Preparation of Fibrous Three-Dimensional Porous Materials and Their Research Progress in the Field of Stealth Protection

Abstract

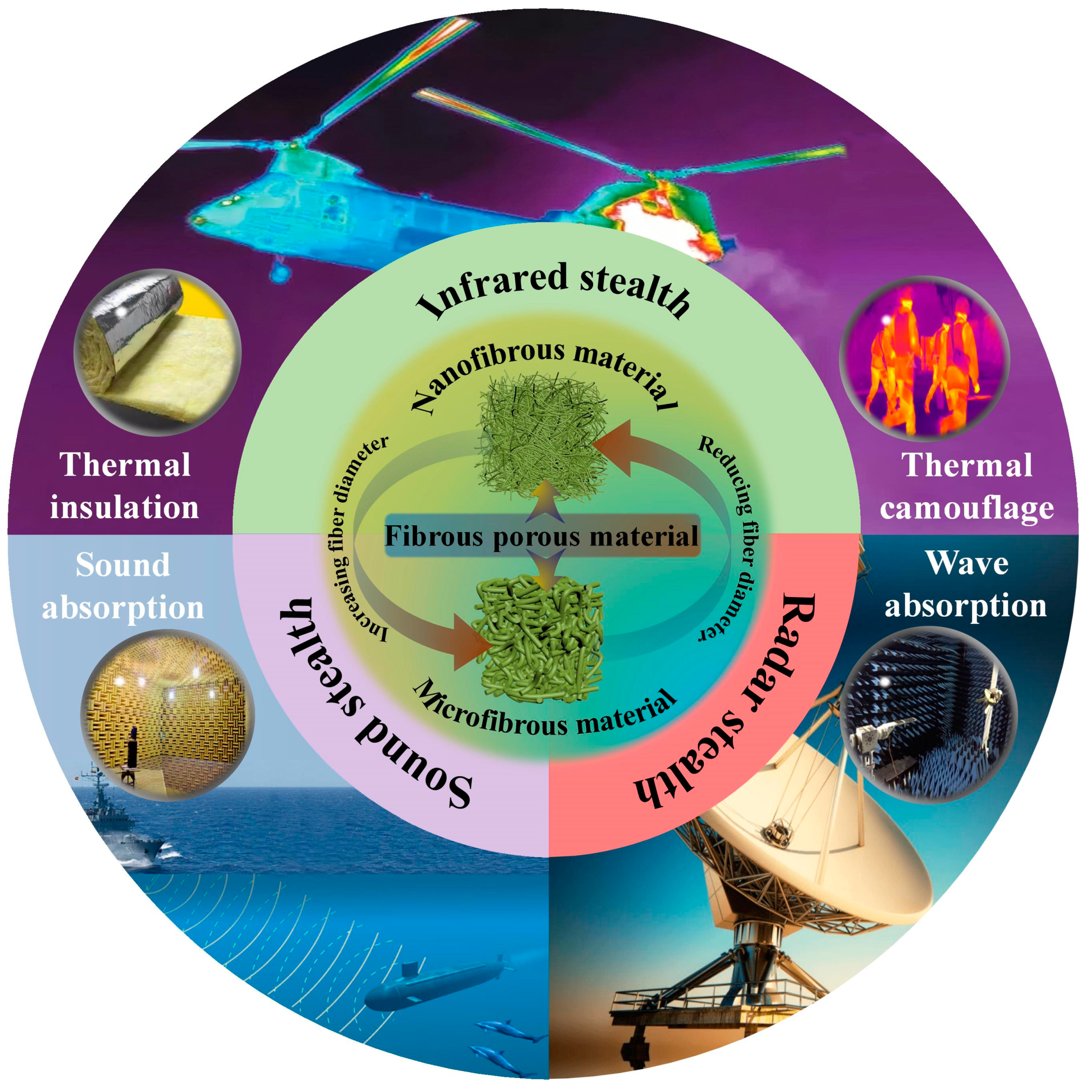

:1. Introduction

2. Material Types

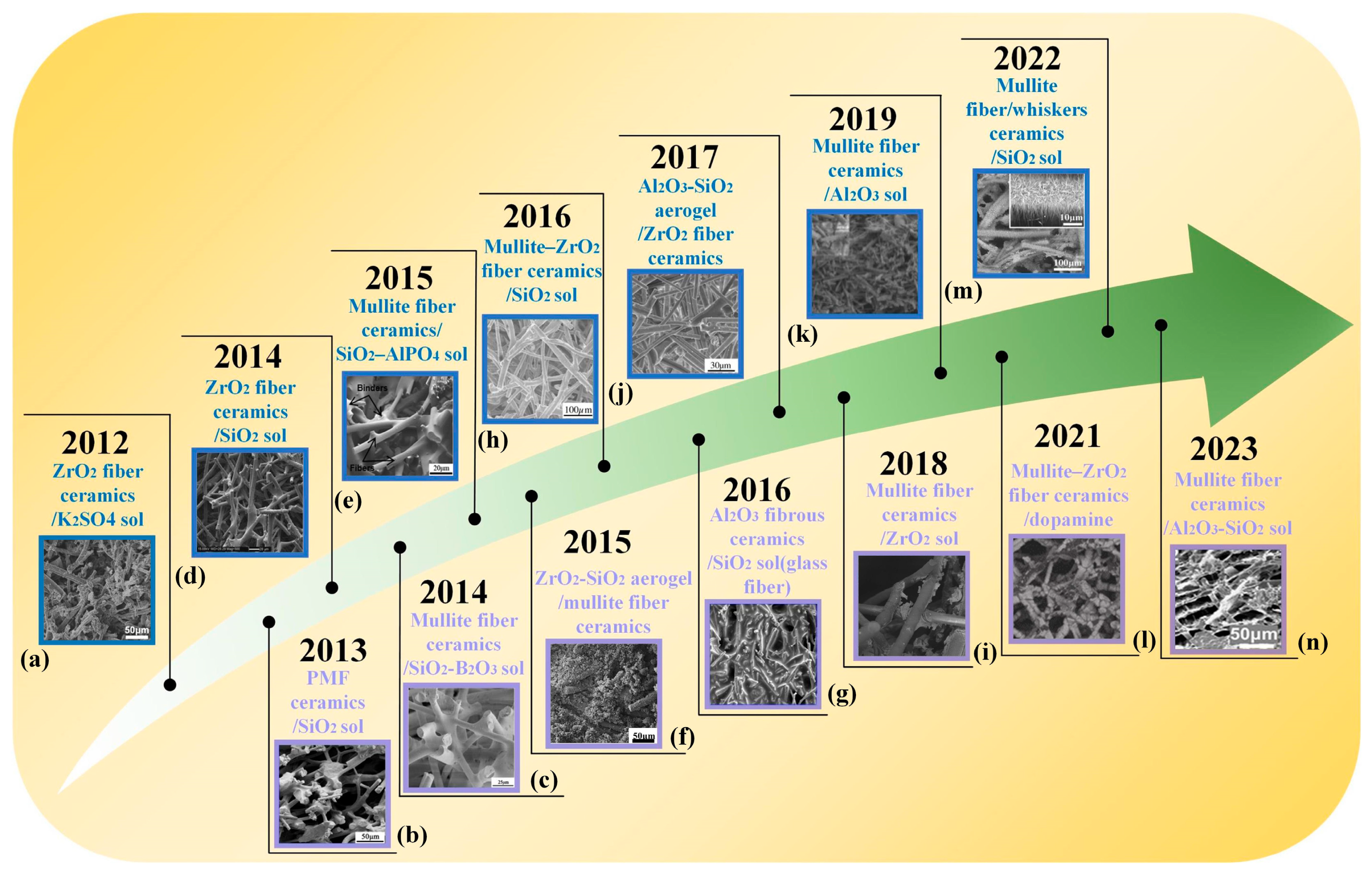

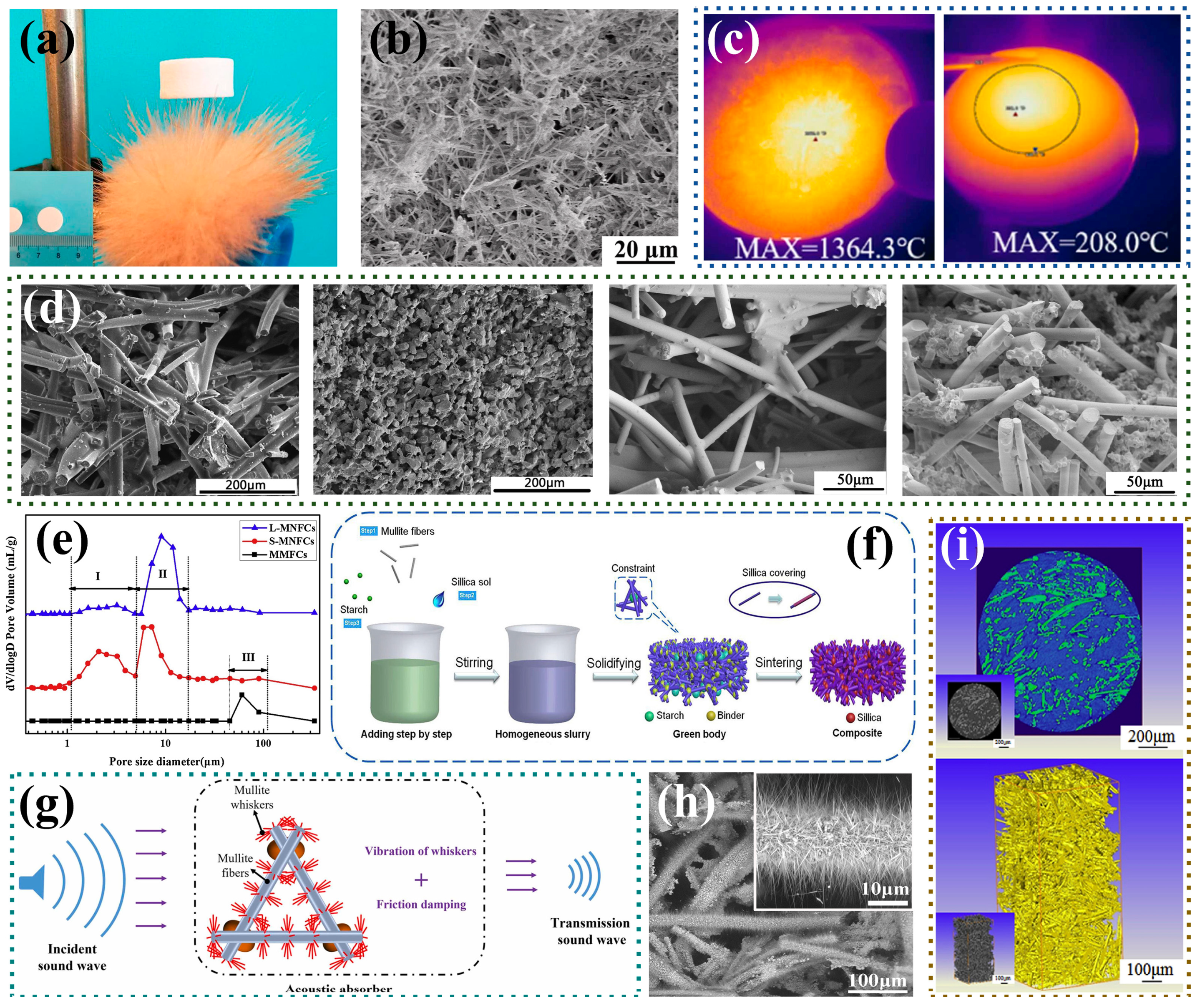

2.1. Microfibrous Three-Dimensional Porous Materials

2.1.1. Characteristics

2.1.2. Development Process

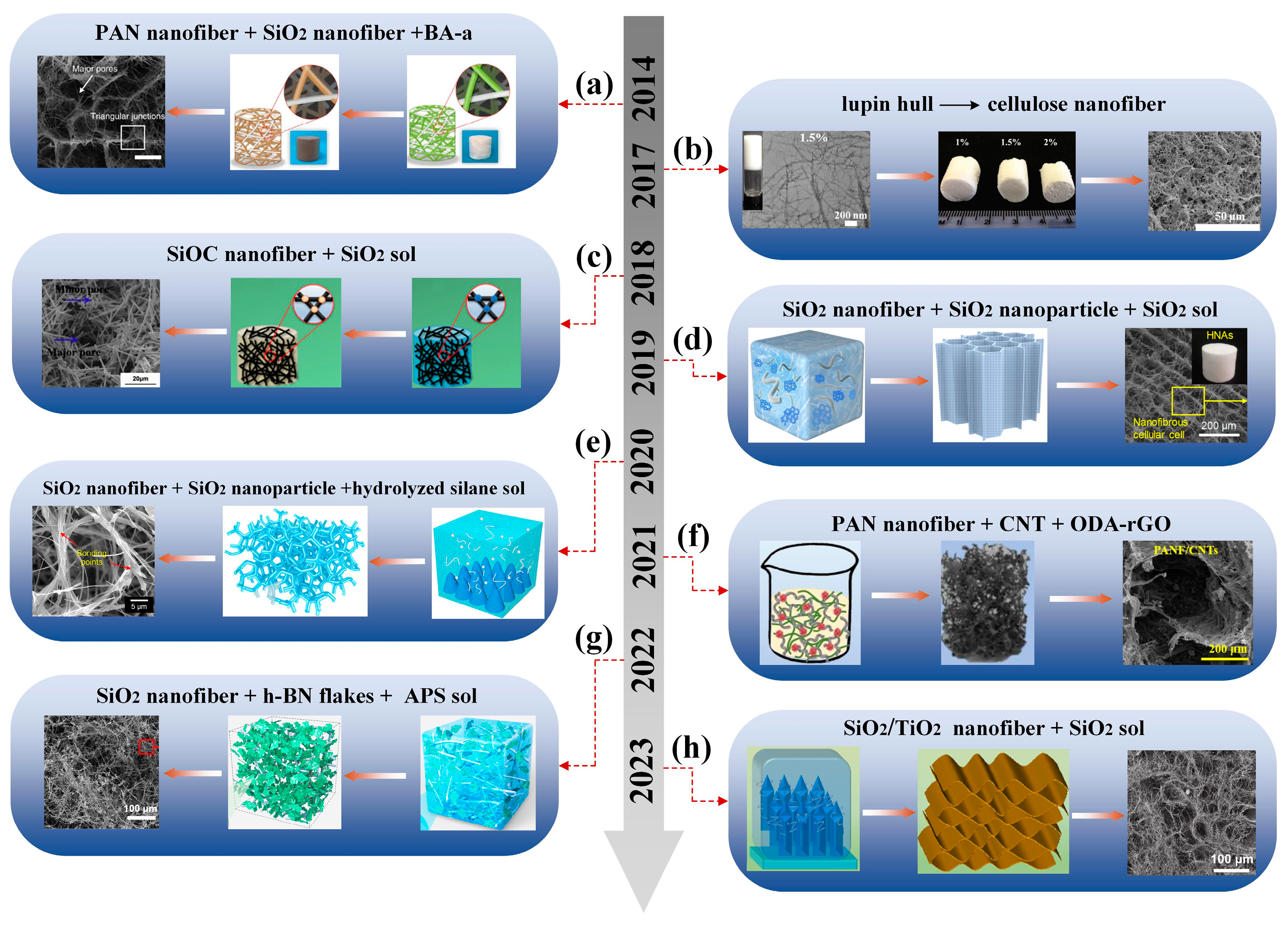

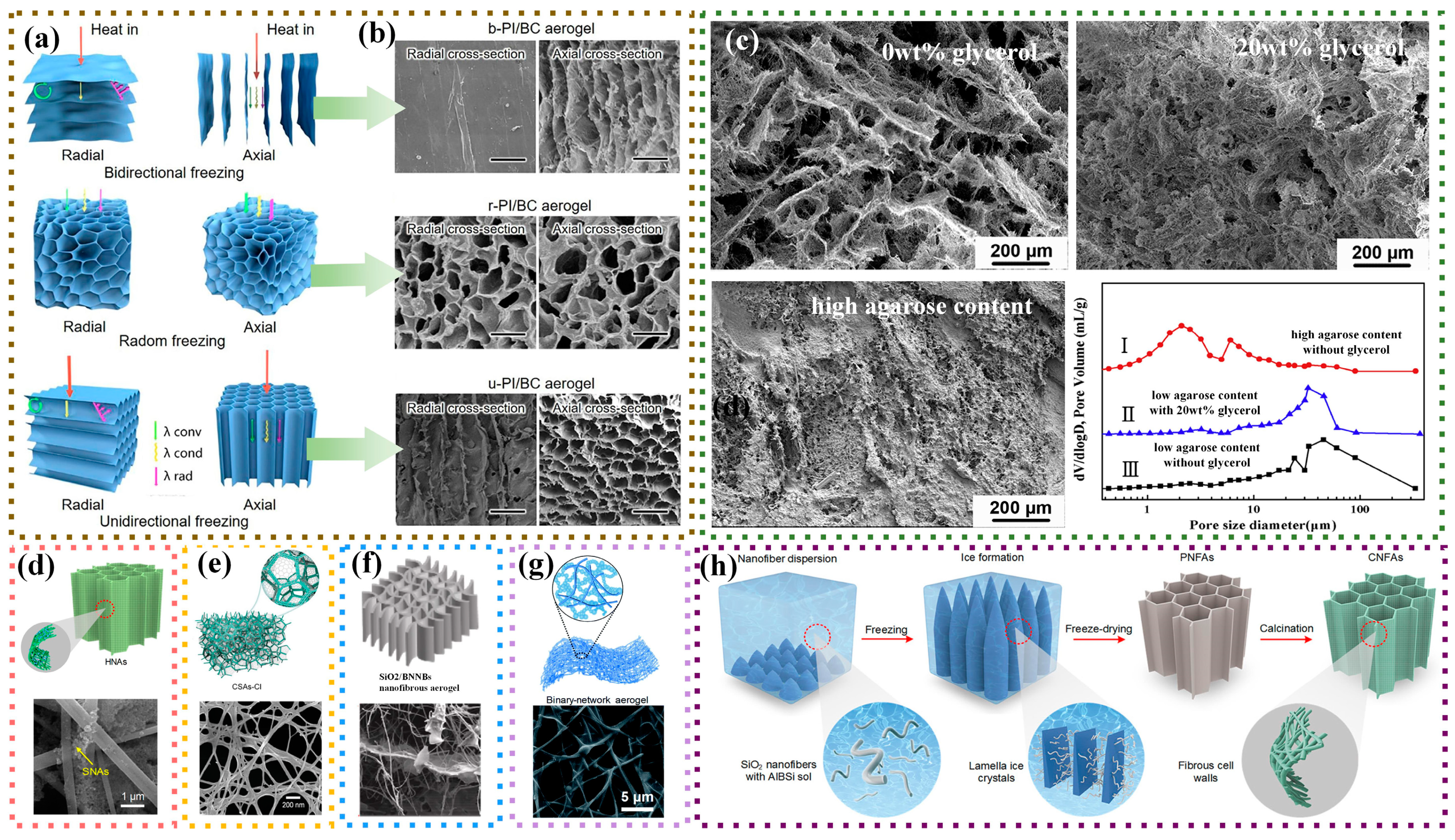

2.2. Nanofibrous Three-Dimensional Porous Materials

2.2.1. Characteristics

2.2.2. Development Process

3. Construction Method of Fibrous Three-Dimensional Porous Materials

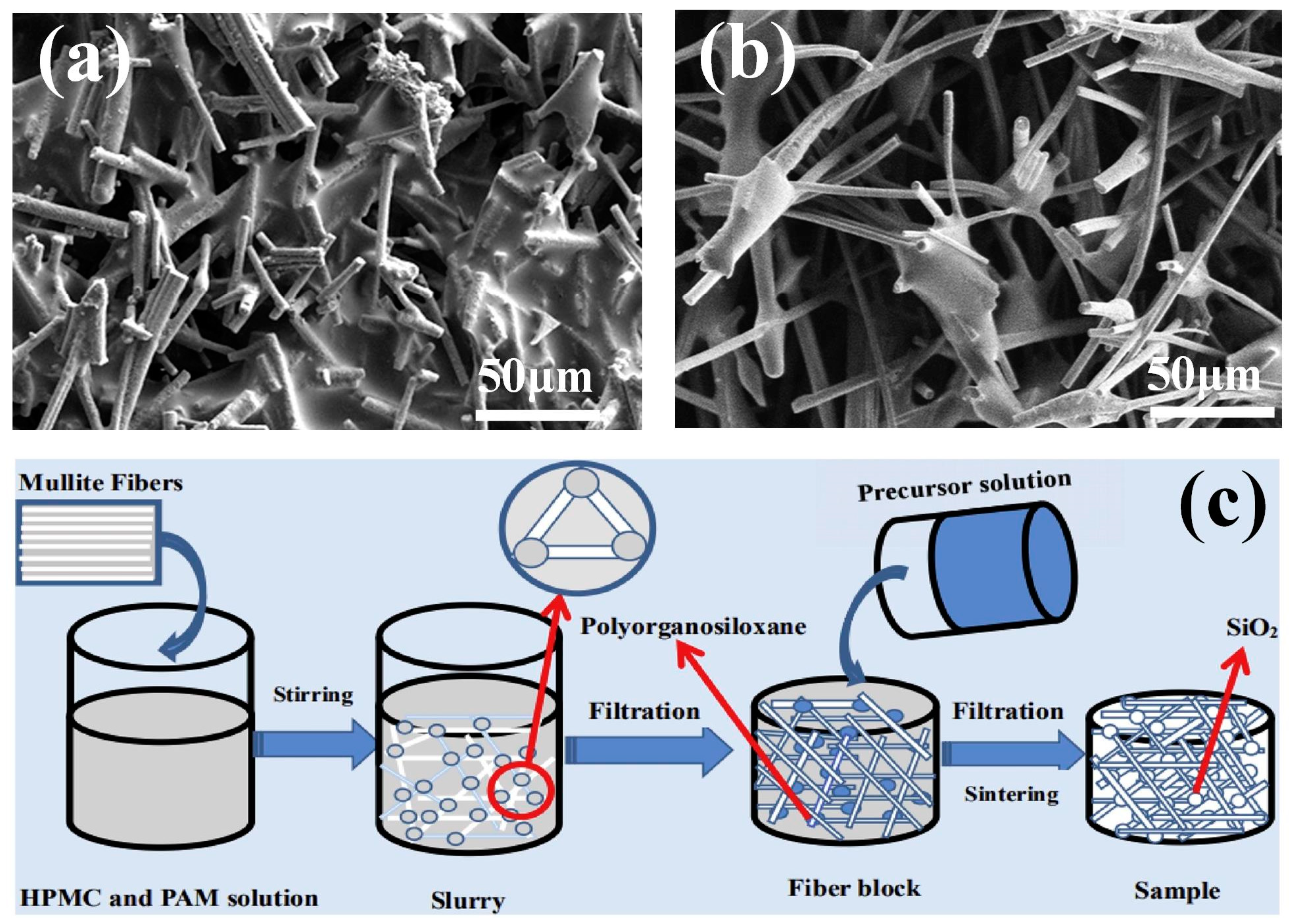

3.1. Vacuum-Forming Method

3.2. Gel Solidification Method

3.3. Freeze-Casting Method

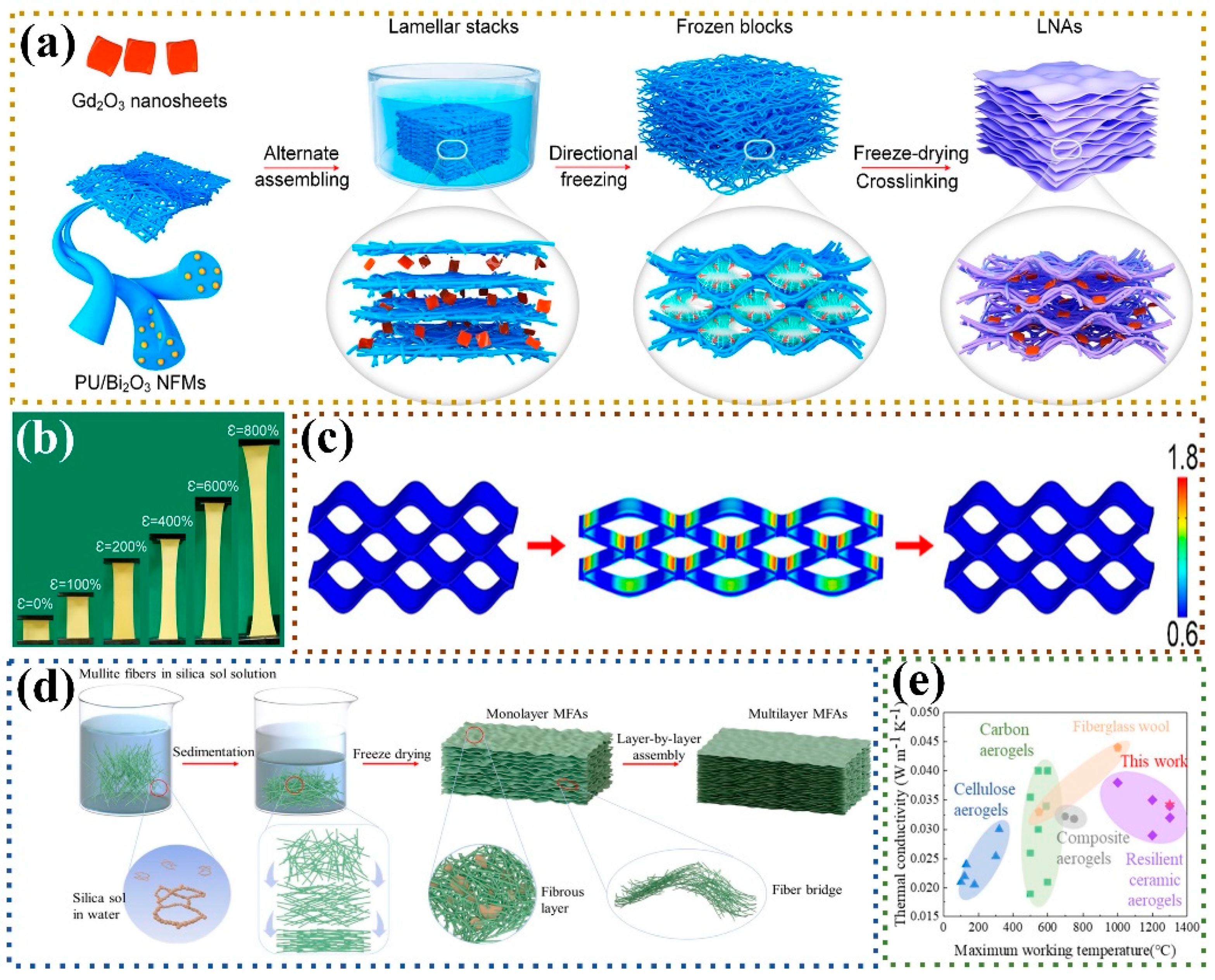

3.4. Impregnation Stacking Method

4. Application of Fibrous Three-Dimensional Porous Materials in Stealth Field

4.1. Infrared Stealth

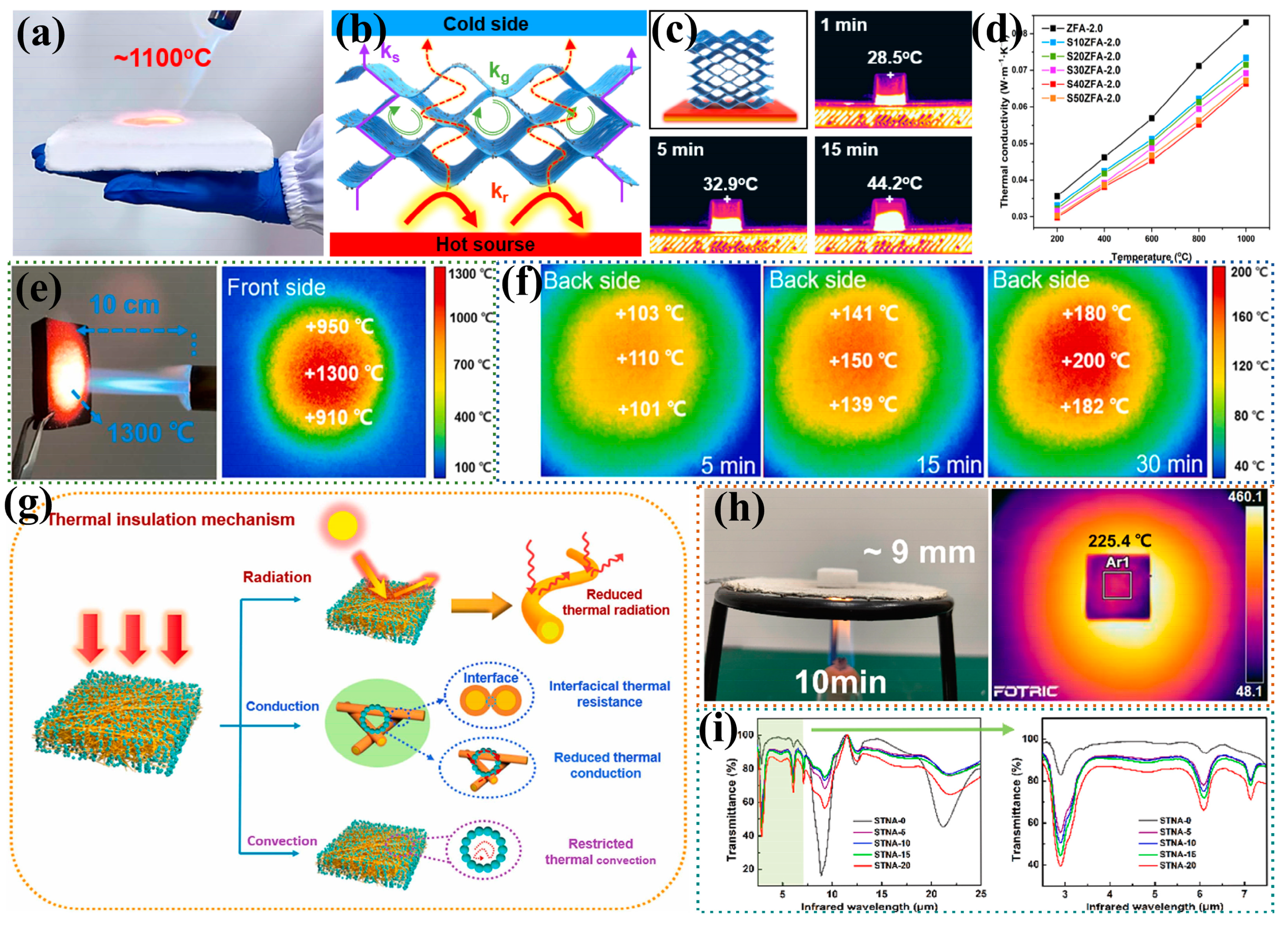

4.1.1. Static Infrared Stealth

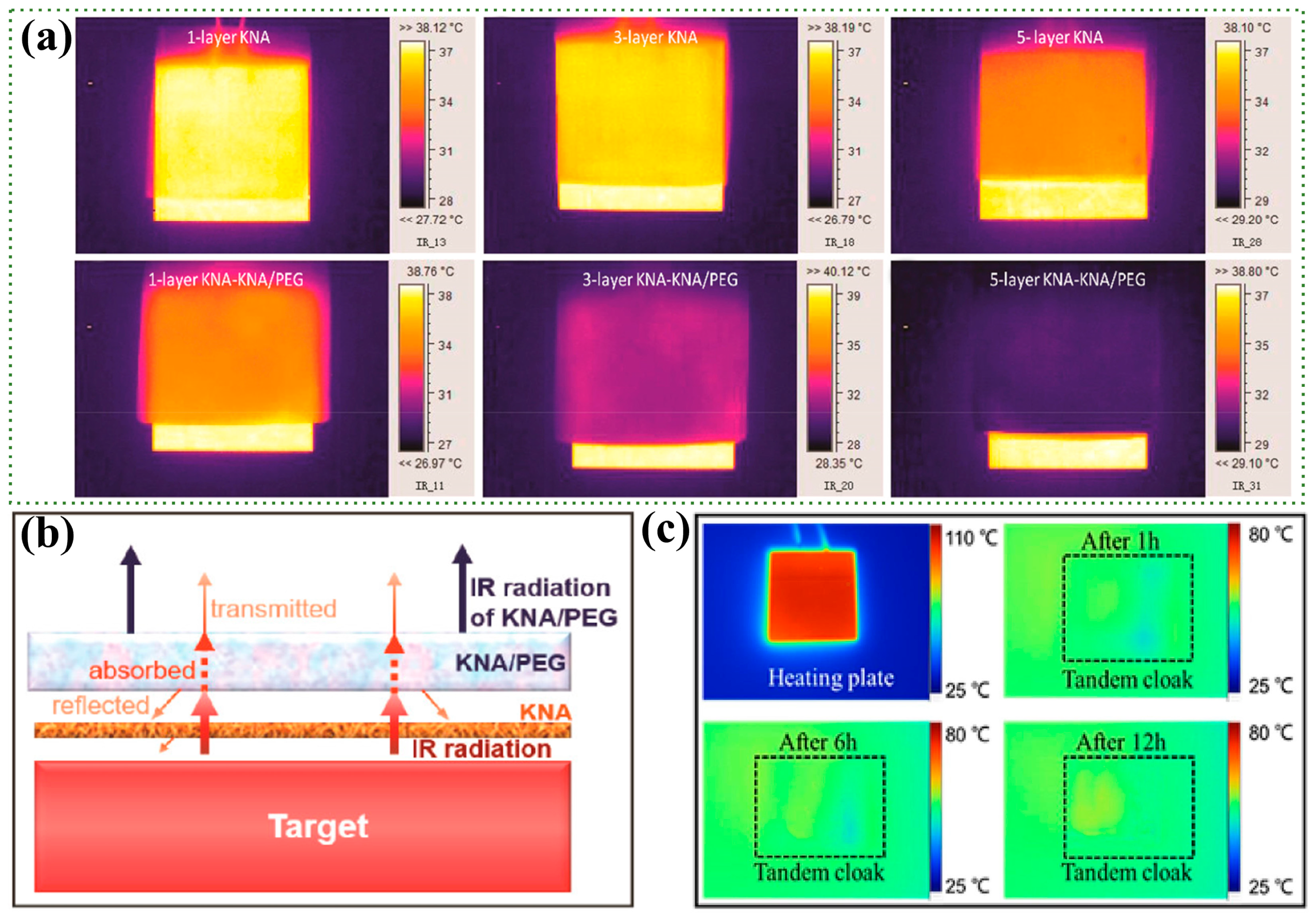

4.1.2. Dynamic Infrared Stealth

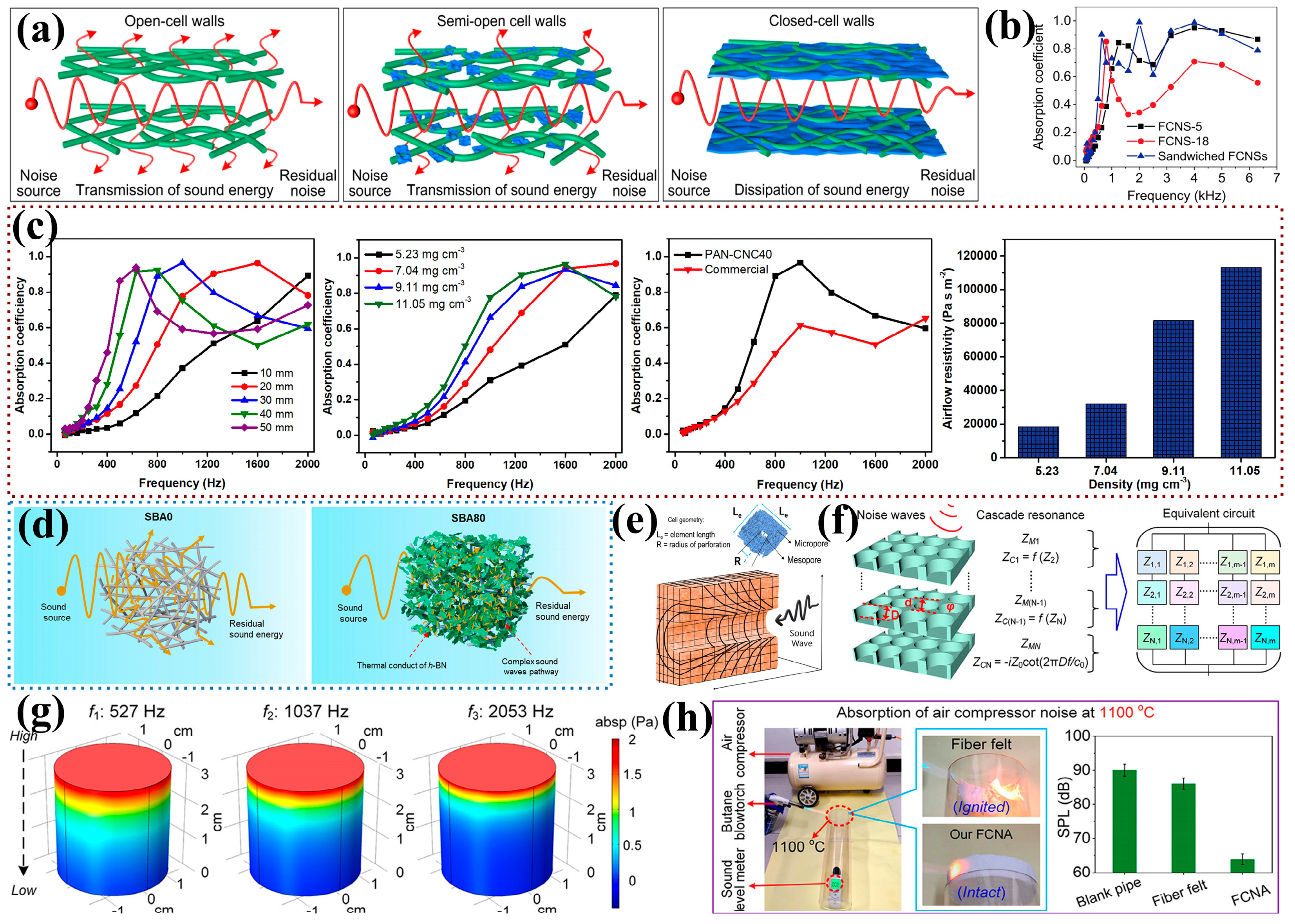

4.2. Acoustic Stealth

4.3. Radar Stealth

5. Conclusions and Prospects

- At present, most fibrous three-dimensional materials are prepared by fixing the fiber skeleton with binders. The physical and chemical bonding of binders at the fiber overlap keeps the stability of the fiber matrix. However, the choice of different fiber monomers and binders has a great impact on the performance of the final material. Neither binders with low strength after sintering nor binders with an excessively high sintering temperature should be chosen. The former will affect the comprehensive mechanical properties of the material, while the latter will affect the characteristics of the fiber monomer itself. Meanwhile, the addition of binders will also affect the pore structure of the material. Therefore, the selection of binders, the amount of addition, and the precise control of the sintering temperature is a challenge. How to achieve the good structural stability of the