Characteristics of Hf0.5Zr0.5O2 Thin Films Prepared by Direct and Remote Plasma Atomic Layer Deposition for Application to Ferroelectric Memory

Abstract

1. Introduction

2. Materials and Methods

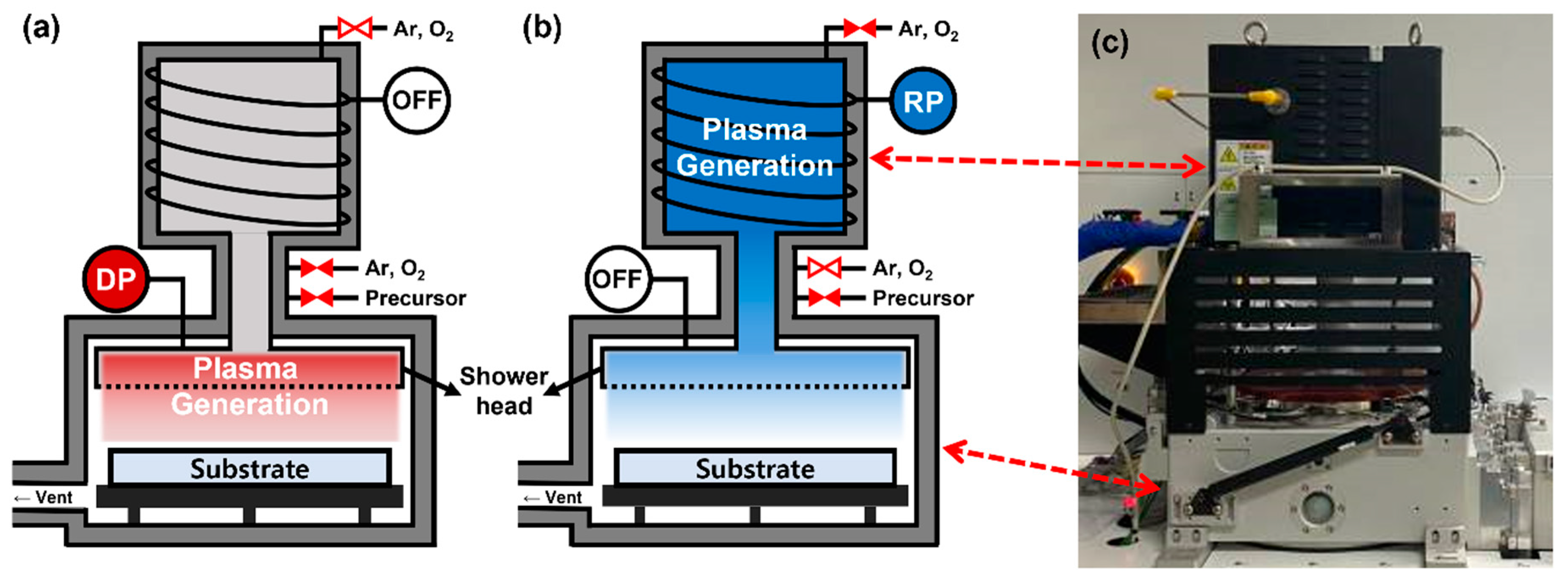

2.1. HZO Thin Film Deposition by DPALD and RPALD Methods

2.2. Evaluation of the Properties of DP HZO and RP HZO Thin Films

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shimizu, T.; Katayama, K.; Kiguchi, T.; Akama, A.; Konno, T.J.; Sakata, O.; Funakubo, H. The demonstration of significant ferroelectricity in epitaxial Y-doped HfO2 film. Sci. Rep. 2016, 6, 32931. [Google Scholar] [CrossRef] [PubMed]

- Mueller, S.; Mueller, J.; Singh, A.; Riedel, S.; Sundqvist, J.; Schroeder, U.; Mikolajick, T. Incipient Ferroelectricity in Al-Doped HfO2 Thin Films. Adv. Funct. Mater. 2012, 22, 2412–2417. [Google Scholar] [CrossRef]

- Mart, C.; Kühnel, K.; Kämpfe, T.; Zybell, S.; Weinreich, W. Ferroelectric and pyroelectric properties of polycrystalline La-doped HfO2 thin films. Appl. Phys. Lett. 2019, 114, 102903. [Google Scholar] [CrossRef]

