A Light-Powered Micropump with Dynamic Collective Behavior for Reparation

Abstract

:1. Introduction

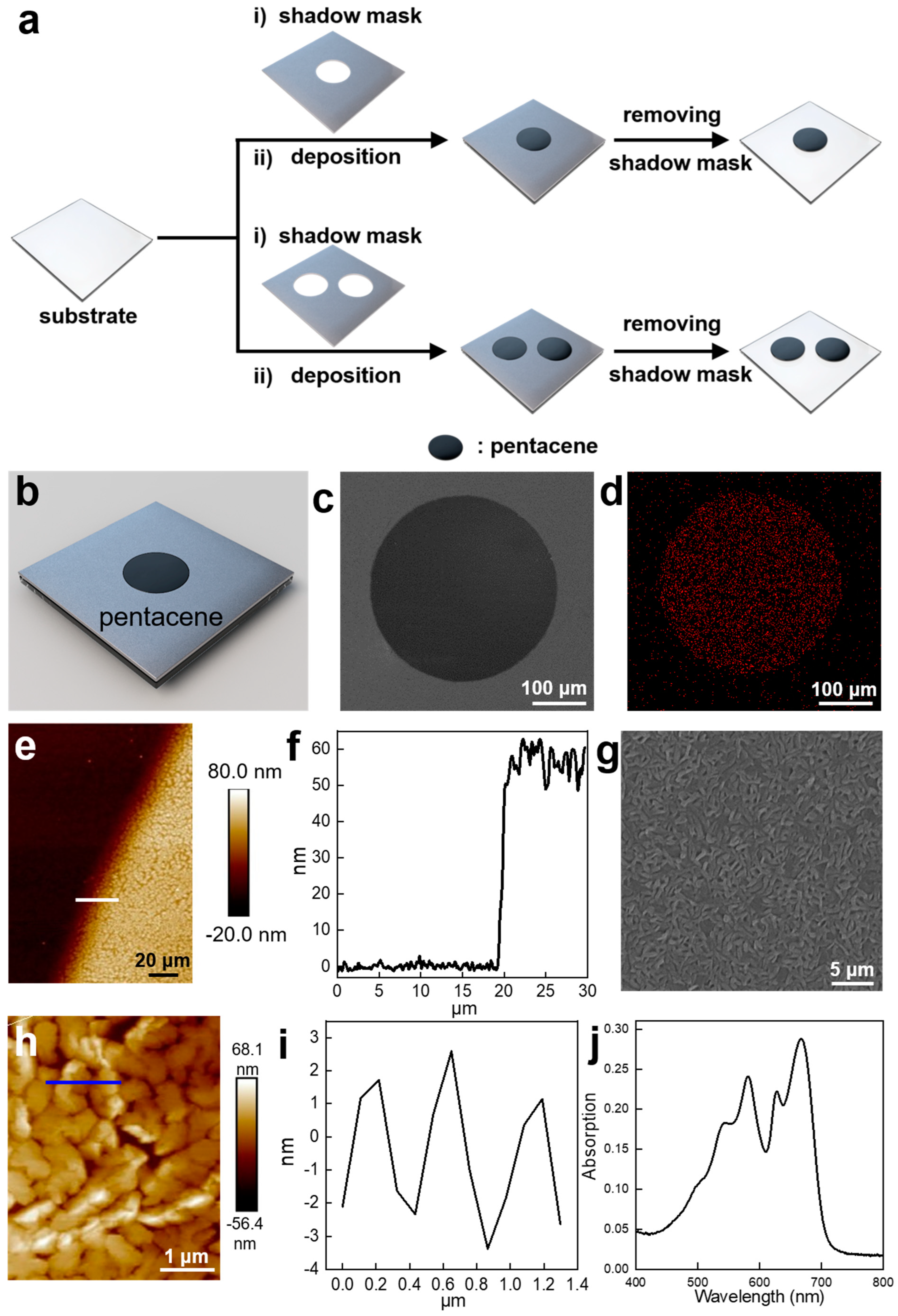

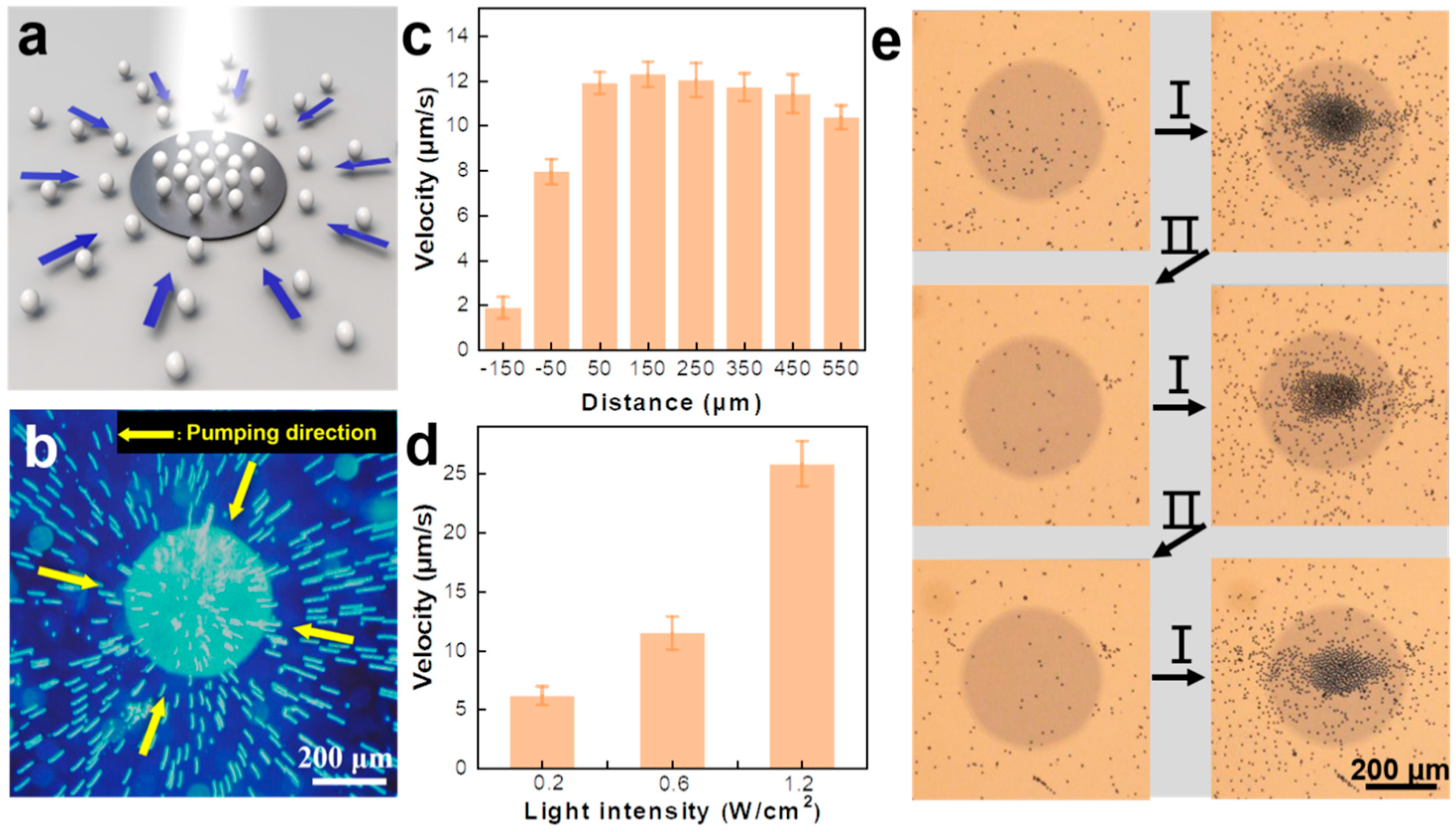

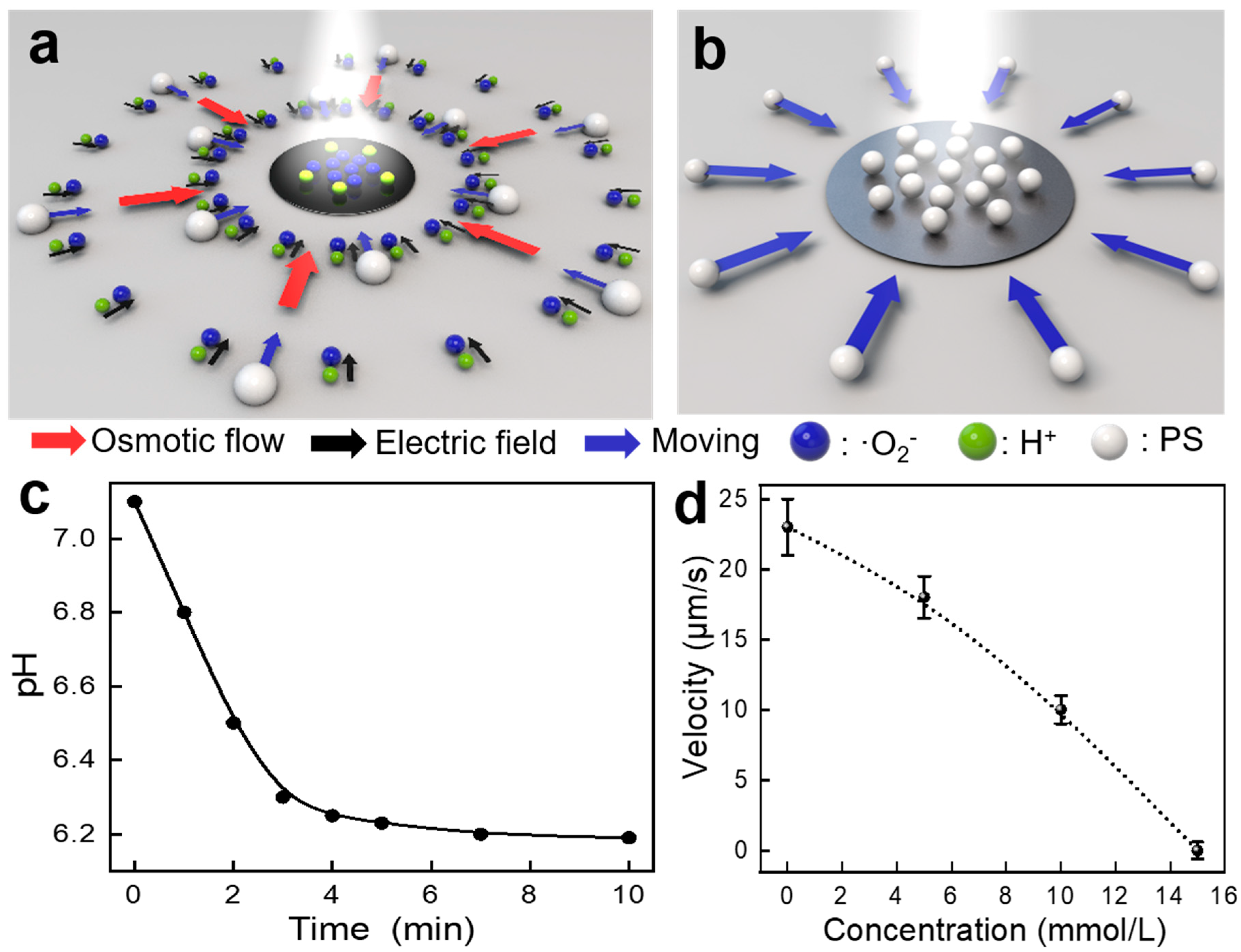

2. Results and Discussion

3. Conclusions

4. Experimental Procedure

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Abid, J.-P.; Frigoli, M.; Pansu, R.; Szeftel, J.; Zyss, J.; Larpent, C.; Brasselet, S. Light-Driven Directed Motion of Azobenzene-Coated Polymer Nanoparticles in an Aqueous Medium. Langmuir 2011, 27, 7967–7971. [Google Scholar] [CrossRef] [PubMed]

- Xuan, M.J.; Wu, Z.G.; Shao, J.X.; Dai, L.R.; Si, T.Y.; He, Q. Near Infrared Light-Powered Janus Mesoporous Silica Nanoparticle Motors. J. Am. Chem. Soc. 2016, 138, 6492–6497. [Google Scholar] [CrossRef] [PubMed]

- Ye, Z.R.; Sun, Y.Y.; Zhang, H.; Song, B.; Dong, B. A Phototactic Micromotor Based on Platinum Nanoparticle Decorated Carbon Nitride. Nanoscale 2017, 9, 18516–18522. [Google Scholar] [CrossRef] [PubMed]

