Ultrastable and Low-Threshold Two-Photon-Pumped Amplified Spontaneous Emission from CsPbBr3/Ag Hybrid Microcavity

Abstract

:1. Introduction

2. Materials and Methods

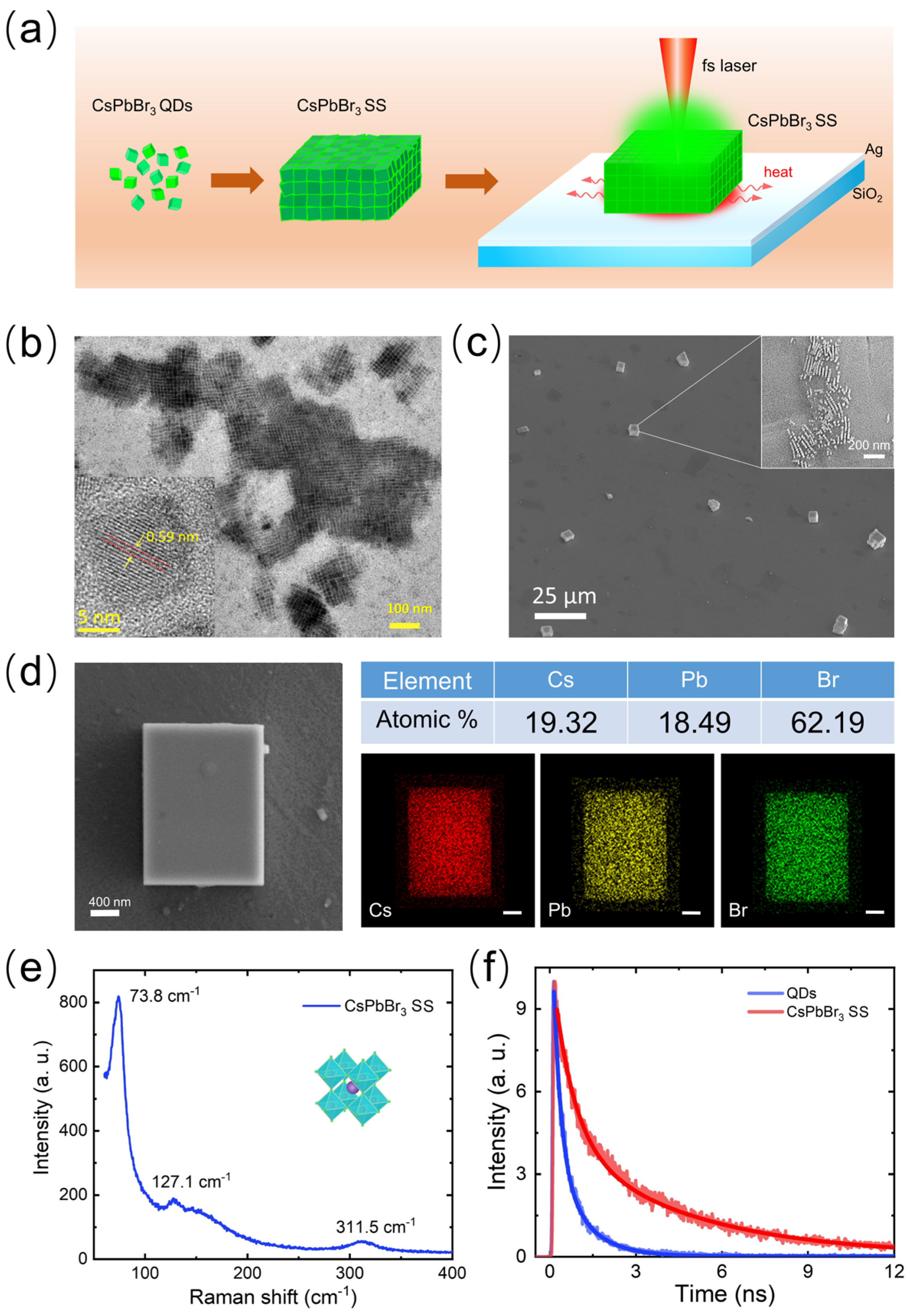

2.1. Sample Preparation and Characterization

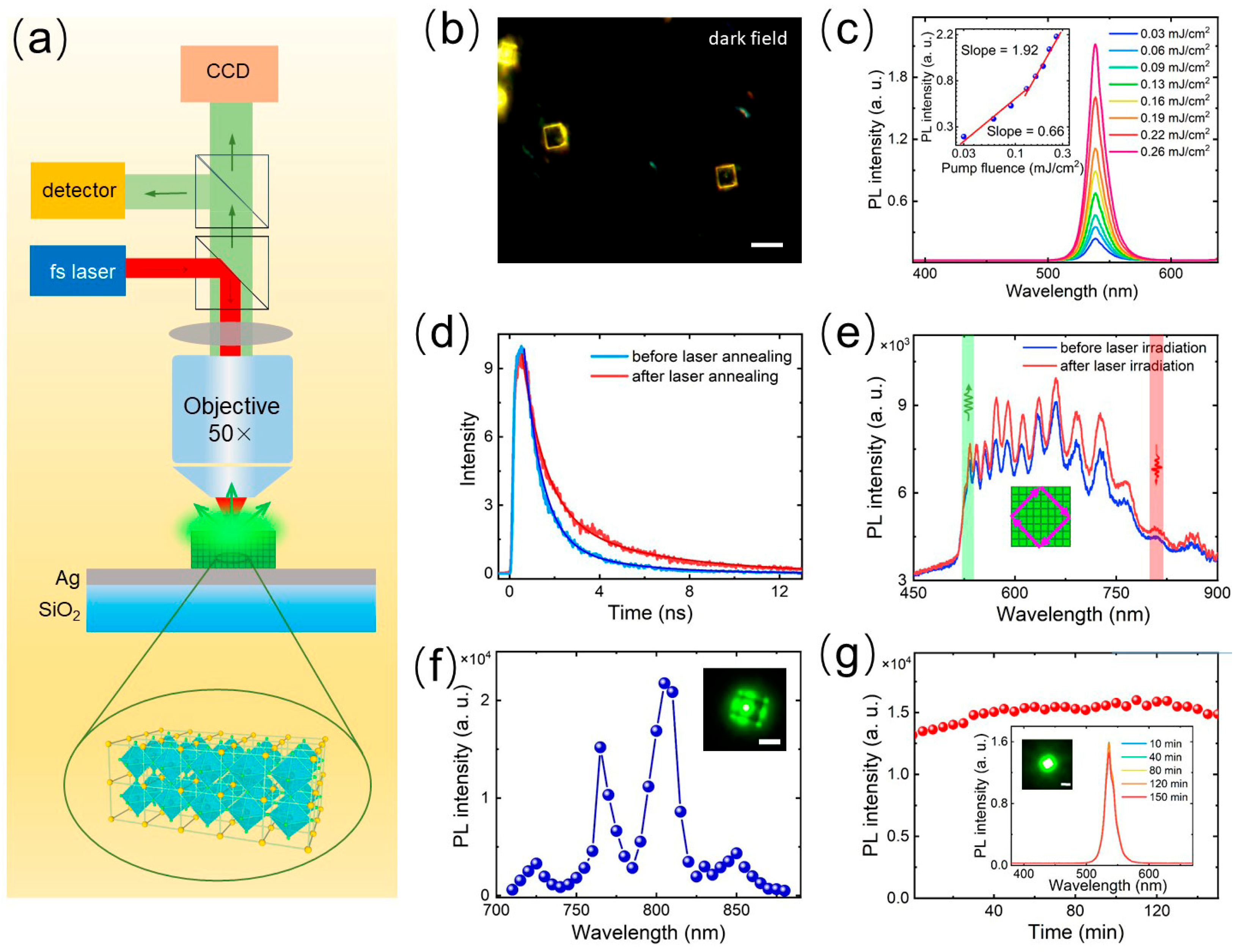

