1. Introduction

Global demand for energy is ever-increasing, which accelerates the consumption of non-renewable resources. To reduce resource consumption and to develop an energy-efficient society, energy utilizing processes should be optimized, as about two-thirds of primary energy are wasted as heat [

1]. Around 60% of waste heat lost is of low or ultralow grade (heat at temperatures between ambient temperature and 80 °C) [

2]. While a perspective method for transforming waste thermal energy back into useful electrical power is to use effective thermoelectric generators (TEGs). However, conventional commercially available TEGs are made of brittle inorganic thermoelectric (TE) materials and have a solid rectangular shape, which limits their usability for the low- and ultralow-grade waste heat capturing as these heat losses mostly occur from curved heated surfaces as, for example, hot pipes or human body. Thus, capturing and conversion of low- and ultralow-grade waste heat requires the development of flexible TE materials.

A perspective type of flexible TE materials for low- and ultra-low-grade waste heat conversion to electricity are nanocomposites consisting of a polymer matrix filled with a TE filler as carbon nanotubes (CNT) [

3] or nanostructured inorganic materials for near-room temperature applications (Bi

2Se

3, Bi

2Te

3, Sb

2Te

3) [

4,

5,

6,

7]. Among the polymer matrices, insulating polymers are considered as more environmentally-friendly, stable, and more affordable in comparison with their electrically-conductive counterparts [

8,

9]. Recently, it was shown that using CNTs as a scaffold for the deposition of inorganic thermoelectric nanostructures as Bi

2Te

3, Bi

2Se

3 or Sb

2Te

3 allows to obtain effective flexible thermoelectric material [

10,

11,

12]. Such networks of Bi

2Se

3-CNT and Sb

2Te

3-CNT heterostructures can also be used for the fabrication of effective flexible thermoelectric composites based on polyvinyl alcohol (PVA) matrix [

6,

7,

13]. For the fabrication of these composites, the TE fillers were prepared by direct deposition of inorganic Bi

2Se

3 or Sb

2Te

3 nanostructures on a multiwalled CNT network [

12], and further mixed-in or encapsulated-by a polymer [

6,

7,

13]. Both mixing and encapsulation approaches resulted in a gradient distribution of the TE filler across the polymer matrix due to the fabrication issues. In the mixing approach, the filler may partially settle on the bottom side of the polymer matrix due to the impact of gravity during the drying of the polymer. However, despite the potential influence of the filler distribution gradient on the properties of the composite, this issue is usually not given sufficient attention. In turn, the encapsulation technology implies location of the CNT-TE filler along one side of the composite film [

7]. For the reliable application of flexible TE composites, it is crucial to understand the impact of uneven distribution of filler in flexible TE materials on their properties upon bending. When bending films, their outer and inner surfaces are always subjected to tension and compression stress respectively. However, quite a limited amount of research attention is paid to the study of the resistance response of the electrically conductive thin films to both compression and tension during the bending. Up to date, most of such studies were devoted to the durability of silver paint electrodes deposited on polymer substrates for wearable electronics [

14,

15], silver networks covered by polymer for flexible thin film heaters [

16], and flexible metal oxide electrodes on polymer substrates for touch-screen panels [

17] and flexible OLED applications [

18]. In most of these works, the resistance measurements were applied to determine the limits for mechanical bending and durability. Some of the works report the difference between the electrical conductance change (commonly increase from the value of not bent sample) in respect to the bending direction (inner/outer), when approaching critical bending radius [

14,

18]. However, almost no attention is paid to the analysis of mechanisms underlying these changes in the electrical conductance of the samples. In addition, generally such studies do not take into account that during the bending, outer and inner surfaces of the film are subjected simultaneously to the opposite (tensile/compressive) types of bending stress. In the case of uneven distribution of the nanostructured functional filler within the film, the changes in properties on the sides of the sample subjected to tensile and compressive stress significantly differ, which will be reflected in the electrical conductance changes. To the best of our knowledge, up to date there is no reports on a systematic and detailed study devoted to the electrical response of thermoelectrical composite materials, based on insulating polymer matrix combined with the functional nanostructured filler, in respect to the impact of filler distribution gradient on the conductance changes when subjected to compressive/tensile stress.

