Improvement of Electrical and Thermal Properties of Carbon Nanotube Sheets by Adding Silver Nanowire and Mxene for an Electromagnetic-Interference-Shielding Property Study

Abstract

:1. Introduction

2. Methods

2.1. Materials

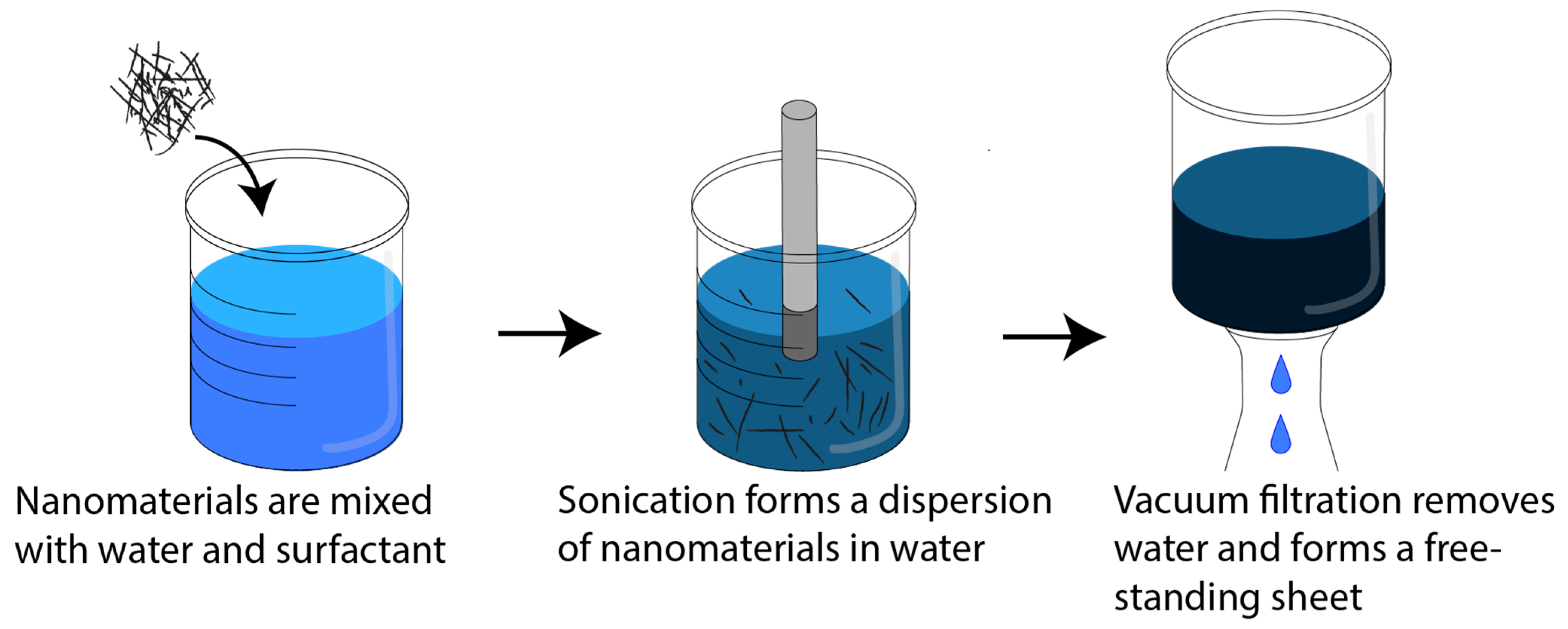

2.2. Fabrication of Hybrid CNT Sheets

2.3. Hybrid Sheet Structure Characterization

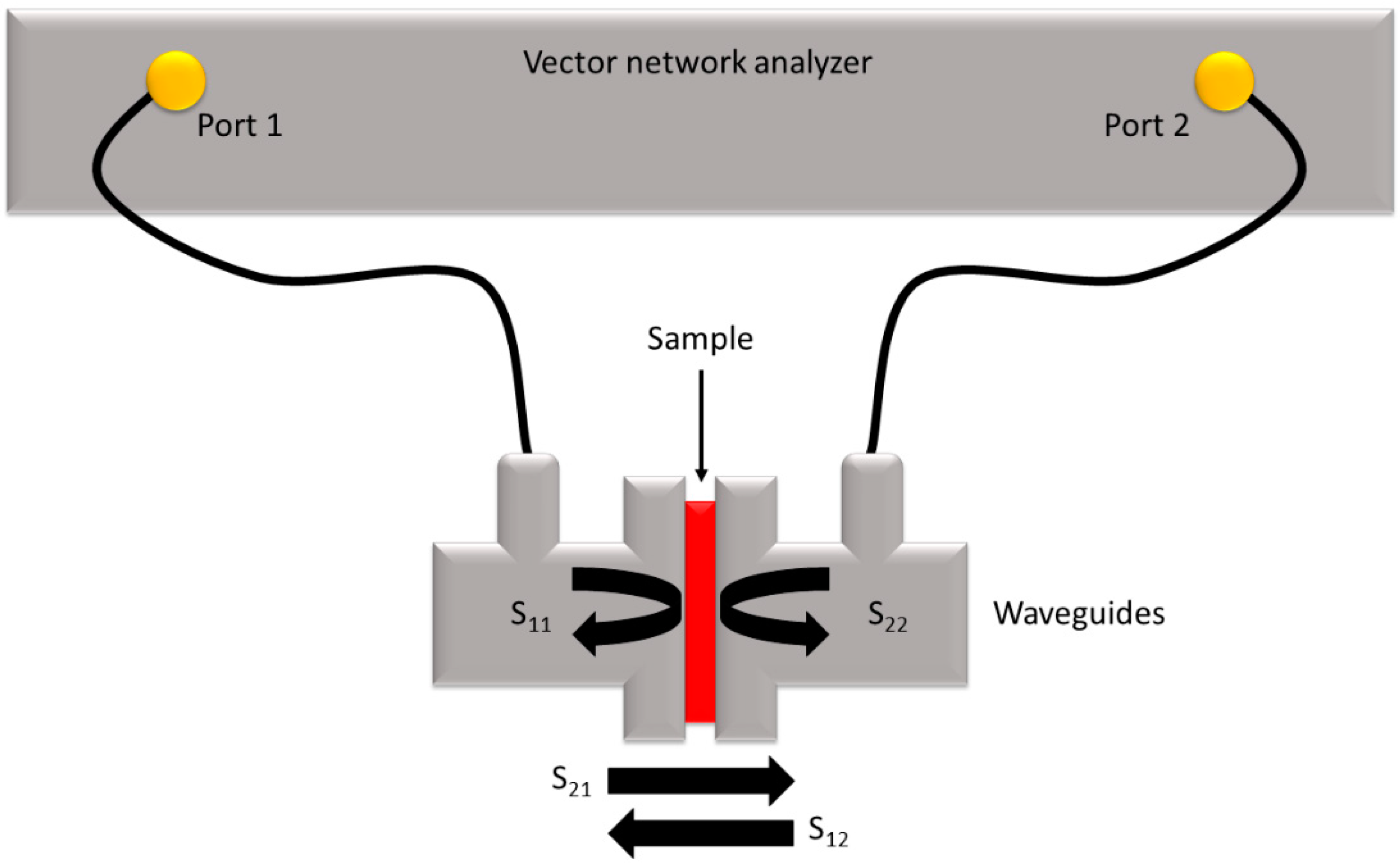

2.4. Measurement of Electrical Properties and EMI Shielding

2.5. Measurement of Thermal Properties

