Study on Oxygen Evolution Reaction of Ir Nanodendrites Supported on Antimony Tin Oxide

Abstract

1. Introduction

2. Materials and Methods

2.1. Synthesis of Ir NDs and Ir ND/ATO

2.2. Characterization of the Samples

2.3. Electrochemical Activity Tests

3. Results and Discussion

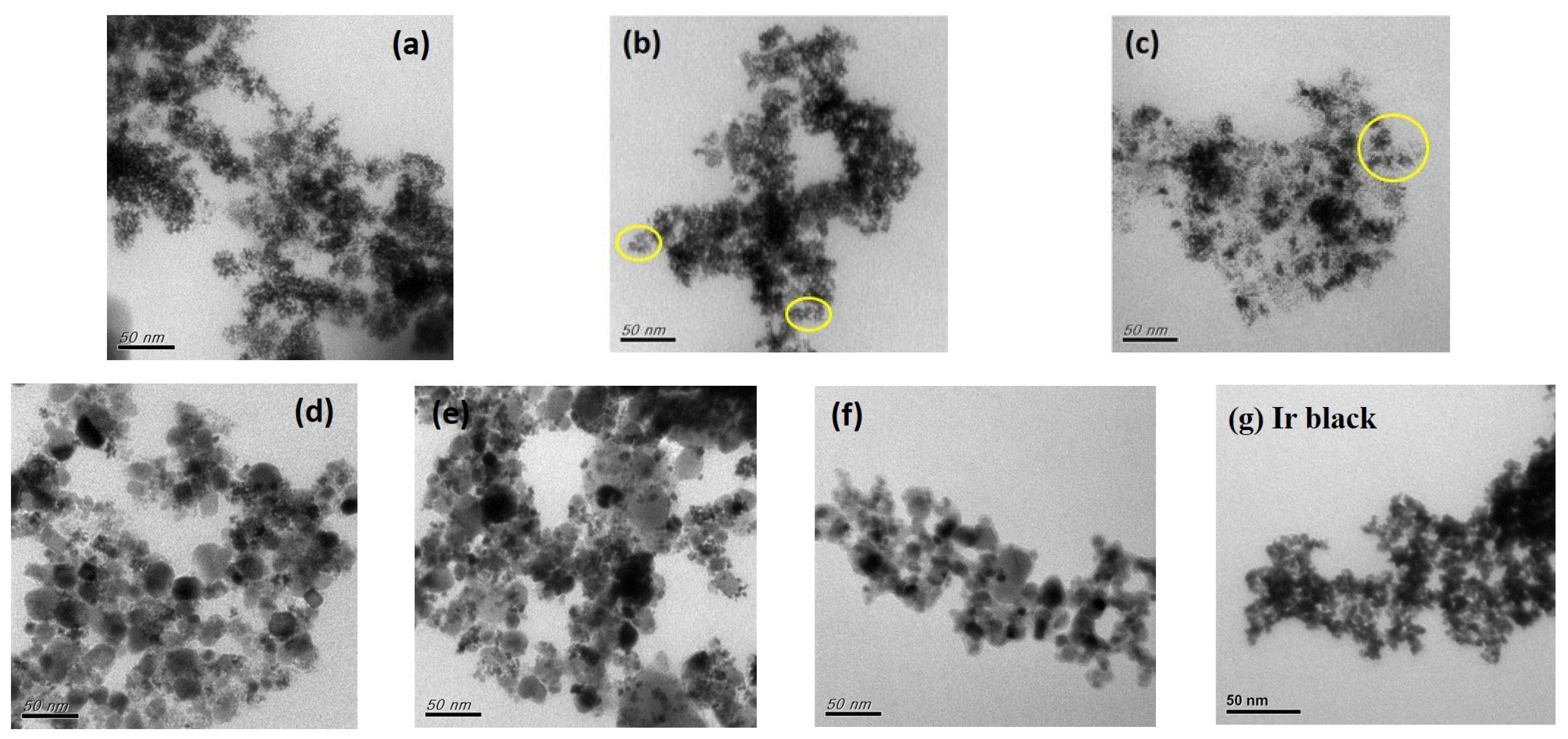

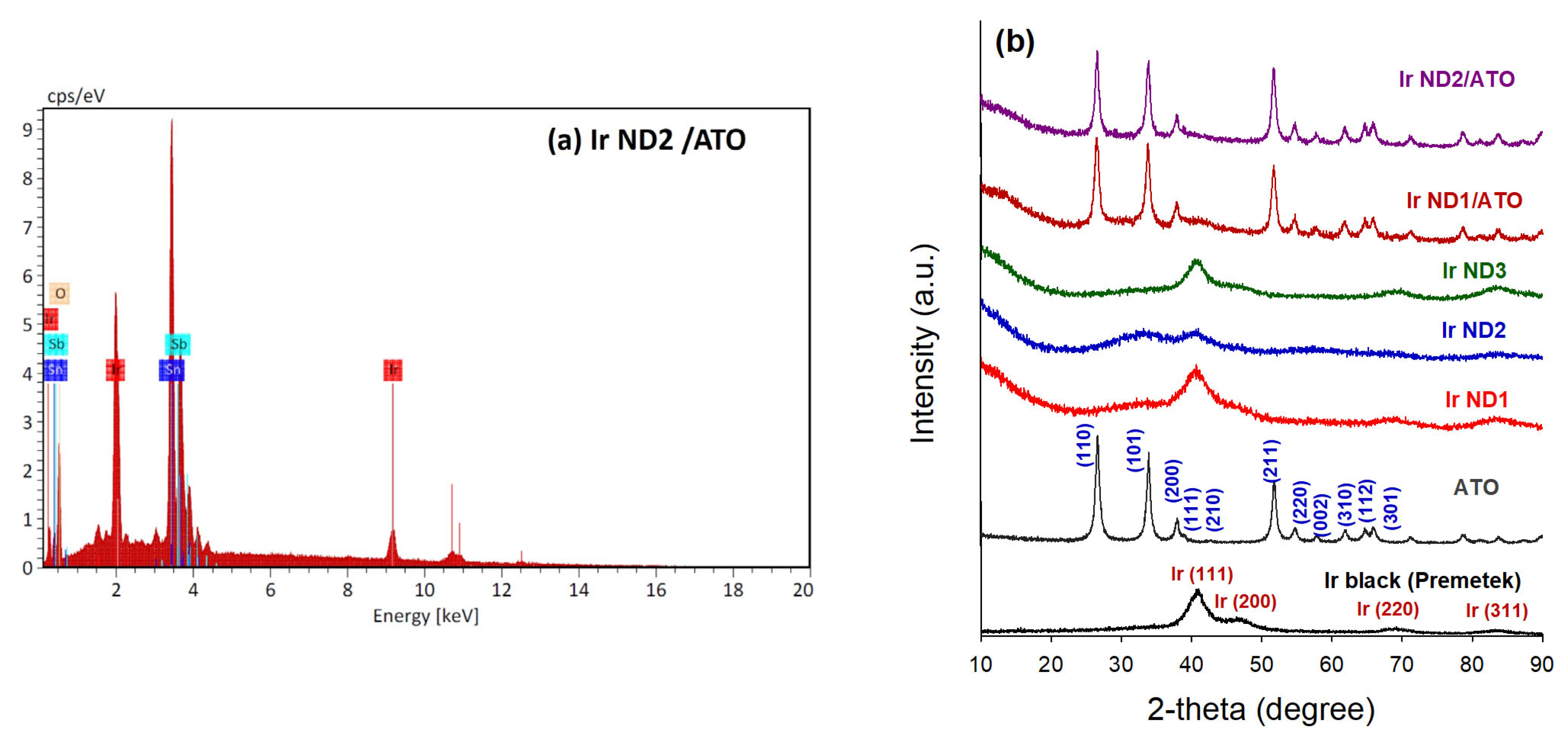

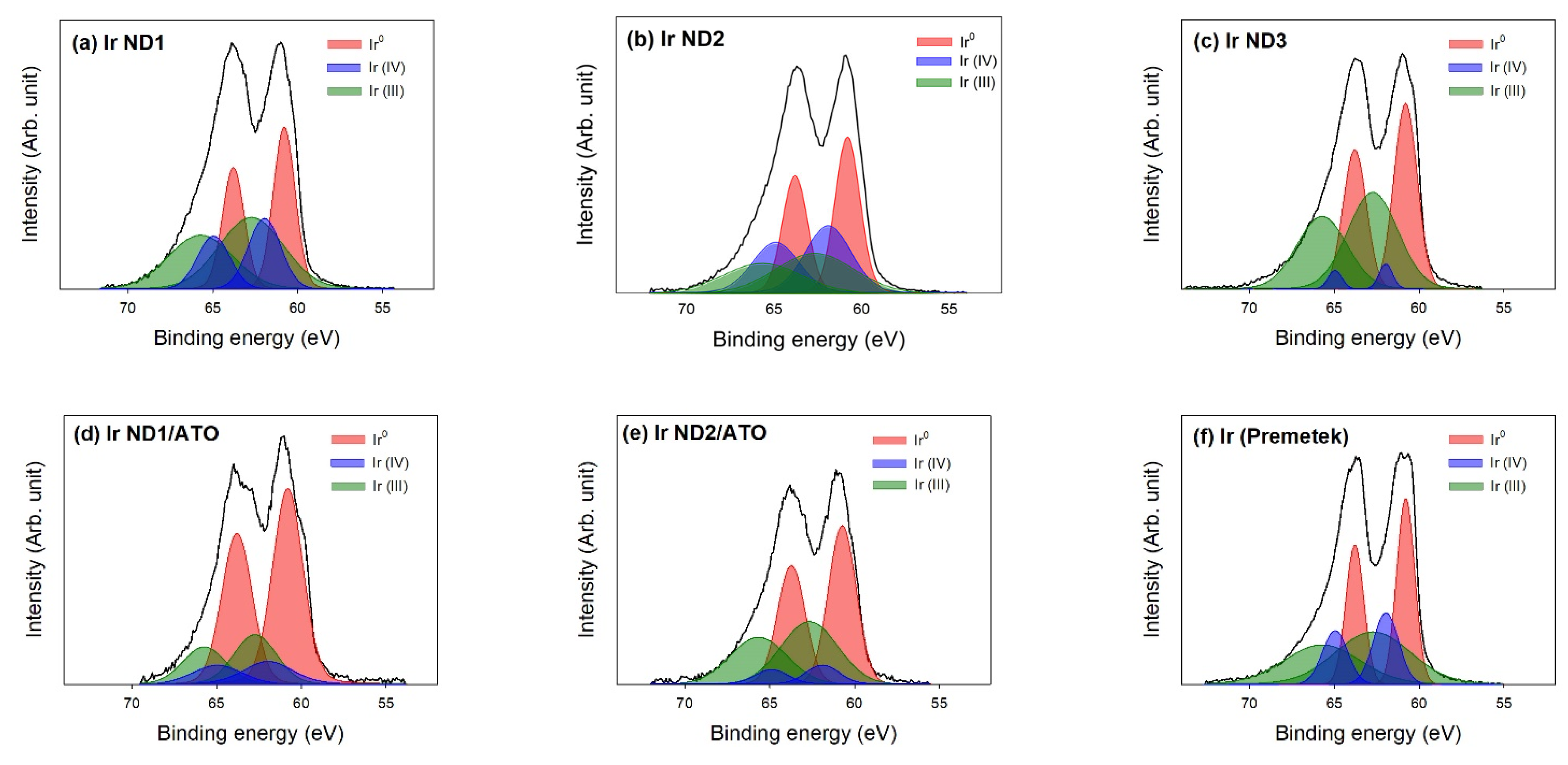

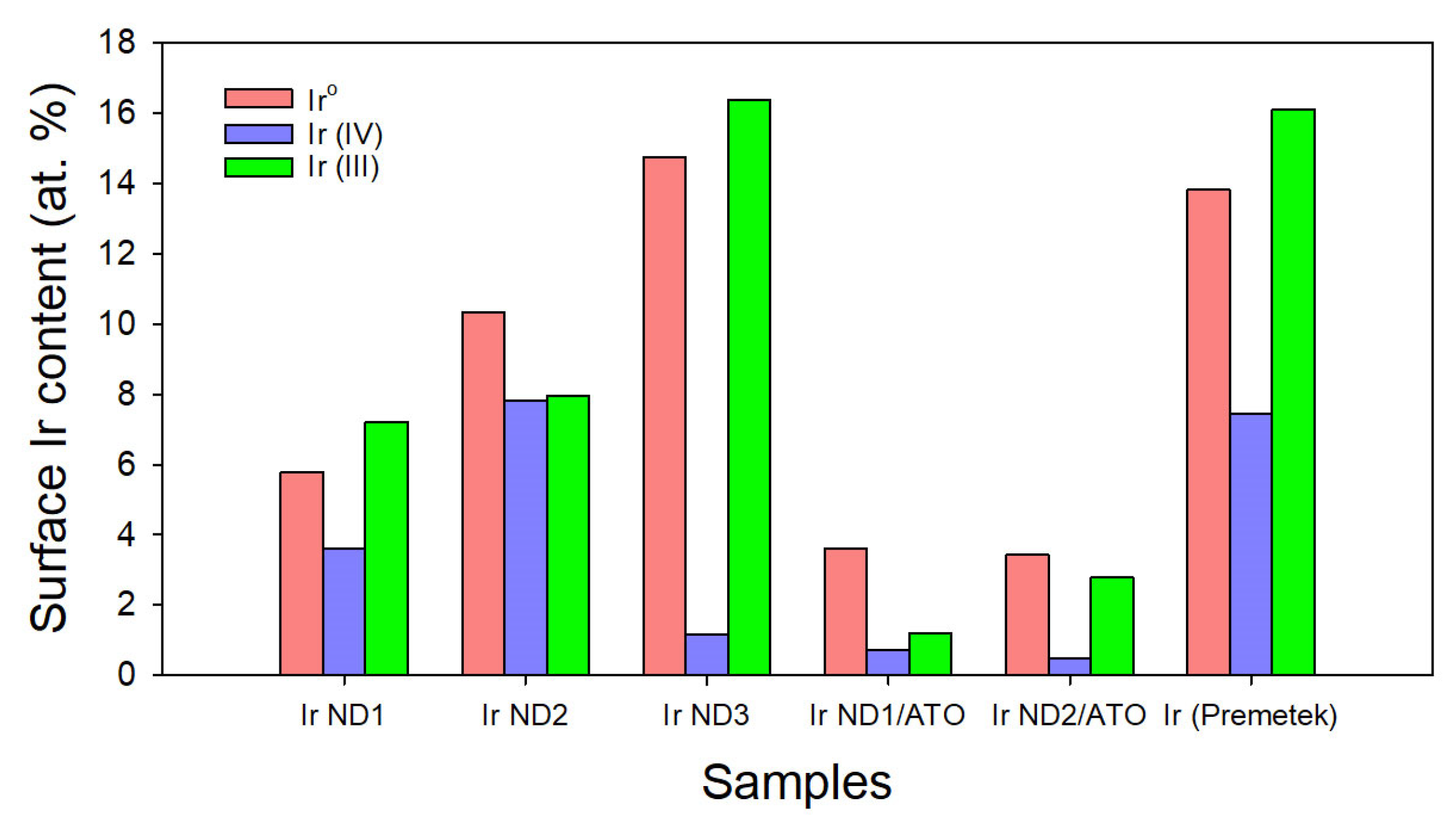

3.1. Physical and Chemical Properties of the Electrocatalysts

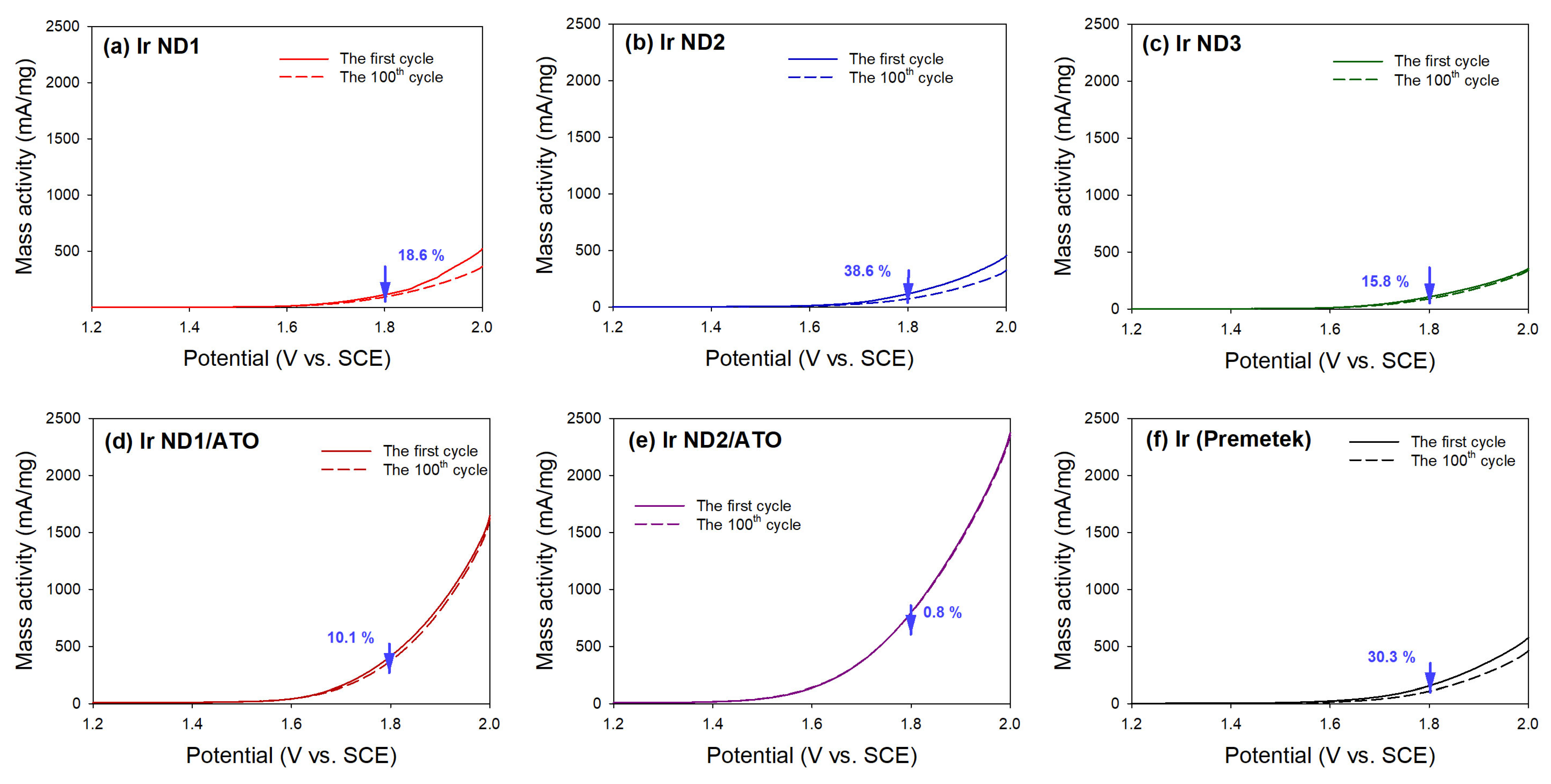

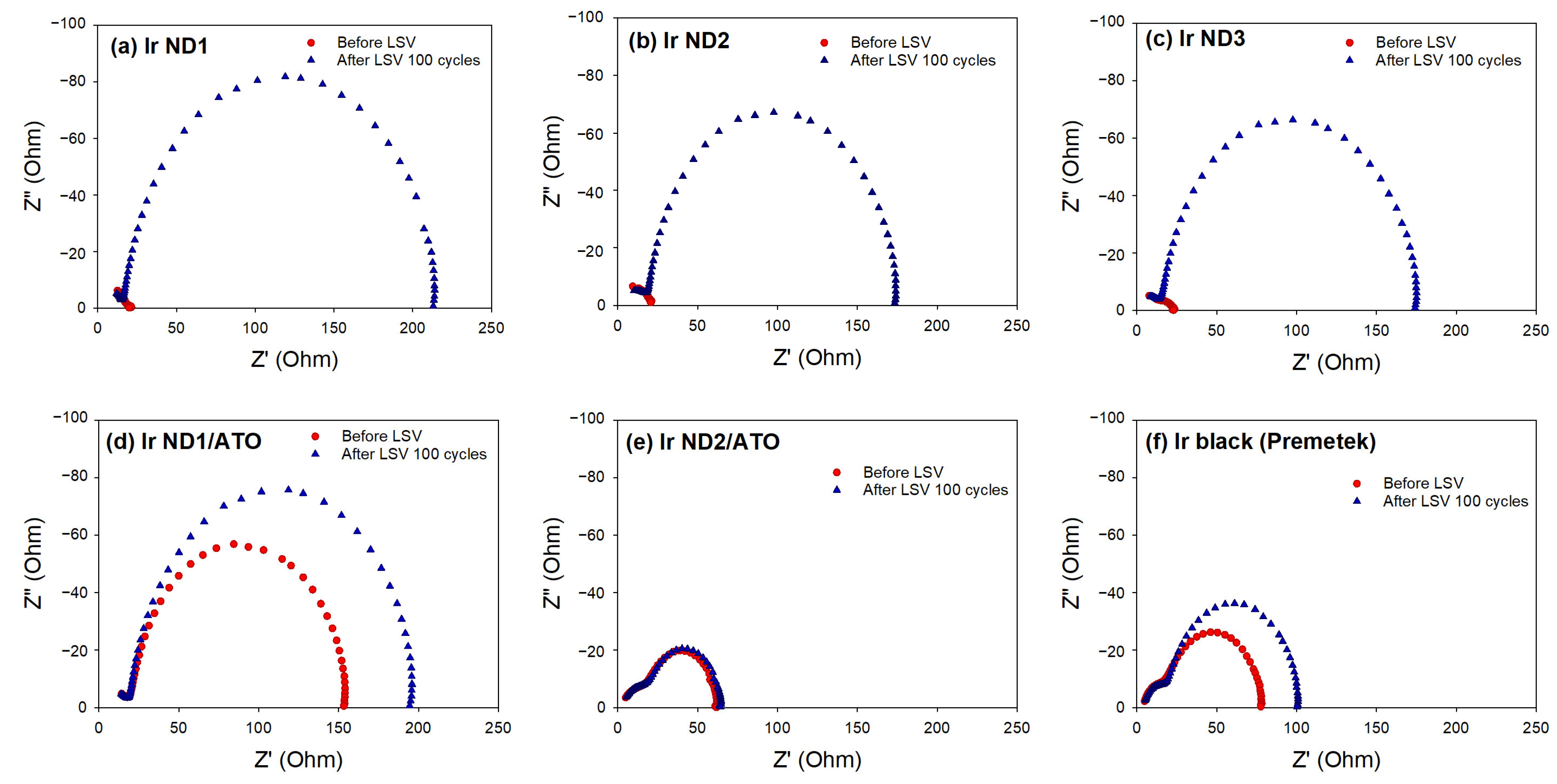

3.2. Electrochemical Properties of the Electrocatalysts

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Barbir, F. PEM electrolysis for production of hydrogen from renewable energy sources. Sol. Energy 2005, 78, 661–669. [Google Scholar] [CrossRef]

