Transient Pressure Behavior of CBM Wells during the Injection Fall-Off Test Considering the Quadratic Pressure Gradient

Abstract

:1. Introduction

2. Methodology

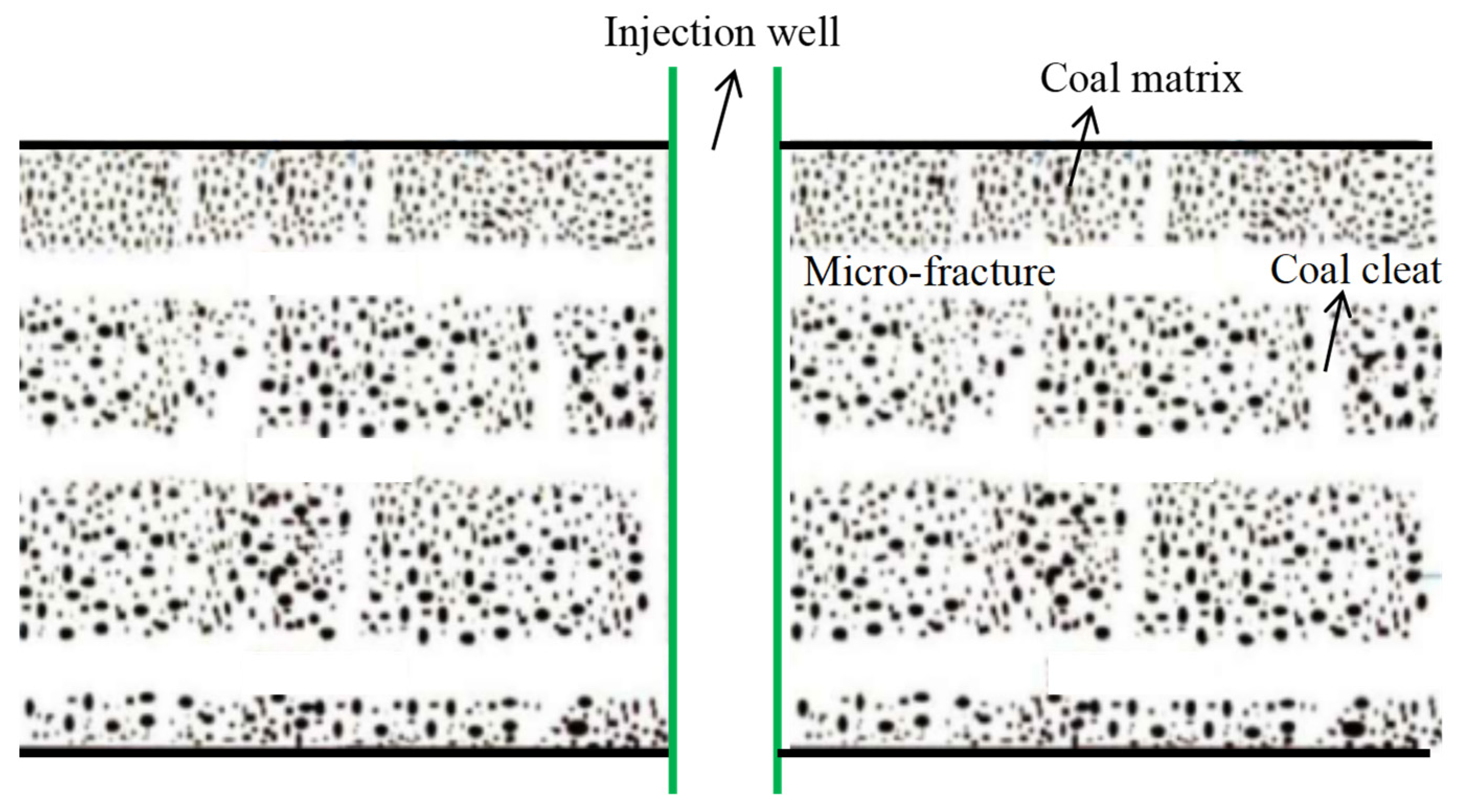

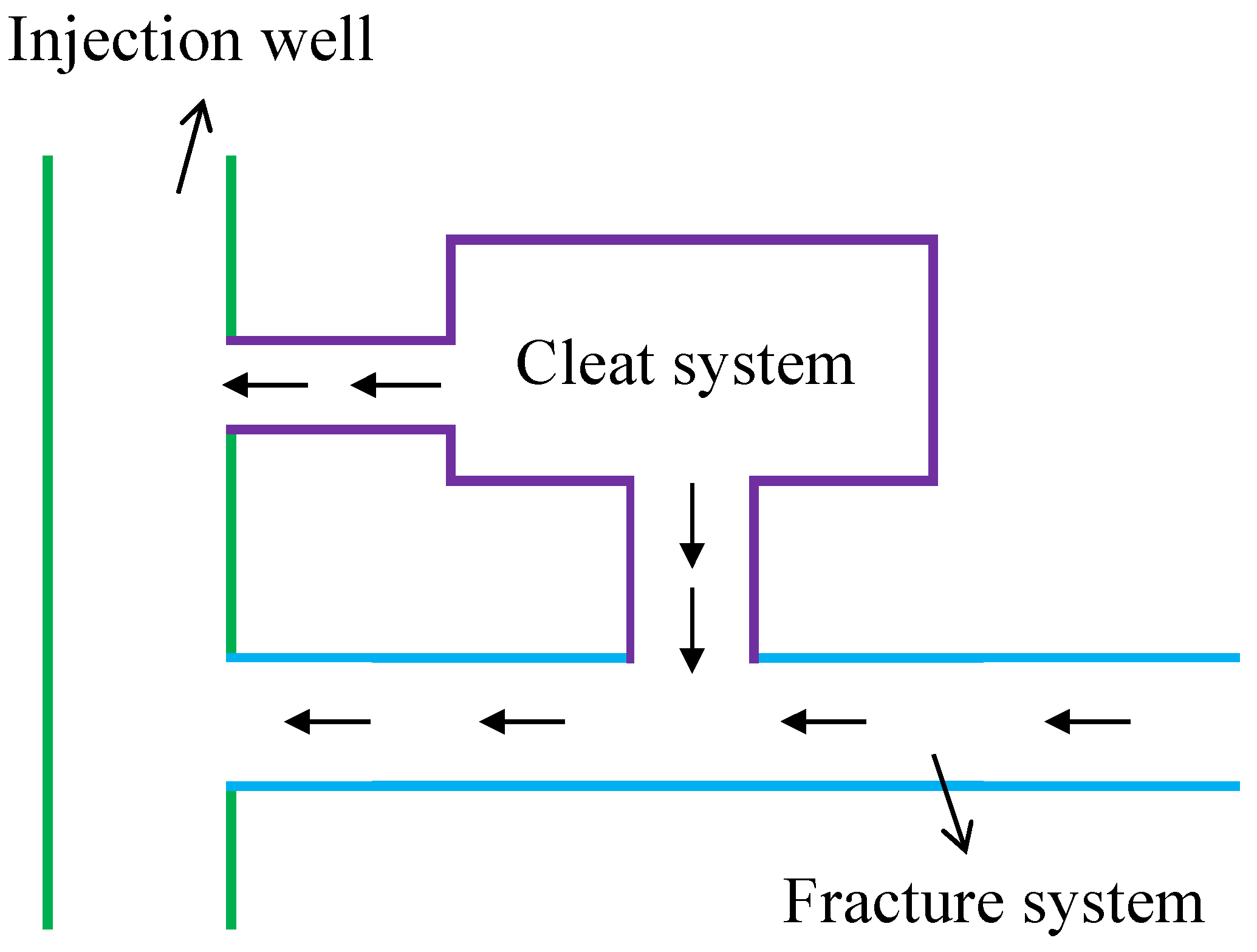

2.1. Physical Model Assumption

- (1)

- Slightly compressible fluid and coal matrix: Both the formation fluid and the coal matrix exhibit slight compressibility, characterized by a constant compressibility coefficient. This implies that the volume of both the fluid and the rock can be slightly compressed or expanded in response to changes in pressure.

- (2)

- Cleat and fracture properties: The permeability within the cleat and natural fracture systems is assumed to be constant and isotropic in the horizontal plane. Isotropy in this context signifies that the permeability does not vary with direction within the horizontal plane.