3. Results and Discussion

3.1. Microstructure Analysis

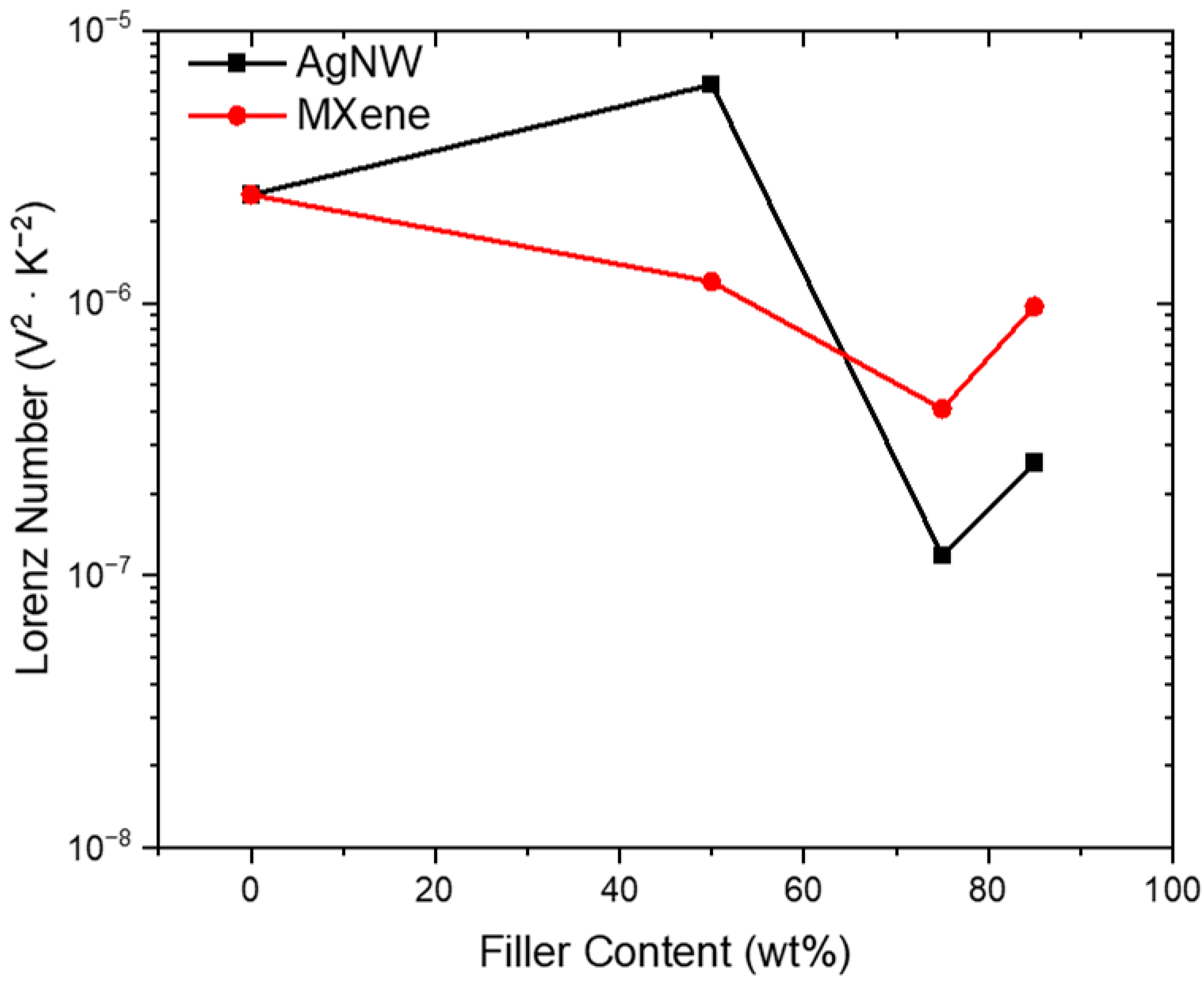

3.2. Electrothermal Analysis

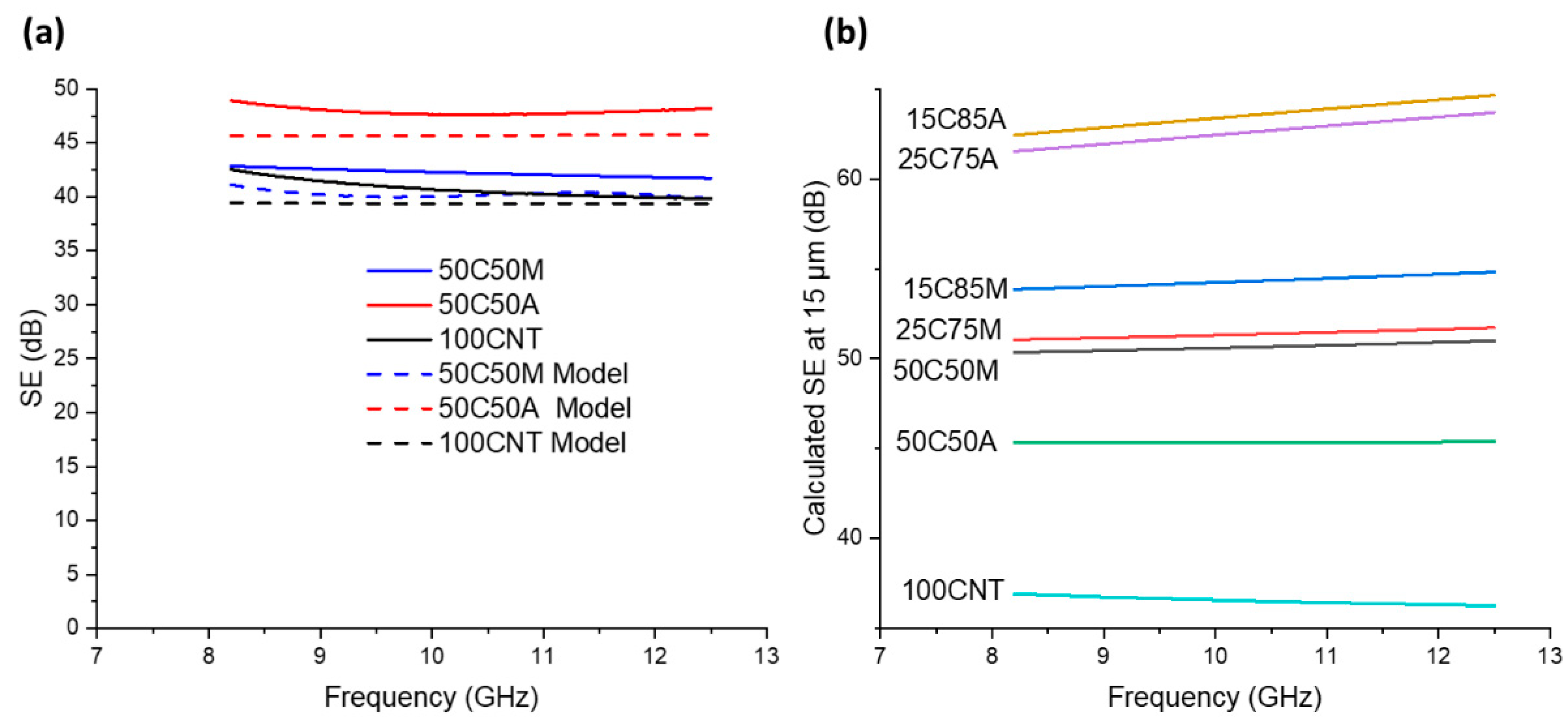

3.3. EMI-Shielding Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rohini, R.; Verma, K.; Bose, S. Interfacial Architecture Constructed Using Functionalized MWNT Resulting in Enhanced EMI Shielding in Epoxy/Carbon Fiber Composites. ACS Omega 2018, 3, 3974–3982. [Google Scholar] [CrossRef] [PubMed]

- Isari, A.A.; Ghaffarkhah, A.; Hashemi, S.A.; Wuttke, S.; Arjmand, M. Structural Design for EMI Shielding: From Underlying Mechanisms to Common Pitfalls. Adv. Mater. 2024, 36, 2310683. [Google Scholar] [CrossRef] [PubMed]

- Munalli, D.; Dimitrakis, G.; Chronopoulos, D.; Greedy, S.; Long, A. Electromagnetic Shielding Effectiveness of Carbon Fibre Reinforced Composites. Compos. Part B Eng. 2019, 173, 106906. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, C.; Ma, C.; Ren, W.; Cheng, H.-M. Lightweight and Flexible Graphene Foam Composites for High-Performance Electromagnetic Interference Shielding. Adv. Mater. 2013, 25, 1296–1300. [Google Scholar] [CrossRef]

- Wei, L.; Zhang, W.; Ma, J.; Bai, S.-L.; Ren, Y.; Liu, C.; Simion, D.; Qin, J. π-π Stacking Interface Design for Improving the Strength and Electromagnetic Interference Shielding of Ultrathin and Flexible Water-Borne Polymer/Sulfonated Graphene Composites. Carbon 2019, 149, 679–692. [Google Scholar] [CrossRef]