- Carmo, M.; Fritz, D.L.; Mergel, J.; Stolten, D. A comprehensive review on PEM water electrolysis. Int. J. Hydrogen Energy 2013, 38, 4901–4934. [Google Scholar] [CrossRef]

- Nieminen, J.; Dincer, I.; Naterer, G. Comparative performance analysis of PEM and solid oxide steam electrolysers. Int. J. Hydrogen Energy 2010, 35, 10842–10850. [Google Scholar] [CrossRef]

- Buttler, A.; Spliethoff, H. Current status of water electrolysis for energy storage, grid balancing and sector coupling via power-to-gas and power-to-liquids. Renew. Sustain. Energy Rev. 2018, 82, 2440–2454. [Google Scholar] [CrossRef]

- Oh, H.S.; Nong, H.N.; Reier, T.; Gliech, M.; Strasser, P. Oxide-supported Ir nanodendrites with high activity and durability for the oxygen evolution reaction in acid PEM water electrolyzers. Chem. Sci. 2015, 6, 3321–3328. [Google Scholar] [CrossRef]

- Siracusano, S.; Baglio, V.; Di Blasi, A.; Briguglio, N.; Stassi, A.; Ornelas, R.; Trifoni, E.; Antonucci, V.; Aricò, A.S. Electrochemical characterization of single cell and short stack PEM electrolyzers based on a nanosized IrO2 anode electrocatalyst. Int. J. Hydrogen Energy 2010, 35, 5558–5568. [Google Scholar] [CrossRef]

- Oh, J.G.; Lee, W.H.; Kim, H. The inhibition of electrochemical carbon corrosion in polymer electrolyte membrane fuel cells using iridium nanodendrites. Int. J. Hydrogen Energy 2012, 37, 2455–2461. [Google Scholar] [CrossRef]

- Siracusano, S.; Van Dijk, N.; Payne-Johnson, E.; Baglio, V.; Aricò, A.S. Nanosized IrOx and IrRuOx electrocatalysts for the O2 evolution reaction in PEM water electrolysers. Appl. Catal. B-Environ. 2015, 164, 488–495. [Google Scholar] [CrossRef]

