The Influence of Etching Method on the Occurrence of Defect Levels in III-V and II-VI Materials

Abstract

1. Introduction

2. Etching Methods

2.1. Wet Chemical Etching

2.2. Dry Etching

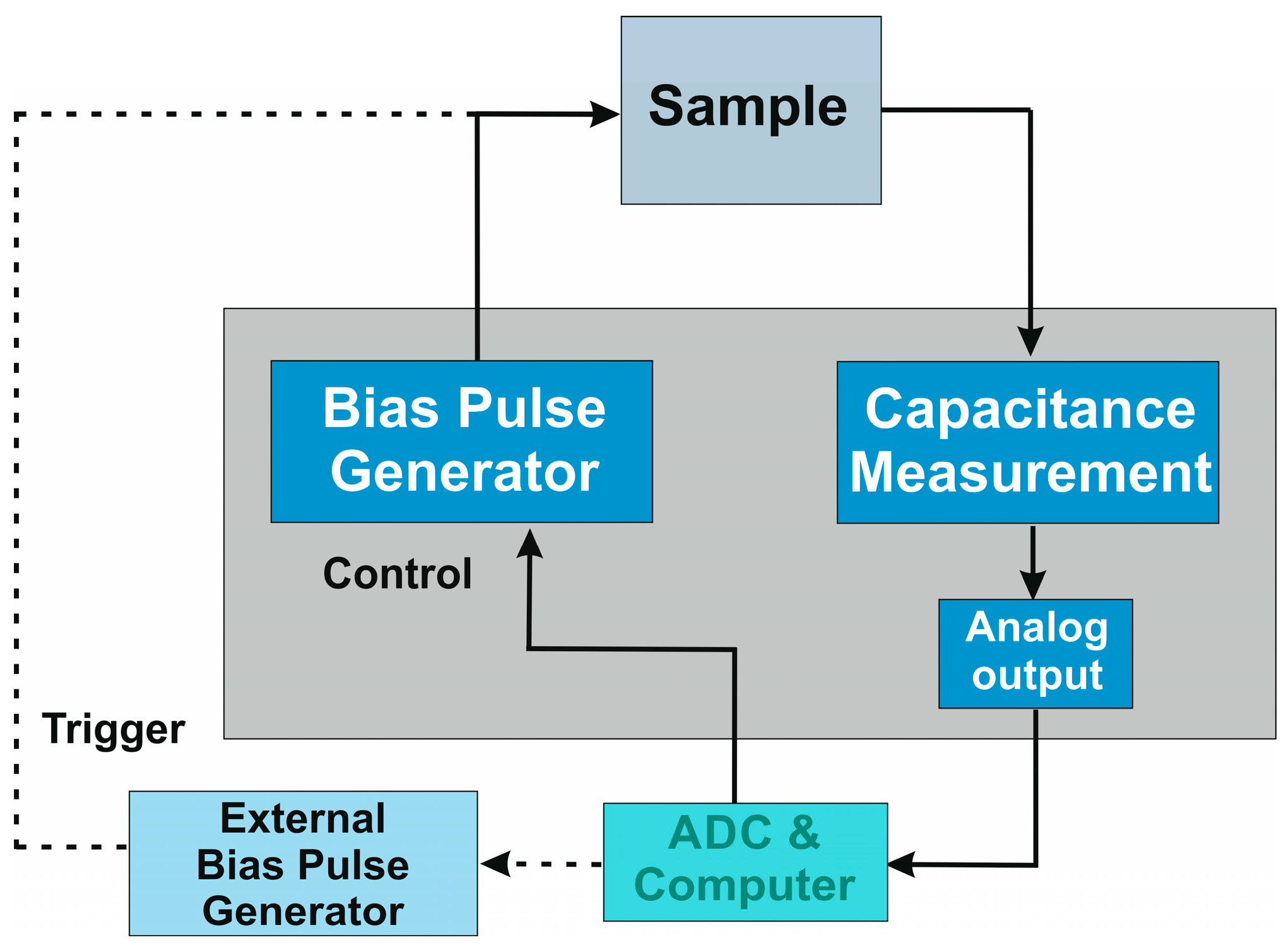

3. Measurement Technique

4. Experiment and Results

