Microstructure Evolution of the Interface in SiCf/TiC-Ti3SiC2 Composite under Sequential Xe-He-H Ion Irradiation and Annealing Process

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of SiCf/TiC-Ti3SiC2 Interface

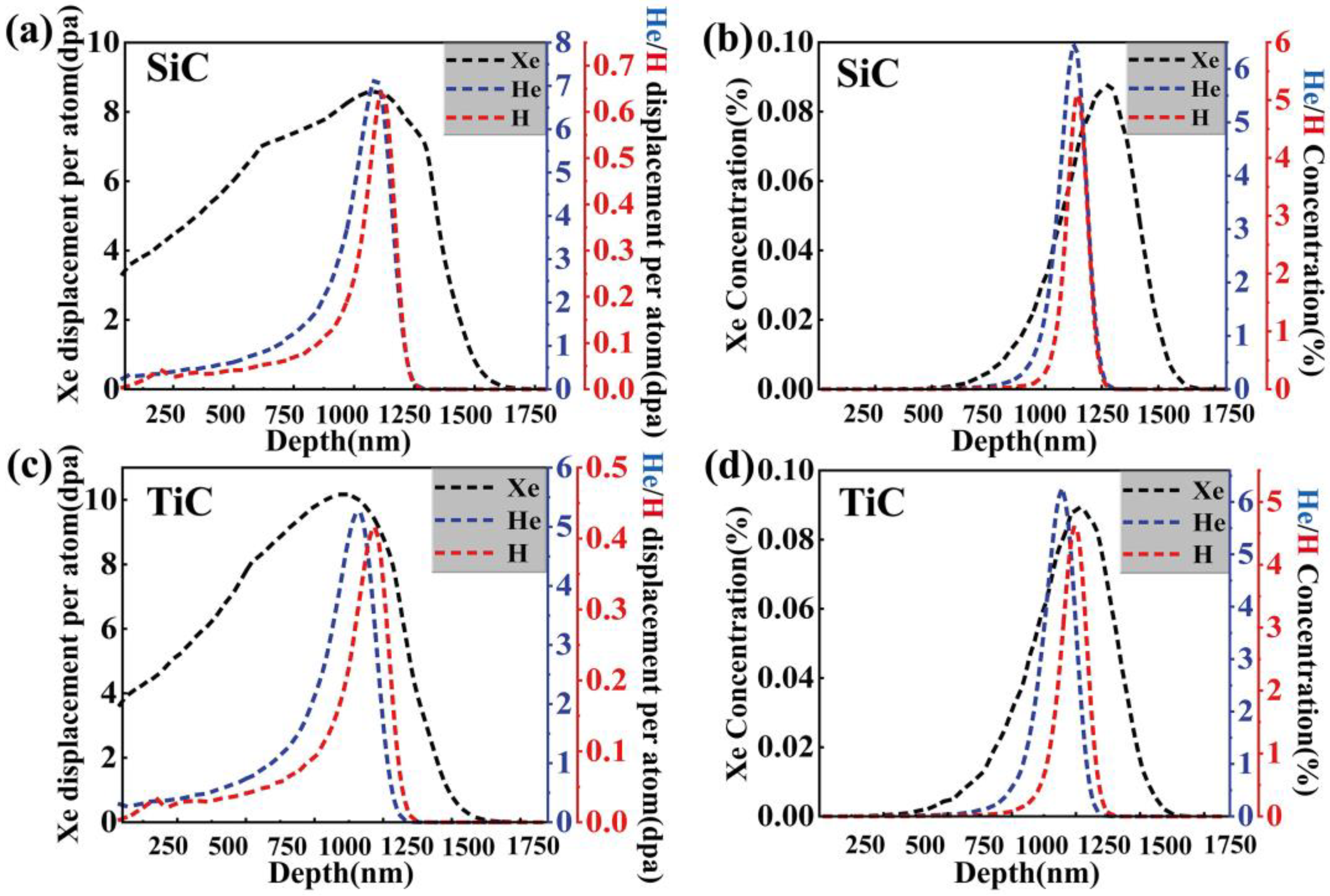

2.3. Ion Irradiation

2.4. Characterization Methods

3. Results

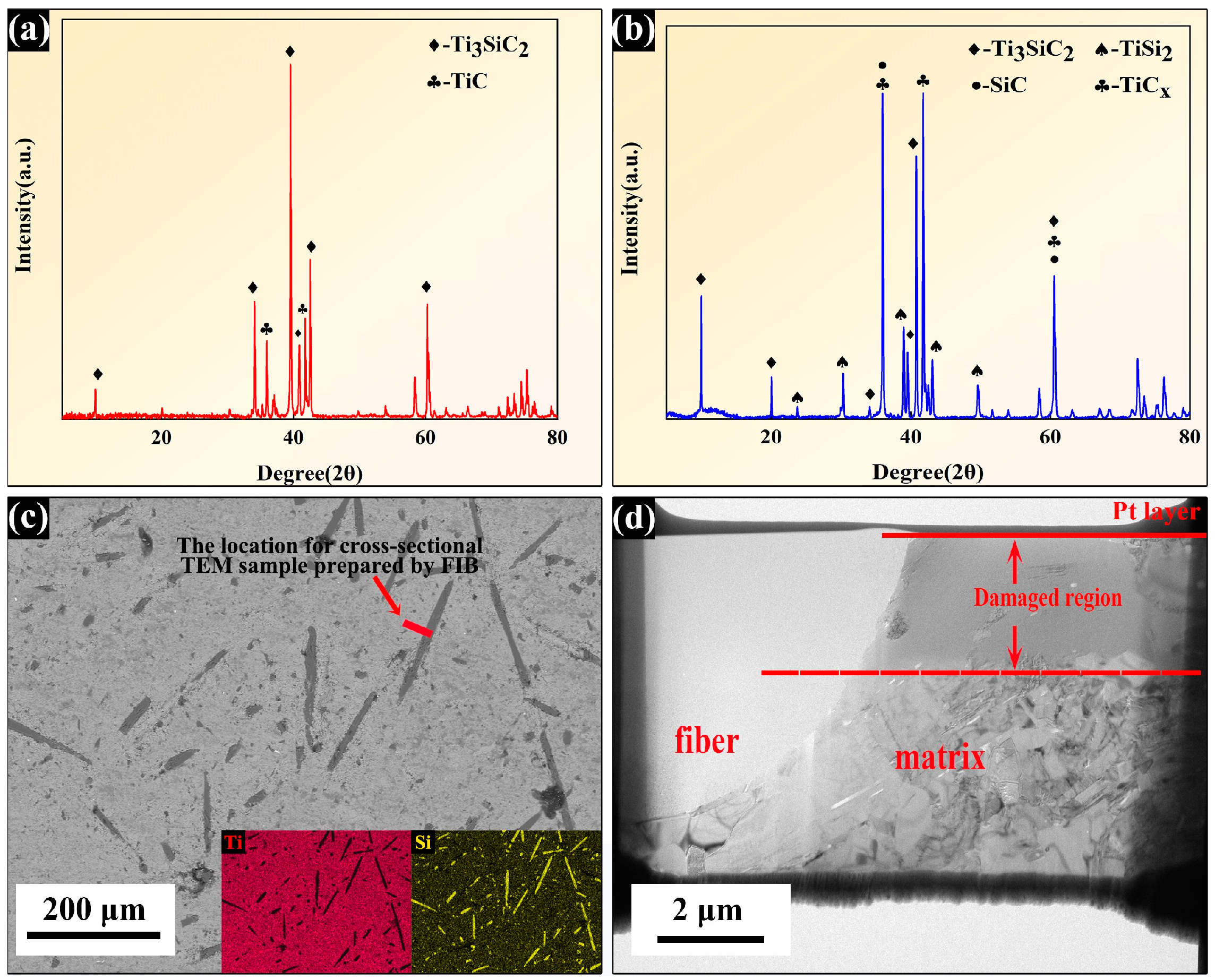

3.1. Characterization of SiCf/TiC-Ti3SiC2 Composites

