A 1.6 kV Ga2O3 Schottky Barrier Diode with a Low Reverse Current of 1.2 × 10−5 A/cm2 Enabled by Field Plates and N Ion-Implantation Edge Termination

Abstract

1. Introduction

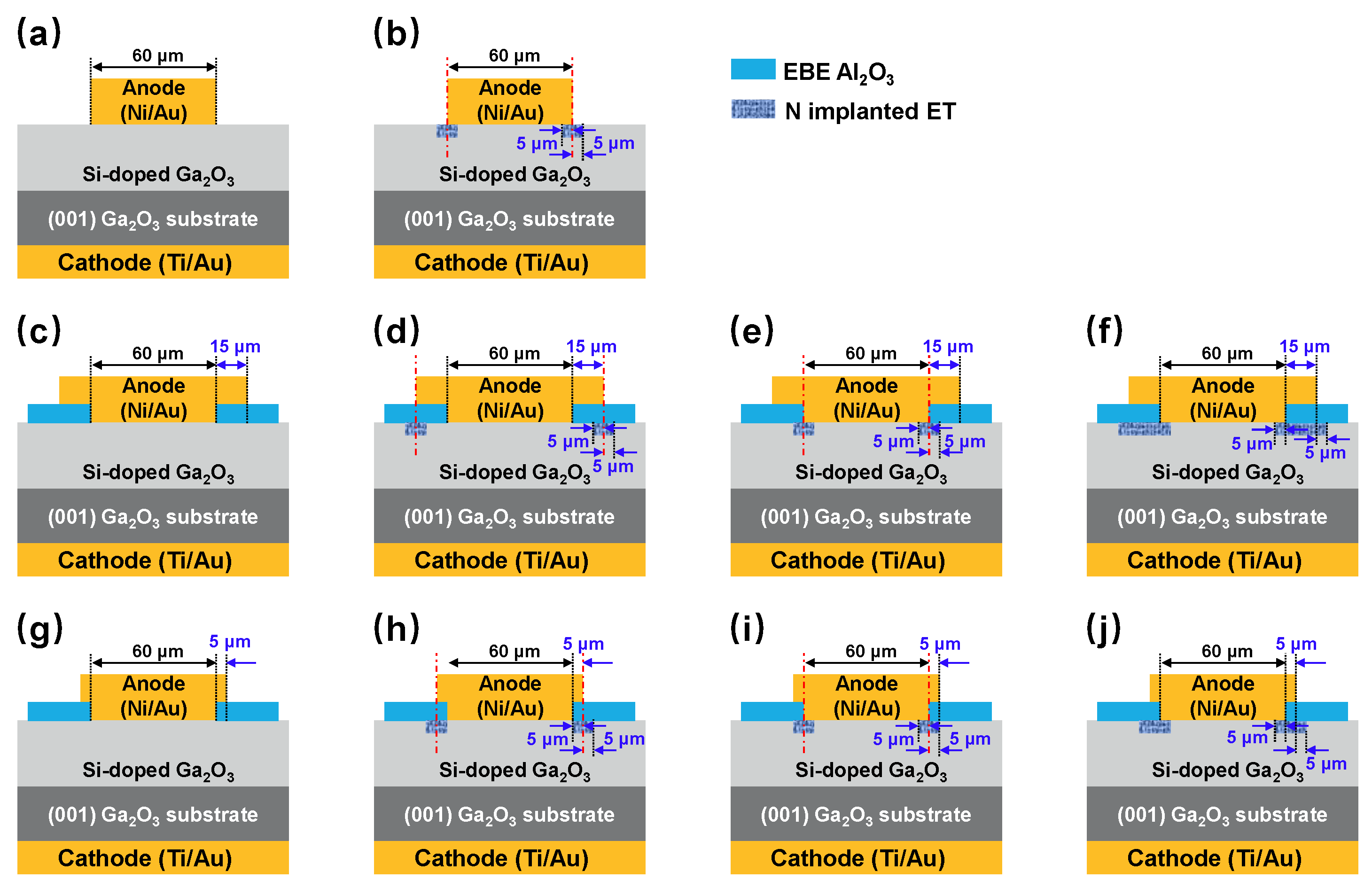

2. Device Structure and Fabrication Process

3. Results and Discussion

3.1. Electrical Properties and Simulations of Devices in Group 1

3.2. Electrical Properties and Simulations of Devices in Group 2

3.3. Electrical Properties and Simulations of Devices in Group 3

3.4. Comprehensive Comparisons and Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pearton, S.J.; Yang, J.; Cary, P.H., IV; Ren, F.; Kim, J.; Tadjer, M.J.; Mastro, M.A. A Review of Ga2O3 Materials, Processing, and Devices. Appl. Phys. Rev. 2018, 5, 011301. [Google Scholar] [CrossRef]

- Xiao, M.; Wang, B.; Liu, J.; Zhang, R.; Zhang, Z.; Ding, C.; Lu, S.; Sasaki, K.; Lu, G.-Q.; Buttay, C.; et al. Packaged Ga2O3 Schottky Rectifiers with over 60-A Surge Current Capability. IEEE Trans. Power Electron. 2021, 36, 8565–8569. [Google Scholar] [CrossRef]

- Kuramata, A.; Koshi, K.; Watanabe, S.; Yamaoka, Y.; Masui, T.; Yamakoshi, S. High-Quality β-Ga2O3 Single Crystals Grown by Edge-Defined Film-Fed Growth. Jpn. J. Appl. Phys. 2016, 55, 1202A2. [Google Scholar] [CrossRef]