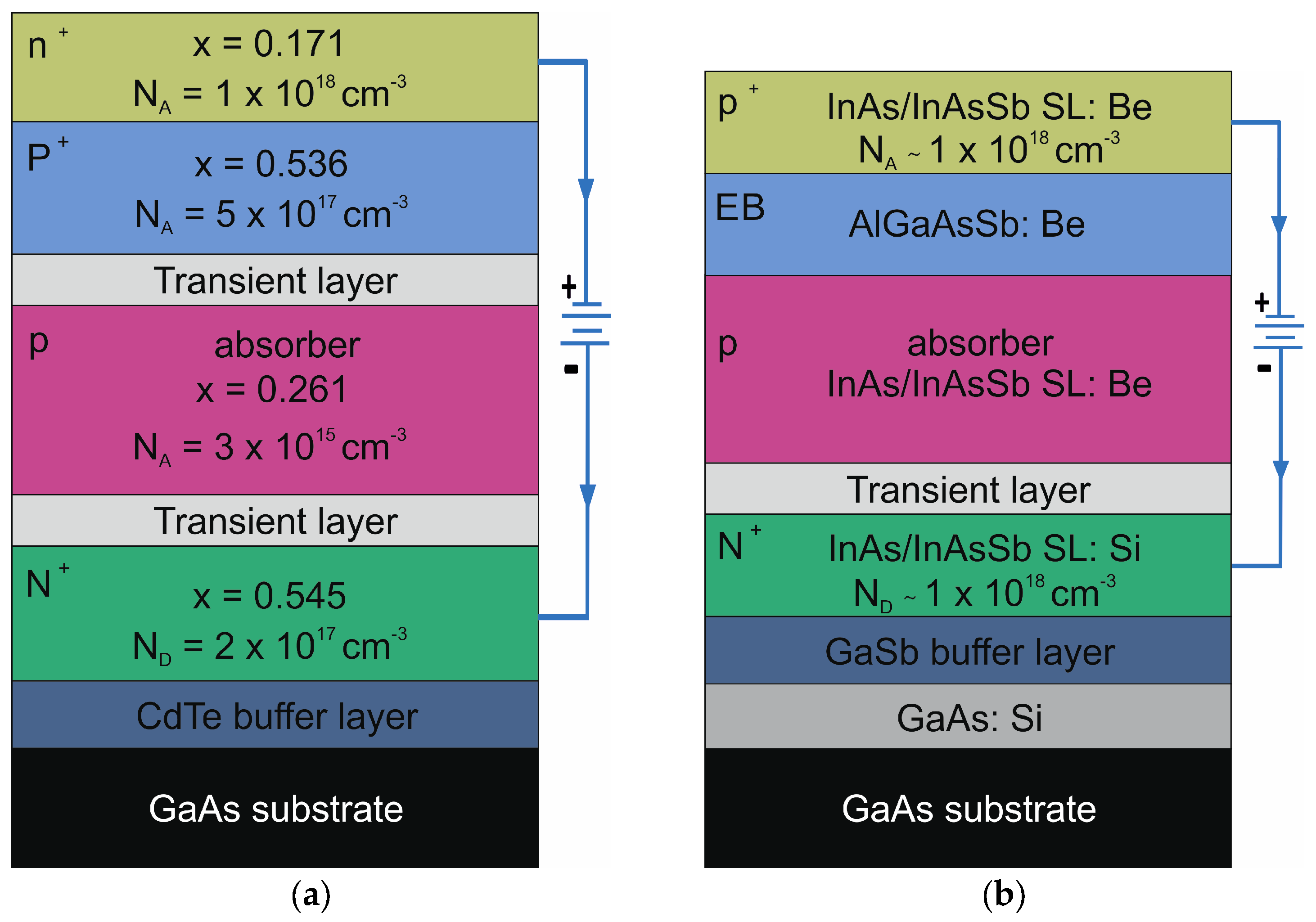

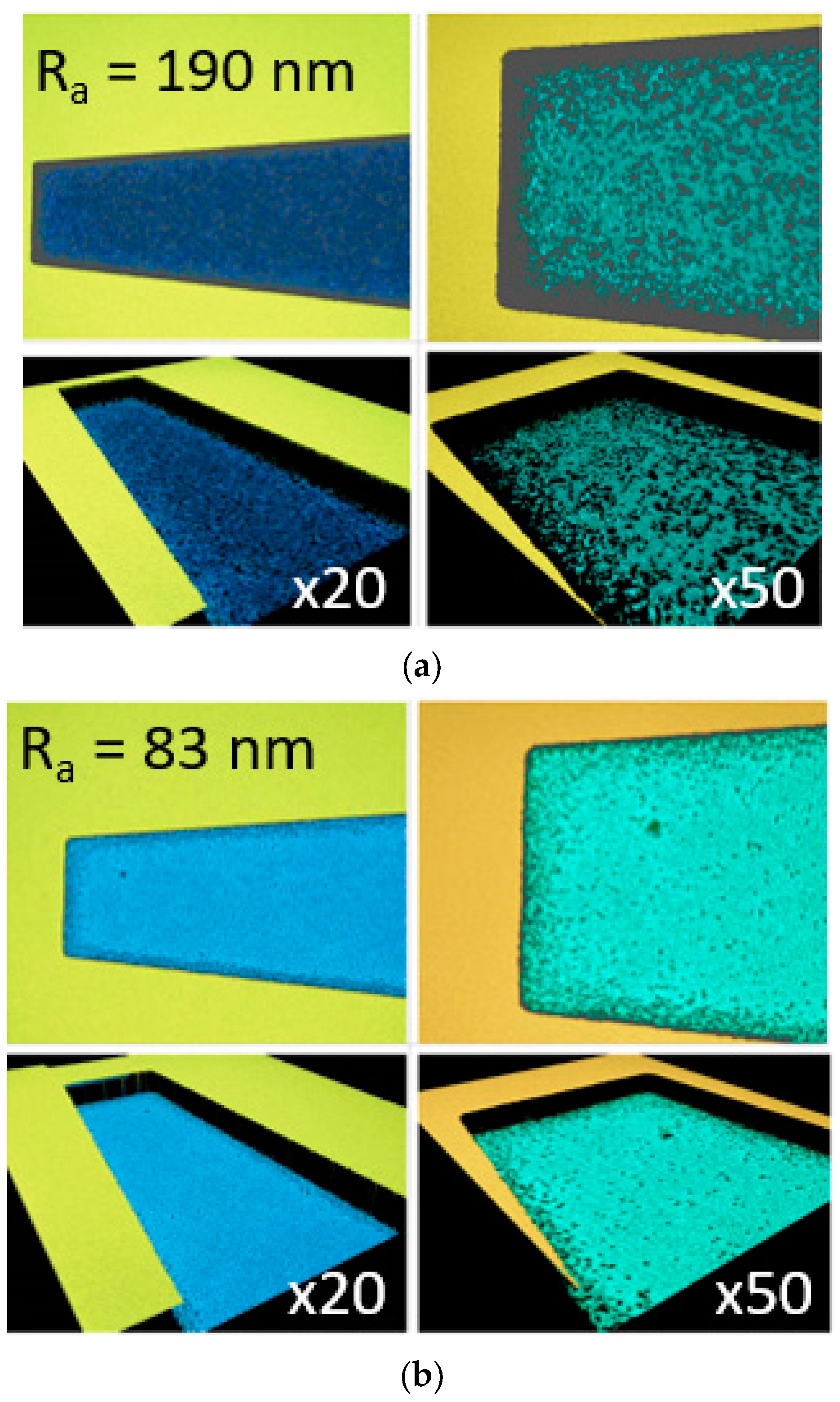

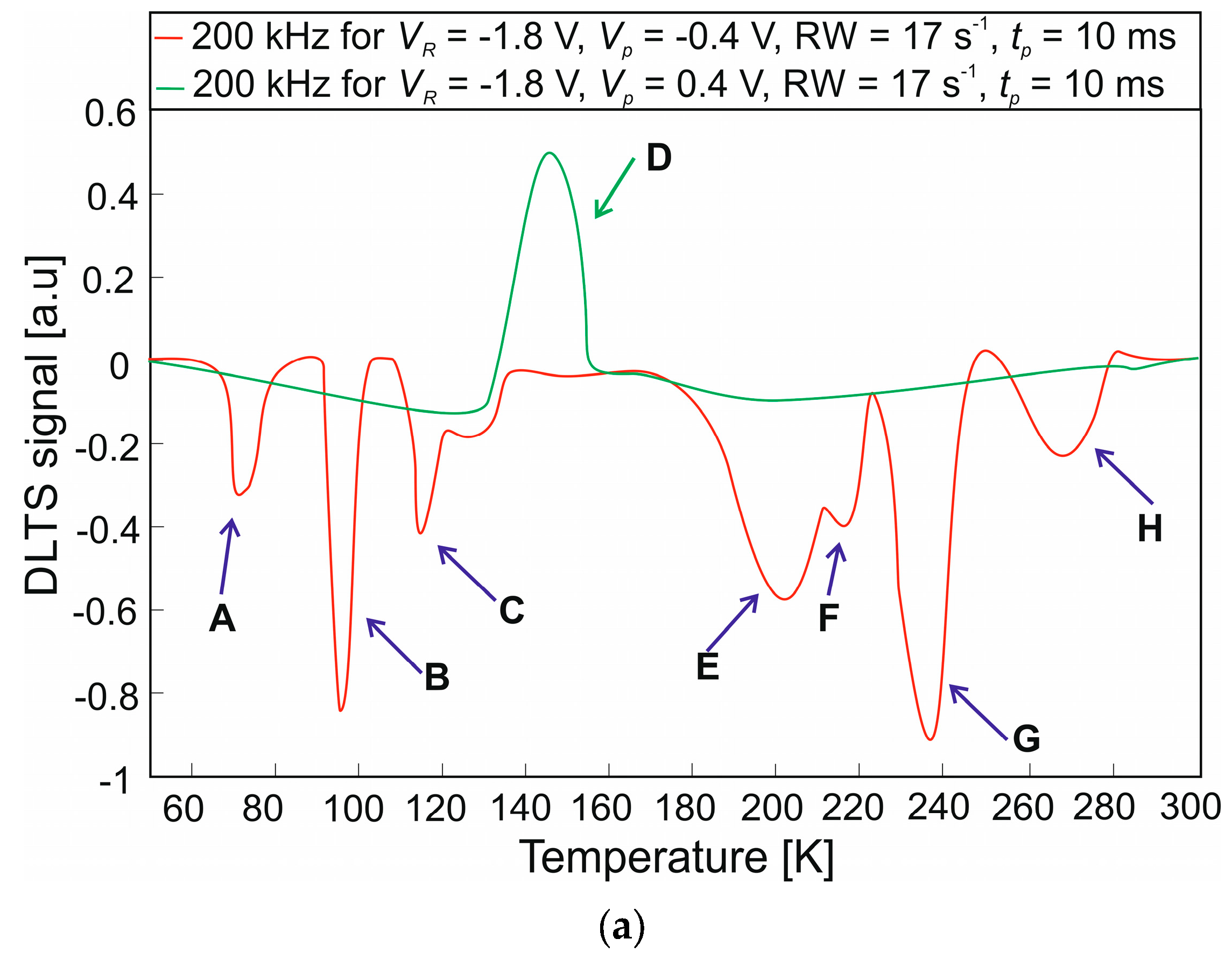

4.1. Wet and Mixed Etching for MCT Structure