- Faustini, M.; Giraud, M.; Jones, D.; Rozière, J.; Dupont, M.; Porter, T.R.; Nowak, S.; Bahri, M.; Ersen, O.; Sanchez, C.; et al. Hierarchically structured ultraporous iridium-based materials: A novel catalyst architecture for proton exchange membrane water electrolyzers. Adv. Energy Mater. 2019, 9, 1802136. [Google Scholar] [CrossRef]

- Hartig-Weiss, A.; Miller, M.; Beyer, H.; Schmitt, A.; Siebel, A.; Freiberg, A.T.S.; Gasteiger, H.A.; El-Sayed, H.A. Iridium oxide catalyst supported on antimony-doped tin oxide for high oxygen evolution reaction activity in acidic media. ACS Appl. Nano Mater. 2020, 3, 2185–2196. [Google Scholar] [CrossRef]

- Song, H.J.; Yoon, H.; Ju, B.; Kim, D.W. Highly efficient perovskite-based electrocatalysts for water oxidation in acidic environments: A Mini Review. Adv. Energy Mater. 2021, 11, 2002428. [Google Scholar] [CrossRef]

- Cherevko, S.; Geiger, S.; Kasian, O.; Mingers, A.; Mayrhofer, K.J.J. Oxygen evolution activity and stability of iridium in acidic media. Part 1.—Metallic iridium. J. Electroanal. Chem. 2016, 773, 69–78. [Google Scholar] [CrossRef]

- Cherevko, S.; Geiger, S.; Kasian, O.; Mingers, A.; Mayrhofer, K.J.J. Oxygen evolution activity and stability of iridium in acidic media. Part 2.—Electrochemically grown hydrous iridium oxide. J. Electroanal. Chem. 2016, 774, 102–110. [Google Scholar] [CrossRef]

- Roy, C.; Rao, R.R.; Stoerzinger, K.A.; Hwang, J.; Rossmeisl, J.; Chorkendorff, I.; Shao-Horn, Y.; Stephens, I.E.L. Trends in activity and dissolution on RuO2 under oxygen evolution conditions: Particles versus well-defined extended surfaces. ACS Energy Lett. 2018, 3, 2045–2051. [Google Scholar] [CrossRef]

- Chen, Z.; Duan, X.; Wei, W.; Wang, S.; Ni, B.J. Electrocatalysts for acidic oxygen evolution reaction: Achievements and perspectives. Nano Energy 2020, 78, 105392. [Google Scholar] [CrossRef]