- Materlik, R.; Künneth, C.; Falkowski, M.; Mikolajick, T.; Kersch, A. Al-, Y-, and La-doping effects favoring intrinsic and field induced ferroelectricity in HfO2: A first principles study. J. Appl. Phys. 2018, 123, 164101. [Google Scholar] [CrossRef]

- Lederer, M.; Kämpfe, T.; Olivo, R.; Lehninger, D.; Mart, C.; Kirbach, S.; Ali, T.; Polakowski, P.; Roy, L.; Seidel, K. Local crystallographic phase detection and texture mapping in ferroelectric Zr doped HfO2 films by transmission-EBSD. Appl. Phys. Lett. 2019, 115, 222902. [Google Scholar] [CrossRef]

- Palade, C.; Lepadatu, A.-M.; Slav, A.; Cojocaru, O.; Iuga, A.; Maraloiu, V.A.; Moldovan, A.; Dinescu, M.; Teodorescu, V.S.; Stoica, T.; et al. A nanoscale continuous transition from the monoclinic to ferroelectric orthorhombic phase inside HfO2 nanocrystals stabilized by HfO2 capping and self-controlled Ge doping. J. Mater. Chem. C 2021, 9, 12353–12366. [Google Scholar] [CrossRef]

- Böscke, T.S.; Müller, J.; Bräuhaus, D.; Schröder, U.; Böttger, U. Ferroelectricity in hafnium oxide thin films. Appl. Phys. Lett. 2011, 99, 102903. [Google Scholar] [CrossRef]

- Müller, J.; Böscke, T.S.; Schröder, U.; Mueller, S.; Bräuhaus, D.; Böttger, U.; Frey, L.; Mikolajick, T. Ferroelectricity in Simple Binary ZrO2 and HfO2. Nano Lett. 2012, 12, 4318–4323. [Google Scholar] [CrossRef]

- Park, M.H.; Lee, Y.H.; Kim, H.J.; Schenk, T.; Lee, W.; Kim, K.D.; Fengler, F.P.G.; Mikolajick, T.; Schroeder, U.; Hwang, C.S. Surface and grain boundary energy as the key enabler of ferroelectricity in nanoscale hafnia-zirconia: A comparison of model and experiment. Nanoscale 2017, 9, 9973–9986. [Google Scholar] [CrossRef]

- Park, M.H.; Kim, H.J.; Lee, G.; Park, J.; Lee, Y.H.; Kim, Y.J.; Moon, T.; Kim, K.D.; Hyun, S.D.; Park, H.W.; et al. A comprehensive study on the mechanism of ferroelectric phase formation in hafnia-zirconia nanolaminates and superlattices. Appl. Phys. Rev. 2019, 6, 041403. [Google Scholar] [CrossRef]

- Onaya, T.; Nabatame, T.; Sawamoto, N.; Ohi, A.; Ikeda, N.; Nagata, T.; Ogura, A. Improvement in ferroelectricity of HfxZr1−xO2 thin films using top- and bottom-ZrO2 nucleation layers. APL Mater. 2019, 7, 061107. [Google Scholar] [CrossRef]

- Park, M.H.; Kim, H.J.; Kim, Y.J.; Lee, W.; Moon, T.; Hwang, C.S. Evolution of phases and ferroelectric properties of thin Hf0.5Zr0.5O2 films according to the thickness and annealing temperature. Appl. Phys. Lett. 2013, 102, 242905. [Google Scholar] [CrossRef]

- Park, M.H.; Kim, H.J.; Kim, Y.J.; Moon, T.; Hwang, C.S. The effects of crystallographic orientation and strain of thin Hf0.5Zr0.5O2 film on its ferroelectricity. Appl. Phys. Lett. 2014, 104, 072901. [Google Scholar] [CrossRef]

- Park, M.H.; Kim, H.J.; Kim, Y.J.; Lee, W.; Kim, H.K.; Hwang, C.S. Effect of forming gas annealing on the ferroelectric properties of Hf0.5Zr0.5O2 thin films with and without Pt electrodes. Appl. Phys. Lett. 2013, 102, 112914. [Google Scholar] [CrossRef]

- Kim, S.J.; Narayan, D.; Lee, J.-G.; Mohan, J.; Lee, J.S.; Lee, J.; Kim, H.S.; Byun, Y.-C.; Lucero, A.T.; Young, C.D.; et al. Large ferroelectric polarization of TiN/Hf0.5Zr0.5O2/TiN capacitors due to stress-induced crystallization at low thermal budget. Appl. Phys. Lett. 2017, 111, 242901. [Google Scholar] [CrossRef]