material without binders is a key issue. Natural nanofibers, such as bacterial cellulose and cellulose nanofibers, are rich in surface functional groups. They can form stable self-supporting structures through physical bonding and chemical cross-linking without additional binders. With a more excellent compression resilience, they are good choices for high-performance fibrous porous materials. Inspired by this, surface grafting modification and other processes can be performed on synthetic high-modulus fibers to endow them with self-cross-linking ability, thus obtaining fibrous porous materials with both a high compression resilience and high strength. This is an important trend for future development.

- Although the unique porous structure of fibrous three-dimensional porous materials can weaken the transmission of thermal energy, sound energy, and microwaves, the underlying mechanism is still immature. While researchers have utilized simulation methods to demonstrate the impact of structure on performance, the established models do not fully align with the actual internal structure, and the simulation methods are limited. Therefore, they cannot fully simulate the actual transmission behavior of thermal energy, sound energy, and microwaves within the material. Consequently, it is crucial to establish a transmission theory for thermal energy, sound energy, microwaves, and other energies within fibrous porous materials, and to construct a theoretical model that incorporates the effects of various properties of fibrous porous materials on the transmission processes of these energies. However, due to the limitations of modeling software and the complexity of the internal structure of fibrous porous materials, establishing an accurate theoretical model remains a significant challenge. In the future, a combination of extensive theoretical simulations and practical applications will be necessary to continuously improve and optimize the model. Only by utilizing an accurate theoretical model to guide the design of fibrous porous materials can we achieve the optimal material selection for different application scenarios, better respond to extreme conditions, and reduce production costs.