- Hu, N.R.S.; Sun, M.M.; Lin, X.K.; Gao, C.Y.; Zhang, B.; Zheng, C.; Xie, H.; He, Q. Self-Propelled Rolled-Up Polyelectrolyte Multilayer Microrockets. Adv. Funct. Mater. 2018, 28, 1705684. [Google Scholar] [CrossRef]

- Xu, B.R.; Zhang, B.R.; Wang, L.; Huang, G.S.; Mei, Y.F. Tubular Micro/Nanomachines: From the Basics to Recent Advances. Adv. Funct. Mater. 2018, 28, 1705872. [Google Scholar] [CrossRef]

- Pavlick, R.A.; Sengupta, S.; McFadden, T.; Zhang, H.; Sen, A. A Polymerization-Powered Motor. Angew. Chem. 2011, 50, 9374–9377. [Google Scholar] [CrossRef] [PubMed]

- Howse, J.R.; Jones, R.A.L.; Ryan, A.J.; Gough, T.; Vafabakhsh, R.; Golestanian, R. Self-Motile Colloidal Particles: From Directed Propulsion to Random Walk. Phys. Rev. Lett. 2007, 99, 048102. [Google Scholar] [CrossRef]

- Dong, Y.G.; Liu, M.; Zhang, H.; Dong, B. Reconfigurable OR and XOR Logic Gates Based on Dual Responsive On-Off-On Micromotors. Nanoscale 2016, 8, 8378–8383. [Google Scholar] [CrossRef]

- Brooks, A.M.; Tasinkevych, M.; Sabrina, S.; Velegol, D.; Sen, A.; Bishop, K.J.M. Shape-Directed Rotation of Homogeneous Micromotors via Catalytic Self-Electrophoresis. Nat. Commun. 2019, 10, 495. [Google Scholar] [CrossRef]

- Dong, R.F.; Hu, Y.; Wu, Y.F.; Gao, W.; Ren, B.Y.; Wang, Q.L.; Cai, Y.P. Visible-Light-Driven BiOI-Based Janus Micromotor in Pure Water. J. Am. Chem. Soc. 2017, 139, 1722–1725. [Google Scholar] [CrossRef]

- Kong, L.; Rohaizad, N.; Nasir, M.Z.M.; Guan, J.G.; Pumera, M. Micromotor-Assisted Human Serum Glucose Biosensing. Anal. Chem. 2019, 91, 5660–5666. [Google Scholar] [CrossRef]

- Zhang, X.Q.; Chen, C.T.; Wu, J.; Ju, H.X. Bubble-Propelled Jellyfish-like Micromotors for DNA Sensing. ACS Appl. Mater. Interfaces 2019, 11, 13581–13588. [Google Scholar] [CrossRef]

- Li, J.X.; Shklyaev, O.E.; Li, T.L.; Liu, W.J.; Shum, H.; Rozen, I.; Balazs, A.C.; Wang, J. Self-Propelled Nanomotors Autonomously Seek and Repair Cracks. Nano Lett. 2015, 15, 7077–7085. [Google Scholar] [CrossRef]

- Xu, D.; Zhou, C.; Zhan, C.; Wang, Y.; You, Y.; Pan, X.; Jiao, J.; Zhang, R.; Dong, Z.; Wang, W.; et al. Enzymatic Micromotors as a Mobile Photosensitizer Platform for Highly Efficient On-Chip Targeted Antibacteria Photodynamic Therapy. Adv. Funct. Mater. 2019, 29, 1807727. [Google Scholar] [CrossRef]

- Gao, C.Y.; Lin, Z.H.; Wang, D.L.; Wu, Z.G.; Xie, H.; He, Q. Red Blood Cell-Mimicking Micromotor for Active Photodynamic Cancer Therapy. ACS Appl. Mater. Interfaces 2019, 11, 23392–23400. [Google Scholar] [CrossRef]

- Pan, D.; Mou, F.Z.; Li, X.F.; Deng, Z.Y.; Sun, J.; Xu, L.L.; Guan, J.G. Multifunctional Magnetic Oleic Acid-Coated MnFe2O4/Polystyrene Janus Particles for Water Treatment. J. Mater. Chem. A 2016, 4, 11768–11774. [Google Scholar] [CrossRef]

