Effect of Inlet Flow Strategies on the Dynamics of Pulsed Fluidized Bed of Nanopowder

Abstract

1. Introduction

2. Experimental

2.1. Single Drainage (SD) Configuration

2.2. Modified Dual Drainage (MDD) Configuration

3. Results and Discussion

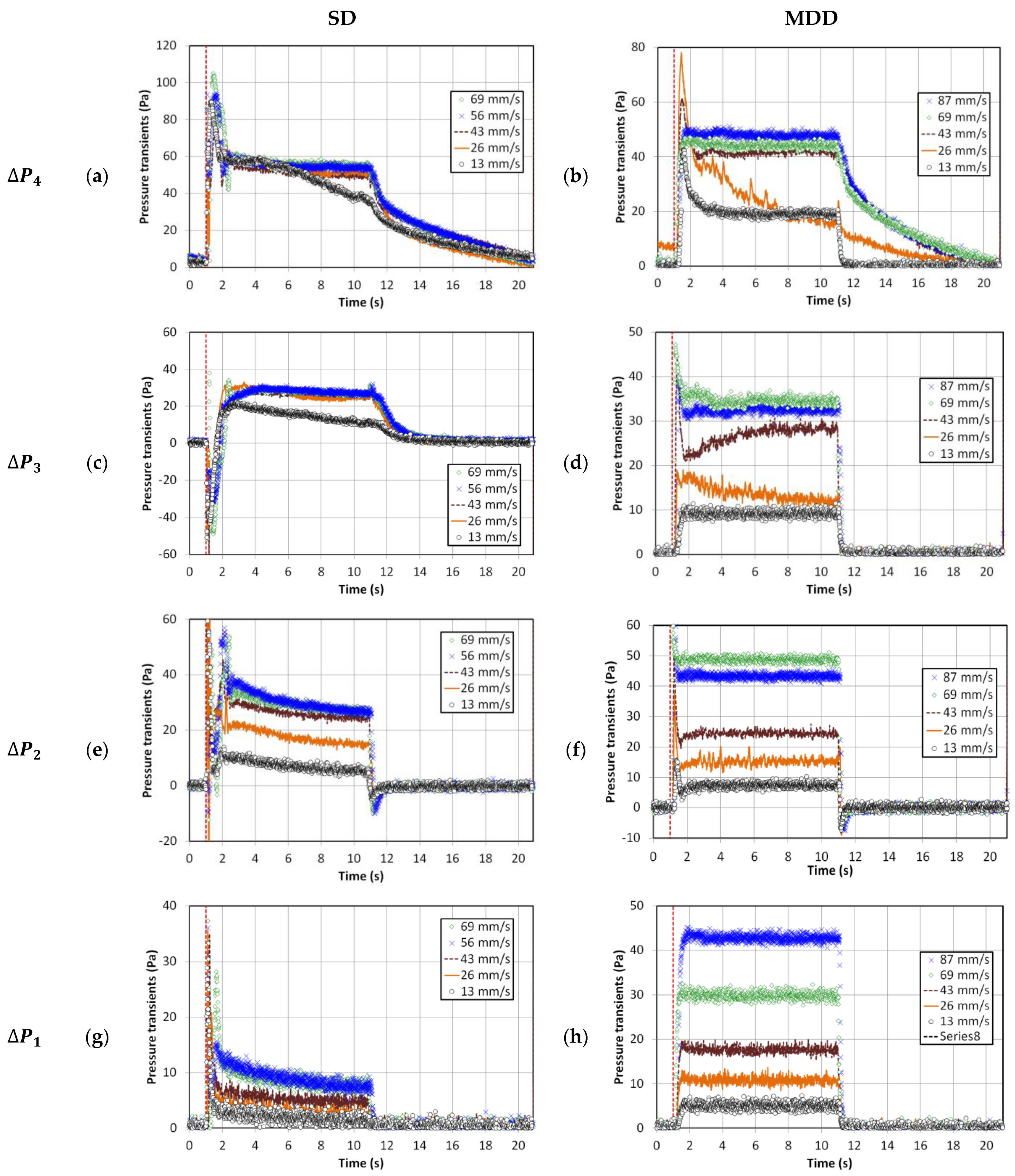

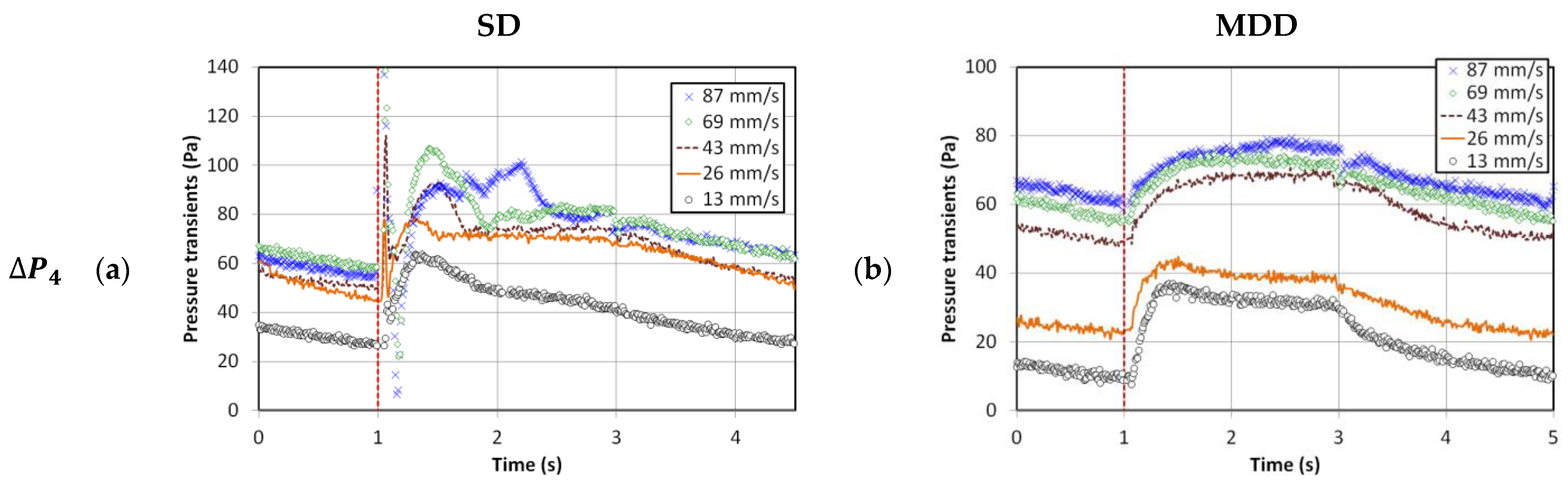

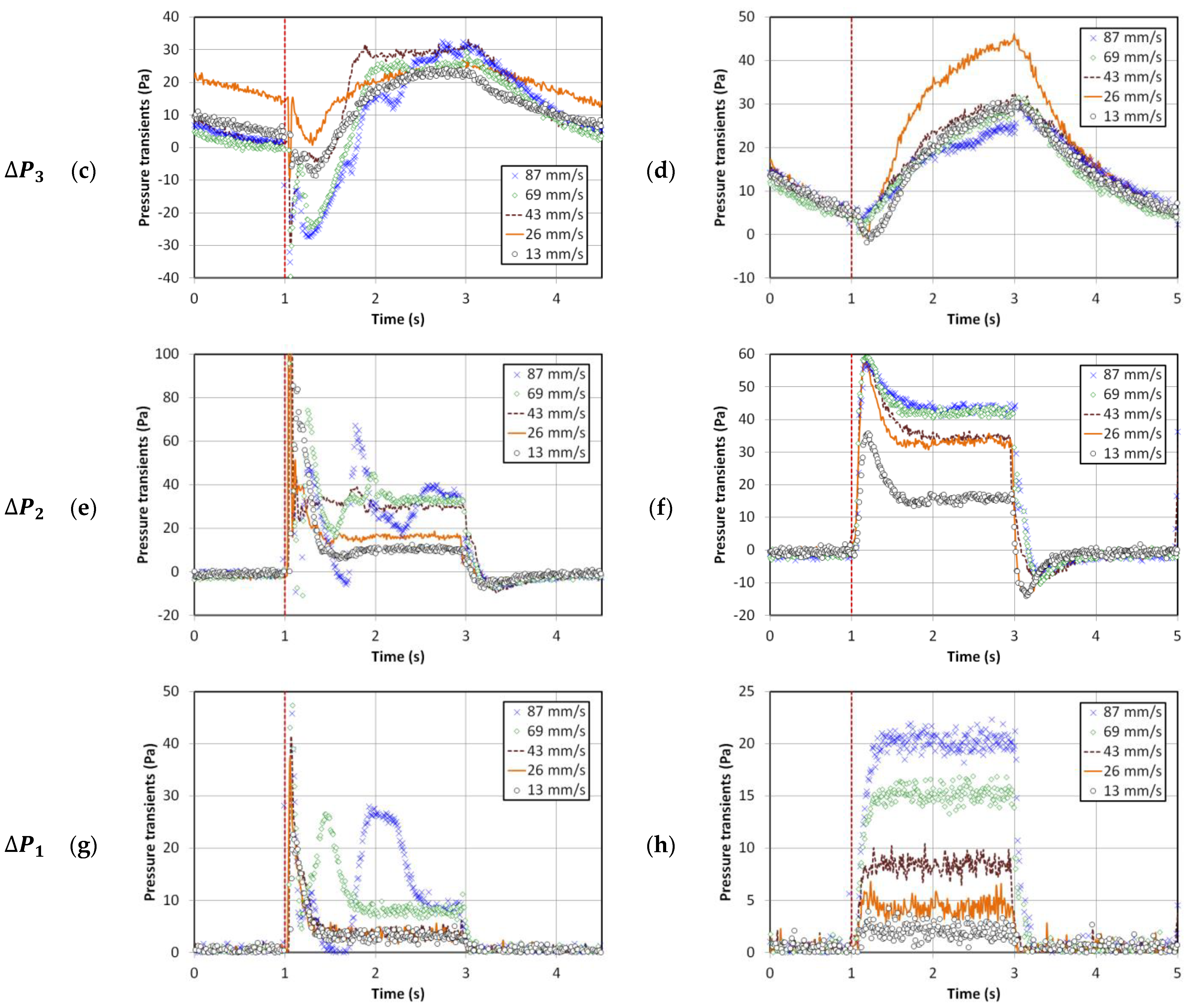

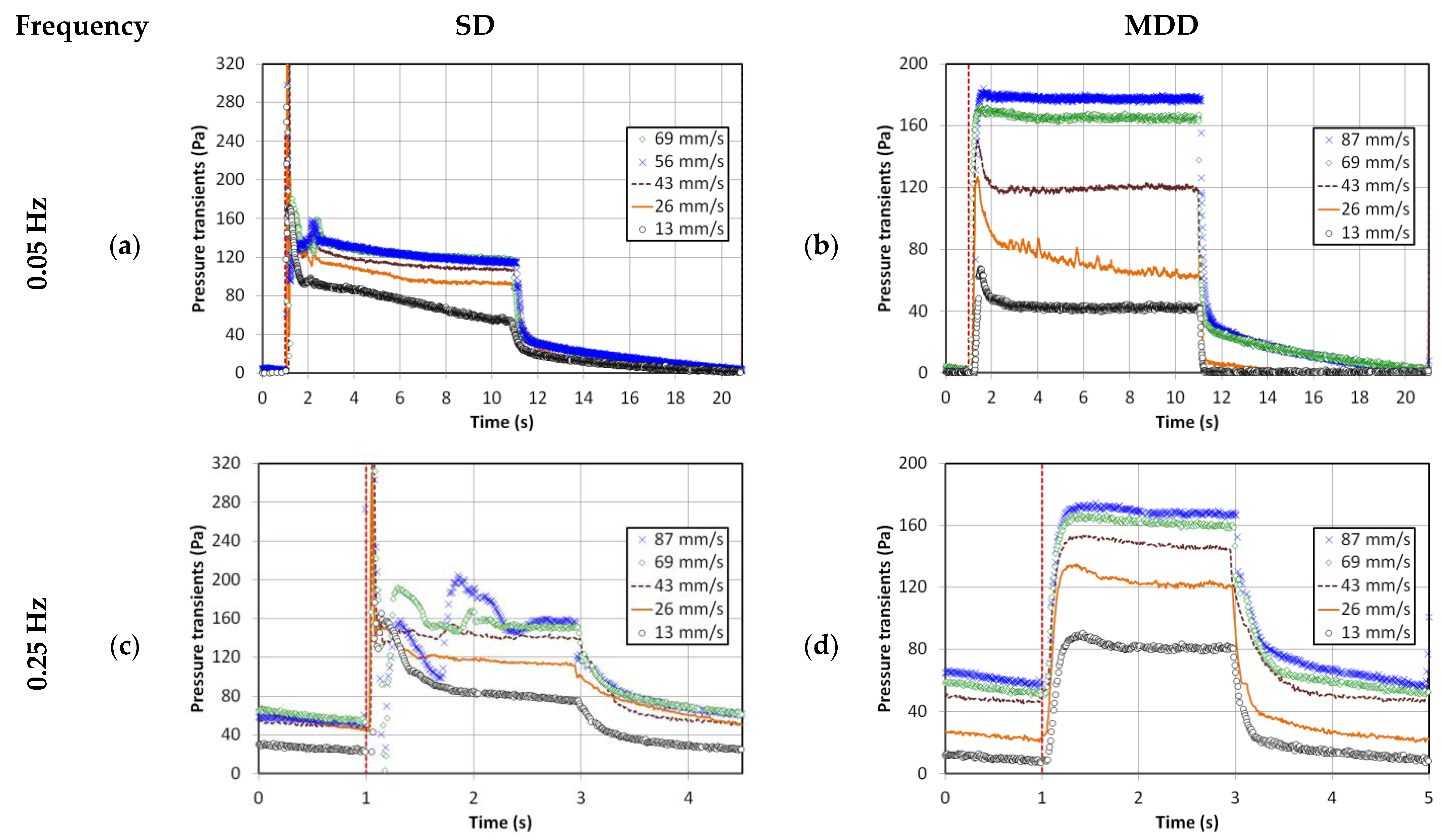

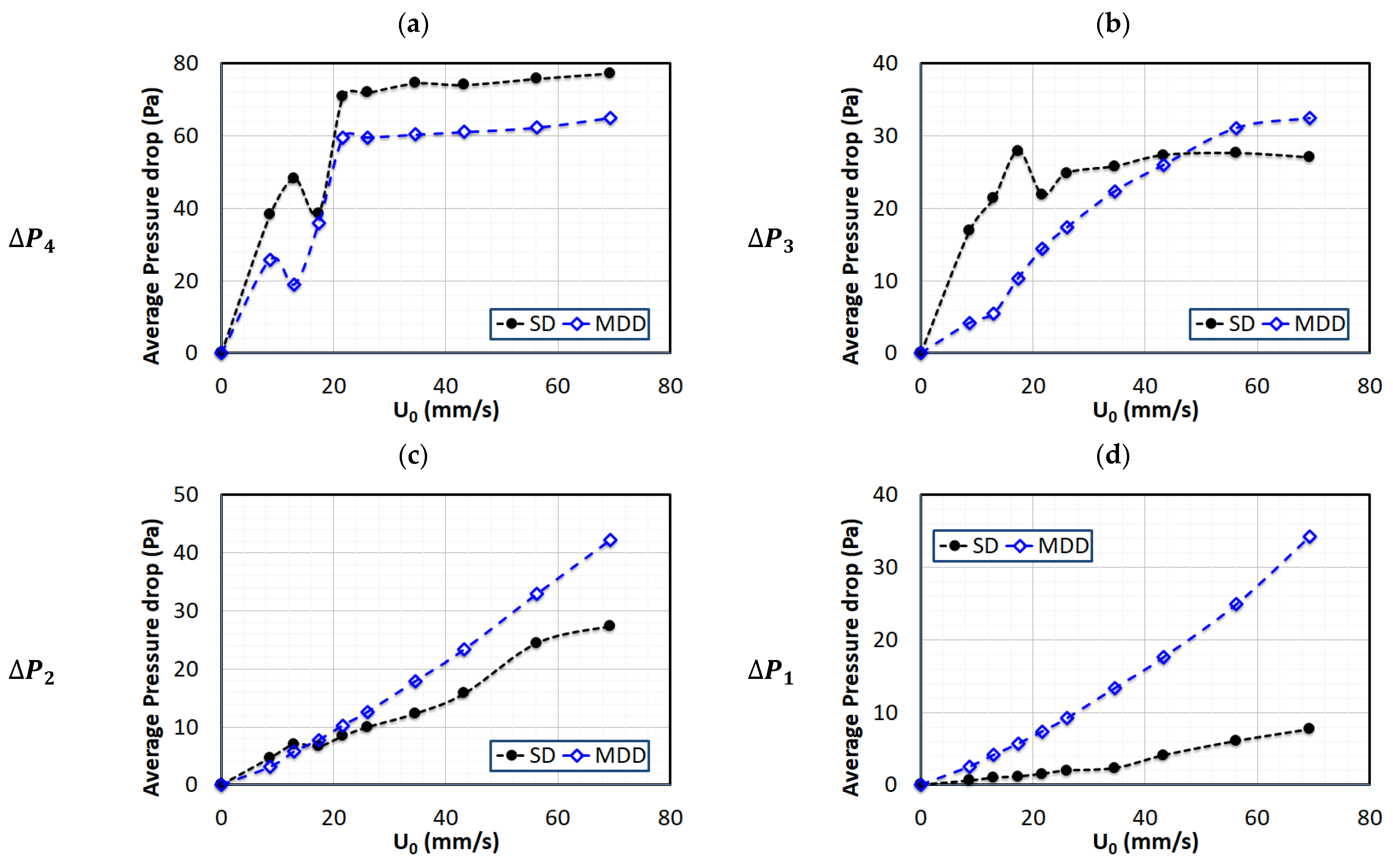

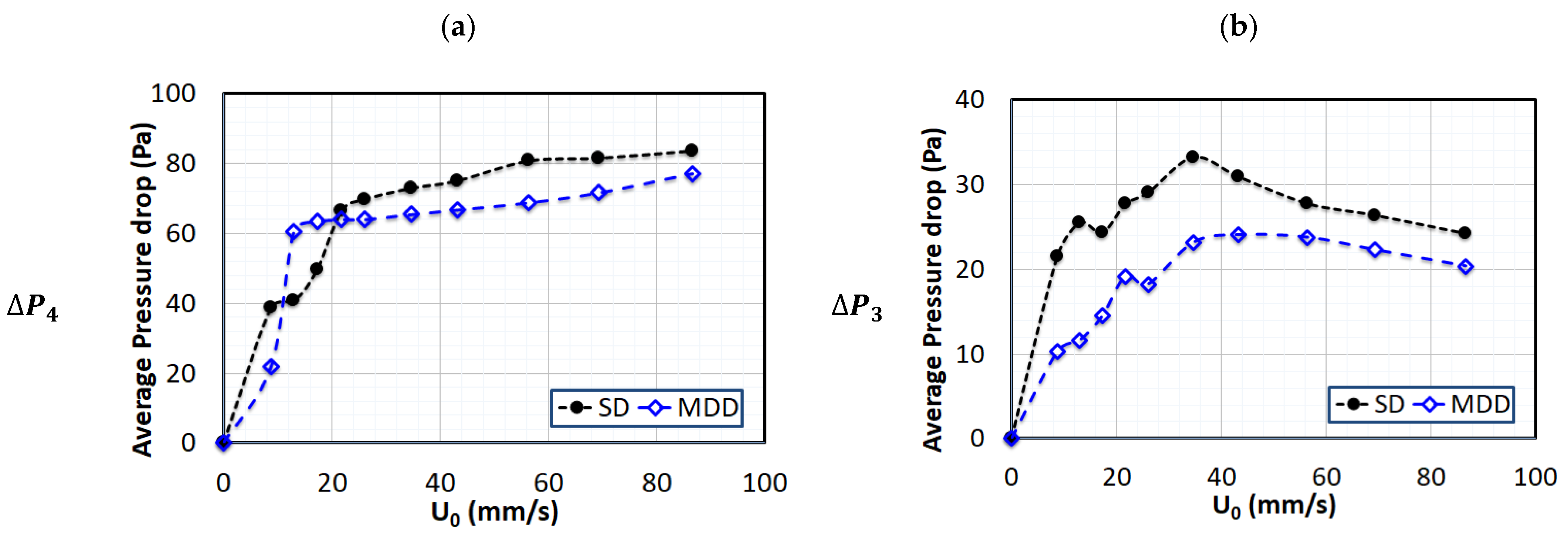