- (3)

- Isothermal Darcy flow: Fluid flow within the cleat and fracture network is governed by the isothermal Darcy’s Law, neglecting the influence of gravity. This assumption implies that the flow is driven by pressure differences within the reservoir and that temperature variations are not considered significant for the purposes of this model.

- (4)

- Wellbore storage and skin effects: The model incorporates the effects of wellbore storage and skin effect, which can significantly impact pressure behavior during well testing. Wellbore storage refers to the volume of fluid contained within the wellbore itself, while skin effect represents the additional pressure drop or gain that occurs near the wellbore due to formation damage or stimulation.

- (5)

- Non-linear flow with quadratic pressure gradient: The model accounts for the non-linear flow behavior arising from the quadratic pressure gradient, a critical factor in CBM reservoirs. The quadratic pressure gradient refers to the phenomenon where the rate of change of pressure with respect to distance is not constant but rather increases with increasing pressure. This non-linearity can have a significant impact on the pressure response observed during well testing.

2.2. Mathematical Model

2.2.1. Nonlinear Governing Equation

2.2.2. Dimensionless Mathematical Model

2.2.3. Solution to Mathematical Model

3. Results and Discussion

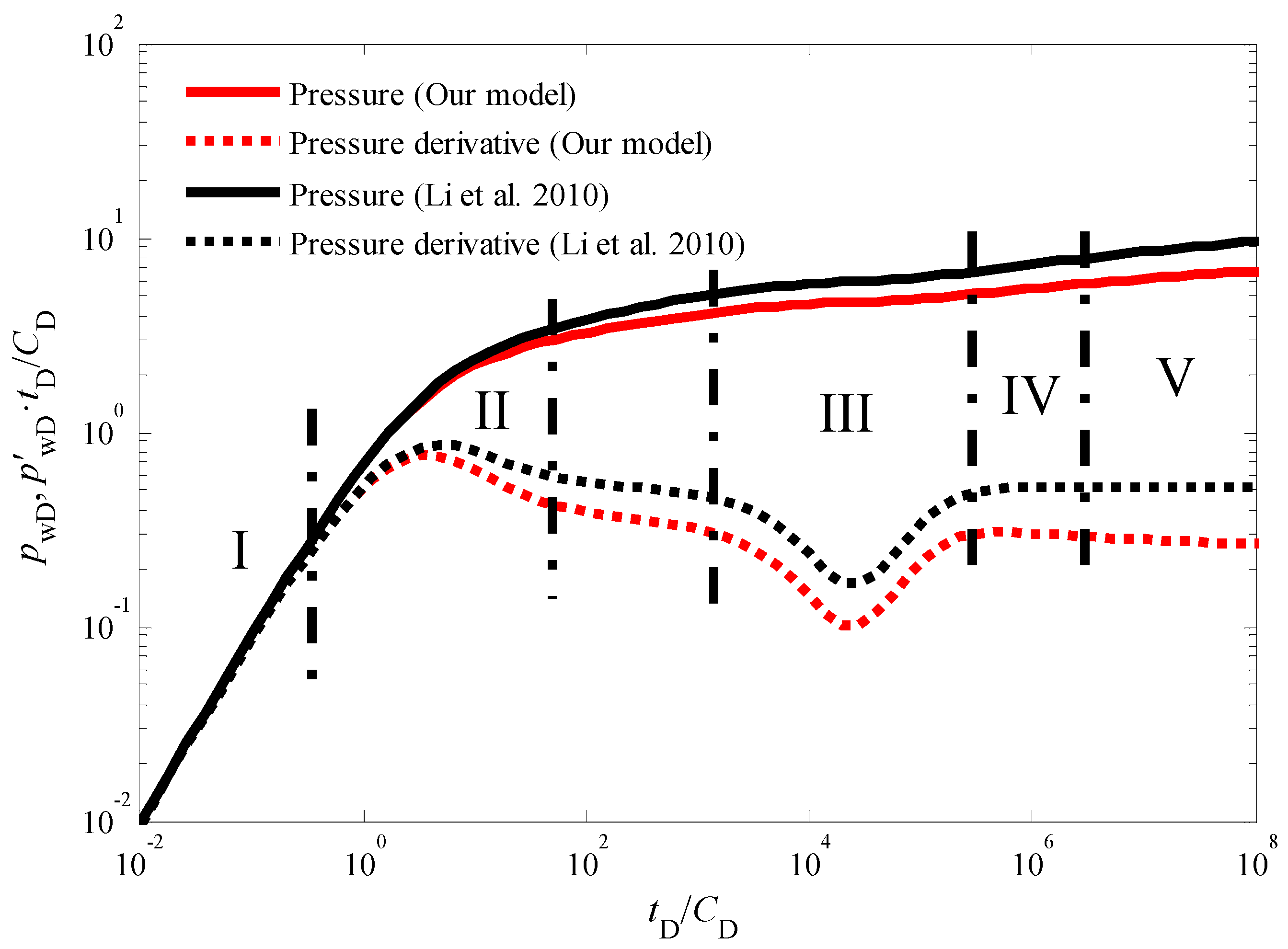

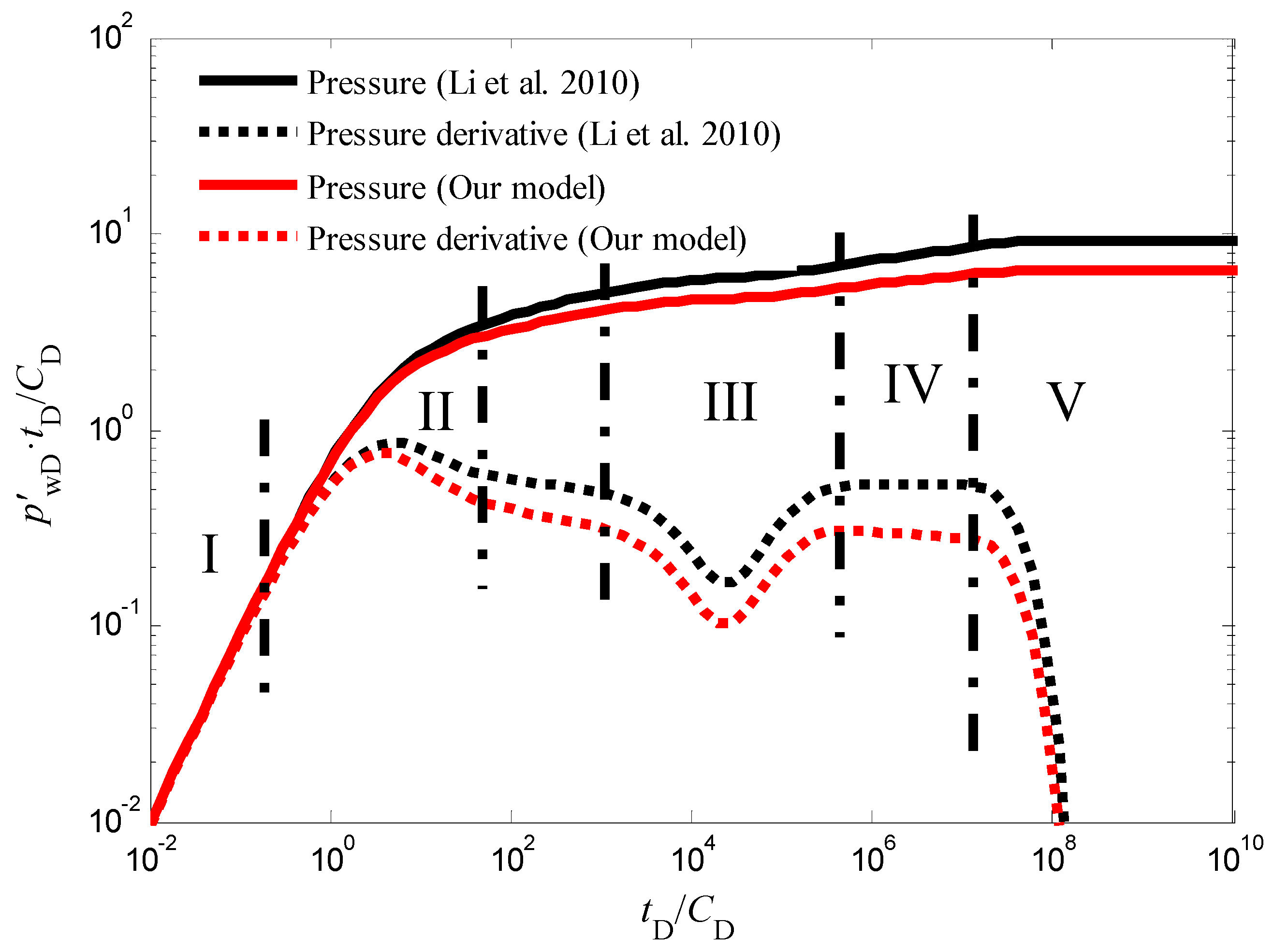

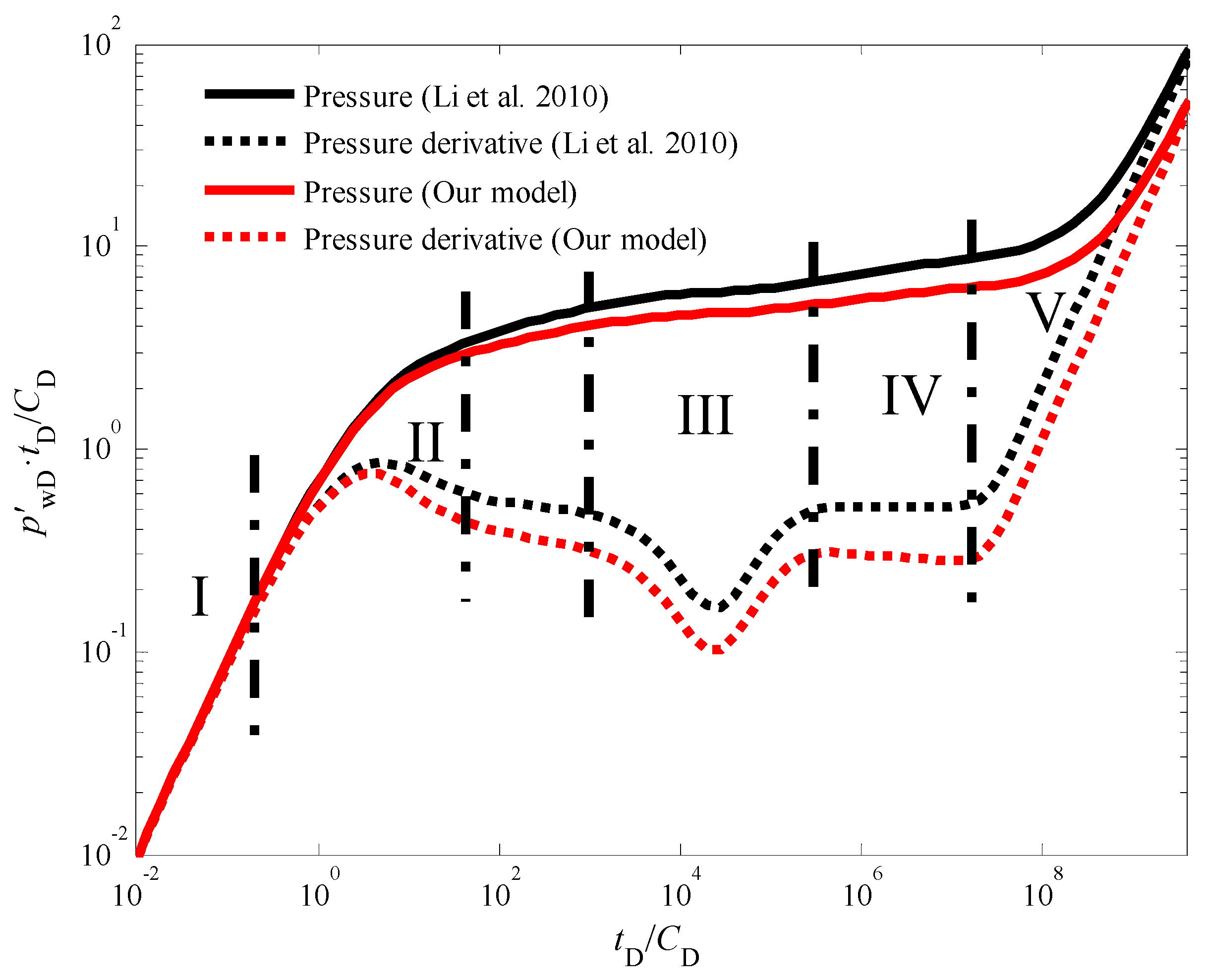

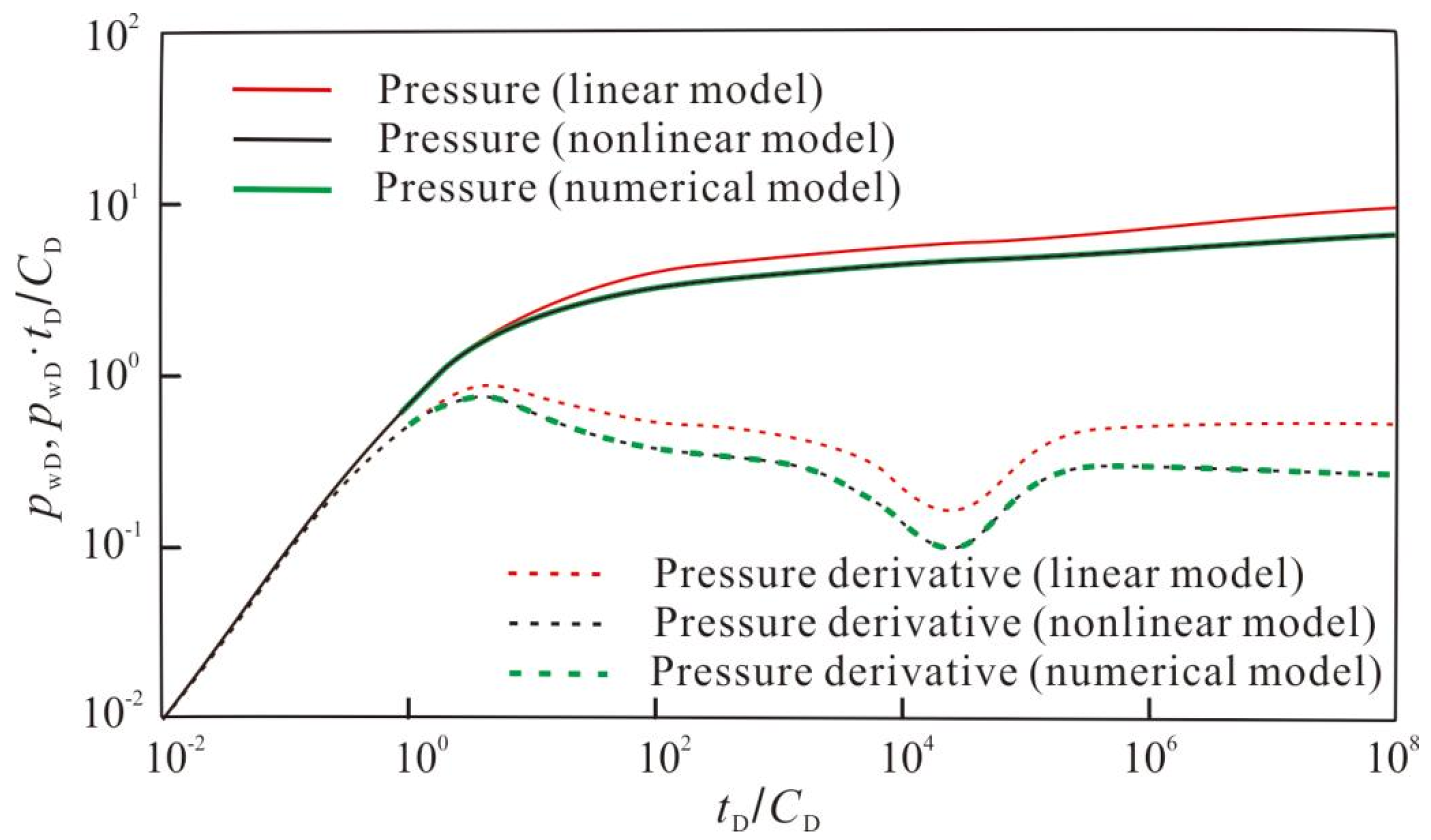

