MIL-Derived Hollow Tubulous-Shaped In2O3/ZnIn2S4 Z-Scheme Heterojunction for Efficient Antibacterial Performance via In Situ Composite

Abstract

:1. Introduction

2. Experimental Section

2.1. Synthesis of Rod-Shaped MIL-68 (MIL)

2.2. Synthesis of MIL-Derived In2O3 Photocatalyst

2.3. Synthesis of ZnIn2S4 Photocatalyst

2.4. Synthesis of In2O3/ZnIn2S4 Composites

2.5. Characterization

2.6. Photoelectrochemical Test

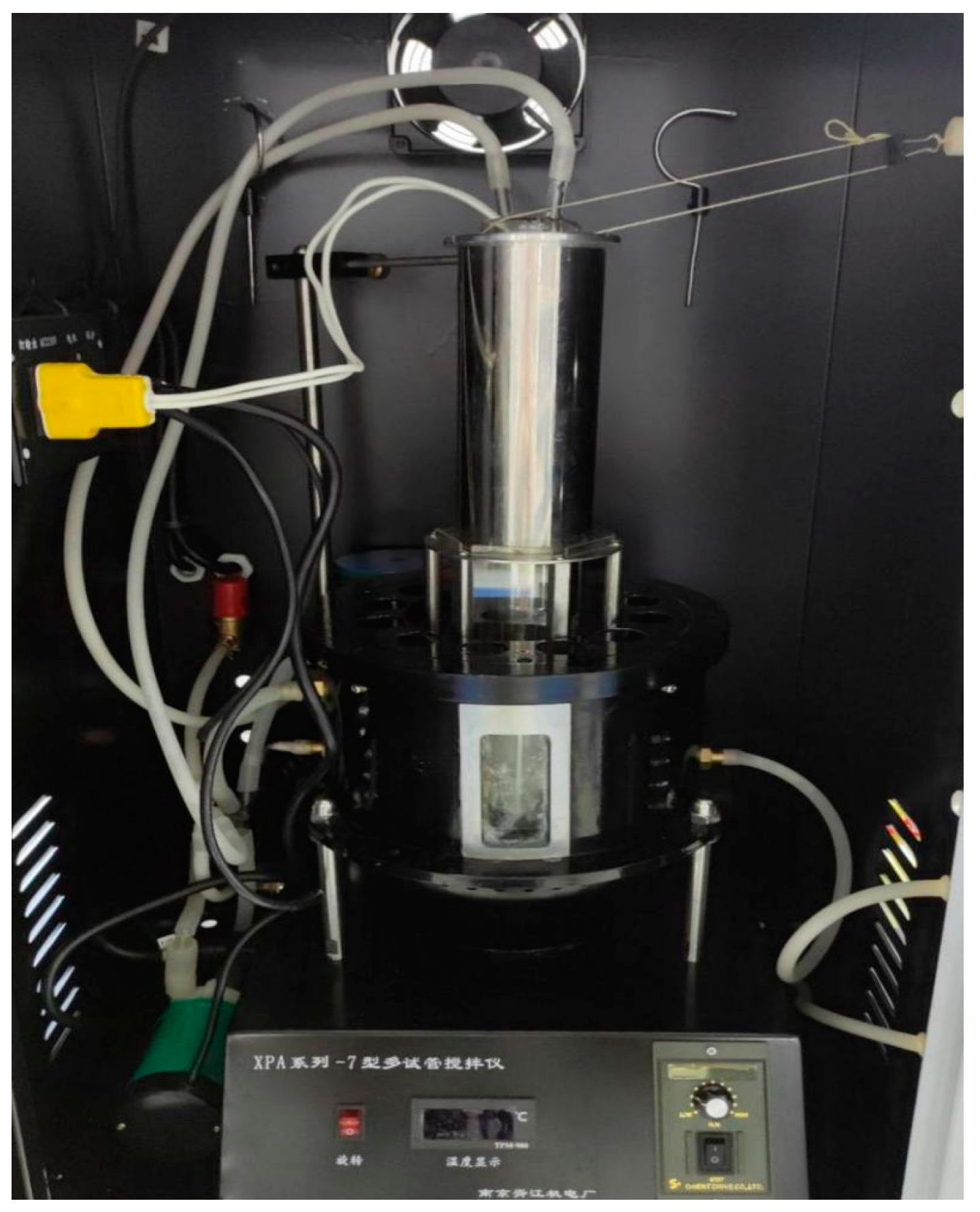

2.7. Photocatalytic Degradation and Photocatalytic Antibacterial Performance

3. Results and Discussion

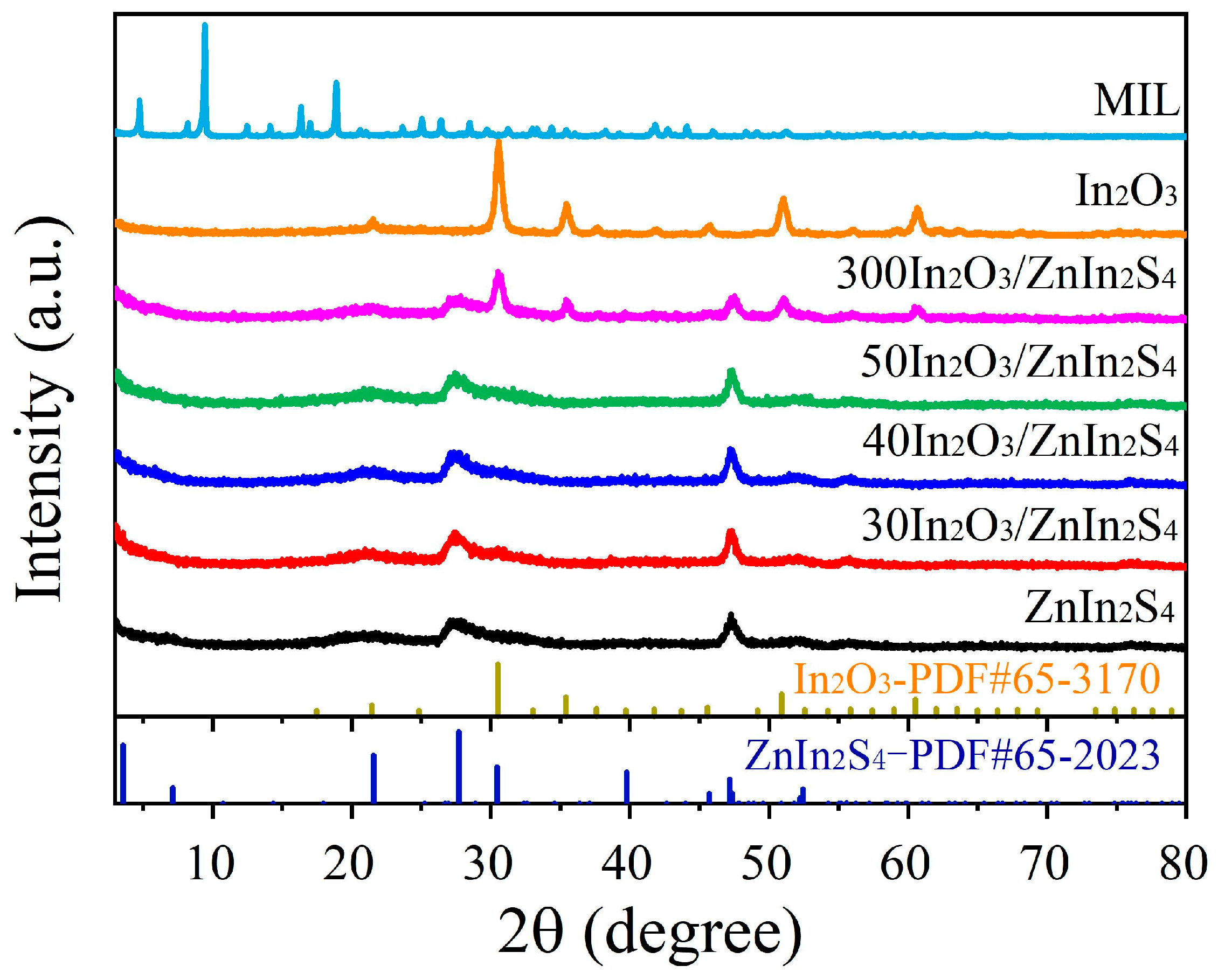

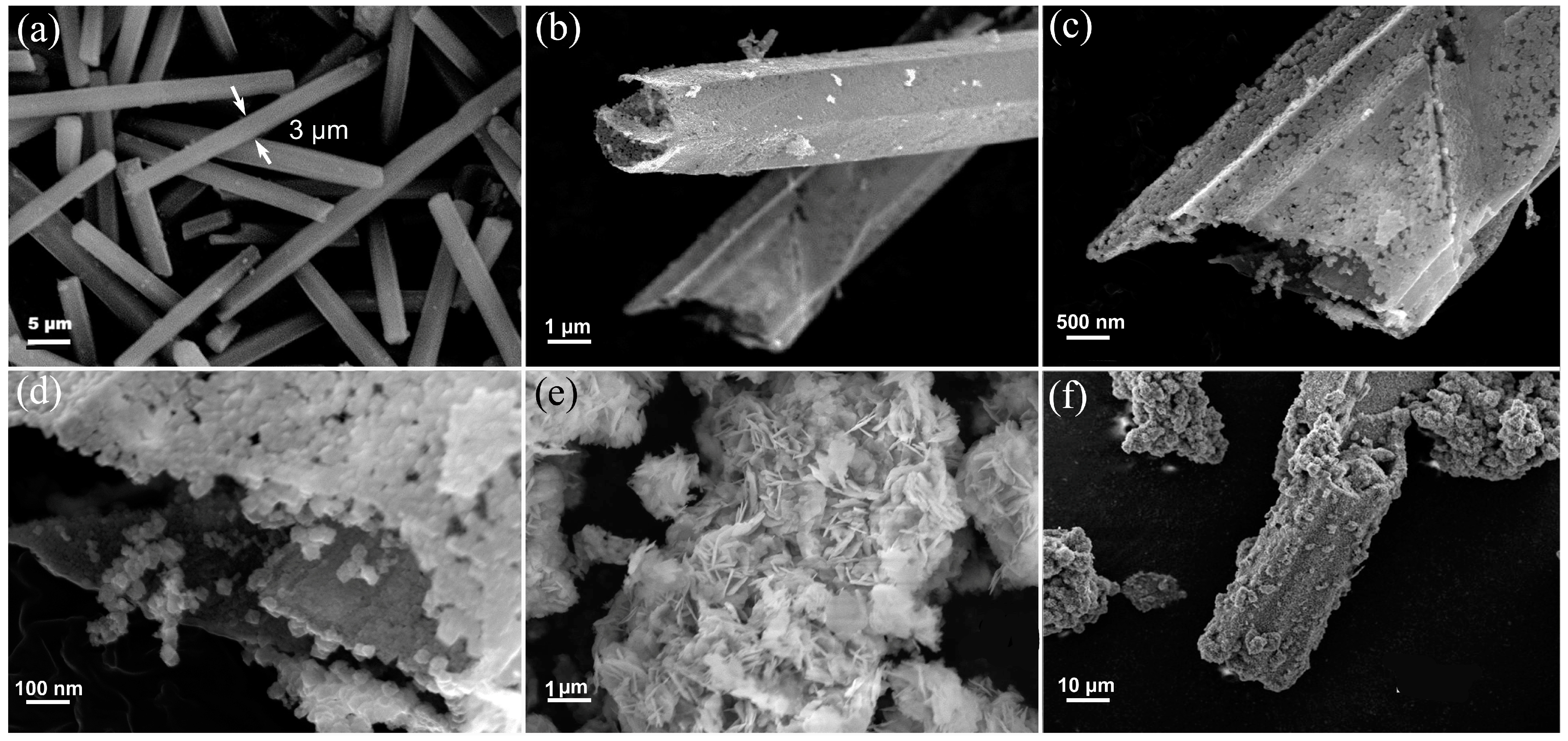

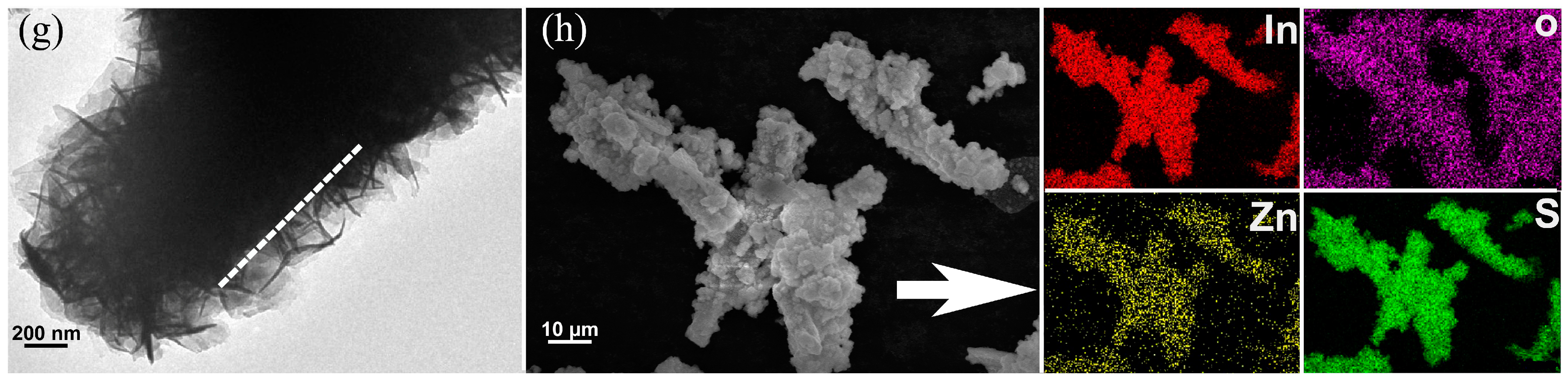

