Vests with Radiative Cooling Materials to Improve Thermal Comfort of Outdoor Workers: An Experimental Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials and Environments

2.2. Experimental Methods

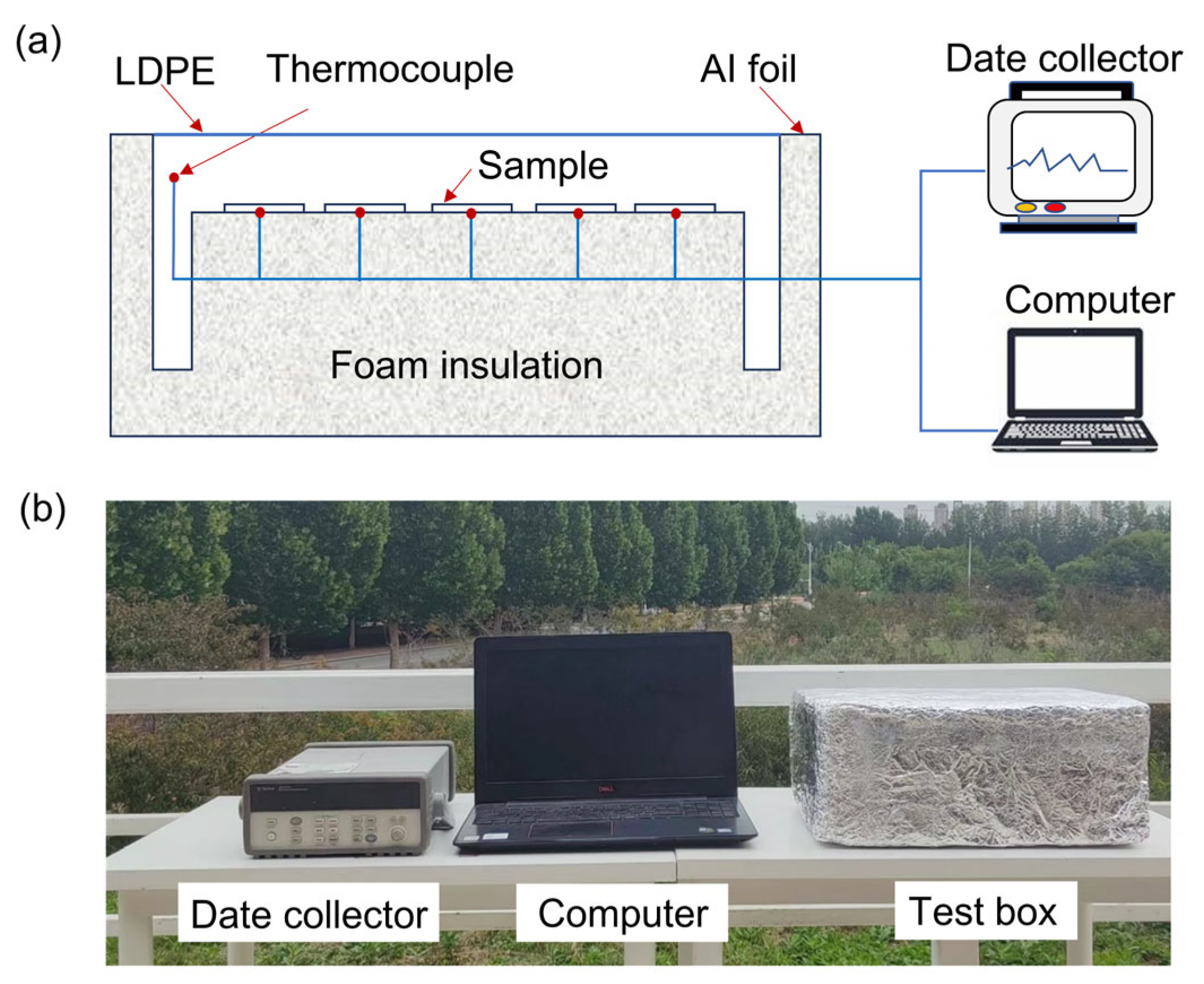

2.2.1. The Radiative Cooling Experiments with Coatings of Different Thicknesses

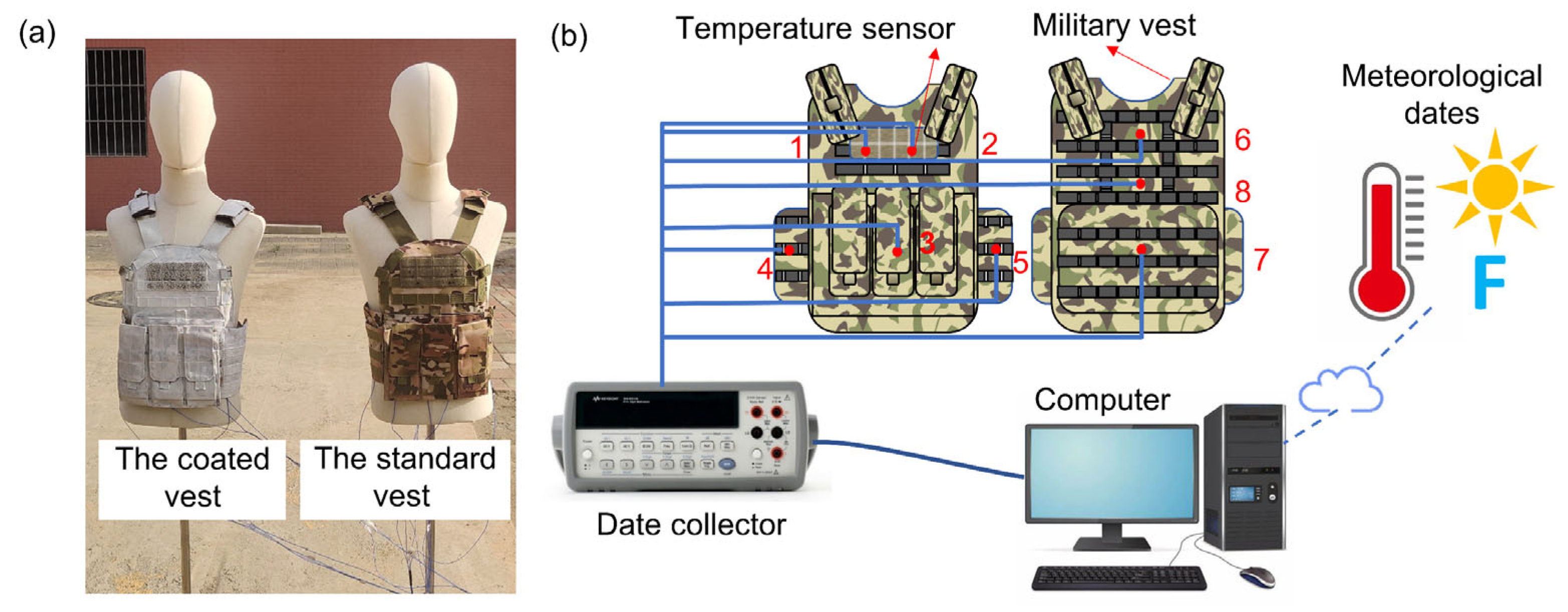

2.2.2. The Comparison Experiments on the Cooling Performance of Two Vests

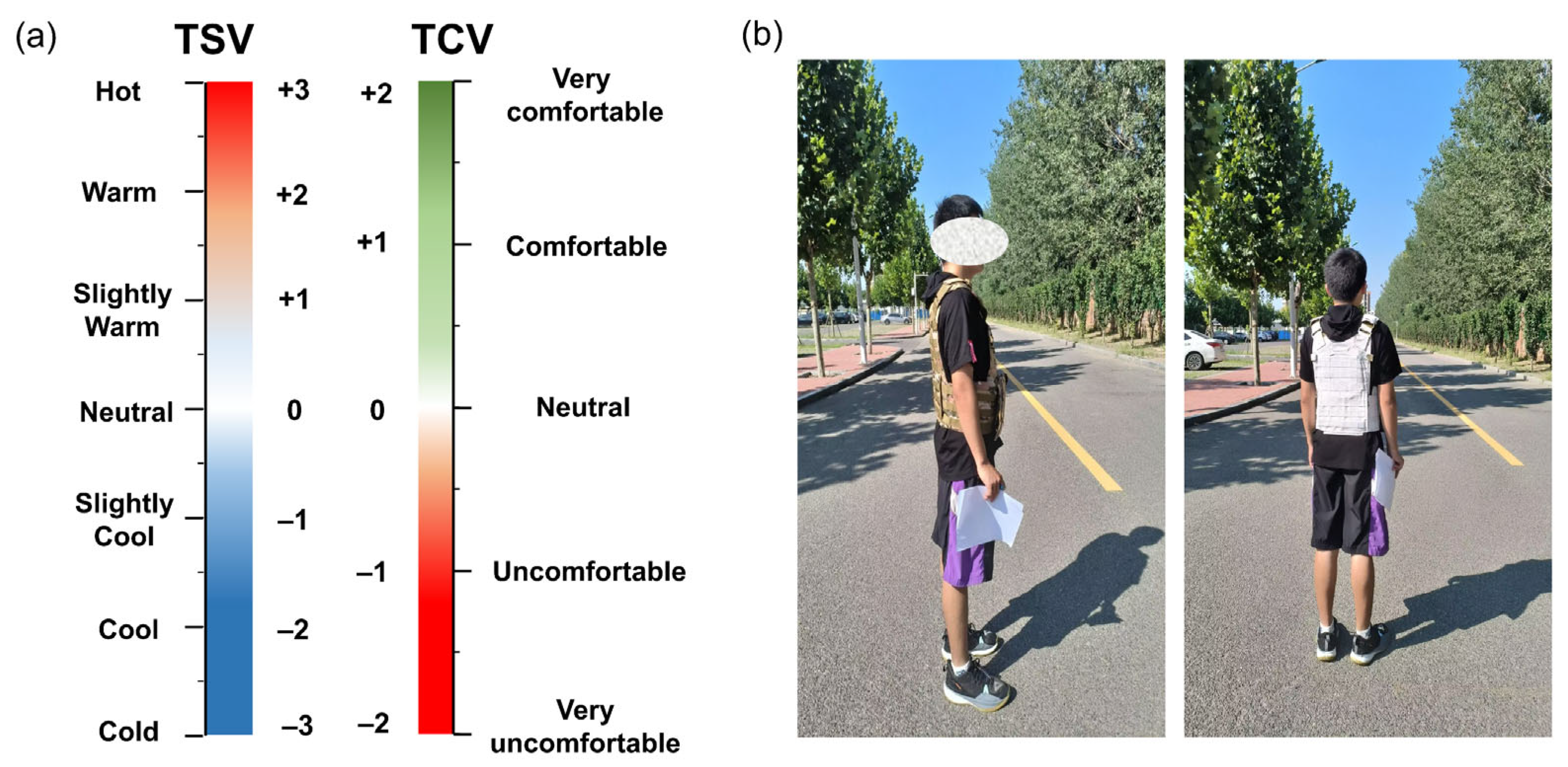

2.2.3. The Thermal Comfort Experiments

3. Results

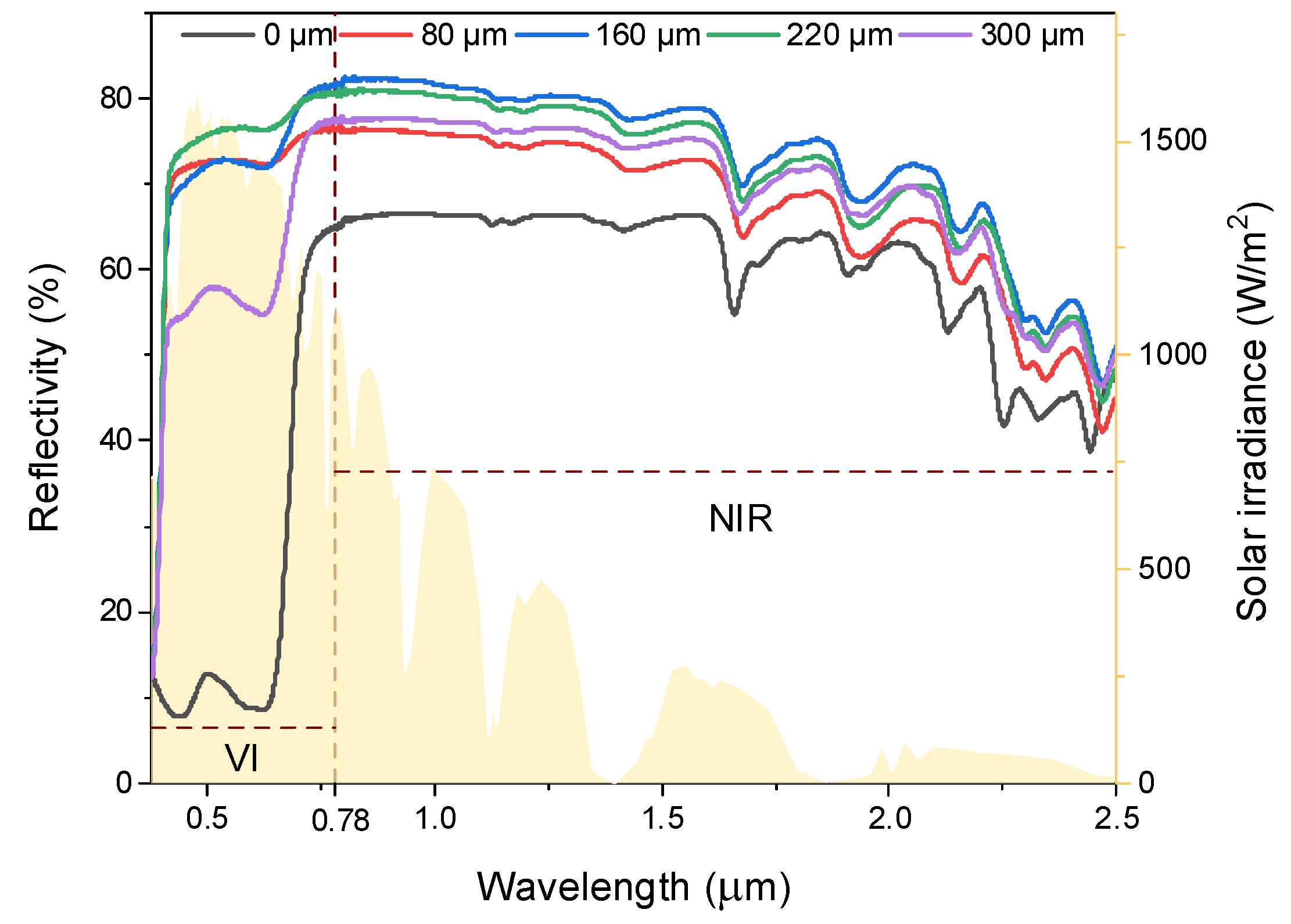