- Nam, I.W.; Lee, H.K.; Jang, J.H. Electromagnetic Interference Shielding/Absorbing Characteristics of CNT-Embedded Epoxy Composites. Compos. Part Appl. Sci. Manuf. 2011, 42, 1110–1118. [Google Scholar] [CrossRef]

- Kumar, P.; Shahzad, F.; Yu, S.; Hong, S.M.; Kim, Y.-H.; Koo, C.M. Large-Area Reduced Graphene Oxide Thin Film with Excellent Thermal Conductivity and Electromagnetic Interference Shielding Effectiveness. Carbon 2015, 94, 494–500. [Google Scholar] [CrossRef]

- Iijima, S. Helical Microtubules of Graphitic Carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Ren, Z.; Chou, T.-W. Advances in the Science and Technology of Carbon Nanotubes and Their Composites: A Review. Compos. Sci. Technol. 2001, 61, 1899–1912. [Google Scholar] [CrossRef]

- Soni, S.K.; Thomas, B.; Kar, V.R. A Comprehensive Review on CNTs and CNT-Reinforced Composites: Syntheses, Characteristics and Applications. Mater. Today Commun. 2020, 25, 101546. [Google Scholar] [CrossRef]

- Zhang, S.; Nguyen, N.; Park, J.G.; Hao, A.; Liang, R. Carbon Nanotubes and Their Assemblies: Applications in Electromagnetic Interference Shielding. In Nanotube Superfiber Materials; Elsevier: Amsterdam, The Netherlands, 2019; pp. 335–357. ISBN 978-0-12-812667-7. [Google Scholar]

- Feng, L.; Zuo, Y.; He, X.; Hou, X.; Fu, Q.; Li, H.; Song, Q. Development of Light Cellular Carbon Nanotube@graphene/Carbon Nanocomposites with Effective Mechanical and EMI Shielding Performance. Carbon 2020, 168, 719–731. [Google Scholar] [CrossRef]

- Wang, H.; Li, S.; Liu, M.; Li, J.; Zhou, X. Review on Shielding Mechanism and Structural Design of Electromagnetic Interference Shielding Composites. Macromol. Mater. Eng. 2021, 306, 2100032. [Google Scholar] [CrossRef]

- Evers, C.; Kurilich, M.; Park, J.G.; Jolowsky, C.; Thagard, K.; Liang, Z. Multifunctional Properties of Carbon Nanotube Yarn/Aerogel Laminate Composites. Compos. Part B Eng. 2024, 280, 111495. [Google Scholar] [CrossRef]

- Shi, S.; Jiang, Y.; Ren, H.; Deng, S.; Sun, J.; Cheng, F.; Jing, J.; Chen, Y. 3D-Printed Carbon-Based Conformal Electromagnetic Interference Shielding Module for Integrated Electronics. Nano-Micro Lett. 2024, 16, 85. [Google Scholar] [CrossRef]

- Naguib, M.; Kurtoglu, M.; Presser, V.; Lu, J.; Niu, J.; Heon, M.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Two-Dimensional Nanocrystals Produced by Exfoliation of Ti3AlC2. Adv. Mater. 2011, 23, 4248–4253. [Google Scholar] [CrossRef]

- Wan, S.; Li, X.; Chen, Y.; Liu, N.; Du, Y.; Dou, S.; Jiang, L.; Cheng, Q. High-Strength Scalable MXene Films through Bridging-Induced Densification. Science 2021, 374, 96–99. [Google Scholar] [CrossRef]

- Li, B.; Wen, X.; Li, R.; Wang, Z.; Clem, P.G.; Fan, H. Stress-Induced Phase Transformation and Optical Coupling of Silver Nanoparticle Superlattices into Mechanically Stable Nanowires. Nat. Commun. 2014, 5, 4179. [Google Scholar] [CrossRef] [PubMed]

- Lee, T.-W.; Lee, S.-E.; Jeong, Y.G. Highly Effective Electromagnetic Interference Shielding Materials Based on Silver Nanowire/Cellulose Papers. ACS Appl. Mater. Interfaces 2016, 8, 13123–13132. [Google Scholar] [CrossRef]