2.2. Optical Characterization of CsPbBr3/Ag Hybrid Microcavities

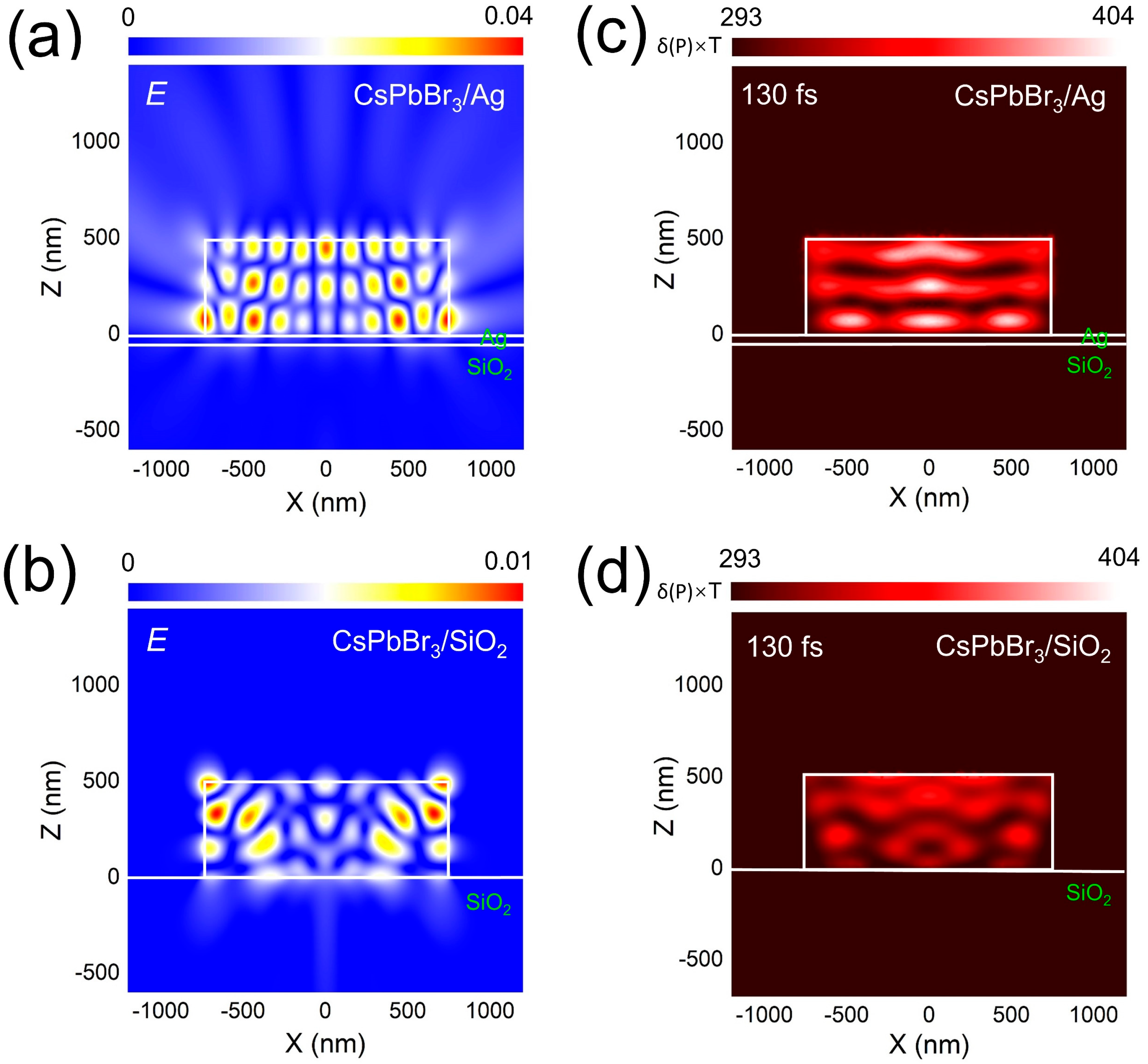

2.3. Numerical Simulation and Analytical Model

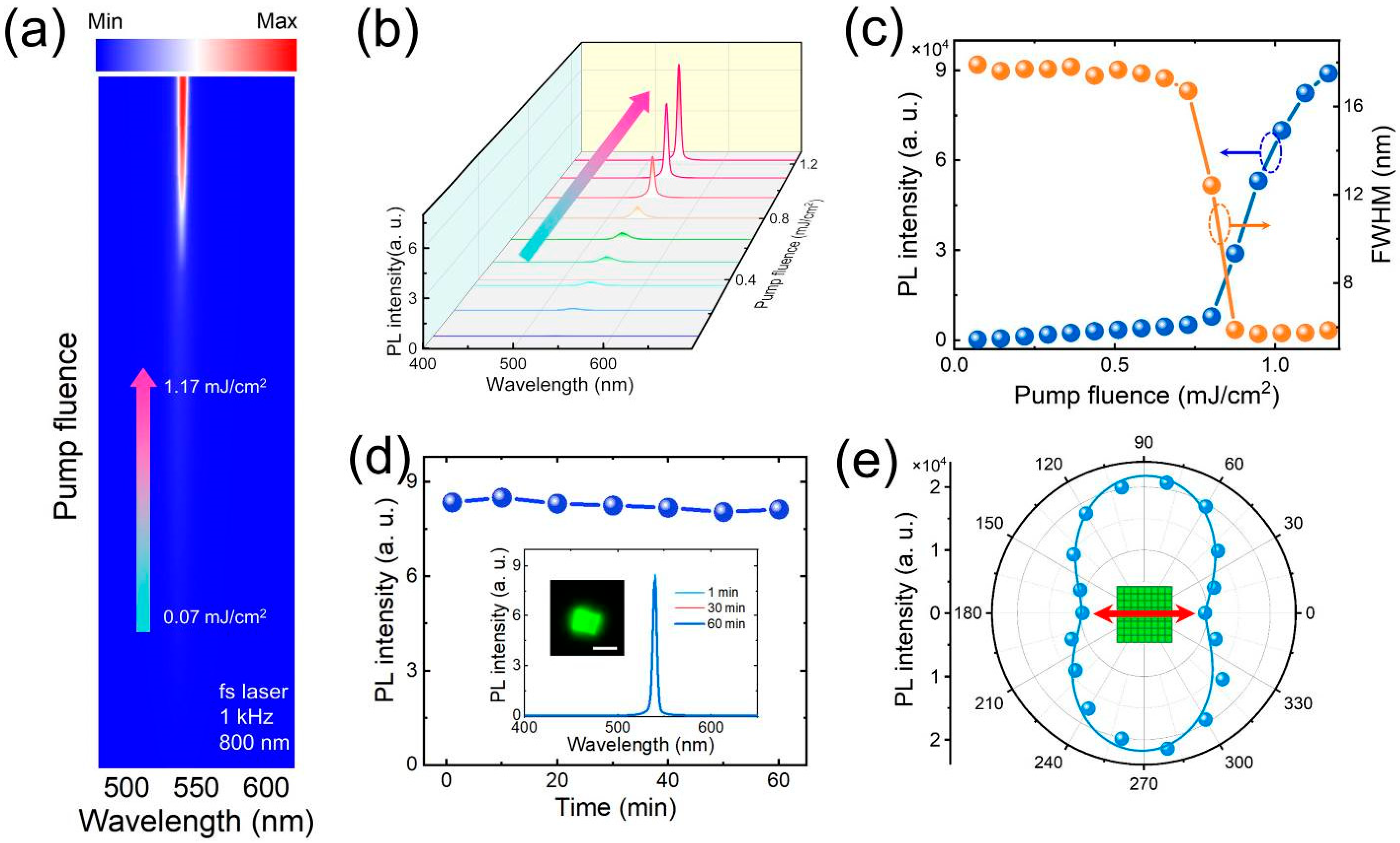

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.; Li, X.; Zhao, X.; Xiao, L.; Zeng, H.; Sun, H. Nonlinear absorption and low-threshold multiphoton pumped stimulated emission from all-inorganic perovskite nanocrystals. Nano Lett. 2016, 16, 448–453. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Chen, Q.; Zhang, C.; Wang, R.; Wu, H.; Zhang, X.; Xing, G.; Yu, W.W.; Wang, X.; Zhang, Y. Two-photon-pumped perovskite semiconductor nanocrystal lasers. J. Am. Chem. Soc. 2016, 138, 3761–3768. [Google Scholar] [CrossRef] [PubMed]

- Bera, S.K.; Bera, S.; Shrivastava, M.; Pradhan, N.; Adarsh, K. Facet engineering for amplified spontaneous emission in metal halide perovskite nanocrystals. Nano Lett. 2022, 22, 8908–8916. [Google Scholar] [CrossRef] [PubMed]