- In the design process of fibrous three-dimensional porous materials, more attention is paid to their compression resilience. Indeed, the demand for material compression resilience is more extensive in practical application scenarios. However, in some specific scenarios, other properties such as bending resistance and stretchability are of greater concern, especially when used as stealth coating materials, where bending and stretching characteristics are prioritized. Nonetheless, the stretching and bending of materials often involve stress in multiple directions, while compression mainly involves unidirectional stress. Moreover, stretching and bending are more likely to lead to material damage or significant deformation, posing a major challenge to improving the comprehensive mechanical properties of fibrous three-dimensional porous materials. In the future, the three-dimensional structure of fibrous porous materials can be improved through various methods, such as changing the internal fiber orientation and constructing negative Poisson’s ratio structures with specific mechanical properties. By altering the stress structure and force transmission mode of the materials, fibrous three-dimensional porous materials with excellent impact resistance, shear resistance, and fracture resistance can be produced.

- The current detection technology tends to be diversified, and a single means of stealth cannot be effectively camouflaged, so the development of multifunctional stealth materials has become the focus of research. However, stealth materials with different functions may mean the introduction of various components, which would influence the overall weight and cost of the materials, and how to enable the materials to possess multifunctional stealth properties within limited installation space is the greatest challenge in the process of design and production. The structural and functional modification of fibrous porous materials is a good choice to solve this problem, and the future direction of development