3.1. Analysis of Physical Properties

3.2. Analysis of Photocatalytic Degradation of MO and Sterilization of P. aeruginosa

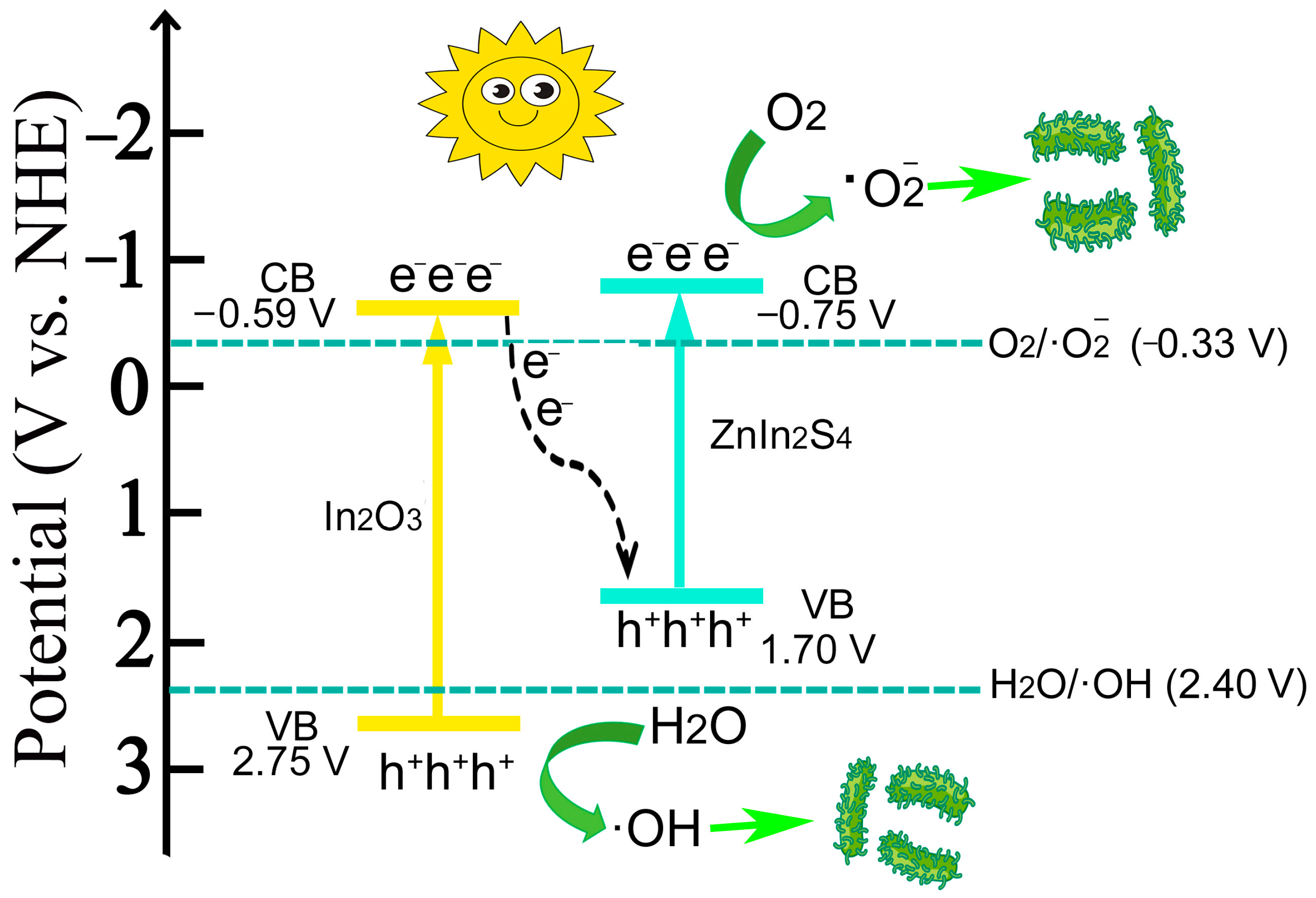

3.3. Mechanism Analysis of the Promotion of Photocatalytic Performance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Vuong, P.; McKinley, A.; Kaur, P. Understanding biofouling and contaminant accretion on submerged marine structures. NPJ Mater. Degrad. 2023, 7, 50. [Google Scholar] [CrossRef]

- Callow, J.A.; Callow, M.E. Trends in the development of environmentally friendly fouling-resistant marine coatings. Nat. Commun. 2011, 2, 244. [Google Scholar] [CrossRef]