- Kim, S.J.; Mohan, J.; Lee, J.; Lee, J.S.; Lucero, A.T.; Young, C.D.; Colombo, L.; Summerfelt, S.R.; San, T.; Kim, J. Effect of film thickness on the ferroelectric and dielectric properties of low-temperature (400 °C) Hf0.5Zr0.5O2 films. Appl. Phys. Lett. 2018, 112, 172902. [Google Scholar] [CrossRef]

- Kim, S.J.; Mohan, J.; Summerfelt, S.R.; Kim, J. Ferroelectric Hf0.5Zr0.5O2 Thin Films: A Review of Recent Advances. JOM 2019, 71, 246–255. [Google Scholar] [CrossRef]

- Park, M.H.; Lee, Y.H.; Kim, H.J.; Kim, Y.J.; Moon, T.; Kim, K.D.; Hyun, S.D.; Mikolajick, T.; Schroeder, U.; Hwang, C.S. Understanding the formation of the metastable ferroelectric phase in hafnia–zirconia solid solution thin films. Nanoscale 2017, 10, 716–725. [Google Scholar] [CrossRef] [PubMed]

- Cao, R.; Liu, Q.; Liu, M.; Song, B.; Shang, D.; Yang, Y.; Luo, Q.; Wu, S.; Li, Y.; Wang, Y.; et al. Improvement of Endurance in HZO-Based Ferroelectric Capacitor Using Ru Electrode. IEEE Electron Device Lett. 2019, 40, 1744–1747. [Google Scholar] [CrossRef]

- Kashir, A.; Kim, H.; Oh, S.; Hwang, H. Large Remnant Polarization in a Wake-Up Free Hf0.5Zr0.5O2 Ferroelectric Film through Bulk and Interface Engineering. ACS Appl. Electron. Mater. 2021, 3, 629–638. [Google Scholar] [CrossRef]

- Kim, K.D.; Lee, Y.H.; Gwon, T.; Kim, Y.J.; Kim, H.J.; Moon, T.; Hyun, S.D.; Park, H.W.; Park, M.H.; Hwang, C.S. Scale-up and optimization of HfO2-ZrO2 solid solution thin films for the electrostatic supercapacitors. Nano Energy 2017, 39, 390–399. [Google Scholar] [CrossRef]

- Cho, D.-Y.; Jung, H.-S.; Hwang, C.S. Structural properties and electronic structure of HfO2-ZrO2composite films. Phys. Rev. B 2010, 82, 094104. [Google Scholar] [CrossRef]

- Goh, Y.; Hwang, J.; Jeon, S. Excellent Reliability and High-Speed Antiferroelectric HfZrO2Tunnel Junction by a High-Pressure Annealing Process and Built-In Bias Engineering. ACS Appl. Mater. Interfaces 2020, 12, 57539–57546. [Google Scholar] [CrossRef]

- Tung, C.-T.; Salahuddin, S.; Hu, C. A Compact Model of Antiferroelectric Capacitor. IEEE Electron Device Lett. 2021, 43, 316–318. [Google Scholar] [CrossRef]

- Hur, J.; Tasneem, N.; Choe, G.; Wang, P.; Wang, Z.; Khan, A.I.; Yu, S. Direct comparison of ferroelectric properties in Hf0.5Zr0.5O2 between thermal and plasma-enhanced atomic layer deposition. Nanotechnology 2020, 31, 505707. [Google Scholar] [CrossRef]

- Kim, H. Atomic layer deposition of metal and nitride thin films: Current research efforts and applications for semiconductor device processing. J. Vac. Sci. Technol. B Microelectron. Nanometer. Struct. 2003, 21, 2231. [Google Scholar] [CrossRef]

- Profijt, H.B.; Potts, S.E.; Van De Sanden, M.C.M.; Kessels, W.M.M. Plasma-Assisted Atomic Layer Deposition: Basics, Opportunities, and Challenges. J. Vac. Sci. Technol. A 2011, 29, 050801. [Google Scholar] [CrossRef]

- Kim, J.; Kim, S.; Jeon, H.; Cho, M.-H.; Chung, K.-B.; Bae, C. Characteristics of HfO2 thin films grown by plasma atomic layer deposition. Appl. Phys. Lett. 2005, 87, 053108. [Google Scholar] [CrossRef]