3.1. Flow Regime Identification

3.2. Quantitative Specification of the Nonlinear Parameters

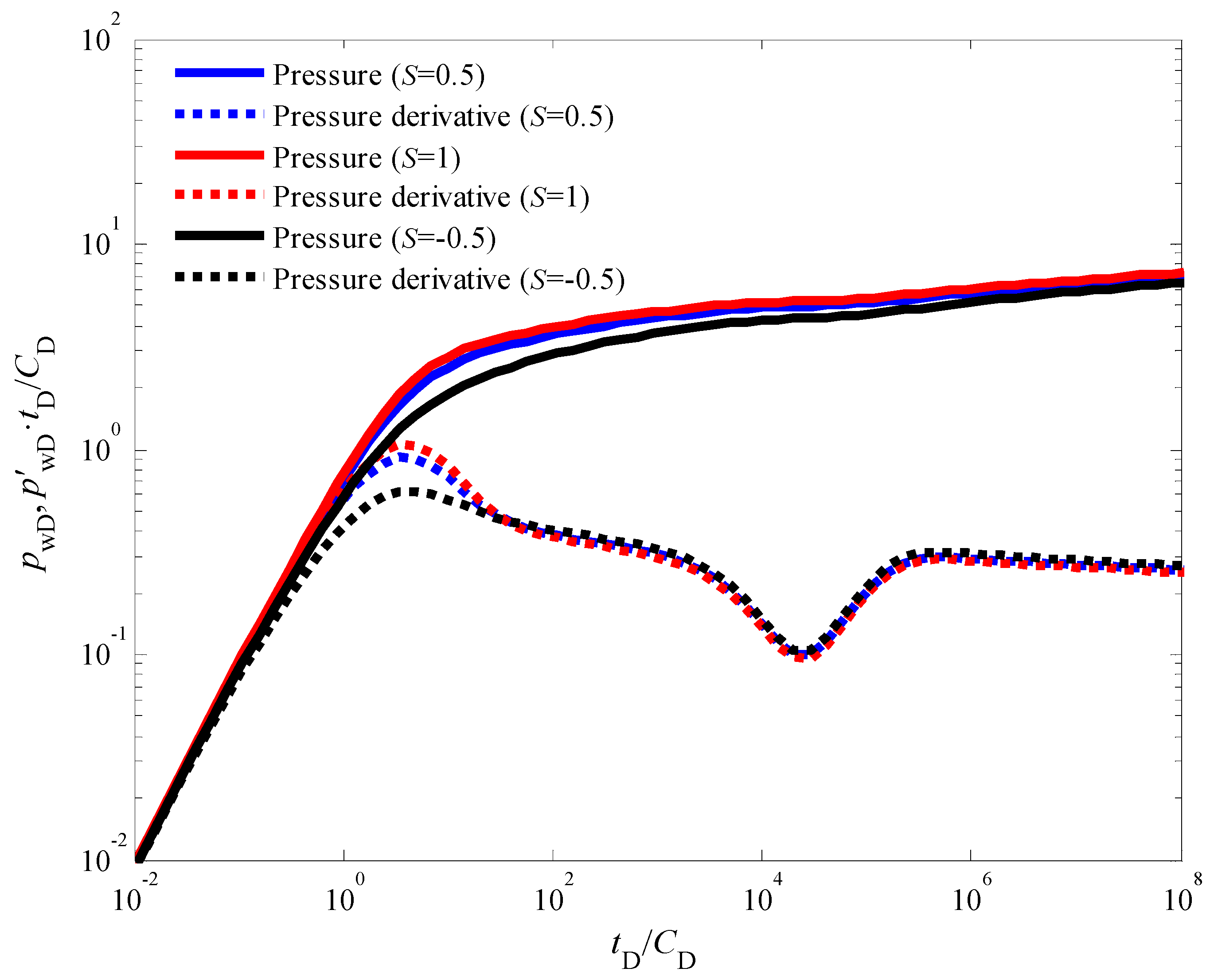

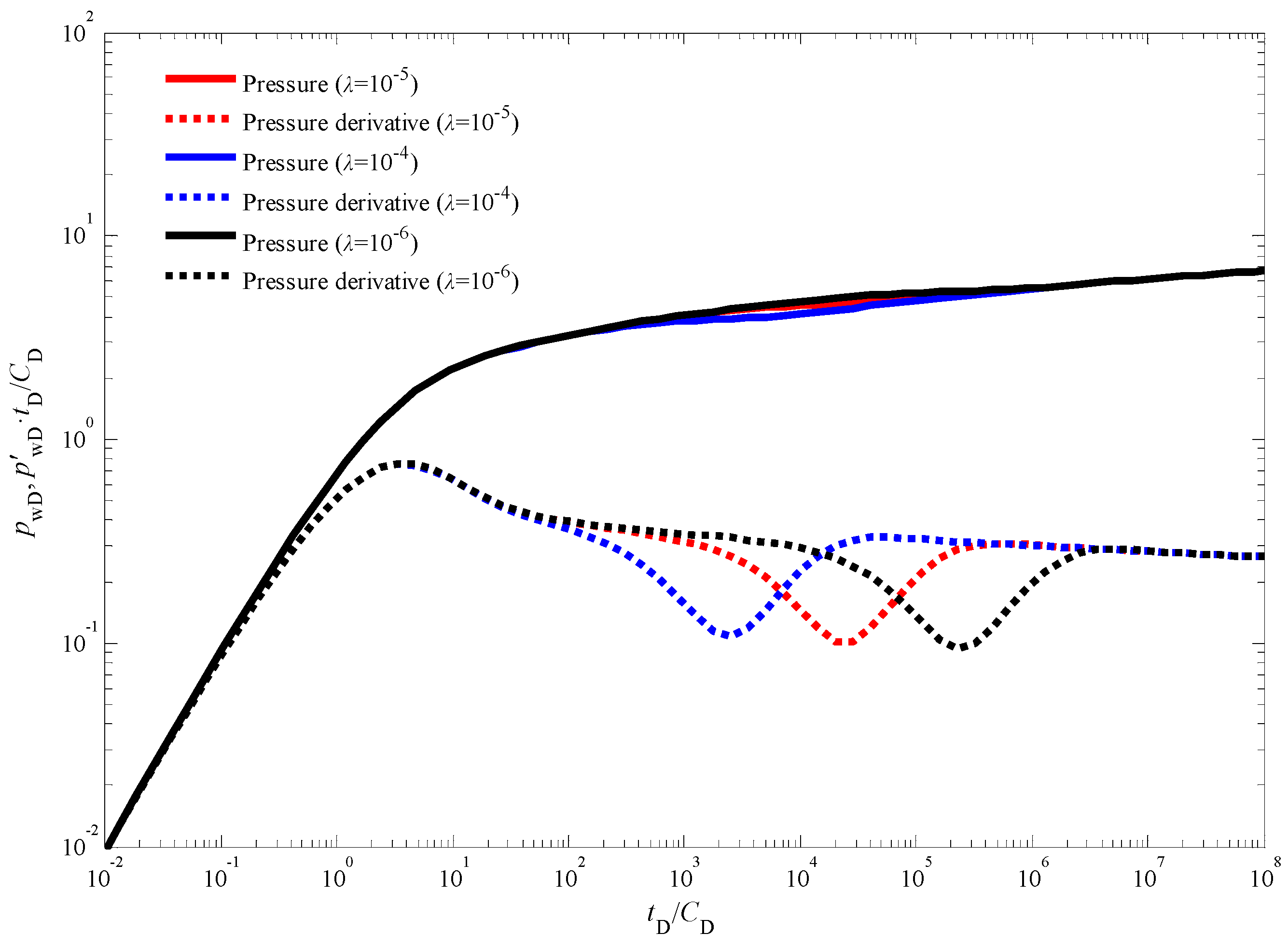

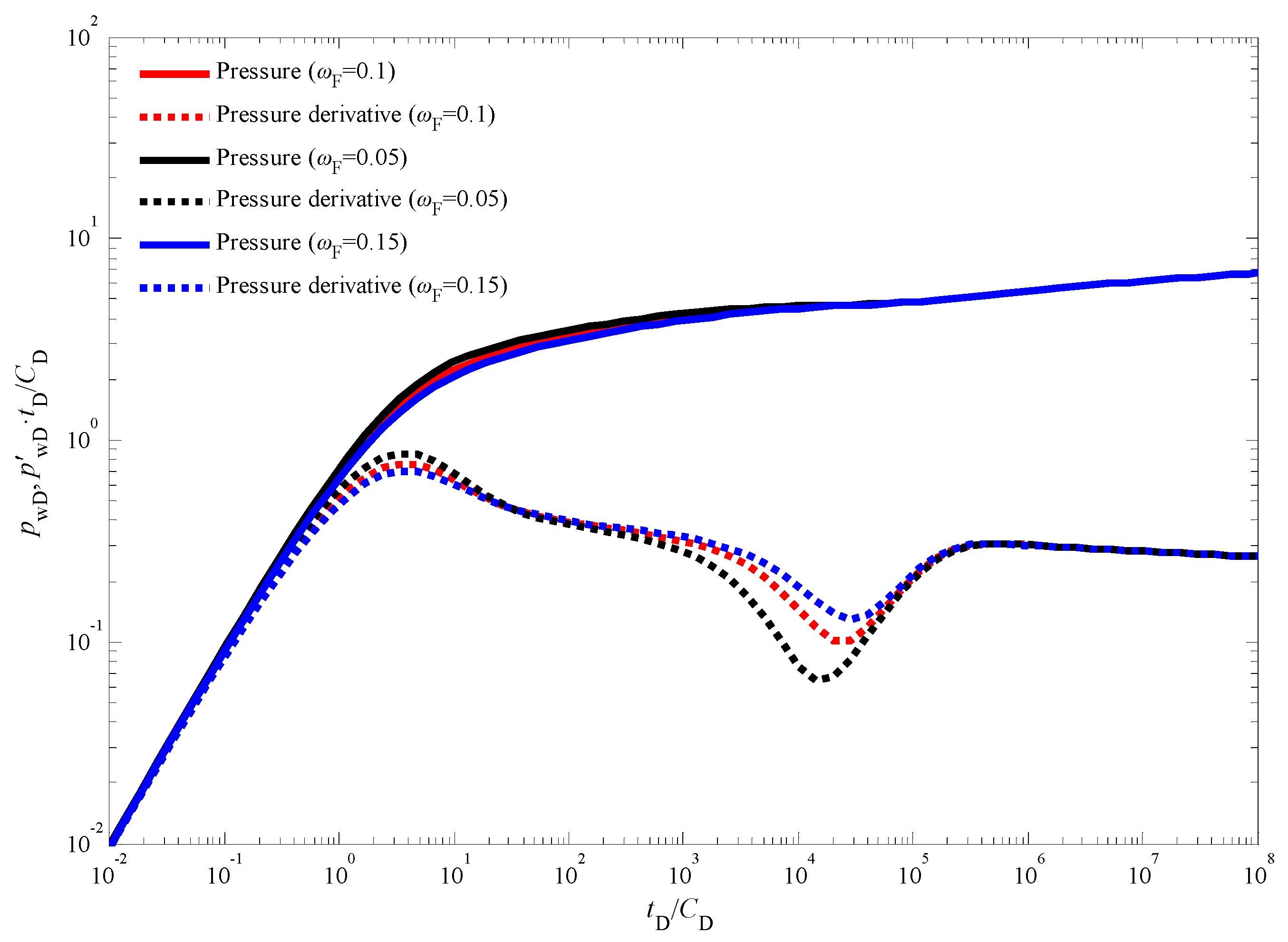

3.3. Sensitivity Analysis

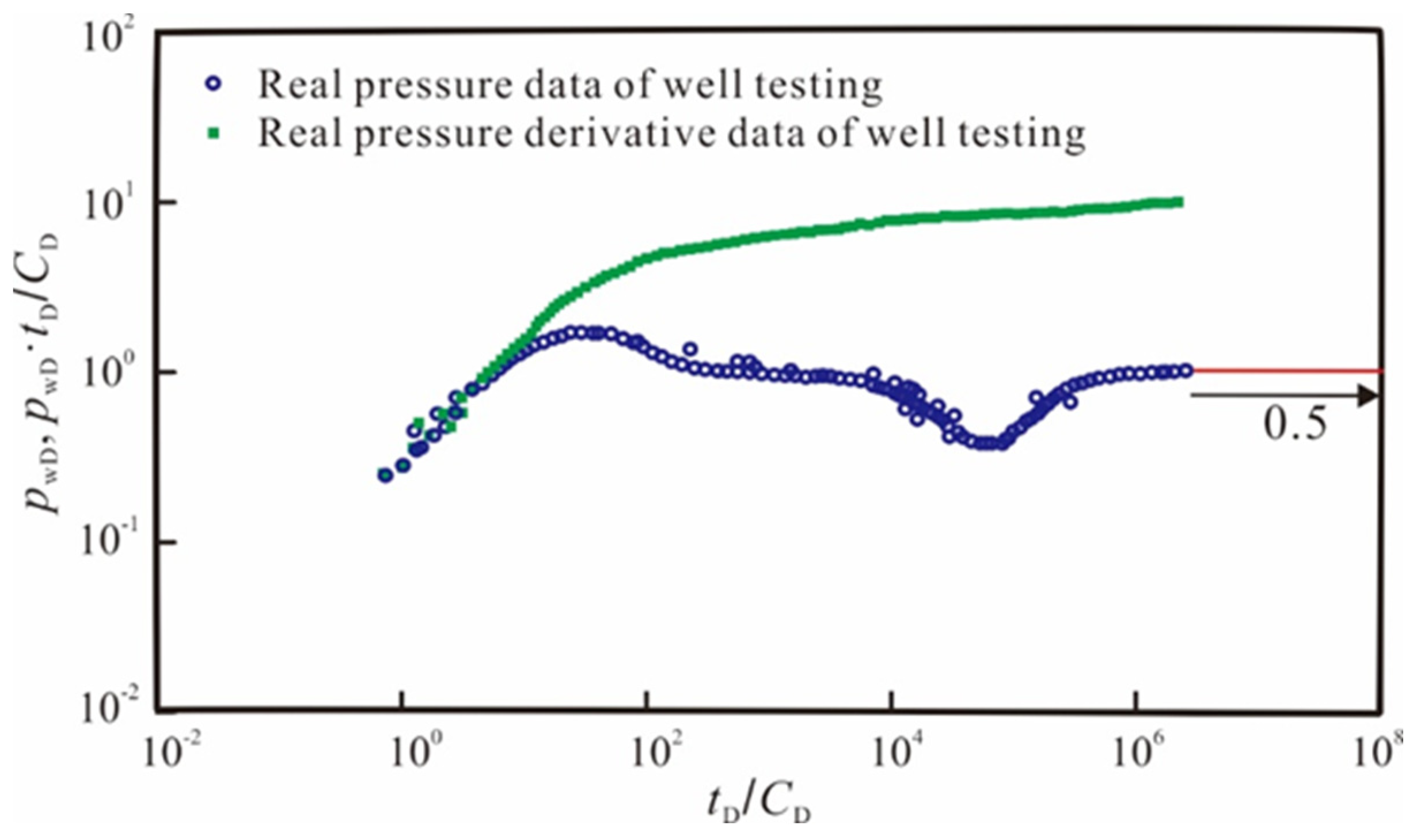

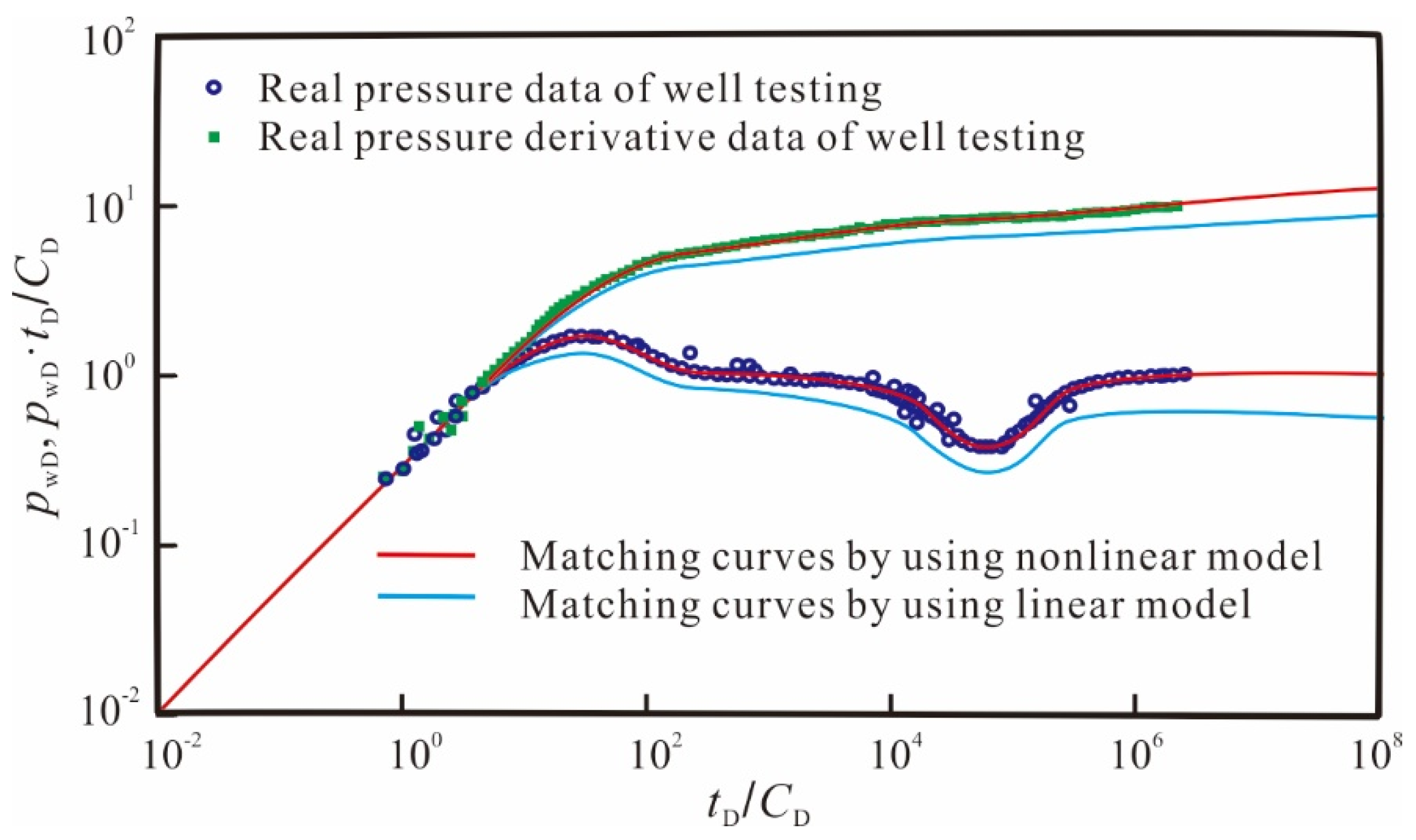

3.4. Field Application

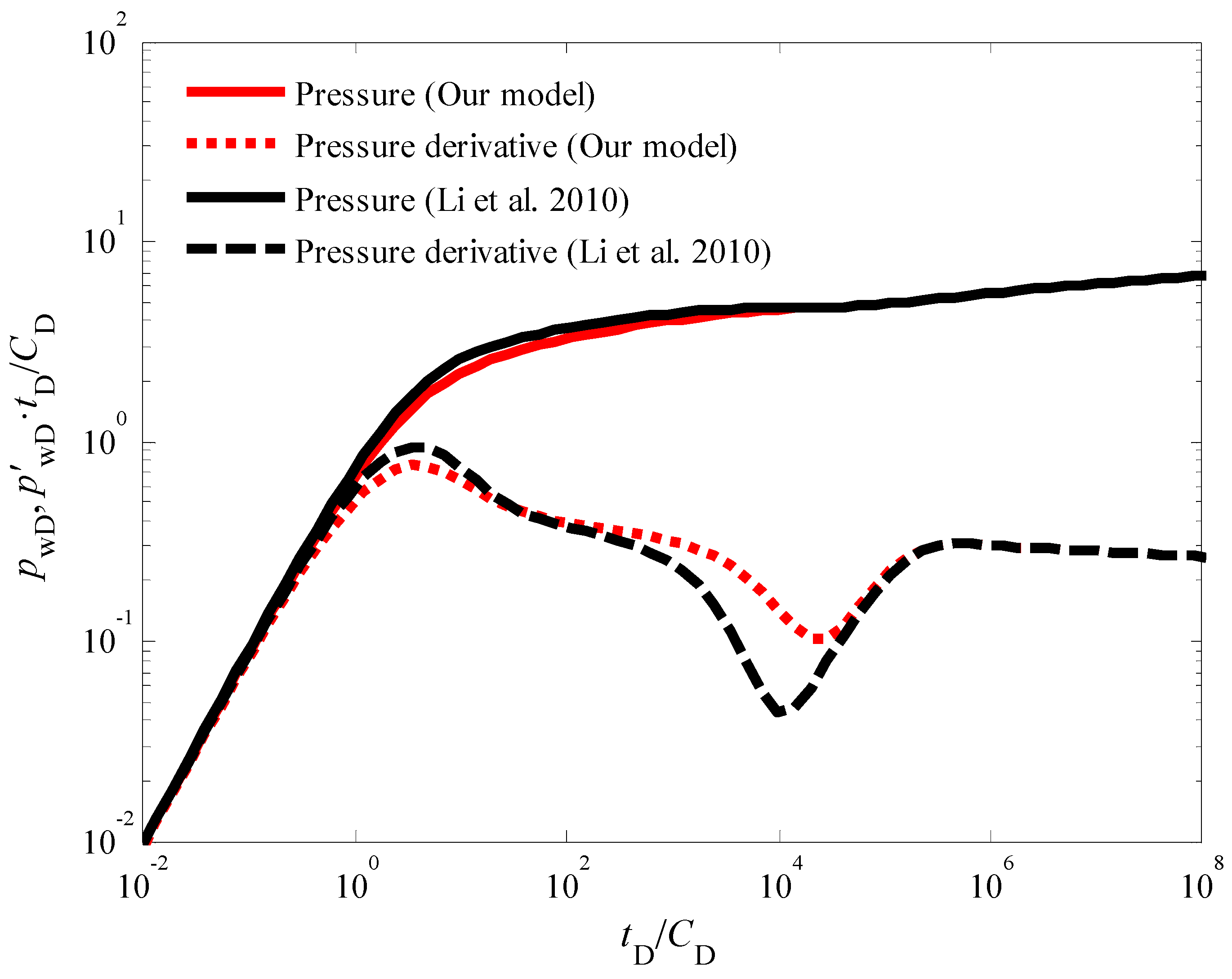

3.5. Model Comparison

4. Conclusions

- (1)

- Impact of the Quadratic Pressure Gradient: The inclusion of the quadratic pressure gradient term in the model exerts a significant influence on the pressure response during the injection fall-off test. This influence is particularly pronounced during two distinct flow stages: the intermediate flow period and the late-time pseudo-radial flow period. When compared to traditional linear models that neglect the quadratic pressure gradient, the proposed model predicts lower bottom-hole pressure and pressure derivative values throughout these two stages. This observation underscores the importance of considering the non-linear flow behavior for accurate pressure response prediction in CBM wells.

- (2)

- Wellbore Storage Effect: The wellbore storage stage, characterized by the dominance of wellbore storage effects, remains unaffected by the quadratic pressure gradient. This is because this initial stage primarily reflects pressure changes confined to the wellbore volume itself, rather than fluid flow within the formation.

- (3)

- Influence of Dimensionless Parameters: The extent of the discrepancy between the pressure and pressure derivative curves obtained from the proposed model and those predicted by conventional linear models is governed by two key dimensionless parameters: the dimensionless quadratic pressure gradient coefficient and the dimensionless production time. As the value of the dimensionless quadratic pressure gradient coefficient increases, the deviation between the curves becomes more pronounced. This signifies a growing impact of the non-linear flow behavior on the pressure response with increasing severity of the pressure gradient. Additionally, the deviation progressively widens with increasing dimensionless production time, highlighting the growing influence of non-linear effects as the injection fall-off test progresses.

