Insights into One-Dimensional Thermoelectric Materials: A Concise Review of Nanowires and Nanotubes

Abstract

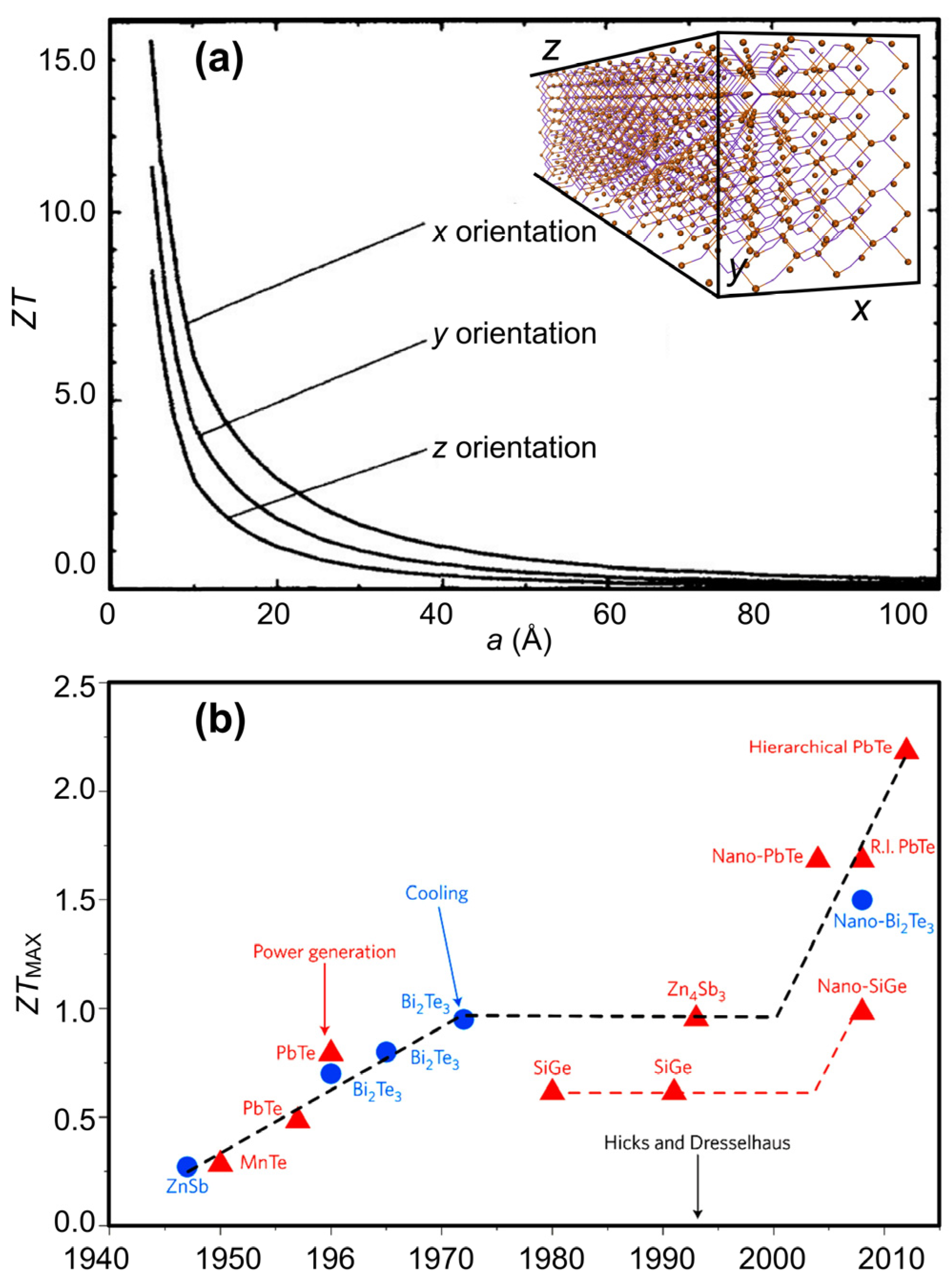

:1. Introduction

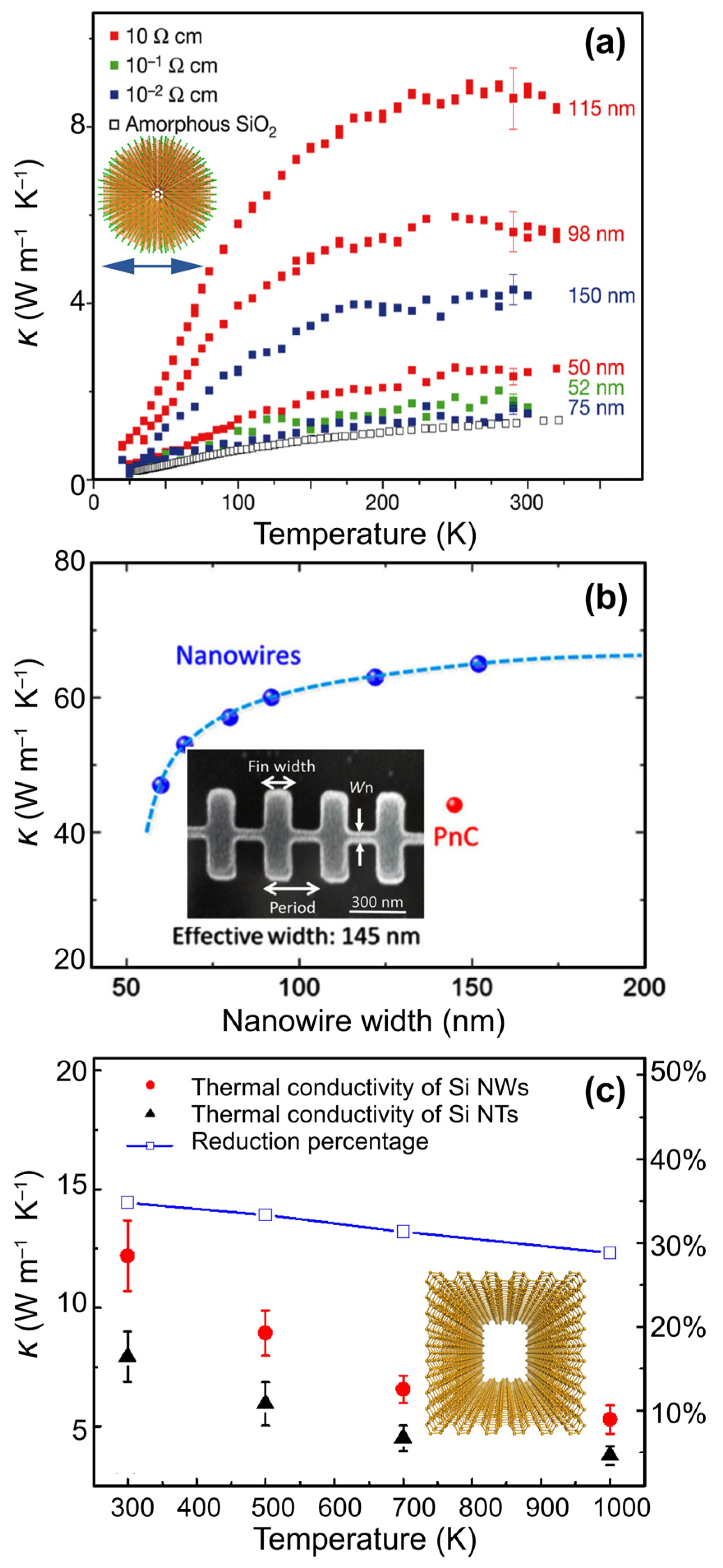

2. Non-Flexible Inorganic 1D Thermoelectric Materials

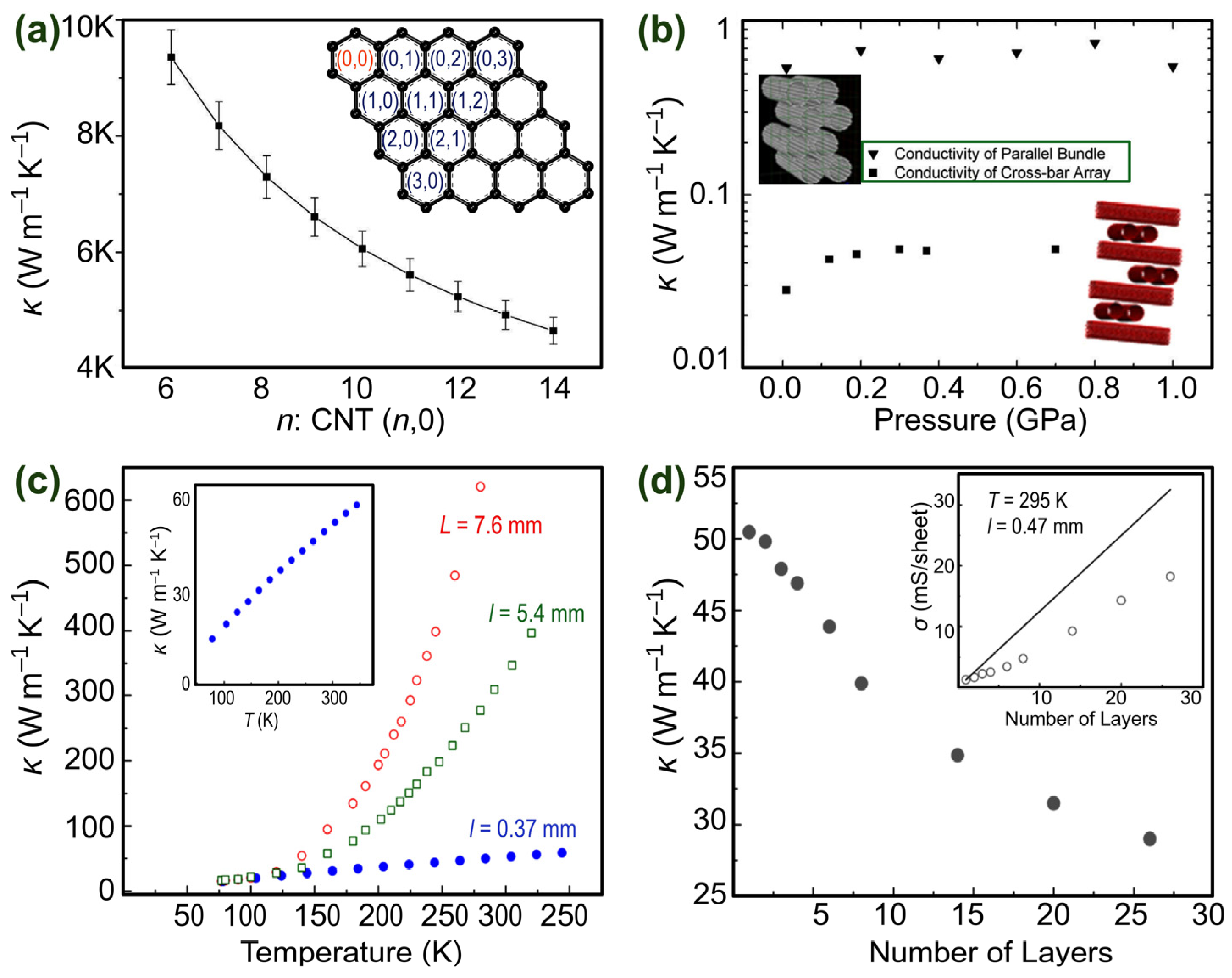

3. Flexible Thermoelectric Devices with 1D Carbon Nanotubes

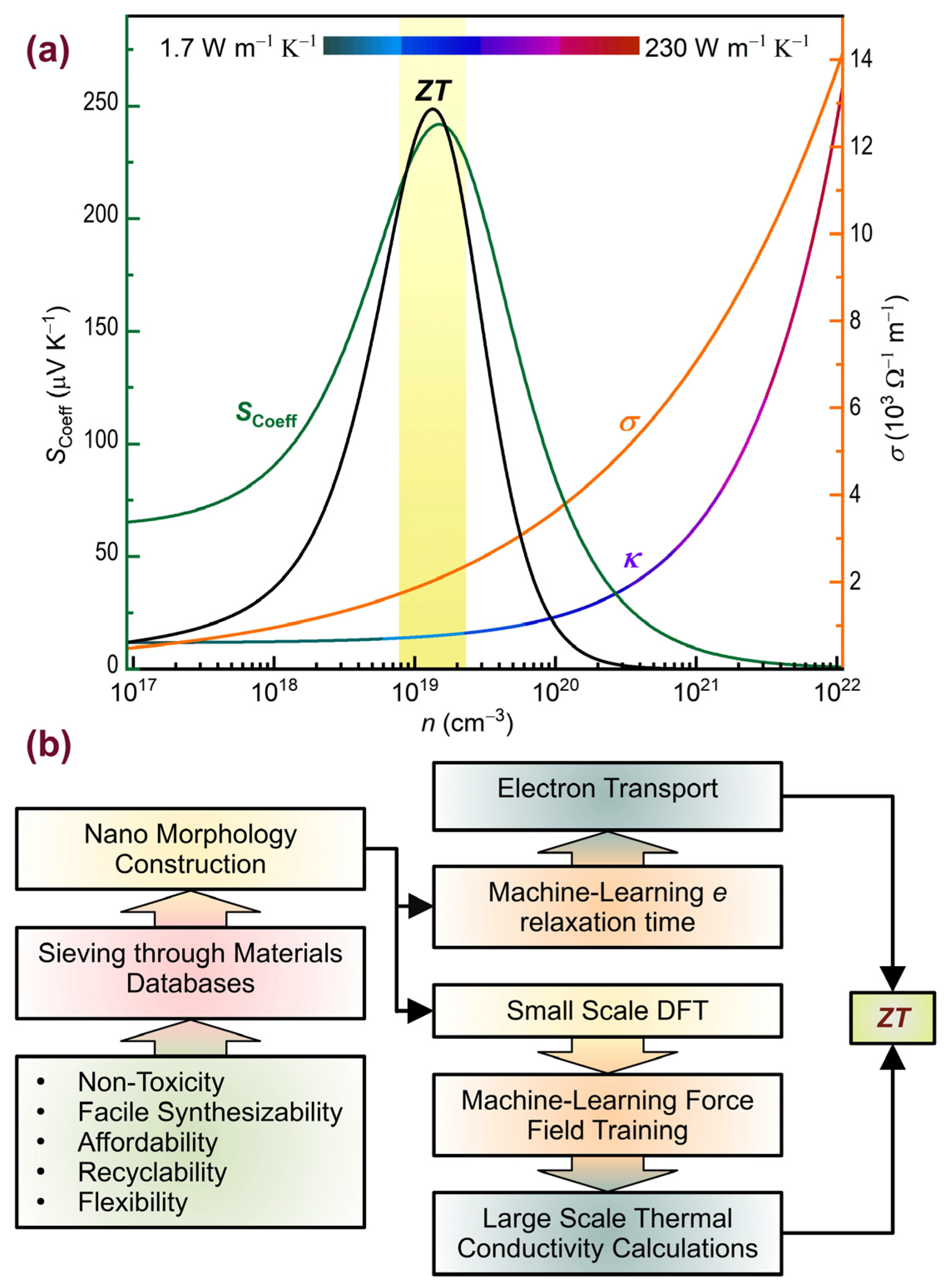

4. Outlook and Perspective

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Arabi, H.; Eivari, H.A. Applying a suitable route for preparation Fe3O4 nanoparticles by Ammonia and investigation of their physical and different magnetic properties. Int. J. Nano Dimens. 2014, 5, 297–303. [Google Scholar]

- Huang, P.; Zhang, P.; Xu, S.; Wang, H.; Zhang, X.; Zhang, H. Recent advances in two-dimensional ferromagnetism: Materials synthesis, physical properties and device applications. Nanoscale 2020, 12, 2309–2327. [Google Scholar] [CrossRef] [PubMed]

- Rahdar, A.; Eivari, H.A.; Sarhaddi, R. Study of structural and optical properties of ZnS:Cr nanoparticles synthesized by co-precipitation method. Indian J. Sci. Technol. 2012, 5, 1855–1858. [Google Scholar] [CrossRef]

- Wu, J.; Ma, H.; Yin, P.; Ge, Y.; Zhang, Y.; Li, L.; Zhang, H.; Lin, H. Two-dimensional materials for integrated photonics: Recent advances and future challenges. Small Sci. 2021, 1, 2000053. [Google Scholar] [CrossRef]