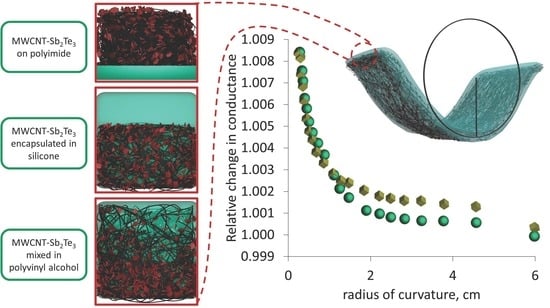

In this work, a systematic study of the electrical conductance changes during the bending of three different types of Sb2Te3-MWCNT heterostructures and bare MWCNT-based thermoelectrical flexible films—the free-standing on a flexible polymer substrate, encapsulated in polydimethylsiloxane (PDMS), and mixed in PVA–is presented. The impact of compression and tension during the bending on the changes in the sample conductance are studied in detail in respect to the processes occurring in the electrical contacts between the MWCNTs and between the components of Sb2Te3-MWCNT heterostructures. It was found that the differences in the behavior of different types of Sb2Te3-MWCNTs heterostructures-based composites when subjected to compression and tension are related to the impact of gradient distribution of Sb2Te3 nanostructures. Similar impact of gradient distribution of bare MWCNTs on the conductance changes upon bending was observed for the samples prepared by mixing MWCNTs with PVA.

2. Materials and Methods

MWCNTs were synthesized via chemical vapor deposition method in a quartz tube reactor (3D Strong Ltd., Ulbroka, Latvia). The process occurred at 850 °C and at carrier gas (Ar) gas flow rate 20 mm/s for 20 min. A mixture on benzene (C6H6, CAS:71-43-2, 99.8% Sigma-Aldrich, Inc., St. Louis, MI, USA), and pyridine (C5H5N, CAS:110-86-1, 99.8%, Sigma-Aldrich, Inc., St. Louis, MI, USA) in 3:1 by volume, with dissolved in this solution 2 wt% of ferrocene (Fe(C5H5)2, CAS:102-54-5, 98%, Sigma-Aldrich, Inc., St. Louis, MI, USA) was used for the formation of catalytic particles for the MWCNT growth.

MWCNT networks were prepared by spray-coating technique on glass and polyimide film (DuPont™ Kapton®, Wilmington, DE, USA) substrates. Polyimide film is flexible, with good chemical and thermal stability from −269 to +300 °C, which makes it suitable substrate for physical vapor deposition process.

Hybrid Sb

2Te

3-MWCNT networks were synthesized using a catalyst-free physical vapor deposition method described in [

12,

19,

20] by direct deposition of Sb

2Te

3 (99.999%, CAS: 1327-50-0, Alfa Aesar, Kandel, Germany) on MWCNT networks in a quartz tube single zone vacuum furnace (OTF-1200X, MTI Corp., Richmond, CA, USA). By varying thickness of MWCNT networks and the time of synthesis, the desired weight percent (wt%) of MWCNT’s in the hybrid structures were achieved (the samples were weighed before each step using analytical scales (KERN ABP 200-5DM, max 220 g, ±1 mg, Balingen, Baden-Wuerttemberg, Germany). For the fabrication of flexible films containing encapsulated Sb

2Te

3-MWCNT or bare MWCNTs, the heterostructures were deposited on polyimide substrates, then coated with PDMS (Sigma-Aldrich, Inc., St. Louis, MI, USA), cured for 10 min in 150 °C, and then the resulting elastic film was lifted off the glass using tweezers. For the fabrication of mixed composite, the Sb

2Te

3-MWCNT heterostructures were deposited on glass substrates, then scrapped off the substrates and mixed in PVA (Sigma-Aldrich, Inc., St. Louis, MI, USA) as described elsewhere [

13].

Morphological and structural characterization of the samples was performed by field-emission scanning electron microscope (SEM) (S-4800, Hitachi, Tokyo, Japan) equipped with energy-dispersive X-ray diffraction analyser (EDX) (Bruker XFlash Quad 5040, Billerica, MA, USA), transmission electron microscope (FET Technai GF 20, FEI Company, Hillsboro, OR, USA), and X-ray diffractometer (XRD, Bruker D8 Discover, Billerica, MA, USA). Identification of the diffraction peaks was performed using the ICDD database PDF-2/Release 2021 (Ref. cards PDF 01-085-4141 (Sb2Te3), PDF 00-001-0727 (Te), and PDF 01-075-1565 Sb2O3).

2-point bending experiments were carried out with a home-build device, allowing simultaneous bending of the sample and measuring of its electrical resistance using Keithley 6430 Sub-Femtoamp remote source meter (Keithley Instruments, Cleveland, OH, USA) combined with a custom software). The resistance of the samples during bending was measured at a constant voltage of 0.1 V applied to the sample.