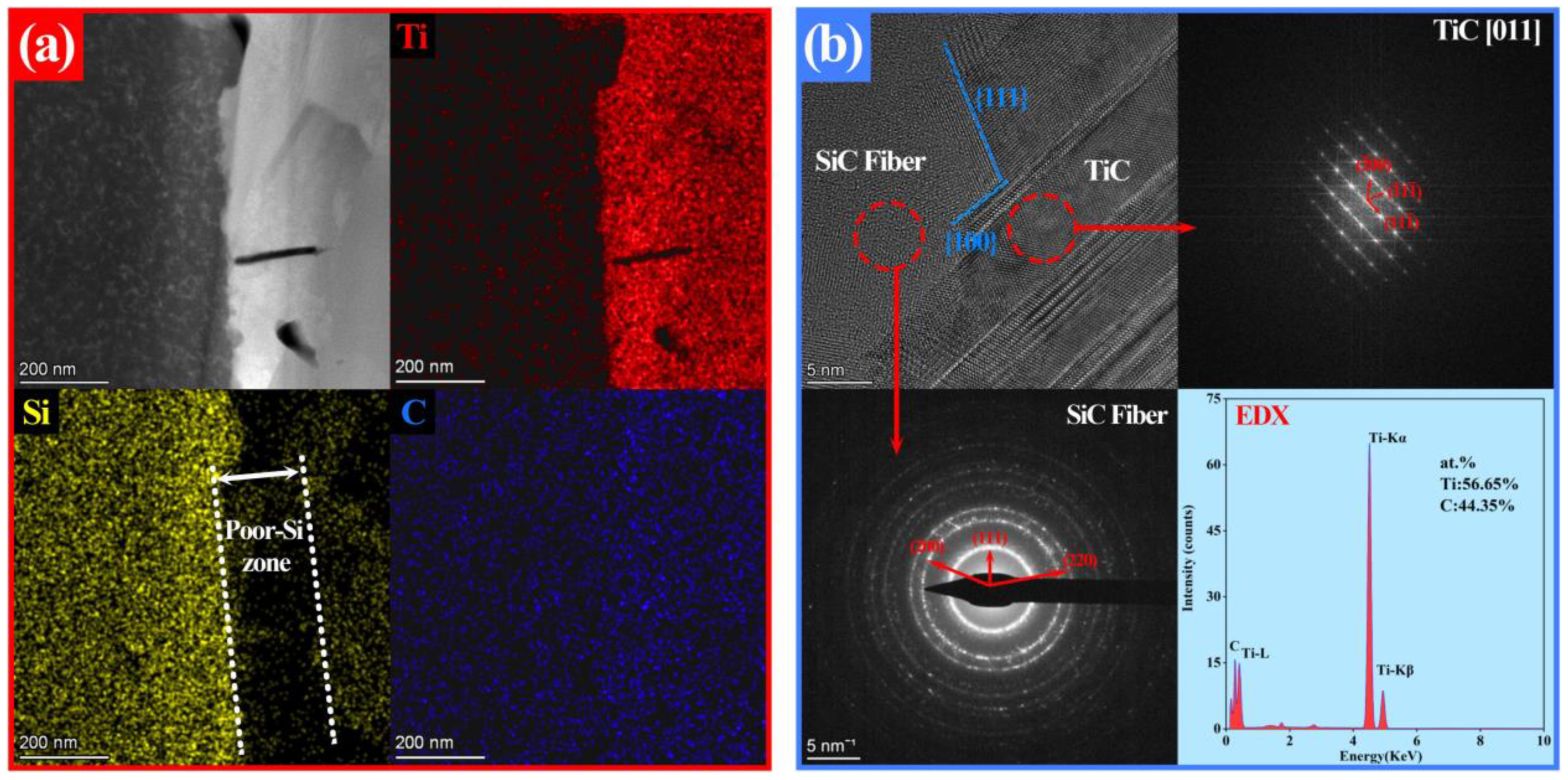

3.2. Microstructure Evolutions of the Irradiated SiCf/TiC Interface before and after Annealing

4. Discussion

4.1. The Decomposition of Ti3SiC2 and the Formation of TiC Coatings

4.2. The Microstructure Evolution of Irradiated SiCf/TiC Interface Structure

4.3. The Phase Transformation and Cracking of Irradiated SiCf/TiC Interface Structure after 900 °C Annealing

5. Conclusions

- (1)

- The behaviors of the SiCf/TiC interface under three different ion irradiation conditions (single Xe, Xe + He, and Xe + He + H) were researched. After irradiation, the SiC fibers became completely amorphous, while partial amorphization and high-density stacking faults were observed in TiC. The implanted H ions introduced more damage, thereby exacerbating the interface coarsening.