- Eivari, H.A.; Ghasemi, S.A.; Tahmasbi, H.; Rostami, S.; Faraji, S.; Rasoulkhani, R.; Goedecker, S.; Amsler, M. Two-dimensional hexagonal sheet of TiO2. Chem. Mater. 2017, 29, 859–8603. [Google Scholar] [CrossRef]

- Li, Z.; Yan, T.; Fang, X. Low-dimensional wide-bandgap semiconductors for UV photodetectors. Nat. Rev. Mater. 2023, 8, 587–603. [Google Scholar] [CrossRef]

- Sadeghi, B.; Garmaroudi, F.S.; Hashemi, M.; Nezhad, H.; Nasrollahi, A.; Ardalan, S.; Ardalan, S. Comparison of the anti-bacterial activity on the nanosilver shapes: Nanoparticles, nanorods and nanoplates. Adv. Powder Technol. 2012, 23, 22–26. [Google Scholar] [CrossRef]

- Khodadad, H.; Hatamjafari, F.; Pourshamsian, K.; Sadeghi, B. Microwave-assisted Synthesis of Novel Pyrazole Derivatives and their Biological Evaluation as Anti-Bacterial Agents. Comb. Chem. High Throughput Screen. 2021, 24, 695–700. [Google Scholar] [CrossRef]

- Sohbatzadeh, Z.; Eivari, H.A.; Fakhrabad, D.V. Formation energy and some mechanical properties of hydrogenated hexagonal monolayer of GeC. Physica B 2018, 547, 88–91. [Google Scholar] [CrossRef]

- Jiang, H.; Zheng, L.; Liu, Z.; Wang, X. Two-dimensional materials: From mechanical properties to flexible mechanical sensors. InfoMat 2020, 2, 1077–1094. [Google Scholar] [CrossRef]

- Eivari, H.A.; Sohbatzadeh, Z.; Mele, P.; Assadi, M.H.N. Low thermal conductivity: Fundamentals and theoretical aspects in thermoelectric applications. Mater. Today Energy 2021, 21, 100744. [Google Scholar] [CrossRef]

- Gutiérrez Moreno, J.J.; Cao, J.; Fronzi, M.; Assadi, M.H.N. A review of recent progress in thermoelectric materials through computational methods. Mater. Renew. Sustain. Energy 2020, 9, 16. [Google Scholar] [CrossRef]

- Yang, B.; Wang, Z.; Zhao, J.; Sun, X.; Wang, R.; Liao, G.; Jia, X. 1D/2D carbon-doped nanowire/ultra-thin nanosheet g-C3N4 isotype heterojunction for effective and durable photocatalytic H2 evolution. Int. J. Hydrogen Energy 2021, 46, 25436–25447. [Google Scholar] [CrossRef]

- Li, C.; Jia, R.; Yang, Y.; Liao, G. A Hierarchical Helical Carbon Nanotube Fiber Artificial Ligament. Adv. Fiber Mater. 2023, 5, 1549–1551. [Google Scholar] [CrossRef]

- Shao, W.; Cen, R.; Sheng, J.; Ma, D.; He, J.; He, J.; Ding, T.; Wu, W. 28.35 mW cm−2 power output assisted concentrating printable CsPbBr3 solar cell-thermoelectric module tandem device using two-pronged strategy. Device 2024, 2, 100285. [Google Scholar] [CrossRef]

- Chen, C.; Li, X.-L.; Zhao, S.; Song, Y.; Zhu, Y.; Wang, Q.; Zhong, C.; Chen, R.; Li, E.; Li, Z.; et al. A biomimetic e-whisker sensor with multimodal perception and stimuli discrimination. Device 2023, 1, 100148. [Google Scholar] [CrossRef]

- Zhang, Q.; Deng, K.; Wilkens, L.; Reith, H.; Nielsch, K. Micro-thermoelectric devices. Nat. Electron. 2022, 5, 333–347. [Google Scholar] [CrossRef]

- Yan, Q.; Kanatzidis, M.G. High-performance thermoelectrics and challenges for practical devices. Nat. Mater. 2022, 21, 503–513. [Google Scholar] [CrossRef]

- Al-Fartoos, M.M.R.; Roy, A.; Mallick, T.K.; Tahir, A.A. Advancing Thermoelectric Materials: A Comprehensive Review Exploring the Significance of One-Dimensional Nano Structuring. Nanomaterials 2023, 13, 2011. [Google Scholar] [CrossRef]

- Wang, J.; Mu, X.; Sun, M. The Thermal, Electrical and Thermoelectric Properties of Graphene Nanomaterials. Nanomaterials 2019, 9, 218. [Google Scholar] [CrossRef]

- Assadi, M.H.N. Na site doping a pathway for enhanced thermoelectric performance in Na1−xCoO2; the case of Gd and Yb dopants. J. Phys. Condens. Matter 2020, 32, 125502. [Google Scholar] [CrossRef] [PubMed]

- Assadi, M.H.N.; Mele, P.; Fronzi, M. Suppression of magnetism and Seebeck effect in Na0.875CoO2 induced by SbCo dopants. Mater. Renew. Sustain. Energy 2020, 9, 5. [Google Scholar] [CrossRef]

- Ovchinnikov, A.A.; Ukrainskii, I.I. Introduction. In Electron-Electron Correlation Effects in Low-Dimensional Conductors and Superconductors; Springer: Berlin/Heidelberg, Germany, 1991; pp. 1–9. [Google Scholar]