3.1. Optical Properties of Coated Fabric

3.2. Effect of Coating Thicknesses on Radiative Cooling Performance

3.3. Radiative Cooling Performance of Vests

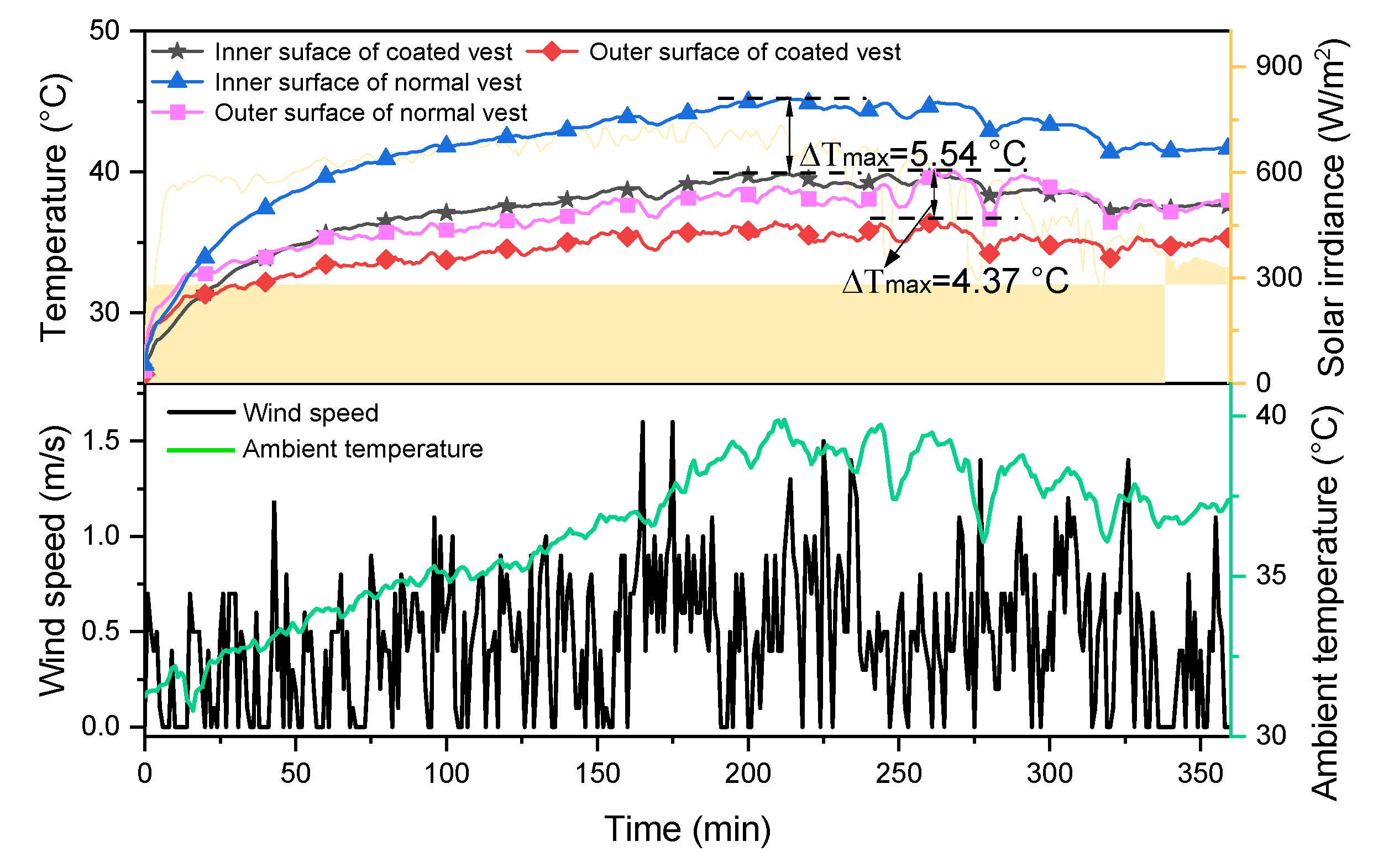

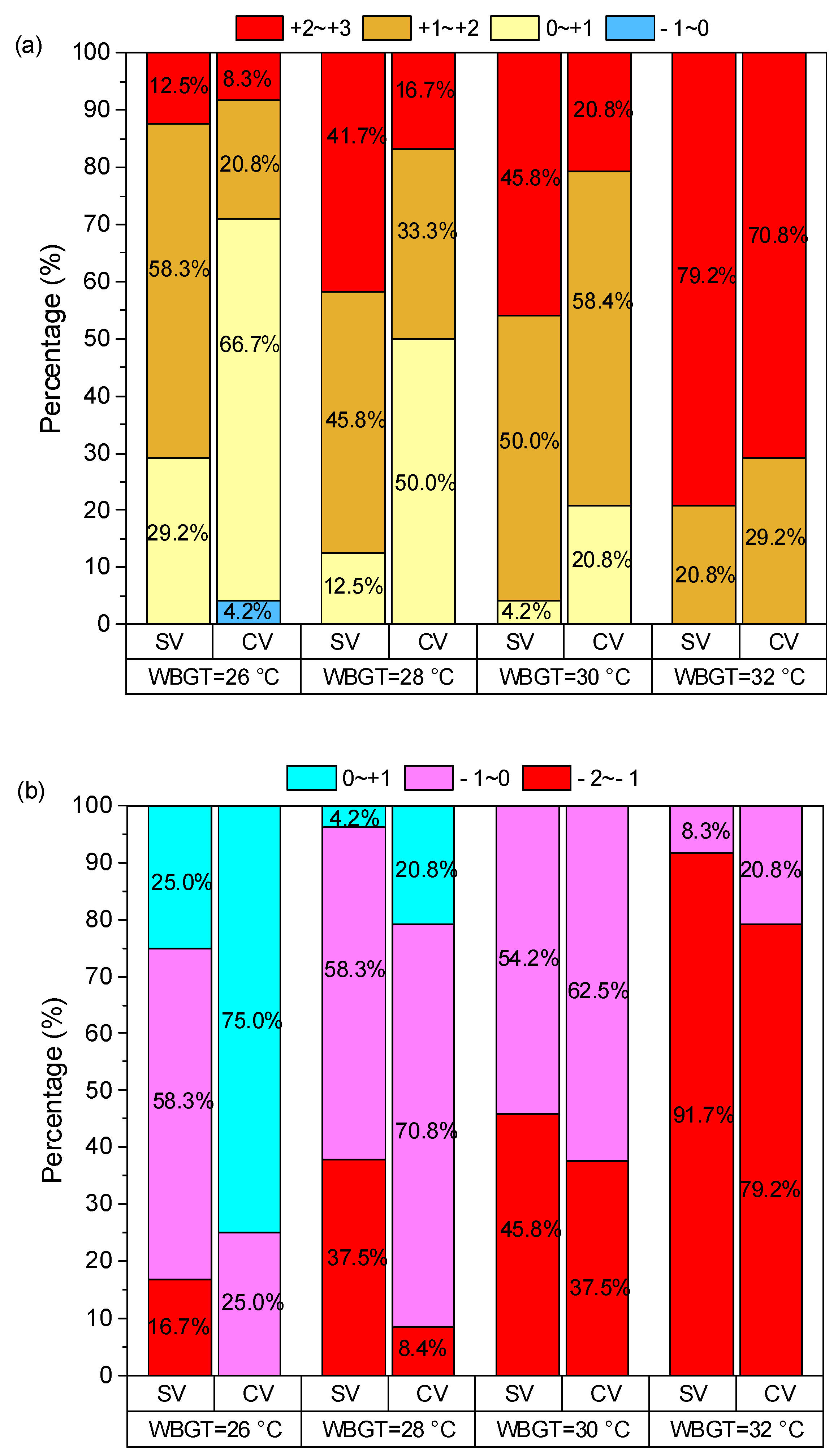

3.4. Thermal Evaluation Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, H.; Xu, Z.; Ge, B.; Li, J. Experimental study on a phase change cooling garment to improve thermal comfort of factory workers. Build. Environ. 2023, 227, 109819. [Google Scholar] [CrossRef]