- (2)

- After 900 °C annealing, the implanted He and H ions preferred to accumulate in the SiCf/TiC interface region and formed bubbles. The H ions reduced surface free energy, thereby promoting the nucleation and growth of bubbles, which caused cracking. Due to the strong absorption effect of the interface on irradiation defects, the SiC fiber regions near the interface returned to their original nano-polycrystalline structure, which suggests that the materials’ resistance to radiation can be enhanced through rational interface designs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ni, N.; Hudson, D.; Wei, J.; Wang, P.; Lozano-Perez, S.; Smith, G.; Sykes, J.; Yardley, S.; Moore, K.; Lyon, S. How the crystallography and nanoscale chemistry of the metal/oxide interface develops during the aqueous oxidation of zirconium cladding alloys. Acta Mater. 2012, 60, 7132–7149. [Google Scholar] [CrossRef]

- Mazères, B.; Desgranges, C.; Toffolon-Masclet, C.; Monceau, D. Experimental study and numerical simulation of high temperature (1100–1250 °C) oxidation of prior-oxidized zirconium alloy. Corros. Sci. 2016, 103, 10–19. [Google Scholar] [CrossRef]

- Kam, D.H.; Lee, J.H.; Lee, T.; Jeong, Y.H. Critical heat flux for SiC-and Cr-coated plates under atmospheric condition. Ann. Nucl. Energy 2015, 76, 335–342. [Google Scholar] [CrossRef]

- Yamamoto, K.; Takayama, T.; Minamino, Y.; Koizumi, Y.; Tokunaga, T.; Hagihara, K. Modification of grain boundary microstructure by controlling dissolution behavior of θ particles in Cr-containing hypereutectoid steel. Mater. Charact. 2023, 205, 113241. [Google Scholar] [CrossRef]

- Zinkle, S.J.; Terrani, K.A.; Gehin, J.C.; Ott, L.J.; Snead, L.L. Accident tolerant fuels for LWRs: A perspective. J. Nucl. Mater. 2014, 448, 374–379. [Google Scholar] [CrossRef]

- Shan, Q.; Xu, Q.; Xue, Y.; Lian, J.; Wang, Y.; Chen, C.; Zhou, Y.; Ma, Q.; Shui, A. The tensile damage behavior of SiCf/SiC–B4C after oxidation in wet atmosphere based on acoustic emission pattern recognition. J. Am. Ceram. Soc. 2021, 104, 4131–4144. [Google Scholar] [CrossRef]

- Fellah, C.; Braun, J.; Sauder, C.; Sirotti, F.; Berger, M.-H. Influence of the carbon interface on the mechanical behavior of SiC/SiC composites. Compos. Part A Appl. Sci. Manuf. 2020, 133, 105867. [Google Scholar] [CrossRef]

- Snead, L.; Burchell, T.; Katoh, Y. Swelling of nuclear graphite and high quality carbon fiber composite under very high irradiation temperature. J. Nucl. Mater. 2008, 381, 55–61. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, X.; Liu, C.; Yang, H.; Chen, B.; Qin, Y.; Xu, S.; Cheng, L.; Zhang, L. Irradiation effects on Amosic-3 silicon carbide composites by Si ions implantation. J. Eur. Ceram. Soc. 2019, 39, 4501–4509. [Google Scholar] [CrossRef]

- Katoh, Y.; Ozawa, K.; Shih, C.; Nozawa, T.; Shinavski, R.J.; Hasegawa, A.; Snead, L.L. Continuous SiC fiber, CVI SiC matrix composites for nuclear applications: Properties and irradiation effects. J. Nucl. Mater. 2014, 448, 448–476. [Google Scholar] [CrossRef]