- Youn, S.; Kim, J.; Lee, H.; Kim, D.H.; Bang, J.; Lee, W. Strong anisotropic transport properties of quasi-one-dimensional ZrTe3 nanoribbons. Nano Energy 2024, 127, 109771. [Google Scholar] [CrossRef]

- Petsagkourakis, I.; Pavlopoulou, E.; Cloutet, E.; Chen, Y.F.; Liu, X.; Fahlman, M.; Berggren, M.; Crispin, X.; Dilhaire, S.; Fleury, G. Correlating the Seebeck coefficient of thermoelectric polymer thin films to their charge transport mechanism. Org. Electron. 2018, 52, 335–341. [Google Scholar] [CrossRef]

- Yang, J. Theory of Thermal Conductivity. In Thermal Conductivity: Theory, Properties, and Applications; Tritt, T.M., Ed.; Springer: Boston, MA, USA, 2004; pp. 1–20. [Google Scholar]

- Maznev, A.; Wright, O. Demystifying umklapp vs normal scattering in lattice thermal conductivity. Am. J. Phys. 2014, 82, 1062–1066. [Google Scholar] [CrossRef]

- El Sachat, A.; Alzina, F.; Sotomayor Torres, C.M.; Chavez-Angel, E. Heat Transport Control and Thermal Characterization of Low-Dimensional Materials: A Review. Nanomaterials 2021, 11, 175. [Google Scholar] [CrossRef] [PubMed]

- Suman, P.H.; Jorgetto, A.O.; Romeiro, F.C.; Felix, A.A.; Morais, P.V.; Melquíades, M.O.; Orlandi, M.O. 1D Hybrid Tin Oxide Nanostructures: Synthesis and Applications. In 1D Semiconducting Hybrid Nanostructures; Wiley-VCH: Weinheim, Germany, 2023; pp. 97–125. [Google Scholar]

- Li, D.; Gong, Y.; Chen, Y.; Lin, J.; Khan, Q.; Zhang, Y.; Li, Y.; Zhang, H.; Xie, H. Recent Progress of Two-Dimensional Thermoelectric Materials. Nano Micro Lett. 2020, 12, 36. [Google Scholar] [CrossRef] [PubMed]

- Kanahashi, K.; Pu, J.; Takenobu, T. 2D Materials for Large-Area Flexible Thermoelectric Devices. Adv. Energy Mater. 2020, 10, 1902842. [Google Scholar] [CrossRef]

- Rowe, D.M. Thermoelectrics Handbook: Macro to Nano; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Hochbaum, A.I.; Chen, R.; Delgado, R.D.; Liang, W.; Garnett, E.C.; Najarian, M.; Majumdar, A.; Yang, P. Enhanced thermoelectric performance of rough silicon nanowires. Nature 2008, 451, 163–167. [Google Scholar] [CrossRef]

- Wang, X.; Wang, H.; Liu, B. Carbon nanotube-based organic thermoelectric materials for energy harvesting. Polymers 2018, 10, 1196. [Google Scholar] [CrossRef]

- Borca-Tasciuc, D.-A.; Chen, G.; Prieto, A.; Martín-González, M.; Stacy, A.; Sands, T.; Ryan, M.; Fleurial, J. Thermal properties of electrodeposited bismuth telluride nanowires embedded in amorphous alumina. Appl. Phys. Lett. 2004, 85, 6001–6003. [Google Scholar] [CrossRef]

- Blackburn, J.L.; Ferguson, A.J.; Cho, C.; Grunlan, J.C. Carbon-nanotube-based thermoelectric materials and devices. Adv. Mater. 2018, 30, 1704386. [Google Scholar] [CrossRef]

- Heremans, J.P.; Dresselhaus, M.S.; Bell, L.E.; Morelli, D.T. When thermoelectrics reached the nanoscale. Nat. Nanotechnol. 2013, 8, 471–473. [Google Scholar] [CrossRef] [PubMed]

- Sanad, M.F.; Shalan, A.E.; Abdellatif, S.O.; Serea, E.S.A.; Adly, M.S.; Ahsan, M.A. Thermoelectric Energy Harvesters: A Review of Recent Developments in Materials and Devices for Different Potential Applications. Top. Curr. Chem. 2020, 378, 1–43. [Google Scholar] [CrossRef]

- Assadi, M.H.N.; Katayama-Yoshida, H. Native point defects in Ti3GeC2 and Ti2GeC. Comput. Mater. Sci. 2017, 128, 103–108. [Google Scholar] [CrossRef]

- Hicks, L.; Dresselhaus, M.S. Thermoelectric figure of merit of a one-dimensional conductor. Phys. Rev. B 1993, 47, 16631–16634. [Google Scholar] [CrossRef] [PubMed]

- Hicks, L.; Dresselhaus, M.S. Effect of quantum-well structures on the thermoelectric figure of merit. Phys. Rev. B 1993, 47, 12727–12731. [Google Scholar] [CrossRef]

- Nomura, M.; Maire, J. Mechanism of the Reduced Thermal Conductivity of Fishbone-Type Si Phononic Crystal Nanostructures. J. Electron. Mater. 2015, 44, 1426–1431. [Google Scholar] [CrossRef]

- Zhang, T.; Wu, S.; Xu, J.; Zheng, R.; Cheng, G. High thermoelectric figure-of-merits from large-area porous silicon nanowire arrays. Nano Energy 2015, 13, 433–441. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, G.; Li, B. Remarkable reduction of thermal conductivity in silicon nanotubes. Nano Lett. 2010, 10, 3978–3983. [Google Scholar] [CrossRef]