- Li, S.; Feng, K.; Li, J.; Li, Y.; Li, Z.; Yu, L.; Xu, X. Marine antifouling strategies: Emerging opportunities for seawater resource utilization. Chem. Eng. J. 2024, 486, 149859. [Google Scholar] [CrossRef]

- Hassaan, M.A.; El-Nemr, M.A.; Elkatory, M.R.; Ragab, S.; Niculescu, V.-C.; El Nemr, A. Principles of Photocatalysts and Their Different Applications: A Review. Top. Curr. Chem. 2023, 381, 31. [Google Scholar] [CrossRef]

- Ma, J.; Shi, Y.; An, D.; Chen, Y.; Guo, J.; Qian, Y.; Wang, S.; Lu, J. Inactivation mechanism of E. coli in water by enhanced photocatalysis under visible light irradiation. Sci. Total Environ. 2023, 866, 161450. [Google Scholar] [CrossRef] [PubMed]

- Luo, L.; Fu, L.; Liu, H.; Xu, Y.; Xing, J.; Chang, C.-R.; Yang, D.-Y.; Tang, J. Synergy of Pd atoms and oxygen vacancies on In2O3 for methane conversion under visible light. Nat. Commun. 2022, 13, 2930. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Dong, Y.; Yan, T.; Hu, Z.; Ali, F.M.; Meira, D.M.; Duchesne, P.N.; Loh, J.Y.Y.; Qiu, C.; Storey, E.E.; et al. Black indium oxide a photothermal CO2 hydrogenation catalyst. Nat. Commun. 2020, 11, 2432. [Google Scholar] [CrossRef] [PubMed]

- Ji, Y.; Cui, M.; Wei, J.; Shi, Y.; Bao, L.; Tian, Z.; Hu, X.; Zhang, X.; Li, C. Interfacial oxygen vacancy engineering and built-in electric field mediated Z-scheme In2O3/Ag3PO4 heterojunction for boosted photocatalytic doxycycline degradation. Chem. Eng. J. 2024, 489, 151216. [Google Scholar] [CrossRef]

- Liu, J.; Guo, C.; Wu, N.; Li, C.; Qu, R.; Wang, Z.; Jin, R.; Qiao, Y.; He, Z.; Lu, J.; et al. Efficient photocatalytic degradation of PFOA in N-doped In2O3/simulated sunlight irradiation system and its mechanism. Chem. Eng. J. 2022, 435, 134627. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, Y.; Liu, X.; Li, L.; Du, L.; Tian, G. Sulfur doped In2O3-CeO2 hollow hexagonal prisms with carbon coating for efficient photocatalytic CO2 reduction. Chem. Eng. J. 2021, 421, 129968. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, P.; Shao, T.; Li, X. In2O3 nanoporous nanosphere: A highly efficient photocatalyst for decomposition of perfluorooctanoic acid. Appl. Catal. B-Environ. 2012, 125, 350–357. [Google Scholar] [CrossRef]

