UV-Nanoimprint and Deep Reactive Ion Etching of High Efficiency Silicon Metalenses: High Throughput at Low Cost with Excellent Resolution and Repeatability

Abstract

1. Introduction

2. Design

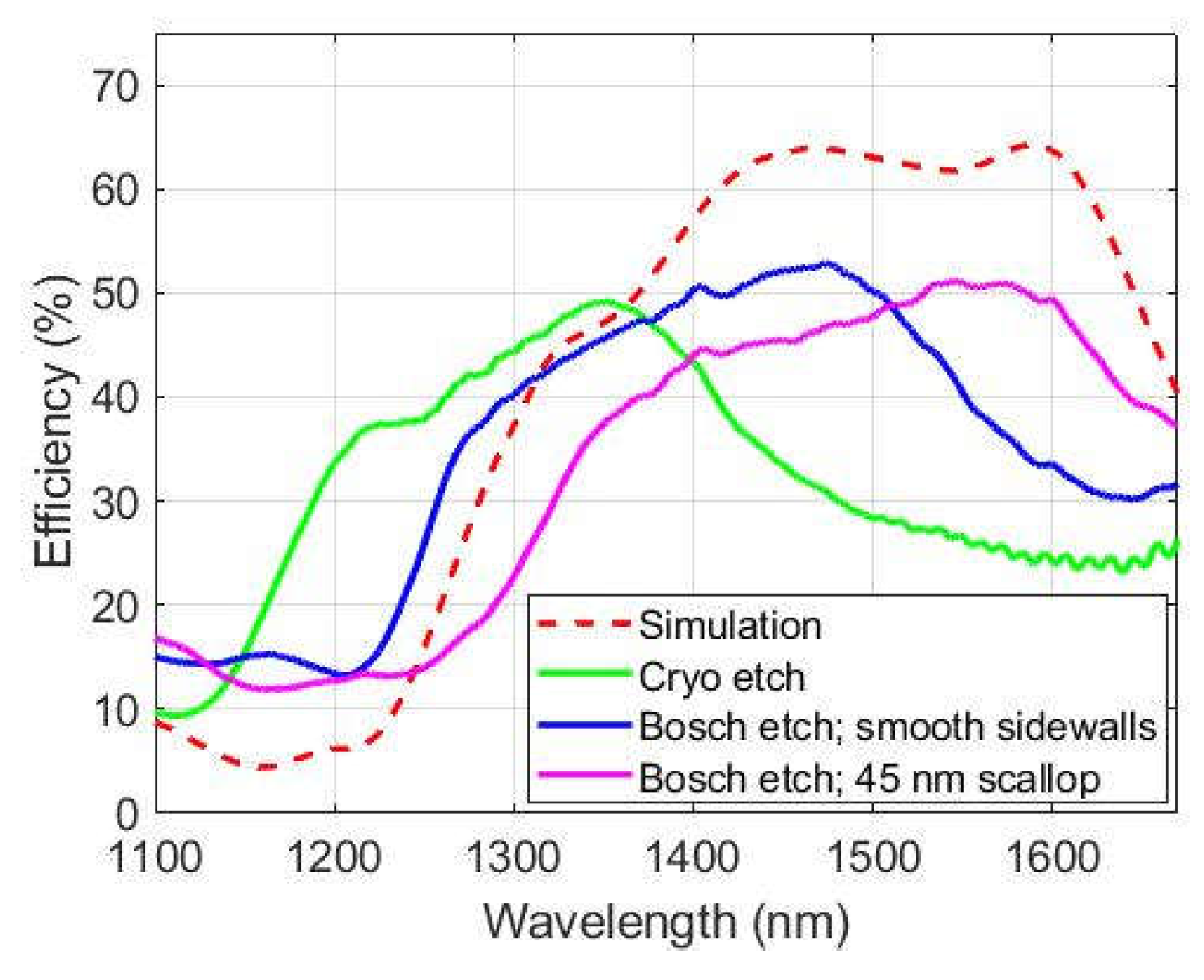

3. Metasurface Fabrication