- Koltun, K.J.; Bird, M.B.; Forse, J.N.; Nindl, B.C. Physiological biomarker monitoring during arduous military training: Maintaining readiness and performance. J. Sci. Med. Sport 2023, 66, S64–S70. [Google Scholar] [CrossRef]

- Moran, D.S.; DeGroot, D.W.; Potter, A.W.; Charkoudian, N. Beating the heat: Military training and operations in the era of global warming. J. Appl. Physiol. 2023, 135, 60–67. [Google Scholar] [CrossRef] [PubMed]

- Pryor, R.R.; Haboian, K.; Fitts, T.; Stooks, J.J. Tarp-Assisted Cooling for Exertional Heat Stroke Treatment in Wildland Firefighting. Wild. Environ. Med. 2023, 34, 490–497. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, F.; Li, J.; Meng, H.; Lin, H. Effects of different zoning thermostat controls on thermal comfort and cooling energy consumption in reading rooms of a library. Energy 2024, 292, 130507. [Google Scholar]

- Heidari, S.; Poshtiri, A.H.; Gilvaei, Z.M. Enhancing thermal comfort and natural ventilation in residential buildings: A design and assessment of an integrated system with horizontal windcatcher and evaporative cooling channels. Energy 2024, 289, 130040. [Google Scholar] [CrossRef]