- Agarwal, S.; Koyanagi, T.; Bhattacharya, A.; Wang, L.; Katoh, Y.; Hu, X.; Pagan, M.; Zinkle, S.J. Neutron irradiation-induced microstructure damage in ultra-high temperature ceramic TiC. Acta Mater. 2020, 186, 1–10. [Google Scholar] [CrossRef]

- Yang, J.; Ye, F.; Cheng, L. In-situ synthesized nano-porous titanium carbide coating on silicon carbide fibres using titanium tetrachloride vapour. Ceram. Int. 2023, 49, 7996–8004. [Google Scholar] [CrossRef]

- Barsoum, M.W. The MN+1AXN phases: A new class of solids: Thermodynamically stable nanolaminates. Prog. Solid State Chem. 2000, 28, 201–281. [Google Scholar] [CrossRef]

- Whittle, K.R.; Blackford, M.; Aughterson, R.; Moricca, S.; Lumpkin, G.R.; Riley, D.; Zaluzec, N. Radiation tolerance of Mn+1AXn phases, Ti3AlC2 and Ti3SiC2. Acta Mater. 2010, 58, 4362–4368. [Google Scholar] [CrossRef]

- Liu, S.; Yang, T.; Zhang, J.; Yan, Z.; Lu, Y.; Han, D.; Wang, C.; Fang, Y.; Wang, Y. Thermal effects in ion irradiated Ti2AlC and Ti3SiC2. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2018, 435, 50–55. [Google Scholar] [CrossRef]

- Zhang, J.W.; Hu, C.F.; Wang, Y.G.; Huang, Q.; Cui, P. Interfacial reactions between polymer derived SiC fiber and Ti3Si(Al)C2. Key Eng. Mater. 2013, 544, 238–244. [Google Scholar] [CrossRef]

- Yang, J.; Ye, F.; Cheng, L. In-situ formation of Ti3SiC2 interphase in SiCf/SiC composites by molten salt synthesis. J. Eur. Ceram. Soc. 2022, 42, 1197–1207. [Google Scholar] [CrossRef]

- Tao, P.; Liu, W.; Wang, Y. Fabrication of SiCf/Ti3SiC2 composites with high thermal conductivity by spark plasma sintering. Ceram. Int. 2020, 46, 2571–2575. [Google Scholar] [CrossRef]

- Cappia, F.; Cullison, M.; Chen, T.; Kombaiah, B.; Bawane, K.; Teng, F.; Madden, J.; Perez, E.; Yao, T.; Lei, P. Grain subdivision and structural modifications by high-energy heavy ions in UO2 with different initial grain size. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2022, 515, 48–60. [Google Scholar] [CrossRef]

- Yao, T.; Guo, X.; Lei, P.; Wang, Y.; Frankel, G.S.; Lian, J. Corrosion interactions between stainless steel and lead vanado-iodoapatite nuclear waste form part II. NPJ Mater. Degrad. 2020, 4, 15. [Google Scholar] [CrossRef]

- Guo, X.; Gin, S.; Lei, P.; Yao, T.; Liu, H.; Schreiber, D.K.; Ngo, D.; Viswanathan, G.; Li, T.; Kim, S.H. Self-accelerated corrosion of nuclear waste forms at material interfaces. Nat. Mater. 2020, 19, 310–316. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Gin, S.; Lei, P.; Yao, T.; Liu, H.; Schreiber, D.K.; Ngo, D.; Viswanathan, G.; Li, T.; Kim, S.H. Reply to: How much does corrosion of nuclear waste matrices matter. Nat. Mater. 2020, 19, 962–963. [Google Scholar] [CrossRef] [PubMed]

- Lei, P.; Yang, K.; Shi, T.; Wei, M.; Ran, G.; Lu, C. Surface alteration and chemical durability of hollandite (Cr, Al and Ti) consolidated by spark plasma sintering in acid solution. J. Nucl. Mater. 2022, 568, 153892. [Google Scholar] [CrossRef]