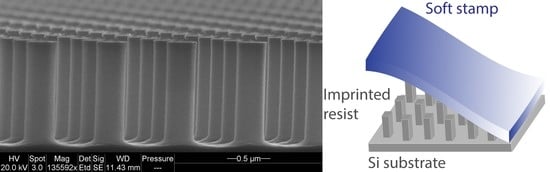

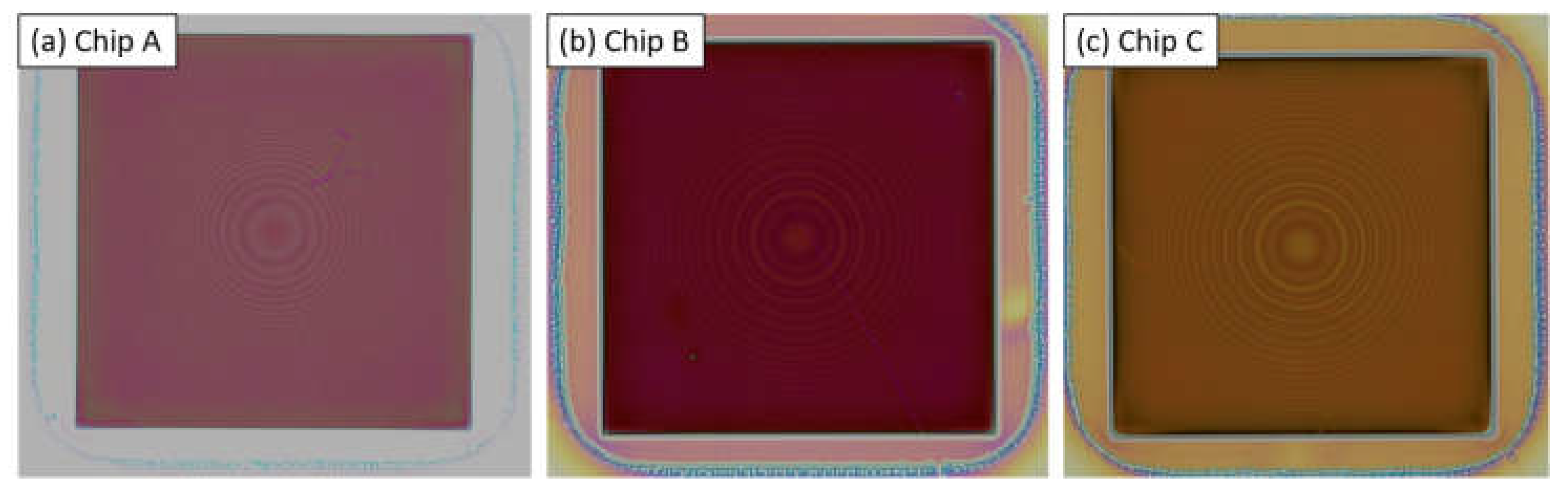

3.1. UV-Nanolithography

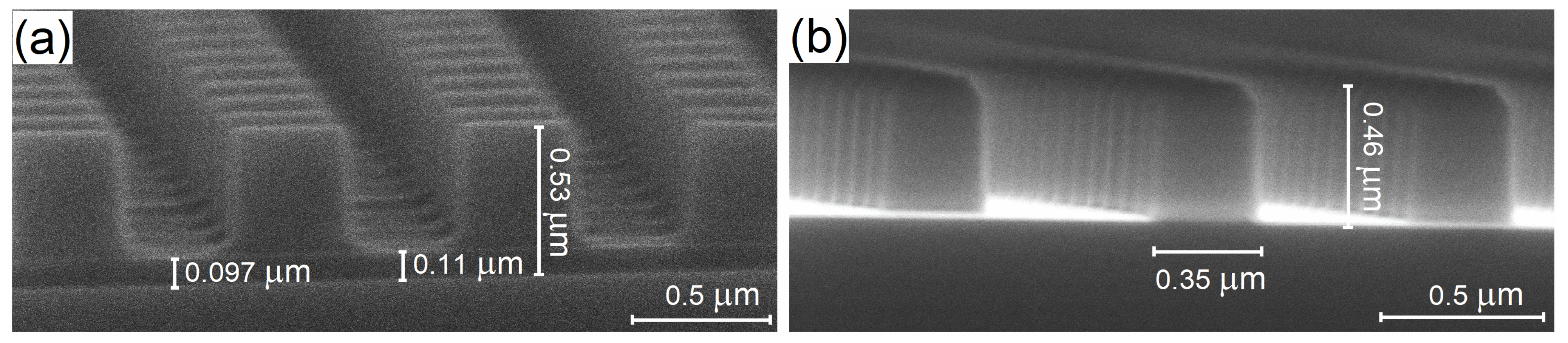

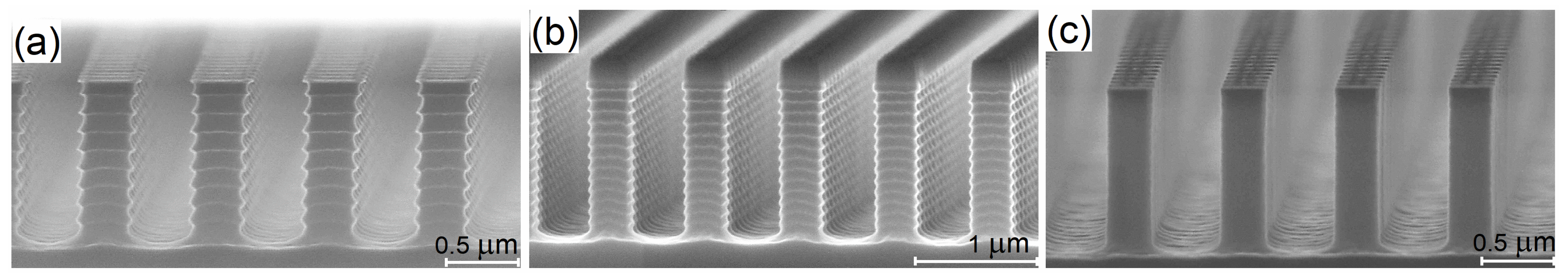

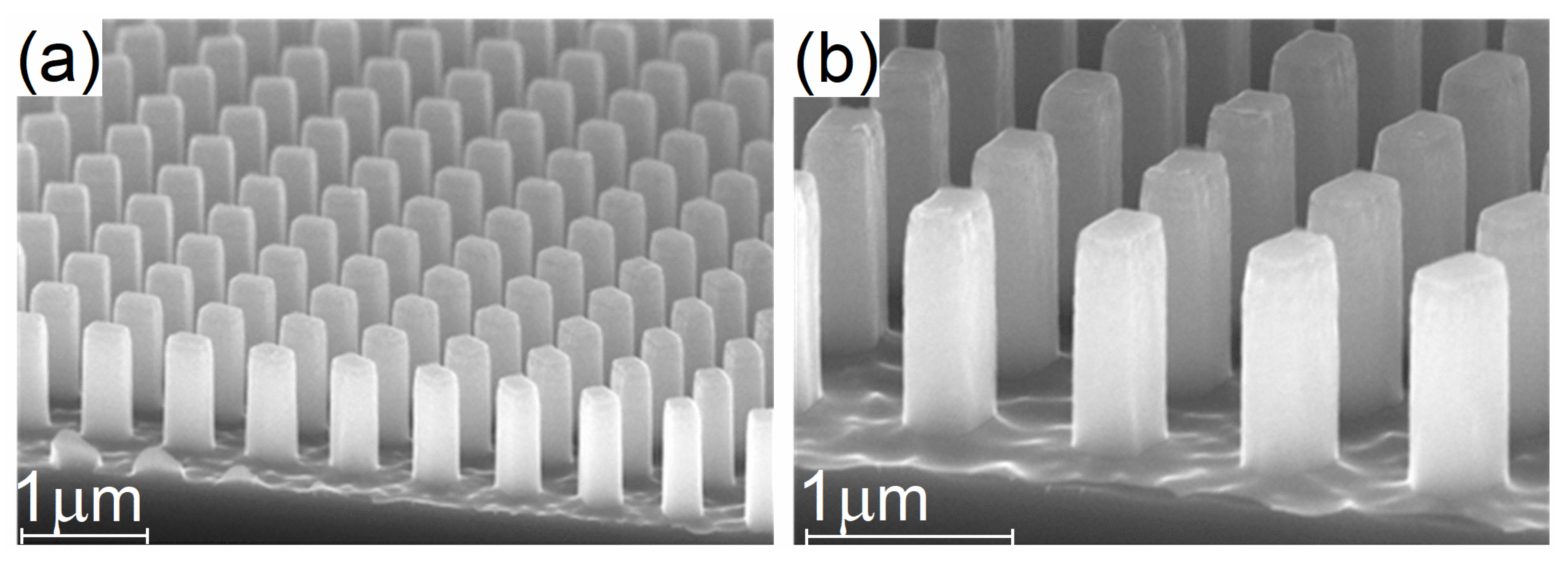

3.2. Deep Reactive Ion Etching

