Laboratory X-ray Microscopy of 3D Nanostructures in the Hard X-ray Regime Enabled by a Combination of Multilayer X-ray Optics

Abstract

1. Introduction

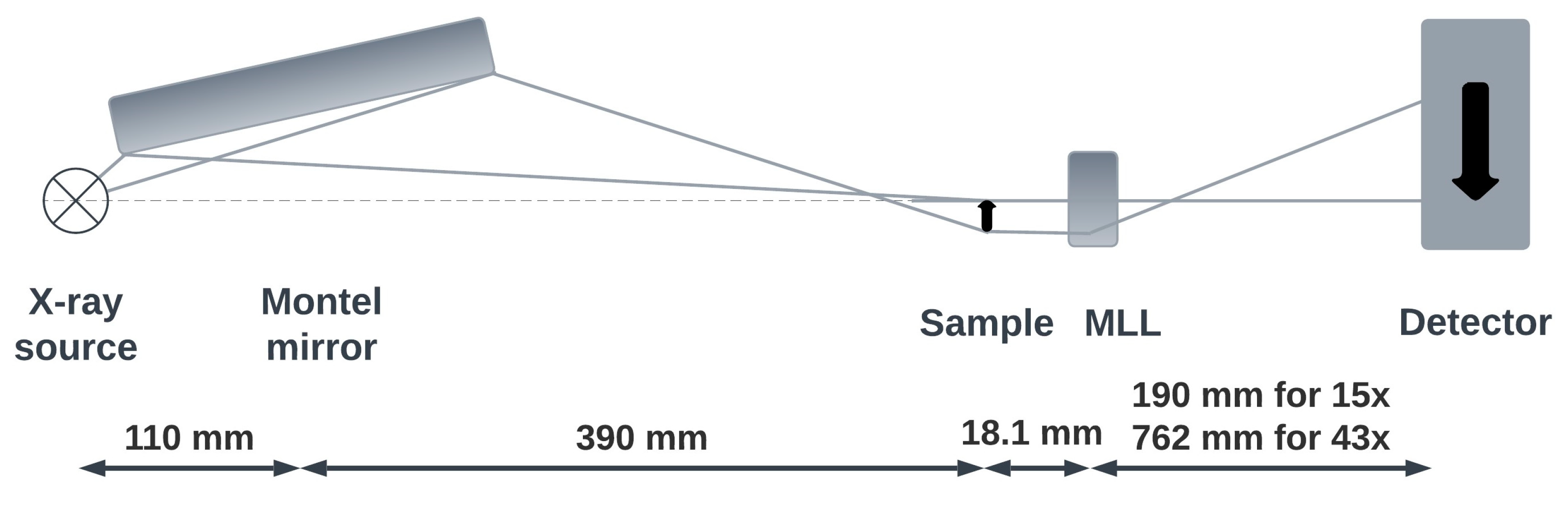

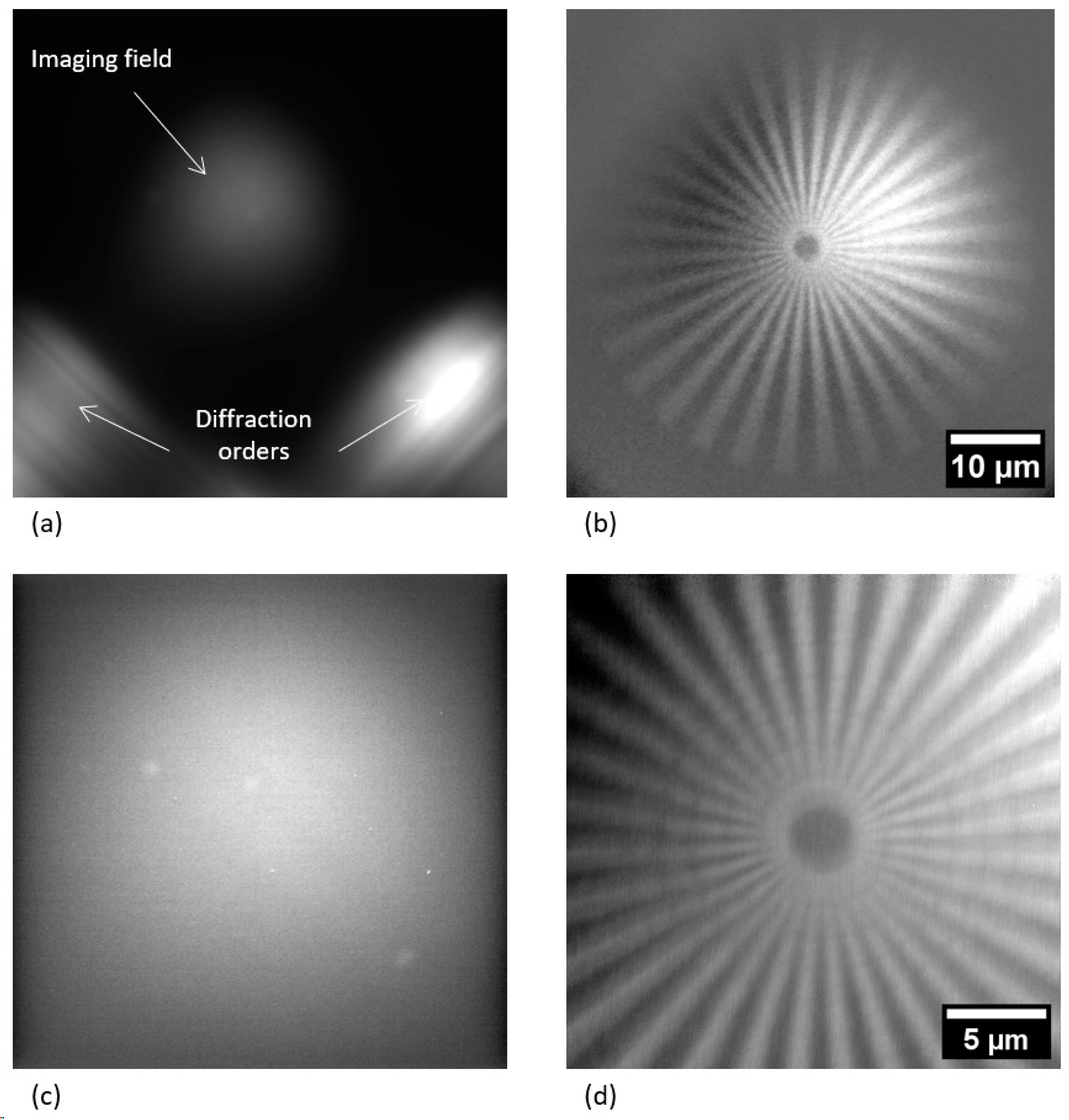

2. Combined Multilayer Optics for Hard X-ray Microscopy

3. Laboratory Hard X-ray Microscopy—Application for Microelectronics

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mueller, B. Recent trends in high-resolution hard X-ray tomography. In Proceedings of the SPIE 11113, Developments in X-Ray Tomography XII, San Diego, CA, USA, 11–15 August 2019; p. 1111302. [Google Scholar]

- Withers, P.J.; Bouman, C.; Carmignato, S.; Cnudde, V.; Grimaldi, D.; Hagen, C.K.; Maire, E.; Manley, M.; Plessis, A.D.; Stock, S.R. X-ray computed tomography. Nat. Rev. Methods Prim. 2021, 1, 18. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, J.; Wang, S.; Wong, C.-P. Challenges and prospects for advanced packaging. Fundam. Res. 2023, in press. [Google Scholar] [CrossRef]

- Bernstein, L. Semiconductor joining by the solid-liquid-interdiffusion (SLID) process. J. Electrochem. Soc. 1966, 113, 1282–1288. [Google Scholar] [CrossRef]

- Aasmundtveit, K.E.; Tekseth, K.R.; Breiby, D.W.; Nguyen, H.-V. High-energy X-ray Tomography for 3D Void Characterization in Au–Sn Solid-Liquid Interdiffusion (SLID) Bonds. In Proceedings of the 2019 22nd European Microelectronics and Packaging Conference & Exhibition (EMPC), Pisa, Italy, 16–19 September 2019. [Google Scholar]

- Jacobsen, C. X-ray Microscopy; Cambridge University Press: Cambridge, UK, 2023. [Google Scholar]

- Hemberg, O.; Otendal, M.; Hertz, H.M. Liquid-metal-jet anode electron-impact X-ray source. Appl. Phys. Lett. 2003, 83, 1483–1485. [Google Scholar] [CrossRef]