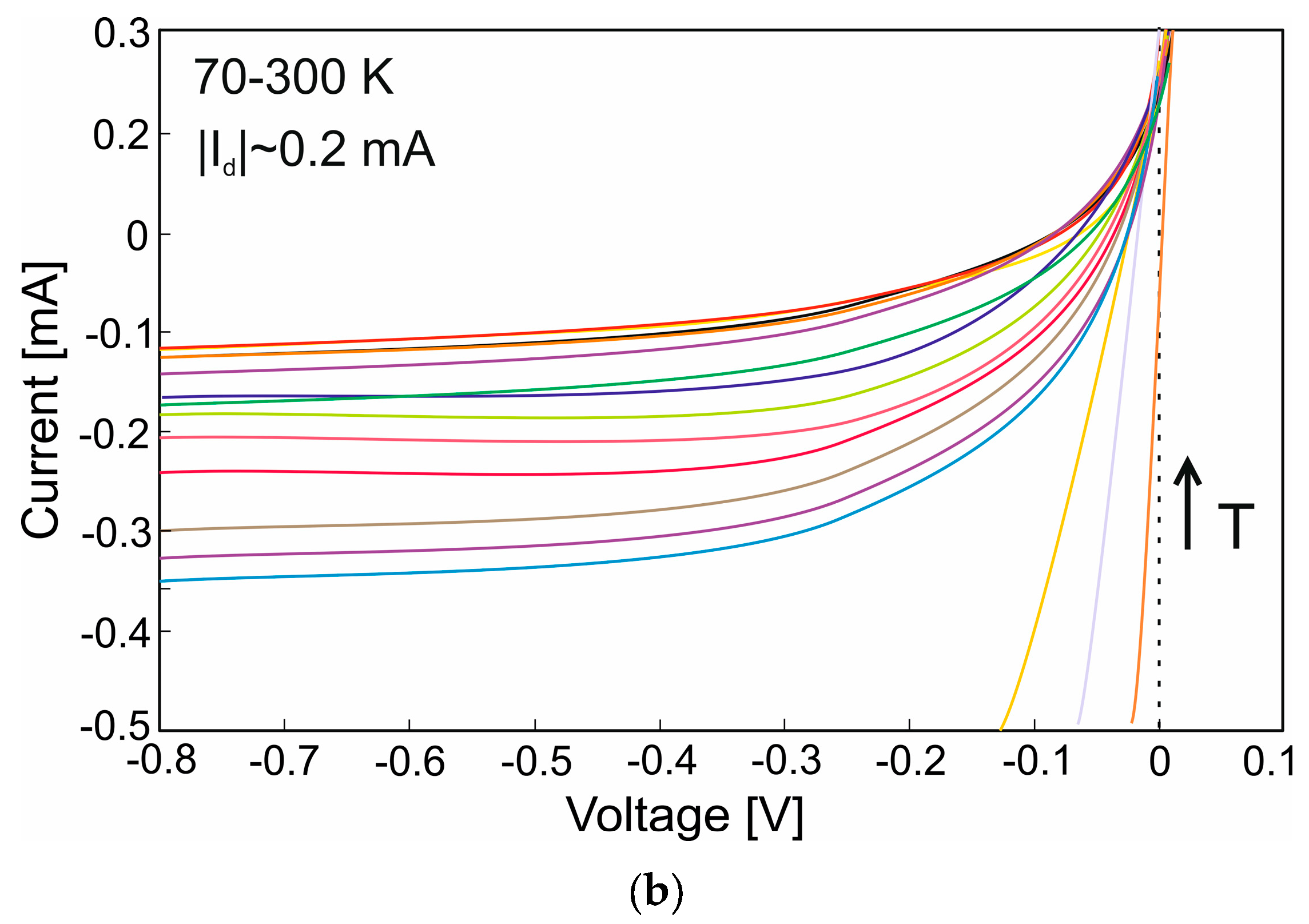

4.2. Wet and Dry Etching for InAs/InAsSb T2SL

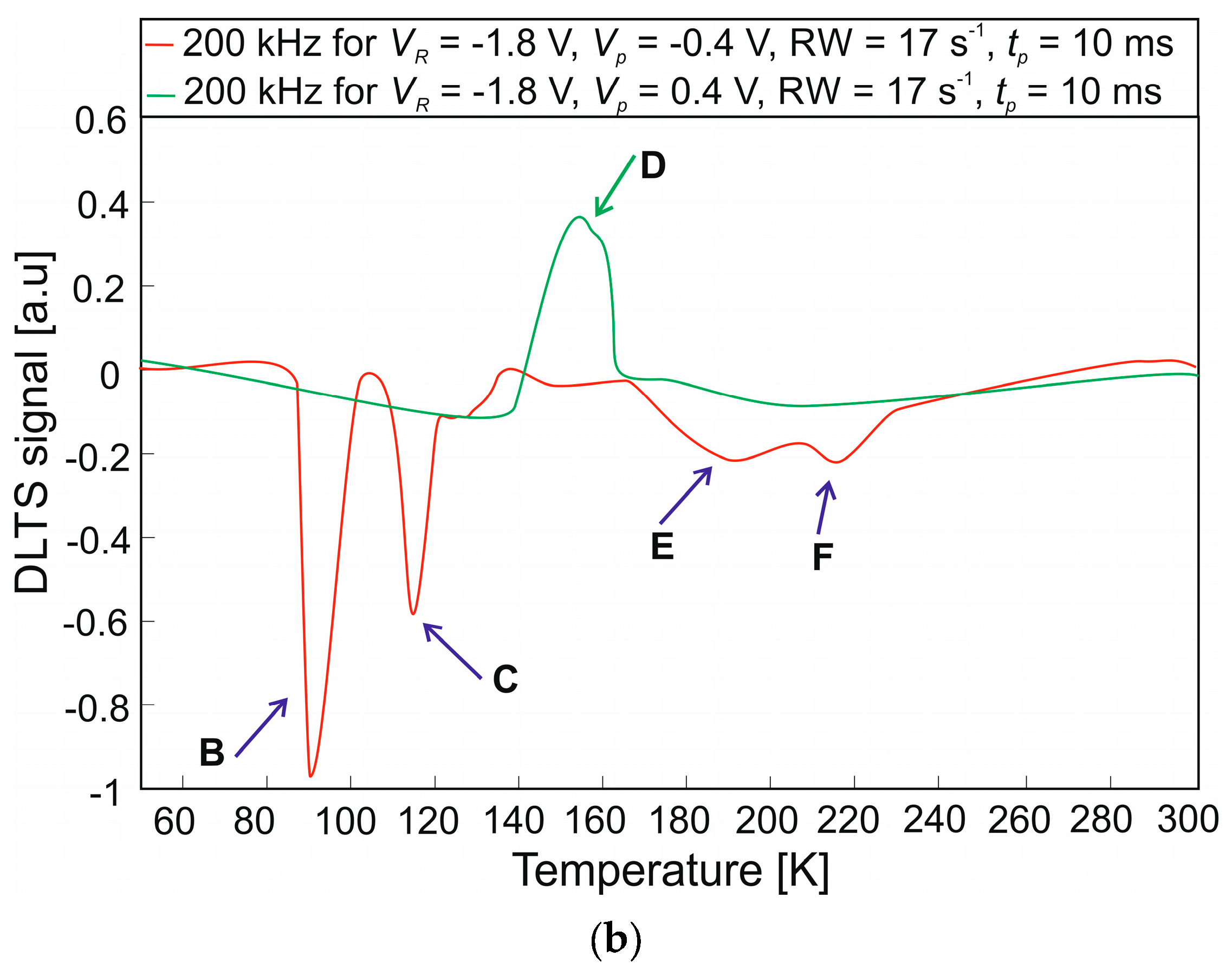

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Rogalski, A.; Bielecki, Z. Detection of Optical Signals; CRC Press: Boca Raton, FL, USA, 2022. [Google Scholar]

- Lax, M. Cascade Capture of Electrons in Solids. Phys. Rev. Apr. 1960, 119, 1502–1523. [Google Scholar] [CrossRef]