- Piallat, F.; Beugin, V.; Gassilloud, R.; Dussault, L.; Pelissier, B.; Leroux, C.; Caubet, P.; Vallée, C. Interface and plasma damage analysis of PEALD TaCN deposited on HfO2 for advanced CMOS studied by angle resolved XPS and C–V. Appl. Surf. Sci. 2014, 303, 388–392. [Google Scholar] [CrossRef]

- Park, S.-H.K.; Hwang, C.-S.; Byun, C.; Ryu, M.; Lee, J.-I.; Chu, H.Y.; Cho, K.I. Challenge to Future Displays: Transparent AM-OLED Driven by PEALD Grown ZnO TFT. Imid 2007 Dig. 12-2 2007, 1249. Available online: https://koreascience.kr/article/CFKO200724282630695.pdf (accessed on 24 February 2023).

- Zhao, M.-J.; Zhang, Z.-X.; Hsu, C.-H.; Wu, W.-Y.; Zhang, X.-Y.; Lien, S.-Y.; Zhu, W.-Z. In2O3 film prepared by a PEALD process with balanced oxygen radical supply and ion bombardment damage. Vacuum 2021, 192, 110411. [Google Scholar] [CrossRef]

- Van Hemmen, J.H.; Heil, S.S.; Klootwijk, J.H.; Roozeboom, F.F.; Hodson, C.J.; Van De Sanden, M.R.; Kessels, W.E. Plasma and Thermal ALD of Al2O3 in a Commercial 200 mm ALD Reactor. J. Electrochem. Soc. 2007, 154, G165–G169. [Google Scholar] [CrossRef]

- Heil, S.B.S.; van Hemmen, J.L.; Hodson, C.J.; Singh, N.; Klootwijk, J.H.; Roozeboom, F.; van de Sanden, M.C.M.; Kessels, W.M.M. Deposition of TiN and HfO2 in a commercial 200 mm remote plasma atomic layer deposition reactor. J. Vac. Sci. Technol. A 2007, 25, 1357. [Google Scholar] [CrossRef]

- Kim, J.Y.; Kim, S.H.; Seo, H.; Kim, J.-H.; Jeon, H. Deposition and Plasma Measurements of Zr-Oxide Films with Low Impurity Concentrations by Remote PEALD. Electrochem. Solid-State Lett. 2005, 8, G82–G84. [Google Scholar] [CrossRef]

- Hsu, T.-Y.; Kuo, C.-L.; Lin, B.-T.; Shieh, J.; Chen, M.-J. The effects of annealing and wake-up cycling on the ferroelectricity of zirconium hafnium oxide ultrathin films prepared by remote plasma atomic layer deposition. Smart Mater. Struct. 2019, 28, 084005. [Google Scholar] [CrossRef]

- Kim, H.-G.; Hong, D.-H.; Yoo, J.-H.; Lee, H.-C. Effect of Process Temperature on Density and Electrical Characteristics of Hf0.5Zr0.5O2 Thin Films Prepared by Plasma-Enhanced Atomic Layer Deposition. Nanomaterials 2022, 12, 548. [Google Scholar] [CrossRef]

- Materano, M.; Mittmann, T.; Lomenzo, P.D.; Zhou, C.; Jones, J.L.; Falkowski, M.; Kersch, A.; Mikolajick, T.; Schroeder, U. Influence of Oxygen Content on the Structure and Reliability of Ferroelectric HfxZr1–xO2 Layers. ACS Appl. Electron. Mater. 2020, 2, 3618–3626. [Google Scholar] [CrossRef]

- Alcala, R.; Richter, C.; Materano, M.; Lomenzo, P.D.; Zhou, C.; Jones, J.L.; Mikolajick, T.; Schroeder, U. Influence of oxygen source on the ferroelectric properties of ALD grown Hf1-xZrxO2 films. J. Phys. D: Appl. Phys. 2020, 54, 035102. [Google Scholar] [CrossRef]

- Jiang, P.; Luo, Q.; Xu, X.; Gong, T.; Yuan, P.; Wang, Y.; Gao, Z.; Wei, W.; Tai, L.; Lv, H. Wake-up Effect in HfO2-Based Ferroelectric Films. Adv. Electron. Mater. 2021, 7, 2000728. [Google Scholar] [CrossRef]

