.; Lovejoy, T.C.; Dellby, N.; Krivanek, O.L.; Schlom, D.G.; Wu, R.; et al. Single-defect phonons imaged by electron microscopy. Nature 2021, 589, 65–69. [Google Scholar] [CrossRef]

- Shapkin, N.P.; Papynov, E.K.; Shichalin, O.O.; Buravlev, I.Y.; Simonenko, E.P.; Simonenko, N.P.; Zavjalov, A.P.; Belov, A.A.; Portnyagin, A.S.; Gerasimenko, A.V.; et al. Spark Plasma Sintering-Reactive Synthesis of SiC and SiC–HfB2 Ceramics Based on Natural Renewable Raw Materials. Russ. J. Inorg. Chem. 2021, 66, 629–637. [Google Scholar] [CrossRef]

- Simonenko, E.P.; Simonenko, N.P.; Gordeev, A.N.; Papynov, E.K.; Shichalin, O.O.; Kolesnikov, A.F.; Avramenko, V.A.; Sevastyanov, V.G.; Kuznetsov, N.T. Study of the Thermal Behavior of Wedge-Shaped Samples of HfB2–45 vol % SiC Ultra-High-Temperature Composite in a High-Enthalpy Air Flow. Russ. J. Inorg. Chem. 2018, 63, 421–432. [Google Scholar] [CrossRef]

- Sevastyanov, V.G.; Simonenko, E.P.; Gordeev, A.N.; Simonenko, N.P.; Kolesnikov, A.F.; Papynov, E.K.; Shichalin, O.O.; Avramenko, V.A.; Kuznetsov, N.T. HfB2-SiC (10–20 vol %) Ceramic Materials: Manufacture and Behavior under Long Term Exposure to Dissociated Air Streams. Russ. J. Inorg. Chem. 2014, 59, 1361–1382. [Google Scholar] [CrossRef]

- Simonenko, E.P.; Gordeev, A.N.; Simonenko, N.P.; Vasilevskii, S.A.; Kolesnikov, A.F.; Papynov, E.K.; Shichalin, O.O.; Avramenko, V.A.; Sevastyanov, V.G.; Kuznetsov, N.T. Behavior of HfB2-SiC (10, 15, and 20 vol %) Ceramic Materials in High-Enthalpy Air Flows. Russ. J. Inorg. Chem. 2016, 61, 1259–1275. [Google Scholar] [CrossRef]

- Shinoda, Y.; Nagano, T. Fabrication of Nanograined Silicon Carbide by Ultrahigh-Pressure Hot Isostatic Pressing. J. Am. Ceram. Soc. 1999, 82, 771–773. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, X.; Jiang, Z.; Mao, Q.; Zhang, T.; Cheng, H.; Liu, Q.; Wang, H. Effect of SiCw volume fraction on microstructure and properties of SiCw/Al composite fabricated by hot isostatic pressing-hot pressing. Mater. Res. Express 2019, 6, 1165. [Google Scholar] [CrossRef]

- Hu, Y.; Luo, F.; Duan, S.; Zhou, W.; Zhu, D. Mechanical and dielectric properties of SiC f/SiC composites fabricated by PIP combined with CIP process. Ceram. Int. 2016, 42, 6800–6806. [Google Scholar] [CrossRef]

- Jin, L.; Zhang, K.; Xu, T.; Zeng, T.; Cheng, S. The fabrication and mechanical properties of SiC/SiC composites prepared by SLS combined with PIP. Ceram. Int. 2018, 44, 20992–20999. [Google Scholar] [CrossRef]

- Imade, M.; Ogura, T.; Uemura, M.; Kawamura, F.; Yoshimura, M.; Kitaoka, Y.; Sasaki, T.; Mori, Y.; Yamazaki, M.; Suwabe, S.; et al. Liquid-phase epitaxy of 2H–SiC film on a (0001) 4H–SiC substrate in Li–Si melt. Mater. Lett. 2009, 63, 649–651. [Google Scholar] [CrossRef]

- Deng, Y.; Zhang, Y.; Zhang, N.; Zhi, Q.; Wang, B.; Yang, J. Preparation and characterization of pure SiC ceramics by high temperature physical vapor transport induced by seeding with nano SiC particles. J. Mater. Sci. Technol. 2019, 35, 2756–2760. [Google Scholar] [CrossRef]

- Zhong, G.; Xie, X.; Wang, D.; Wang, X.; Sun, L.; Yang, X.; Peng, Y.; Chen, X.; Hu, X.; Xu, X. Growth of p-type 4H-SiC single crystals by physical vapor transport using p-type SiC powder. CrystEngComm 2022, 24, 7861–7868. [Google Scholar] [CrossRef]

- Yang, W.; Araki, H.; Thaveethavorn, S.; Suzuki, H.; Noda, T. In situ synthesis and characterization of pure SiC nanowires on silicon wafer. Appl. Surf. Sci. 2005, 241, 236–240. [Google Scholar] [CrossRef]

- Lundgren, C.; Kakanakova-Georgieva, A.; Gueorguiev, G.K. A perspective on thermal stability and mechanical properties of 2D Indium Bismide from ab initio molecular dynamics. Nanotechnology 2022, 33, 335706. [Google Scholar] [CrossRef]