- Zhan, Z.; Hu, Z.; Huang, S.; Dong, S.; Li, Q.; Liu, Z.; Du, J.; Leng, Y. Ionic Solvent-Assisted MAPbBr3 Perovskite Film for Two-Photon Pumped Single-Mode Laser. J. Phys. Chem. Lett. 2023, 14, 7903–7909. [Google Scholar] [CrossRef]

- Zhang, Z.-Y.; Wang, H.-Y.; Zhang, Y.-X.; Li, K.-J.; Zhan, X.-P.; Gao, B.-R.; Chen, Q.-D.; Sun, H.-B. Size-dependent one-photon-and two-photon-pumped amplified spontaneous emission from organometal halide CH3NH3PbBr3 perovskite cubic microcrystals. PCCP 2017, 19, 2217–2224. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Zhou, H.; Yuan, S.; Zheng, W.; Jiang, Y.; Zhuang, X.; Liu, H.; Zhang, Q.; Zhu, X.; Wang, X. Cesium lead halide perovskite triangular nanorods as high-gain medium and effective cavities for multiphoton-pumped lasing. Nano Res. 2017, 10, 3385–3395. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, M.; Fang, L.; Jiang, S.; Zhou, J.; Ding, H.; Huang, H.; Wen, W.; Luo, Z.; Zhang, Q. Great Disparity in Photoluminesence Quantum Yields of Colloidal CsPbBr3 Nanocrystals with Varied Shape: The Effect of Crystal Lattice Strain. J. Phys. Chem. Lett. 2017, 8, 3115–3121. [Google Scholar] [CrossRef] [PubMed]

- Tang, X.; Senevirathne, C.A.; Matsushima, T.; Sandanayaka, A.S.; Adachi, C. Progress and Perspective toward Continuous-Wave Organic Solid-State Lasers. Adv. Mater. 2024, 36, 2211873. [Google Scholar] [CrossRef]

- Lang, Q.; Li, X.; Zhou, J.; Xu, Y.; Lin, Q.; Lu, M. Two silver energetic coordination polymers based on a new N-amino-contained ligand: Towards good detonation performance and excellent laser-initiating ability. Chem. Eng. J. 2023, 452, 139473. [Google Scholar] [CrossRef]

- Zhang, Q.; Shang, Q.; Su, R.; Do, T.T.H.; Xiong, Q. Halide perovskite semiconductor lasers: Materials, cavity design, and low threshold. Nano Lett. 2021, 21, 1903–1914. [Google Scholar] [CrossRef]

- Akkerman, Q.A.; Rainò, G.; Kovalenko, M.V.; Manna, L. Genesis, challenges and opportunities for colloidal lead halide perovskite nanocrystals. Nat. Mater. 2018, 17, 394–405. [Google Scholar] [CrossRef] [PubMed]

- Elbaz, G.A.; Ong, W.-L.; Doud, E.A.; Kim, P.; Paley, D.W.; Roy, X.; Malen, J.A. Phonon speed, not scattering, differentiates thermal transport in lead halide perovskites. Nano Lett. 2017, 17, 5734–5739. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.C.; Bao, Z.; Tsai, H.Y.; Tang, A.C.; Liu, R.S. Perovskite quantum dots and their application in light-emitting diodes. Small 2018, 14, 1702433. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.-K.; Xu, W.; Bai, S.; Jin, Y.; Wang, J.; Friend, R.H.; Gao, F. Metal halide perovskites for light-emitting diodes. Nat. Mater. 2021, 20, 10–21. [Google Scholar] [CrossRef] [PubMed]

- Kakavelakis, G.; Gedda, M.; Panagiotopoulos, A.; Kymakis, E.; Anthopoulos, T.D.; Petridis, K. Metal halide perovskites for high-energy radiation detection. Adv. Sci. 2020, 7, 2002098. [Google Scholar] [CrossRef]

- Lin, Z.; Huang, R.; Li, S.; Liu, S.; Song, J.; Panmai, M.; Lan, S. Ultralow Threshold Lasing from a Continuous-Wave-Pumped SiNx/CsPbBr3/Ag Thin Film Mediated by the Whispering Gallery Modes of a SiO2 Microsphere. J. Phys. Chem. Lett. 2022, 13, 9967–9974. [Google Scholar] [CrossRef]

