A Core-Shell MWCNT-Pt Nanowire Electron Source with Anomalously Long-Term Stable Field Emission

Abstract

:1. Introduction

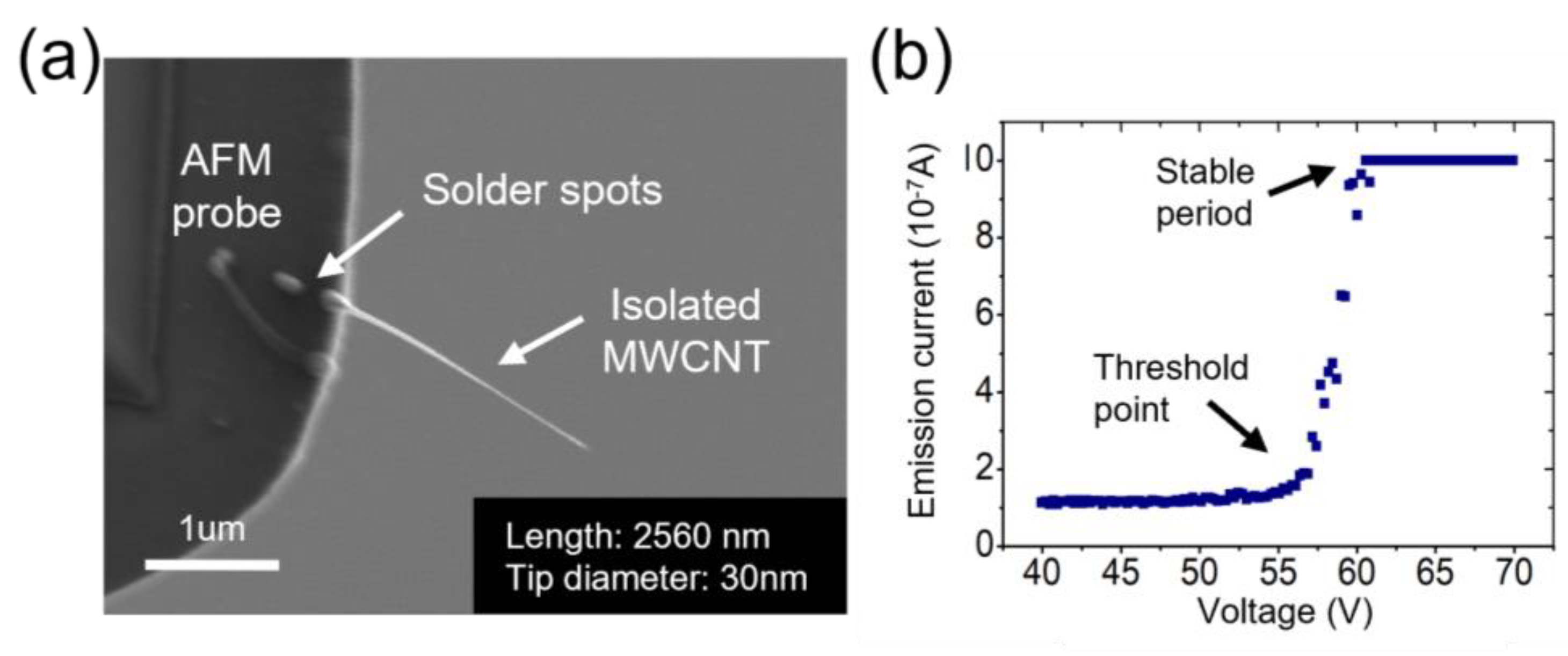

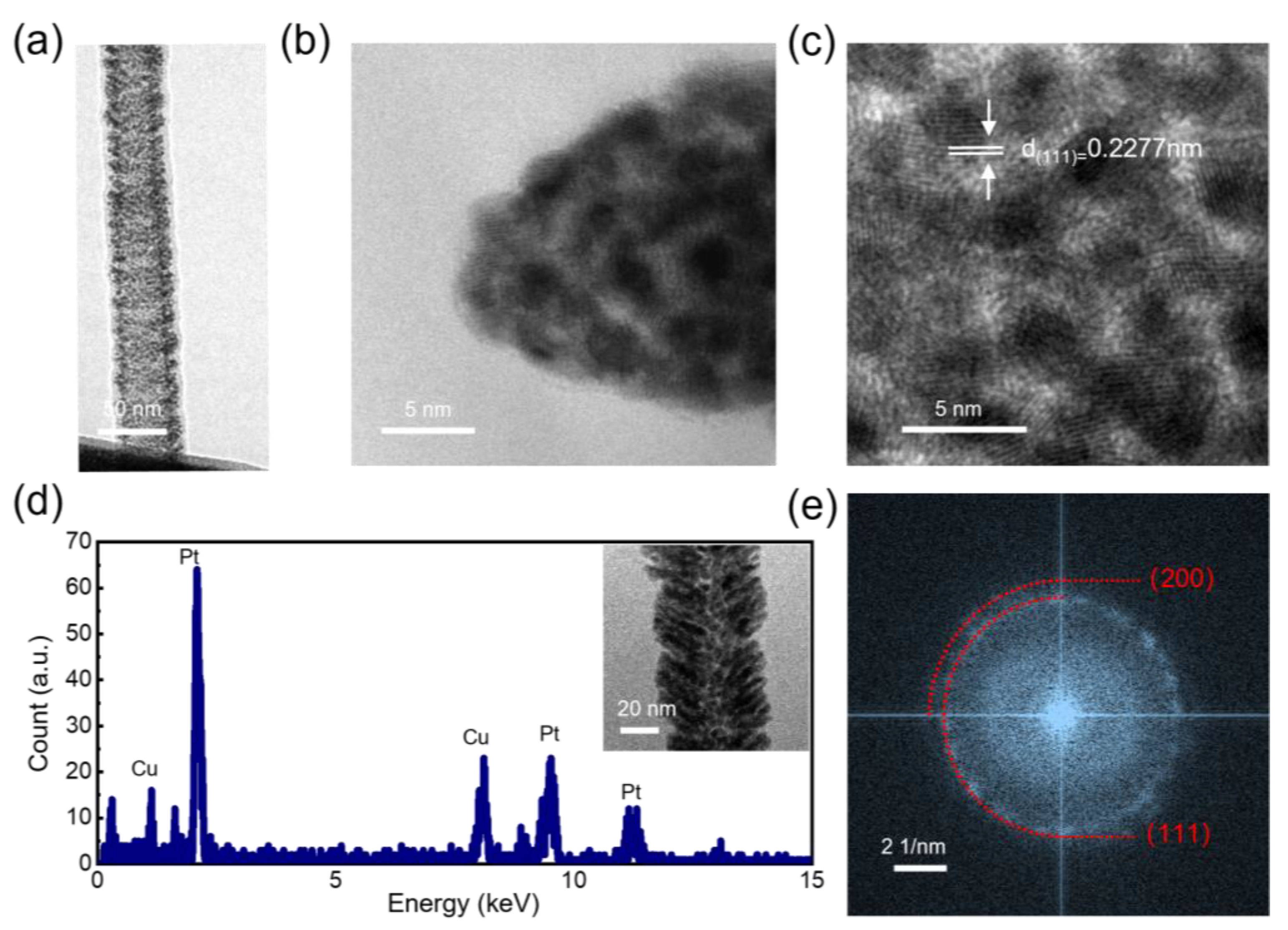

2. Materials and Methods

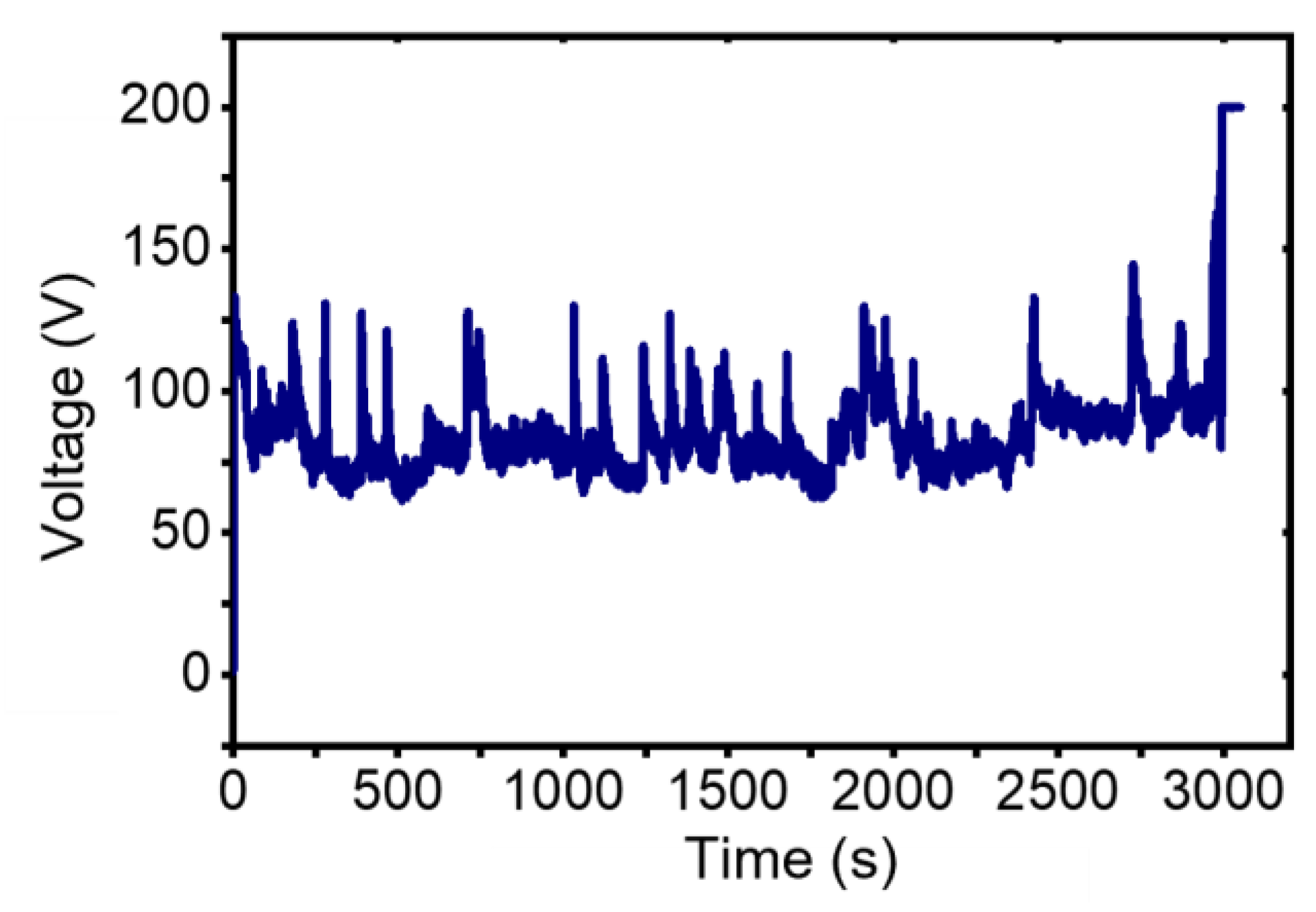

