The Optimization of Hole Injection Layer in Organic Light-Emitting Diodes

Abstract

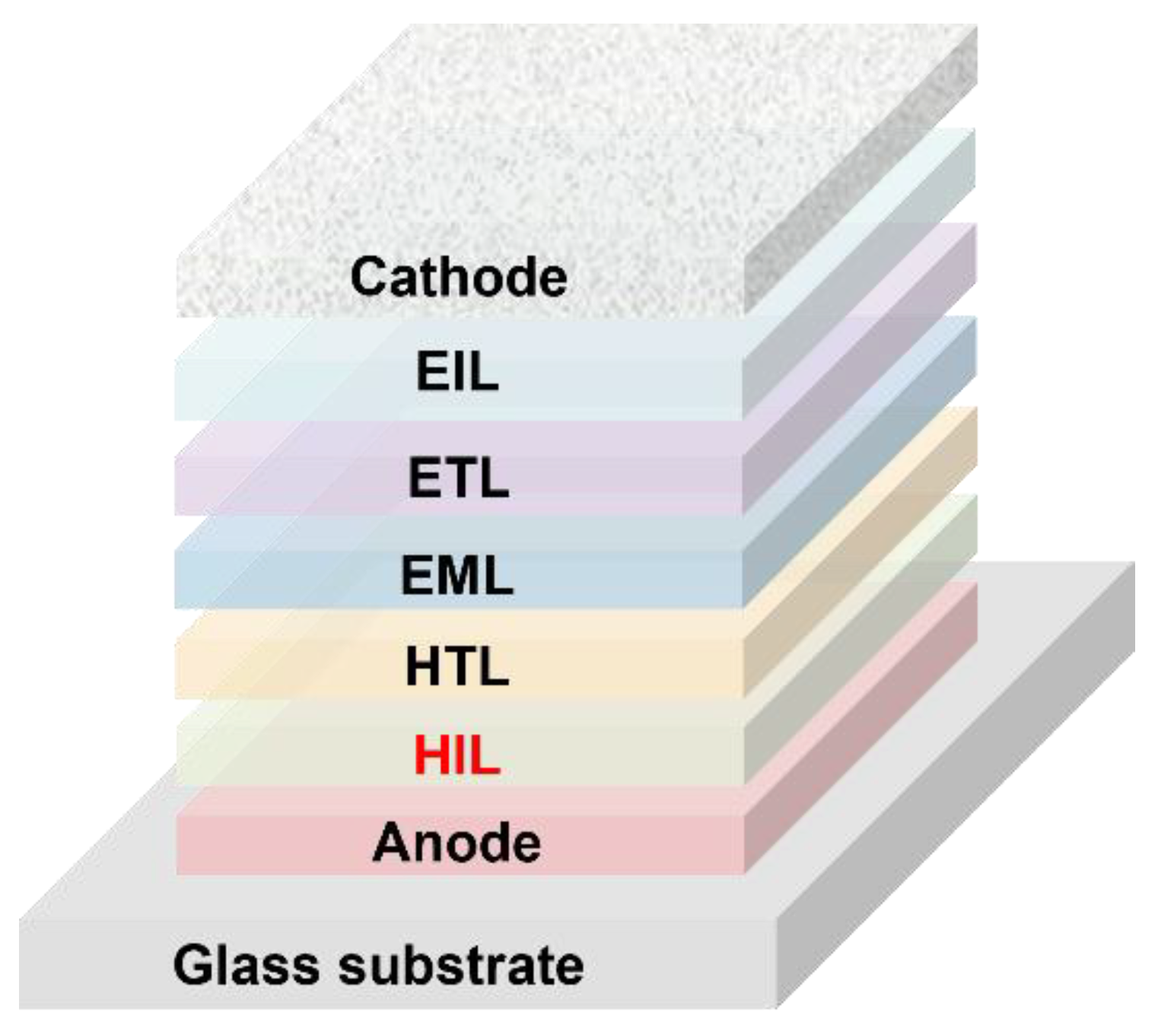

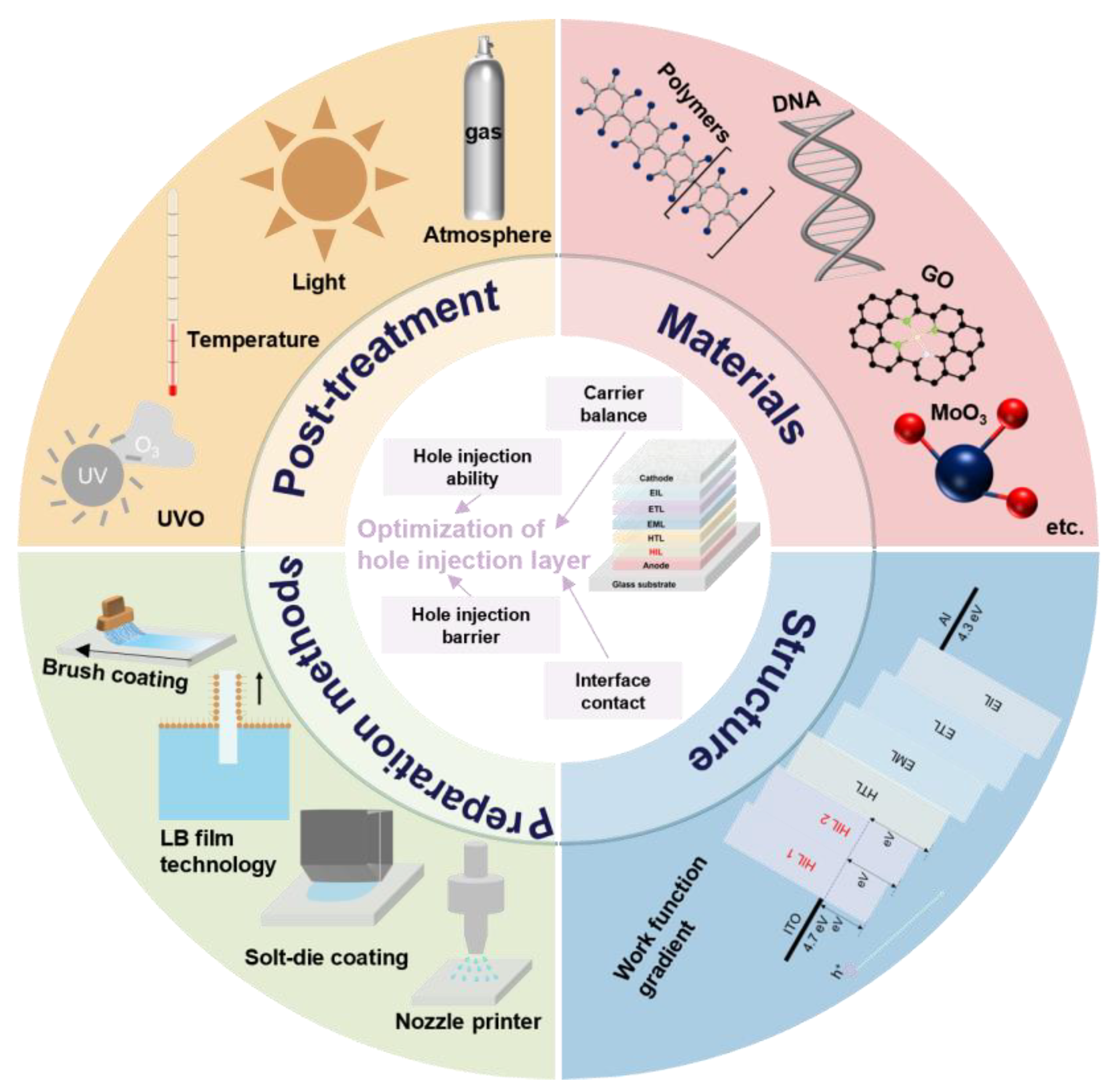

1. Introduction

2. Hole Injection Layer Materials

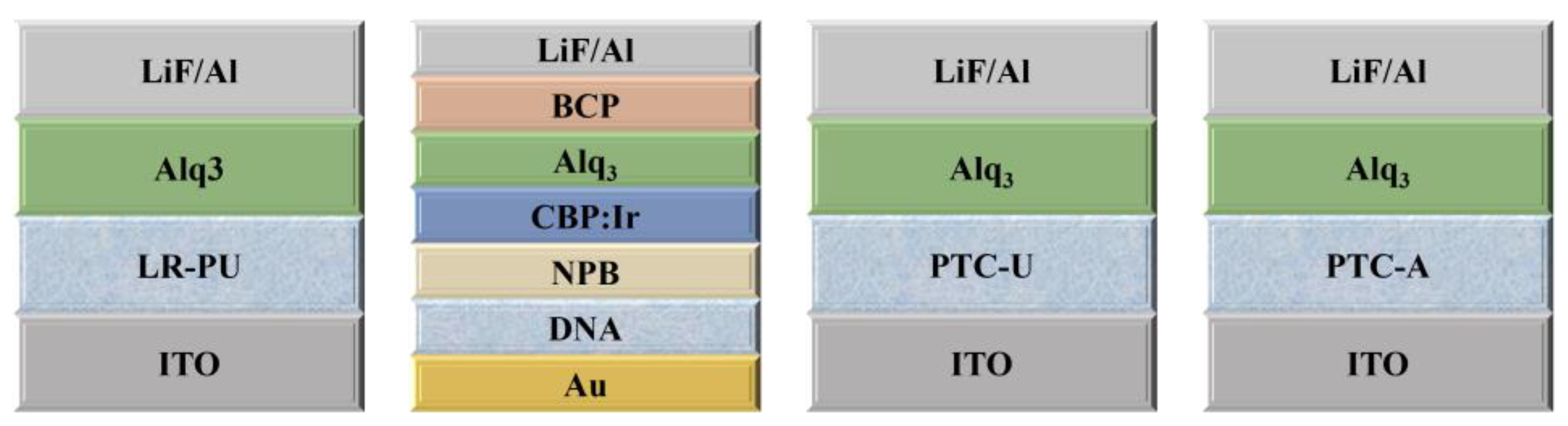

2.1. Organic Materials

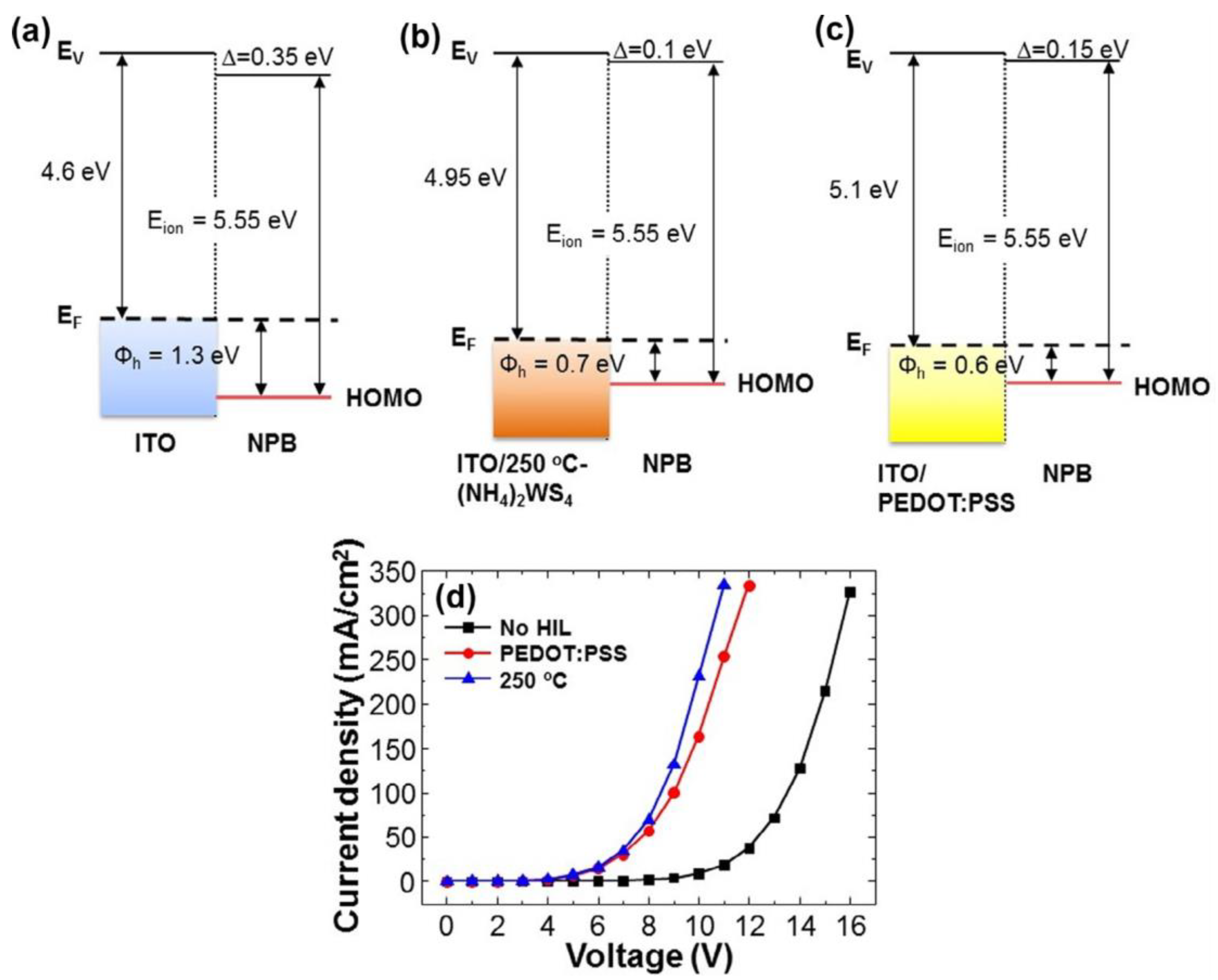

2.2. Inorganic Materials

3. Doped Hole Injection Layer

3.1. Polymer Materials

3.2. Transition Metal Oxide Materials

3.3. Metal and Metal Compound Materials

4. Composite Hole Injection Layer Structure

5. Preparation Methods

6. Different Treatment Methods

7. Conclusions and Outlook

Funding

Conflicts of Interest

References

- Shahnawaz, S.; Sudheendran Swayamprabha, S.; Nagar, M.R.; Yadav, R.A.K.; Gull, S.; Dubey, D.K.; Jou, J.-H. Hole-transporting materials for organic light-emitting diodes: An overview. J. Mater. Chem. C 2019, 7, 7144–7158. [Google Scholar] [CrossRef]