is to design both a variety of functional characteristics of fibrous porous materials, which can be prepared through the regulation of the pore structure of heat-insulating–acoustic absorbing integration of materials for infrared and acoustic stealth, through the selection of the substrate to prepare the heat-insulating–wave absorption integration of materials for infrared and radar stealth, or to simultaneously modulate the pore structure of the material, change the matrix, and give the fiber surface functionalization characteristics, so as to prepare heat-insulating–acoustic and wave-absorbing integrated materials for infrared, acoustic, radar stealth, etc.. In addition, micro-nanofiber composite aerogels can be prepared in order to expand the range of its pore structure and extend the space of its functionalization modification.

- Currently, the preparation of fibrous porous materials is mostly confined to the laboratory stage, the materials produced are mainly small-sized samples, and the batch production of large-sized samples remains unresolved. The main reasons lie in the issues of cost and usability. On the one hand, the preparation of large-sized samples requires more fibers and solvents, as well as larger drying equipment and a longer drying time, which determines higher costs and technological difficulties. On the other hand, it remains a significant challenge whether large-sized samples can maintain and extend the mechanical properties of small-sized samples. As the radial size of the samples increases, their deflection may not be able to support their own gravity and cause fracture. Therefore, more attention needs to be paid to various mechanical performance indicators of the material during the design of large-sized samples to obtain practically usable large-sized fibrous porous materials. As a result, searching for low-cost, green, and renewable fiber raw materials, and conducting in-depth research on the relationship between material mechanical properties and size, are inevitable paths for fibrous three-dimensional porous materials to move towards practical applications.