- Sangiovanni, D.G.; Faccio, R.; Gueorguiev, G.K.; Kakanakova-Georgieva, A. Discovering atomistic pathways for supply of metal atoms from methyl-based precursors to graphene surface. Phys. Chem. Chem. Phys. 2023, 25, 829–837. [Google Scholar] [CrossRef]

- Huang, H.; Zhong, Y.; Cai, B.; Wang, J.; Liu, Z.; Peng, Q. Size- and temperature-dependent thermal transport across a Cu−diamond interface: Non-equilibrium molecular dynamics simulations. Surf. Interfaces 2023, 37, 102736. [Google Scholar] [CrossRef]

- Feng, T.; Zhong, Y.; Shi, J.; Ruan, X. Unexpected high inelastic phonon transport across solid-solid interface: Modal nonequilibrium molecular dynamics simulations and Landauer analysis. Phys. Rev. B 2019, 99, 45301. [Google Scholar] [CrossRef] [Green Version]

- Szpunar, B.; Malakkal, L.; Rahman, J.; Szpunar, J.A. Atomistic modeling of thermo-mechanical properties of cubic SiC. J. Am. Ceram. Soc. 2018, 101, 4753–4762. [Google Scholar] [CrossRef]

- Mao, Y.; Li, Y.; Xiong, Y.; Xiao, W. Point defect effects on the thermal conductivity of β-SiC by molecular dynamics simulations. Comput. Mater. Sci. 2018, 152, 300–307. [Google Scholar] [CrossRef]

- Islam, A.; Islam, M.S.; Ferdous, N.; Park, J.; Bhuiyan, A.G.; Hashimoto, A. Anomalous temperature dependent thermal conductivity of two-dimensional silicon carbide. Nanotechnology 2019, 30, 445707. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 15012. [Google Scholar] [CrossRef]

- Roy Chowdhury, P.; Reynolds, C.; Garrett, A.; Feng, T.; Adiga, S.P.; Ruan, X. Machine learning maximized Anderson localization of phonons in aperiodic superlattices. Nano Energy 2020, 69, 104428. [Google Scholar] [CrossRef]

- Liu, Y.; Hao, J.; Chernatynskiy, A.; Ren, G.; Zhang, J. Effect of period length distribution on the thermal conductivity of Si/Ge superlattice. Int. J. Therm. Sci. 2021, 170, 107157. [Google Scholar] [CrossRef]

- Thompson, A.P.; Aktulga, H.M.; Berger, R.; Bolintineanu, D.S.; Brown, W.M.; Crozier, P.S.; In T Veld, P.J.; Kohlmeyer, A.; Moore, S.G.; Nguyen, T.D.; et al. LAMMPS—A flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales. Comput. Phys. Commun. 2022, 271, 108171. [Google Scholar] [CrossRef]

- Hu, M.; Poulikakos, D. Si/Ge Superlattice Nanowires with Ultralow Thermal Conductivity. Nano Lett. 2012, 12, 5487–5494. [Google Scholar] [CrossRef]

- Lindsay, L. Optimized Tersoff and Brenner empirical potential parameters for lattice dynamics and phonon thermal transport in carbon nanotubes and graphene. Phys. Rev. B 2010, 81, 205441. [Google Scholar] [CrossRef] [Green Version]

- Xu, K.; Gabourie, A.J.; Hashemi, A.; Fan, Z.; Wei, N.; Farimani, A.B.; Komsa, H.; Krasheninnikov, A.V.; Pop, E.; Ala-Nissila, T. Thermal transport in MoS2 from molecular dynamics using different empirical potentials. Phys. Rev. B 2019, 99, 54303. [Google Scholar] [CrossRef] [Green Version]

- Shi, L.; Ma, X.; Li, M.; Zhong, Y.; Yang, L.; Yin, W.; He, X. Molecular dynamics simulation of phonon thermal transport in nanotwinned diamond with a new optimized Tersoff potential. Phys. Chem. Chem. Phys. 2021, 23, 8336–8343. [Google Scholar] [CrossRef]

- Tadano, T.; Gohda, Y.; Tsuneyuki, S. Anharmonic force constants extracted from first-principles molecular dynamics: Applications to heat transfer simulations. J. Phys. Condens. Matter 2014, 26, 225402. [Google Scholar] [CrossRef]

- Tersoff, J. Modeling solid-state chemistry: Interatomic potentials for mnlticomponent systems. Phys. Rev. B 1989, 39, 5566–5568. [Google Scholar] [CrossRef]

- Tersoff, J. Carbon defects and defect reactions in silicon. Phys. Rev. Lett. 1990, 64, 1757–1760. [Google Scholar] [CrossRef]

- Erhart, P.; Albe, K. Analytical potential for atomistic simulations of silicon, carbon, and silicon carbide. Phys. Rev. B Condens. Matter Mater. Phys. 2005, 71, 35211. [Google Scholar] [CrossRef] [Green Version]