- Feng, Y.; Xu, J.; Shan, H.; Dong, L.; Sun, X.; Hu, Q.; Wang, Y.; Roy, V.A.L.; Xu, Z.-X. Organometal halide perovskite as hole injection enhancer in organic light-emitting diode. Org. Electron. 2017, 51, 257–263. [Google Scholar] [CrossRef]

- Jou, J.-H.; Sahoo, S.; Dubey, D.K.; Yadav, R.A.K.; Swayamprabha, S.S.; Chavhan, S.D. Molecule-based monochromatic and polychromatic OLEDs with wet-process feasibility. J. Mater. Chem. C 2018, 6, 11492–11518. [Google Scholar] [CrossRef]

- Zhao, B.; Miao, Y.; Wang, Z.; Wang, K.; Wang, H.; Hao, Y.; Xu, B.; Li, W. High efficiency and low roll-off green OLEDs with simple structure by utilizing thermally activated delayed fluorescence material as the universal host. Nanophotonics 2017, 6, 1133–1140. [Google Scholar] [CrossRef]

- McEwan, J.A.; Clulow, A.J.; Nelson, A.; Wang, R.; Burn, P.L.; Gentle, I.R. Influence of Dopant Concentration and Steric Bulk on Interlayer Diffusion in OLEDs. Adv. Mater. Interfaces 2018, 5, 1700872. [Google Scholar] [CrossRef]