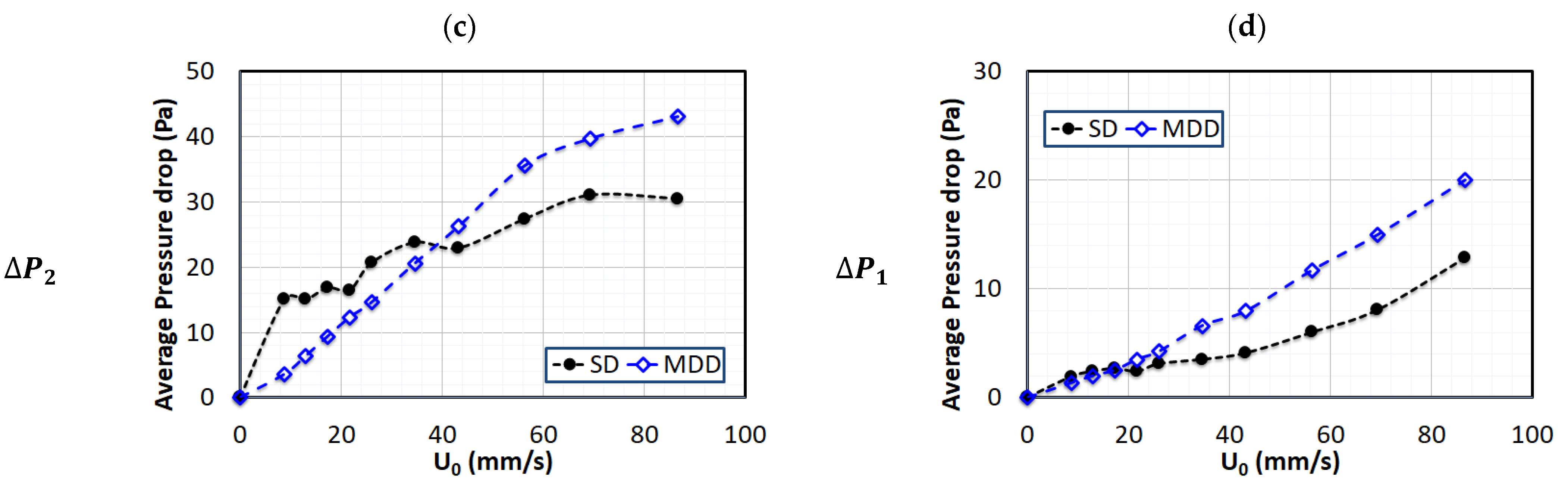

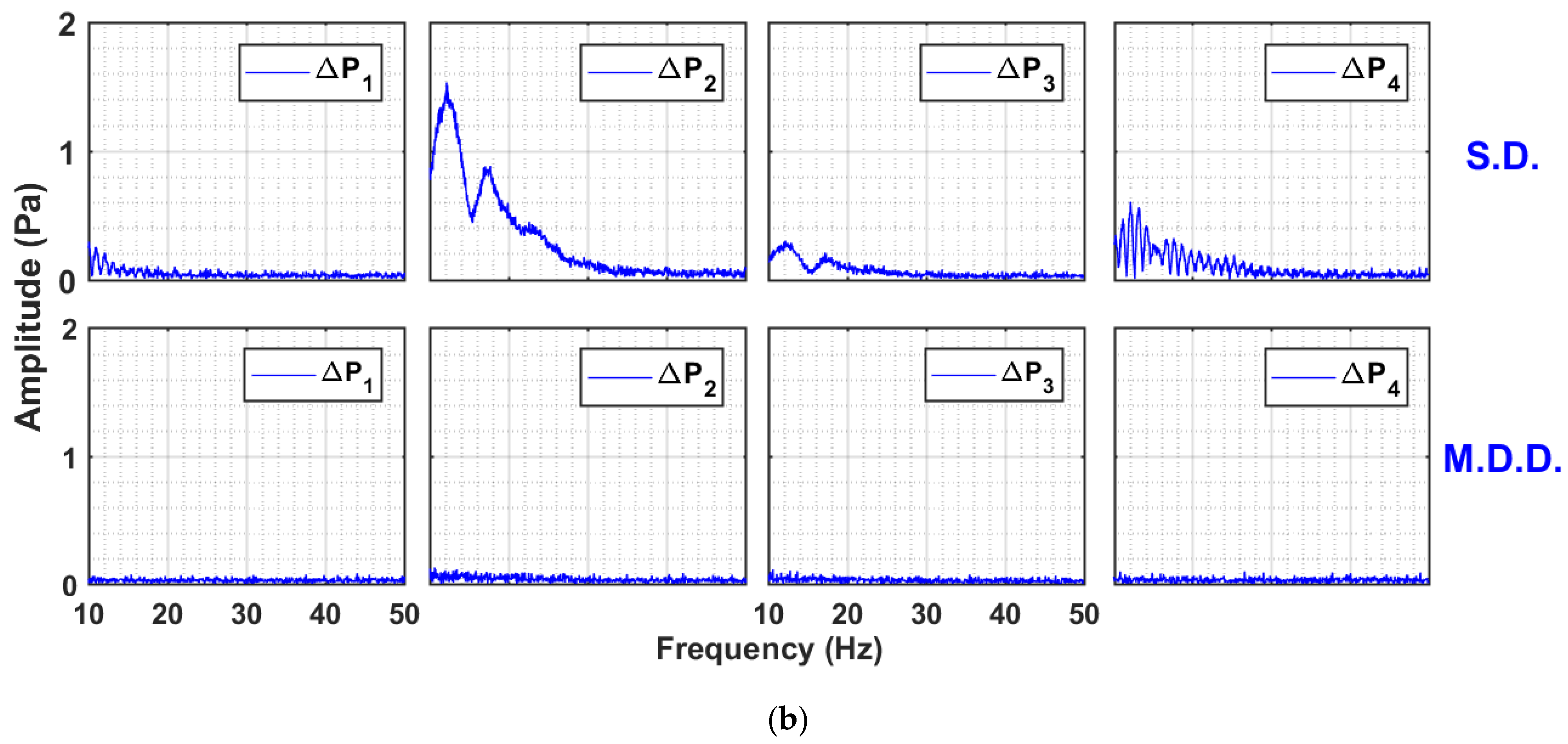

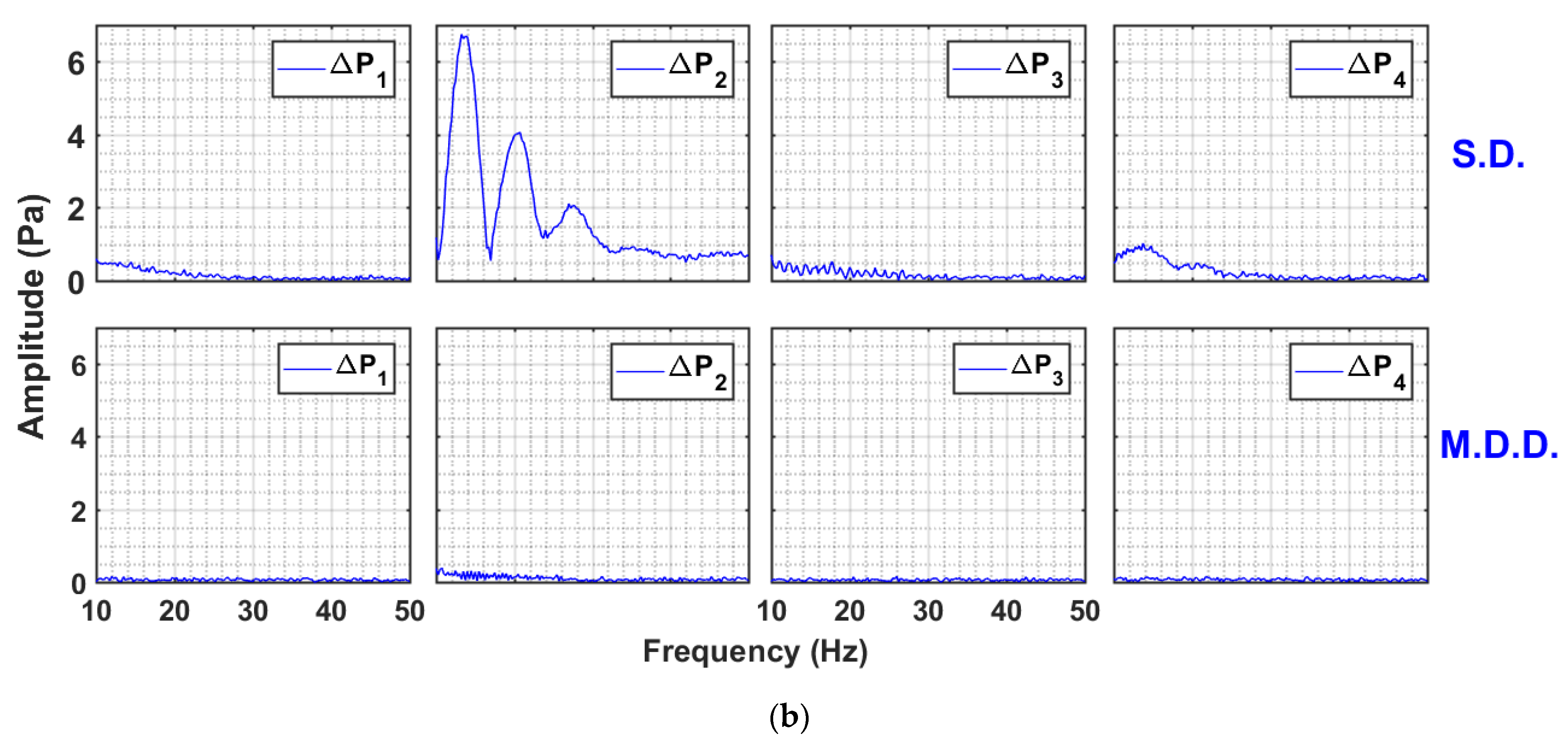

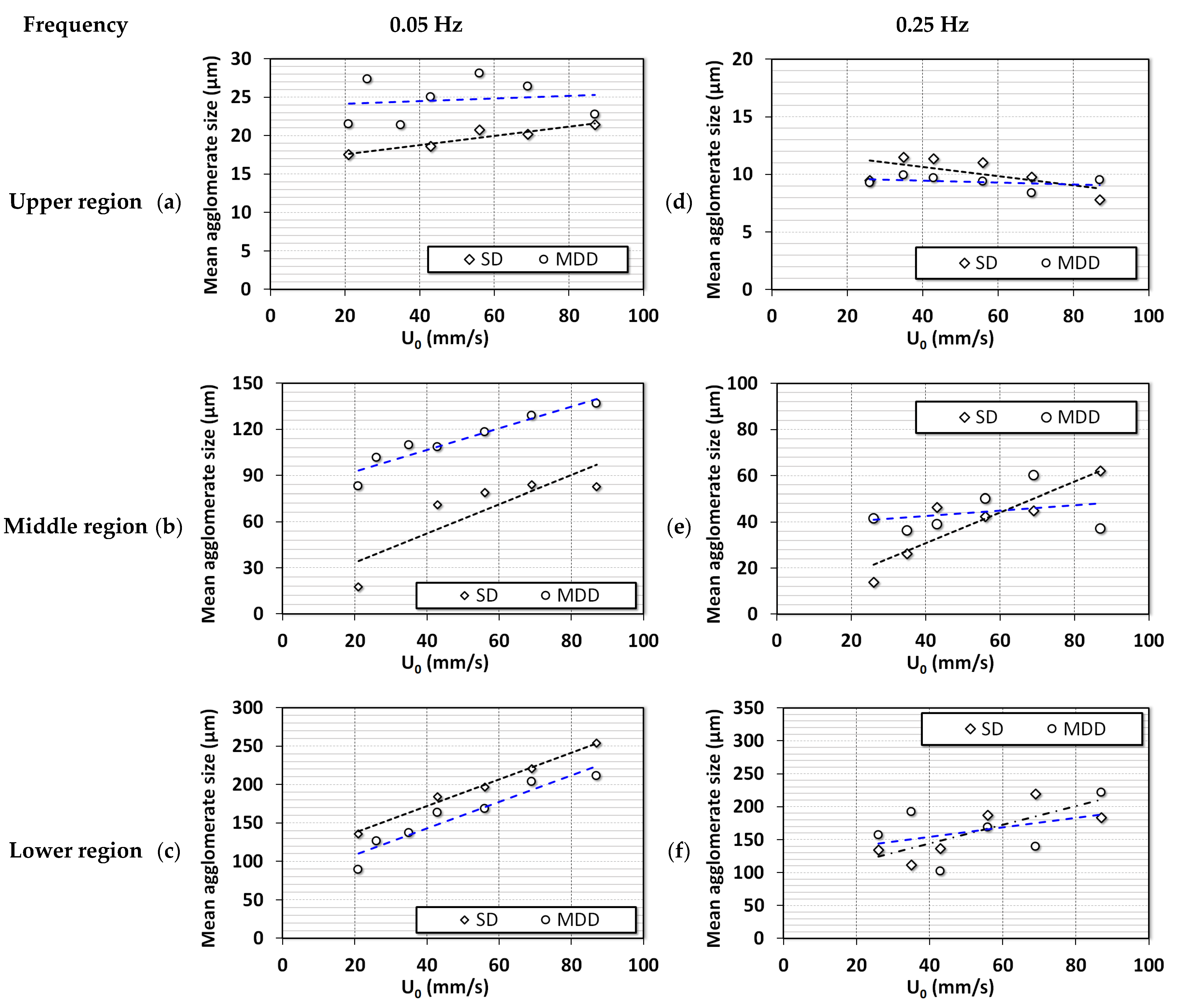

Evolution of Local Pressure Drop Transients

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ali, S.S.; Hossain, S.K.S.; Asif, M. Dynamics of partially collapsing pulsed fluidized bed. Can. J. Chem. Eng. 2021, 99, 2333–2344. [Google Scholar] [CrossRef]

- Lehmann, S.; Hartge, E.-U.; Jongsma, A.; Deleeuw, I.-M.; Innings, F.; Heinrich, S. Fluidization characteristics of cohesive powders in vibrated fluidized bed drying at low vibration frequencies. Powder Technol. 2019, 357, 54–63. [Google Scholar] [CrossRef]

- Bakhurji, A.; Bi, X.; Grace, J.R. Hydrodynamics and solids mixing in fluidized beds with inclined-hole distributors. Particuology 2019, 43, 19–28. [Google Scholar] [CrossRef]

- Raganati, F.; Chirone, R.; Ammendola, P. Gas–solid fluidization of cohesive powders. Chem. Eng. Res. Des. 2018, 133, 347–387. [Google Scholar] [CrossRef]