- Jerman, M.; Qiao, Z.; Mergel, D. Refractive index of thin films of SiO2, ZrO2, and HfO2 as a function of the films’ mass density. Appl. Opt. 2005, 44, 3006–3012. [Google Scholar] [CrossRef]

- Gaddam, V.; Das, D.; Jeon, S. Insertion of HfO2 Seed/Dielectric Layer to the Ferroelectric HZO Films for Heightened Remanent Polarization in MFM Capacitors. IEEE Trans. Electron Devices 2020, 67, 745–750. [Google Scholar] [CrossRef]

- Yan, X.; Xiao, Z.; Lu, C. Characteristic investigation of highly oriented Hf0.5Zr0.5O2 thin-film resistive memory devices. Appl. Phys. Lett. 2020, 116, 013506. [Google Scholar] [CrossRef]

- Song, T.; Estandía, S.; Dix, N.; Gàzquez, J.; Gich, M.; Fina, I.; Sánchez, F. Ferroelectric Hf0.5Zr0.5O2 films on SrTiO3(111). J. Mater. Chem. C 2022, 10, 8407–8413. [Google Scholar] [CrossRef]

- Gaddam, V.; Kim, G.; Kim, T.; Jung, M.; Kim, C.; Jeon, S. Novel Approach to High κ (∼59) and Low EOT (∼3.8 Å) near the Morphotrophic Phase Boundary with AFE/FE (ZrO2/HZO) Bilayer Heterostructures and High-Pressure Annealing. ACS Appl. Mater. Interfaces 2022, 14, 43463–43473. [Google Scholar] [CrossRef]

- Kim, S.; Lee, S.H.; Kim, M.J.; Hwang, W.S.; Jin, H.S.; Cho, B.J. Method to Achieve the Morphotropic Phase Boundary in HfxZr1−xO2 by Electric Field Cycling for DRAM Cell Capacitor Applications. IEEE Electron Device Lett. 2021, 42, 517–520. [Google Scholar] [CrossRef]

- Chourasia, A.R.; Hickman, J.L.; Miller, R.L.; Nixon, G.A.; Seabolt, M.A. X-Ray Photoemission Study of the Oxidation of Hafnium. Int. J. Spectrosc. 2009, 2009, 6. [Google Scholar] [CrossRef]

- Kim, K.-M.; Jang, J.S.; Yoon, S.-G.; Yun, J.-Y.; Chung, N.-K. Structural, Optical and Electrical Properties of HfO2 Thin Films Deposited at Low-Temperature Using Plasma-Enhanced Atomic Layer Deposition. Materials 2020, 13, 2008. [Google Scholar] [CrossRef]

- Sokolov, A.S.; Jeon, Y.-R.; Kim, S.; Ku, B.; Lim, D.; Han, H.; Chae, M.G.; Lee, J.; Gil Ha, B.; Choi, C. Influence of oxygen vacancies in ALD HfO2−x thin films on non-volatile resistive switching phenomena with a Ti/HfO2−x/Pt structure. Appl. Surf. Sci. 2018, 434, 822–830. [Google Scholar] [CrossRef]

- Cho, H.W.; Pujar, P.; Choi, M.; Kang, S.; Hong, S.; Park, J.; Baek, S.; Kim, Y.; Lee, J.; Kim, S. Direct growth of orthorhombic Hf0.5Zr0.5O2 thin films for hysteresis-free MoS2 negative capacitance field-effect transistors. NPJ 2D Mater. Appl. 2021, 5, 46. [Google Scholar] [CrossRef]

- Ahn, Y.; Jeon, Y.; Lim, S.; Kim, J.; Kim, J.; Duy, L.T.; Seo, H. Effects of plasma power on ferroelectric properties of HfO2-ZrO2 nanolaminates produced by plasma enhanced atomic layer deposition. Surfaces Interfaces 2023, 37, 102669. [Google Scholar] [CrossRef]

- Lee, Y.; Goh, Y.; Hwang, J.; Das, D.; Jeon, S. The Influence of Top and Bottom Metal Electrodes on Ferroelectricity of Hafnia. IEEE Trans. Electron Devices 2021, 68, 523–528. [Google Scholar] [CrossRef]