- Togashi, R.; Nomura, K.; Eguchi, C.; Fukizawa, T.; Goto, K.; Thieu, Q.T.; Murakami, H.; Kumagai, Y.; Kuramata, A.; Yamakoshi, S.; et al. Thermal Stability of β-Ga2O3 in Mixed Flows of H2 and N2. Jpn. J. Appl. Phys. 2015, 54, 041102. [Google Scholar] [CrossRef]

- Gucmann, F.; Nadazdy, P.; Husekova, K.; Dobrocka, E.; Priesol, J.; Egyenes, F.; Satka, A.; Rosova, A.; Tapajna, M. Thermal Stability of Rhombohedral α- and Monoclinic β-Ga2O3 Grown on Sapphire by Liquid-Injection MOCVD. Mater. Sci. Semicond. Process. 2023, 156, 107289. [Google Scholar] [CrossRef]

- Konishi, K.; Goto, K.; Murakami, H.; Kumagai, Y.; Kuramata, A.; Yamakoshi, S.; Higashiwaki, M. 1-kV Vertical Ga2O3 Field-Plated Schottky Barrier Diodes. Appl. Phys. Lett. 2017, 110, 103506. [Google Scholar] [CrossRef]

- Sasaki, K.; Wakimoto, D.; Thieu, Q.T.; Koishikawa, Y.; Kuramata, A.; Higashiwaki, M.; Yamakoshi, S. First Demonstration of Ga2O3 Trench MOS-Type Schottky Barrier Diodes. IEEE Electron Device Lett. 2017, 38, 783–785. [Google Scholar] [CrossRef]

- Hu, Z.; Lv, Y.; Zhao, C.; Feng, Q.; Feng, Z.; Dang, K.; Tian, X.; Zhang, Y.; Ning, J.; Zhou, H.; et al. Beveled Fluoride Plasma Treatment for Vertical β-Ga2O3 Schottky Barrier Diode with High Reverse Blocking Voltage and Low Turn-On Voltage. IEEE Electron Device Lett. 2020, 41, 441–444. [Google Scholar] [CrossRef]