- (4)

- Inter-Porosity and Storativity Effects: The inter-porosity flow coefficient, which governs the rate of fluid exchange between the cleat and natural fracture systems within the CBM reservoir, primarily affects the timing of the appearance of a characteristic concave-shaped trough in the pressure derivative curves. This trough signifies the transition from flow within the cleat system to flow within the fracture network. Conversely, the storativity coefficient, which represents the relative amount of fluid initially stored within the cleat and fracture systems, influences the width and depth of this concave trough in the pressure derivative curves. A smaller storativity coefficient, indicative of a lower initial fluid volume within the cleats, leads to wider and deeper troughs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, F.Y.; Yan, X.; Li, S.G.; Xiong, X.; Wang, Y.; Zhang, L.; Liu, C.; Han, J.; Feng, Y.; Zhen, H.; et al. Theoretical and technological difficulties and countermeasures of deep CBM exploration and development in the eastern edge of Ordos Basin. Coal Geol. Explor. 2023, 51, 115–130. [Google Scholar]

- Zhang, Z.; Qin, Y.; You, Z.; Yang, Z. Distribution Characteristics of In Situ Stress Field and Vertical Development Unit Division of CBM in Western Guizhou, China. Nat. Resour. Res. 2021, 30, 3659–3671. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Bustin, R.M.; Seidle, J.P. Production-Data Analysis of Single-Phase (Gas) Coalbed-Methane Wells. SPE Reserv. Evaluation Eng. 2007, 10, 312–331. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, C.; Tang, D.; Gan, Q.; Niu, X.; Wang, K.; Shen, R. Coal pore size distributions controlled by the coalification process: An experimental study of coals from the Junggar, Ordos and Qinshui basins in China. Fuel 2017, 206, 352–363. [Google Scholar] [CrossRef]

- Zhao, Y.; Sun, Y.; Liu, S.; Wang, K.; Jiang, Y. Pore structure characterization of coal by NMR cryoporometry. Fuel 2017, 190, 359–369. [Google Scholar] [CrossRef]

- Zheng, S.; Yao, Y.; Liu, D.; Cai, Y.; Liu, Y. Characterizations of full-scale pore size distribution, porosity and per-meability of coals: A novel methodology by nuclear magnetic resonance and fractal analysis theory. Int. J. Coal Geol. 2018, 196, 148–158. [Google Scholar] [CrossRef]

- Xu, C.; Yang, G.; Wang, K.; Fu, Q. Uneven stress and permeability variation of mining-disturbed coal seam for targeted CBM drainage: A case study in Baode coal mine, eastern Ordos Basin, China. Fuel 2021, 289, 119911. [Google Scholar] [CrossRef]

- Liu, A.; Liu, S.; Liu, P.; Harpalani, S. The role of sorption-induced coal matrix shrinkage on permeability and stress evolutions under replicated in situ condition for CBM reservoirs. Fuel 2021, 294, 120530. [Google Scholar] [CrossRef]

- Guo, C.; Qin, Y.; Sun, X.; Wang, S.; Xia, Y.; Ma, D.; Bian, H.; Shi, Q.; Chen, Y.; Bao, Y.; et al. Physical simulation and compatibility evaluation of multi-seam CBM co-production: Implications for the development of stacked CBM systems. J. Pet. Sci. Eng. 2021, 204, 108702. [Google Scholar] [CrossRef]

- Wang, S.; Bai, Y.; Xu, B.; Li, Y.; Chen, L.; Dong, Z. Semi-analytical model of production prediction for tight sandstone gas wells considering gas-water two phase flow behavior. Sci. Technol. Eng. 2022, 22, 9105–9114. [Google Scholar]

- Bai, Y.; Wang, S.; Xu, B.; Li, D.; Fan, W.; Wu, J.; Jiang, B.; Huang, S. Prediction Model for Tight Gas Wells with Time-Dependent Mechanism and Stress Sensitivity Effect. ACS Omega 2023, 8, 43037–43050. [Google Scholar] [CrossRef] [PubMed]

- Yu, P.; Mali, A.; Velaga, T.; Bi, A.; Yu, J.; Marone, C.; Shokouhi, P.; Elsworth, D. Crustal permeability generated through microearthquakes is constrained by seismic moment. Nat. Commun. 2024, 15, 2057. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Huang, B.; Liu, Y.; Jiang, Y.; Zhang, Z.; Hou, M.; Li, Y. Gas-phase production equation for CBM reservoirs: Interaction between hydraulic fracturing and coal orthotropic feature. J. Pet. Sci. Eng. 2022, 213, 110428. [Google Scholar] [CrossRef]

- Huang, Q.; Wu, B.; Liu, Y.; Guo, Z.; Wang, G.; Sun, L. Experimental and simulation investigations of the impact of polyacrylamide on CBM ad-/desorption. J. Pet. Sci. Eng. 2022, 208, 109300. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, Y. Characteristics of low-rank coal reservoir and exploration potential in Junggar Basin: New frontier of low-rank CBM exploration in China. J. Pet. Explor. Prod. Technol. 2020, 10, 2207–2223. [Google Scholar] [CrossRef]

- King, G.R.; Ertekin, T.; Schwerer, F.C. Numerical Simulation of the Transient Behavior of Coal-Seam Degasification Wells. SPE Form. Evaluation 1986, 1, 165–183. [Google Scholar] [CrossRef]

- Yu, P.; Dempsey, D.; Archer, R. Techno-Economic feasibility of enhanced geothermal systems (EGS) with partially bridging Multi-Stage fractures for district heating applications. Energy Convers. Manag. 2022, 257, 115405. [Google Scholar] [CrossRef]

- Liang, W.; Yan, J.; Zhang, B.; Hou, D. Review on Coal Bed Methane Recovery Theory and Technology: Recent Progress and Perspectives. Energy Fuels 2021, 35, 4633–4643. [Google Scholar] [CrossRef]

- Pavlišič, A.; Ceglar, R.; Pohar, A.; Likozar, B. Comparison of computational fluid dynamics (CFD) and pressure drop correlations in laminar flow regime for packed bed reactors and columns. Powder Technol. 2018, 328, 130–139. [Google Scholar] [CrossRef]

- Philpot, J.A.; Mazumder, S.; Naicker, S.; Chang, G.; Boostani, M.; Tovar, M.; Sharma, V. Coalbed methane modelling best practices. In Proceedings of the International Petroleum Technology Conference, Beijing, China, 26–28 March 2013; pp. IPTC–17137. [Google Scholar]

- Jurković, D.L.; Liu, J.-L.; Pohar, A.; Likozar, B. Methane Dry Reforming over Ni/Al2O3 Catalyst in Spark Plasma Reactor: Linking Computational Fluid Dynamics (CFD) with Reaction Kinetic Modelling. Catal. Today 2021, 362, 11–21. [Google Scholar] [CrossRef]

- Pavlišič, A.; Huš, M.; Prašnikar, A.; Likozar, B. Multiscale modelling of CO2 reduction to methanol over industrial Cu/ZnO/Al2O3 heterogeneous catalyst: Linking ab initio surface reaction kinetics with reactor fluid dynamics. J. Clean. Prod. 2020, 275, 122958. [Google Scholar] [CrossRef]

- Zhu, Q. Improving the production efficiency of high rank coal bed methane in the Qinshui Basin. Nat. Gas Ind. B 2022, 9, 477–486. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, S.; Xiong, H.; Wu, K.; Shi, J. Optimal nanocone geometry for water flow. AIChE J. 2022, 68, e17543. [Google Scholar] [CrossRef]

- Wang, S.; Li, D.; Li, W. A Semi-Analytical Model for Production Prediction of Deep CBM Wells Considering Gas-Water Two-Phase Flow. Processes 2023, 11, 3022. [Google Scholar] [CrossRef]

- Li, K.; Horne, R.N. Method to Evaluate the Potential of Water Injection in Naturally Fractured Reservoirs. Transp. Porous Media 2010, 83, 699–709. [Google Scholar] [CrossRef]

- Yu, P.; Dempsey, D.; Rinaldi, A.P.; Calibugan, A.; Ritz, V.A.; Archer, R. Association between Injection and Micro-seismicity in Geothermal Fields with Multiple Wells: Data-driven Modelling of Rotokawa, New Zealand, and Húsmúli, Iceland. J. Geophys. Res. Solid Earth 2022, 128, e2022JB025952. [Google Scholar] [CrossRef]

- Yu, P.; Dempsey, D.; Archer, R. A three-dimensional coupled thermo-hydro-mechanical numerical model with partially bridging multi-stage contact fractures in horizontal-well enhanced geothermal system. Int. J. Rock Mech. Min. Sci. Géoméch. Abstr. 2021, 143, 104787. [Google Scholar] [CrossRef]

- Okuszko, K.; Gault, B.; Mattar, L. Production Decline Performance of CBM Wells. J. Can. Pet. Technol. 2008, 47. [Google Scholar] [CrossRef]

- Finjord, J.; Aadnoy, B.S. Effects of the quadratic gradient term in steady-state and semisteady-state solutions for res-ervoir pressure. SPE Form. Eval. 1989, 4, 413–417. [Google Scholar] [CrossRef]

