Design and Implementation of Electrochromic Smart Windows with Self-Driven Thermoelectric Power Generation

Abstract

:1. Introduction

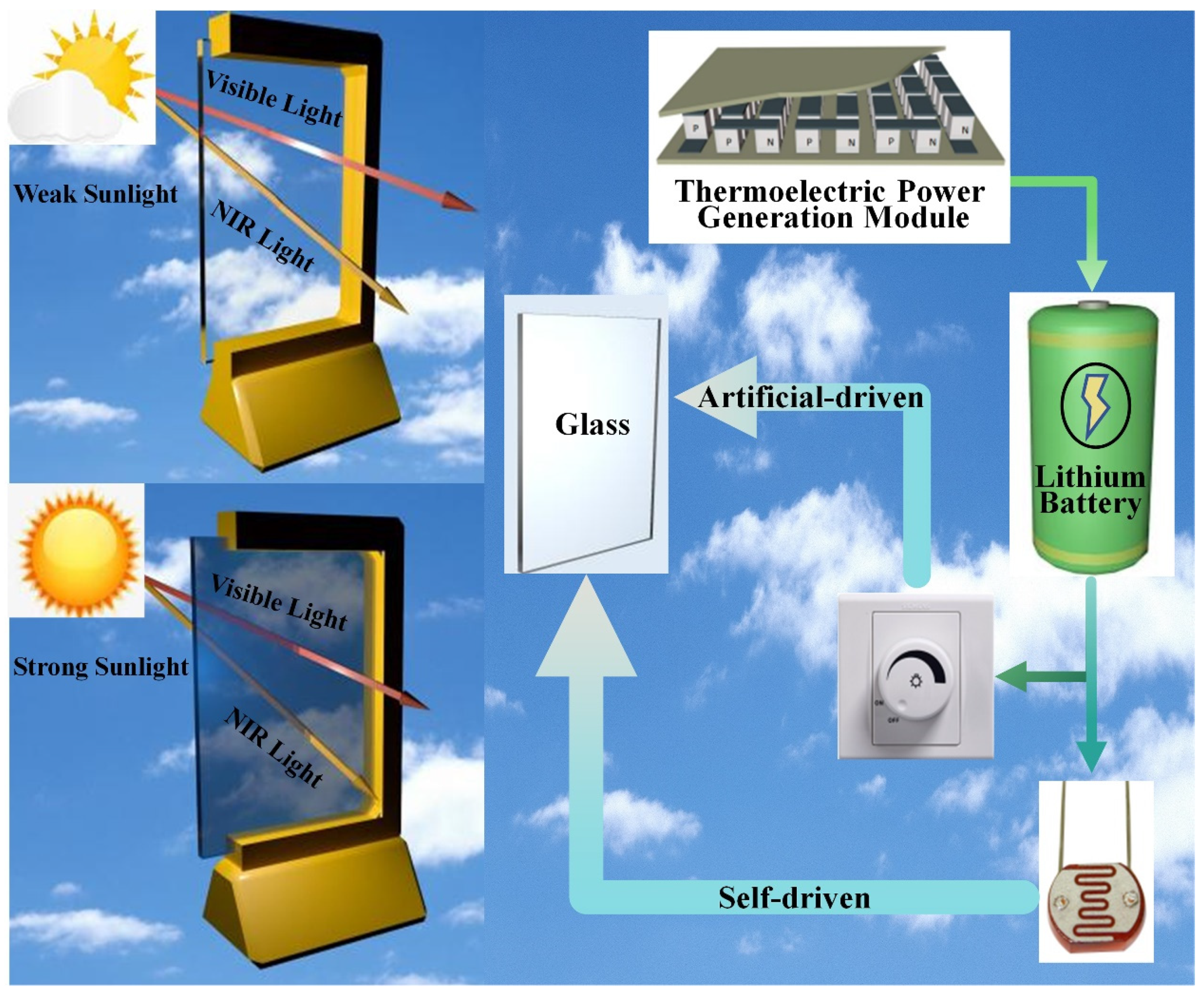

2. System Summarization

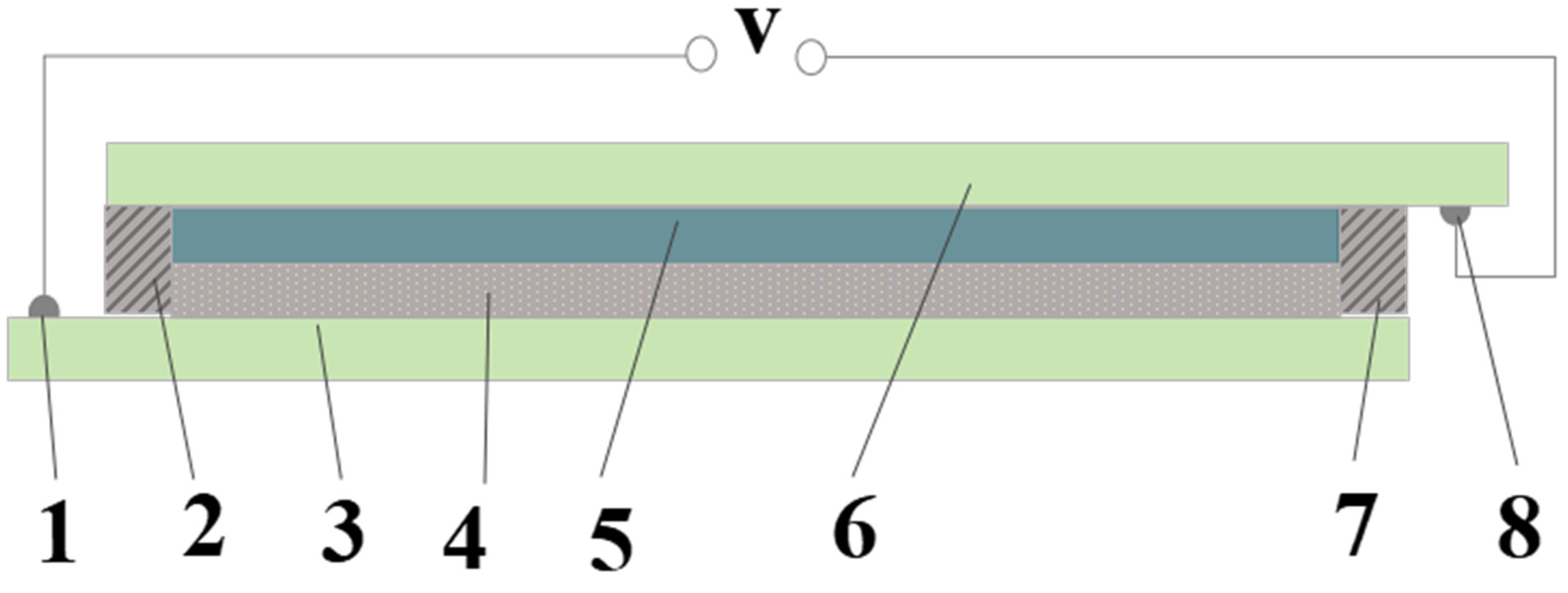

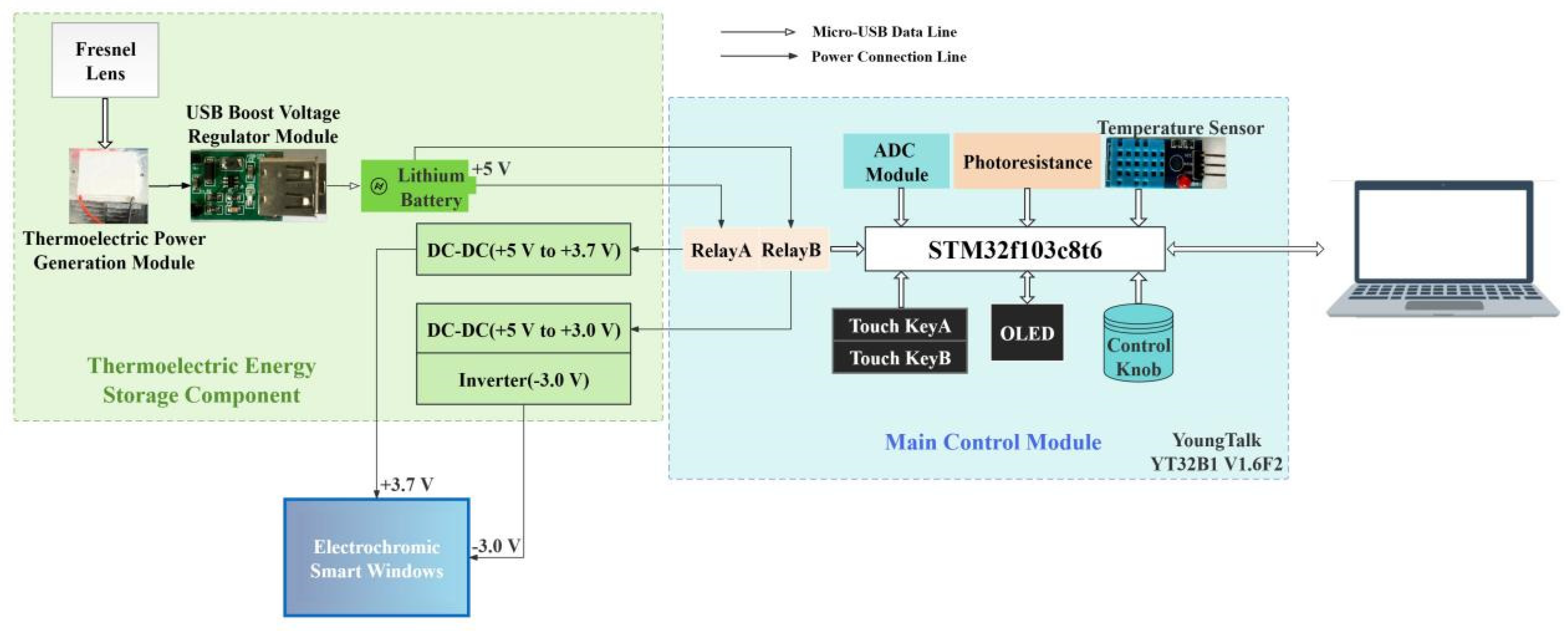

2.1. Hardware Scheme

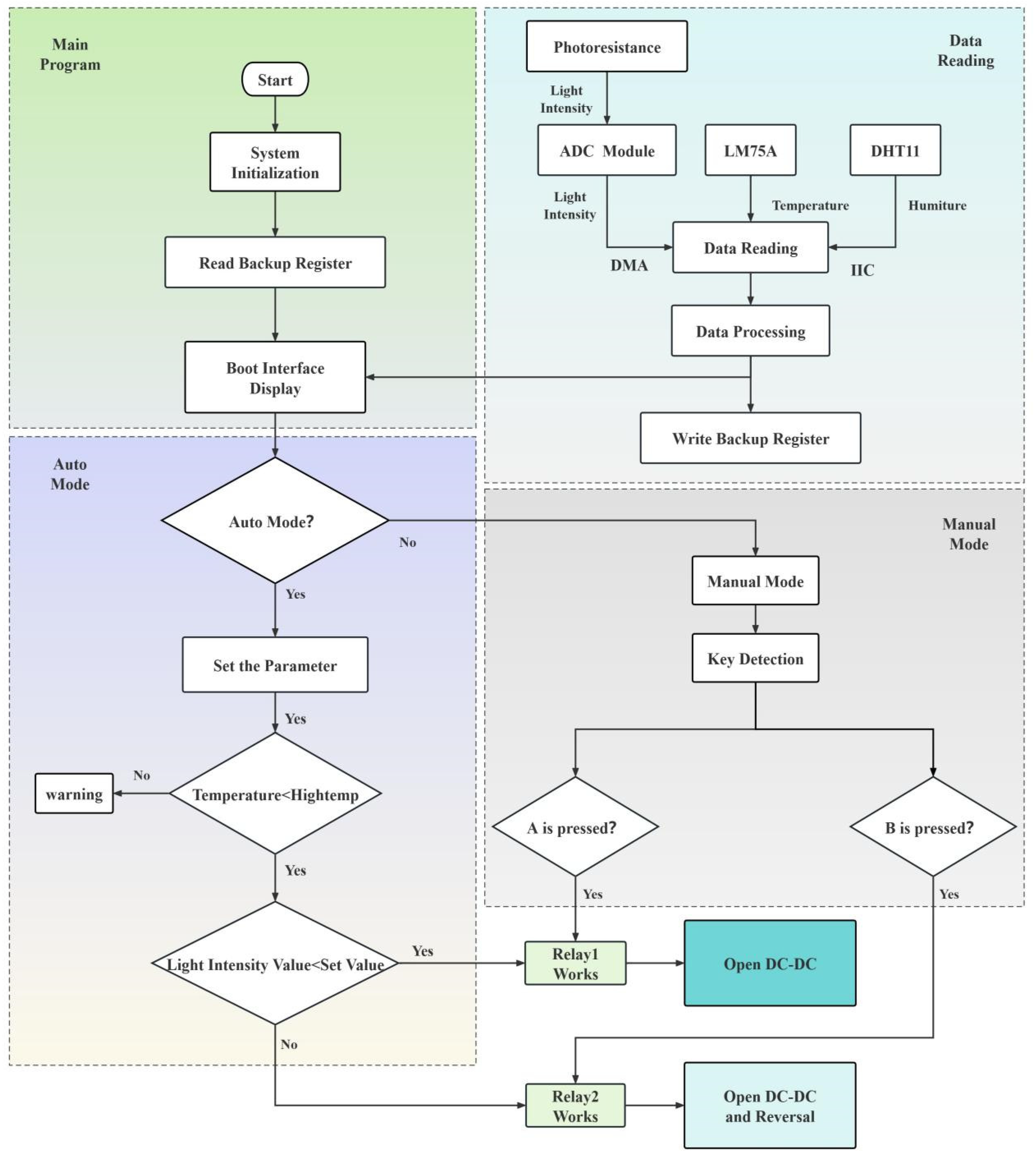

2.2. Software Scheme