- Huang, H.; Ghoniem, N.; Wong, J.; Baskes, M. Molecular dynamics determination of defect energetics in beta -SiC using three representative empirical potentials. Model. Simul. Mater. Sci. Eng. 1995, 3, 615–627. [Google Scholar] [CrossRef]

- Gao, F.; Weber, W.J. Empirical potential approach for defect properties in 3C-SiC. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2002, 191, 504–508. [Google Scholar] [CrossRef]

- Feldman, D.W.; Parker, J.H., Jr. Phonon Dispersion Curves by Raman Scattering in SiC, Polytypes 3C, 4H, 6H, 15R, and 21R. Phys. Rev. 1968, 173, 787–793. [Google Scholar] [CrossRef]

- Karch, K.; Pavone, P.; Windl, W.; Schutt, O.; Strauch, D. Ab initio calculation of structural and lattice-dynamical properties of silicon carbide. Phys. Rev. B Condens. Matter 1994, 50, 17054–17063. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Ordonez-Miranda, J.; Gluchko, S.; Anufriev, R.; De Sousa Meneses, D.; Del Campo, L.; Volz, S.; Nomura, M. Enhanced thermal conduction by phonon-polaritons. Sci. Adv. 2020, 6, eabb4461. [Google Scholar] [CrossRef]

- Schelling, P.K.; Phillpot, S.R.; Keblinski, P. Comparison of atomic-level simulation methods for computing thermal conductivity. Phys. Rev. B 2002, 65, 144306. [Google Scholar] [CrossRef] [Green Version]

- Ravichandran, J.; Yadav, A.K.; Cheaito, R.; Rossen, P.B.; Soukiassian, A.; Suresha, S.J.; Duda, J.C.; Foley, B.M.; Lee, C.; Zhu, Y.; et al. Crossover from incoherent to coherent phonon scattering in epitaxial oxide superlattices. Nat. Mater. 2014, 13, 168–172. [Google Scholar] [CrossRef] [PubMed]

- Mu, X.; Zhang, T.; Go, D.B.; Luo, T. Coherent and incoherent phonon thermal transport in isotopically modified graphene superlattices. Carbon 2015, 83, 208–216. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, H. Stability of single-wall silicon carbide nanotubes—Molecular dynamics simulations. Comput. Mater. Sci. 2008, 43, 664–669. [Google Scholar] [CrossRef]

- Liu, Y.; Bian, Y.; Chernatynskiy, A.; Han, Z. Effect of grain boundary angle on the thermal conductivity of nanostructured bicrystal ZnO based on the molecular dynamics simulation method. Int. J. Heat Mass Transf. 2019, 145, 118791. [Google Scholar] [CrossRef]

- Murphy, K.F.; Piccione, B.; Zanjani, M.B.; Lukes, J.R.; Gianola, D.S. Strain-and Defect-Mediated Thermal Conductivity in Silicon Nanowires. Nano Lett. 2014, 14, 3785–3792. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Maute, K.; Dunn, M.L.; Yang, R. Strain effects on the thermal conductivity of nanostructures. Phys. Review. B Condens. Matter Mater. Phys. 2010, 81, 245318. [Google Scholar] [CrossRef]

- Liang, X.; Wang, C. Insights into strain dependent lattice thermal conductivity of tin oxide. Acta Mater. 2022, 239, 118289. [Google Scholar] [CrossRef]

| Raw Material | Fabrication Method | Reference |

|---|---|---|

| SiC powder, rice husk | Spark plasma sintering (SPS) | [26,27,28,29] |

| SiC powder, SiC whiskers | Hot isostatic pressing (HIP) | [30,31] |

| SiC fiber, polycarbosilane | Cold isostatic pressing (CIP) | [32,33] |

| 4H–SiC substrate | Liquid-phase epitaxy (LPE) | [34] |

| SiC powder, Si powder, C powder | Physical vapor transport (PVT) | [35,36] |

| Silicon wafers, methyltrichlorosilane | Chemical vapor deposition (CVD) | [16,37] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, K.; Shi, L.; Ma, X.; Zhong, Y.; Li, M.; He, X. Thermal Conductivity of 3C/4H-SiC Nanowires by Molecular Dynamics Simulation. Nanomaterials 2023, 13, 2196. https://doi.org/10.3390/nano13152196

Yin K, Shi L, Ma X, Zhong Y, Li M, He X. Thermal Conductivity of 3C/4H-SiC Nanowires by Molecular Dynamics Simulation. Nanomaterials. 2023; 13(15):2196. https://doi.org/10.3390/nano13152196

Chicago/Turabian StyleYin, Kaili, Liping Shi, Xiaoliang Ma, Yesheng Zhong, Mingwei Li, and Xiaodong He. 2023. "Thermal Conductivity of 3C/4H-SiC Nanowires by Molecular Dynamics Simulation" Nanomaterials 13, no. 15: 2196. https://doi.org/10.3390/nano13152196

APA StyleYin, K., Shi, L., Ma, X., Zhong, Y., Li, M., & He, X. (2023). Thermal Conductivity of 3C/4H-SiC Nanowires by Molecular Dynamics Simulation. Nanomaterials, 13(15), 2196. https://doi.org/10.3390/nano13152196