3.2.1. The Bosch Process

3.2.2. Cryogenic Deep Reactive Ion Etching

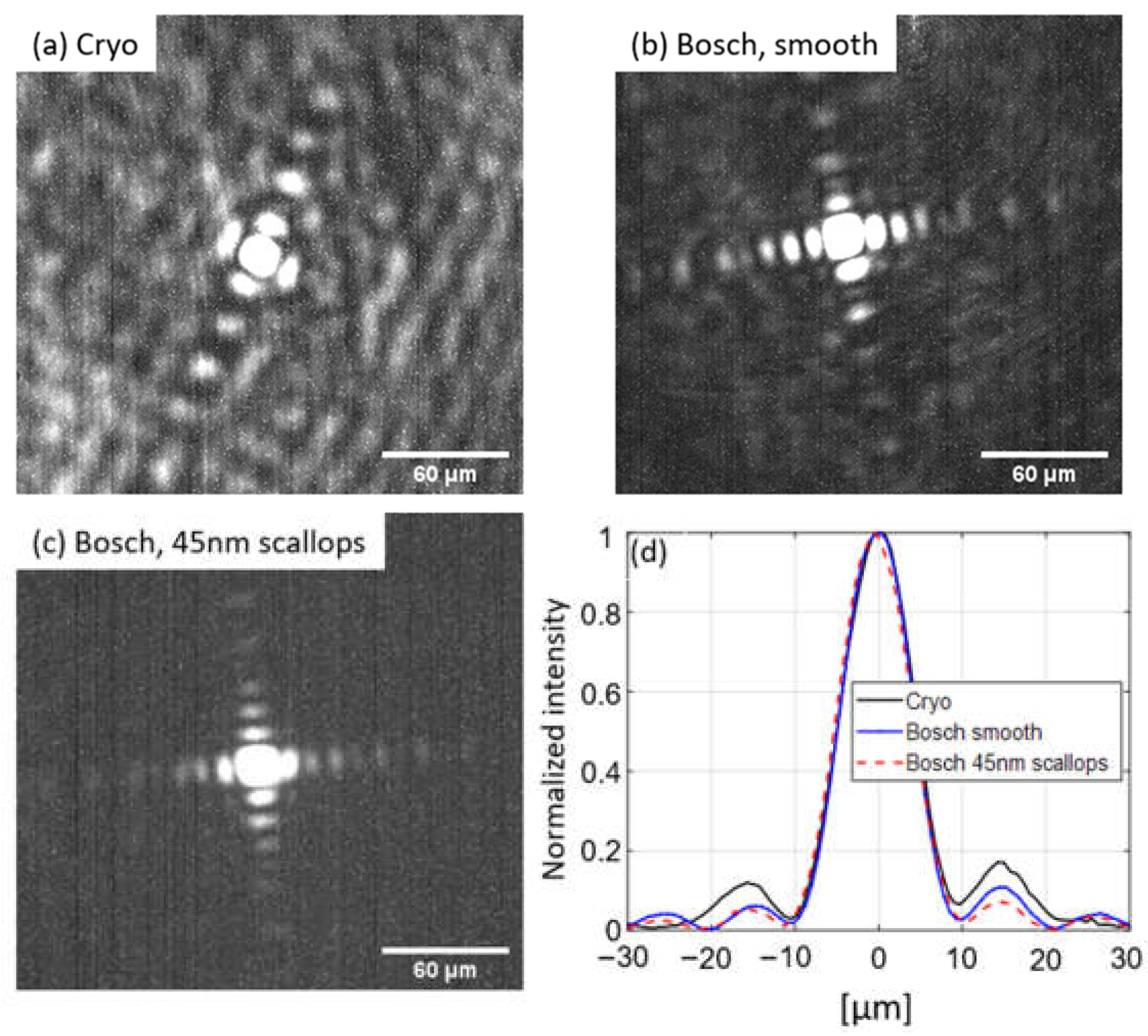

4. Optical Characterization

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tsilipakos, O.; Tasolamprou, A.; Pitilakis, A.; Liu, F.; Wang, X.; Mirmoosa, M.; Tzarouchis, D.; Abadal, S.; Taghvaee, H.; Liaskos, C.; et al. Toward Intelligent Metasurfaces: The Progress from Globally Tunable Metasurfaces to Software-Defined Metasurfaces with an Embedded Network of Controllers. Adv. Opt. Mater. 2020, 8, 2000783. [Google Scholar] [CrossRef]