- Chen, Z.; Duan, X.; Wei, W.; Wang, S.; Ni, B.J. Iridium-based nanomaterials for electrochemical water splitting. Nano Energy 2020, 78, 105270. [Google Scholar] [CrossRef]

- She, L.; Zhao, G.; Ma, T.; Chen, J.; Sun, W.; Pan, H. On the durability of iridium-based electrocatalysts toward the oxygen evolution reaction under acid environment. Adv. Funct. Mater. 2022, 32, 2108465. [Google Scholar] [CrossRef]

- Abbou, S.; Chattot, R.; Martin, V.; Claudel, F.; Solà-Hernandez, L.; Beauger, C.; Dubau, L.; Maillard, F. Manipulating the corrosion resistance of SnO2 aerogels through doping for efficient and durable oxygen evolution reaction electrocatalysis in acidic media. ACS Catal. 2020, 10, 7283–7294. [Google Scholar] [CrossRef]

- Hayden, B.E. Particle size and support effects in electrocatalysis. Acc. Chem. Res. 2013, 46, 1858–1866. [Google Scholar] [CrossRef]

- Puthiyapura, V.K.; Mamlouk, M.; Pasupathi, S.; Pollet, B.G.; Scott, K. Physical and electrochemical evaluation of ATO supported IrO2 catalyst for proton exchange membrane water electrolyser. J. Power Sources 2014, 269, 451–460. [Google Scholar] [CrossRef]

- Da Silva, C.D.F.; Claudel, F.; Martin, V.; Chattot, R.; Abbou, S.; Kumar, K.; Jiménez-Morales, I.; Cavaliere, S.; Jones, D.; Rozière, J.; et al. Oxygen evolution reaction activity and stability benchmarks for supported and unsupported IrOx electrocatalysts. ACS Catal. 2021, 11, 4107–4116. [Google Scholar] [CrossRef]

- Wang, L.; Song, F.; Ozouf, G.; Geiger, D.; Morawietz, T.; Handl, M.; Gazdzicki, P.; Beauger, C.; Kaiser, U.; Hiesgen, R.; et al. Improving the activity and stability of Ir catalysts for PEM electrolyzer anodes by SnO2: Sb aerogel supports: Does V addition play an active role in electrocatalysis? J. Mater. Chem. A 2017, 5, 3172–3178. [Google Scholar] [CrossRef]

- Böhm, D.; Beetz, M.; Schuster, M.; Peters, K.; Hufnagel, A.G.; Döblinger, M.; Böller, B.; Bein, T.; Fattakhova-Rohlfing, D. Efficient OER catalyst with low Ir volume density obtained by homogeneous deposition of iridium oxide nanoparticles on macroporous antimony-doped tin oxide support. Adv. Funct. Mater. 2020, 30, 1906670. [Google Scholar] [CrossRef]

- Kim, E.J.; Shin, J.; Bak, J.; Lee, S.J.; Kim, K.H.; Song, D.H.; Roh, J.H.; Lee, Y.; Kim, H.W.; Lee, K.S.; et al. Stabilizing role of Mo in TiO2-MoOx supported Ir catalyst toward oxygen evolution reaction. Appl. Catal. B-Environ. 2021, 280, 119433. [Google Scholar] [CrossRef]

- Chatterjee, S.; Peng, X.; Intikhab, S.; Zeng, G.; Kariuki, N.N.; Myers, D.J.; Danilovic, N.; Snyder, J. Nanoporous iridium nanosheets for polymer electrolyte membrane electrolysis. Adv. Energy Mater. 2021, 11, 2101438. [Google Scholar] [CrossRef]

- Zhuang, Z.; Wang, Y.; Xu, C.Q.; Liu, S.; Chen, C.; Peng, Q.; Zhuang, Z.; Xiao, H.; Pan, Y.; Lu, S.; et al. Three-dimensional open nano-netcage electrocatalysts for efficient pH-universal overall water splitting. Nat. Commun. 2019, 10, 4875. [Google Scholar] [CrossRef]

- Wang, Y.Z.; Yang, M.; Ding, Y.M.; Li, N.W.; Yu, L. Recent advances in complex hollow electrocatalysts for water splitting. Adv. Funct. Mater. 2022, 32, 2108681. [Google Scholar] [CrossRef]

- Lim, J.; Kang, G.; Lee, J.W.; Jeon, S.; Jeon, H.; Kang, P.W.; Lee, H. Amorphous Ir atomic clusters anchored on crystalline IrO2 nanoneedles for proton exchange membrane water oxidation. J. Power Sources 2022, 524, 231069. [Google Scholar] [CrossRef]

- Claudel, F.; Dubau, L.; Berthome, G.; Sola-Hernandez, L.; Beauger, C.; Piccolo, L.; Maillard, F. Degradation mechanisms of oxygen evolution reaction electrocatalysts: A combined identical-location transmission electron microscopy and X-ray photoelectron spectroscopy study. ACS Catal. 2019, 9, 4688–4698. [Google Scholar] [CrossRef]

- Lee, W.H.; Kim, H. Oxidized iridium nanodendrites as catalysts for oxygen evolution reactions. Catal. Commun. 2011, 12, 408–411. [Google Scholar] [CrossRef]

- Kim, C.; Oh, J.-G.; Kim, Y.-T.; Kim, H.; Lee, H. Platinum dendrites with controlled sizes for oxygen reduction reaction. Electrochem. Commun. 2010, 12, 1596–1599. [Google Scholar] [CrossRef]

- Wang, C.; Xiao, G.J.; Sui, Y.M.; Yang, X.Y.; Liu, G.; Jia, M.J.; Han, W.; Liu, B.B.; Zou, B. Synthesis of dendritic iridium nanostructures based on the oriented attachment mechanism and their enhanced CO and ammonia catalytic activities. Nanoscale 2014, 6, 15059–15065. [Google Scholar] [CrossRef]