- Feng, C.; Zheng, X.; Xu, R.; Zhou, Y.; Hu, H.; Guo, T.; Ding, J.; Ying, L.; Li, F. Highly efficient inkjet printed flexible organic light-emitting diodes with hybrid hole injection layer. Org. Electron. 2020, 85, 105822. [Google Scholar] [CrossRef]

- Li, B.; Gan, L.; Cai, X.; Li, X.-L.; Wang, Z.; Gao, K.; Chen, D.; Cao, Y.; Su, S.-J. An Effective Strategy toward High-Efficiency Fluorescent OLEDs by Radiative Coupling of Spatially Separated Electron-Hole Pairs. Adv. Mater. Interfaces 2018, 5, 1800025. [Google Scholar] [CrossRef]

- Hu, Y.; Song, L.; Zhang, S.; Lv, Y.; Lin, J.; Guo, X.; Liu, X. Improving the Efficiency of Multilayer Organic Light-Emitting Transistors by Exploring the Hole Blocking Effect. Adv. Mater. Interfaces 2020, 7, 2000657. [Google Scholar] [CrossRef]

- Wang, M.; Zhu, W.; Yin, Z.; Huang, L.; Li, J. Synergistic effects of Li-doped NiO film prepared by low-temperature combustion as hole-injection layer for high performance OLED devices. Org. Electron. 2020, 85, 105823. [Google Scholar] [CrossRef]

- Benor, A.; Takizawa, S.; Pérez-Bolívar, C.; Anzenbacher, P. Efficiency improvement of fluorescent OLEDs by tuning the working function of PEDOT:PSS using UV–ozone exposure. Org. Electron. 2010, 11, 938–945. [Google Scholar] [CrossRef]

- Salsberg, E.; Aziz, H. Degradation of PEDOT:PSS hole injection layers by electrons in organic light emitting devices. Org. Electron. 2019, 69, 313–319. [Google Scholar] [CrossRef]

- Wu, S.; Han, S.; Zheng, Y.; Zheng, H.; Liu, N.; Wang, L.; Cao, Y.; Wang, J. pH-neutral PEDOT:PSS as hole injection layer in polymer light emitting diodes. Org. Electron. 2011, 12, 504–508. [Google Scholar] [CrossRef]

- Li, M.; Wang, J.; Zhang, Y.; Dai, Y.; Chen, L.; Zheng, C.; Lv, W.; Chen, R.; Huang, W. Thermal imprinting and vapor annealing of interfacial layers for high-performance organic light-emitting diodes. J. Mater. Chem. C 2019, 7, 10281–10288. [Google Scholar] [CrossRef]

- Chen, S.; Jiang, X.; So, F. Hole injection polymer effect on degradation of organic light-emitting diodes. Org. Electron. 2013, 14, 2518–2522. [Google Scholar] [CrossRef]

- Lee, S.; Ha, H.; Lee, J.Y.; Shon, H.K.; Lee, T.G.; Suh, M.C.; Park, Y. Degradation Mechanism of Solution-Processed Organic Light-Emitting Diodes: Sputter Depth-Profile Study. Appl. Surf. Sci. 2021, 564, 150402. [Google Scholar] [CrossRef]

- Tyagi, P.; Dalai, M.K.; Suman, C.K.; Tuli, S.; Srivastava, R. Study of 2,3,5,6-tetrafluoro-7,70,8,80-tetracyano quinodimethane diffusion in organic light emitting diodes using secondary ion mass spectroscopy. RSC Adv. 2013, 3, 24553–24559. [Google Scholar] [CrossRef]

- Ma, Y.-Y.; Hua, X.-C.; Zhai, T.-S.; Li, Y.-H.; Lu, X.; Duhm, S.; Fung, M.-K. Doped copper phthalocyanine via an aqueous solution process for high-performance organic light-emitting diodes. Org. Electron. 2019, 68, 236–241. [Google Scholar] [CrossRef]

- Huang, X.-L.; Zou, J.-H.; Liu, J.-Z.; Jin, G.; Li, J.-B.; Yao, S.-L.; Peng, J.-B.; Cao, Y.; Zhu, X.-H. A high T g small-molecule arylamine derivative as a doped hole-injection/transport material for stable organic light-emitting diodes. Org. Electron. 2018, 58, 139–144. [Google Scholar] [CrossRef]

- Gomez, E.F.; Steckl, A.J. Improved Performance of OLEDs on Cellulose/Epoxy Substrate Using Adenine as a Hole Injection Layer. ACS Photonics 2015, 2, 439–445. [Google Scholar] [CrossRef]

- Cheng, C.-C.; Chu, Y.-L.; Huang, P.-H.; Yen, Y.-C.; Chu, C.-W.; Yang, A.C.-M.; Ko, F.-H.; Chen, J.-K.; Chang, F.-C. Bioinspired hole-conducting polymers for application in organic light-emitting diodes. J. Mater. Chem. 2012, 22, 18127. [Google Scholar] [CrossRef]

- Cheng, C.-C.; Chu, Y.-L.; Chang, F.-C.; Lee, D.-J.; Yen, Y.-C.; Chen, J.-K.; Chu, C.-W.; Xin, Z. New bioinspired hole injection/transport materials for highly efficient solution-processed phosphorescent organic light-emitting diodes. Nano Energy 2015, 13, 1–8. [Google Scholar] [CrossRef]

- Shih, H.-K.; Chen, Y.-H.; Chu, Y.-L.; Cheng, C.-C.; Chang, F.-C.; Zhu, C.-Y.; Kuo, S.-W. Photo-Crosslinking of Pendent Uracil Units Provides Supramolecular Hole Injection/Transport Conducting Polymers for Highly Efficient Light-Emitting Diodes. Polymers 2015, 7, 804–818. [Google Scholar] [CrossRef]

- Lee, H.; Kwon, Y.; Lee, C. Improved performances in organic and polymer light-emitting diodes using solution-processed vanadium pentoxide as a hole injection layer: OLEDs and PLEDs with solution-processed V2O5. J. Soc. Inf. Disp. 2012, 20, 640–645. [Google Scholar] [CrossRef]

- Meyer, J.; Hamwi, S.; Kröger, M.; Kowalsky, W.; Riedl, T.; Kahn, A. Transition Metal Oxides for Organic Electronics: Energetics, Device Physics and Applications. Adv. Mater. 2012, 24, 5408–5427. [Google Scholar] [CrossRef] [PubMed]

- Tokito, S.; Noda, K.; Taga, Y. Strongly directed single mode emission from organic electroluminescent diode with a microcavity. Appl. Phys. Lett. 1996, 68, 2633–2635. [Google Scholar] [CrossRef]

- Wu, J.; Hou, J.; Cheng, Y.; Xie, Z.; Wang, L. Efficient top-emitting organic light-emitting diodes with a V2O5 modified silver anode. Semicond. Sci. Tech. 2007, 22, 824–826. [Google Scholar] [CrossRef]

- Li, J.; Yahiro, M.; Ishida, K.; Yamada, H.; Matsushige, K. Enhanced performance of organic light emitting device by insertion of conducting/insulating WO3 anodic buffer layer. Synth. Met. 2005, 151, 141–146. [Google Scholar] [CrossRef]

- Meyer, J.; Hamwi, S.; Bülow, T.; Johannes, H.-H.; Riedl, T.; Kowalsky, W. Highly efficient simplified organic light emitting diodes. Appl. Phys. Lett. 2007, 91, 113506. [Google Scholar] [CrossRef]

- Tokito, S.; Noda, K.; Taga, Y. Metal oxides as a hole-injecting layer for an organic electroluminescent device. J. Phys. D Appl. Phys. 1996, 29, 2750–2753. [Google Scholar] [CrossRef]