4. Discussion

The experimental results can be interpreted using a thin film bending scheme (

Figure 7a). Following this scheme, the side of the film, subjected to tension during the bending, will be stretched relative to the middle line of the thin film, representing the length of not-bent thin film, due to r

t > r

0, causing separation of the components of the heterostructures. In contrast, the side of the film, subjected to compression stress, will be squeezed due to r

c < r

0, which will result in convergence of the components of the heterostructures. The ratios of the lengths of stretched or squeezed layers of the thin film relative to its middle line depend on the thickness of the thin film and can be calculated by simple formulas L

t/L

0 = (r

0 + h/2)/r

0 and L

c/L

0 = (r

0 − h/2)/r

0, where L

t, L

c and L

o are respectively lengths of the thin film sides subjected to tension, compression, and the middle line, and h is the total thickness of the sample.

The conductance in the sample is determined by the number and type of electrical contacts established between the components of the heterostructures. The components of the heterostructured network may be in direct and/or tunnel electrical contact with each other (

Figure 7c,f), both contributing to the total conductance of the sample.

The schematic shows only simplified contacts between two Sb

2Te

3 nanoparticles (

Figure 7b–d) and between two MWCNTs (

Figure 7e,f), and their changes for compressive and tension bending modes figures respectively. It is presumed in these modes, that the direct electrical contacts between the Sb

2Te

3 nanostructures, as well as between two MWCNTs are ohmic, however, the formation of Schottky barriers between the Sb

2Te

3 and MWCNT cannot be excluded. Subjection of the thin film to the compressive stress during its bending will result in convergence of the network components (MWCNTs, Sb

2Te

3 nanostructures), leading to the increase of the active area of previously established direct and tunnel electrical contacts between the nanostructures (

Figure 7b), as well as to the establishment of a few new electrical contacts. The opposite process—distancing of the network components, resulting in a disruption or decrease of the active area of previously established between the nanostructures direct and tunnel electrical contacts—will occur when the film is subjected to the tensile stress during the bending (

Figure 7d).

At low relative changes in the lengths of bent and not bent samples, it can be assumed that the increase or decrease of the active area of an electrical contact is proportional to the sample length change, and thus, the changes in the electrical conductance will be directly proportional to the changes in the active contact area. The changes in the tunnel current densities J when the sample is bent can be estimated using analytical equation for the electric tunnel effect between similar electrodes separated by a thin insulator film for rectangular potential barrier J = (6.2·10

10/s

2)(φ

0 − V/2) exp (−1.025 s (φ

0 − V/2)

1/2) − (φ

0 + V/2) exp (1.025 s (φ

0 + V/2)

1/2) [

21], where J is the tunnel current density in A/cm

2, s is the insulating layer thickness in Å, φ

0 is the height of rectangular barrier in volts, and V is the voltage across the film. In the calculations, it was assumed that the height of the tunnel barrier is 4.45 eV [

22] and 5 eV [

23] for Sb

2Te

3 and MWCNT respectively, the initial barrier width of not bent sample is 1 nm, and the changes in the width of the potential barrier depended on the thickness of the film. The estimations of changes in linear dimensions of the thin films during the bending and related changes in the active areas of direct and tunnel contacts are summarized in

Table 1. It can be seen from the

Table 1 that the larger total thin film thickness is related to the larger changes the tunnel currents densities, as well as to the larger changes in the active area of the direct electrical contacts, and consequently, the larger changes in direct electrical current.

In what follows, the experimentally observed changes in the conduction of the Sb2Te3-MWCNTs heterostructures and bare MWCNTs based thin films are interpreted using the above models.

As is seen from the estimations shown in

Table 1, the expected changes in the active electrical contact areas for the free-standing MWCNTs is the increase by ~0.3% (direct contact area) and 6.9% (tunnel current density) when the MWCNT network is subjected to compressive stress, and decrease by the same values (0.3% direct contact area, 7.5% tunnel current density) when the MWCNT network is subjected to tensile stress during the bending. Thus, the expected behavior of the free-standing MWCNT network would be a slight increase of the conduction in compression mode and decrease of the conduction in the tension mode. However, the experimental observations showed the decrease in the conductance of free-standing bare MWCNT networks by ~0.4–0.6% for both compression (

Figure 4c) and tension (

Figure 4d) bending modes. In the case of bare long MWCNTs, the direct electrical contacts may be dominating, and the contribution of the tunnel contacts to the total changes in conductance may be insignificant. In both compression and tension bending modes, long bare MWCNTs may slide relatively each other. Re-organizing (sliding) of the MWCNTs one relative to the other during compression (

Figure 7e) or tension (

Figure 7g) equally results in the decrease of the active area of direct electrical contacts between the CNTs and consequently, in the decrease of electrical conductance.