3. Experimental Section

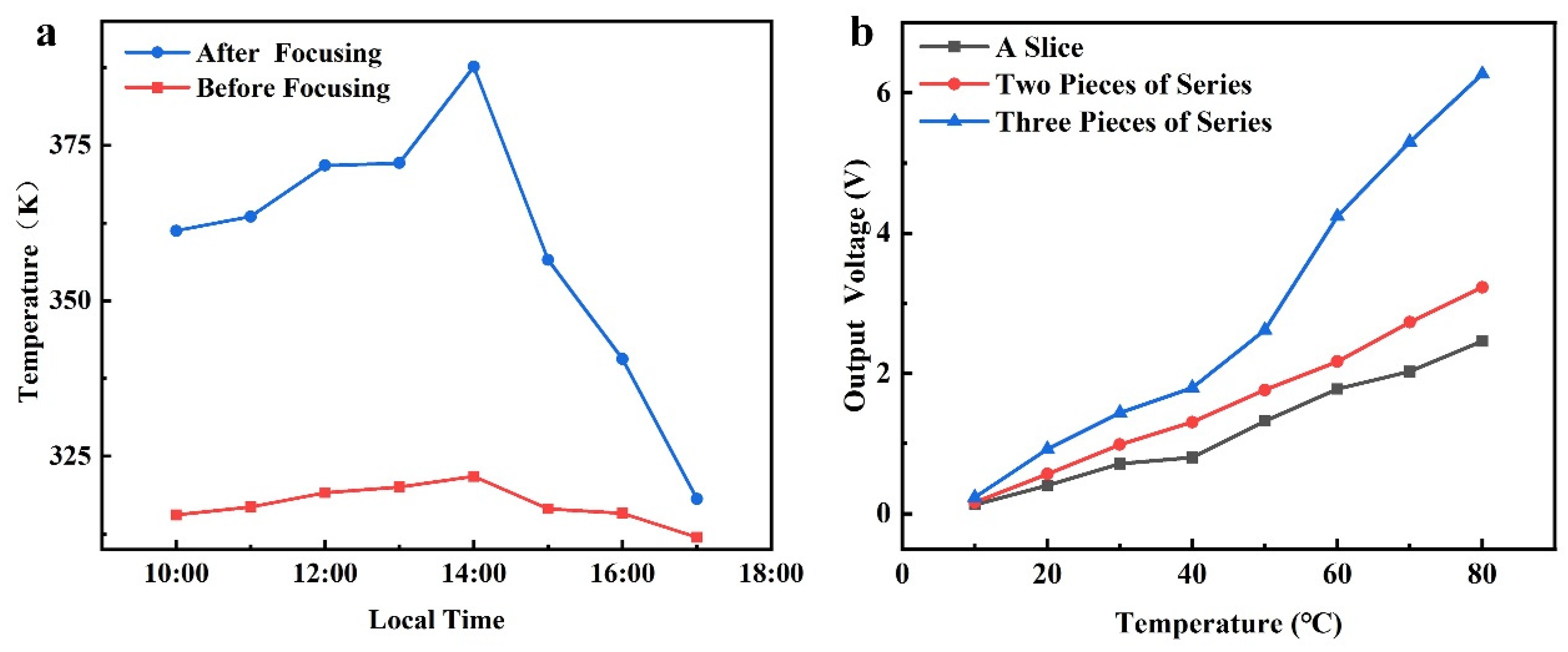

3.1. Focusing Experiment Using the Fresnel Lens

3.2. Performance Test of Thermoelectric Power Generation Components

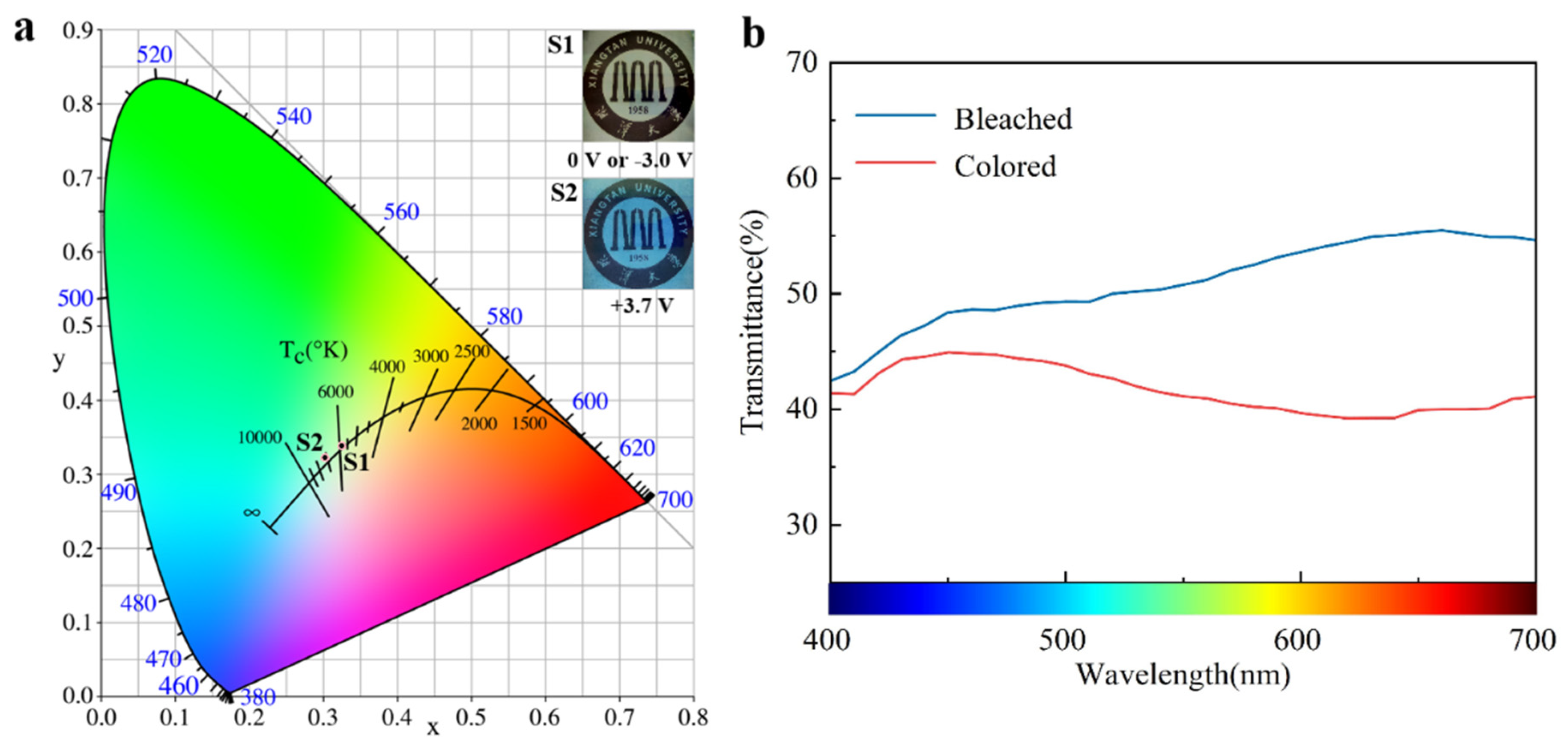

3.3. Optical Properties Experiment

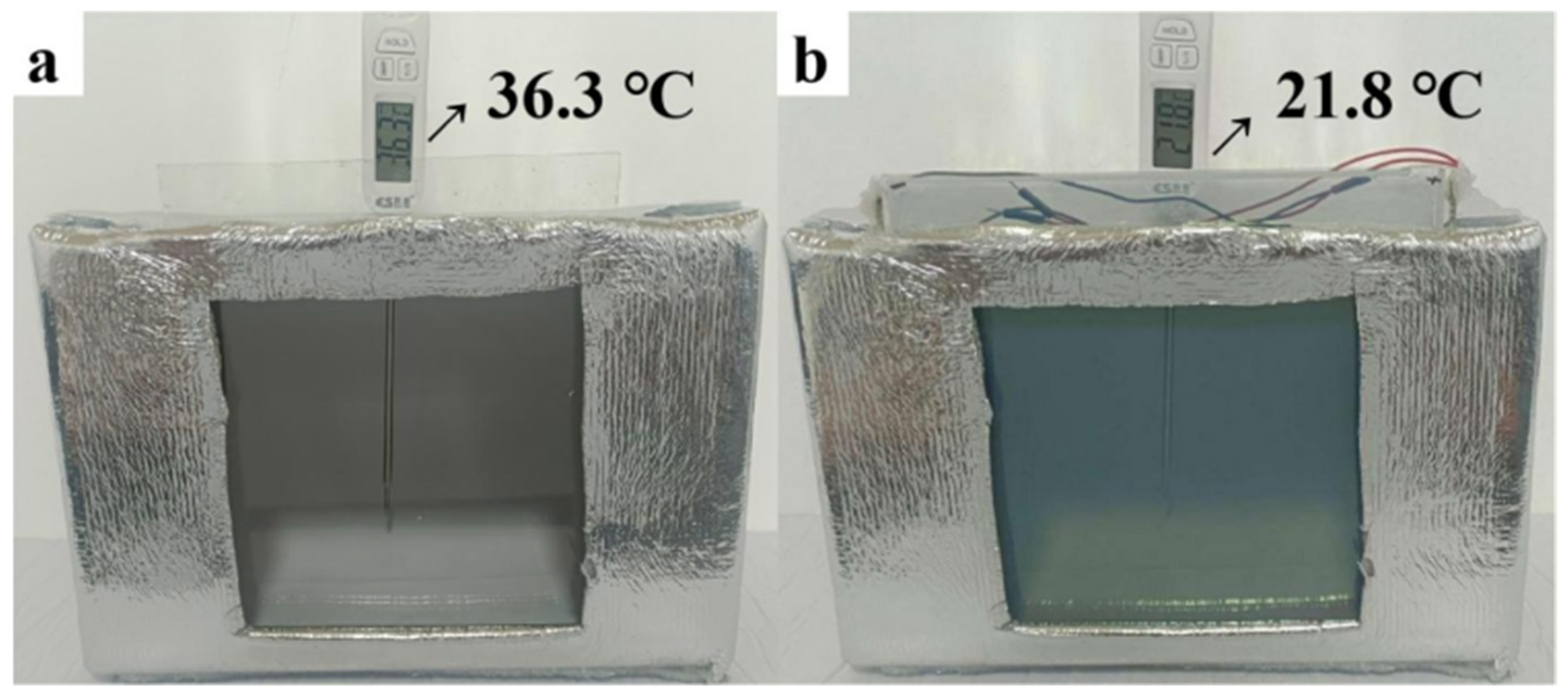

3.4. Thermal Performance Test

4. Results and Discussion

4.1. Thermoelectric Performance