- Chaudhari, N.K.; Joo, J.; Kwon, H.; Kim, B.; Kim, H.Y.; Joo, S.H.; Lee, K. Nanodendrites of platinum-group metals for electrocatalytic applications. Nano Res. 2018, 11, 6111–6140. [Google Scholar] [CrossRef]

- Zhang, G.; Shao, Z.G.; Lu, W.; Li, G.; Liu, F.; Yi, B. One-pot synthesis of Ir@Pt nanodendrites as highly active bifunctional electrocatalysts for oxygen reduction and oxygen evolution in acidic medium. Electrochem. Commun. 2012, 22, 145–148. [Google Scholar] [CrossRef]

- Fu, L.; Zeng, X.; Cheng, G.; Luo, W. IrCo nanodendrite as an efficient bifunctional electrocatalyst for overall water splitting under acidic conditions. ACS Appl. Mater. Interfaces 2018, 10, 24993–24998. [Google Scholar] [CrossRef] [PubMed]

- Lv, F.; Feng, J.; Wang, K.; Dou, Z.; Zhang, W.; Zhou, J.; Yang, C.; Luo, M.; Yang, Y.; Li, Y.; et al. Iridium−tungsten alloy nanodendrites as pH-universal water-splitting electrocatalysts. ACS Cent. Sci. 2018, 4, 1244–1252. [Google Scholar] [CrossRef]

- Fadil, Y.; Dinh, L.N.M.; Yap, M.O.Y.; Kuchel, R.P.; Yao, Y.; Omura, T.; Aregueta-Robles, U.A.; Song, N.; Huang, S.; Jasinski, F.; et al. Ambient-temperature waterborne polymer/rGO nanocomposite films: Effect of rGO distribution on electrical conductivity. ACS Appl. Mater. Interfaces 2019, 11, 48450–48458. [Google Scholar] [CrossRef]

- Gu, J.; Zhang, Y.W.; Tao, F. Shape control of bimetallic nanocatalysts through well-designed colloidal chemistry approaches. Chem. Soc. Rev. 2012, 41, 8050–8065. [Google Scholar] [CrossRef]

- Li, W.; Liang, C.; Zhou, W.; Qui, J.; Zhou, Z.; Sun, G.; Xin, Q. Preparation and characterization of multiwalled carbon nanotube-supported platinum for cathode catalysts of direct methanol fuel cells. J. Phys. Chem. B 2003, 107, 6292–6299. [Google Scholar] [CrossRef]

- Kojima, Y.; Suzuki, K.I.; Fukumoto, K.; Sasaki, M.; Yamamoto, T.; Kawai, Y.; Hayashi, H. Hydrogen generation using sodium borohydride solution and metal catalyst coated on metal oxide. Int. J. Hydrogen Energy 2002, 27, 1029–1034. [Google Scholar] [CrossRef]

- Jiménez-Morales, I.; Cavaliere, S.; Dupont, M.; Jones, D.; Roziere, J. On the stability of antimony doped tin oxide supports in proton exchange membrane fuel cell and water electrolysers. Sustain. Energy Fuels 2019, 3, 1526–1535. [Google Scholar] [CrossRef]