- Yang, J.; Fares, C.; Elhassani, R.; Xian, M.; Ren, F.; Pearton, S.J.; Tadjer, M.; Kuramata, A. Reverse Breakdown in Large Area, Field-Plated, Vertical β-Ga2O3 Rectifiers. ECS J. Solid State Sci. Technol. 2019, 8, Q3159. [Google Scholar] [CrossRef]

- Lv, Y.; Zhou, X.; Long, S.; Song, X.; Wang, Y.; Liang, S.; He, Z.; Han, T.; Tan, X.; Feng, Z.; et al. Source-Field-Plated β-Ga2O3 MOSFET with Record Power Figure of Merit of 50.4 MW/cm2. IEEE Electron Device Lett. 2019, 40, 83–86. [Google Scholar] [CrossRef]

- Lv, Y.; Liu, H.; Zhou, X.; Wang, Y.; Song, X.; Cai, Y.; Yan, Q.; Wang, C.; Liang, S.; Zhang, J.; et al. Lateral β-Ga2O3 MOSFETs with High Power Figure of Merit of 277 MW/cm2. IEEE Electron Device Lett. 2020, 41, 537–540. [Google Scholar] [CrossRef]

- Montgomery, R.H.; Zhang, Y.; Yuan, C.; Kim, S.; Shi, J.; Itoh, T.; Mauze, A.; Kumar, S.; Speck, J.; Graham, S. Thermal Management Strategies for Gallium Oxide Vertical Trench-Fin MOSFETs. J. Appl. Phys. 2021, 129, 085301. [Google Scholar] [CrossRef]

- Zhou, X.; Ma, Y.; Xu, G.; Liu, Q.; Liu, J.; He, Q.; Zhao, X.; Long, S. Enhancement-Mode β-Ga2O3 U-Shaped Gate Trench Vertical MOSFET Realized by Oxygen Annealing. Appl. Phys. Lett. 2022, 121, 223501. [Google Scholar] [CrossRef]

- Roy, S.; Bhattacharyya, A.; Peterson, C.; Krishnamoorthy, S. 2.1 kV (001) β-Ga2O3 Vertical Schottky Barrier Diode with High-k Oxide Field Plate. Appl. Phys. Lett. 2023, 122, 152101. [Google Scholar] [CrossRef]

- Allen, N.; Xiao, M.; Yan, X.; Sasaki, K.; Tadjer, M.J.; Ma, J.; Zhang, R.; Wang, H.; Zhang, Y. Vertical Ga2O3 Schottky Barrier Diodes with Small-Angle Beveled Field Plates: A Baliga’s Figure-of-Merit of 0.6 GW/cm2. IEEE Electron Device Lett. 2019, 40, 1399–1402. [Google Scholar] [CrossRef]

- Li, W.; Hu, Z.; Nomoto, K.; Jinno, R.; Zhang, Z.; Tu, T.Q.; Sasaki, K.; Kuramata, A.; Jena, D.; Xing, H.G. 2.44 kV Ga2O3 Vertical Trench Schottky Barrier Diodes with Very Low Reverse Leakage Current. In Proceedings of the IEEE Annual International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 1–5 December 2018. [Google Scholar]

- Li, W.; Nomoto, K.; Hu, Z.; Jena, D.; Xing, H.G. Fin-Channel Orientation Dependence of Forward Conduction in kV-Class Ga2O3 Trench Schottky Barrier Diodes. Appl. Phys. Express 2019, 12, 061007. [Google Scholar] [CrossRef]

- Li, W.; Nomoto, K.; Hu, Z.; Jena, D.; Xing, H.G. Field-Plated Ga2O3 Trench Schottky Barrier Diodes With a BV2/Ron,sp of up to 0.95 GW/cm2. IEEE Electron Device Lett. 2020, 41, 107–110. [Google Scholar] [CrossRef]