- Raja, S.N.; Bekenstein, Y.; Koc, M.A.; Fischer, S.; Zhang, D.; Lin, L.; Ritchie, R.O.; Yang, P.; Alivisatos, A.P. Encapsulation of perovskite nanocrystals into macroscale polymer matrices: Enhanced stability and polarization. ACS Appl. Mater. Interfaces 2016, 8, 35523–35533. [Google Scholar] [CrossRef]

- Konidakis, I.; Karagiannaki, A.; Stratakis, E. Advanced composite glasses with metallic, perovskite, and two-dimensional nanocrystals for optoelectronic and photonic applications. Nanoscale 2022, 14, 2966–2989. [Google Scholar] [CrossRef]

- Li, X.; Luo, D.; Green, P.B.; Qiu, C.; Wei, M.; Yu, H.; Sargent, E.H.; Wilson, M.W.; Lu, Z.H. Vapor-Phase Deposition of Highly Luminescent Embedded Perovskite Nanocrystals. Adv. Opt. Mater. 2022, 10, 2102809. [Google Scholar] [CrossRef]

- Huang, H.; Feil, M.W.; Fuchs, S.; Debnath, T.; Richter, A.F.; Tong, Y.; Wu, L.; Wang, Y.; Döblinger, M.; Nickel, B. Growth of perovskite CsPbBr3 nanocrystals and their formed superstructures revealed by in situ spectroscopy. Chem. Mater. 2020, 32, 8877–8884. [Google Scholar] [CrossRef]

- Yang, D.; Zhang, X.; Yang, Y.; Xu, Z.; Liu, S.; Cheng, K.; Guo, S.; Xu, Q.; Jeon, S.; Li, L. Revealing the Self-Assembly Behavior of CsPbBr3 Nanoscale Supercrystals Mediated by Packed Clusters. ACS Mater. Lett. 2024, 6, 1439–1446. [Google Scholar] [CrossRef]

- Liu, Z.; Qin, X.; Chen, Q.; Jiang, T.; Chen, Q.; Liu, X. Metal–Halide Perovskite Nanocrystal Superlattice: Self-Assembly and Optical Fingerprints. Adv. Mater. 2023, 35, 2209279. [Google Scholar] [CrossRef] [PubMed]

- Chan, W.K.; Chen, J.; Zhou, D.; Ye, J.; Vázquez, R.J.; Zhou, C.; Bazan, G.C.; Rao, A.; Yu, Z.; Tan, T.T.Y. Hybrid Organic–Inorganic Perovskite Superstructures for Ultrapure Green Emissions. Nanomaterials 2023, 13, 815. [Google Scholar] [CrossRef] [PubMed]

- Cherniukh, I.; Rainò, G.; Stöferle, T.; Burian, M.; Travesset, A.; Naumenko, D.; Amenitsch, H.; Erni, R.; Mahrt, R.F.; Bodnarchuk, M.I. Perovskite-type superlattices from lead halide perovskite nanocubes. Nature 2021, 593, 535–542. [Google Scholar] [CrossRef] [PubMed]

- Chan, W.K.; Zhou, D.; Yu, Z.; Tan, T.T.Y. Mechanistic studies of CsPbBr3 superstructure formation. J. Mater. Chem. C 2021, 9, 14699–14708. [Google Scholar] [CrossRef]

- Pashaei Adl, H.; Gorji, S.; Muñoz-Matutano, G.; Gualdrón-Reyes, A.F.; Suárez, I.; Chirvony, V.S.; Mora-Seró, I.; Martínez-Pastor, J.P. Superradiance emission and its thermal decoherence in lead halide perovskites superlattices. Adv. Opt. Mater. 2023, 11, 2202497. [Google Scholar] [CrossRef]

- Pan, J.; Li, X.; Gong, X.; Yin, J.; Zhou, D.; Sinatra, L.; Huang, R.; Liu, J.; Chen, J.; Dursun, I. Halogen Vacancies Enable Ligand-Assisted Self-Assembly of Perovskite Quantum Dots into Nanowires. Angew. Chem. Int. Ed. 2019, 58, 16077–16081. [Google Scholar] [CrossRef]

- Zhang, E.J.; Srinivasan, S.; Sundaresan, N.; Bogorin, D.F.; Martin, Y.; Hertzberg, J.B.; Timmerwilke, J.; Pritchett, E.J.; Yau, J.-B.; Wang, C. High-performance superconducting quantum processors via laser annealing of transmon qubits. Sci. Adv. 2022, 8, eabi6690. [Google Scholar] [CrossRef]