Author Contributions

Funding

Conflicts of Interest

References

- Zhao, Y.; Ji, G.B. Multi-spectrum bands compatibility: New trends in stealth materials research. Sci. China-Mater. 2022, 65, 2936–2941. [Google Scholar] [CrossRef]

- Wang, H.Y.; Li, Z.X.; Li, D.Y.; Chen, P.; Pi, L.J.; Zhou, X.; Zhai, T.Y. Van der waals integration based on two-dimensional materials for high-performance infrared photodetectors. Adv. Funct. Mater. 2021, 31, 2103106. [Google Scholar] [CrossRef]

- Teng, S.; Liu, A.; Ye, X.; Wang, J.; Fu, J.; Wu, Z.; Chen, B.; Liu, C.; Zhou, H.; Zeng, Y.; et al. Review of intelligent detection and health assessment of underwater structures. Eng. Struct. 2024, 308, 117958. [Google Scholar] [CrossRef]

- Wu, Y.; Tan, S.J.; Zhao, Y.; Liang, L.L.; Zhou, M.; Ji, G.B. Broadband multispectral compatible absorbers for radar, infrared and visible stealth application. Prog. Mater. Sci. 2023, 135, 101088. [Google Scholar] [CrossRef]

- Fu, Z.; Pang, A.; Luo, H.; Zhou, K.; Yang, H. Research progress of ceramic matrix composites for high temperature stealth technology based on multi-scale collaborative design. J. Mater. Res. Technol. 2022, 18, 2770–2783. [Google Scholar] [CrossRef]

- Jin, L.; Zhao, Y.; Chen, C.; Zhang, J.; He, Y.; Yin, C.; Wu, N.; Tang, J.; Xing, S. Application, development, and challenges of stealth materials/structures in next-generation aviation equipment. Appl. Surf. Sci. Adv. 2024, 19, 100575. [Google Scholar] [CrossRef]

- Kang, M.; Wang, X.; Wei, Y.; Yu, Z.; Liu, Z. Latest research progress of infrared stealth textiles. Infrared Phys. Technol. 2024, 139, 105313. [Google Scholar] [CrossRef]

- Liu, Z.W.; Lyu, J.; Fang, D.; Zhang, X.T. Nanofibrous kevlar aerogel threads for thermal insulation in harsh environments. ACS Nano 2019, 13, 5703–5711. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Liu, C.; Wang, F.; Yin, X.; Yu, J.Y.; Zhang, S.C.; Ding, B. Recent advances in ultrafine fibrous materials for effective warmth retention. Adv. Fiber Mater. 2023, 5, 847–867. [Google Scholar] [CrossRef]

- Yang, M.M.; Chen, Z.F.; Ding, Y.; Qiong, W.; Liu, T.L.; Li, M.N.; Yang, L.X.; Cui, S. A lightweight and high compressive resistance thermal insulation material with dual-network structure. Nano Res. 2023, 16, 12942–12948. [Google Scholar] [CrossRef]

- Du, Y.; Kim, H.E. Research trends of the application of aerogel materials in clothing. Fash. Text. 2022, 9, 23. [Google Scholar] [CrossRef]

- Lyu, J.; Liu, Z.W.; Wu, X.H.; Li, G.Y.; Fang, D.; Zhang, X.T. Nanofibrous kevlar aerogel films and their phase-change composites for highly efficient infrared stealth. ACS Nano 2019, 13, 2236–2245. [Google Scholar] [CrossRef] [PubMed]

- Ding, C.Y.; Shao, C.S.; Wu, S.S.; Liu, Y.; Ma, S.Q.; Hu, X.S.; Cao, Z.Y.; Ren, X.Z.; Zhong, B.; Wen, G.W.; et al. A review of 1D carbon-based materials assembly design for lightweight microwave absorption. Carbon 2023, 213, 118279. [Google Scholar] [CrossRef]

- Tang, X.N. Recent advances on nanofibrous acoustic materials for noise reduction applications. J. Text. Inst. 2023, 114, 1581–1591. [Google Scholar] [CrossRef]

- Liu, H.L.; Zhang, X.X.; Liao, Y.L.; Yu, J.Y.; Liu, Y.T.; Ding, B. Building-envelope-inspired, thermomechanically robust all-fiber ceramic meta-aerogel for temperature-controlled dominant infrared camouflage. Adv. Mater. 2024; early view. [Google Scholar] [CrossRef] [PubMed]

- Sun, B.; Long, Y.Z.; Zhang, H.D.; Li, M.M.; Duvail, J.L.; Jiang, X.Y.; Yin, H.L. Advances in three-dimensional nanofibrous macrostructures via electrospinning. Prog. Polym. Sci. 2014, 39, 862–890. [Google Scholar] [CrossRef]

- Al-Dhahebi, A.M.; Ling, J.K.; Krishnan, S.G.; Yousefzadeh, M.; Elumalai, N.K.; Saheed, M.S.M.; Ramakrishna, S.; Jose, R. Electrospinning research and products: The road and the way forward. Appl. Phys. Rev. 2022, 9, 011319. [Google Scholar] [CrossRef]

- Keirouz, A.; Wang, Z.; Reddy, V.S.; Nagy, Z.K.; Vass, P.; Buzgo, M.; Ramakrishna, S.; Radacsi, N. The history of electrospinning: Past, present, and future developments. Adv. Mater. Technol. 2023, 8, 2201723. [Google Scholar] [CrossRef]

- Su, L.; Wang, H.; Niu, M.; Fan, X.; Ma, M.; Shi, Z.; Guo, S.-W. Ultralight, recoverable, and high-temperature-resistant SiC nanowire aerogel. ACS Nano 2018, 12, 3103–3111. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, Q.; Hao, M.; Hu, Y.; Lin, Z.; Peng, L.; Wang, T.; Ren, X.; Wang, C.; Zhao, Z.; et al. Double-negative-index ceramic aerogels for thermal superinsulation. Science 2019, 363, 723–727. [Google Scholar] [CrossRef]

- Xia, Y.; Zhang, Z.; Li, K.; Zhao, S.; Chen, G.; Fei, Z.; Li, X.; Gan, Z.; Li, X.; Yang, Z. Lightweight and high-strength SiC/MWCNTs nanofibrous aerogel derived from RGO/MWCNTs aerogel for microwave absorption. Chem. Eng. J. 2024, 486, 150417. [Google Scholar] [CrossRef]

- Azwar, E.; Wan Mahari, W.A.; Chuah, J.H.; Vo, D.V.N.; Ma, N.L.; Lam, W.H.; Lam, S.S. Transformation of biomass into carbon nanofiber for supercapacitor application—A review. Int. J. Hydrogen Energy 2018, 43, 20811–20821. [Google Scholar] [CrossRef]

- Chen, W.; Wang, H.H.; Lan, W.; Zhang, A.P.; Liu, C.F. Fabrication of sugarcane bagasse ester-based porous nanofiber membrane by electrospinning for efficient oil-water separation. Ind. Crops Prod. 2022, 187, 115480. [Google Scholar] [CrossRef]

- Zhuang, J.; Rong, N.N.; Wang, X.R.; Chen, C.C.; Xu, Z.Y. Adsorption of small size microplastics based on cellulose nanofiber aerogel modified by quaternary ammonium salt in water. Sep. Purif. Technol. 2022, 293, 121133. [Google Scholar] [CrossRef]

- Qin, Z.; Xu, X.J.; Xu, T.F.; Cao, Y.Q.; Wu, J.Y.; Yan, L.W.; Hou, F.; Liu, J.C.; Guo, A.R. High-strength thermal insulating porous mullite fiber-based ceramics. J. Eur. Ceram. Soc. 2022, 42, 7209–7218. [Google Scholar] [CrossRef]

- Dong, X.; Zheng, Y.; Xie, D.W.; Li, D.H. Multi-functional mullite fiber-based porous ceramics with a multilevel pore structure assembled by alumina platelets and mullite whiskers. Ceram. Int. 2023, 49, 847–854. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Xu, X.J.; Xu, T.F.; Dong, X.; Wu, Z.; Wu, J.Y.; Yan, L.W.; Liu, J.C.; Guo, A.R. Porous mullite fiber-based ceramics inspired by biomimetic natural pine wood. Ceram. Int. 2024, 50, 584–592. [Google Scholar] [CrossRef]

- Zhu, J.X.; Zhu, R.J.; Hu, Y.W.; Wang, Z.M. Mullite fiber porous ceramic with high quality factor for high-temperature PM filtration. J. Eur. Ceram. Soc. 2024, 44, 2630–2637. [Google Scholar] [CrossRef]

- Liu, D.Z.; Hu, P.; Zhao, G.D.; Han, W.B. Silica bonded mullite fiber composite with isotropic geometry and properties for thermal insulating. J. Alloys Compd. 2017, 728, 1049–1057. [Google Scholar] [CrossRef]

- Yang, F.; Zhao, S.; Chen, G.; Li, K.; Fei, Z.; Mummery, P.; Yang, Z. High-strength, multifunctional and 3D printable mullite-based porous ceramics with a controllable shell-pore structure. Adv. Powder Mater. 2024, 3, 100153. [Google Scholar] [CrossRef]

- Goldstein, H.E.; Smith, M.; Leiser, D. Silica Reusable Surface Insulation. U.S. Patent 3952083A, 20 April 1976. [Google Scholar]

- Frosch, R.A.; Leiser, D.B.; Goldstein, H.E.; Smith, M. Fibrous Refractory Composite Insulation. U.S. Patent 4148962A, 10 April 1979. [Google Scholar]

- Smith, M.; Leiser, D.; Goldstein, H. Alumina-enhanced thermal barrier. NASA Tech. Briefs 1989, 13, 89B10177. [Google Scholar]

- Dong, Y.H.; Wang, C.A.; Zhou, J.; Hong, Z.L. A novel way to fabricate highly porous fibrous YSZ ceramics with improved thermal and mechanical properties. J. Eur. Ceram. Soc. 2012, 32, 2213–2218. [Google Scholar] [CrossRef]

- Hou, Z.G.; Du, H.Y.; Liu, J.C.; Hao, R.H.; Dong, X.; Liu, M.X. Fabrication and properties of mullite fiber matrix porous ceramics by a TBA-based gel-casting process. J. Eur. Ceram. Soc. 2013, 33, 717–725. [Google Scholar] [CrossRef]

- Dong, X.; Sui, G.F.; Liu, J.C.; Guo, A.R.; Ren, S.; Wang, M.C.; Du, H.Y. Mechanical behavior of fibrous ceramics with a bird’s nest structure. Compos. Sci. Technol. 2014, 100, 92–98. [Google Scholar] [CrossRef]

- Sun, J.; Hu, Z.; Li, J.; Zhang, H.; Sun, C. Thermal and mechanical properties of fibrous zirconia ceramics with ultra-high porosity. Ceram. Int. 2014, 40, 11787–11793. [Google Scholar] [CrossRef]

- Dong, X.; Lv, H.Y.; Sui, G.F.; Liu, J.C.; Guo, A.R.; Tao, X.; Xu, X.Q.; Du, H.Y. Synthesis and properties of lightweight fibrous ceramics with a 3D skeleton structure prepared by infiltration. Mater. Sci. Eng. A 2015, 635, 43–49. [Google Scholar] [CrossRef]