- Matsushima, T.; Kinoshita, Y.; Murata, H. Formation of Ohmic hole injection by inserting an ultrathin layer of molybdenum trioxide between indium tin oxide and organic hole-transporting layers. Appl. Phys. Lett. 2007, 91, 253504. [Google Scholar] [CrossRef]

- You, H.; Dai, Y.; Zhang, Z.; Ma, D. Improved performances of organic light-emitting diodes with metal oxide as anode buffer. J. Appl. Phys. 2007, 101, 026105. [Google Scholar] [CrossRef]

- Liu, R.; Xu, C.; Biswas, R.; Shinar, J.; Shinar, R. MoO3 as combined hole injection layer and tapered spacer in combinatorial multicolor microcavity organic light emitting diodes. Appl. Phys. Lett. 2011, 99, 093305. [Google Scholar] [CrossRef]

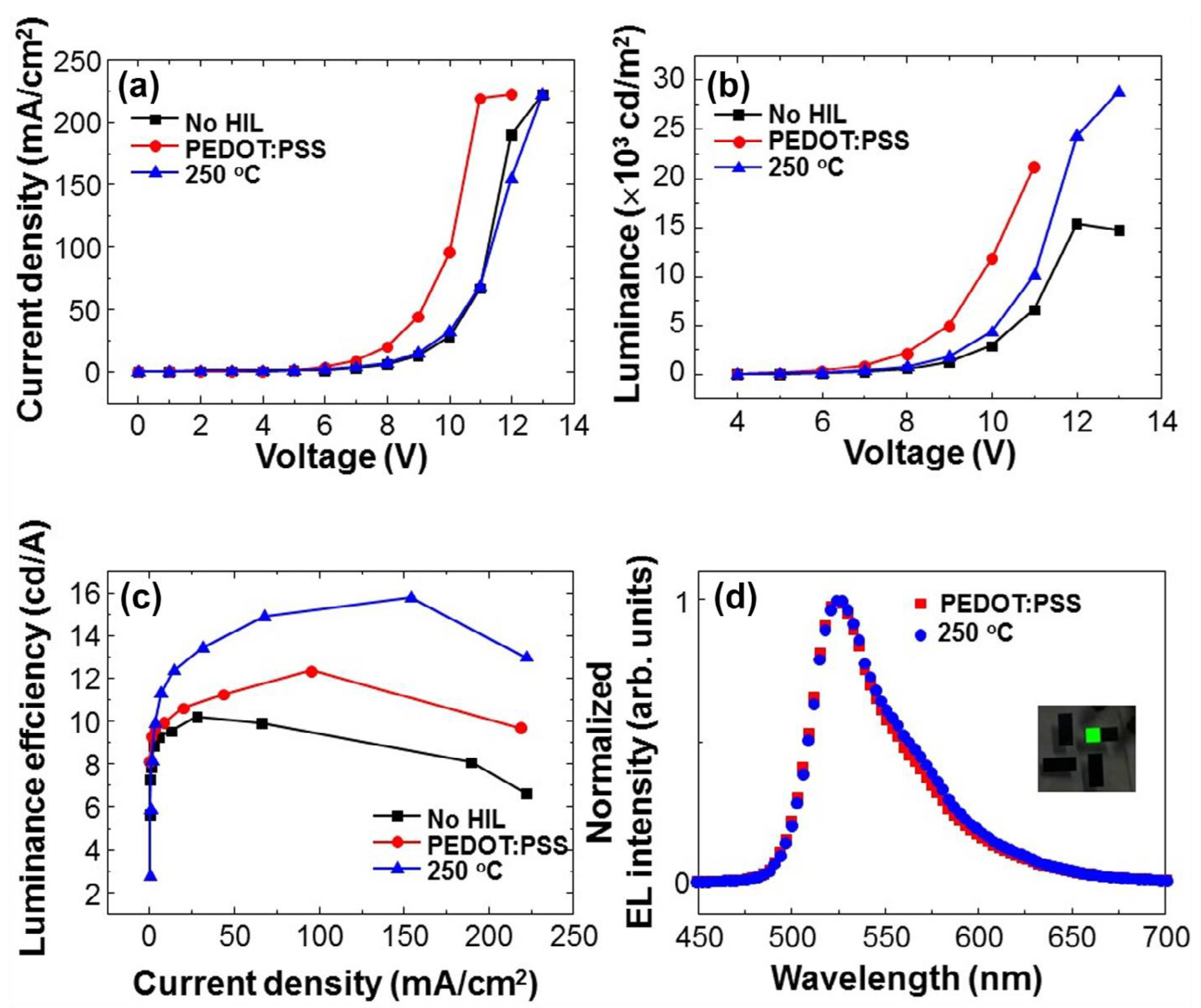

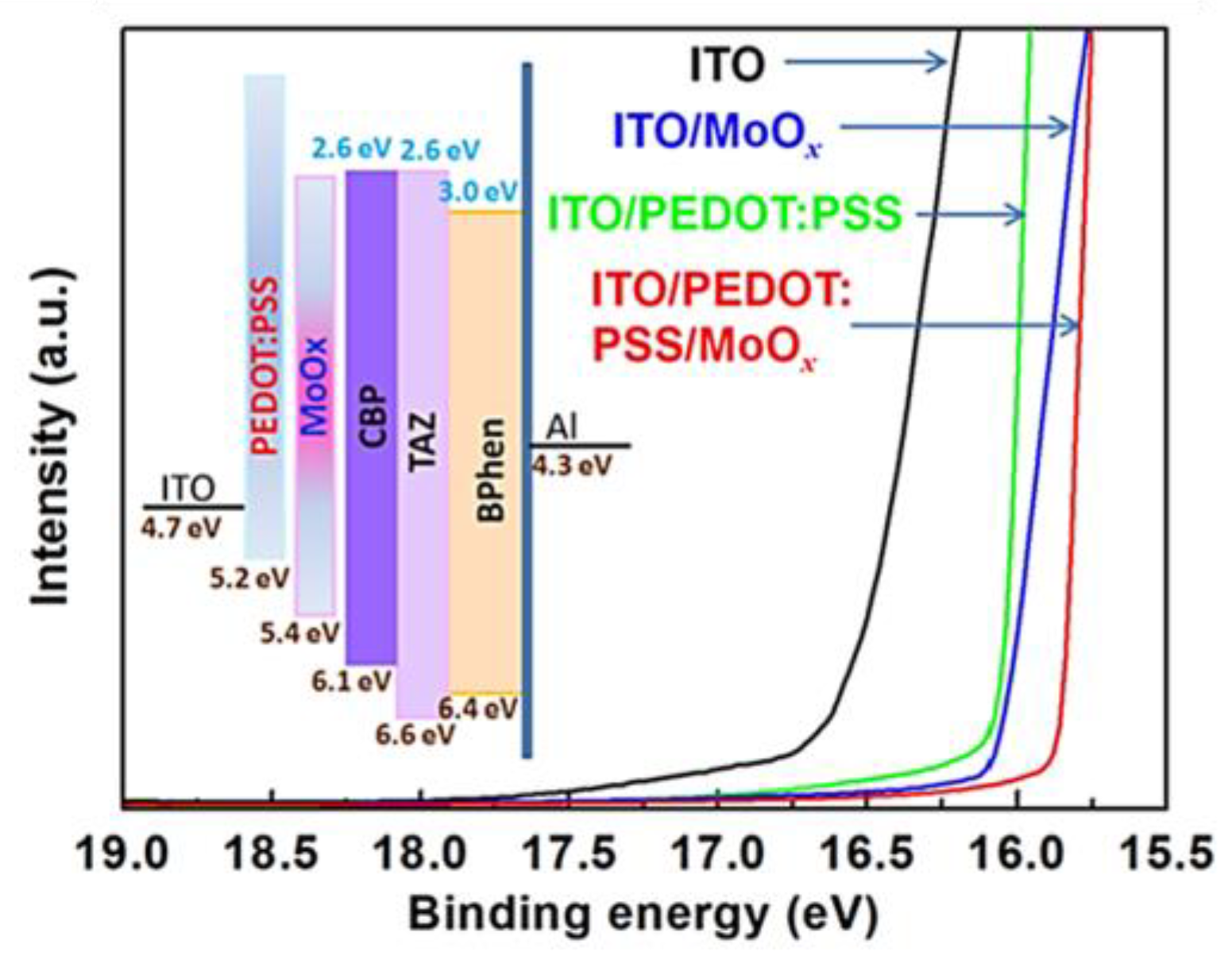

- Zhang, X.; You, F.; Zheng, Q.; Zhang, Z.; Cai, P.; Xue, X.; Xiong, J.; Zhang, J. Solution-processed MoOx hole injection layer towards efficient organic light-emitting diode. Org. Electron. 2016, 39, 43–49. [Google Scholar] [CrossRef]