- Braeuning, S.; Jelmert, T.A.; Vik, S.A. The effect of the quadratic gradient term on variable-rate well-tests. J. Pet. Sci. Eng. 1998, 21, 203–222. [Google Scholar] [CrossRef]

- Xu-Long, C.; Deng-Ke, T.; Rui-He, W. Exact solutions for nonlinear transient flow model including a quadratic gradient term. Appl. Math. Mech. 2004, 25, 102–109. [Google Scholar] [CrossRef]

- Ren, J.; Guo, P. Nonlinear flow model of multiple fractured horizontal wells with stimulated reservoir volume including the quadratic gradient term. J. Hydrol. 2017, 554, 155–172. [Google Scholar] [CrossRef]

- Chakrabarty, C.; Ali, S.M.F.; Tortike, W.S. Analytical solutions for radial pressure distribution including the effects of the quadratic-gradient term. Water Resour. Res. 1993, 29, 1171–1177. [Google Scholar] [CrossRef]

- Giachetti, D.; Maroscia, G. Existence results for a class of porous medium type equations with a quadratic gradient term. J. Evol. Equations 2008, 8, 155–188. [Google Scholar] [CrossRef]

- Dewei, M.; Ailin, J.; Chengye, J.; Qian, Z.; Dongbo, H. Research on Transient Flow Regulation with the Effect of Quadratic Pressure Gradient. Pet. Sci. Technol. 2013, 31, 408–417. [Google Scholar] [CrossRef]

- Liu, W.; Yao, J.; Chen, Z.; Liu, Y. Effect of quadratic pressure gradient term on a one-dimensional moving boundary problem based on modified Darcy’s law. Acta Mech. Sin. 2016, 32, 38–53. [Google Scholar] [CrossRef]

- Wang, Y.; Dusseault, M.B. The Effect of Quadratic Gradient Terms on the Borehole Solution in Poroelastic Media. Water Resour. Res. 1991, 27, 3215–3223. [Google Scholar] [CrossRef]

- Bai, M.; Roegiers, J.-C. On the correlation of nonlinear flow and linear transport with application to dual-porosity modeling. J. Pet. Sci. Eng. 1994, 11, 63–72. [Google Scholar] [CrossRef]

- Deng-Ke, T.; Rui-He, W. Exact Solution of Pressure Transient Model for Fluid Flow in Fractal Reservoir Including a Quadratic Gradient Term. Energy Sources 2005, 27, 1205–1215. [Google Scholar] [CrossRef]

- Abbasi, M.; Izadmehr, M.; Karimi, M.; Sharifi, M.; Kazemi, A. Analytical study of fluid flow modeling by diffusivity equation including the quadratic pressure gradient term. Comput. Geotech. 2017, 89, 1–8. [Google Scholar] [CrossRef]

- Liu, X.; Song, D.; He, X.; Wang, Z.; Zeng, M.; Deng, K. Nanopore structure of deep-burial coals explored by AFM. Fuel 2019, 246, 9–17. [Google Scholar] [CrossRef]

- Coetzee, G.H.; Sakurovs, R.; Neomagus, H.W.; Everson, R.C.; Mathews, J.P.; Bunt, J.R. Particle size influence on the pore development of nanopores in coal gasification chars: From micron to millimeter particles. Carbon 2017, 112, 37–46. [Google Scholar] [CrossRef]

- Stehfest, H. Numerical inversion of Laplace transforms. Commun. ACM 1970, 13, 47–49. [Google Scholar] [CrossRef]

- Zhang, Z.; Qin, Y.; Wang, G.; Sun, H.; You, Z.; Jin, J.; Yang, Z. Evaluation of coal body structures and their distributions by geo-physical logging methods: Case study in the Laochang block, eastern Yunnan, China. Nat. Resour. Res. 2021, 30, 2225–2239. [Google Scholar] [CrossRef]

- Wang, Z.; Hurter, S.; You, Z.; Honari, V.; Sun, Y. Influences of negative pressure on air-leakage of coal seam gas extraction: Laboratory and CFD-DEM simulations. J. Pet. Sci. Eng. 2021, 196, 107731. [Google Scholar] [CrossRef]

- Zhu, S.; Du, Z.; Li, C.; You, Z.; Peng, X.; Jiang, H.; Wang, C.; Deng, P. Effects of numerical dispersion on pressure diffusion in CBM reservoirs. Fuel 2019, 251, 534–542. [Google Scholar] [CrossRef]

- Warren, J.; Root, P. The Behavior of Naturally Fractured Reservoirs. Soc. Pet. Eng. J. 1963, 3, 245–255. [Google Scholar] [CrossRef]

- Nie, R.-S.; Meng, Y.-F.; Jia, Y.-L.; Zhang, F.-X.; Yang, X.-T.; Niu, X.-N. Dual Porosity and Dual Permeability Modeling of Horizontal Well in Naturally Fractured Reservoir. Transp. Porous Media 2012, 92, 213–235. [Google Scholar] [CrossRef]

- Liu, X.; Li, H.; Han, L.; Wang, B. Application of radial composite model in CBM well test interpretation and case study. Coal Geol. China 2018, 30, 1674–1803. [Google Scholar]

| Parameters | Symbol | Definition |

|---|---|---|

| Dimensionless pressure of natural fracture | ||

| Dimensionless pressure of cleats | ||

| Dimensionless pseudo time | ||

| Dimensionless radial distance | ||

| Dimensionless wellbore storage coefficient | ||

| Dimensionless pseudo permeability modulus | ||

| The permeability ratio of the natural fracture system to the sum of fracture and cleat systems | ||

| Capacitance coefficient of natural fracture | ||

| Capacitance coefficient of cleats | ||

| Inter-porosity flow factor of cleat system into natural fracture system |

| tD/CD | pwD | DV | RDV (%) | p’wD·tD/CD | DV | RDV (%) | ||

|---|---|---|---|---|---|---|---|---|

| Linear Models [26,48,49] | Our Model | Traditional Models | Our Model | |||||

| 10 | 0.71 | 0.65 | 0.06 | 8.45 | 0.57 | 0.52 | 0.05 | 8.77 |

| 103 | 5.14 | 4.57 | 0.57 | 11.09 | 0.49 | 0.41 | 0.08 | 16.33 |

| 107 | 8.51 | 7.31 | 1.2 | 14.10 | 0.51 | 0.39 | 0.12 | 23.53 |

| tD/CD | pwD | DV | RDV (%) | p’wD·tD/CD | DV | RDV (%) | ||

|---|---|---|---|---|---|---|---|---|

| Linear Models [26,48,49] | Our Model | Traditional Models | Our Model | |||||

| 10 | 0.71 | 0.63 | 0.08 | 11.27 | 0.57 | 0.45 | 0.12 | 21.05 |

| 103 | 5.14 | 3.62 | 1.52 | 29.57 | 0.49 | 0.31 | 0.18 | 36.73 |

| 107 | 8.51 | 6.05 | 2.46 | 28.91 | 0.51 | 0.28 | 0.23 | 45.10 |

| p’wD·tD/CD | Models | Results | DV | RDV (%) |

| Measured data | 1.547 | 0 | 0 | |

| Linear model | 1.121 | 0.426 | 27.5 | |

| Our model | 1.458 | 0.089 | 5.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, W.; Wu, J.; Sun, Z. Transient Pressure Behavior of CBM Wells during the Injection Fall-Off Test Considering the Quadratic Pressure Gradient. Nanomaterials 2024, 14, 1070. https://doi.org/10.3390/nano14131070

Gu W, Wu J, Sun Z. Transient Pressure Behavior of CBM Wells during the Injection Fall-Off Test Considering the Quadratic Pressure Gradient. Nanomaterials. 2024; 14(13):1070. https://doi.org/10.3390/nano14131070

Chicago/Turabian StyleGu, Wei, Jiaqi Wu, and Zheng Sun. 2024. "Transient Pressure Behavior of CBM Wells during the Injection Fall-Off Test Considering the Quadratic Pressure Gradient" Nanomaterials 14, no. 13: 1070. https://doi.org/10.3390/nano14131070

APA StyleGu, W., Wu, J., & Sun, Z. (2024). Transient Pressure Behavior of CBM Wells during the Injection Fall-Off Test Considering the Quadratic Pressure Gradient. Nanomaterials, 14(13), 1070. https://doi.org/10.3390/nano14131070