4.2. Optical Performance

4.3. Thermal Performance

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gao, Y.; Ruan, Y.; Fang, C.; Yin, S. Deep learning and transfer learning models of energy consumption forecasting for a building with poor information data. Energy Build. 2020, 223, 110156. [Google Scholar] [CrossRef]

- Somu, N.; M R, G.R.; Ramamritham, K. A deep learning framework for building energy consumption forecast. Renew. Sustain. Energy Rev. 2020, 137, 110591. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, Y.; Li, J.; Song, Y.; Wang, Z. Does the energy efficiency of buildings bring price premiums? Evidence from urban micro-level energy data. Renew. Sustain. Energy Rev. 2023, 181, 113315. [Google Scholar] [CrossRef]

- Wang, Y.; Ji, H.; Liu, B.; Tang, P.; Chen, Y.; Huang, J.; Ou, Y.; Tao, J. Radiative Cooling: Structure Design and Application. J. Mater. Chem. A 2024, 12, 9962–9978. [Google Scholar] [CrossRef]

- Pan, X.; Shao, T.; Zheng, X.; Zhang, Y.; Ma, X.; Zhang, Q. Energy and sustainable development nexus: A review. Energy Strat. Rev. 2023, 47, 101078. [Google Scholar] [CrossRef]

- Cai, G.; Eh AL, S.; Ji, L.; Lee, P.S. Recent advances in electrochromic smart fenestration. Adv. Sustain. Syst. 2017, 1, 1700074. [Google Scholar] [CrossRef]

- Zhao, Y.; Ji, H.; Ou, Y.; Wang, Y.; Chen, Y.; Tao, J.; Liu, B.; Lu, M.; Huang, Y.; Wang, J. Novel sunlight-driven Cu7S4/VO2 composite films for smart windows. J. Mater. Chem. C 2024, 12, 2534–2543. [Google Scholar] [CrossRef]