- Choi, H.Y.; Lee, T.-W.; Lee, S.-E.; Lim, J.; Jeong, Y.G. Silver Nanowire/Carbon Nanotube/Cellulose Hybrid Papers for Electrically Conductive and Electromagnetic Interference Shielding Elements. Compos. Sci. Technol. 2017, 150, 45–53. [Google Scholar] [CrossRef]

- Wang, Z.; Kong, Q.-Q.; Yi, Z.-L.; Xie, L.-J.; Jia, H.; Chen, J.-P.; Liu, D.; Jiang, D.; Chen, C.-M. Electromagnetic Interference Shielding Material for Super-Broadband: Multi-Walled Carbon Nanotube/Silver Nanowire Film with an Ultrathin Sandwich Structure. J. Mater. Chem. A 2021, 9, 25999–26009. [Google Scholar] [CrossRef]

- Shahzad, F.; Alhabeb, M.; Hatter, C.B.; Anasori, B.; Man Hong, S.; Koo, C.M.; Gogotsi, Y. Electromagnetic Interference Shielding with 2D Transition Metal Carbides (MXenes). Science 2016, 353, 1137–1140. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Huang, Y.; Du, F.; He, X.; Lin, X.; Gao, H.; Ma, Y.; Li, F.; Chen, Y.; Eklund, P.C. Electromagnetic Interference (EMI) Shielding of Single-Walled Carbon Nanotube Epoxy Composites. Nano Lett. 2006, 6, 1141–1145. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Pang, L.; Li, Y.; Luo, H.; Duan, G.; Mei, C.; Xu, W.; Zhou, W.; Liu, K.; Jiang, S. Ultra-Thin and Highly Flexible Cellulose Nanofiber/Silver Nanowire Conductive Paper for Effective Electromagnetic Interference Shielding. Compos. Part Appl. Sci. Manuf. 2020, 135, 105960. [Google Scholar] [CrossRef]

- Cao, W.; Ma, C.; Tan, S.; Ma, M.; Wan, P.; Chen, F. Ultrathin and Flexible CNTs/MXene/Cellulose Nanofibrils Composite Paper for Electromagnetic Interference Shielding. Nano-Micro Lett. 2019, 11, 72. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Yang, H.; Liu, Z.; Liu, A. Formation of Core-Shell Structure from Carbon Nanotube and Silver Nanowire. J. Alloys Compd. 2018, 765, 140–145. [Google Scholar] [CrossRef]

- Jing, M.; Han, C.; Li, M.; Shen, X. High Performance of Carbon Nanotubes/Silver Nanowires-PET Hybrid Flexible Transparent Conductive Films via Facile Pressing-Transfer Technique. Nanoscale Res. Lett. 2014, 9, 588. [Google Scholar] [CrossRef]

- Oluwalowo, A.; Nguyen, N.; Zhang, S.; Park, J.G.; Liang, R. Electrical and Thermal Conductivity Improvement of Carbon Nanotube and Silver Composites. Carbon 2019, 146, 224–231. [Google Scholar] [CrossRef]

- Zhao, M.-Q.; Ren, C.E.; Ling, Z.; Lukatskaya, M.R.; Zhang, C.; Van Aken, K.L.; Barsoum, M.W.; Gogotsi, Y. Flexible MXene/Carbon Nanotube Composite Paper with High Volumetric Capacitance. Adv. Mater. 2015, 27, 339–345. [Google Scholar] [CrossRef]

- Liang, X.; Rangom, Y.; Kwok, C.Y.; Pang, Q.; Nazar, L.F. Interwoven MXene Nanosheet/Carbon-Nanotube Composites as Li-S Cathode Hosts. Adv. Mater. 2017, 29, 1603040. [Google Scholar] [CrossRef]

- Yang, R.; Gui, X.; Yao, L.; Hu, Q.; Yang, L.; Zhang, H.; Yao, Y.; Mei, H.; Tang, Z. Ultrathin, Lightweight, and Flexible CNT Buckypaper Enhanced Using MXenes for Electromagnetic Interference Shielding. Nano-Micro Lett. 2021, 13, 66. [Google Scholar] [CrossRef]