- Cao, S.W.; Liu, X.F.; Yuan, Y.P.; Zhang, Z.Y.; Liao, Y.-S.; Fang, J.; Loo, S.C.J.; Sum, T.C.; Xue, C. Solar-to-fuels conversion over In2O3/g-C3N4 hybrid photocatalysts. Appl. Catal. B-Environ. 2014, 147, 940–946. [Google Scholar] [CrossRef]

- Mu, F.; Liu, C.; Xie, Y.; Zhou, S.; Dai, B.; Xia, D.; Huang, H.; Zhao, W.; Sun, C.; Kong, Y.; et al. Metal-organic framework-derived rodlike AgCl/Ag/In2O3: A plasmonic Z-scheme visible light photocatalyst. Chem. Eng. J. 2021, 415, 129010. [Google Scholar] [CrossRef]

- Han, L.; Jing, F.; Zhang, J.; Luo, X.-Z.; Zhong, Y.-L.; Wang, K.; Zang, S.-H.; Teng, D.-H.; Liu, Y.; Chen, J.; et al. Environment friendly and remarkably efficient photocatalytic hydrogen evolution based on metal organic framework derived hexagonal/cubic In2O3 phase-junction. Appl. Catal. B-Environ. 2021, 282, 119602. [Google Scholar] [CrossRef]

- Yang, H.; Tang, J.; Luo, Y.; Zhan, X.; Liang, Z.; Jiang, L.; Hou, H.; Yang, W. MOFs-derived fusiform In2O3 mesoporous nanorods anchored with ultrafine CdZnS nanoparticles for boosting visible-light photocatalytic hydrogen evolution. Small 2021, 17, 2102307. [Google Scholar] [CrossRef]

- Yu, J.; Yan, P.; Chen, F.; Jin, S.; Xu, X.; Qian, J. MgIn2S4@In2O3 hierarchical tubular heterostructures with expedited photocarrier separation for efficient visible-light-driven antimicrobial activity. Chem. Eng. J. 2023, 452, 139559. [Google Scholar] [CrossRef]

- Kulkarni, P.; Nataraj, S.K.; Balakrishna, R.G.; Nagaraju, D.H.; Reddy, M.V. Nanostructured binary and ternary metal sulfides: Synthesis methods and their application in energy conversion and storage devices. J. Mater. Chem. A 2017, 5, 22040–22094. [Google Scholar] [CrossRef]

- Meng, S.; Wu, H.; Cui, Y.; Zheng, X.; Wang, H.; Chen, S.; Wang, Y.; Fu, X. One-step synthesis of 2D/2D-3D NiS/Zn3In2S6 hierarchical structure toward solar-to-chemical energy transformation of biomass-relevant alcohols. Appl. Catal. B-Environ. 2020, 266, 118617. [Google Scholar] [CrossRef]

- Wang, D.; Xu, Y.; Jing, L.; Xie, M.; Song, Y.; Xu, H.; Li, H.; Xie, J. In situ construction efficient visible-light-driven three-dimensional Polypyrrole/Zn3In2S6 nanoflower to systematically explore the photoreduction of Cr(VI): Performance, factors and mechanism. J. Hazard. Mater. 2020, 384, 121480. [Google Scholar] [CrossRef]

- Qiu, C.; Qian, K.; Yu, J.; Sun, M.Z.; Cao, S.F.; Gao, J.Q.; Yu, R.X.; Fang, L.Z.; Yao, Y.W.; Lu, X.Q.; et al. MOF-Transformed In2O3-x@C Nanocorn Electrocatalyst for Efficient CO2 Reduction to HCOOH. Nano-Micro Lett. 2022, 14, 16. [Google Scholar] [CrossRef]

- Wang, J.; Sun, S.; Zhou, R.; Li, Y.; He, Z.; Ding, H.; Chen, D.; Ao, W. A review: Synthesis, modification and photocatalytic applications of ZnIn2S4. J. Mater. Sci. Technol. 2021, 78, 1–19. [Google Scholar] [CrossRef]