- Fedorov, A.V.; Yazykov, N.A.; Bulavchenko, O.A.; Saraev, A.A.; Kaichev, V.V.; Yakovlev, V. CuFeAl Nanocomposite Catalysts for Coal Combustion in Fluidized Bed. Nanomaterials 2020, 10, 1002. [Google Scholar] [CrossRef] [PubMed]

- Geldart, D. Types of gas fluidization. Powder Technol. 1973, 7, 285–292. [Google Scholar] [CrossRef]

- Lettieri, P.; Macrì, D. Effect of Process Conditions on Fluidization. KONA Powder Part. J. 2016, 33, 86–108. [Google Scholar] [CrossRef]

- Asif, M.; Ali, S.S. Bed collapse dynamics of fluidized beds of nano-powder. Adv. Powder Technol. 2013, 24, 939–946. [Google Scholar] [CrossRef]

- Ali, S.S.; Arsad, A.; Roberts, K.; Asif, M. Effect of Voidage on the Collapsing Bed Dynamics of Fine Particles: A Detailed Region-Wise Study. Nanomaterials 2022, 12, 2019. [Google Scholar] [CrossRef]

- van Ommen, J.R.; Valverde, J.; Pfeffer, R. Fluidization of nanopowders: A review. J. Nanoparticle Res. 2012, 14, 737. [Google Scholar] [CrossRef]

- Shabanian, J.; Jafari, R.; Chaouki, J. Fluidization of Ultrafine Powders. Int. Rev. Chem. Eng. 2012, 4, 16–50. [Google Scholar]

- Shabanian, J.; Chaouki, J. Influence of interparticle forces on solids motion in a bubbling gas-solid fluidized bed. Powder Technol. 2016, 299 (Suppl. C), 98–106. [Google Scholar] [CrossRef]

- Asif, M.; Al-Ghurabi, E.H.; Ajbar, A.; Kumar, N.S. Hydrodynamics of Pulsed Fluidized Bed of Ultrafine Powder: Fully Collapsing Fluidized Bed. Processes 2020, 8, 807. [Google Scholar] [CrossRef]

- Ali, S.S.; Asif, M.; Ajbar, A. Bed collapse behavior of pulsed fluidized beds of nano-powder. Adv. Powder Technol. 2014, 25, 331–337. [Google Scholar] [CrossRef]

- Ali, S.S.; Asif, M. Effect of particle mixing on the hydrodynamics of fluidized bed of nanoparticles. Powder Technol. 2017, 310, 234–240. [Google Scholar] [CrossRef]

- Al-Ghurabi, E.H.; Shahabuddin, M.; Kumar, N.S.; Asif, M. Deagglomeration of Ultrafine Hydrophilic Nanopowder Using Low-Frequency Pulsed Fluidization. Nanomaterials 2020, 10, 388. [Google Scholar] [CrossRef]

- Tamadondar, M.R.; Zarghami, R.; Tahmasebpoor, M.; Mostoufi, N. Characterization of the bubbling fluidization of nanoparticles. Particuology 2014, 16, 75–83. [Google Scholar] [CrossRef]

- Ali, S.S.; Arsad, A.; Asif, M. Effect of modified inlet flow strategy on the segregation phenomenon in pulsed fluidized bed of ultrafine particles: A collapse bed study. Chem. Eng. Process. Process Intensif. 2021, 159, 108243. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, D.; Ma, J.; Chen, X. Fluidization of nanoparticle agglomerates assisted by combining vibration and stirring methods. Chem. Eng. J. 2020, 388, 124213. [Google Scholar] [CrossRef]

- Lee, J.-R.; Lee, K.S.; Park, Y.O.; Lee, K.Y. Fluidization characteristics of fine cohesive particles assisted by vertical vibration in a fluidized bed reactor. Chem. Eng. J. 2020, 380, 122454. [Google Scholar] [CrossRef]

- Ding, P.; Pacek, A. De-agglomeration of goethite nano-particles using ultrasonic comminution device. Powder Technol. 2008, 187, 1–10. [Google Scholar] [CrossRef]

- Ding, P.; Orwa, M.; Pacek, A. De-agglomeration of hydrophobic and hydrophilic silica nano-powders in a high shear mixer. Powder Technol. 2009, 195, 221–226. [Google Scholar] [CrossRef]

- Al-Ghurabi, E.H.; Ali, S.S.; Alfadul, S.M.; Shahabuddin, M.; Asif, M. Experimental investigation of fluidized bed dynamics under resonant frequency of sound waves. Adv. Powder Technol. 2019, 30, 2812–2822. [Google Scholar] [CrossRef]

- Ajbar, A.; Bakhbakhi, Y.; Ali, S.; Asif, M. Fluidization of nano-powders: Effect of sound vibration and pre-mixing with group A particles. Powder Technol. 2011, 206, 327–337. [Google Scholar] [CrossRef]

- Raganati, F.; Ammendolab, P.; Chirone, R. CO2 capture by adsorption on fine activated carbon in a sound assisted fluidized bed. Chem. Eng. Trans. 2015, 43, 1033–1038. [Google Scholar]

- Ali, S.S.; Arsad, A.; Hossain, S.S.; Asif, M. A Detailed Insight into Acoustic Attenuation in a Static Bed of Hydrophilic Nanosilica. Nanomaterials 2022, 12, 1509. [Google Scholar] [CrossRef]

- Lee, J.-R.; Lee, K.S.; Hasolli, N.; Park, Y.O.; Lee, K.Y.; Kim, Y.H. Fluidization and mixing behaviors of Geldart groups A, B and C particles assisted by vertical vibration in fluidized bed. Chem. Eng. Process. Process Intensif. 2020, 149, 107856. [Google Scholar] [CrossRef]

- Zhou, L.; Diao, R.; Zhou, T.; Wang, H.; Kage, H.; Mawatari, Y. Behavior of magnetic Fe3O4 nano-particles in magnetically assisted gas-fluidized beds. Adv. Powder Technol. 2011, 22, 427–432. [Google Scholar] [CrossRef]