- Yang, W.; Qu, G.; Lai, F.; Liu, Y.; Ji, Z.; Xu, Y.; Song, Q.; Han, J.; Xiao, S. Dynamic Bifunctional Metasurfaces for Holography and Color Display. Adv. Mater. 2021, 33, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Leitis, A.; Heßler, A.; Wahl, S.; Wuttig, M.; Taubner, T.; Tittl, A.; Altug, H. All-Dielectric Programmable Huygens’ Metasurfaces. Adv. Funct. Mater. 2020, 30, 1910259. [Google Scholar] [CrossRef]

- Pu, M.; Guo, Y.; Ma, X.; Li, X.; Luo, X. Methodologies for On-Demand Dispersion Engineering of Waves in Metasurfaces. Adv. Opt. Mater. 2019, 7, 1–14. [Google Scholar] [CrossRef]

- Bohn, B.J.; Schnell, M.; Kats, M.; Aieta, F.; Hillenbrand, R.; Capasso, F. Near-Field Imaging of Phased Array Metasurfaces. Nano Lett. 2015, 15, 3851–3858. [Google Scholar] [CrossRef]

- Zhao, R.; Huang, L.; Tang, C.; Li, J.; Li, X.; Wang, Y.; Zentgraf, T. Nanoscale Polarization Manipulation and Encryption Based on Dielectric Metasurfaces. Adv. Opt. Mater. 2018, 6, 1–8. [Google Scholar] [CrossRef]

- Wu, Z.; Zheng, Y. Metamaterials and Metasurfaces. Adv. Opt. Mater. 2018, 6, 1–14. [Google Scholar] [CrossRef]

- Zou, C.; Amaya, C.; Fasold, S.; Muravsky, A.; Murauski, A.; Pertsch, T.; Staude, I. Multiresponsive Dielectric Metasurfaces. ACS Photonics 2021, 8, 1775–1783. [Google Scholar] [CrossRef]

- Rubin, N.A.; Chevalier, P.; Juhl, M.; Tamagnone, M.; Chipman, R.; Capasso, F. Imaging polarimetry through metasurface polarization gratings. Opt. Express 2022, 30, 9389. [Google Scholar] [CrossRef]

- Liu, W.; Cheng, H.; Tian, J.; Chen, S. Diffractive metalens: From fundamentals, practical applications to current trends. Adv. Phys. X 2020, 5, 1742584. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, Y.; Qi, D.; Yu, W.; Zheng, H. Progress in the design, nanofabrication, and performance of metalenses. J. Opt. 2022, 24, 033001. [Google Scholar] [CrossRef]

- Yu, N.; Capasso, F. Flat optics with designer metasurfaces. Nat. Mater. 2014, 13, 139–150. [Google Scholar] [CrossRef]

- Sun, T.; Hu, J.; Zhu, X.; Xu, F.; Wang, C. Broadband Single-Chip Full Stokes Polarization-Spectral Imaging Based on All-Dielectric Spatial Multiplexing Metalens. Laser Photon. Rev. 2022, 16, 2100650. [Google Scholar] [CrossRef]

- Ding, F.; Pors, A.; Bozhevolnyi, S.I. Gradient metasurfaces: A review of fundamentals and applications. Reports Prog. Phys. 2018, 81, 026401. [Google Scholar] [CrossRef]

- Search on Clarivate Web of Science for Articles with Topic “Metasurfaces”. Available online: https://www.webofscience.com/wos/woscc/summary/739488a3-5a75-4bfd-afd1-1fe6a897ce50-5871a3d3/relevance/1. (accessed on 12 December 2022).