For the free-standing Sb

2Te

3-MWCNT heterostructures, the observed increase by 0.5% in the electrical conductance when subjected to compression (

Figure 4a) and its decrease by 1–1.2% when Sb

2Te

3-MWCNT heterostructures were subjected to tension (

Figure 4b). Such behavior is in agreement with the tendencies showed by the estimations (

Table 1), and most likely is related to the distribution of Sb

2Te

3 in the films based on Sb

2Te

3-MWCNT heterostructures. In the Sb

2Te

3-MWCNT heterostructures, even though the conductance of the Sb

2Te

3 nanostructures itself is lower in comparison to MWCNTs, the larger impact of Sb

2Te

3 nanostructures on the conductance changes upon bending may be related to the smaller number of nanotubes compared to the number of Sb

2Te

3. Thus, the dominating contribution to the total conductance will be the electrical current through the Sb

2Te

3 nanostructures, with the higher contribution of the changes in tunnel contacts upon bending. Consequently, compression of the Sb

2Te

3 layer results in the formation of an additional number of new electrical contacts between the Sb

2Te

3 nanostructures and between the Sb

2Te

3 and CNTs, as well as in the increase of the active areas of direct and tunnel electrical contacts (

Figure 7b,

Table 1) and consequent increase of conductance. When subjected to tension, distraction of the Sb

2Te

3 nanostructures will result in disruption of a number of established electrical contacts, as well as in decrease of the active contact area of the electrical contacts (

Figure 7d,

Table 1), leading to the decrease in conductance. A slightly higher decrease in conductance when subjected to tension in comparison with its increase when subjected to compression (1–1.2% vs. 0.5%) may be explained by the contribution to the conductance decrease of the MWCNTs in the layers of Sb

2Te

3-MWCNT heterostructures, where MWCNTs are dominating, in both compression and tension modes, as it was observed for in the case of uniform distribution of the MWCNTs in the thin film.

For the encapsulated Sb

2Te

3-MWCNT heterostructures, the significant (~20–25%) increase in the electrical conductance of the encapsulated Sb

2Te

3-MWCNT samples when subjected to compression (

Figure 5a) and its decrease by ~15–20% when subjected to tension (

Figure 5b) may be explained by the impact of large total thickness of the film (~500 μm,

Table 1), leading to the larger changes of the direct electrical contact area and consequently, in larger changes in direct (~7.7%) and tunnel (~−83.5% and +507% for tension and compression respectively) currents between the components of the heterostructures (

Table 1). These tendencies in the conductance changes of the encapsulated Sb

2Te

3-MWCNT heterostructures, as well as the experimentally observed decrease in the conductance by ~4% of the encapsulated bare MWCNT networks when subjected to compression and tension during the bending (

Figure 5c,d) allows presumption that the mechanisms of the conductance changes in the encapsulated samples are similar to ones in the free-standing samples, where conduction changes in the Sb

2Te

3-MWCNT heterostructures are governed by the processes occurring in the dense Sb

2Te

3 layer. However, despite the contribution of the decrease in the conductance of the MWCNTs in the lower layers of Sb

2Te

3-MWCNT heterostructures in both compressive and tension modes, the absolute values of the increase in the conduction, when the encapsulated Sb

2Te

3-MWCNT-based sample is subjected to compressive stress, is by ~5% higher than the absolute values of its decrease when subjected to tension (

Figure 5a,b). This effect may be due to the significant increase in the tunnel current density in compression mode of the sample (~507%), which is ~6 times higher in comparison with the estimated tunnel current decrease in the tension mode (~83.5%,

Table 1). In addition, the impact of PDMS on the interfaces between Sb

2Te

3 nanostructures in the Sb

2Te

3-MWCNT networks should be considered. Encapsulation is known to decrease the film overall conductance [

7], possibly as a result of polymer penetration between the nanostructures. As the PDMS polymer is elastic, it may also change the distance between the nanostructures, as well as the height of the potential barriers between the nanostructures in case of tunnel electrical contacts. When the layer with the highest concentration of Sb

2Te

3 is compressed, it is possible that the polymer is compressed or partially extruded from the interface between the nanostructures, resulting in the reduction of the height of the potential barrier between the nanostructures, as well as the increase of direct electrical contact area between the nanostructures upon further compression.