- Shen, Q.; Sun, L.; Zhuang, Y.; Zhan, W.; Wang, X.; Han, X. Hollow Dodecahedral Structure of In2O3-In2S3 Heterojunction Encapsulated by N-Doped C as an Excellent Visible-Light-Active Photocatalyst for Organic Transformation. Inorg. Chem. 2020, 59, 17650–17658. [Google Scholar] [CrossRef]

- Sun, Y.; Zhu, Q.; Bai, B.; Li, Y.; He, C. Novel all-solid-state Z-scheme SnO2/Pt/In2O3 photocatalyst with boosted photocatalytic performance on water splitting and 2,4-dichlorophenol degradation under visible light. Chem. Eng. J. 2020, 390, 124518. [Google Scholar] [CrossRef]

- Jiang, C.; Wang, H.; Wang, Y.; Ji, H. All solid-state Z-scheme CeO2/ZnIn2S4 hybrid for the photocatalytic selective oxidation of aromatic alcohols coupled with hydrogen evolution. Appl. Catal. B-Environ. 2020, 277, 119235. [Google Scholar] [CrossRef]

- Liu, C.; Wang, L.; Tang, Y.; Luo, S.; Liu, Y.; Zhang, S.; Zeng, Y.; Xu, Y. Vertical single or few-layer MoS2 nanosheets rooting into TiO2 nanofibers for highly efficient photocatalytic hydrogen evolution. Appl. Catal. B-Environ. 2015, 164, 1–9. [Google Scholar] [CrossRef]

- Wang, F.; Jin, Z.; Jiang, Y.; Backus, E.H.G.; Bonn, M.; Lou, S.N.; Turchinovich, D.; Amal, R. Probing the charge separation process on In2S3/Pt-TiO2 nanocomposites for boosted visible-light photocatalytic hydrogen production. Appl. Catal. B-Environ. 2016, 198, 25–31. [Google Scholar] [CrossRef]

- Ma, X.; Cheng, H.F. Synergy of nitrogen vacancies and intercalation of carbon species for enhancing sunlight photocatalytic hydrogen production of carbon nitride. Appl. Catal. B-Environ. 2022, 314, 121497. [Google Scholar] [CrossRef]

- Peng, Y.; Geng, M.; Yu, J.; Zhang, Y.; Tian, F.; Guo, Y.n.; Zhang, D.; Yang, X.; Li, Z.; Li, Z.; et al. Vacancy-induced 2H@1T MoS2 phase-incorporation on ZnIn2S4 for boosting photocatalytic hydrogen evolution. Appl. Catal. B-Environ. 2021, 298, 120570. [Google Scholar] [CrossRef]

- Li, P.; Liang, T.; Liu, H.; Li, J.; Duo, S.; Xu, X.; Qiu, L.; Wen, X.; Shi, R. In2O3 microspheres decorated with ZnIn2S4 nanosheets as core-shell hybrids for boosting visible-light photodegradation of organic dyes. Mater. Res. Express 2021, 8, 025505. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, J.; Zhang, H.; Zhang, J.; Sun, M.; Duan, J. MIL-Derived Hollow Tubulous-Shaped In2O3/ZnIn2S4 Z-Scheme Heterojunction for Efficient Antibacterial Performance via In Situ Composite. Nanomaterials 2024, 14, 1366. https://doi.org/10.3390/nano14161366

Duan J, Zhang H, Zhang J, Sun M, Duan J. MIL-Derived Hollow Tubulous-Shaped In2O3/ZnIn2S4 Z-Scheme Heterojunction for Efficient Antibacterial Performance via In Situ Composite. Nanomaterials. 2024; 14(16):1366. https://doi.org/10.3390/nano14161366

Chicago/Turabian StyleDuan, Jiao, Hui Zhang, Jie Zhang, Mengmeng Sun, and Jizhou Duan. 2024. "MIL-Derived Hollow Tubulous-Shaped In2O3/ZnIn2S4 Z-Scheme Heterojunction for Efficient Antibacterial Performance via In Situ Composite" Nanomaterials 14, no. 16: 1366. https://doi.org/10.3390/nano14161366