- Chiu, T.-L.; Chuang, Y.-T. Spectral observations of hole injection with transition metal oxides for an efficient organic light-emitting diode. J. Phys. D Appl. Phys. 2015, 48, 075101. [Google Scholar] [CrossRef]

- Park, M.; Nguyen, T.P.; Choi, K.S.; Park, J.; Ozturk, A.; Kim, S.Y. MoS2-nanosheet/graphene-oxide composite hole injection layer in organic light-emitting diodes. Electron. Mater. Lett. 2017, 13, 344–350. [Google Scholar] [CrossRef]

- Kim, S.Y. Bottom-Up Synthesis of MeSx Nanodots for Optoelectronic Device Applications. Adv. Opt. Mater. 2016, 4, 1796–1804. [Google Scholar]

- Liu, L.; Li, W.; Zeng, L.; Wang, Y.; Wang, H.; Miao, Y.; Wang, L.; Lu, Z.; Zhang, X. Isopropanol solvent-treated MoS2 nanosheets from liquid phase exfoliation and their applications to solution-processed anode buffer layer of organic light-emitting diode. J. Mater. Sci. Mater. Electron. 2022, 33, 12137–12146. [Google Scholar] [CrossRef]

- Le, Q.V. (NH4)2WS4 precursor as a hole-injection layer in organic optoelectronic devices. Chem. Eng. J. 2016, 284, 285–293. [Google Scholar] [CrossRef]

- Ohisa, S.; Kagami, S.; Pu, Y.-J.; Chiba, T.; Kido, J. A Solution-Processed Heteropoly Acid Containing MoO3 Units as a Hole-Injection Material for Highly Stable Organic Light-Emitting Devices. ACS Appl. Mater. Interfaces 2016, 8, 20946–20954. [Google Scholar] [CrossRef]

- Dong, D.; Lian, L.; Wang, H.; He, G. An efficient solution-processed hole injection layer with phosphomolybdic acid in quantum dot light-emitting diodes. Org. Electron. 2018, 62, 320–326. [Google Scholar] [CrossRef]

- Miao, Y.; Yin, M.; Wang, C.; Wei, X.; Wang, Z.; Zhao, M.; Wang, Y.; Jia, Z.; Wang, H.; Zhu, F. Small-size graphene oxide (GO) as a hole injection layer for high-performance green phosphorescent organic light-emitting diodes. J. Mater. Chem. C 2021, 9, 12408–12419. [Google Scholar] [CrossRef]

- Hung, L.S.; Liao, L.S.; Lee, C.S.; Lee, S.T. Sputter deposition of cathodes in organic light emitting diodes. J. Appl. Phys. 1999, 86, 4607–4612. [Google Scholar] [CrossRef]

- Li, Y.; Tan, L.-W.; Hao, X.-T.; Ong, K.S.; Zhu, F.; Hung, L.-S. Flexible top-emitting electroluminescent devices on polyethylene terephthalate substrates. Appl. Phys. Lett. 2005, 86, 153508. [Google Scholar] [CrossRef]

- Yu, S.-Y.; Huang, D.-C.; Chen, Y.-L.; Wu, K.-Y.; Tao, Y.-T. Approaching Charge Balance in Organic Light-Emitting Diodes by Tuning Charge Injection Barriers with Mixed Monolayers. Langmuir 2012, 28, 424–430. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.-I.; Lin, C.-T.; Chen, Y.-H.; Chen, M.-H.; Lu, Y.-J.; Wu, C.-C. Electronic structures and electron-injection mechanisms of cesium-carbonate-incorporated cathode structures for organic light-emitting devices. Appl. Phys. Lett. 2006, 88, 152104. [Google Scholar] [CrossRef]

- Lee, H.; Cho, S.W.; Han, K.; Jeon, P.E.; Whang, C.-N.; Jeong, K.; Cho, K.; Yi, Y. The origin of the hole injection improvements at indium tin oxide/molybdenum trioxide/N,N′-bis(1-naphthyl)-N,N′-diphenyl-1,1′-biphenyl- 4,4′-diamine interfaces. Appl. Phys. Lett. 2008, 93, 043308. [Google Scholar] [CrossRef]

- Park, Y.; Kim, B.; Lee, C.; Hyun, A.; Jang, S.; Lee, J.-H.; Gal, Y.-S.; Kim, T.H.; Kim, K.-S.; Park, J. Highly Efficient New Hole Injection Materials for OLEDs Based on Dimeric Phenothiazine and Phenoxazine Derivatives. J. Phys. Chem. C 2011, 115, 4843–4850. [Google Scholar] [CrossRef]

- Xu, L.; Li, Y.; Chen, L.; Wang, J.; Zheng, C.; Qi, Y.; Chen, R.; Huang, W. Annealing Solution-Processed CuSCN Hole Injection Layer for Blue Phosphorescent Organic Light-Emitting Diodes with Extremely Low Efficiency Roll-Off. ACS Sustain. Chem. Eng. 2018, 6, 17178–17183. [Google Scholar] [CrossRef]

- Chavhan, S.D.; Ou, T.H.; Jiang, M.R.; Wang, C.W.; Jou, J.H. Enabling High-Efficiency Organic Light-Emitting Diode with Trifunctional Solution-Processable Copper(I) Thiocyanate. J. Phys. Chem. C. Nanomater. Interfaces 2018, 122, 18836–18840. [Google Scholar] [CrossRef]

- Chen, Y.; Wu, X.; Liu, Y.; Chen, L.; Li, H.; Wang, W.; Wang, S.; Tian, H.; Tong, H.; Wang, L. Water-soluble pH neutral triazatruxene-based small molecules as hole injection materials for solution-processable organic light-emitting diodes. J. Mater. Chem. C 2019, 7, 7900–7905. [Google Scholar] [CrossRef]

- Özdemir, A.D.; Kaiser, S.; Neumann, T.; Symalla, F.; Wenzel, W. Systematic kMC Study of Doped Hole Injection Layers in Organic Electronics. Front. Chem. 2022, 9, 809415. [Google Scholar] [CrossRef]

- Kim, J.-S.; Friend, R.H.; Grizzi, I.; Burroughes, J.H. Spin-cast thin semiconducting polymer interlayer for improving device efficiency of polymer light-emitting diodes. Appl. Phys. Lett. 2005, 87, 023506. [Google Scholar] [CrossRef]

- Yan, H.; Scott, B.J.; Huang, Q.; Marks, T.J. Enhanced Polymer Light-Emitting Diode Performance Using a Crosslinked-Network Electron-Blocking Interlayer. Adv. Mater. 2004, 16, 1948–1953. [Google Scholar] [CrossRef]

- Zhang, Y.; Aslan, K.; Previte, M.J.R.; Geddes, C.D. Metal-enhanced fluorescence from copper substrates. Appl. Phys. Lett. 2007, 90, 173116. [Google Scholar] [CrossRef]

- Jang, K.-S.; Kim, D.O.; Lee, J.-H.; Hong, S.-C.; Lee, T.-W.; Lee, Y.; Nam, J.-D. Synchronous vapor-phase polymerization of poly(3,4-ethylenedioxythiophene) and poly(3-hexylthiophene) copolymer systems for tunable optoelectronic properties. Org. Electron. 2010, 11, 1668–1675. [Google Scholar] [CrossRef]