- Fella, C.; Balles, A.; Zabler, S.; Hanke, R.; Tjeung, R.; Nguyen, S.; Pelliccia, D. Laboratory x-ray microscopy on high brilliance sources equipped with waveguides. J. Appl. Phys. 2015, 118, 034904. [Google Scholar] [CrossRef]

- Balles, A.; Dittmann, J.; Fella, C.; Hanke, R.; Zabler, S. Quantitative phase contrast and X-ray scattering micro-tomography with the 9.2 keV liquid metal jet anode: Applications on materials and life science. In Proceedings of the SPIE 10391, Developments in X-Ray Tomography XI, San Diego, CA, USA, 6–10 August 2017; p. 1039109. [Google Scholar]

- Sutherland, M.; Powell, C.; Downes, S. Software automation and optimization of an X-ray microscope custom designed for integrated circuit inspection. Microsc. Microanal. 2018, 24 (Suppl. 2), 112–113. [Google Scholar] [CrossRef][Green Version]

- Montel, M. The X-Ray Microscope with Catamegonic Roof-Shaped Objective. In X-ray Microscopy and Microradiography; Cosslett, V.E., Engstrom, A., Pattee, H.H., Eds.; Academic Press: New York, NY, USA, 1957; pp. 177–185. [Google Scholar]

- Guilherme, A.; Buzanich, G.; Carvalho, M. Focusing systems for the generation of X-ray micro beam: An overview. Spectrochim. Acta Part B At. Spectrosc. 2012, 77, 1–8. [Google Scholar] [CrossRef]

- Schroer, C.G. Focusing hard X rays to nanometer dimensions using Fresnel zone plates. Phys. Rev. B 2006, 74, 033405. [Google Scholar] [CrossRef]

- Rehbein, S.; Heim, S.; Guttmann, P.; Werner, S.; Schneider, G. Ultrahigh-resolution soft-X-ray microscopy with zone plates in high orders of diffraction. Phys. Rev. Lett. 2009, 103, 110801. [Google Scholar] [CrossRef]

- Chao, W.; Fischer, P.; Tyliszczak, T.; Rekawa, S.; Anderson, E.; Naulleau, P. Real space soft X-ray imaging at 10 nm spatial resolution. Opt. Express 2012, 20, 9777–9783. [Google Scholar] [CrossRef]

- Chao, W.; Harteneck, B.D.; Liddle, J.A.; Anderson, E.H.; Attwood, D.T. Soft X-ray microscopy at a spatial resolution better than 15 nm. Nature 2005, 435, 1210–1213. [Google Scholar] [CrossRef]

- Jefimovs, K.; Vila-Comamala, J.; Pilvi, T.; Raabe, J.; Ritala, M.; David, C. Zone-doubling technique to produce ultrahigh-resolution X-ray optics. Phys. Rev. Lett. 2007, 99, 264801. [Google Scholar] [CrossRef] [PubMed]

- Maser, J.; Stephenson, G.B.; Vogt, S.; Yun, W.; Macrander, A.; Kang, H.C.; Liu, C.; Conley, R. Multilayer Laue lenses as high-resolution x-ray optics. In Proceedings of the SPIE 5539 Optical Science and Technology, the SPIE 49th Annual Meeting, Denver, CO, USA, 2–6 August 2004; pp. 185–194. [Google Scholar]

- Yan, H.; Conley, R.; Bouet, N.; Chu, Y.S. Hard x-ray nanofocusing by multilayer Laue lenses. J. Phys. D Appl. Phys. 2014, 47, 263001. [Google Scholar] [CrossRef]

- Yan, H.; Rose, V.; Shu, D.; Lima, E.; Kang, H.C.; Conley, R.; Liu, C.; Jahedi, N.; Macrander, A.T.; Stephenson, G.B.; et al. Two dimensional hard x-ray nanofocusing with crossed multilayer Laue lenses. Opt. Express 2011, 19, 15069–15076. [Google Scholar] [CrossRef] [PubMed]

- Shu, D.; Nazaretski, E.; Kim, J.; Yan, H.; Lauer, K.; Mullany, B.; Kuhne, D.; Maser, J.; Chu, Y.S. Optomechanical design of a multilayer laue lens test bed for 10-nm focusing of hard X-rays. J. Phys. Conf. Ser. 2013, 463, 012029. [Google Scholar] [CrossRef]