- Zhang, J.; Mou, F.; Wu, Z.; Tang, S.; Xie, H.; You, M.; Liang, X.; Xu, L.; Guan, J. Simple-Structured Micromotors Based on Inherent Asymmetry in Crystalline Phases: Design, Large-Scale Preparation, and Environmental Application. ACS Appl. Mater. Interfaces 2019, 11, 16639–16646. [Google Scholar] [CrossRef] [PubMed]

- Tu, Y.F.; Peng, F.; White, P.B.; Wilson, D.A. Redox-Sensitive Stomatocyte Nanomotors: Destruction and Drug Release in the Presence of Glutathione. Angew. Chem. 2017, 56, 7620–7624. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.L.; Zhu, H.L.; Shi, Y.; Ge, Y.; Feng, X.M.; Liu, R.Q.; Li, Y.; Ma, Y.W.; Wang, L.H. Novel Catalytic Micromotor of Porous Zeolitic Imidazolate Framework-67 for Precise Drug Delivery. Nanoscale 2018, 10, 11384–11391. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Duan, W.T.; Zhang, Z.X.; Sun, M.; Sen, A.; Mallouk, T.E. A Tale of Two Forces: Simultaneous Chemical and Acoustic Propulsion of Bimetallic Micromotors. Chem. Commun. 2015, 51, 1020–1023. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.; Zhao, L.L.; Wei, M.S.; Wang, W. Twists and Turns of Orbiting and Spinning Metallic Microparticles Powered by Megahertz Ultrasound. ACS Nano 2017, 11, 12668–12676. [Google Scholar] [CrossRef] [PubMed]

- Fan, D.L.; Yin, Z.Z.; Cheong, R.; Zhu, F.Q.; Cammarata, R.C.; Chien, C.L.; Levchenko, A. Subcellular-resolution delivery of a cytokine through precisely manipulated nanowires. Nat. Nanotechnol. 2010, 5, 545–551. [Google Scholar] [CrossRef] [PubMed]

- Dai, B.; Wang, J.; Xiong, Z.; Zhan, X.; Dai, W.; Li, C.C.; Feng, S.P.; Tang, J. Programmable Artificial Phototactic Microswimmer. Nat. Nanotechnol. 2016, 11, 1087–1092. [Google Scholar] [CrossRef] [PubMed]

- Maric, T.; Nasir, M.Z.M.; Webster, R.D.; Pumera, M. Tailoring Metal/TiO2 Interface to Influence Motion of Light-Activated Janus Micromotors. Adv. Funct. Mater. 2020, 30, 1908614. [Google Scholar] [CrossRef]

- Maric, T.; Lovind, A.; Zhang, Z.; Geng, J.; Boisen, A. Near-Infrared Light-Driven Mesoporous SiO2/Au Nanomotors for Eradication of Pseudomonas aeruginosa Biofilm. Adv. Healthc. Mater. 2023, 12, e2203018. [Google Scholar] [CrossRef] [PubMed]

- Maric, T.; Nasir, M.Z.M.; Budanovic, M.; Alduhaish, O.; Webster, R.D.; Pumera, M. Corrosion of Light Powered Pt/TiO2 Microrobots. Appl. Mater. Today 2020, 20, 100659. [Google Scholar] [CrossRef]

- Solovev, A.A.; Sanchez, S.; Schmidt, O.G. Collective Behaviour of Self-Propelled Catalytic Micromotors. Nanoscale 2013, 5, 1284–1293. [Google Scholar] [CrossRef]

- Ibele, M.; Mallouk, T.E.; Sen, A. Schooling Behavior of Light-Powered Autonomous Micromotors in Water. Angew. Chem. 2009, 48, 3308–3312. [Google Scholar] [CrossRef]

- Palacci, J.; Sacanna, S.; Steinberg, A.P.; Pine, D.J.; Chaikin, P.M. Living Crystals of Light-Activated Colloidal Surfers. Science 2013, 339, 936–940. [Google Scholar] [CrossRef]

- Deng, Z.Y.; Mou, F.Z.; Tang, S.W.; Xu, L.L.; Luo, M.; Guan, J.G. Swarming and Collective Migration of Micromotors under Near Infrared Light. Appl. Mater. Today 2018, 13, 45–53. [Google Scholar] [CrossRef]