- Lee, C.; Kang, D.J.; Kang, H.; Kim, T.; Park, J.; Lee, J.; Yoo, S.; Kim, B.J. Simultaneously Enhancing Light Extraction and Device Stability of Organic Light-Emitting Diodes using a Corrugated Polymer Nanosphere Templated PEDOT:PSS Layer. Adv. Energy Mater. 2014, 4, 1301345. [Google Scholar] [CrossRef]

- Baek, M.-G.; Park, S.-G. Differences in ITO Surfaces According to the Formation of Aromatic Rings and Aliphatic Self-Assembled Monolayers for Organic Light-Emitting Diode Applications. Nanomaterials 2021, 11, 2520. [Google Scholar] [CrossRef]

- Lo, C.-C.; Sudheendran Swayamprabha, S.; Hsueh, T.-C.; Chavhan, S.D.; Yadav, R.A.K.; Lee, J.-R.; Kesavan, K.K.; Chen, S.-Z.; Wang, C.-W.; Jou, J.-H. Modification effect of hole injection layer on efficiency performance of wet-processed blue organic light emitting diodes. Org. Electron. 2021, 92, 106084. [Google Scholar] [CrossRef]

- Su, W.; Chen, R.; Chen, Y. Thermally crosslinkable hole-transporting poly(fluorene- co -triphenylamine) for multilayer polymer light-emitting diodes. J. Polym. Sci. A Polym. Chem. 2011, 49, 352–360. [Google Scholar] [CrossRef]

- Fallahi, A.; Alahbakhshi, M.; Mohajerani, E.; Afshar Taromi, F.; Mohebbi, A.R.; Shahinpoor, M. Cationic Water-Soluble Conjugated Polyelectrolytes/Graphene Oxide Nanocomposites as Efficient Green Hole Injection Layers in Organic Light Emitting Diodes. J. Phys. Chem. C 2015, 119, 13144–13152. [Google Scholar] [CrossRef]

- Vacca, P.; Petrosino, M.; Chierchia, R.; Guerra, A.; Minarini, C.; Rubino, A. Influence of Electrical, Chemical and Morphological Properties of Inorganic/Organic Interface on Light Emitting Devices Performance. Macromol. Symp. 2007, 247, 333–339. [Google Scholar] [CrossRef]

- Deng, W.; Wang, S.; Xiao, Y.; Zhou, N.; Li, X. Solution-processed phosphorus-tungsten oxide film as hole injection layer for application in efficient organic light-emitting diode. Mater. Sci. Semicond. Process. 2018, 85, 106–112. [Google Scholar] [CrossRef]

- De Girolamo Del Mauro, A.; Nenna, G.; Bizzarro, V.; Grimaldi, I.A.; Villani, F.; Minarini, C. Analysis of the performances of organic light-emitting devices with a doped or an undoped polyaniline-poly(4-styrenesulfonate) hole-injection layer. J. Appl. Polym. Sci. 2011, 122, 3618–3623. [Google Scholar] [CrossRef]

- Choi, M.-R.; Woo, S.-H.; Han, T.-H.; Lim, K.-G.; Min, S.-Y.; Yun, W.M.; Kwon, O.K.; Park, C.E.; Kim, K.-D.; Shin, H.-K.; et al. Polyaniline-Based Conducting Polymer Compositions with a High Work Function for Hole-Injection Layers in Organic Light-Emitting Diodes: Formation of Ohmic Contacts. ChemSusChem 2011, 4, 363–368. [Google Scholar] [CrossRef]

- Boileau, N.T. Metal phthalocyanine organic thin-film transistors: Changes in electrical performance and stability in response to temperature and environment. RSC Adv. 2019, 9, 21478–21485. [Google Scholar] [CrossRef]

- Li, L.; Guan, M.; Cao, G.; Li, Y.; Zeng, Y. Low operating-voltage and high power-efficiency OLED employing MoO3-doped CuPc as hole injection layer. Displays 2012, 33, 17–20. [Google Scholar] [CrossRef]

- Zheng, Q.; You, F.; Xu, J.; Xiong, J.; Xue, X.; Cai, P.; Zhang, X.; Wang, H.; Wei, B.; Wang, L. Solution-processed aqueous composite hole injection layer of PEDOT:PSSþMoOx for efficient ultraviolet organic light-emitting diode. Org. Electron. 2017, 46, 7–13. [Google Scholar] [CrossRef]

- Zhu, W.; Chen, X.-L.; Chang, J.; Yu, R.-M.; Li, H.; Liang, D.; Wu, X.-Y.; Wang, Y.; Lu, C.-Z. Doped polyaniline-hybridized tungsten oxide nanocrystals as hole injection layers for efficient organic light-emitting diodes. J. Mater. Chem. C 2018, 6, 7242–7248. [Google Scholar] [CrossRef]

- Nagar, M.R.; Yadav, R.A.K.; Dubey, D.K.; Jou, J.-H. Solution Process Feasible Highly Efficient Organic Light Emitting Diode with Hybrid Metal Oxide Based Hole Injection/Transport Layer. MRS Adv. 2019, 4, 1801–1809. [Google Scholar] [CrossRef]

- Chan, I.-M.; Hsu, T.-Y.; Hong, F.C. Enhanced hole injections in organic light-emitting devices by depositing nickel oxide on indium tin oxide anode. Appl. Phys. Lett. 2002, 81, 1899–1901. [Google Scholar] [CrossRef]

- Corani, A.; Li, M.-H.; Shen, P.-S.; Chen, P.; Guo, T.-F.; El Nahhas, A.; Zheng, K.; Yartsev, A.; Sundström, V.; Ponseca, C.S. Ultrafast Dynamics of Hole Injection and Recombination in Organometal Halide Perovskite Using Nickel Oxide as p-Type Contact Electrode. J. Phys. Chem. Lett. 2016, 7, 1096–1101. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.H.L.; Xi, K.; Blamire, M.G.; Egdell, R.G. P -type transparent conducting oxides. J. Phys. Condens. Mat. 2016, 28, 383002. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Li, L.; Huang, J.; Jin, H.; Fang, X.; Liu, W.; Zhang, N.; Wang, H.; Wang, X. Engineering Ni3+ Cations in NiO Lattice at the Atomic Level by Li+ Doping: The Roles of Ni3+ and Oxygen Species for CO Oxidation. ACS Catal. 2018, 8, 8033–8045. [Google Scholar] [CrossRef]

- Liu, A.; Zhu, H.; Guo, Z.; Meng, Y.; Liu, G.; Fortunato, E.; Martins, R.; Shan, F. Solution Combustion Synthesis: Low-Temperature Processing for p-Type Cu:NiO Thin Films for Transparent Electronics. Adv. Mater. 2017, 29, 1701599. [Google Scholar] [CrossRef]

- Zheng, J.; Hu, L.; Yun, J.S.; Zhang, M.; Lau, C.F.J.; Bing, J.; Deng, X.; Ma, Q.; Cho, Y.; Fu, W.; et al. Solution-Processed, Silver-Doped NiOx as Hole Transporting Layer for High-Efficiency Inverted Perovskite Solar Cells. ACS Appl. Energ. Mater. 2018, 1, 561–570. [Google Scholar] [CrossRef]

- Shan, M.; Jiang, H.; Guan, Y.; Sun, D.; Wang, Y.; Hua, J.; Wang, J. Enhanced hole injection in organic light-emitting diodes utilizing a copper iodide-doped hole injection layer. RSC Adv. 2017, 7, 13584–13589. [Google Scholar] [CrossRef]

- Jayabharathi, J. A dodecanethiol-functionalized Ag nanoparticle-modified ITO anode for efficient performance of organic light-emitting devices. RSC Adv. 2017, 7, 38923–38934. [Google Scholar] [CrossRef]