- Wang, Y.; Lv, Y.; Long, S.; Zhou, X.; Song, X.; Liang, S.; Han, T.; Tan, X.; Feng, Z.; Cai, S.; et al. High-Voltage (−201) β-Ga2O3 Vertical Schottky Barrier Diode with Thermally-Oxidized Termination. IEEE Electron Device Lett. 2020, 41, 131–134. [Google Scholar] [CrossRef]

- Yan, Q.; Gong, H.; Zhang, J.; Ye, J.; Zhou, H.; Liu, Z.; Xu, S.; Wang, C.; Hu, Z.; Feng, Q.; et al. β-Ga2O3 Hetero-Junction Barrier Schottky Diode with Reverse Leakage Current Modulation and BV2/Ron,sp Value of 0.93 GW/cm2. Appl. Phys. Lett. 2021, 118, 122102. [Google Scholar] [CrossRef]

- Gong, H.H.; Yu, X.X.; Xu, Y.; Chen, X.H.; Kuang, Y.; Lv, Y.J.; Yang, Y.; Ren, F.-F.; Feng, Z.H.; Gu, S.L.; et al. β-Ga2O3 Vertical Heterojunction Barrier Schottky Diodes Terminated with p-NiO Field Limiting Rings. Appl. Phys. Lett. 2021, 118, 202102. [Google Scholar] [CrossRef]

- Zhou, H.; Yan, Q.; Zhang, J.; Lv, Y.; Liu, Z.; Zhang, Y.; Dang, K.; Dong, P.; Feng, Z.; Feng, Q.; et al. High-Performance Vertical β-Ga2O3 Schottky Barrier Diode with Implanted Edge Termination. IEEE Electron Device Lett. 2019, 40, 1788–1791. [Google Scholar] [CrossRef]

- Yang, J.; Ren, F.; Tadjer, M.; Pearton, S.J.; Kuramata, A. 2300V Reverse Breakdown Voltage Ga2O3 Schottky Rectifiers. ECS J. Solid State Sci. Technol. 2018, 7, Q92. [Google Scholar] [CrossRef]

- Lin, C.-H.; Yuda, Y.; Wong, M.H.; Sato, M.; Takekawa, N.; Konishi, K.; Watahiki, T.; Yamamuka, M.; Murakami, H.; Kumagai, Y.; et al. Vertical Ga2O3 Schottky Barrier Diodes with Guard Ring Formed by Nitrogen-Ion Implantation. IEEE Electron Device Lett. 2019, 40, 1487–1490. [Google Scholar] [CrossRef]

- Gao, Y.; Li, A.; Feng, Q.; Hu, Z.; Feng, Z.; Zhang, K.; Lu, X.; Zhang, C.; Zhou, H.; Mu, W.; et al. High-Voltage β-Ga2O3 Schottky Diode with Argon-Implanted Edge Termination. Nanoscale Res. Lett. 2019, 14, 8. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhang, J.; Feng, Z.; Hu, Z.; Chen, J.; Dang, K.; Yan, Q.; Dong, P.; Zhou, H.; Hao, Y. Impact of Implanted Edge Termination on Vertical β-Ga2O3 Schottky Barrier Diodes under OFF-State Stressing. IEEE Trans. Electron Devices 2020, 67, 3948–3953. [Google Scholar] [CrossRef]

- Murakami, H.; Nomura, K.; Goto, K.; Sasaki, K.; Kawara, K.; Thieu, Q.T.; Togashi, R.; Kumagai, Y.; Higashiwaki, M.; Kuramata, A.; et al. Homoepitaxial Growth of β-Ga2O3 Layers by Halide Vapor Phase Epitaxy. Appl. Phys. Express 2014, 8, 015503. [Google Scholar] [CrossRef]

- Goto, K.; Konishi, K.; Murakami, H.; Kumagai, Y.; Monemar, B.; Higashiwaki, M.; Kuramata, A.; Yamakoshi, S. Halide Vapor Phase Epitaxy of Si Doped β-Ga2O3 and Its Electrical Properties. Thin Solid Films 2018, 666, 182–184. [Google Scholar] [CrossRef]