- Emiola-Sadiq, T.; Wang, J.; Zhang, L.; Dalai, A. Mixing and segregation of binary mixtures of biomass and silica sand in a fluidized bed. Particuology 2021, 58, 58–73. [Google Scholar] [CrossRef]

- Ali, S.S.; Basu, A.; Alfadul, S.M.; Asif, M. Nanopowder Fluidization Using the Combined Assisted Fluidization Techniques of Particle Mixing and Flow Pulsation. Appl. Sci. 2019, 9, 572. [Google Scholar] [CrossRef]

- Ali, S.S.; Al-Ghurabi, E.H.; Ibrahim, A.A.; Asif, M. Effect of adding Geldart group A particles on the collapse of fluidized bed of hydrophilic nanoparticles. Powder Technol. 2018, 330, 50–57. [Google Scholar] [CrossRef]

- Ireland, E.; Pitt, K.; Smith, R. A review of pulsed flow fluidisation; the effects of intermittent gas flow on fluidised gas–solid bed behaviour. Powder Technol. 2016, 292, 108–121. [Google Scholar] [CrossRef]

- Ali, S.S.; Asif, M. Fluidization of nano-powders: Effect of flow pulsation. Powder Technol. 2012, 225, 86–92. [Google Scholar] [CrossRef]

- Sung, W.C.; Jung, H.S.; Bae, J.W.; Kim, J.Y.; Lee, D.H. Segregation phenomena of binary solids in a pulsed fluidized bed. Powder Technol. 2022, 410, 117881. [Google Scholar] [CrossRef]

- Akhavan, A.; van Ommen, J.R.; Nijenhuis, J.; Wang, X.S.; Coppens, M.-O.; Rhodes, M.J. Improved Drying in a Pulsation-Assisted Fluidized Bed. Ind. Eng. Chem. Res. 2009, 48, 302–309. [Google Scholar] [CrossRef]

- Jia, D.; Cathary, O.; Peng, J.; Bi, X.; Lim, C.J.; Sokhansanj, S.; Liu, Y.; Wang, R.; Tsutsumi, A. Fluidization and drying of biomass particles in a vibrating fluidized bed with pulsed gas flow. Fuel Process. Technol. 2015, 138, 471–482. [Google Scholar] [CrossRef]

- Dong, L.; Zhang, Y.; Zhao, Y.; Peng, L.; Zhou, E.; Cai, L.; Zhang, B.; Duan, C. Effect of active pulsing air flow on gas-vibro fluidized bed for fine coal separation. Adv. Powder Technol. 2016, 27, 2257–2264. [Google Scholar] [CrossRef]

- Saidi, M.; Tabrizi, H.B.; Chaichi, S.; Dehghani, M. Pulsating flow effect on the segregation of binary particles in a gas–solid fluidized bed. Powder Technol. 2014, 264, 570–576. [Google Scholar] [CrossRef]

- Liu, Y.; Ohara, H.; Tsutsumi, A. Pulsation-assisted fluidized bed for the fluidization of easily agglomerated particles with wide size distributions. Powder Technol. 2017, 316, 388–399. [Google Scholar] [CrossRef]

- Akhavan, A.; Rahman, F.; Wang, S.; Rhodes, M. Enhanced fluidization of nanoparticles with gas phase pulsation assistance. Powder Technol. 2015, 284, 521–529. [Google Scholar] [CrossRef]

- Ali, S.S.; Al-Ghurabi, E.H.; Ajbar, A.; Mohammed, Y.A.; Boumaza, M.; Asif, M. Effect of Frequency on Pulsed Fluidized Beds of Ultrafine Powders. J. Nanomater. 2016, 2016, 23. [Google Scholar] [CrossRef]

- Lorences, M.J.; Patience, G.S.; Dıíez, F.V.; Coca, J. Fines effects on collapsing fluidized beds. Powder Technol. 2003, 131, 234–240. [Google Scholar] [CrossRef]

- Cherntongchai, P.; Innan, T.; Brandani, S. Mathematical description of pressure drop profile for the 1-valve and 2-valve bed collapse experiment. Chem. Eng. Sci. 2011, 66, 973–981. [Google Scholar] [CrossRef]

- Cherntongchai, P.; Brandani, S. A model for the interpretation of the bed collapse experiment. Powder Technol. 2005, 151, 37–43. [Google Scholar] [CrossRef]

- Available online: https://www.l-i.co.uk/contentfiles/270.pdf (accessed on 10 December 2022).

- Nie, Y.; Liu, D. Dynamics of collapsing fluidized beds and its application in the simulation of pulsed fluidized beds. Powder Technol. 1998, 99, 132–139. [Google Scholar] [CrossRef]

| Pressure Drop | Bed Region | Pressure Tap Positions (from the Distributor) |

|---|---|---|

| Lower | 0.5–0.1 m | |

| Lower middle | 0.1–0.2 m | |

| Upper middle | 0.2–0.3 m | |

| Upper | 0.3 m–open | |

| Overall | 0.05 m–open |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, S.S.; Arsad, A.; Roberts, K.L.; Asif, M. Effect of Inlet Flow Strategies on the Dynamics of Pulsed Fluidized Bed of Nanopowder. Nanomaterials 2023, 13, 304. https://doi.org/10.3390/nano13020304

Ali SS, Arsad A, Roberts KL, Asif M. Effect of Inlet Flow Strategies on the Dynamics of Pulsed Fluidized Bed of Nanopowder. Nanomaterials. 2023; 13(2):304. https://doi.org/10.3390/nano13020304

Chicago/Turabian StyleAli, Syed Sadiq, Agus Arsad, Kenneth L. Roberts, and Mohammad Asif. 2023. "Effect of Inlet Flow Strategies on the Dynamics of Pulsed Fluidized Bed of Nanopowder" Nanomaterials 13, no. 2: 304. https://doi.org/10.3390/nano13020304

APA StyleAli, S. S., Arsad, A., Roberts, K. L., & Asif, M. (2023). Effect of Inlet Flow Strategies on the Dynamics of Pulsed Fluidized Bed of Nanopowder. Nanomaterials, 13(2), 304. https://doi.org/10.3390/nano13020304