- Tang, J.; Wang, H.-T.; Lee, D.H.; Fardy, M.; Huo, Z.; Russell, T.P.; Yang, P. Holey silicon as an efficient thermoelectric material. Nano Lett. 2010, 10, 4279–4283. [Google Scholar] [CrossRef] [PubMed]

- Elyamny, S.; Dimaggio, E.; Magagna, S.; Narducci, D.; Pennelli, G. High power thermoelectric generator based on vertical silicon nanowires. Nano Lett. 2020, 20, 4748–4753. [Google Scholar] [CrossRef] [PubMed]

- Ding, C.; Lu, T.; Wazir, N.; Ma, W.; Guo, S.; Xin, Y.; Li, A.; Liu, R.; Zou, B. New Type of Thermoelectric CdSSe Nanowire Chip. ACS Appl. Mater. Interfaces 2021, 13, 30959–30966. [Google Scholar] [CrossRef] [PubMed]

- Neophytou, N.; Wagner, M.; Kosina, H.; Selberherr, S. Analysis of thermoelectric properties of scaled silicon nanowires using an atomistic tight-binding model. J. Electron. Mater. 2010, 39, 1902–1908. [Google Scholar] [CrossRef]

- Sansoz, F. Surface faceting dependence of thermal transport in silicon nanowires. Nano Lett. 2011, 11, 5378–5382. [Google Scholar] [CrossRef]

- Stillinger, F.H.; Weber, T.A. Computer simulation of local order in condensed phases of silicon. Phys. Rev. B 1985, 31, 5262–5271. [Google Scholar] [CrossRef]

- Jean, V.; Fumeron, S.; Termentzidis, K.; Zianni, X.; Lacroix, D. Monte Carlo simulations of phonon transport in Si nanowires with constrictions. Int. J. Heat Mass Transf. 2015, 86, 648–655. [Google Scholar] [CrossRef]

- Lin, Y.-M.; Sun, X.; Dresselhaus, M. Theoretical investigation of thermoelectric transport properties of cylindrical Bi nanowires. Phys. Rev. B 2000, 62, 4610–4623. [Google Scholar] [CrossRef]

- Zhou, G.; Li, L.; Li, G. Enhancement of thermoelectric figure of merit in bismuth nanotubes. Appl. Phys. Lett. 2010, 97, 023112. [Google Scholar] [CrossRef]

- Kubo, R. Statistical-Mechanical Theory of Irreversible Processes. I. General Theory and Simple Applications to Magnetic and Conduction Problems. J. Phys. Soc. Jpn. 1957, 12, 570–586. [Google Scholar] [CrossRef]

- Green, M.S. Markoff Random Processes and the Statistical Mechanics of Time-Dependent Phenomena. II. Irreversible Processes in Fluids. J. Chem. Phys. 1954, 22, 398–413. [Google Scholar] [CrossRef]

- Demchenko, D.O.; Heinz, P.D.; Lee, B. Determining factors of thermoelectric properties of semiconductor nanowires. Nanoscale Res. Lett. 2011, 6, 502. [Google Scholar] [CrossRef] [PubMed]

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 1996, 77, 3865–3868. [Google Scholar] [CrossRef]

- Shi, L.; Yao, D.; Zhang, G.; Li, B. Large thermoelectric figure of merit in Si1−xGex nanowires. Appl. Phys. Lett. 2010, 96, 173108. [Google Scholar] [CrossRef]

- Lee, K.-M.; Lee, S.-K.; Choi, T.-Y. Highly enhanced thermoelectric figure of merit of a β-SiC nanowire with a nanoelectromechanical measurement approach. Appl. Phys. A 2012, 106, 955–960. [Google Scholar] [CrossRef]

- Gogoc, S.; Data, P. Organic Thermoelectric Materials as the Waste Heat Remedy. Molecules 2022, 27, 1016. [Google Scholar] [CrossRef] [PubMed]

- Taborowska, P.; Janas, D. Seamless design of thermoelectric modules from single-walled carbon nanotubes. J. Mater. Chem. C 2022, 10, 6818–6826. [Google Scholar] [CrossRef]

- Rao, A.M.; Ji, X.; Tritt, T.M. Properties of nanostructured one-dimensional and composite thermoelectric materials. MRS Bull. 2006, 31, 218–223. [Google Scholar] [CrossRef]

- Asadikia, A.; Mirjalily, S.A.A.; Nasirizadeh, N.; Kargarsharifabad, H. Hybrid nanofluid based on CuO nanoparticles and single-walled Carbon nanotubes: Optimization, thermal, and electrical properties. Int. J. Nano Dimens. 2020, 11, 277–289. [Google Scholar]

- Jiang, P.; Liu, H.; Fan, D.; Cheng, L.; Wei, J.; Zhang, J.; Liang, J.; Shi, J. Enhanced thermoelectric performance of carbon nanotubes at elevated temperature. Phys. Chem. Chem. Phys. 2015, 17, 27558–27564. [Google Scholar] [CrossRef]

- Hung, N.T.; Nugraha, A.R.; Hasdeo, E.H.; Dresselhaus, M.S.; Saito, R. Diameter dependence of thermoelectric power of semiconducting carbon nanotubes. Phys. Rev. B 2015, 92, 165426. [Google Scholar] [CrossRef]