| Sample | Elemental Composition | |||||||

|---|---|---|---|---|---|---|---|---|

| Weight Percentage (wt.%) | Atomic Percentage (at.%) | |||||||

| Ir | O | Sn | Sb | Ir | O | Sn | Sb | |

| Ir ND1 | 88.8 | 11.2 | — | — | 39.8 | 60.2 | — | — |

| Ir ND2 | 88.1 | 11.9 | — | — | 38.2 | 61.8 | — | — |

| Ir ND3 | 95.5 | 4.5 | — | — | 63.63 | 36.37 | — | — |

| Ir ND1/ATO | 20.9 | 13.7 | 59.5 | 5.9 | 7.2 | 56.5 | 33.1 | 3.2 |

| Ir ND2/ATO | 26.1 | 14.6 | 56.4 | 2.9 | 8.7 | 59.0 | 30.7 | 1.6 |

| Ir black (Premetek) | 92.8 | 7.2 | — | — | 51.7 | 48.3 | — | — |

| ATO | — | 31.3 | 58.3 | 10.4 | — | 77.2 | 19.4 | 3.4 |

| Sample | Ir 4f | Binding Energy (eV) | |||||

|---|---|---|---|---|---|---|---|

| Iro | Ir (IV) | Ir (III) | |||||

| 60.8 | 63.8 | 61.9 | 64.9 | 62.7 | 65.7 | ||

| Ir ND1 | 16.6 | 3.30 | 2.48 | 2.07 | 1.55 | 4.11 | 3.09 |

| Ir ND2 | 26.1 | 5.90 | 4.43 | 4.47 | 3.35 | 4.54 | 3.41 |

| Ir ND3 | 32.3 | 8.43 | 6.32 | 0.66 | 0.50 | 9.37 | 7.03 |

| Ir ND1/ATO | 5.51 | 2.07 | 1.55 | 0.40 | 0.30 | 0.68 | 0.51 |

| Ir ND2/ATO | 6.68 | 1.96 | 1.47 | 0.28 | 0.21 | 1.59 | 1.19 |

| Ir black (Premetek) | 37.4 | 7.90 | 5.92 | 4.26 | 3.20 | 9.21 | 6.91 |

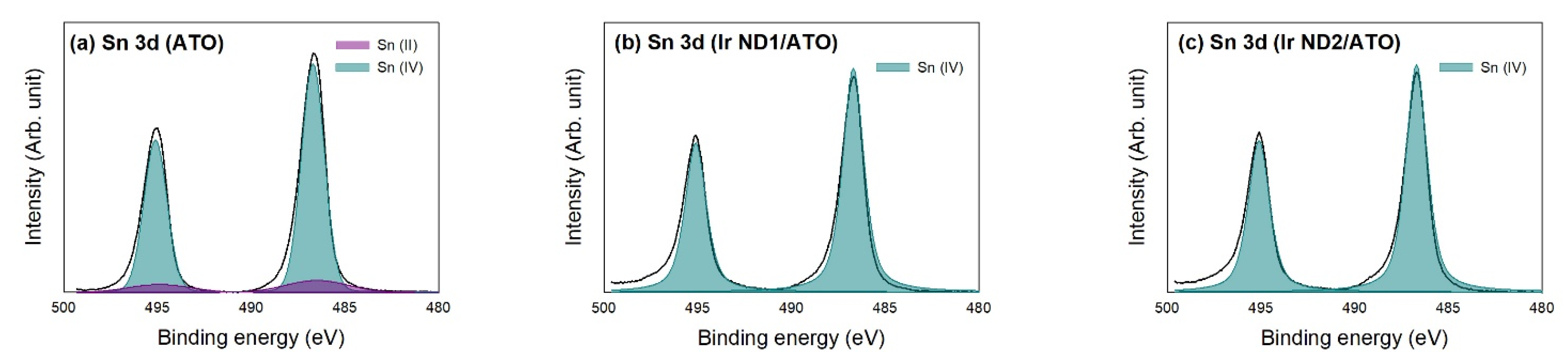

| Sample | Sn 3d | Binding Energy (eV) | |||

|---|---|---|---|---|---|

| Sn (II) | Sn (IV) | ||||

| 486.5 | 494.91 | 486.7 | 495.11 | ||

| ATO | 23.3 | 1.71 | 1.14 | 12.27 | 8.18 |

| Ir ND1/ATO | 21.1 | — | — | 12.66 | 8.44 |

| Ir ND2/ATO | 23.32 | — | — | 13.99 | 9.33 |

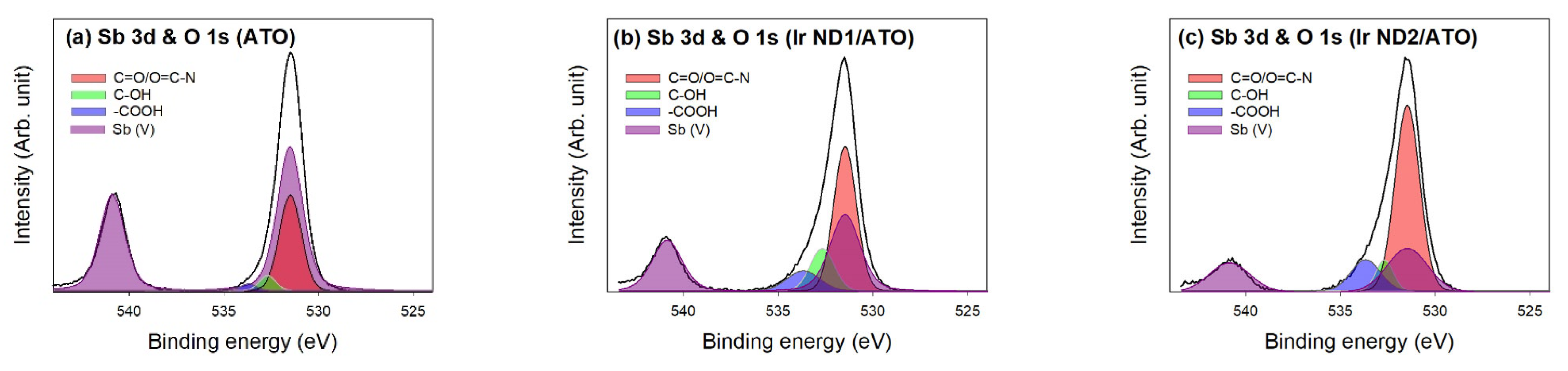

| Sample | Sb3d | O1s | Binding Energy (eV) | ||||

|---|---|---|---|---|---|---|---|

| Sb (V) | C=O | C-OH | -COOH | ||||

| 531.5 | 540.88 | 531.5 | 532.7 | 533.7 | |||

| ATO | 10.9 | 65.8 | 6.54 | 4.36 | 56.80 | 6.38 | 2.62 |

| Ir ND1/ATO | 3 | 70.39 | 1.80 | 1.20 | 46.71 | 14.46 | 9.23 |

| Ir ND2/ATO | 2.03 | 67.97 | 1.22 | 0.81 | 51.69 | 6.02 | 10.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chiang, Y.-C.; Pu, Z.-H.; Wang, Z. Study on Oxygen Evolution Reaction of Ir Nanodendrites Supported on Antimony Tin Oxide. Nanomaterials 2023, 13, 2264. https://doi.org/10.3390/nano13152264

Chiang Y-C, Pu Z-H, Wang Z. Study on Oxygen Evolution Reaction of Ir Nanodendrites Supported on Antimony Tin Oxide. Nanomaterials. 2023; 13(15):2264. https://doi.org/10.3390/nano13152264

Chicago/Turabian StyleChiang, Yu-Chun, Zhi-Hui Pu, and Ziyi Wang. 2023. "Study on Oxygen Evolution Reaction of Ir Nanodendrites Supported on Antimony Tin Oxide" Nanomaterials 13, no. 15: 2264. https://doi.org/10.3390/nano13152264

APA StyleChiang, Y.-C., Pu, Z.-H., & Wang, Z. (2023). Study on Oxygen Evolution Reaction of Ir Nanodendrites Supported on Antimony Tin Oxide. Nanomaterials, 13(15), 2264. https://doi.org/10.3390/nano13152264