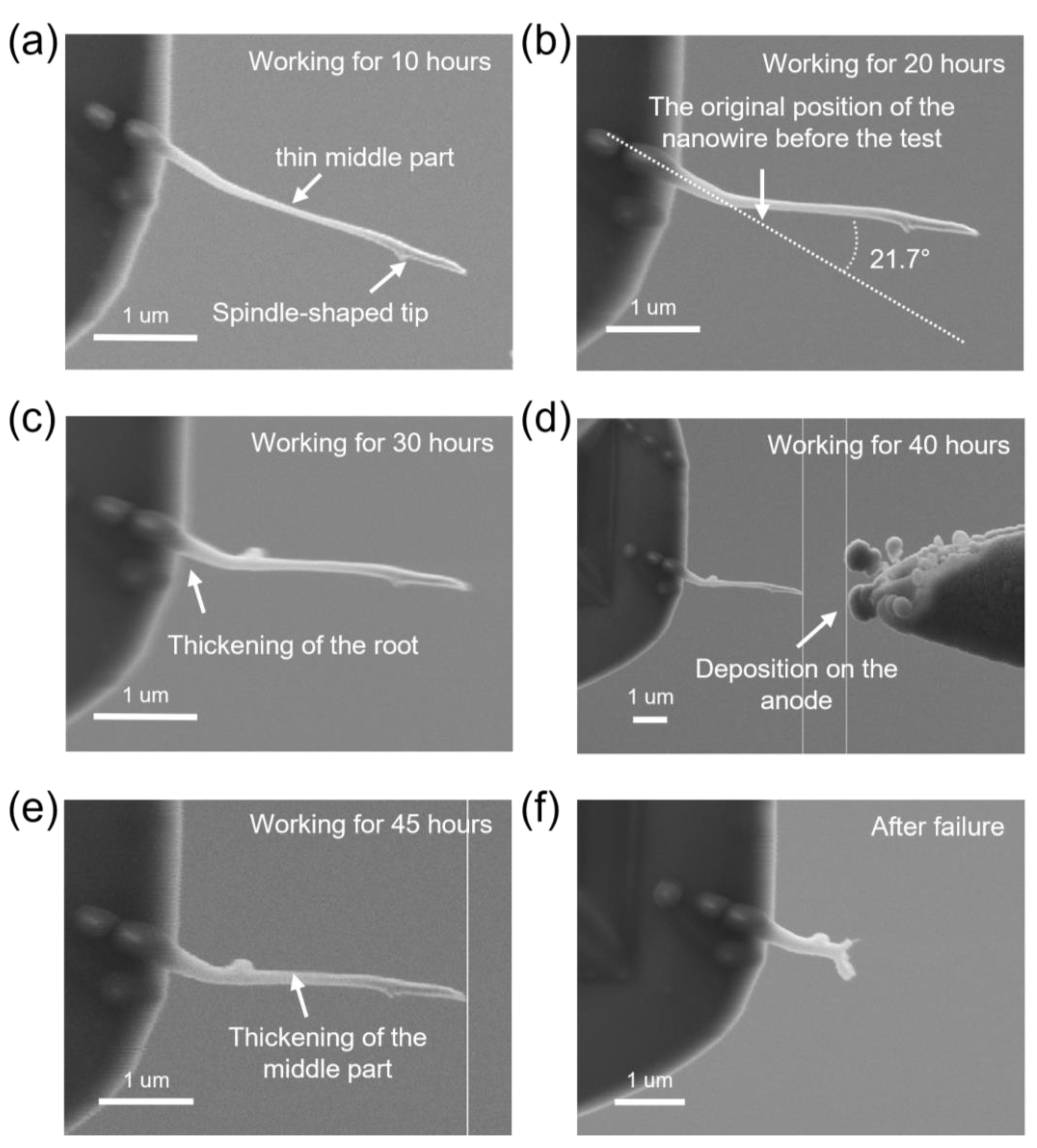

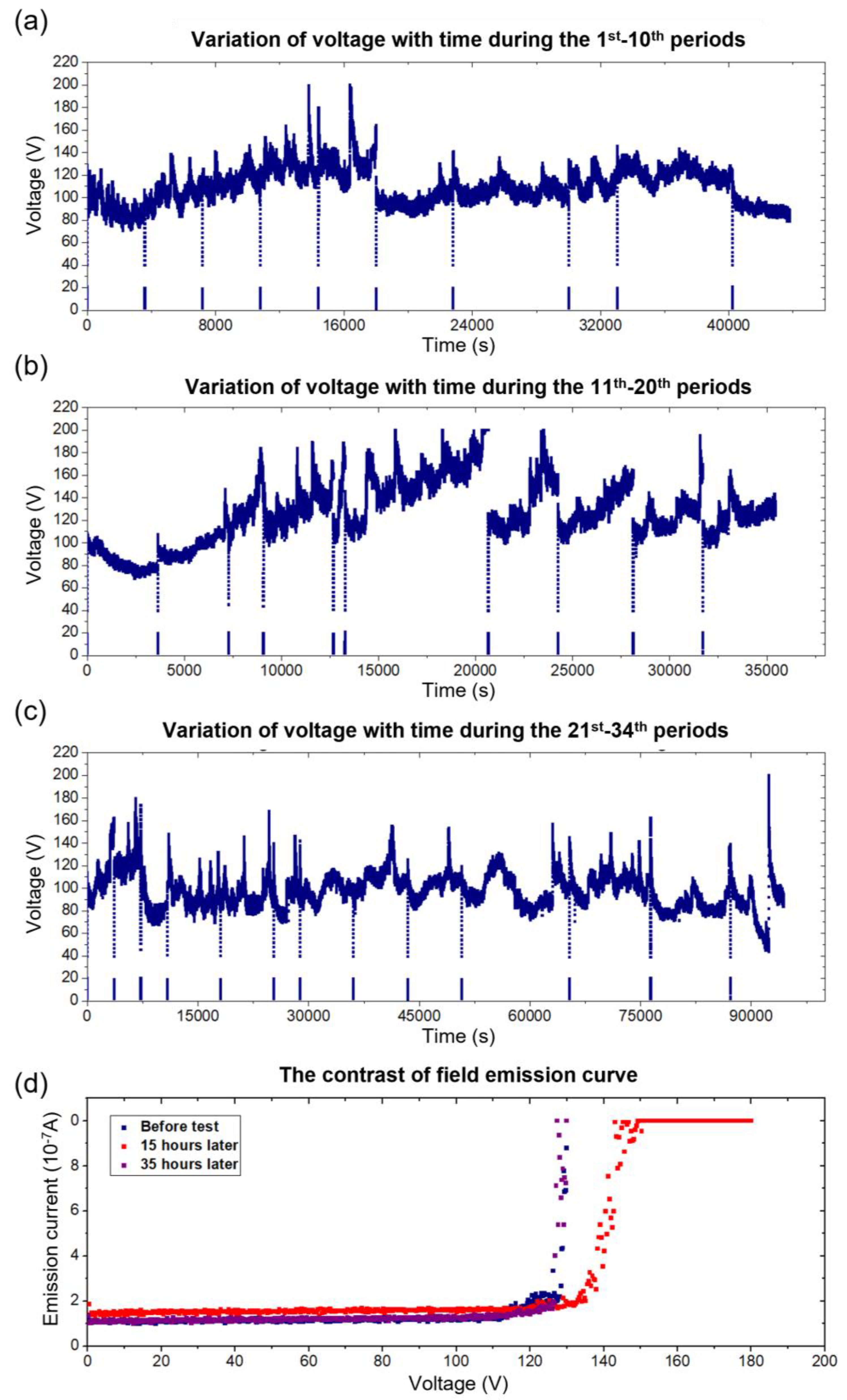

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- De Jonge, N.; Lamy, Y.; Schoots, K.; Oosterkamp, T.H. High brightness electron beam from a multi-walled carbon nanotube. Nature 2002, 420, 393–395. [Google Scholar] [CrossRef] [PubMed]

- Teo, K.B.; Minoux, E.; Hudanski, L.; Peauger, F.; Schnell, J.-P.; Gangloff, L.; Legagneux, P.; Dieumegard, D.; Amaratunga, G.A.; Milne, W.I. Carbon nanotubes as cold cathodes. Nature 2005, 437, 968. [Google Scholar] [CrossRef]

- Choi, W.B.; Chung, D.S.; Kang, J.H.; Kim, H.Y.; Jin, Y.W.; Han, I.T.; Lee, Y.H.; Jung, J.E.; Lee, N.S.; Park, G.S. Fully sealed, high-brightness carbon-nanotube field-emission display. Appl. Phys. Lett. 1999, 75, 3129–3131. [Google Scholar] [CrossRef] [Green Version]

- Saito, Y.; Uemura, S. Field emission from carbon nanotubes and its application to electron sources. Carbon 2000, 38, 169–182. [Google Scholar] [CrossRef]

- de Heer, W.A.; Chatelain, A.; Ugarte, D. A carbon nanotube field-emission electron source. Science 1995, 270, 1179–1180. [Google Scholar] [CrossRef]