- Tam, F.; Goodrich, G.P.; Johnson, B.R.; Halas, N.J. Plasmonic Enhancement of Molecular Fluorescence. Nano Lett. 2007, 7, 496–501. [Google Scholar] [CrossRef]

- Sung, H.; Lee, J.; Han, K.; Lee, J.-K.; Sung, J.; Kim, D.; Choi, M.; Kim, C. Controlled positioning of metal nanoparticles in an organic light-emitting device for enhanced quantum efficiency. Org. Electron. 2014, 15, 491–499. [Google Scholar] [CrossRef]

- Ko, S.-J.; Choi, H.; Lee, W.; Kim, T.; Lee, B.R.; Jung, J.-W.; Jeong, J.-R.; Song, M.H.; Lee, J.C.; Woo, H.Y.; et al. Highly efficient plasmonic organic optoelectronic devices based on a conducting polymer electrode incorporated with silver nanoparticles. Energy Environ. Sci. 2013, 6, 1949. [Google Scholar] [CrossRef]

- Tanaka, T.; Totoki, Y.; Fujiki, A.; Zettsu, N.; Miyake, Y.; Akai-Kasaya, M.; Saito, A.; Ogawa, T.; Kuwahara, Y. Enhanced Red-Light Emission by Local Plasmon Coupling of Au Nanorods in an Organic Light-Emitting Diode. Appl. Phys. Express 2011, 4, 032105. [Google Scholar] [CrossRef]

- Qiu, T.; Kong, F.; Yu, X.; Zhang, W.; Lang, X.; Chu, P.K. Tailoring light emission properties of organic emitter by coupling to resonance-tuned silver nanoantenna arrays. Appl. Phys. Lett. 2009, 95, 213104. [Google Scholar] [CrossRef]

- Wu, X.; Liu, L.; Yu, T.; Yu, L.; Xie, Z.; Mo, Y.; Xu, S.; Ma, Y. Gold nanoparticles modified ITO anode for enhanced PLEDs brightness and efficiency. J. Mater. Chem. C 2013, 1, 7020. [Google Scholar] [CrossRef]

- Jayabharathi, J.; Abirama Sundari, G.; Thanikachalam, V.; Panimozhi, S. Enhanced internal quantum efficiency of organic light-emitting diodes: A synergistic effect. J. Photochem. Photobiol. A Chem. 2018, 364, 577–587. [Google Scholar] [CrossRef]

- Feng, J.; Sun, D.; Mei, S.; Shi, W.; Mei, F.; Zhou, Y.; Xu, J.; Jiang, Y.; Wu, L. Plasmonic-Enhanced Organic Light-Emitting Diodes Based on a Graphene Oxide/Au Nanoparticles Composite Hole Injection Layer. Front. Mater. 2018, 5, 75. [Google Scholar] [CrossRef]

- da Silva, W.J.; Mohd Yusoff, A.R.B.; Jang, J. GO:PEDOT:PSS for High-Performance Green Phosphorescent Organic Light-Emitting Diode. IEEE Electron Device Lett. 2013, 34, 1566–1568. [Google Scholar] [CrossRef]

- Lian, H.; Tang, Z.; Guo, H.; Zhong, Z.; Wu, J.; Dong, Q.; Zhu, F.; Wei, B.; Wong, W.-Y. Magnetic nanoparticles/PEDOT:PSS composite hole-injection layer for efficient organic light-emitting diodes. J. Mater. Chem. C 2018, 6, 4903–4911. [Google Scholar] [CrossRef]

- Zhang, D.; Xu, J. Multiple regulation of efficient organic light-emitting diodes using magnetic composite nanoparticles. Opt. Lett. 2019, 44, 3210. [Google Scholar] [CrossRef]

- Lin, H.-P.; Zhou, F.; Zhang, X.-W.; Yu, D.-B.; Li, J.; Zhang, L.; Jiang, X.-Y.; Zhang, Z.-L. Efficient hole injection in blue organic light-emitting devices by using a double hole injection layer to improve chromaticity and electrical characteristics. Curr. Appl. Phys. 2011, 11, 853–859. [Google Scholar] [CrossRef]

- Zhang, X.; Mo, B.; You, F.; Zhou, X.; Liu, L.; Wang, H.; Wei, B. Electroluminescence enhancement in ultraviolet organic light-emitting diode with graded hole-injection and -transporting structure: Electroluminescence enhancement in ultraviolet organic light-emitting diode with graded hole-injection and -transporting structure. Phys. Status Solidi RRL 2015, 9, 353–357. [Google Scholar]

- Tsai, C.-T.; Liu, Y.-H.; Tang, J.-F.; Kao, P.-C.; Chiang, C.-H.; Chu, S.-Y. Effects of novel transition metal oxide doped bilayer structure on hole injection and transport characteristics for organic light-emitting diodes. Synth. Met. 2018, 243, 121–126. [Google Scholar] [CrossRef]

- Xu, Y.; Niu, Y.; Gong, C.; Shi, W.; Yang, X.; Wei, B.; Wong, W. High-Performance Inverted Tandem OLEDs with the Charge Generation Layer based on MoO x and Ag Doped Planar Heterojunction. Adv. Opt. Mater. 2022, 10, 2200984. [Google Scholar] [CrossRef]

- Wu, S.P.; Kang, Y.; Liu, T.L.; Jin, Z.H.; Jiang, N.; Lu, Z.H. Formation of charge-transfer-complex in organic:metal oxides systems. Appl. Phys. Lett. 2013, 102, 163304. [Google Scholar] [CrossRef]

- Huh, Y.H.; Kwon, O.E.; Park, B.; Ji, S.; Lee, S.S.; Lim, J.; An, K.-S. Improved impedance characteristics of all-water-processable triple-stacked hole-selective layers in solution-processed OLEDs. Opt. Express 2016, 24, A846. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Wang, S.; Li, D.; Fang, Y.; Shen, H.; Li, L.S.; Du, Z. Simultaneous Improvement of Efficiency and Lifetime of Quantum Dot Light-Emitting Diodes with a Bilayer Hole Injection-Layer Consisting of PEDOT:PSS and Solution-Processed WO3. ACS Appl. Mater. Interfaces 2018, 10, 24232–24241. [Google Scholar] [CrossRef] [PubMed]

- Lu, L.; Yu, J.; Long, L.; Yu, F.; Zhang, J.; Zhang, H.; Wei, B. Low-voltage and high-stability p-type doped blue organic light-emitting diodes with bilayer hole-injection layers. Phys. Status Solidi A 2011, 208, 2321–2324. [Google Scholar] [CrossRef]

- Zhang, X.; You, F.; Liu, S.; Mo, B.; Zhang, Z.; Xiong, J.; Cai, P.; Xue, X.; Zhang, J.; Wei, B. Exceeding 4% external quantum efficiency in ultraviolet organic light-emitting diode using PEDOT:PSS/MoOx double-stacked hole injection layer. Appl. Phys. Lett. 2017, 110, 043301. [Google Scholar] [CrossRef]

- Narayan, K.; Varadharajaperumal, S.; Mohan Rao, G.; Manoj Varma, M.; Srinivas, T. Effect of thickness variation of hole injection and hole blocking layers on the performance of fluorescent green organic light emitting diodes. Curr. Appl. Phys. 2013, 13, 18–25. [Google Scholar] [CrossRef]

- Zhang, X.; An, J.; Xu, Y.; Wang, Y.; Lu, Y.; Qin, Y.; Lai, W.-Y.; Chen, Y.; Huang, W. Efficient small molecule organic light-emitting diodes fabricated by brush-coating. J. Mater. Chem. C 2021, 9, 2190–2197. [Google Scholar] [CrossRef]

- Hussain, S.A.; Dey, B.; Bhattacharjee, D.; Mehta, N. Unique supramolecular assembly through Langmuir—Blodgett (LB) technique. Heliyon 2018, 4, e01038. [Google Scholar] [CrossRef]