- Xue, T.; Yang, Y.; Yu, D.; Wali, Q.; Wang, Z.; Cao, X.; Fan, W.; Liu, T. 3D Printed Integrated Gradient-Conductive MXene/CNT/Polyimide Aerogel Frames for Electromagnetic Interference Shielding with Ultra-Low Reflection. Nano-Micro Lett. 2023, 15, 45. [Google Scholar] [CrossRef] [PubMed]

- Panda, P.K.; Tasi, T.-P.; Wu, M.-W.; Dash, P.; Hsieh, C.-T.; Yang, P.-C.; Chang, J.-K. Development of Carbon Composite Coatings for Fire Retardancy and Electromagnetic Interference Shielding. Prog. Org. Coat. 2024, 194, 108628. [Google Scholar] [CrossRef]

- Patadia, M.; Quinn, A.; Tank, M.; Jolowsky, C.; Luiz, L.; Psulkowski, A.; Kurilich, M.; De Leon, A.; Liang, R.; Sweat, R. Enhanced Multifunctionality in Carbon Fiber/Carbon Nanotube Reinforced PEEK Hybrid Composites: Superior Combination of Mechanical Properties, Electrical Conductivity, and EMI Shielding. Compos. Part B Eng. 2024, 284, 111674. [Google Scholar] [CrossRef]

- Kharissova, O.V.; Kharisov, B.I.; De Casas Ortiz, E.G. Dispersion of Carbon Nanotubes in Water and Non-Aqueous Solvents. RSC Adv. 2013, 3, 24812. [Google Scholar] [CrossRef]

- Petersen, E.J.; Flores-Cervantes, D.X.; Bucheli, T.D.; Elliott, L.C.C.; Fagan, J.A.; Gogos, A.; Hanna, S.; Kägi, R.; Mansfield, E.; Bustos, A.R.M.; et al. Quantification of Carbon Nanotubes in Environmental Matrices: Current Capabilities, Case Studies, and Future Prospects. Environ. Sci. Technol. 2016, 50, 4587–4605. [Google Scholar] [CrossRef]

- Wang, H. Dispersing Carbon Nanotubes Using Surfactants. Curr. Opin. Colloid Interface Sci. 2009, 14, 364–371. [Google Scholar] [CrossRef]

- Yang, M.; Li, M.; Luo, S.; Liang, R. Real-Time Monitoring of Carbon Nanotube Dispersion Using Dynamic Light Scattering and UV-Vis Spectroscopy. Int. J. Adv. Manuf. Technol. 2016, 82, 361–367. [Google Scholar] [CrossRef]

- Cui, J.; Mei, H.; Zhang, J.; Fan, Z.; Yang, J.; Wang, W.; Tohmyoh, H.; Mei, X. Interfacial Contact Behavior between CNTs and AgNW with Molecular Dynamics Simulation. Materials 2020, 13, 1290. [Google Scholar] [CrossRef]

- Xu, W.; Xu, Z.; Liang, Y.; Liu, L.; Weng, W. Enhanced Tensile and Electrochemical Performance of MXene/CNT Hierarchical Film. Nanotechnology 2021, 32, 355706. [Google Scholar] [CrossRef]

- Serway, R.A. Principles of Physics, 2nd ed.; Saunders golden sunburst series; Saunders College Pub: Fort Worth, TX, USA, 1998; ISBN 978-0-03-020457-9. [Google Scholar]

- Mathis, T.S.; Maleski, K.; Goad, A.; Sarycheva, A.; Anayee, M.; Foucher, A.C.; Hantanasirisakul, K.; Shuck, C.E.; Stach, E.A.; Gogotsi, Y. Modified MAX Phase Synthesis for Environmentally Stable and Highly Conductive Ti3C2 MXene. ACS Nano 2021, 15, 6420–6429. [Google Scholar] [CrossRef]

- Cheng, Z.; Liu, L.; Xu, S.; Lu, M.; Wang, X. Temperature Dependence of Electrical and Thermal Conduction in Single Silver Nanowire. Sci. Rep. 2015, 5, 10718. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Kushnir, K.; Dong, Y.; Chertopalov, S.; Rao, A.M.; Mochalin, V.N.; Podila, R.; Titova, L.V. Equilibrium and Non-Equilibrium Free Carrier Dynamics in 2D Ti3C2Tx MXenes: THz Spectroscopy Study. 2D Mater. 2018, 5, 035043. [Google Scholar] [CrossRef]