- Wong, M.H.; Goto, K.; Murakami, H.; Kumagai, Y.; Higashiwaki, M. Current Aperture Vertical β-Ga2O3 MOSFETs Fabricated by N- and Si-Ion Implantation Doping. IEEE Electron Device Lett. 2019, 40, 431–434. [Google Scholar] [CrossRef]

- Wong, M.H.; Lin, C.-H.; Kuramata, A.; Yamakoshi, S.; Murakami, H.; Kumagai, Y.; Higashiwaki, M. Acceptor Doping of β-Ga2O3 by Mg and N Ion Implantations. Appl. Phys. Lett. 2018, 113, 102103. [Google Scholar] [CrossRef]

| Parameters | β-Ga2O3 |

|---|---|

| Bandgap (eV) | 4.8 |

| Affinity (eV) | 4.0 |

| NC (cm−3) | 3.7 × 1018 |

| NV (cm−3) | 5.0 × 1018 |

| Relative permittivity | 10.0 |

| Electron mobility (cm2 V−1 s−1) | 200 |

| Saturation velocity (cm s−1) | 2 × 107 |

| Device | Vbr (V) | Ron,sp (mΩ·cm2) | Von (V) | Jrev (A/cm2 @ −1000 V) |

|---|---|---|---|---|

| Sample 1 | 572 | 4.16 | 0.84 | |

| Sample 2 | 920 | 4.68 | 0.89 | |

| Sample 3 | 1276 | 4.20 | 0.84 | 2.6 × 10−2 |

| Sample 4 | 1422 | 4.67 | 0.85 | 4.4 × 10−4 |

| Sample 5 | 1616 | 5.11 | 0.90 | 1.2 × 10−5 |

| Sample 6 | 1610 | 6.31 | 0.91 | 4.1 × 10−6 |

| Sample 7 | 1223 | 4.05 | 0.89 | 4.1 × 10−2 |

| Sample 8 | 1307 | 4.29 | 0.90 | 3.8 × 10−5 |

| Sample 9 | 1454 | 5.16 | 0.95 | 6.4 × 10−6 |

| Sample 10 | 1469 | 5.34 | 0.95 | 5.5 × 10−6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, X.; Yang, J.; Zhang, H.; Liu, Y.; Xie, G.; Liu, W. A 1.6 kV Ga2O3 Schottky Barrier Diode with a Low Reverse Current of 1.2 × 10−5 A/cm2 Enabled by Field Plates and N Ion-Implantation Edge Termination. Nanomaterials 2024, 14, 978. https://doi.org/10.3390/nano14110978

Zhou X, Yang J, Zhang H, Liu Y, Xie G, Liu W. A 1.6 kV Ga2O3 Schottky Barrier Diode with a Low Reverse Current of 1.2 × 10−5 A/cm2 Enabled by Field Plates and N Ion-Implantation Edge Termination. Nanomaterials. 2024; 14(11):978. https://doi.org/10.3390/nano14110978

Chicago/Turabian StyleZhou, Xinlong, Jining Yang, Hao Zhang, Yinchi Liu, Genran Xie, and Wenjun Liu. 2024. "A 1.6 kV Ga2O3 Schottky Barrier Diode with a Low Reverse Current of 1.2 × 10−5 A/cm2 Enabled by Field Plates and N Ion-Implantation Edge Termination" Nanomaterials 14, no. 11: 978. https://doi.org/10.3390/nano14110978

APA StyleZhou, X., Yang, J., Zhang, H., Liu, Y., Xie, G., & Liu, W. (2024). A 1.6 kV Ga2O3 Schottky Barrier Diode with a Low Reverse Current of 1.2 × 10−5 A/cm2 Enabled by Field Plates and N Ion-Implantation Edge Termination. Nanomaterials, 14(11), 978. https://doi.org/10.3390/nano14110978