- Lei, P.; Yao, T.; Gong, B.; Zhu, W.; Ran, G.; Lian, J. Spark plasma sintering-densified vanadinite apatite-based chlorine waste forms with high thermal stability and chlorine confinement. J. Nucl. Mater. 2020, 528, 151857. [Google Scholar] [CrossRef]

- Lei, P.; Ji, X.; Qiu, J.; Si, J.; Peng, T.; Teng, C.; Wu, L. The Influence of Grain Size on Microstructure Evolution in CeO2 under Xenon Ion Irradiation. Nanomaterials 2024, 14, 1498. [Google Scholar] [CrossRef]

- Chen, J.; Ye, F.; Cheng, L.; Yang, J.; Chen, X. Preparation and properties of Ti3SiC2 preform reinforced SiC ceramic matrix composites. J. Eur. Ceram. Soc. 2023, 43, 3146–3157. [Google Scholar] [CrossRef]

- Kimura, T. Molten salt synthesis of ceramic powders. In Advances in Ceramics—Synthesis and Characterization, Processing and Specific Applications; IntechOpen: London, UK, 2011; pp. 75–100. [Google Scholar]

- Dash, A.; Sohn, Y.J.; Vaßen, R.; Guillon, O.; Gonzalez-Julian, J. Synthesis of Ti3SiC2 MAX phase powder by a molten salt shielded synthesis (MS3) method in air. J. Eur. Ceram. Soc. 2019, 39, 3651–3659. [Google Scholar] [CrossRef]

- Ziegler, J.F.; Ziegler, M.D.; Biersack, J.P. SRIM–The stopping and range of ions in matter (2010). Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2010, 268, 1818–1823. [Google Scholar] [CrossRef]

- Emmerlich, J.; Music, D.; Eklund, P.; Wilhelmsson, O.; Jansson, U.; Schneider, J.M.; Högberg, H.; Hultman, L. Thermal stability of Ti3SiC2 thin films. Acta Mater. 2007, 55, 1479–1488. [Google Scholar] [CrossRef]

- Qin, J.; He, D. Phase stability of Ti3SiC2 at high pressure and high temperature. Ceram. Int. 2013, 39, 9361–9367. [Google Scholar] [CrossRef]

- Magnus, C.; Rainforth, W.M. Spark plasma sintering (SPS) synthesis and tribological behaviour of MAX phase composite of the family Tin+1SiCn (n = 2). Wear 2019, 438, 203062. [Google Scholar] [CrossRef]

- He, G.; Xu, J.; Zhang, Z.; Qian, Y.; Zuo, J.; Li, M.; Liu, C. Interfacial reactions and mechanical properties of SiC fiber reinforced Ti3SiC2 and Ti3(SiAl)C2 composites. Mater. Sci. Eng. A 2021, 827, 142069. [Google Scholar] [CrossRef]

- Barr, C.M.; Chen, E.Y.; Nathaniel, J.E.; Lu, P.; Adams, D.P.; Dingreville, R.; Boyce, B.L.; Hattar, K.; Medlin, D.L. Irradiation-induced grain boundary facet motion: In situ observations and atomic-scale mechanisms. Sci. Adv. 2022, 8, eabn0900. [Google Scholar] [CrossRef]

- Zinkle, S. 1.03—Radiation-Induced effects on microstructure. Compr. Nucl. Mater. 2012, 1, 65–98. [Google Scholar]

- Hobbs, L.W.; Clinard, F.W., Jr.; Zinkle, S.J.; Ewing, R.C. Radiation effects in ceramics. J. Nucl. Mater. 1994, 216, 291–321. [Google Scholar] [CrossRef]

- Chen, C.-H.; Zhang, Y.; Fu, E.; Wang, Y.; Crespillo, M.L.; Liu, C.-Z.; Shannon, S.; Weber, W.J. Irradiation-induced microstructural change in helium-implanted single crystal and nano-engineered SiC. J. Nucl. Mater. 2014, 453, 280–286. [Google Scholar] [CrossRef]

- Pramono, Y.; Sasaki, K.; Yano, T. Release and diffusion rate of helium in neutron-irradiated SiC. J. Nucl. Sci. Technol. 2004, 41, 751–755. [Google Scholar] [CrossRef]