- Castrucci, P.; Scilletta, C.; Gobbo, S.D.; Scarselli, M.; Camilli, L.; Simeoni, M.; Delley, B.; Continenza, A.; Crescenzi, M.D. Light Harvesting with Multiwall Carbon Nanotube/Silicon Heterojunctions. Nanotechnology 2011, 22, 115701. [Google Scholar] [CrossRef]

- Park, J.G.; Cheng, Q.; Lu, J.; Bao, J.; Li, S.; Tian, Y.; Liang, Z.; Zhang, C.; Wang, B. Thermal Conductivity of MWCNT/Epoxy Composites: The Effects of Length, Alignment and Functionalization. Carbon 2012, 50, 2083–2090. [Google Scholar] [CrossRef]

- Pop, E.; Mann, D.A.; Goodson, K.E.; Dai, H. Electrical and Thermal Transport in Metallic Single-Wall Carbon Nanotubes on Insulating Substrates. J. Appl. Phys. 2007, 101, 093710. [Google Scholar] [CrossRef]

- Kumar, G.S.; Prasad, G.; Pohl, R.O. Experimental Determinations of the Lorenz Number. J. Mater. Sci. 1993, 28, 4261–4272. [Google Scholar] [CrossRef]

- Zhang, Z.; Ouyang, Y.; Cheng, Y.; Chen, J.; Li, N.; Zhang, G. Size-Dependent Phononic Thermal Transport in Low-Dimensional Nanomaterials. Phys. Rep. 2020, 860, 1–26. [Google Scholar] [CrossRef]

- Saini, P.; Arora, M. Microwave Absorption and EMI Shielding Behavior of Nanocomposites Based on Intrinsically Conducting Polymers, Graphene and Carbon Nanotubes. New Polym. Spec. Appl. 2012, 3, 73–112. [Google Scholar]

| Sample Name | Filler (wt%) | Filler (vol%) |

|---|---|---|

| 100C | 0% | 0% |

| 50C50A | 50% AgNW | 6.25% AgNW |

| 25C75A | 75% AgNW | 9.1% AgNW |

| 15C85A | 85% AgNW | 10.19% AgNW |

| 50C50M | 50% MXene | 15.91% MXene |

| 25C75M | 75% MXene | 22.10% MXene |

| 15C85M | 85% MXene | 24.34% MXene |

| Sample | Electrical Conductivity (S·cm−1) | Thermal Conductivity (W·m−1·K−1) |

|---|---|---|

| 100C | 227 | 16.9 ± 3.1 |

| 50C50A | 679 | 128.0 ± 15.7 |

| 25C75A | 3294 | 11.7 ± 8.9 |

| 15C85A | 3610 | 27.9 ± 2.9 |

| 50C50M | 1189 | 42.4 ± 4.5 |

| 25C75M | 1285 | 15.6 ± 3.2 |

| 15C85M | 1717 | 49.7 ± 3.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurilich, M.; Park, J.G.; Degraff, J.; Wu, Q.; Liang, R. Improvement of Electrical and Thermal Properties of Carbon Nanotube Sheets by Adding Silver Nanowire and Mxene for an Electromagnetic-Interference-Shielding Property Study. Nanomaterials 2024, 14, 1587. https://doi.org/10.3390/nano14191587

Kurilich M, Park JG, Degraff J, Wu Q, Liang R. Improvement of Electrical and Thermal Properties of Carbon Nanotube Sheets by Adding Silver Nanowire and Mxene for an Electromagnetic-Interference-Shielding Property Study. Nanomaterials. 2024; 14(19):1587. https://doi.org/10.3390/nano14191587

Chicago/Turabian StyleKurilich, Matthew, Jin Gyu Park, Joshua Degraff, Qiang Wu, and Richard Liang. 2024. "Improvement of Electrical and Thermal Properties of Carbon Nanotube Sheets by Adding Silver Nanowire and Mxene for an Electromagnetic-Interference-Shielding Property Study" Nanomaterials 14, no. 19: 1587. https://doi.org/10.3390/nano14191587