- Bartkowiak, G.; Dąbrowska, A.; Włodarczyk, B. Construction of a garment for an integrated liquid cooling system. Text. Res. J. 2015, 85, 1809–1816. [Google Scholar] [CrossRef]

- Wang, T.; Wang, L.; Bai, L.; Lin, G.; Bu, X.; Liu, X.; Xie, G. Experimental study on the performance of a liquid cooling garment with the application of MEPCMS. Energ. Convers. Manage. 2015, 103, 943–957. [Google Scholar] [CrossRef]

- Fan, C.; Zhang, Z.; Li, L. Sensitivity and preference of local airflows beneath garments with personalised temperatures and velocities. Build. Environ. 2023, 234, 110128. [Google Scholar] [CrossRef]

- Yang, Y.; Stapleton, J.; Diagne, B.T.; Kenny, G.P.; Lan, C.Q. Man-portable personal cooling garment based on vacuum desiccant cooling. Appl. Therm. Eng. 2012, 47, 18–24. [Google Scholar] [CrossRef]

- Del Ferraro, S.; Falcone, T.; Morabito, M.; Messeri, A.; Bonafede, M.; Marinaccio, A.; Gao, C.; Molinaro, V. Cooling garments against environmental heat conditions in occupational fields: Measurements of the effect of a ventilation jacket on the total thermal insulation. Int. J. Ind. Ergon. 2021, 86, 103230. [Google Scholar] [CrossRef]