- Lin, Z.H.; Si, T.Y.; Wu, Z.G.; Gao, C.Y.; Lin, X.K.; He, Q. Light-Activated Active Colloid Ribbons. Angew. Chem. 2017, 56, 13517–13520. [Google Scholar] [CrossRef]

- Jin, D.D.; Yu, J.F.; Yuan, K.; Zhang, L. Mimicking the Structure and Function of Ant Bridges in a Reconfigurable Microswarm for Electronic Applications. ACS Nano 2019, 13, 5999–6007. [Google Scholar] [CrossRef] [PubMed]

- McDermott, J.J.; Kar, A.; Daher, M.; Klara, S.; Wang, G.; Sen, A.; Velegol, D. Self-Generated Diffusioosmotic Flows from Calcium Carbonate Micropumps. Langmuir 2012, 28, 15491–15497. [Google Scholar] [CrossRef] [PubMed]

- Ortiz-Rivera, I.; Shum, H.; Agrawal, A.; Sen, A.; Balazs, A.C. Convective Flow Reversal in Self-Powered Enzyme Micropumps. Proc. Natl. Acad. Sci. USA 2016, 113, 2585–2590. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Pei, A.; Dong, R.F.; Wang, J. Catalytic Iridium-Based Janus Micromotors Powered by Ultralow Levels of Chemical Fuels. J. Am. Chem. Soc. 2014, 136, 2276–2279. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Wang, X.; Hahn, K.; Sanchez, S. Motion Control of Urea-Powered Biocompatible Hollow Microcapsules. ACS Nano 2016, 10, 3597–3605. [Google Scholar] [CrossRef]

- Sengupta, S.; Patra, D.; Rivera, I.O.; Agrawal, A.; Shklyaev, S.; Dey, K.K.; Figueroa, U.C.; Mallouk, T.E.; Sen, A. Self-Powered Enzyme Micropumps. Nat. Chem. 2014, 6, 415–422. [Google Scholar] [CrossRef]

- Okawa, D.; Pastine, S.J.; Zettl, A.; Frechet, J.M.J. Surface Tension Mediated Conversion of Light to Work. J. Am. Chem. Soc. 2009, 131, 5396–5398. [Google Scholar] [CrossRef]

- Yadav, V.; Zhang, H.; Pavlick, R.; Sen, A. Triggered “On/Off” Micropumps and Colloidal Photodiode. J. Am. Chem. Soc. 2012, 134, 15688–15691. [Google Scholar] [CrossRef]

- Esplandiu, M.J.; Farniya, A.A.; Bachtold, A. Silicon-Based Chemical Motors: An Efficient Pump for Triggering and Guiding Fluid Motion Using Visible Light. ACS Nano 2015, 9, 11234–11240. [Google Scholar] [CrossRef]

- Guo, Y.T.; Wang, D.C.; Li, J.A.; Sun, Y.Y.; Li, M.T.; Zhang, H.; Duan, R.M.; Zhang, D.F.; Song, B.; Dong, B. A Fuel-free Polymer-based Micropump with Optically Tunable Pumping Directions. J. Mater. Chem. C 2019, 7, 2299–2304. [Google Scholar] [CrossRef]

- Farniya, A.A.; Esplandiu, M.J.; Bachtold, A. Sequential Tasks Performed by Catalytic Pumps for Colloidal Crystallization. Langmuir 2014, 30, 11841–11845. [Google Scholar] [CrossRef] [PubMed]

- Patra, D.; Zhang, H.; Sengupta, S.; Sen, A. Dual Stimuli-Responsive, Rechargeable Micropumps via “Host-Guest” Interactions. ACS Nano 2013, 7, 7674–7679. [Google Scholar] [CrossRef] [PubMed]

- Caruso, M.M.; Schelkopf, S.R.; Jackson, A.C.; Landry, A.M.; Braun, P.V.; Moore, J.S. Microcapsules Containing Suspensions of Carbon Nanotubes. J. Mater. Chem. 2009, 19, 6093. [Google Scholar] [CrossRef]

- Chiechi, R.C.; Weiss, E.A.; Dickey, M.D.; Whitesides, G.M. Eutectic gallium-indium (EGaIn): A moldable liquid metal for electrical characterization of self-assembled monolayers. Angew. Chem. 2008, 47, 142–144. [Google Scholar] [CrossRef] [PubMed]