- Yun, S.; Roh, S.; Lee, S.; Park, H.; Lim, M.; Ahn, S.; Choo, H. Highly Efficient Color Separation and Focusing in the Sub-micron CMOS Image Sensor. In 2021 IEEE International Electron Devices Meeting (IEDM); IEEE: San Francisco, CA, USA, 2021; pp. 30.1.1–30.1.4. [Google Scholar] [CrossRef]

- Fretty, P. Opt. Laser Focus World. 2022. Available online: https://www.laserfocusworld.com/optics/article/14277991/worlds-first-metasurface-for-consumer-electronics-makes-commercial-debut. (accessed on 15 June 2022).

- Xu, H.-X.; Tang, S.; Cai, T.; Sun, S.; He, Q.; Zhou, L. Multifunctional Metasurfaces: Design Principles and Device Realizations (Synthesis Lectures on Materials and Optics); Morgan & Claypool: San Rafael, California, USA, 2021; Volume 2, pp. 1–184. ISBN 978-3-031-02390-3. [Google Scholar]

- Hong, Y.H.; Hsu, W.; Tsai, W.; Huang, Y.; Chen, S.; Kuo, H.C. Ultracompact Nanophotonics: Light Emission and Manipulation with Metasurfaces. Nanoscale Res. Lett. 2022, 17, 41. [Google Scholar] [CrossRef]

- Wen, D.; Meng, J.; Cadusch, J.; Crozier, K.B. VCSELs with On-Facet Metasurfaces for Polarization State Generation and Detection. Adv. Opt. Mater. 2021, 9, 1–9. [Google Scholar] [CrossRef]

- Li, N.; Xu, Z.; Dong, Y.; Hu, T.; Zhong, Q.; Fu, Y.; Zhu, S.; Singh, N. Large-area metasurface on CMOS-compatible fabrication platform: Driving flat optics from lab to fab. Nanophotonics 2020, 9, 3071–3087. [Google Scholar] [CrossRef]

- Park, J.S.; Zhang, S.; She, A.; Chen, W.; Lin, P.; Yousef, K.; Cheng, J.; Capasso, F. All-Glass, Large Metalens at Visible Wavelength Using Deep-Ultraviolet Projection Lithography. Nano Lett. 2019, 19, 8673–8682. [Google Scholar] [CrossRef]

- Keil, M.; Wetzel, A.; Wu, K.; Khomtchenko, E.; Urbankova, J.; Boisen, A.; Rindzevicius, T.; Bunea, A.; Taboryski, R.J. Large plasmonic color metasurfaces fabricated by super resolution deep UV lithography. Nanoscale Adv. 2021, 3, 2236–2244. [Google Scholar] [CrossRef]

- Leitis, A.; Tseng, M.; John-Herpin, A.; Kivshar, Y.; Altug, H. Wafer-Scale Functional Metasurfaces for Mid-Infrared Photonics and Biosensing. Adv. Mater. 2021, 33, 2102232. [Google Scholar] [CrossRef]

- Thanner, C.; Dudus, A.; Treiblmayr, D.; Berger, G.; Chouiki, M.; Martens, S.; Jurisch, M.; Hartbaum, J.; Eibelhuber, M. Optical Architectures for Displays and Sensing in Augmented, Virtual, and Mixed Reality (AR, VR, MR). Proc. SPIE 2020, 11310, 290–295. [Google Scholar] [CrossRef]

- Mohamed, K.; Alkaisi, M.; Blaikie, R.J. A three-dimensional ultraviolet curable nanoimprint lithography (3D UV-NIL). AIP Conf. Proc. 2009, 1151, 114–117. [Google Scholar] [CrossRef]

- Senn, T.; Esquivel, J.; Sabaté, N.; Löchel, B. Fabrication of high aspect ratio nanostructures on 3D surfaces. Microelectron. Eng. 2011, 88, 3043–3048. [Google Scholar] [CrossRef]

- Taniguchi, J.; Kamiya, Y.; Unno, N. Fabrication of anti-reflection structure using photo-curable polymer. Photopolym. Sci. Technol. 2011, 24, 105–110. [Google Scholar] [CrossRef]

- Dirdal, C.A.; Jensen, G.; Angelskår, H.; Thrane, P.V.; Gjessing, J.; Ordnung, D.A. Towards high-throughput large-area metalens fabrication using UV-nanoimprint lithography and Bosch deep reactive ion etching. Opt. Express 2020, 28, 15542. [Google Scholar] [CrossRef]