- Shi, Y.; Li, R.; Yin, G.; Zhang, X.; Yu, X.; Meng, B.; Wei, Z.; Chen, R. Laser-Induced Secondary Crystallization of CsPbBr3 Perovskite Film for Robust and Low Threshold Amplified Spontaneous Emission. Adv. Funct. Mater. 2022, 32, 2207206. [Google Scholar] [CrossRef]

- Vashishtha, P.; Jain, S.K.; Prajapat, P.; Verma, A.K.; Aggarwal, N.; Murdoch, B.J.; Walia, S.; Gupta, G. A Self-Driven Bidirectional Photocurrent Photodetector for Optically Controlled Logic Gates Utilizes a GaN-Nanowall Network. ACS Appl. Opt. Mater. 2024, 2, 1353–1359. [Google Scholar] [CrossRef]

- Vashishtha, P.; Dash, A.; Prajapat, P.; Goswami, P.; Walia, S.; Gupta, G. Self-Powered Broadband Photodetection of MoS2/Sb2Se3 Heterostructure. ACS Appl. Opt. Mater. 2023, 1, 1952–1962. [Google Scholar] [CrossRef]

- Mao, W.; Hall, C.R.; Bernardi, S.; Cheng, Y.-B.; Widmer-Cooper, A.; Smith, T.A.; Bach, U. Light-induced reversal of ion segregation in mixed-halide perovskites. Nat. Mater. 2021, 20, 55–61. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Yuan, M.; Zhuang, W.; Zhao, X.; Tie, S.; Xiang, J.; Lan, S. Optically-controlled quantum size effect in a hybrid nanocavity composed of a perovskite nanoparticle and a thin gold film. Laser Photonics Rev. 2021, 15, 2000480. [Google Scholar] [CrossRef]

- Zhuang, W.; Li, S.; Deng, F.; Li, G.; Tie, S.; Lan, S. Laser writing of CsPbBr3 nanocrystals mediated by closely-packed Au nanoislands. Appl. Surf. Sci. 2021, 538, 148143. [Google Scholar] [CrossRef]

- Tiguntseva, E.Y.; Baranov, D.G.; Pushkarev, A.P.; Munkhbat, B.; Komissarenko, F.; Franckevicius, M.; Zakhidov, A.A.; Shegai, T.; Kivshar, Y.S.; Makarov, S.V. Tunable hybrid Fano resonances in halide perovskite nanoparticles. Nano Lett. 2018, 18, 5522–5529. [Google Scholar] [CrossRef]

- Zhang, Z.; Song, F.; Li, Z.; Gao, Y.-F.; Sun, Y.-J.; Lou, W.-K.; Liu, X.; Zhang, Q.; Tan, P.-H.; Chang, K. Double-Cavity Modulation of Exciton Polaritons in CsPbBr3 Microwire. Nano Lett. 2022, 22, 9365–9371. [Google Scholar] [CrossRef]

- Zhang, Z.; Song, F.; Xu, K.-X.; Lou, W.-K.; Chang, K.; Zhang, J. Single-Mode Surface-Emitting Polariton Lasing with Switchable Polarization in a CsPbBr3 Microwire Folded Fabry–Pérot Cavity. ACS Photonics 2024, 11, 1085–1092. [Google Scholar] [CrossRef]

- Zhong, Y.; Zhou, C.; Hou, L.; Li, J.; Xie, W.; Dong, H.; Zhang, L. Ultrafast Optical Properties of Cavity-Enhanced Superfluorescence. Adv. Opt. Mater. 2022, 10, 2102290. [Google Scholar] [CrossRef]

- Yan, Y.; Yang, L.; Liu, W.; Wang, Q.; Li, S.; Xu, C. Spontaneous radiation amplification in a microsphere-coupled CsPbBr3 perovskite vertical structure. Adv. Opt. Mater. 2021, 9, 2001932. [Google Scholar] [CrossRef]

- Wang, C.; Chen, Z.; Liu, Z.; Ma, T.; Chen, X.; Zhang, M.; Luo, D.; Hyun, B.R.; Liu, X. Adjusting Microscale to Atomic-Scale Structural Order in PbS Nanocrystal Superlattice for Enhanced Photodetector Performance. Small 2023, 19, 2300975. [Google Scholar] [CrossRef]