- Tee, B.C.K.; Wang, C.; Allen, R.; Bao, Z.N. An Electrically and Mechanically Self-Healing Composite with Pressure- and Flexion-Sensitive Properties for Electronic Skin Applications. Nat. Nanotechnol. 2012, 7, 825–832. [Google Scholar] [CrossRef] [PubMed]

- Aboudzadeh, M.A.; Munoz, M.E.; Santamaria, A.; Marcilla, R.; Mecerreyes, D. Facile Synthesis of Supramolecular Ionic Polymers that Combine Unique Rheological, Ionic Conductivity, and Self-healing Properties. Macromol. Rapid Commun. 2012, 33, 314–318. [Google Scholar] [CrossRef]

- Gong, C.K.; Liang, J.J.; Hu, W.; Niu, X.F.; Ma, S.W.; Hahn, H.T.; Pei, Q.B. A Healable, Semitransparent Silver Nanowire-Polymer Composite Conductor. Adv. Mater. 2013, 25, 4186–4191. [Google Scholar] [CrossRef]

- Odom, S.A.; Caruso, M.M.; Finke, A.D.; Prokup, A.M.; Ritchey, J.A.; Leonard, J.H.; White, S.R.; Sottos, N.R.; Moore, J.S. Restoration of Conductivity with TTF-TCNQ Charge-Transfer Salts. Adv. Funct. Mater. 2010, 20, 1721–1727. [Google Scholar] [CrossRef]

- Odom, S.A.; Tyler, T.P.; Caruso, M.M.; Ritchey, J.A.; Schulmerich, M.V.; Robinson, S.J.; Bhargava, R.; Sottos, N.R.; White, S.R.; Hersam, M.C.; et al. Autonomic Restoration of Electrical Conductivity Using Polymer-Stabilized Carbon Nanotube and Graphene Microcapsules. Appl. Phys. Lett. 2012, 101, 043106. [Google Scholar] [CrossRef]

- Kang, S.; Jones, A.R.; Moore, J.S.; White, S.R.; Sottos, N.R. Microencapsulated Carbon Black Suspensions for Restoration of Electrical Conductivity. Adv. Funct. Mater. 2014, 24, 2947–2956. [Google Scholar] [CrossRef]

- Hwang, J.; Sunesh, C.D.; Chandran, M.; Lee, J.; Choe, Y. Performance Characteristics of Pentacene-based Organic Photovoltaic Cells. Org. Electron. 2012, 13, 1809–1818. [Google Scholar] [CrossRef]

- Dong, R.F.; Zhang, Q.L.; Gao, W.; Pei, A.; Ren, B.Y. Highly Efficient Light-Driven TiO2-Au Janus Micromotors. ACS Nano 2016, 10, 839–844. [Google Scholar] [CrossRef] [PubMed]

- Duan, W.T.; Liu, R.; Sen, A. Transition between Collective Behaviors of Micromotors in Response to Different Stimuli. J. Am. Chem. Soc. 2013, 135, 1280–1283. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Wang, H.; Jiang, J.; Zhang, H.; Liu, L.; Zhang, K.; Song, B.; Dong, B. A Light-Powered Micropump with Dynamic Collective Behavior for Reparation. Nanomaterials 2024, 14, 517. https://doi.org/10.3390/nano14060517

Sun Y, Wang H, Jiang J, Zhang H, Liu L, Zhang K, Song B, Dong B. A Light-Powered Micropump with Dynamic Collective Behavior for Reparation. Nanomaterials. 2024; 14(6):517. https://doi.org/10.3390/nano14060517

Chicago/Turabian StyleSun, Yunyu, Hao Wang, Jiwei Jiang, Hui Zhang, Limei Liu, Keying Zhang, Bo Song, and Bin Dong. 2024. "A Light-Powered Micropump with Dynamic Collective Behavior for Reparation" Nanomaterials 14, no. 6: 517. https://doi.org/10.3390/nano14060517

APA StyleSun, Y., Wang, H., Jiang, J., Zhang, H., Liu, L., Zhang, K., Song, B., & Dong, B. (2024). A Light-Powered Micropump with Dynamic Collective Behavior for Reparation. Nanomaterials, 14(6), 517. https://doi.org/10.3390/nano14060517