- Zhang, M.; Li, Z.; Wang, Q.; Yuan, T.; Xu, Y. Research on refrigerant optimization and characteristic parameters based on thermoelectric refrigeration cooling garment. Appl. Therm. Eng. 2022, 212, 118606. [Google Scholar] [CrossRef]

- Liu, B.; Wang, H.; Zhang, G.; Zhang, G.; Li, J. Experimental study on improvement effect of a cooling vest on thermal comfort of manufactory workers. J. Build. Eng. 2023, 68, 106067. [Google Scholar] [CrossRef]

- Wei, W.; Wu, B.; Guo, Y.; Hu, Y.; Liao, Y.; Wu, C.; Zhang, Q.; Li, Y.; Chen, J.; Hou, H.; et al. A multimodal cooling garment for personal thermal comfort management. Appl. Energy 2023, 352, 121973. [Google Scholar] [CrossRef]

- Hossain, M.M.; Gu, M. Radiative cooling: Principles, progress, and potentials. Adv. Sci. 2016, 3, 1500360. [Google Scholar] [CrossRef]

- Lee, J.Y.; Wang, C.M.; Chi, C.L.; Wu, S.R.; Lin, Y.X.; Wei, M.K.; Lin, C.H. Enhanced heat-electric conversion via photonic-assisted radiative cooling. Nanomaterials 2021, 11, 983. [Google Scholar] [CrossRef]

- Wang, Y.; Shou, D.; Shang, S.; Chiu, K.L.; Jiang, S. Cooling performance of a bioinspired micro-crystal-bars coated composite fabric with solar reflectance. Compos. Commun. 2021, 27, 100814. [Google Scholar] [CrossRef]

- Ma, B.; Cheng, Y.; Hu, P.; Fang, D.; Wang, J. Passive daytime radiative cooling of silica aerogels. Nanomaterials 2023, 13, 467. [Google Scholar] [CrossRef] [PubMed]

- Dong, Y.; Han, H.; Wang, F.; Zhang, Y.; Cheng, Z.; Shu, X.; Yan, Y. A Low-Cost Sustainable Coating: Improving Passive Daytime Radiative Cooling Performance Using the Spectral Band Complementarity Method. Renew. Energ. 2022, 19, 606–616. [Google Scholar] [CrossRef]

- Xin, Y.; Gao, W.; Zhang, C.; Chen, Y. Scalable and sustainable radiative cooling enabled by renewable poplar catkin-derived films. Energy 2024, 290, 130186. [Google Scholar] [CrossRef]

- Liu, J.; Xu, C.; Ao, X.; Lu, K.; Zhao, B. A dual-layer polymer-based film for all-day sub-ambient radiative sky cooling. Energy 2022, 254, 124350. [Google Scholar] [CrossRef]

- Gao, M.; Xia, Y.; Li, R.; Zhang, Z.; He, Y.; Zhang, C.; Chen, L.; Qi, L.; Si, Y.; Zhang, Q.; et al. The design of near-perfect spectrum-selective mirror based on photonic structures for passive cooling of silicon solar cells. Nanomaterials 2020, 10, 2483. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, W.; Shao, Z.; Li, Y.; Su, Y.; Zhang, Q.; Hou, C.; Wang, H. A moisture-wicking passive radiative cooling hierarchical metafabric. ACS. Nano 2022, 16, 2188–2197. [Google Scholar] [CrossRef]

- Zeng, S.; Pian, S.; Su, M.; Wang, Z.; Wu, M.; Liu, X.; Chen, M.; Xiang, Y.; Wu, J.; Zhang, M.; et al. Hierarchical-morphology metafabric for scalable passive daytime radiative cooling. Science 2021, 373, 692–696. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Z.; Han, H.; Wang, F.; Yan, Y.; Shi, X.; Liang, H.; Zhang, X.; Shuai, Y. Efficient radiative cooling coating with biomimetic human skin wrinkle structure, Nano. Energy 2021, 89, 106377. [Google Scholar]

- Zhang, J.; Xu, S.; Cai, Y.; Yi, L. Colorfully coated cotton fabric for passive daytime radiative cooling. Prog. Org. Coat. 2023, 182, 107678. [Google Scholar] [CrossRef]

- Xiao, T.; Feng, H.; Ding, H.; Yang, J.; Xu, J. Application research of radiative cooling technology on safety helmet. J. Saf. Sci. Technol. 2020, 16, 187–192. [Google Scholar]