- Zhou, S.H.; Chen, K.; Cole, M.T.; Li, Z.J.; Chen, J.; Li, C.; Dai, Q. Ultrafast field-emission electron sources based on nanomaterials. Adv. Mater. 2019, 31, 1805845. [Google Scholar] [CrossRef] [PubMed]

- Dong, L.X.; Arai, F.; Fukuda, T. Electron-beam-induced deposition with carbon nanotube emitters. Appl. Phys. Lett. 2002, 81, 1919–1921. [Google Scholar] [CrossRef] [Green Version]

- Huang, W.J.; Huang, Y.M.; Liu, R.Z.; Zhu, W.; Kang, S.; Qian, W.J.; Dong, C.K. A dual-functional micro-focus X-ray source based on carbon nanotube field emission. Diam. Relat. Mat. 2022, 125, 108970. [Google Scholar] [CrossRef]

- Ahn, Y.; Kim, S.J.; Jeong, J.W.; Park, S.; Kim, J.W.; Go, E.; Lee, J.W.; Kang, J.T.; Yun, K.N.; Choi, S. Overall control of field emission from carbon nanotube paste-emitters through macro-geometries for high-performance electron source applications. Carbon 2022, 189, 519–529. [Google Scholar] [CrossRef]

- Rathinavel, S.; Priyadharshini, K.; Panda, D. A review on carbon nanotube: An overview of synthesis, properties, functionalization, characterization, and the application. Mater. Sci. Eng. B 2021, 268, 115095. [Google Scholar] [CrossRef]

- Subramanian, A.; Dong, L.X.; Nelson, B.J.; Ferreira, A. Supermolecular switches based on multiwalled carbon nanotubes. Appl. Phys. Lett. 2010, 96, 073116. [Google Scholar] [CrossRef] [Green Version]

- Katkov, V.L.; Osipov, V.A. Energy distributions of field emitted electrons from carbon nanosheets: Manifestation of the quantum size effect. JETP Lett. 2009, 90, 278–283. [Google Scholar] [CrossRef] [Green Version]

- Fransen, M.J.; Van Rooy, T.; Kruit, P. Field emission energy distributions from individual multiwalled carbon nanotubes. Appl. Surf. Sci. 1999, 146, 312–327. [Google Scholar] [CrossRef]

- Ma, X.C.; Wang, E.G.; Zhou, W.Z.; Jefferson, D.A.; Chen, J.; Deng, S.Z.; Xu, N.S.; Yuan, J. Polymerized carbon nanobells and their field-emission properties. Appl. Phys. Lett. 1999, 75, 3105–3107. [Google Scholar] [CrossRef]

- Zhang, Y.; Tan, Y.M.; Wang, L.Z.; Li, B.H.; Ke, Y.L.; Liao, M.X.; Xu, N.S.; Chen, J.; Deng, S.Z. Electron emission and structure stability of carbon nanotube cold cathode driven by millisecond pulsed voltage. Vacuum 2020, 172, 109071. [Google Scholar] [CrossRef]

- Dong, L.X.; Arai, F.; Fukuda, T. Nanoassembly of carbon nanotubes through mechanochemical nanorobotic manipulations. Jpn. J. Appl. Phys. 2003, 42, 295–298. [Google Scholar] [CrossRef]

- Kim, C.; Choi, Y.S.; Lee, S.M.; Park, J.T.; Kim, B.; Lee, Y.H. The effect of gas adsorption on the field emission mechanism of carbon nanotubes. J. Am. Chem. Soc. 2002, 124, 9906–9911. [Google Scholar] [CrossRef]

- Lim, S.C.; Choi, Y.C.; Jeong, H.J.; Shin, Y.M.; An, K.H.; Bae, D.J.; Lee, Y.H.; Lee, N.S.; Kim, J.M. Effect of gas exposure on field emission properties of carbon nanotube arrays. Adv. Mater. 2001, 13, 1563–1567. [Google Scholar] [CrossRef]

- Williams, L.T.; Kumsomboone, V.; Ready, W.J.; Walker, M.L.R. Lifetime and failure mechanisms of an arrayed carbon nanotube field emission cathode. IEEE Trans. Electron Devices 2010, 57, 3163–3168. [Google Scholar] [CrossRef]