- C, A.; Colella, M.; Griffin, J.; Kingsley, J.; Scarratt, N.; Luszczynska, B.; Ulanski, J. Slot-Die Coating of Double Polymer Layers for the Fabrication of Organic Light Emitting Diodes. Micromachines 2019, 10, 53. [Google Scholar] [CrossRef] [PubMed]

- Yoon, D.G.; Kang, M.; Kim, J.B.; Kang, K.-T. Nozzle Printed-PEDOT:PSS for Organic Light Emitting Diodes with Various Dilution Rates of Ethanol. Appl. Sci. 2018, 8, 203. [Google Scholar] [CrossRef]

- Sakata, T.; Kajiya, D.; Saitow, K. Brush Printing Creates Polarized Green Fluorescence: 3D Orientation Mapping and Stochastic Analysis of Conductive Polymer Films. ACS Appl. Mater. Interfaces 2020, 12, 46598–46608. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Yang, X.; Yang, W.; Li, S.; Xu, J.; Jiang, Y. Ordered and ultrathin reduced graphene oxide LB films as hole injection layers for organic light-emitting diode. Nanoscale Res. Lett. 2014, 9, 537. [Google Scholar] [CrossRef]

- Choi, K.-J.; Lee, J.-Y.; Park, J.; Seo, Y.-S. Multilayer slot-die coating of large-area organic light-emitting diodes. Org. Electron. 2015, 26, 66–74. [Google Scholar] [CrossRef]

- C, A.; Dubey, D.K.; Pahlevani, M.; Welch, G.C. Slot-Die Coating of All Organic/Polymer Layers for Large-Area Flexible OLEDs: Improved Device Performance with Interlayer Modification. Adv. Mater. Technol. 2021, 6, 2100264. [Google Scholar] [CrossRef]

- Shin, K.-Y.; Kang, M.; Cho, K.H.; Kang, K.-T.; Lee, S.-H. Micro multi-nozzle jet coating of organic thin film for organic light-emitting diode lighting devices. Micro Nano Syst. Lett. 2021, 9, 15. [Google Scholar] [CrossRef]

- Lu, H.-W.; Kao, P.-C.; Juang, Y.-D.; Chu, S.-Y. The effects of ultraviolet-ozone-treated ultra-thin MnO-doped ZnO film as anode buffer layer on the electrical characteristics of organic light-emitting diodes. J. Appl. Phys. 2015, 118, 185501. [Google Scholar] [CrossRef]

- Lu, H.-W.; Kao, P.-C.; Chu, S.-Y. Effects of Ultra-Thin Al2O3-Doped ZnO Film as Anode Buffer Layer Grown by Thermal Evaporation for Organic Light-Emitting Diodes. ECS J. Solid State Sci. Technol. 2017, 6, R14–R19. [Google Scholar] [CrossRef]

- Park, Y.W.; Choi, H.J.; Choi, J.H.; Park, T.H.; Jeong, J.-W.; Song, E.H.; Ju, B.K. Enhanced Power Efficiency of Organic Light-Emitting Diodes using Pentacene on CF4-Plasma-Treated Indium Tin Oxide Anodes. IEEE Electron Device Lett. 2012, 33, 1156–1158. [Google Scholar] [CrossRef]

- Kim, J.H. The effect of Ar plasma bombardment upon physical property of tungsten oxide thin film in inverted top-emitting organic light-emitting diodes. Org. Electron. 2011, 12, 285–290. [Google Scholar] [CrossRef]

- Choi, S.A.; Kim, K.; Lee, S.J.; Lee, H.; Babajanyan, A.; Friedman, B.; Lee, K. Effects of thermal preparation on Copper Phthalocyanine organic light emitting diodes. J. Lumin. 2016, 171, 149–153. [Google Scholar] [CrossRef]

- Ning, Y.; Zhao, S.; Song, D.; Qiao, B.; Xu, Z.; Zhou, Y.; Chen, J.; Swelm, W.; Al-Ghamdi, A. The Improvement of the Performance of Sky-Blue OLEDs by Decreasing Interface Traps and Balancing Carriers with PSVA Treatment. Polymers 2022, 14, 622. [Google Scholar] [CrossRef] [PubMed]

- Dagar, J.; Tyagi, P.; Ahmad, R.; Singh, R.; Sinha, O.P.; Suman, C.K.; Srivastava, R. Application of 2D-MoO3 nano-flakes in organic light emitting diodes: Effect of semiconductor to metal transition with irradiation. RSC Adv. 2015, 5, 8397–8403. [Google Scholar] [CrossRef]

| Commercial Symbol | Work Function [eV] | CE [cd A−1] | PE [lm W−1] | EQE [%] | Turn-On Voltage [V] | Maximum Brightness [cd m−2] | Ref. |

|---|---|---|---|---|---|---|---|

| LR-PU | - | - | 1.24 | 0.37 | 3.7 | 6310 | [20] |

| DNA | - | - | - | - | 4.25 | 45,000 | [19] |

| PTC-U | - | - | 3.8 | 2.3 | 3.5 | 43,652 | [21] |

| PTC-A | - | - | 4.6 | 2.4 | 3 | 47,226 | [21] |

| Commercial Symbol | Work Function [eV] | CE [cd A−1] | PE [lm W−1] | EQE [%] | Turn-On Voltage [V] | Maximum Brightness [cd m−2] | Ref. |

|---|---|---|---|---|---|---|---|

| MoO3 | - | - | - | - | 2.4 | 140,000 | [32] |

| V2O5 | 5.6 | 65 | 35 | - | 5.8 | 153,600 | [23] |

| WO3 | 5.6 | 12.7 | - | - | [34] | ||

| MoO3 | 5.67 | 32.6 | 25.1 | 13.7 | - | - | [34] |

| V2O5 | 5.8 | - | - | 11 | - | - | [34] |

| MoOx | - | - | 5 | - | 5.2 | - | [33] |

| Commercial Symbol | Work Function (eV) | CE (cd A−1) | PE (lm W−1) | EQE (%) | Turn-On Voltage (V) | Maximum Brightness (cd m−2) | Ref. |

|---|---|---|---|---|---|---|---|

| 1-PNA-BPBPOX | 4.86 | - | 2.8 | - | 5.7 | - | [47] |

| PTT: PFFSA | - | - | - | - | - | - | [14] |

| MeSx | 5.1 | - | - | - | 4 | 23,300 | [36] |

| CH3NH3PbI3 | - | - | 3.210 | - | 2.5 | 19,110 | [2] |

| CuSCN | - | 17.6 | 5.6 | 9.2 | 5.6 | 26,424 | [48] |

| CuSCN | - | 53.7 | 40.3 | 13.9 | 4.2 | 15,180 | [49] |

| TAT-4C | - | - | 39.2 | 11 | 2.7 | - | [50] |

| GO | 5.16 | 73.14 | 53.95 | 20.63 | 3 | 131,600 | [41] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, X.; Wu, Z.; Sun, Y.; Liu, Y.; Dong, X.; Li, S.; Wang, W. The Optimization of Hole Injection Layer in Organic Light-Emitting Diodes. Nanomaterials 2024, 14, 161. https://doi.org/10.3390/nano14020161

Xing X, Wu Z, Sun Y, Liu Y, Dong X, Li S, Wang W. The Optimization of Hole Injection Layer in Organic Light-Emitting Diodes. Nanomaterials. 2024; 14(2):161. https://doi.org/10.3390/nano14020161

Chicago/Turabian StyleXing, Xiaolin, Ziye Wu, Yingying Sun, Yunlong Liu, Xiaochen Dong, Shuhong Li, and Wenjun Wang. 2024. "The Optimization of Hole Injection Layer in Organic Light-Emitting Diodes" Nanomaterials 14, no. 2: 161. https://doi.org/10.3390/nano14020161

APA StyleXing, X., Wu, Z., Sun, Y., Liu, Y., Dong, X., Li, S., & Wang, W. (2024). The Optimization of Hole Injection Layer in Organic Light-Emitting Diodes. Nanomaterials, 14(2), 161. https://doi.org/10.3390/nano14020161