- Ji, H.; Zhao, Y.; Lu, M.; Tao, J.; Chen, Y.; Ou, Y.; Wang, Y.; Mao, Y. Novel warm/cool-tone switchable VO2-based smart window composite films with excellent optical performance. Ceram. Int. 2023, 49, 22630–22635. [Google Scholar] [CrossRef]

- Kahsay, M.T.; Bitsuamlak, G.T.; Tariku, F. Thermal zoning and window optimization framework for high-rise buildings. Appl. Energy 2021, 292, 116894. [Google Scholar] [CrossRef]

- Wang, J.-L.; Sheng, S.-Z.; He, Z.; Wang, R.; Pan, Z.; Zhao, H.-Y.; Liu, J.-W.; Yu, S.-H. Self-Powered Flexible Electrochromic Smart Window. Nano Lett. 2021, 21, 9976–9982. [Google Scholar] [CrossRef]

- Bai, T.; Li, W.; Fu, G.; Zhang, Q.; Zhou, K.; Wang, H. Dual-band electrochromic smart windows towards building energy conservation. Sol. Energy Mater. Sol. Cells 2023, 256, 112320. [Google Scholar] [CrossRef]

- Tao, X.; Liu, D.; Yu, J.; Cheng, H. Reversible Metal Electrodeposition Devices: An Emerging Approach to Effective Light Modulation and Thermal Management. Adv. Opt. Mater. 2021, 9, 2001847. [Google Scholar] [CrossRef]

- Halder, S.; Chakraborty, C. Porous covalent polymer framework-based molecular platform for polychromatic Vis-to-NIR electrochromic smart window to modulate solar irradiation. Sol. Energy Mater. Sol. Cells 2024, 270, 112800. [Google Scholar] [CrossRef]

- Nejad, M.A.F.; Ranjbar, S.; Parolo, C.; Nguyen, E.P.; Álvarez-Diduk, R.; Hormozi-Nezhad, M.R.; Merkoçi, A. Electrochromism: An emerging and promising approach in (bio)sensing technology. Mater. Today 2021, 50, 476–498. [Google Scholar] [CrossRef]

- Cai, G.; Wang, J.; Lee, P.S. Next-Generation Multifunctional Electrochromic Devices. Accounts Chem. Res. 2016, 49, 1469–1476. [Google Scholar] [CrossRef] [PubMed]

- Fan, H.; Wei, W.; Hou, C.; Zhang, Q.; Li, Y.; Li, K.; Wang, H. Wearable electrochromic materials and devices: From visible to infrared modulation. J. Mater. Chem. C 2023, 11, 7183–7210. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, B.; Zhu, N.; Huang, Y.; Wang, F.; Li, R.; Zhao, Y.; Jiang, Q.; Wu, X.; Zhang, R. Dual-band electrochromic materials for energy-saving smart windows. Carbon Neutralization 2023, 2, 4–27. [Google Scholar] [CrossRef]

- Deb, S.K.; Lee, S.-H.; Tracy, C.E.; Pitts, J.R.; Gregg, B.A.; Branz, H.M. Stand-alone photovoltaic-powered electrochromic smart window. Electrochimica Acta 2001, 46, 2125–2130. [Google Scholar] [CrossRef]

- Martín-Chivelet, N.; Guillén, C.; Trigo, J.F.; Herrero, J.; Pérez, J.J.; Chenlo, F. Comparative performance of semi-transparent PV modules and electrochromic windows for improving energy efficiency in buildings. Energies 2018, 11, 1526. [Google Scholar] [CrossRef]

- Zhang, H.; Feng, J.; Sun, F.; Zhou, D.; Cao, G.; Wang, S.; Hu, X.; Ma, J.; Su, F.; Tian, Y.; et al. Self-Driven Ni-Based Electrochromic Devices for Energy-Efficient Smart Windows. Adv. Mater. Technol. 2023, 8, 2201688. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Z.; Zhang, M.; Huo, X.; Guo, M. Toward Next-Generation Smart Windows: An In-depth Analysis of Dual-Band Electrochromic Materials and Devices. Adv. Opt. Mater. 2024, 12, 2302344. [Google Scholar] [CrossRef]

- Hossain, H.; Ah, C.S.; Ryu, H. Investigation for a Highly Efficient Self-Powered Electrochromic Smart Window for Fast Response and Greater Maximum Transmittance Modulation. ACS Appl. Electron. Mater. 2024, 6, 1514–1520. [Google Scholar] [CrossRef]