- Pešić, M.; Hoffmann, M.; Richter, C.; Mikolajick, T.; Schroeder, U. Nonvolatile Random Access Memory and Energy Storage Based on Antiferroelectric Like Hysteresis in ZrO2. Adv. Funct. Mater. 2016, 26, 7486–7494. [Google Scholar] [CrossRef]

- Hoffmann, M.; Schroeder, U.; Schenk, T.; Shimizu, T.; Funakubo, H.; Sakata, O.; Pohl, D.; Drescher, M.; Adelmann, C.; Materlik, R.; et al. Stabilizing the ferroelectric phase in doped hafnium oxide. J. Appl. Phys. 2015, 118, 072006. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, Y.; Yang, Q.; Jiang, J.; Fan, P.; Liao, M. The effects of oxygen vacancies on ferroelectric phase transition of HfO2-based thin film from first-principle. Comput. Mater. Sci. 2019, 167, 143–150. [Google Scholar] [CrossRef]

- Mittmann, T.; Materano, M.; Chang, S.-C.; Karpov, I.; Mikolajick, T.; Schroeder, U. Impact of Oxygen Vacancy Content in Ferroelectric HZO films on the Device Performance. In Proceedings of the 2020 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 12–18 December 2020; pp. 18.4.1–18.4.4. [Google Scholar] [CrossRef]

- Goh, Y.; Cho, S.H.; Park, S.-H.K.; Jeon, S. Oxygen vacancy control as a strategy to achieve highly reliable hafnia ferroelectrics using oxide electrode. Nanoscale 2020, 12, 9024–9031. [Google Scholar] [CrossRef] [PubMed]

- Kashir, A.; Oh, S.; Hwang, H. Defect Engineering to Achieve Wake-up Free HfO2-Based Ferroelectrics. Adv. Eng. Mater. 2021, 23, 2000791. [Google Scholar] [CrossRef]

- Lo, V.C. Modeling the role of oxygen vacancy on ferroelectric properties in thin films. J. Appl. Phys. 2002, 92, 6778–6786. [Google Scholar] [CrossRef]

- Lou, X.J. Why do antiferroelectrics show higher fatigue resistance than ferroelectrics under bipolar electrical cycling? Appl. Phys. Lett. 2009, 94, 072901. [Google Scholar] [CrossRef]

| (a) DPALD | (b) RPALD | ||||

|---|---|---|---|---|---|

| TEMA-(Hf, Zr) 1:1 cycle | Pressure: 1.3 Torr | TEMA-(Hf, Zr) 1:1 cycle | Pressure: 1.7 Torr | ||

| Source |  | Source |  | ||

| Ar Purge |  | Ar Purge |  | ||

| RF Plasma |  | RF Plasma |  | ||

| O2 Reactant |  | O2 Reactant |  | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, D.H.; Yoo, J.H.; Park, W.J.; Kim, S.W.; Kim, J.H.; Uhm, S.H.; Lee, H.C. Characteristics of Hf0.5Zr0.5O2 Thin Films Prepared by Direct and Remote Plasma Atomic Layer Deposition for Application to Ferroelectric Memory. Nanomaterials 2023, 13, 900. https://doi.org/10.3390/nano13050900

Hong DH, Yoo JH, Park WJ, Kim SW, Kim JH, Uhm SH, Lee HC. Characteristics of Hf0.5Zr0.5O2 Thin Films Prepared by Direct and Remote Plasma Atomic Layer Deposition for Application to Ferroelectric Memory. Nanomaterials. 2023; 13(5):900. https://doi.org/10.3390/nano13050900

Chicago/Turabian StyleHong, Da Hee, Jae Hoon Yoo, Won Ji Park, So Won Kim, Jong Hwan Kim, Sae Hoon Uhm, and Hee Chul Lee. 2023. "Characteristics of Hf0.5Zr0.5O2 Thin Films Prepared by Direct and Remote Plasma Atomic Layer Deposition for Application to Ferroelectric Memory" Nanomaterials 13, no. 5: 900. https://doi.org/10.3390/nano13050900

APA StyleHong, D. H., Yoo, J. H., Park, W. J., Kim, S. W., Kim, J. H., Uhm, S. H., & Lee, H. C. (2023). Characteristics of Hf0.5Zr0.5O2 Thin Films Prepared by Direct and Remote Plasma Atomic Layer Deposition for Application to Ferroelectric Memory. Nanomaterials, 13(5), 900. https://doi.org/10.3390/nano13050900