- Tripathi, M.; Mittelberger, A.; Pike, N.A.; Mangler, C.; Meyer, J.C.; Verstraete, M.J.; Kotakoski, J.; Susi, T. Electron-beam manipulation of silicon dopants in graphene. Nano Lett. 2018, 18, 5319–5323. [Google Scholar] [CrossRef]

- Wang, Z.L.; Gao, R.P.; de Heer, W.A.; Poncharal, P. In situ imaging of field emission from individual carbon nanotubes and their structural damage. Appl. Phys. Lett. 2002, 80, 856–858. [Google Scholar] [CrossRef] [Green Version]

- Floweri, O.; Jo, H.; Seo, Y.; Lee, N. Improving the thermal stability of carbon nanotubes and their field emission characteristics by adding boron and phosphorus compounds. Carbon 2018, 139, 404–414. [Google Scholar] [CrossRef]

- Zhang, Y.G.; Dai, H.J. Formation of metal nanowires on suspended single-walled carbon nanotubes. Appl. Phys. Lett. 2000, 77, 3015–3017. [Google Scholar] [CrossRef]

- Liu, P.; Arai, F.; Fukuda, T. Controlled nanowire growth with a nanorobotic manipulator. Nanotechnology 2006, 17, 3023. [Google Scholar] [CrossRef]

- Tay, A.; Thong, J. High-resolution nanowire atomic force microscope probe grown by a field-emission induced process. Appl. Phys. Lett. 2004, 84, 5207–5209. [Google Scholar] [CrossRef] [Green Version]

- Oon, C.; Khong, S.; Boothroyd, C.; Thong, J. Characteristics of single metallic nanowire growth via a field-emission induced process. J. Appl. Phys. 2006, 99, 064309. [Google Scholar] [CrossRef]

- Dong, L.X.; Arai, F.; Fukuda, T. 3-D Nanorobotic manipulation of nanometer-scale objects. J. Robot. Mechatron. 2001, 13, 146–153. [Google Scholar] [CrossRef]

- Dong, L.X.; Arai, F.; Fukuda, T. Three-dimensional nanorobotic manipulations of carbon nanotubes. J. Robot. Mechatron. 2002, 14, 245–252. [Google Scholar] [CrossRef]

- Saito, Y.; Yoshikawa, T.; Inagaki, M.; Tomita, M.; Hayashi, T. Growth and structure of graphitic tubules and polyhedral particles in arc-discharge. Chem. Phys. Lett. 1993, 204, 277–282. [Google Scholar] [CrossRef]

- Roberts, N.A.; Gonzalez, C.M.; Fowlkes, J.D.; Rack, P.D. Enhanced by-product desorption via laser assisted electron beam induced deposition of W(CO)6 with improved conductivity and resolution. Nanotechnology 2013, 24, 415301. [Google Scholar] [CrossRef] [PubMed]

- Fukuda, T.; Liu, P.; Kantola, K. Nanoscale cutting, bending and welding in a nanoassembly. In Proceedings of the 2nd IEEE International Conference on Nano/Micro Engineered and Molecular Systems (IEEE-NEMS 2007), Bangkok, Thailand, 16–19 January 2007; pp. 548–551. [Google Scholar]

- Koplitz, L.V.; Shuh, D.K.; Chen, Y.J.; Williams, R.S.; Zink, J.I. Laser-driven chemical vapor deposition of platinum at atmospheric pressure and room temperature from CpPt (CH3)3. Appl. Phys. Lett. 1988, 53, 1705–1707. [Google Scholar] [CrossRef]

- Yang, Z.; Nakajima, M.; Saito, Y.; Ode, Y.; Fukuda, T. Isolated high-purity platinum nanowire growth via field emission from a multi-walled carbon nanotube. Appl. Phys. Express 2011, 4, 035001. [Google Scholar] [CrossRef]

- Xue, Z.L.; Thridandam, H.; Kaesz, H.D.; Hicks, R.F. Organometallic chemical vapor deposition of platinum. Reaction kinetics and vapor pressures of precursors. Chem. Mat. 1992, 4, 162–166. [Google Scholar] [CrossRef]