In the samples, prepared by mixing the Sb

2Te

3-MWCNT heterostructures and bare MWCNTs in PVA, the increase by 0.6–0.8% and decrease by 0.4–0.5% in the electrical conductance when subjected to compression and tension respectively (

Figure 6) is in agreement with the estimated for these samples changes: ~0.5% increase (when subjected to compression) or decrease (when subjected to tension, accompanied by the increase or decrease in the tunnel current by ~10.5–12% depending on the bending mode (

Table 1). It should be noted that in contrast with the free-standing and encapsulated samples, where the active material is located at one side of the film, and consequently, is subjected to compression or tension during the bending, in the mixed samples the active material is present throughout the film. That means that during the bending of these films, while one side of the film is subjected to the compression, the opposite side of the film is subjected to tension, and the processes, occurring at both sides, contribute to the changes of total conductance of the film. During the mixing process of Sb

2Te

3-MWCNT heterostructures and bare MWCNTs with PVA, the components of the Sb

2Te

3-MWCNT heterostructures and MWCNTs are preserved in the PVA matrix apart from each other, forming direct and tunnel contacts. Gradient distribution and restriction of motion (sliding) of the MWCNTs in the PVA results in higher contribution of tunnel currents to the total conduction, and consequently, in bending behavior similar to the samples based on Sb

2Te

3-MWCNT heterostructures. During the bending, the impact of the sample side with higher concentration of nanostructures and MWCNTs is higher due to the higher number of newly formed, disrupted, or impacted contacts between them, which results in the increase of the electrical conductance when the sample is subjected to compression, and its decrease when the sample is subjected to tension.

5. Conclusions

In this work, bare p-type MWCNT networks and Sb2Te3-MWCNT heterostructures, fabricated by direct deposition of Sb2Te3 on MWCNT networks, were used for the preparation of three types of flexible films: free-standing networks on flexible polyimide substrates, encapsulated in PDMS, and mixed in PVA. Prepared films were subsequently subjected to compressive or tensile stress during the bending down to the radius of 3 mm, and the changes in the electrical conductance of the films in respect to the distribution gradient of the heterostructures or MWCNTs in these films was studied for the first time. It was found that the magnitude of the conductance changes was increasing with the increase of the total thickness of the film. All Sb2Te3-MWCNT heterostructures-based samples showed similar tendencies of the changes of the electrical response to bending, which was the increase of the electrical conductance under compressive stress and its decrease under tensile stress. Such tendencies most likely are related to the formation of new electrical contacts and/or convergence of the existing contacts between the Sb2Te3 nanostructures, MWCNTs, as well as between the Sb2Te3 and MWCNTs under compression stress, resulting in the increase of direct and tunnel contact areas, and to the disruption and/or distancing of previously established electrical contacts between these components under tensile stress, resulting in decrease of the direct electrical contact areas, transition of these contacts from direct to tunnel mode or disappearance of the contacts. Dominating contribution of Sb2Te3 nanostructures to the changes of electrical conductance under compressive stress of the Sb2Te3-MWCNT heterostructures-based films was proved by the data, obtained for the bare MWCNT-based films, were similar to the Sb2Te3-MWCNT heterostructures-based films behavior was not observed. Most of the bare MWCNTs-based samples showed a decrease in electrical conductance for both compressive and tensile stress. This effect is explained by the dominance of the direct electrical contacts in the MWCNT networks and equal decrease of the active contact area within the MWCNT network in both bending modes.

However, for the encapsulated Sb2Te3-MWCNT heterostructures, the changes in the conductance reached 20–25% from the initial conductance value. While the mechanism of the increase and decrease of the electrical conductance of the encapsulated samples was similar to the described above for the free-standing networks, significantly larger by the absolute values changes in the conductance can be explained by larger changes in the distances between the components of heterostructures during the bending due to the larger thickness of the film.

For the free-standing Sb2Te3-MWCNT heterostructures and MWCNT networks, as well as for the composites prepared by mixing them with PVA, the changes in the conductance remained within ~1% from the initial conductance value of not-bent sample. After unbending (straightening), the conductance values of all types of studied flexible films returned to the initial values with deviations not exceeding 0.5%. This proves stability of the investigated films and their suitability for the applications in flexible devices, for example, wearable electronics or low-power thermoelectrical generators. Expressed reversible changes in the electrical conductance of the encapsulated Sb2Te3-MWCNT heterostructures in response to bending indicated their usability for the applications on curved surfaces, as well as makes these films perspective for applications as strain-stress sensors. In addition, changes in electrical conductance when subjecting samples to compressive or tensile stress can be used to control the uniformity of distribution of components in materials composed of various heterostructures, as well as for the control of distribution of fillers in polymer-based composites.