- Baracu, A.M.; Dirdal, C.; Avram, A.; Dinescu, A.; Muller, R.; Jensen, G.; Thrane, P.; Angelskår, H. Metasurface Fabrication by Cryogenic and Bosch Deep Reactive Ion Etching. Micromachines 2021, 12, 501. [Google Scholar] [CrossRef]

- Cardoso, G.; Hamouda, F.; Dagens, B. Improved PDMS mold fabrication by direct etch with nanosphere self-assembly mask for Soft UV-NIL subwavelength metasurfaces fabrication. Microelectron. Eng. 2022, 258, 111755. [Google Scholar] [CrossRef]

- Brière, G.; Ni, P.; Héron, S.; Chenot, S.; Vézian, S.; Brändli, V.; Damilano, B.; Duboz, J.; Iwanaga, M.; Genevet, P. Etching-Free Approach Toward Large-Scale Light-Emitting Metasurfaces. Adv. Opt. Mater. 2019, 7, 1801271. [Google Scholar] [CrossRef]

- Nagal, V.; Li, T.; Khurgin, J.; Gracias, D.H. Large-Area Arrays of Quasi-3D Au Nanostructures for Polarization-Selective Mid-Infrared Metasurfaces. ACS Appl. Nano Mater. 2020, 3, 7029–7039. [Google Scholar] [CrossRef]

- Yoon, G.; Kim, K.; Kim, S.; Han, S.; Lee, H.; Rho, J. Printable Nanocomposite Metalens for High-Contrast Near-Infrared Imaging. ACS Nano 2021, 15, 698–706. [Google Scholar] [CrossRef]

- Einck, V.J.; Torfeh, M.; McClung, A.; Jung, D.; Mansouree, M.; Arbabi, A.; Watkins, J.J. Scalable Nanoimprint Lithography Process for Manufacturing Visible Metasurfaces Composed of High Aspect Ratio TiO2 Meta-Atoms. ACS Photonics 2021, 8, 2400–2409. [Google Scholar] [CrossRef]

- Masanobu, I.; Bongseok, C.; Hideki, M.; Yoshimasa, S.; Kazuaki, S.J. Large-Area Resonance-Tuned Metasurfaces for On-Demand Enhanced Spectroscopy. J. Nanomater. 2015, 507656. [Google Scholar] [CrossRef]

- Lee, G.Y.; Hong, J.; Hwang, S.; Moon, S.; Kang, H.; Jeon, S.; Kim, H.; Jeong, J.; Lee, B. Metasurface eyepiece for augmented reality. Nat. Commun. Nat. Commun. 2018, 9, 1–10. [Google Scholar] [CrossRef]

- Baracu, A.M.; Avram, M.; Breazu, C.; Bunea, M.; Socol, M.; Stanculescu, A.; Matei, E.; Thrane, P.; Dirdal, C.; Dinescu, A.; et al. Silicon metalens fabrication from electron beam to uv-nanoimprint lithography. Nanomaterials 2021, 11, 1–17. [Google Scholar] [CrossRef]

- Wang, S.; Wu, P.; Su, V.; Lai, Y.; Chu, C.H.; Chen, J.; Lu, S.; Chen, J.; Xu, B.; Kuan, C.; et al. Broadband achromatic optical metasurface devices. Nat. Commun. 2017, 8, 1–9. [Google Scholar] [CrossRef]

- Kang, M.; Feng, T.; Wang, H.-T.; Li, J. Wave front engineering from an array of thin aperture antennas. Opt. Express 2012, 20, 15882. [Google Scholar] [CrossRef]

- Chen, W.T.; Zhu, A.; Sisler, J.; Bharwani, Z.; Capasso, F. A broadband achromatic polarization-insensitive metalens consisting of anisotropic nanostructures. Nat. Commun. 2019, 10, 1–7. [Google Scholar] [CrossRef]

- Khorasaninejad, M.; Chen, W.; Devlin, R.; Oh, J.; Zhu, A.; Capasso, F. Metalenses at visible wavelengths: Diffraction-limited focusing and subwavelength resolution imaging. Science 2016, 352, 1190–1194. [Google Scholar] [CrossRef]