- Taborowska, P.; Wasiak, T.; Sahlman, M.; Lundström, M.; Janas, D. Carbon Nanotube-Based Thermoelectric Modules Enhanced by ZnO Nanowires. Materials 2022, 15, 1924. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W.; Fan, Q.; Zhang, Q.; Cai, L.; Li, K.; Gu, X.; Yang, F.; Zhang, N.; Wang, Y.; Liu, H. High-performance and compact-designed flexible thermoelectric modules enabled by a reticulate carbon nanotube architecture. Nat. Commun. 2017, 8, 14886. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Qiao, J.; Zhao, Y.; Lan, Q.; Mao, P.; Qiu, J.; Tai, K.; Liu, C.; Cheng, H. A flexible thermoelectric device based on a Bi2Te3-carbon nanotube hybrid. J. Mater. Sci. Technol. 2020, 58, 80–85. [Google Scholar] [CrossRef]

- Kumanek, B.; Janas, D. Thermal conductivity of carbon nanotube networks: A review. J. Mater. Sci. 2019, 54, 7397–7427. [Google Scholar] [CrossRef]

- Marconnet, A.M.; Panzer, M.A.; Goodson, K.E. Thermal conduction phenomena in carbon nanotubes and related nanostructured materials. Rev. Mod. Phys. 2013, 85, 1295–1326. [Google Scholar] [CrossRef]

- Pop, E.; Mann, D.; Wang, Q.; Goodson, K.; Dai, H. Thermal conductance of an individual single-wall carbon nanotube above room temperature. Nano Lett. 2006, 6, 96–100. [Google Scholar] [CrossRef] [PubMed]

- Balandin, A.A. Thermal properties of graphene and nanostructured carbon materials. Nat. Mater. 2011, 10, 569–581. [Google Scholar] [CrossRef] [PubMed]

- Hone, J.; Llaguno, M.; Biercuk, M.; Johnson, A.; Batlogg, B.; Benes, Z.; Fischer, J. Thermal properties of carbon nanotubes and nanotube-based materials. Appl. Phys. A 2002, 74, 339–343. [Google Scholar] [CrossRef]

- Han, Z.; Fina, A. Thermal conductivity of carbon nanotubes and their polymer nanocomposites: A review. Prog. Polym. Sci. 2011, 36, 914–944. [Google Scholar] [CrossRef]

- Cao, J.X.; Yan, X.H.; Xiao, Y.; Ding, J.W. Thermal conductivity of zigzag single-walled carbon nanotubes: Role of the umklapp process. Phys. Rev. B 2004, 69, 073407. [Google Scholar] [CrossRef]

- Evans, W.J.; Shen, M.; Keblinski, P. Inter-tube thermal conductance in carbon nanotubes arrays and bundles: Effects of contact area and pressure. Appl. Phys. Lett. 2012, 100, 261908. [Google Scholar] [CrossRef]

- Stuart, S.J.; Tutein, A.B.; Harrison, J.A. A reactive potential for hydrocarbons with intermolecular interactions. J. Chem. Phys. 2000, 112, 6472–6486. [Google Scholar] [CrossRef]

- Boroushak, S.; Ansari, R.; Ajori, S. Molecular dynamics simulations of the thermal conductivity of cross-linked functionalized single-and double-walled carbon nanotubes with polyethylene chains. Diam. Relat. Mater. 2018, 86, 173–178. [Google Scholar] [CrossRef]

- Chalopin, Y.; Volz, S.; Mingo, N. Upper bound to the thermal conductivity of carbon nanotube pellets. J. Appl. Phys. 2009, 105, 084301. [Google Scholar] [CrossRef]

- Aliev, A.E.; Guthy, C.; Zhang, M.; Fang, S.; Zakhidov, A.A.; Fischer, J.E.; Baughman, R.H. Thermal transport in MWCNT sheets and yarns. Carbon 2007, 45, 2880–2888. [Google Scholar] [CrossRef]

- Berber, S.; Kwon, Y.-K.; Tománek, D. Unusually high thermal conductivity of carbon nanotubes. Phys. Rev. Lett. 2000, 84, 4613–4616. [Google Scholar] [CrossRef]

- Speranza, G. Carbon nanomaterials: Synthesis, functionalization and sensing applications. Nanomaterials 2021, 11, 967. [Google Scholar] [CrossRef] [PubMed]

- Voznyakovskii, A.; Neverovskaya, A.; Vozniakovskii, A.; Kidalov, S. A Quantitative chemical method for determining the surface concentration of stone–Wales defects for 1D and 2D carbon nanomaterials. Nanomaterials 2022, 12, 883. [Google Scholar] [CrossRef]

- Batra, R.; Song, L.; Ramprasad, R. Emerging materials intelligence ecosystems propelled by machine learning. Nat. Rev. Mater. 2021, 6, 655–678. [Google Scholar] [CrossRef]

- Hart, G.L.W.; Mueller, T.; Toher, C.; Curtarolo, S. Machine learning for alloys. Nat. Rev. Mater. 2021, 6, 730–755. [Google Scholar] [CrossRef]

- Choudhary, K.; DeCost, B.; Chen, C.; Jain, A.; Tavazza, F.; Cohn, R.; Park, C.W.; Choudhary, A.; Agrawal, A.; Billinge, S.J.L.; et al. Recent advances and applications of deep learning methods in materials science. NPJ Comput. Mater. 2022, 8, 59. [Google Scholar] [CrossRef]

- Atwal, G.S.; Ashcroft, N.W. Relaxation of an electron system: Conserving approximation. Phys. Rev. B 2002, 65, 115109. [Google Scholar] [CrossRef]

- Hirosawa, T.; Schäfer, F.; Maebashi, H.; Matsuura, H.; Ogata, M. Data-Driven Reconstruction of Spectral Conductivity and Chemical Potential Using Thermoelectric Transport Properties. J. Phys. Soc. Jpn. 2022, 91, 114603. [Google Scholar] [CrossRef]