- Yang, B.; Xin, Y.; Rujirawat, S.; Browning, N.D.; Sivananthan, S. Molecular beam epitaxial growth and structural properties of HgCdTe layers on CdTe (211)B/Si (211) substrates. J. Appl. Phys. 2000, 88, 115–119. [Google Scholar] [CrossRef]

- Blood, P.; Orton, J.W. The Electrical Characterization of Semiconductors: Majority Carriers and Electron States; Academic Press: London, UK, 1992. [Google Scholar]

- Chang, Y.; Becker, C.R.; Grein, C.H.; Zhao, J.; Fulk, C.; Casselman, T.; Kiran, R.; Wang, X.J.; Robinson, E.; An, S.Y.; et al. Surface Morphology and Defect Formation Mechanisms for MCT (211)B Grown by Molecular Beam Epitaxy. J. Electron. Mater. 2008, 37, 1171–1183. [Google Scholar] [CrossRef]

- Gilmore, A.S.; Bangs, J.; Gerrish, A. Current Voltage Modeling of Current Limiting Mechanisms in HgCdTe Focal Plane Array Photodetectors. J. Electron. Mater. 2005, 34, 913–921. [Google Scholar] [CrossRef]

- Zhang, L.H.; Summers, C. A study of void defects in metalorganic molecular-beam epitaxy grown HgCdTe. J. Electron. Mater. 1998, 27, 634–639. [Google Scholar] [CrossRef]

- Krishnamurthy, S.; Gang, Y.U.Z. Green’s function-based defect identification in InAs-InAs1−xSbx strained layer superlattices. AIP Adv. 2017, 7, 065310. [Google Scholar] [CrossRef]

- Aytac, Y.; Olson, B.V.; Kim, J.K.; Shaner, E.A.; Hawkins, S.D.; Klem, J.F.; Flatt, M.E.; Boggess, T.F. Evidence of a Shockley-Read-Hall Defect State Independent of the Superlattice Band Edge Energies in InAs/InAsSb Type-II Superlattices. Phys. Rev. Appl. 2016, 5, 054016. [Google Scholar] [CrossRef]

- Lang, D.V. Deep-level transient spectroscopy: A new method to characterize traps in semiconductors. J. Appl. Phys. 1974, 45, 3023–3032. [Google Scholar] [CrossRef]

- Rubaldo, L.; Brunner, A.; Berthoz, J.; Pere-Laperne, N.; Kerlain, A.; Abraham, P.; Bauza, D.; Reimbold, G.; Gravrand, O. Defects Study in HgxCd1−xTe Infrared Photodetectors by Deep Level Transient Spectroscopy. J. Electron. Mater. 2014, 43, 3065–3069. [Google Scholar] [CrossRef]

- Vallone, M.; Mandurrino, M.; Goano, M.; Bertazzi, F.; Ghione, G.; Schirmacher, W.; Hanna, S.; Figgemeier, H. Numerical Modeling of SRH and Tunneling Mechanisms in High-Operating-Temperature MWIR HgCdTe Photodetectors. J. Electron. Mater. 2015, 44, 3056–3063. [Google Scholar] [CrossRef]

- Steenbergen, E.H.; Connelly, B.C.; Metcalfe, G.D.; Shen, H.; Wraback, M.; Lubyshev, D.; Qiu, Y.; Fastenau, J.M.; Liu, A.W.K.; Elhamri, S.; et al. Significantly improved minority carrier lifetime observed in a long-wavelength infrared III–V type-II superlattice comprised of InAs/InAsSb. Appl. Phys. Lett. 2011, 99, 25. [Google Scholar] [CrossRef]

- Boguski, J.; Kolwas, K.; Kubiszyn, Ł.; Michalczewski, K.; Piotrowski, J.; Wróbel, J.; Gorczyca, K.; Kębłowski, A.; Martyniuk, P. Study on the specific contact resistance of evaporated or electroplated golden contacts to n- and p-type InAs epitaxial layers grown by MBE. Mater. Sci. Semicond. Process. 2018, 81, 60–63. [Google Scholar] [CrossRef]