- Hossain, M.H.; Ah, C.S.; Ryu, H. Empowering Zero-Energy Buildings with Cutting-Edge Self-Powered Electrochromic Smart Window Technology. Phys. Status Solidi (A) 2024, 2300891. [Google Scholar] [CrossRef]

- Gugliermetti, F.; Bisegna, F. Visual and energy management of electrochromic windows in Mediterranean climate. J. Affect. Disord. 2003, 38, 479–492. [Google Scholar] [CrossRef]

- Wang, K.; Wu, H.; Meng, Y.; Zhang, Y.; Wei, Z. Integrated energy storage and electrochromic function in one flexible device: An energy storage smart window. Energy Environ. Sci. 2012, 5, 8384–8389. [Google Scholar] [CrossRef]

- Yeh, M.-H.; Lin, L.; Yang, P.-K.; Wang, Z.L. Motion-Driven Electrochromic Reactions for Self-Powered Smart Window System. ACS Nano 2015, 9, 4757–4765. [Google Scholar] [CrossRef]

- Ling, H.; Wu, J.; Su, F.; Tian, Y.; Liu, Y.J. Automatic light-adjusting electrochromic device powered by perovskite solar cell. Nat. Commun. 2021, 12, 1–8. [Google Scholar] [CrossRef]

- Cannavale, A.; Ayr, U.; Fiorito, F.; Martellotta, F. Smart Electrochromic Windows to Enhance Building Energy Efficiency and Visual Comfort. Energies 2020, 13, 1449. [Google Scholar] [CrossRef]

- Zhou, Z.; Chen, Z.; Ma, D.; Wang, J. Porous WO3·2H2O film with large optical modulation and high coloration efficiency for electrochromic smart window. Sol. Energy Mater. Sol. Cells 2023, 253, 112226. [Google Scholar] [CrossRef]

- Lei, P.; Wang, J.; Gao, Y.; Hu, C.; Zhang, S.; Tong, X.; Wang, Z.; Gao, Y.; Cai, G. An Electrochromic Nickel Phosphate Film for Large-Area Smart Window with Ultra-Large Optical Modulation. Nano-Micro Lett. 2023, 15, 1–13. [Google Scholar] [CrossRef]

- Shao, Z.; Huang, A.; Cao, C.; Ji, X.; Hu, W.; Luo, H.; Bell, J.; Jin, P.; Yang, R.; Cao, X. Tri-band electrochromic smart window for energy savings in buildings. Nat. Sustain. 2024, 1–8. [Google Scholar] [CrossRef]

| State | L* | a* | b* | x | y | z | R | G | B |

|---|---|---|---|---|---|---|---|---|---|

| Bleached | 77.49 | 1.89 | 4.22 | 0.32566 | 0.33870 | 0.33653 | 8.46 | 9.44 | 9.18 |

| Colored | 69.87 | −1.61 | −3.93 | 0.30220 | 0.32294 | 0.37486 | 5.55 | 7.52 | 8.34 |

| State | Number of Cycles | Infrared Radiation Rejection (780 to 2500 nm) | UV Blocking Rate |

|---|---|---|---|

| Bleached | 1 | 77.3% | 91.6% |

| Bleached | 2000 | 77.3% | 91.3% |

| Colored | 1 | 77.7% | 91.0% |

| Colored | 2000 | 77.7% | 90.9% |

| Type of Glass | Infrared Radiation Rejection (780 to 2500 nm) | UV Blocking Rate | Visible Transmittance |

|---|---|---|---|

| Electrochromic glass | 77.3% | 91.0% | 39.2–56.4% |

| Ordinary glass | 16.1% | 20.2% | 88.2% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, X.; Ji, H.; Wang, L.; Wang, S.; Chen, Q.; Luo, R. Design and Implementation of Electrochromic Smart Windows with Self-Driven Thermoelectric Power Generation. Nanomaterials 2024, 14, 1027. https://doi.org/10.3390/nano14121027

Xie X, Ji H, Wang L, Wang S, Chen Q, Luo R. Design and Implementation of Electrochromic Smart Windows with Self-Driven Thermoelectric Power Generation. Nanomaterials. 2024; 14(12):1027. https://doi.org/10.3390/nano14121027

Chicago/Turabian StyleXie, Xiaohan, Haining Ji, Lingcan Wang, Shaomei Wang, Qi Chen, and Runteng Luo. 2024. "Design and Implementation of Electrochromic Smart Windows with Self-Driven Thermoelectric Power Generation" Nanomaterials 14, no. 12: 1027. https://doi.org/10.3390/nano14121027