- He, J.; Li, X.L.; Su, D.; Ji, H.M.; Wang, X.J. Ultra-low thermal conductivity and high strength of aerogels/fibrous ceramic composites. J. Eur. Ceram. Soc. 2016, 36, 1487–1493. [Google Scholar] [CrossRef]

- Zang, W.J.; Guo, F.; Liu, J.C.; Du, H.Y.; Hou, F.; Guo, A.R. Lightweight alumina based fibrous ceramics with different high temperature binder. Ceram. Int. 2016, 42, 10310–10316. [Google Scholar] [CrossRef]

- Zhang, R.B.; Hou, X.B.; Ye, C.S.; Wang, B.L.; Fang, D.N. Fabrication and properties of fibrous porous mullite-zirconia fiber networks with a quasi-layered structure. J. Eur. Ceram. Soc. 2016, 36, 3539–3544. [Google Scholar] [CrossRef]

- Yang, M.M.; Luo, X.D.; Yi, J.; Yu, M.; Zhang, X.F. A novel way to fabricate fibrous mullite ceramic using sol-gel vacuum impregnation. Ceram. Int. 2018, 44, 12664–12669. [Google Scholar] [CrossRef]

- Zhang, R.B.; Ye, C.S.; Wang, B.L. Novel Al2O3–SiO2 aerogel/porous zirconia composite with ultra-low thermal conductivity. J. Porous Mater. 2018, 25, 171–178. [Google Scholar] [CrossRef]

- Yang, M.M.; Luo, X.D.; Yi, J.; Zhang, X.F.; Peng, Z.J. Fabrication of fibrous mullite-alumina ceramic with high strength and low thermal conductivity. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2019, 34, 1415–1420. [Google Scholar] [CrossRef]

- Yuan, L.; Liu, Z.L.; Tian, C.; Han, L.; Wen, T.P.; Yu, J.K.; Hou, X.H.; Zhu, Q. Synthesis and characterization of mullite-ZrO2 porous fibrous ceramic for highly efficient oil-water separation. Ceram. Int. 2021, 47, 22709–22716. [Google Scholar] [CrossRef]

- Yang, F.Y.; Zhao, S.; Sun, W.C.; Li, K.F.; Chen, J.; Fei, Z.F.; Yang, Z.C. Fibrous porous mullite ceramics modified by mullite whiskers for thermal insulation and sound absorption. J. Eur. Ceram. Soc. 2023, 43, 521–529. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Guo, A.R.; Ma, X.H.; Du, H.Y.; Yan, L.W.; Hou, F.; Liu, J.C. Cuttlefish-bone-structure-like lamellar porous fiber-based ceramics with enhanced mechanical performances. ACS Appl. Mater. Interfaces 2023, 15, 13121–13130. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Xu, T.F.; Xu, X.J.; Dong, X.; Wang, Z.Y.; Wu, J.Y.; Yan, L.W.; Liu, J.C.; Guo, A.R. Fabrication of mullite micro/nano fiber-based porous ceramic with excellent mechanical and thermal insulation properties. Ceram. Int. 2024, 50, 2415–2423. [Google Scholar] [CrossRef]

- Dong, X.Y.; Si, Y.; Chen, C.J.; Ding, B.; Deng, H.B. Reed Leaves Inspired Silica Nanofibrous Aerogels with Parallel-Arranged Vessels for Salt-Resistant Solar Desalination. ACS Nano 2021, 15, 12256–12266. [Google Scholar] [CrossRef] [PubMed]

- Ma, W.J.; Jiang, Z.C.; Lu, T.; Xiong, R.H.; Huang, C.B. Lightweight, elastic and superhydrophobic multifunctional nanofibrous aerogel for self-cleaning, oil/water separation and pressure sensing. Chem. Eng. J. 2022, 430, 132989. [Google Scholar] [CrossRef]

- Ma, W.J.; Lu, T.; Cao, W.X.; Xiong, R.H.; Huang, C.B. Bioinspired nanofibrous aerogel with vertically aligned channels for efficient water purification and salt-rejecting solar desalination. Adv. Funct. Mater. 2023, 33, 2214157. [Google Scholar] [CrossRef]

- Huang, R.M.; Jiang, Y.G.; Liu, F.Q.; Feng, J.Z.; Li, L.J.; Jian, F. Research Advances on High-Temperature Infrared Modification of Oxide Aerogels. Prog. Chem. 2024, 36, 234–243. [Google Scholar] [CrossRef]

- Si, Y.; Wang, X.; Dou, L.; Yu, J.; Ding, B. Ultralight and fire-resistant ceramic nanofibrous aerogels with temperature-invariant superelasticity. Sci. Adv. 2018, 4, eaas8925. [Google Scholar] [CrossRef]

- Dou, L.; Zhang, X.; Cheng, X.; Ma, Z.; Wang, X.; Si, Y.; Yu, J.; Ding, B. Hierarchical cellular structured ceramic nanofibrous aerogels with temperature-invariant superelasticity for thermal insulation. ACS Appl. Mater. Interfaces 2019, 11, 29056–29064. [Google Scholar] [CrossRef] [PubMed]

- Dou, L.; Zhang, X.; Shan, H.; Cheng, X.; Si, Y.; Yu, J.; Ding, B. Interweaved cellular structured ceramic nanofibrous aerogels with superior bendability and compressibility. Adv. Funct. Mater. 2020, 30, 2005928. [Google Scholar] [CrossRef]

- Hu, Z.; Yan, S.; Li, X.; You, R.; Zhang, Q.; Kaplan, D.L. Natural Silk Nanofibril Aerogels with Distinctive Filtration Capacity and Heat-Retention Performance. ACS Nano 2021, 15, 8171–8183. [Google Scholar] [CrossRef]

- Dang, W.; Wang, B.W.; Xu, Z.L.; Zhang, X.Y.; Li, F.P.; Zhao, K.; Hu, X.; Tang, Y.F. Pore structure, thermal insulation and compressive property of ZrO2 nanofiber aerogels with carbon junction fabricated by freeze drying. J. Non-Cryst. Solids 2023, 600, 122031. [Google Scholar] [CrossRef]

- Si, Y.; Yu, J.; Tang, X.; Ge, J.; Ding, B. Ultralight nanofibre-assembled cellular aerogels with superelasticity and multifunctionality. Nat. Commun. 2014, 5, 5802. [Google Scholar] [CrossRef]

- Ciftci, D.; Ubeyitogullari, A.; Huerta, R.R.; Ciftci, O.N.; Flores, R.A.; Saldaña, M.D.A. Lupin hull cellulose nanofiber aerogel preparation by supercritical CO2 and freeze drying. J. Supercrit. Fluids 2017, 127, 137–145. [Google Scholar] [CrossRef]

- Dong, X.; Liu, R.; Dong, W.; Wang, Z.; Guo, A.; Liu, J.; Chen, C.; Jiang, Y. Fabrication and properties of lightweight SiOC fiber-based assembly aerogels with hierarchical pore structure. Ceram. Int. 2018, 44, 22760–22766. [Google Scholar] [CrossRef]

- Wang, F.; Dai, J.W.; Huang, L.Q.; Si, Y.; Yu, J.Y.; Ding, B. Biomimetic and superelastic silica nanofibrous aerogels with rechargeable bactericidal function for antifouling water disinfection. ACS Nano 2020, 14, 8975–8984. [Google Scholar] [CrossRef]

- Cao, L.T.; Shan, H.R.; Zong, D.D.; Yu, X.; Yin, X.; Si, Y.; Yu, J.Y.; Ding, B. Fire-resistant and hierarchically structured elastic ceramic nanofibrous aerogels for efficient low-frequency noise reduction. Nano Lett. 2022, 22, 1609–1617. [Google Scholar] [CrossRef]

- Ding, Y.; Yang, L.X.; Yang, M.M.; Yin, L.P.; Wu, Q.; Wang, Y.P.; Chen, Z.F.; Erisen, D.E.; Xie, J.Y.; Lu, L.; et al. Optimization of ultralight SiO2/TiO2 nanofibrous aerogel for high-temperature application. Ceram. Int. 2023, 49, 38058–38069. [Google Scholar] [CrossRef]

- Zou, W.B.; Wang, X.D.; Wu, Y.; Zou, L.P.; Zu, G.Q.; Chen, D.; Shen, J. Opacifier embedded and fiber reinforced alumina-based aerogel composites for ultra-high temperature thermal insulation. Ceram. Int. 2019, 45, 644–650. [Google Scholar] [CrossRef]

- Feng, Y.Y.; Zong, D.D.; Hou, Y.J.; Yin, X.; Zhang, S.C.; Duan, L.Y.; Si, Y.; Jia, Y.T.; Ding, B. Gradient structured micro/nanofibrous sponges with superior compressibility and stretchability for broadband sound absorption. J. Colloid Interface Sci. 2021, 593, 59–66. [Google Scholar] [CrossRef] [PubMed]

- Dong, J.; Xie, Y.; Liu, L.; Deng, Z.; Liu, W.; Zhu, L.; Wang, X.; Xu, D.; Zhang, G. Lightweight and resilient ZrO2–TiO2 fiber sponges with layered structure for thermal insulation. Adv. Eng. Mater. 2022, 24, 2101603. [Google Scholar] [CrossRef]

- Zong, D.D.; Zhang, X.X.; Yin, X.; Wang, F.; Yu, J.Y.; Zhang, S.C.; Ding, B. Electrospun fibrous sponges: Principle, fabrication, and applications. Adv. Fiber Mater. 2022, 4, 1434–1462. [Google Scholar] [CrossRef]

- Su, L.; Li, M.; Wang, H.; Niu, M.; Lu, D.; Cai, Z. Resilient Si3N4 nanobelt aerogel as fire-resistant and electromagnetic wave-transparent thermal insulator. ACS Appl. Mater. Interfaces 2019, 11, 15795–15803. [Google Scholar] [CrossRef] [PubMed]

- Dong, X.; Liu, J.C.; Hao, R.H.; Guo, A.R.; Hou, Z.G.; Liu, M.X. High-temperature elasticity of fibrous ceramics with a bird’s nest structure. J. Eur. Ceram. Soc. 2013, 33, 3477–3481. [Google Scholar] [CrossRef]

- Zhu, W.J.; Guo, A.R.; Xue, Y.J.; Zhang, J.J.; Liu, Z.H.; Cao, C.H.; Zhang, F.F.; Liu, J.C. Mechanical evaluations of mullite fibrous ceramics processed by filtration and in situ pyrolysis of organic precursor. J. Eur. Ceram. Soc. 2019, 39, 1329–1335. [Google Scholar] [CrossRef]

- Zhang, R.B.; Ye, C.S.; Hou, X.B.; Li, S.H.; Wang, B.L. Microstructure and properties of lightweight fibrous porous mullite ceramics prepared by vacuum squeeze moulding technique. Ceram. Int. 2016, 42, 14843–14848. [Google Scholar] [CrossRef]

- Liu, R.; Dong, X.; Xie, S.; Jia, T.; Xue, Y.; Liu, J.; Jing, W.; Guo, A. Ultralight, thermal insulating, and high-temperature-resistant mullite-based nanofibrous aerogels. Chem. Eng. J. 2019, 360, 464–472. [Google Scholar] [CrossRef]