- Polla, D.L.; Jones, C.E. Deep level studies of Hg1−xCdxTe. I: Narrow-band-gap space-charge spectroscopy. J. Appl. Phys. 1981, 52, 5118–5131. [Google Scholar] [CrossRef]

- Michalczewski, K.; Jureńczyk, J.; Kubiszyn, Ł.; Martyniuk, P. The dependence of InAs/InAsSb Superlattice Detectors’ spectral response on molecular beam epitaxy growth temperature. Appl. Sci. 2022, 12, 1368. [Google Scholar] [CrossRef]

- Majkowycz, K.; Kopytko, M.; Murawski, K.; Martyniuk, P. The method for extracting defect levels in the MCT multilayer low-bandgap heterostructures. Opto-Electron. Rev. 2024, 32, 149182. [Google Scholar] [CrossRef]

- Majkowycz, K.; Murawski, K.; Kopytko, M. New insight into defect energy levels in HgCdTe. Infrared Phys. Technol. 2024, 137, 105126. [Google Scholar] [CrossRef]

| xCd | Peak | T [K] | Eg [meV] | Wet Etching ∆Ea [meV] | Et [meV] | Mixed Etching ∆Ea [meV] | Et [meV] |

|---|---|---|---|---|---|---|---|

| 0.261 | B | 100 | 185 | − 175 | 10 | − 171 | 14 |

| 0.261 | C | 120 | 190 | − 147 | 43 | − 152 | 38 |

| 0.261 | D | 150 | 198 | + 134 | 134 | + 154 | 154 |

| 0.261 | E | 200 | 211 | − 194 | 17 | − 202 | 9 |

| 0.536 | G | 240 | 618 | − 336 | 281 | - | - |

| 0.536 | H | 280 | 617 | − 351 | 266 | - | - |

| Peak | T [K] | Eg [meV] | ∆Ea [meV] | Et [meV] |

|---|---|---|---|---|

| Wet etching | ||||

| 1A | 110 | 240 | − 108 | 132 |

| 1B | 178 | 226 | + 220 | 220 |

| 1C | 230 | 215 | + 589 | 589 |

| 3A | 138 | 235 | − 86 | 149 |

| 3B | 170 | 228 | + 291 | 291 |

| Dry etching | ||||

| 2B | 182 | 226 | + 213 | 213 |

| 2C | 270 | 207 | + 603 | 603 |

| 4A | 130 | 238 | − 87 | 151 |

| 4B | 160 | 232 | + 320 | 320 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Majkowycz, K.; Murawski, K.; Kopytko, M.; Nowakowski-Szkudlarek, K.; Witkowska-Baran, M.; Martyniuk, P. The Influence of Etching Method on the Occurrence of Defect Levels in III-V and II-VI Materials. Nanomaterials 2024, 14, 1612. https://doi.org/10.3390/nano14191612

Majkowycz K, Murawski K, Kopytko M, Nowakowski-Szkudlarek K, Witkowska-Baran M, Martyniuk P. The Influence of Etching Method on the Occurrence of Defect Levels in III-V and II-VI Materials. Nanomaterials. 2024; 14(19):1612. https://doi.org/10.3390/nano14191612

Chicago/Turabian StyleMajkowycz, Kinga, Krzysztof Murawski, Małgorzata Kopytko, Krzesimir Nowakowski-Szkudlarek, Marta Witkowska-Baran, and Piotr Martyniuk. 2024. "The Influence of Etching Method on the Occurrence of Defect Levels in III-V and II-VI Materials" Nanomaterials 14, no. 19: 1612. https://doi.org/10.3390/nano14191612

APA StyleMajkowycz, K., Murawski, K., Kopytko, M., Nowakowski-Szkudlarek, K., Witkowska-Baran, M., & Martyniuk, P. (2024). The Influence of Etching Method on the Occurrence of Defect Levels in III-V and II-VI Materials. Nanomaterials, 14(19), 1612. https://doi.org/10.3390/nano14191612