- Koops, H.W.P.; Kaya, A.; Weber, M. Fabrication and characterization of platinum nanocrystalline material grown by electron-beam induced deposition. J. Vac. Sci. Technol. B 1995, 13, 2400–2403. [Google Scholar] [CrossRef]

- Bulyarskiy, S.V.; Dudin, A.A.; Lakalin, A.V.; Orlov, A.P.; Pavlov, A.A.; Ryazanov, R.M.; Shamanaev, A.A. Effect of heating and resistance on emission properties of carbon nanotubes. Charact. Appl. Nanomater. 2020, 3, 49–59. [Google Scholar] [CrossRef]

- Aaltonen, T.; Ritala, M.; Sajavaara, T.; Keinonen, J.; Leskelä, M. Atomic layer deposition of platinum thin films. Chem. Mat. 2003, 15, 1924–1928. [Google Scholar] [CrossRef]

- Cizmar, P.; Vladár, A.E.; Postek, M.T. Real-time scanning charged-particle microscope image composition with correction of drift. Microsc. Microanal. 2011, 17, 302–308. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fowler, R.H.; Nordheim, L. Electron emission in intense electric fields. Proc. R. Soc. Lond. 1928, 119, 173–181. [Google Scholar]

- Michaelson, H.B. The work function of the elements and its periodicity. J. Appl. Phys. 1977, 48, 4729–4733. [Google Scholar] [CrossRef] [Green Version]

- Murphy, E.L.; Good, R., Jr. Thermionic emission, field emission, and the transition region. Phys. Rev. 1956, 102, 1464. [Google Scholar] [CrossRef]

- Sun, J.P.; Zhang, Z.X.; Hou, S.M.; Zhang, G.; Gu, Z.N.; Zhao, X.Y.; Liu, W.M.; Xue, Z.Q. Work function of single-walled carbon nanotubes determined by field emission microscopy. Appl. Phys. A 2002, 75, 479–483. [Google Scholar] [CrossRef]

- Li, Y.H.; Hung, T.H.; Chen, C.A.P.L. A first-principles study of nitrogen-and boron-assisted platinum adsorption on carbon nanotubes. Carbon 2009, 47, 850–855. [Google Scholar] [CrossRef]

- Zuo, H.W.; Lu, C.H.; Ren, Y.R.; Li, Y.; Zhang, Y.F.; Chen, W.K. Pt4 clusters supported on monolayer graphitic carbon nitride sheets for oxygen adsorption: A first-principles study. Acta Phys. Chim. Sin. 2016, 32, 1183–1190. [Google Scholar] [CrossRef]

- Shang, W.; Wang, W.J.; Wang, S. DFT calculations on the adsorption of small gas molecules onto Pt-doped carbon nanotubes. Acta Chim. Sin. 2010, 68, 2389–2394. [Google Scholar]

- Cho, Y.; Kim, C.; Moon, H.; Choi, Y.; Park, S.; Lee, C.K.; Han, S. Electronic structure tailoring and selective adsorption mechanism of metal-coated nanotubes. Nano Lett. 2008, 8, 81–86. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Chao, P.; Chen, D.; Yang, Z.; Dong, L. A Core-Shell MWCNT-Pt Nanowire Electron Source with Anomalously Long-Term Stable Field Emission. Nanomaterials 2023, 13, 532. https://doi.org/10.3390/nano13030532

Zhang W, Chao P, Chen D, Yang Z, Dong L. A Core-Shell MWCNT-Pt Nanowire Electron Source with Anomalously Long-Term Stable Field Emission. Nanomaterials. 2023; 13(3):532. https://doi.org/10.3390/nano13030532

Chicago/Turabian StyleZhang, Wenqi, Peidong Chao, Donglei Chen, Zhan Yang, and Lixin Dong. 2023. "A Core-Shell MWCNT-Pt Nanowire Electron Source with Anomalously Long-Term Stable Field Emission" Nanomaterials 13, no. 3: 532. https://doi.org/10.3390/nano13030532