- She, A.; Zhang, S.; Shian, S.; Clarke, D.R.; Capasso, F. Large area metalenses: Design, characterization, and mass manufacturing. Opt. Express 2018, 26, 1573. [Google Scholar] [CrossRef]

| Chip | Pillar Width (nm) | Pillar Length (nm) |

|---|---|---|

| Chip A | 351 | 475 |

| Chip B | 292 | 416 |

| Chip C | 237 | 361 |

| Process Pressure (mTorr) | 5 |

|---|---|

| ICP Source Power (W) | 1500 |

| Platen Power (W) | 30 |

| Ar gas flow (sccm) | 100 |

| Substrate holder temperature (°C) | 10 |

| He backside pressure (Torr) | 10 |

| Process time (s) | Variable (150–300 s) |

| Scallop Sizes (nm) | 45 | 25 | 10 | ||||||

| Total Etch Cycles | 9 | 14 | 35 | ||||||

| Process Parameter | Step in Bosch Process | Step in Bosch Process | Step in Bosch Process | ||||||

| Passivation | Depassivation | Si etch | Passivation | Depassivation | Si etch | Passivation | Depassivation | Si etch | |

| Process time (s) | 1.5 | 1.0 | 1.8 | 1.5 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Process Pressure (mTorr) | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| ICP Source Power (W) | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 1500 | 1500 | 1500 |

| Platen Low Frequency RF Power (W) | 0 | 130 | 30 | 0 | 130 | 30 | 0 | 50 | 25 |

| Platen Power Duty Cycle (%) | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| C4F8 gas flow (sccm) | 300 | 0 | 0 | 300 | 0 | 0 | 100 | 0 | 0 |

| SF6 gas flow (sccm) | 0 | 300 | 300 | 0 | 300 | 300 | 0 | 100 | 100 |

| Substrate holder Temp. (°C) | 10 | 10 | 10 | ||||||

| Process Pressure (mTorr) | 7.5 |

|---|---|

| RF Power (W) | 200 |

| Ar flow (sccm) | 20 |

| Substrate holder temperature (°C) | 15 |

| Process time (s) | 60 |

| Process Parameter | Step in Cryogenic Process | |

|---|---|---|

| Ignition | Process | |

| Process Pressure (mTorr) | 7.5 | 7.5 |

| ICP Source Power (W) | 1000 | 1000 |

| RF Power (W) | 3 | 5 |

| SF6 gas flow (sccm) | 0 | 60 |

| O2 flow (sccm) | 10 | 8 |

| Ar flow (sccm) | 10 | 0 |

| Substrate holder temp. (°C) | 0 | −115 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dirdal, C.A.; Milenko, K.; Summanwar, A.; Dullo, F.T.; Thrane, P.C.V.; Rasoga, O.; Avram, A.M.; Dinescu, A.; Baracu, A.M. UV-Nanoimprint and Deep Reactive Ion Etching of High Efficiency Silicon Metalenses: High Throughput at Low Cost with Excellent Resolution and Repeatability. Nanomaterials 2023, 13, 436. https://doi.org/10.3390/nano13030436

Dirdal CA, Milenko K, Summanwar A, Dullo FT, Thrane PCV, Rasoga O, Avram AM, Dinescu A, Baracu AM. UV-Nanoimprint and Deep Reactive Ion Etching of High Efficiency Silicon Metalenses: High Throughput at Low Cost with Excellent Resolution and Repeatability. Nanomaterials. 2023; 13(3):436. https://doi.org/10.3390/nano13030436

Chicago/Turabian StyleDirdal, Christopher A., Karolina Milenko, Anand Summanwar, Firehun T. Dullo, Paul C. V. Thrane, Oana Rasoga, Andrei M. Avram, Adrian Dinescu, and Angela M. Baracu. 2023. "UV-Nanoimprint and Deep Reactive Ion Etching of High Efficiency Silicon Metalenses: High Throughput at Low Cost with Excellent Resolution and Repeatability" Nanomaterials 13, no. 3: 436. https://doi.org/10.3390/nano13030436

APA StyleDirdal, C. A., Milenko, K., Summanwar, A., Dullo, F. T., Thrane, P. C. V., Rasoga, O., Avram, A. M., Dinescu, A., & Baracu, A. M. (2023). UV-Nanoimprint and Deep Reactive Ion Etching of High Efficiency Silicon Metalenses: High Throughput at Low Cost with Excellent Resolution and Repeatability. Nanomaterials, 13(3), 436. https://doi.org/10.3390/nano13030436