- Ye, C.; Xue, J.; Liu, T.; Shu, R.; Yan, Y.; Liao, Y.; Ren, Q.; Ran, G.; Sun, K.; Jiang, L. The microstructure evolution in a SiCf/SiC composite under triple ion beam irradiation. Ceram. Int. 2020, 46, 9901–9906. [Google Scholar] [CrossRef]

- Liu, Y.-L.; Zhang, Y.; Zhou, H.-B.; Lu, G.-H.; Liu, F.; Luo, G.-N. Vacancy trapping mechanism for hydrogen bubble formation in metal. Phys. Rev. B Condens. Matter Mater. Phys. 2009, 79, 172103. [Google Scholar] [CrossRef]

- Jastrzebski, Z.D.; Komanduri, R. The Nature and Properties of Engineering Materials; Wiley: Hoboken, NJ, USA, 1988. [Google Scholar]

- Sun, J.; You, Y.-W.; Hou, J.; Li, X.; Li, B.; Liu, C.; Wang, Z. The effect of irradiation-induced point defects on energetics and kinetics of hydrogen in 3C-SiC in a fusion environment. Nucl. Fusion 2017, 57, 066031. [Google Scholar] [CrossRef]

- Dong, W.; Shen, Q.; Wei, M.; Lei, P.; Song, L.; Chang, Q.; Ye, C. Research on the surface damage of Si+ and H+ co-implanted 6H-SiC before and after annealing. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2023, 538, 81–86. [Google Scholar] [CrossRef]

| Materials | Purity | Supplier |

|---|---|---|

| Ti | 99.8% | Aladdin lnc., Shanghai, China |

| Si | 99.9% | Aladdin lnc., Shanghai, China |

| graphite | 99.95% | Macklin Inc., Shanghai, China |

| NaCl | 99.8% | Macklin Inc., Shanghai, China |

| KCl | 99.9% | Macklin Inc., Shanghai, China |

| ethanol | 99.70% | Sinopharm Chemical Reagent Co., Ltd., Shanghai, China |

| Influence (Ions/cm2) | Temperature for Annealing (°C) | Time for Annealing (h) | ||

|---|---|---|---|---|

| Xe Ions | He Ions | H Ions | ||

| 3.5 × 1015 | 900 | 2 | ||

| 3.5 × 1015 | 1 × 1017 | |||

| 3.5 × 1015 | 1 × 1017 | 6 × 1016 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, P.; Chang, Q.; Xiao, M.; Ye, C.; Qi, P.; Shi, F.; Hang, Y.; Li, Q.; Peng, Q. Microstructure Evolution of the Interface in SiCf/TiC-Ti3SiC2 Composite under Sequential Xe-He-H Ion Irradiation and Annealing Process. Nanomaterials 2024, 14, 1629. https://doi.org/10.3390/nano14201629

Lei P, Chang Q, Xiao M, Ye C, Qi P, Shi F, Hang Y, Li Q, Peng Q. Microstructure Evolution of the Interface in SiCf/TiC-Ti3SiC2 Composite under Sequential Xe-He-H Ion Irradiation and Annealing Process. Nanomaterials. 2024; 14(20):1629. https://doi.org/10.3390/nano14201629

Chicago/Turabian StyleLei, Penghui, Qing Chang, Mingkun Xiao, Chao Ye, Pan Qi, Fangjie Shi, Yuhua Hang, Qianwu Li, and Qing Peng. 2024. "Microstructure Evolution of the Interface in SiCf/TiC-Ti3SiC2 Composite under Sequential Xe-He-H Ion Irradiation and Annealing Process" Nanomaterials 14, no. 20: 1629. https://doi.org/10.3390/nano14201629

APA StyleLei, P., Chang, Q., Xiao, M., Ye, C., Qi, P., Shi, F., Hang, Y., Li, Q., & Peng, Q. (2024). Microstructure Evolution of the Interface in SiCf/TiC-Ti3SiC2 Composite under Sequential Xe-He-H Ion Irradiation and Annealing Process. Nanomaterials, 14(20), 1629. https://doi.org/10.3390/nano14201629