- Wang, C.; Han, D.; Wang, J.; Yang, Y.; Liu, X.; Huang, S.; Zhang, X.; Chang, S.; Wu, K.; Zhong, H. Dimension control of in situ fabricated CsPbClBr2 nanocrystal films toward efficient blue light-emitting diodes. Nat. Commun. 2020, 11, 6428. [Google Scholar] [CrossRef] [PubMed]

- Johnson, P.B.; Christy, R.-W. Optical constants of the noble metals. Phys. Rev. B 1972, 6, 4370. [Google Scholar] [CrossRef]

- Haeger, T.; Ketterer, M.; Bahr, J.; Pourdavoud, N.; Runkel, M.; Heiderhoff, R.; Riedl, T. Thermal properties of CsPbCl3 thin films across phase transitions. J. Phys. Mater. 2020, 3, 024004. [Google Scholar] [CrossRef]

- Evarestov, R.; Kotomin, E.; Senocrate, A.; Kremer, R.; Maier, J. First-principles comparative study of perfect and defective CsPbX3 (X= Br, I) crystals. Phys. Chem. Chem. Phys. 2020, 22, 3914–3920. [Google Scholar] [CrossRef] [PubMed]

- Cha, J.-H.; Han, J.H.; Yin, W.; Park, C.; Park, Y.; Ahn, T.K.; Cho, J.H.; Jung, D.-Y. Photoresponse of CsPbBr3 and Cs4PbBr6 perovskite single crystals. J. Phys. Chem. Lett. 2017, 8, 565–570. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, S.; Zhang, Y.; Meng, J.; Tan, X.; Chen, J.; Panmai, M.; Xiang, J. Dynamic control of the directional scattering of single Mie particle by laser induced metal insulator transitions. Nanophotonics 2024, 13, 3815–3823. [Google Scholar] [CrossRef]

- Li, S.; Deng, F.; Zhou, L.; Lin, Z.; Panmai, M.; Liu, S.; Mao, Y.; Luo, J.; Xiang, J.; Dai, J. Revealing defect-bound excitons in WS2 monolayer at room temperature by exploiting the transverse electric polarized wave supported by a Si3N4/Ag heterostructure. Nanophotonics 2023, 12, 4485–4494. [Google Scholar] [CrossRef]

- Li, S.; Panmai, M.; Tie, S.; Xu, Y.; Xiang, J.; Lan, S. Regulating disordered plasmonic nanoparticles into polarization sensitive metasurfaces. Nanophotonics 2021, 10, 1553–1563. [Google Scholar] [CrossRef]

- Chen, J.; Tzou, D.; Beraun, J. A semiclassical two-temperature model for ultrafast laser heating. Int. J. Heat Mass Transf. 2006, 49, 307–316. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Zhang, Y.; Zhao, Z.; Cheng, S.; Li, Z.; Liu, Y.; Deng, Q.; Dai, J.; Zheng, Y.; Lin, Z. Ultrastable and Low-Threshold Two-Photon-Pumped Amplified Spontaneous Emission from CsPbBr3/Ag Hybrid Microcavity. Nanomaterials 2024, 14, 1622. https://doi.org/10.3390/nano14201622

Li S, Zhang Y, Zhao Z, Cheng S, Li Z, Liu Y, Deng Q, Dai J, Zheng Y, Lin Z. Ultrastable and Low-Threshold Two-Photon-Pumped Amplified Spontaneous Emission from CsPbBr3/Ag Hybrid Microcavity. Nanomaterials. 2024; 14(20):1622. https://doi.org/10.3390/nano14201622

Chicago/Turabian StyleLi, Shulei, Yatao Zhang, Zhiran Zhao, Shiyi Cheng, Zixin Li, Yuanyuan Liu, Quantong Deng, Jun Dai, Yunbao Zheng, and Zhenxu Lin. 2024. "Ultrastable and Low-Threshold Two-Photon-Pumped Amplified Spontaneous Emission from CsPbBr3/Ag Hybrid Microcavity" Nanomaterials 14, no. 20: 1622. https://doi.org/10.3390/nano14201622