- Dong, Y.; Dong, X.; Li, L.; Wu, J.; Yan, L.; Liu, J.; Guo, A. Lightweight and thermally insulating aluminum borate nanofibrous porous ceramics. Ceram. Int. 2021, 47, 21029–21037. [Google Scholar] [CrossRef]

- Zhang, R.Z.; Reece, M.J. Review of high entropy ceramics: Design, synthesis, structure and properties. J. Mater. Chem. A 2019, 7, 22148–22162. [Google Scholar] [CrossRef]

- Oses, C.; Toher, C.; Curtarolo, S. High-entropy ceramics. Nat. Rev. Mater. 2020, 5, 295–309. [Google Scholar] [CrossRef]

- Shao, Y.; Xu, J.; Wei, M.; Wang, H.; Lin, L.; Fan, F.; Feng, X.; Zhang, P.; Gao, F. Rare-earth zirconate high-entropy nanofibrous porous ceramics for high-temperature thermal insulation applications. J. Eur. Ceram. Soc. 2023, 43, 7635–7643. [Google Scholar] [CrossRef]

- Xu, X.; Dong, X.; Guo, A.; Wang, M.; Sui, G.; Liu, J. Effect of binder types on the properties of the mullite fibrous ceramics prepared by TBA-based gel-casting method. Ceram. Int. 2017, 43, 228–233. [Google Scholar] [CrossRef]

- Zhang, J.; Dong, X.; Hou, F.; Du, H.; Liu, J.; Guo, A. Effects of fiber length and solid loading on the properties of lightweight elastic mullite fibrous ceramics. Ceram. Int. 2016, 42, 5018–5023. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, Y.; Yang, X.; Li, D.; Zhang, X.; Dong, X.; Yao, X.; Liu, J.; Guo, A. High-strength thermal insulating mullite nanofibrous porous ceramics. J. Eur. Ceram. Soc. 2020, 40, 2090–2096. [Google Scholar] [CrossRef]

- Yuan, L.; Liu, Z.L.; Hou, X.H.; Tian, C.; Zhu, Q.; Wang, S.G.; Ma, B.Y.; Yu, J.K. A novel aqueous gel-casting for fabricating Al2O3-bonded fibrous mullite ceramics. J. Alloys Compd. 2019, 811, 152009. [Google Scholar] [CrossRef]

- Deville, S. Freeze-casting of porous ceramics: A review of current achievements and issues. Adv. Eng. Mater. 2008, 10, 155–169. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, X.Y.; Xue, T.T.; Yang, F.; Fan, W.; Liu, T.X. Bidirectional anisotropic polyimide/bacterial cellulose aerogels by freeze-drying for super-thermal insulation. Chem. Eng. J. 2020, 385, 123963. [Google Scholar] [CrossRef]

- Li, X.; Zhu, L.T.; Kasuga, T.; Nogi, M.; Koga, H. Chitin-derived-carbon nanofibrous aerogel with anisotropic porous channels and defective carbon structures for strong microwave absorption. Chem. Eng. J. 2022, 450, 137943. [Google Scholar] [CrossRef]

- Liao, Y.L.; Song, J.; Si, Y.; Yu, J.Y.; Ding, B. Superelastic and photothermal RGO/Zr-doped TiO2 nanofibrous aerogels enable the rapid decomposition of chemical warfare agents. Nano Lett. 2022, 22, 4368–4375. [Google Scholar] [CrossRef] [PubMed]

- Mi, H.Y.; Jing, X.; Politowicz, A.L.; Chen, E.; Huang, H.X.; Turng, L.S. Highly compressible ultra-light anisotropic cellulose/graphene aerogel fabricated by bidirectional freeze drying for selective oil absorption. Carbon 2018, 132, 199–209. [Google Scholar] [CrossRef]

- Feng, P.Y.; Wang, X.W.; Yang, J. Biomimetic, highly reusable and hydrophobic graphene/polyvinyl alcohol/cellulose nanofiber aerogels as oil-Removing absorbents. Polymers 2022, 14, 1077. [Google Scholar] [CrossRef] [PubMed]

- Mi, H.Y.; Li, H.; Jing, X.; Zhang, Q.; Feng, P.Y.; He, P.; Liu, Y.J. Superhydrophobic cellulose nanofibril/silica fiber/Fe3O4 nanocomposite aerogel for magnetically driven selective oil absorption. Cellulose 2020, 27, 8909–8922. [Google Scholar] [CrossRef]

- Zhang, R.A.; Li, B.; Yang, Y.F.; Wu, N.; Sui, Z.Y.; Ban, Q.F.; Wu, L.L.; Liu, W.; Liu, J.R.; Zeng, Z.H. Ultralight aerogel sphere composed of nanocellulose-derived carbon nanofiber and graphene for excellent electromagnetic wave absorption. Nano Res. 2023, 16, 7931–7940. [Google Scholar] [CrossRef]

- Xian, L.; Zhang, Y.; Wu, Y.J.; Zhang, X.Y.; Dong, X.; Liu, J.C.; Guo, A.R. Microstructural evolution of mullite nanofibrous aerogels with different ice crystal growth inhibitors. Ceram. Int. 2020, 46, 1869–1875. [Google Scholar] [CrossRef]

- Wang, F.; Si, Y.; Yu, J.Y.; Ding, B. Tailoring nanonets-engineered superflexible nanofibrous aerogels with hierarchical cage-like architecture enables renewable antimicrobial air Filtration. Adv. Funct. Mater. 2021, 31, 2107223. [Google Scholar] [CrossRef]

- Yang, M.M.; Yang, L.X.; Chen, Z.F.; Ding, Y.; Liu, L.H.; Qiong, W.; Liu, T.L.; Li, M.N. Multifunctional flexible SiO2/BNNBs nanofibrous aerogel for thermal insulation, infrared stealth and sound-absorption. Ceram. Int. 2023, 49, 22393–22399. [Google Scholar] [CrossRef]

- Dou, L.; Cheng, X.T.; Zhang, X.X.; Si, Y.; Yu, J.Y.; Ding, B. Temperature-invariant superelastic, fatigue resistant, and binary-network structured silica nanofibrous aerogels for thermal superinsulation. J. Mater. Chem. A 2020, 8, 7775–7783. [Google Scholar] [CrossRef]

- Wang, F.; Dou, L.Y.; Dai, J.W.; Li, Y.Y.; Huang, L.Q.; Si, Y.; Yu, J.Y.; Ding, B. In situ synthesis of biomimetic silica nanofibrous aerogels with temperature-invariant superelasticity over one million compressions. Angew. Chem.-Int. Ed. 2020, 59, 8285–8292. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.J.; Song, J.W.; Zhu, S.Z.; Li, Y.J.; Kuang, Y.D.; Wan, J.Y.; Kirsch, D.; Xu, L.S.; Wang, Y.B.; Gao, T.T.; et al. Scalable and sustainable approach toward highly compressible, anisotropic, lamellar carbon sponge. Chem 2018, 4, 544–554. [Google Scholar] [CrossRef]

- Guan, H.; Cheng, Z.Y.; Wang, X.Q. Highly compressible wood sponges with a spring-like lamellar structure as effective and reusable oil absorbents. ACS Nano 2018, 12, 10365–10373. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.X.; Wang, F.; Dou, L.Y.; Cheng, X.T.; Si, Y.; Yu, J.Y.; Ding, B. Ultrastrong, superelastic, and lamellar multiarch structured ZrO2-Al2O3 nanofibrous aerogels with high-temperature resistance over 1300 °C. ACS Nano 2020, 14, 15616–15625. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.X.; Cheng, X.T.; Si, Y.; Yu, J.Y.; Ding, B. Elastic and highly fatigue resistant ZrO2-SiO2 nanofibrous aerogel with low energy dissipation for thermal insulation. Chem. Eng. J. 2022, 433, 133628. [Google Scholar] [CrossRef]

- Zhang, X.X.; Cheng, X.T.; Si, Y.; Yu, J.Y.; Ding, B. All-Ceramic and Elastic Aerogels with Nanofibrous-Granular Binary Synergistic Structure for Thermal Superinsulation. ACS Nano 2022, 16, 5487–5495. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Huang, L.Q.; Yu, J.Y.; Si, Y.; Ding, B. Ultralight and superelastic Gd2O3/Bi2O3 nanofibrous aerogels with nacre-mimetic brick-mortar structure for superior X-ray shielding. Nano Lett. 2022, 22, 8711–8718. [Google Scholar] [CrossRef] [PubMed]

- Li, W.J.; Jiang, Y.C.; Liu, H.; Wang, C.; Zhou, X.; Jiang, S.Y.; Mu, Y.W.; Wang, L.Y.; He, X.D.; Li, M.W.; et al. Fiber sedimentation and layer-by-layer assembly strategy for designing biomimetic quasi-ordered mullite fiber aerogels as extreme conditions thermal insulators. ACS Appl. Mater. Interfaces 2023, 15, 46010–46021. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.Q.; Xu, X.J.; Qin, Z.; He, C.; Yan, L.W.; Hou, F.; Liu, J.C.; Guo, A.R. Vat photopolymerization 3D printing of thermal insulating mullite fiber-based porous ceramics. Addit. Manuf. 2022, 60, 103235. [Google Scholar] [CrossRef]

- Fan, S.T.; Zhang, Y.; Tan, M.; Wang, J.X.; Huang, C.Y.; Li, B.J.; Zhang, S. Multifunctional elastic aerogels of nanofibrous metal-organic framework for thermal insulation and broadband low-frequency sound absorption. Compos. Sci. Technol. 2023, 242, 110183. [Google Scholar] [CrossRef]

- Zong, D.D.; Bai, W.Y.; Yin, X.; Yu, J.Y.; Zhang, S.C.; Ding, B. Gradient Pore Structured Elastic Ceramic Nanofiber Aerogels with Cellulose Nanonets for Noise Absorption. Adv. Funct. Mater. 2023, 33, 2301870. [Google Scholar] [CrossRef]

- Hou, Y.; Quan, J.; Thai, B.Q.; Zhao, Y.J.; Lan, X.L.; Yu, X.; Zhai, W.; Yang, Y.; Khoo, B.C. Ultralight biomass-derived carbon fibre aerogels for electromagnetic and acoustic noise mitigation. J. Mater. Chem. A 2022, 10, 22771–22780. [Google Scholar] [CrossRef]

- Li, Y.; Shi, Q.; Peng, L.G.; Chang, M.J.; Zhou, F.; Gong, C.D.; Wu, Y.; Zhang, L.Q. Carbon nanotubes/cellulose composite aerogels with controllable microstructure for electromagnetic interference shielding. J. Appl. Polym. Sci. 2023, 140, e53535. [Google Scholar] [CrossRef]

- Yang, J.J.; Zhang, X.F.; Zhang, X.; Wang, L.; Feng, W.; Li, Q. Beyond the visible: Bioinspired infrared adaptive materials. Adv. Mater. 2021, 33, 2004754. [Google Scholar] [CrossRef]

- Zhu, H.Z.; Li, Q.; Zheng, C.Q.; Hong, Y.; Xu, Z.Q.; Wang, H.; Shen, W.D.; Kaur, S.; Ghosh, P.; Qiu, M. High-temperature infrared camouflage with efficient thermal management. Light-Sci. Appl. 2020, 9, 60. [Google Scholar] [CrossRef] [PubMed]