- Nazaretski, E.; Xu, W.; Bouet, N.; Zhou, J.; Yan, H.; Huang, X.; Chu, Y.S. Development and characterization of monolithic multilayer Laue lens nanofocusing optics. Appl. Phys. Lett. 2016, 108, 261102. [Google Scholar] [CrossRef]

- Niese, S.; Krueger, P.; Kubec, A.; Braun, S.; Patommel, J.; Schroer, C.; Leson, A.; Zschech, E. Full-field X-ray Microscopy with Crossed Partial Multilayer Laue Lenses. Opt. Express 2014, 22, 20008. [Google Scholar] [CrossRef]

- Tordoff, B.; Hartfield, C.; Holwell, A.J.; Hiller, S.; Kaestner, M.; Kelly, S.; Lee, J.; Müller, S.; Perez-Willard, F.; Volkenandt, T.; et al. The LaserFIB: New application opportunities combining a high-performance FIB-SEM with femtosecond laser processing in an integrated second chamber. Appl. Microsc. 2020, 50, 1–11. [Google Scholar] [CrossRef]

- Kong, L.W.; Lloyd, J.R.; Yeap, K.B.; Zschech, E.; Rudack, A.; Liehr, M.; Diebold, A. Applying x-Ray Microscopy and Finite Element Modeling to Identify the Mechanism of Stress-Assisted Void Growth in Through-Silicon Vias. J. Appl. Phys. 2011, 110, 053502. [Google Scholar] [CrossRef]

- Kutukova, K.; Gluch, J.; Kraatz, M.; Clausner, A.; Zschech, E. In-situ X-ray tomographic imaging and controlled steering of microcracks in 3D nanopatterned structures. Mater. Des. 2022, 221, 110946. [Google Scholar] [CrossRef]

- Panchenko, I.; Croes, K.; De Wolf, I.; De Messemaeker, J.; Beyne, E.; Wolter, K.-J. Degradation of Cu6Sn5 intermetallic compound by pore formation in solid–liquid interdiffusion Cu/Sn microbump interconnects. Microelectron. Eng. 2014, 117, 26–34. [Google Scholar] [CrossRef]

- Sanli, U.T.; Jiao, C.; Baluktsian, M.; Grévent, C.; Hahn, K.; Wang, Y.; Srot, V.; Richter, G.; Bykova, I.; Weigand, M.; et al. 3D Nanofabrication of High-Resolution Multilayer Fresnel Zone Plates. Adv. Sci. 2018, 5, 1800346. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lechowski, B.; Kutukova, K.; Grenzer, J.; Panchenko, I.; Krueger, P.; Clausner, A.; Zschech, E. Laboratory X-ray Microscopy of 3D Nanostructures in the Hard X-ray Regime Enabled by a Combination of Multilayer X-ray Optics. Nanomaterials 2024, 14, 233. https://doi.org/10.3390/nano14020233

Lechowski B, Kutukova K, Grenzer J, Panchenko I, Krueger P, Clausner A, Zschech E. Laboratory X-ray Microscopy of 3D Nanostructures in the Hard X-ray Regime Enabled by a Combination of Multilayer X-ray Optics. Nanomaterials. 2024; 14(2):233. https://doi.org/10.3390/nano14020233

Chicago/Turabian StyleLechowski, Bartlomiej, Kristina Kutukova, Joerg Grenzer, Iuliana Panchenko, Peter Krueger, Andre Clausner, and Ehrenfried Zschech. 2024. "Laboratory X-ray Microscopy of 3D Nanostructures in the Hard X-ray Regime Enabled by a Combination of Multilayer X-ray Optics" Nanomaterials 14, no. 2: 233. https://doi.org/10.3390/nano14020233

APA StyleLechowski, B., Kutukova, K., Grenzer, J., Panchenko, I., Krueger, P., Clausner, A., & Zschech, E. (2024). Laboratory X-ray Microscopy of 3D Nanostructures in the Hard X-ray Regime Enabled by a Combination of Multilayer X-ray Optics. Nanomaterials, 14(2), 233. https://doi.org/10.3390/nano14020233