- Kimura, K.; Iwasaki, Y. Solving Long-standing Problems in Thermoelectric Properties using Machine Learning. JPSJ News Comments 2023, 20, 01. [Google Scholar] [CrossRef]

- Unke, O.T.; Chmiela, S.; Sauceda, H.E.; Gastegger, M.; Poltavsky, I.; Schütt, K.T.; Tkatchenko, A.; Müller, K.-R. Machine Learning Force Fields. Chem. Rev. 2021, 121, 10142–10186. [Google Scholar] [CrossRef] [PubMed]

- Poltavsky, I.; Tkatchenko, A. Machine Learning Force Fields: Recent Advances and Remaining Challenges. J. Phys. Chem. Lett. 2021, 12, 6551–6564. [Google Scholar] [CrossRef] [PubMed]

- Sauceda, H.E.; Gálvez-González, L.E.; Chmiela, S.; Paz-Borbón, L.O.; Müller, K.-R.; Tkatchenko, A. BIGDML—Towards accurate quantum machine learning force fields for materials. Nat. Commun. 2022, 13, 3733. [Google Scholar] [CrossRef] [PubMed]

- Qin, G.; Wei, Y.; Yu, L.; Xu, J.; Ojih, J.; Rodriguez, A.D.; Wang, H.; Qin, Z.; Hu, M. Predicting lattice thermal conductivity from fundamental material properties using machine learning techniques. J. Mater. Chem. A 2023, 11, 5801–5810. [Google Scholar] [CrossRef]

- Cui, C.; Zhang, Y.; Ouyang, T.; Chen, M.; Tang, C.; Chen, Q.; He, C.; Li, J.; Zhong, J. On-the-fly machine learning potential accelerated accurate prediction of lattice thermal conductivity of metastable silicon crystals. Phys. Rev. Mater. 2023, 7, 033803. [Google Scholar] [CrossRef]

- Jain, A.; Ong, S.P.; Hautier, G.; Chen, W.; Richards, W.D.; Dacek, S.; Cholia, S.; Gunter, D.; Skinner, D.; Ceder, G.; et al. Commentary: The Materials Project: A materials genome approach to accelerating materials innovation. APL Mater. 2013, 1, 011002. [Google Scholar] [CrossRef]

- Xu, Y.; Yamazaki, M.; Villars, P. Inorganic Materials Database for Exploring the Nature of Material. Jpn. J. Appl. Phys. 2011, 50, 11RH02. [Google Scholar] [CrossRef]

- Zhou, J.; Shen, L.; Costa, M.D.; Persson, K.A.; Ong, S.P.; Huck, P.; Lu, Y.; Ma, X.; Chen, Y.; Tang, H.; et al. 2DMatPedia, an open computational database of two-dimensional materials from top-down and bottom-up approaches. Sci. Data 2019, 6, 86. [Google Scholar] [CrossRef] [PubMed]

- Wei, Q.; Xiong, F.; Tan, S.; Huang, L.; Lan, E.H.; Dunn, B.; Mai, L. Porous One-Dimensional Nanomaterials: Design, Fabrication and Applications in Electrochemical Energy Storage. Adv. Mater. 2017, 29, 1602300. [Google Scholar] [CrossRef] [PubMed]

- Jin, T.; Han, Q.; Wang, Y.; Jiao, L. 1D Nanomaterials: Design, Synthesis, and Applications in Sodium–Ion Batteries. Small 2018, 14, 1703086. [Google Scholar] [CrossRef] [PubMed]

- Duong, H.M.; Einarsson, E.; Okawa, J.; Xiang, R.; Maruyama, S. Thermal degradation of single-walled carbon nanotubes. Jpn. J. Appl. Phys. 2008, 47, 1994–1999. [Google Scholar] [CrossRef]

- Mahajan, A.; Kingon, A.; Kukovecz, Á.; Konya, Z.; Vilarinho, P.M. Studies on the thermal decomposition of multiwall carbon nanotubes under different atmospheres. Mater. Lett. 2013, 90, 165–168. [Google Scholar] [CrossRef]

- Yee, S.K.; LeBlanc, S.; Goodson, K.E.; Dames, C. $ per W metrics for thermoelectric power generation: Beyond ZT. Energy Environ. Sci. 2013, 6, 2561–2571. [Google Scholar] [CrossRef]

- Kim, S.I.; Lee, K.H.; Mun, H.A.; Kim, H.S.; Hwang, S.W.; Roh, J.W.; Yang, D.J.; Shin, W.H.; Li, X.S.; Lee, Y.H.; et al. Dense dislocation arrays embedded in grain boundaries for high-performance bulk thermoelectrics. Science 2015, 348, 109–114. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Latronico, G.; Asnaashari Eivari, H.; Mele, P.; Assadi, M.H.N. Insights into One-Dimensional Thermoelectric Materials: A Concise Review of Nanowires and Nanotubes. Nanomaterials 2024, 14, 1272. https://doi.org/10.3390/nano14151272

Latronico G, Asnaashari Eivari H, Mele P, Assadi MHN. Insights into One-Dimensional Thermoelectric Materials: A Concise Review of Nanowires and Nanotubes. Nanomaterials. 2024; 14(15):1272. https://doi.org/10.3390/nano14151272

Chicago/Turabian StyleLatronico, Giovanna, Hossein Asnaashari Eivari, Paolo Mele, and Mohammad Hussein Naseef Assadi. 2024. "Insights into One-Dimensional Thermoelectric Materials: A Concise Review of Nanowires and Nanotubes" Nanomaterials 14, no. 15: 1272. https://doi.org/10.3390/nano14151272