- Hou, X.; Li, Y.; Luo, X.; Zhang, R. SiC whiskers-reinforced polyimide aerogel composites with robust compressive properties and efficient thermal insulation performance. J. Appl. Polym. Sci. 2021, 138, 49892. [Google Scholar] [CrossRef]

- Okafor, P.E.; Tang, G.H. Study of effective thermal conductivity of a novel SiO2 aerogel composite for high-temperature thermal insulation. Int. J. Heat Mass Transf. 2023, 212, 124242. [Google Scholar] [CrossRef]

- Davraz, M.; Koru, M.; Bayrakçi, H.C.; Yusufoglu, Y.; Ipek, O. The effect of opacifier properties on thermal conductivity of vacuum insulation panel with fumed silica. J. Therm. Anal. Calorim. 2020, 142, 1377–1386. [Google Scholar] [CrossRef]

- Liu, F.Q.; He, C.B.; Jiang, Y.G.; Feng, J.Z.; Li, L.J.; Tang, G.H.; Feng, J. Ultralight Ceramic Fiber Aerogel for High-Temperature Thermal Superinsulation. Nanomaterials 2023, 13, 1305. [Google Scholar] [CrossRef]

- Zhong, Y.; Li, H.Y.; Liu, H.L.; Wang, J.J.; Han, X.; Lu, L.; Xia, S.L. Elytra-mimetic ceramic fiber aerogel with excellent mechanical, anti-oxidation, and thermal insulation properties. J. Eur. Ceram. Soc. 2023, 43, 1407–1416. [Google Scholar] [CrossRef]

- de Amorim, J.D.P.; de Souza, K.C.; Duarte, C.R.; Duarte, I.D.; Ribeiro, F.D.S.; Silva, G.S.; de Farias, P.M.A.; Stingl, A.; Costa, A.F.S.; Vinhas, G.M.; et al. Plant and bacterial nanocellulose: Production, properties and applications in medicine, food, cosmetics, electronics and engineering. A review. Environ. Chem. Lett. 2020, 18, 851–869. [Google Scholar] [CrossRef]

- Yan, Z.F.; Zhu, K.X.; Li, X.Q.; Wu, X. Recyclable Bacterial Cellulose Aerogel for Oil and Water Separation. J. Polym. Environ. 2022, 30, 2774–2784. [Google Scholar] [CrossRef]

- Hu, X.D.; Zhang, S.S.; Yang, B.; Hao, M.; Chen, Z.J.; Liu, Y.B.; Ramakrishna, S.; Wang, X.X.; Yao, J.B. Bacterial cellulose composite aerogel with high elasticity and adjustable wettability for dye absorption and oil-water separation. Appl. Surf. Sci. 2023, 640, 158299. [Google Scholar] [CrossRef]

- Wang, D.; Peng, H.Y.; Yu, B.; Zhou, K.Q.; Pan, H.F.; Zhang, L.P.; Li, M.; Liu, M.M.; Tian, A.L.; Fu, S.H. Biomimetic structural cellulose nanofiber aerogels with exceptional mechanical, flame-retardant and thermal-insulating properties. Chem. Eng. J. 2020, 389, 124449. [Google Scholar] [CrossRef]

- Liu, P.P.; Chen, X.; Li, Y.; Cheng, P.; Tang, Z.D.; Lv, J.J.; Aftab, W.; Wang, G. Aerogels Meet Phase Change Materials: Fundamentals, Advances, and Beyond. ACS Nano 2022, 16, 15586–15626. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Tang, Z.D.; Gao, Y.; Liu, P.P.; Li, Y.; Li, A.; Chen, X. Phase Change Thermal Storage Materials for Interdisciplinary Applications. Chem. Rev. 2023, 123, 6953–7024. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.M.; Lyu, J.; Shi, N.; Cheng, Q.Q.; Liu, Z.W.; Xiong, Y.B.; Zhang, X.T. Kevlar nanofibrous aerogel-based 3-layer tandem cloak enables highly efficient and long-lasting infrared stealth. Chem. Eng. J. 2023, 462, 142249. [Google Scholar] [CrossRef]

- Ahn, J.; Lim, T.; Yeo, C.S.; Hong, T.; Jeong, S.M.; Park, S.Y.; Ju, S. Infrared invisibility cloak based on polyurethane-tin oxide composite microtubes. ACS Appl. Mater. Interfaces 2019, 11, 14296–14304. [Google Scholar] [CrossRef] [PubMed]

- Tao, Z.; Yang, M.; Wu, L.M.; Yan, J.M.; Yang, F.; Lin, J.; Wang, J.J.; Wang, G. Phase change material based on polypyrrole/Fe3O4-functionalized hollow kapok fiber aerogel matrix for solar /magnetic-thermal energy conversion and storage. Chem. Eng. J. 2021, 423, 130180. [Google Scholar] [CrossRef]

- Zong, D.D.; Cao, L.T.; Yin, X.; Si, Y.; Zhang, S.C.; Yu, J.Y.; Ding, B. Flexible ceramic nanofibrous sponges with hierarchically entangled graphene networks enable noise absorption. Nat. Commun. 2021, 12, 6599. [Google Scholar] [CrossRef]

- Cao, L.T.; Yu, X.; Yin, X.; Si, Y.; Yu, J.Y.; Ding, B. Hierarchically maze-like structured nanofiber aerogels for effective low-frequency sound absorption. J. Colloid Interface Sci. 2021, 597, 21–28. [Google Scholar] [CrossRef] [PubMed]

- Puguan, J.M.C.; Pornea, A.G.M.; Ruello, J.L.A.; Kim, H. Double-porous PET waste-derived nanofibrous aerogel for effective broadband acoustic absorption and transmission. ACS Appl. Polym. Mater. 2022, 4, 2626–2635. [Google Scholar] [CrossRef]

- Xie, S.C.; Li, Z.; Yan, H.Y.; Yang, S.C. Ultra-broadband sound absorption performance of a multi-cavity composite structure filled with polyurethane. Appl. Acoust. 2022, 189, 108612. [Google Scholar] [CrossRef]

- Gui, Y.; Fei, Z.F.; Zhao, S.; Zhang, Z.; Shao, H.L.; Chen, J.; Li, K.F.; Du, H.; Yang, Z.C. High-strength and multifunctional honeycomb polyimide aerogel fabricated by a freeze casting-assisted extrusion printing and building block-assembly strategy for sound absorbing metamaterials. Addit. Manuf. 2023, 77, 103799. [Google Scholar] [CrossRef]

- Zong, D.D.; Bai, W.Y.; Geng, M.; Yin, X.; Yu, J.Y.; Zhang, S.C.; Ding, B. Bubble Templated Flexible Ceramic Nanofiber Aerogels with Cascaded Resonant Cavities for High-Temperature Noise Absorption. ACS Nano 2022, 16, 13740–13749. [Google Scholar] [CrossRef] [PubMed]

- Hou, Y.L.; Sheng, Z.Z.; Fu, C.; Kong, J.; Zhang, X.T. Hygroscopic holey graphene aerogel fibers enable highly efficient moisture capture, heat allocation and microwave absorption. Nat. Commun. 2022, 13, 1227. [Google Scholar] [CrossRef] [PubMed]

- Sheng, Z.Z.; Liu, Z.W.; Hou, Y.L.; Jiang, H.T.; Li, Y.Z.; Li, G.Y.; Zhang, X.T. The Rising Aerogel Fibers: Status, Challenges, and Opportunities. Adv. Sci. 2023, 10, 2205762. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.X.; Xu, C.Y.; Duan, G.Y.; Xu, W.; Pi, F.W. Review of Broadband Metamaterial Absorbers: From Principles, Design Strategies, and Tunable Properties to Functional Applications. Adv. Funct. Mater. 2023, 33, 2213818. [Google Scholar] [CrossRef]

- Liu, Q.; Tang, L.; Li, J.Z.; Chen, Y.; Xu, Z.K.; Li, J.T.; Chen, X.Y.; Meng, F.B. Multifunctional aramid nanofibers reinforced RGO aerogels integrated with high-efficiency microwave absorption, sound absorption and heat insulation performance. J. Mater. Sci. Technol. 2022, 130, 166–175. [Google Scholar] [CrossRef]

- Huang, Z.; Qin, R.; Zhang, H.; Guo, M.; Zhang, D.; Gao, C.; Gao, F.; Chen, X.; Terrones, M.; Wang, Y. Ambient-drying to construct unidirectional cellulose nanofibers/carbon nanotubes aerogel with ultra-lightweight, robust, and superior microwave absorption performance. Carbon 2023, 212, 118150. [Google Scholar] [CrossRef]

- An, Z.M.; Ye, C.S.; Zhang, R.B.; Zhou, P. Flexible and recoverable SiC nanofiber aerogels for electromagnetic wave absorption. Ceram. Int. 2019, 45, 22793–22801. [Google Scholar] [CrossRef]

- Sun, M.; Guo, Z.Y.; Zhang, W.T.; Ding, E.J.; Li, X.; Yin, M.; Luo, C.Y.; Zhang, L.Y. A strategy to fabricate hierarchical microporous architecture of polyimide nanofibrous aerogels with efficient electromagnetic wave absorption and thermal insulation. Compos. Part A Appl. Sci. Manuf. 2024, 177, 107940. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L.; He, J.X.; Wang, R.W.; Chen, X.G.; Xu, Y.Y.; Zhao, X.; Feng, Y.L. Ultralight and superelastic multifunctional PI composite aerogels with a nanofibrous-laminar synergistic structure for highly efficient electromagnetic wave absorption. J. Appl. Polym. Sci. 2023, 140, e54660. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Zhao, S.; Chen, G.; Li, K.; Chen, J.; Zhang, Z.; Yang, F.; Yang, Z. Preparation of Fibrous Three-Dimensional Porous Materials and Their Research Progress in the Field of Stealth Protection. Nanomaterials 2024, 14, 1003. https://doi.org/10.3390/nano14121003

Zhang P, Zhao S, Chen G, Li K, Chen J, Zhang Z, Yang F, Yang Z. Preparation of Fibrous Three-Dimensional Porous Materials and Their Research Progress in the Field of Stealth Protection. Nanomaterials. 2024; 14(12):1003. https://doi.org/10.3390/nano14121003

Chicago/Turabian StyleZhang, Peng, Shuang Zhao, Guobing Chen, Kunfeng Li, Jun Chen, Zhen Zhang, Feiyue Yang, and Zichun Yang. 2024. "Preparation of Fibrous Three-Dimensional Porous Materials and Their Research Progress in the Field of Stealth Protection" Nanomaterials 14, no. 12: 1003. https://doi.org/10.3390/nano14121003

APA StyleZhang, P., Zhao, S., Chen, G., Li, K., Chen, J., Zhang, Z., Yang, F., & Yang, Z. (2024). Preparation of Fibrous Three-Dimensional Porous Materials and Their Research Progress in the Field of Stealth Protection. Nanomaterials, 14(12), 1003. https://doi.org/10.3390/nano14121003