- Zhang, L.; Meng, X.; Liu, F.; Xu, L.; Long, E. Effect of retro-reflective materials on temperature environment in tents. Case Stud. Therm. 2017, 9, 122–127. [Google Scholar] [CrossRef]

- Zhong, S.; Yi, L.; Zhang, J.; Xu, T.; Xu, L.; Zhang, X.; Zuo, T.; Cai, Y. Self-cleaning and spectrally Selective Coating on Cotton Fabric for Passive Daytime Radiative Cooling. Chem. Eng. J. 2021, 407, 127104. [Google Scholar] [CrossRef]

- Cui, C.; Lu, J.; Zhang, S.; Han, J. Hierarchical-porous Coating Coupled with Textile for Passive Daytime Radiative Cooling and Self-cleaning. Sol. Energy Mater Sol. Cells 2022, 247, 111954. [Google Scholar] [CrossRef]

- Mahgoub, A.O.; Gowid, S.; Ghani, S. Global evaluation of WBGT and SET indices for outdoor environments using thermal imaging and artificial neural networks. Sustain. Cities. Soc. 2020, 60, 102182. [Google Scholar] [CrossRef]

- Yang, H.; Cao, B.; Ju, Y.; Zhu, Y. The effects of local cooling at different torso parts in improving body thermal comfort in hot indoor environments. Energy. Build. 2019, 198, 528–541. [Google Scholar] [CrossRef]

- Ghani, S.; Mahgoub, A.O.; Bakochristou, F.; ElBialy, E.A. Assessment of thermal comfort indices in an open air-conditioned stadium in hot and arid environment. J. Build. Eng. 2021, 40, 102378. [Google Scholar] [CrossRef]

- ANSI/ASHRAE Standard 55; Thermal Environmental Conditions for Human Occupancy. ANSI: Washington, DC, USA; ASHRAE: Peachtree Corners, GA, USA, 2020.

- World Medical Association. World medical association declaration of Helsinki: Ethical principles for medical research involving human subjects. Bull. World Health Organ. 2001, 79, 373. [Google Scholar]

- International Standard ISO 10551; Ergonomics of the Thermal Environment—Assessment of the Influence of the Thermal Environment Using Subjective Judgment Scales. ISO: Geneva, Switzerland, 2019.

| Type | Coating Thickness (µm) | Atmospheric Window Emissivity (%) | Reflectivity (%) | Absorptivity (%) |

|---|---|---|---|---|

| Coated vests | 160 | 90.2 | 82.5 | 17.5 |

| Standard vests | 0 | 89.7 | 65.1 | 34.9 |

| Subjects | Age (years old) | Height (cm) | Weight (kg) | BMI (kg/m2) |

|---|---|---|---|---|

| A | 22 | 174 | 62 | 20.5 |

| B | 22 | 173 | 68 | 22.7 |

| C | 24 | 175 | 70 | 22.8 |

| D | 23 | 176 | 69 | 22.3 |

| E | 23 | 179 | 67 | 20.9 |

| F | 24 | 178 | 75 | 23.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Zhao, B.; Zhu, H.; Yang, W.; Li, T.; Cao, Z.; Wang, J. Vests with Radiative Cooling Materials to Improve Thermal Comfort of Outdoor Workers: An Experimental Study. Nanomaterials 2024, 14, 1119. https://doi.org/10.3390/nano14131119

Wang Y, Zhao B, Zhu H, Yang W, Li T, Cao Z, Wang J. Vests with Radiative Cooling Materials to Improve Thermal Comfort of Outdoor Workers: An Experimental Study. Nanomaterials. 2024; 14(13):1119. https://doi.org/10.3390/nano14131119

Chicago/Turabian StyleWang, Yao, Bohao Zhao, Hengxuan Zhu, Wei Yang, Tianpeng Li, Zhen Cao, and Jin Wang. 2024. "Vests with Radiative Cooling Materials to Improve Thermal Comfort of Outdoor Workers: An Experimental Study" Nanomaterials 14, no. 13: 1119. https://doi.org/10.3390/nano14131119

APA StyleWang, Y., Zhao, B., Zhu, H., Yang, W., Li, T., Cao, Z., & Wang, J. (2024). Vests with Radiative Cooling Materials to Improve Thermal Comfort of Outdoor Workers: An Experimental Study. Nanomaterials, 14(13), 1119. https://doi.org/10.3390/nano14131119