Disinfectant-Assisted Preparation of Hierarchical ZSM-5 Zeolite with Excellent Catalytic Stabilities in Propane Aromatization

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Catalyst Preparation

2.3. Catalyst Characterization

2.4. Catalyst Evaluation

3. Results and Discussion

3.1. Catalytic Characterization

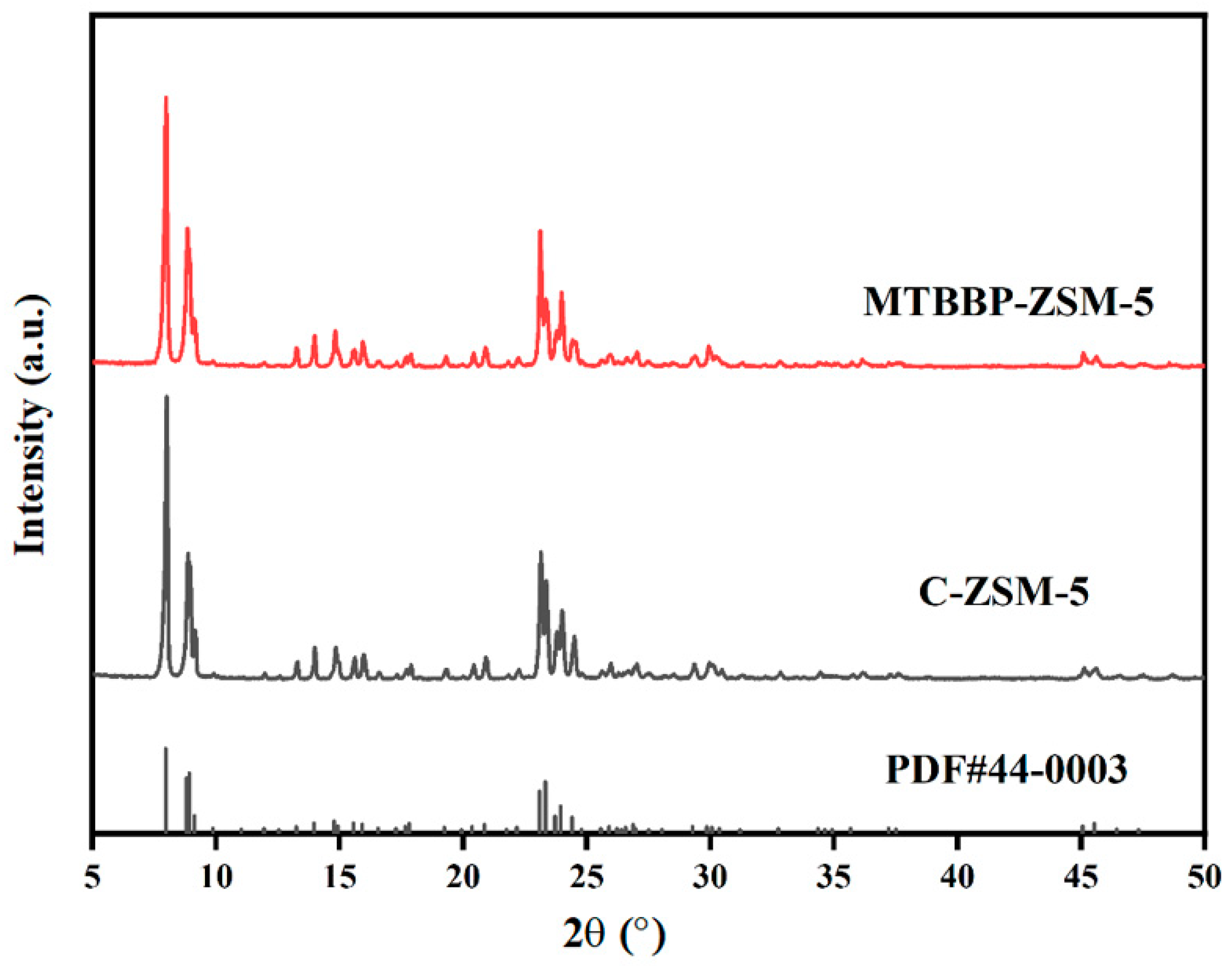

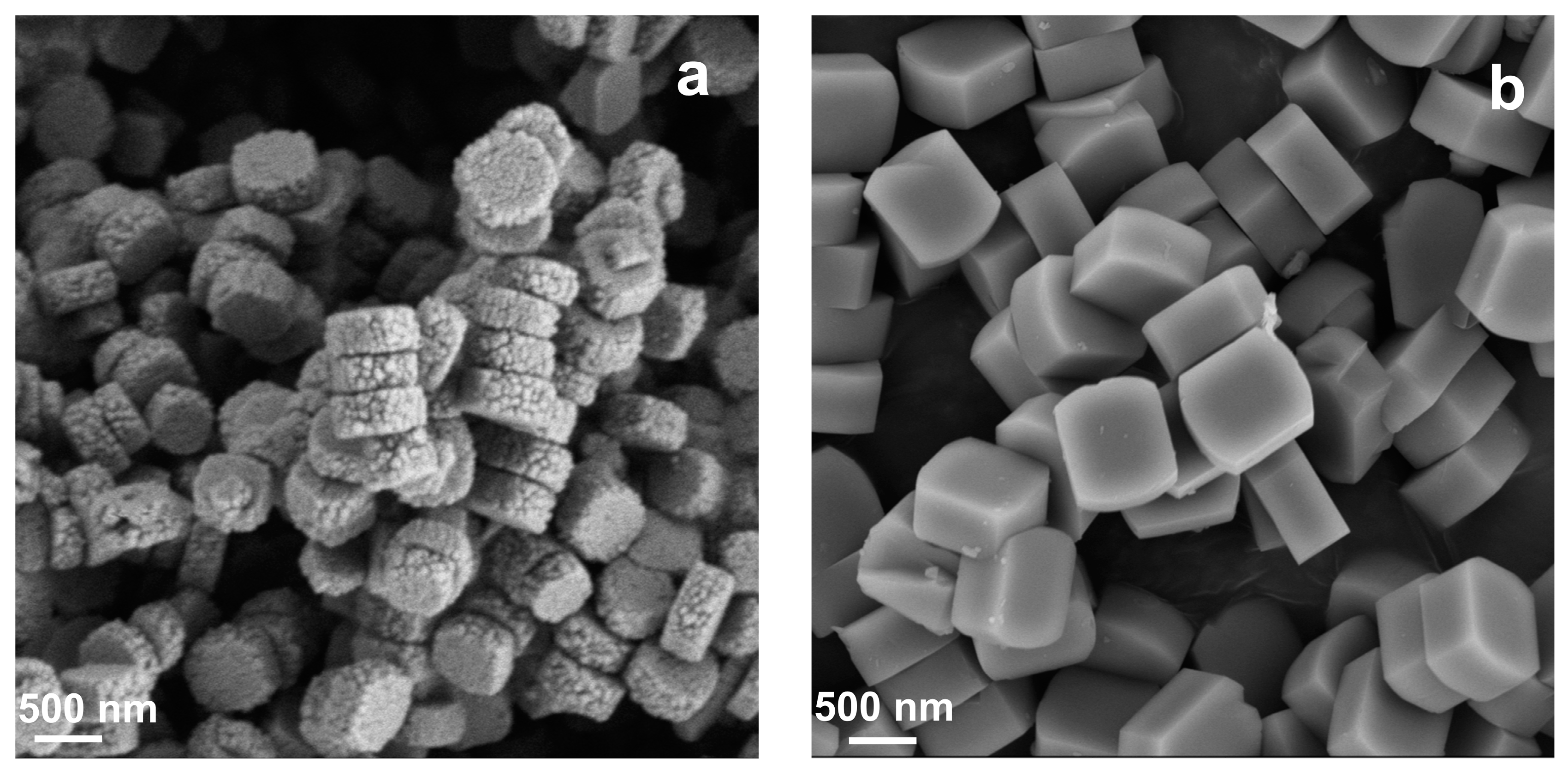

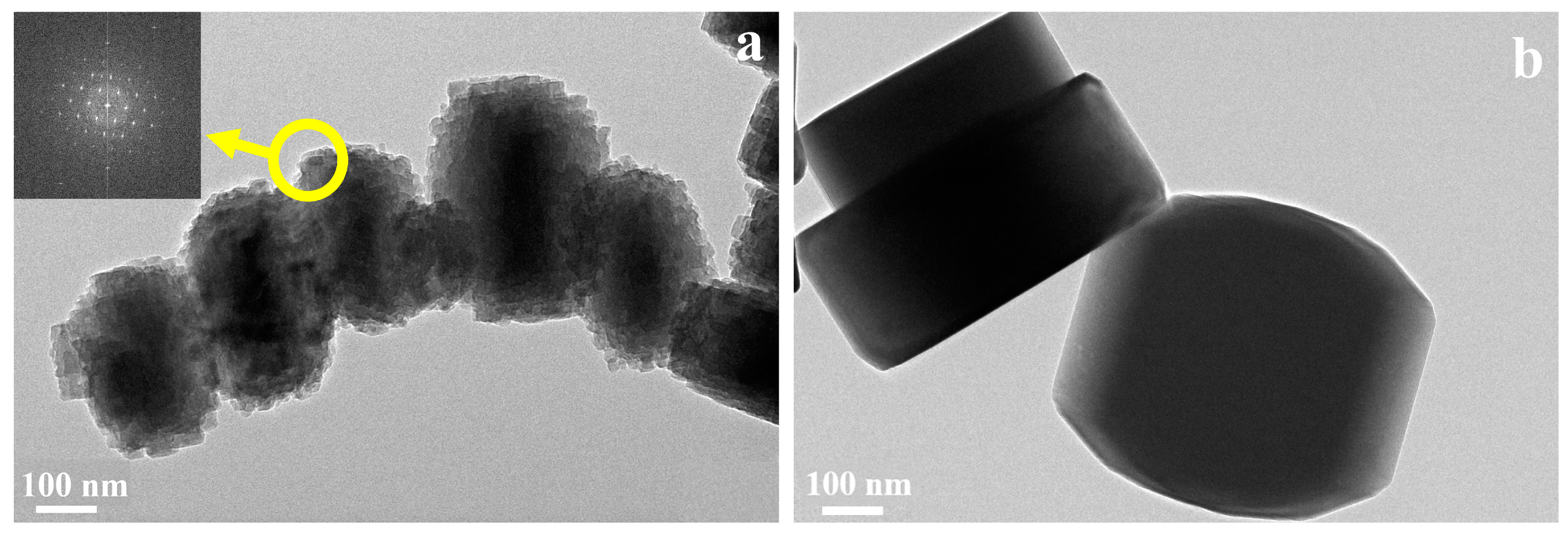

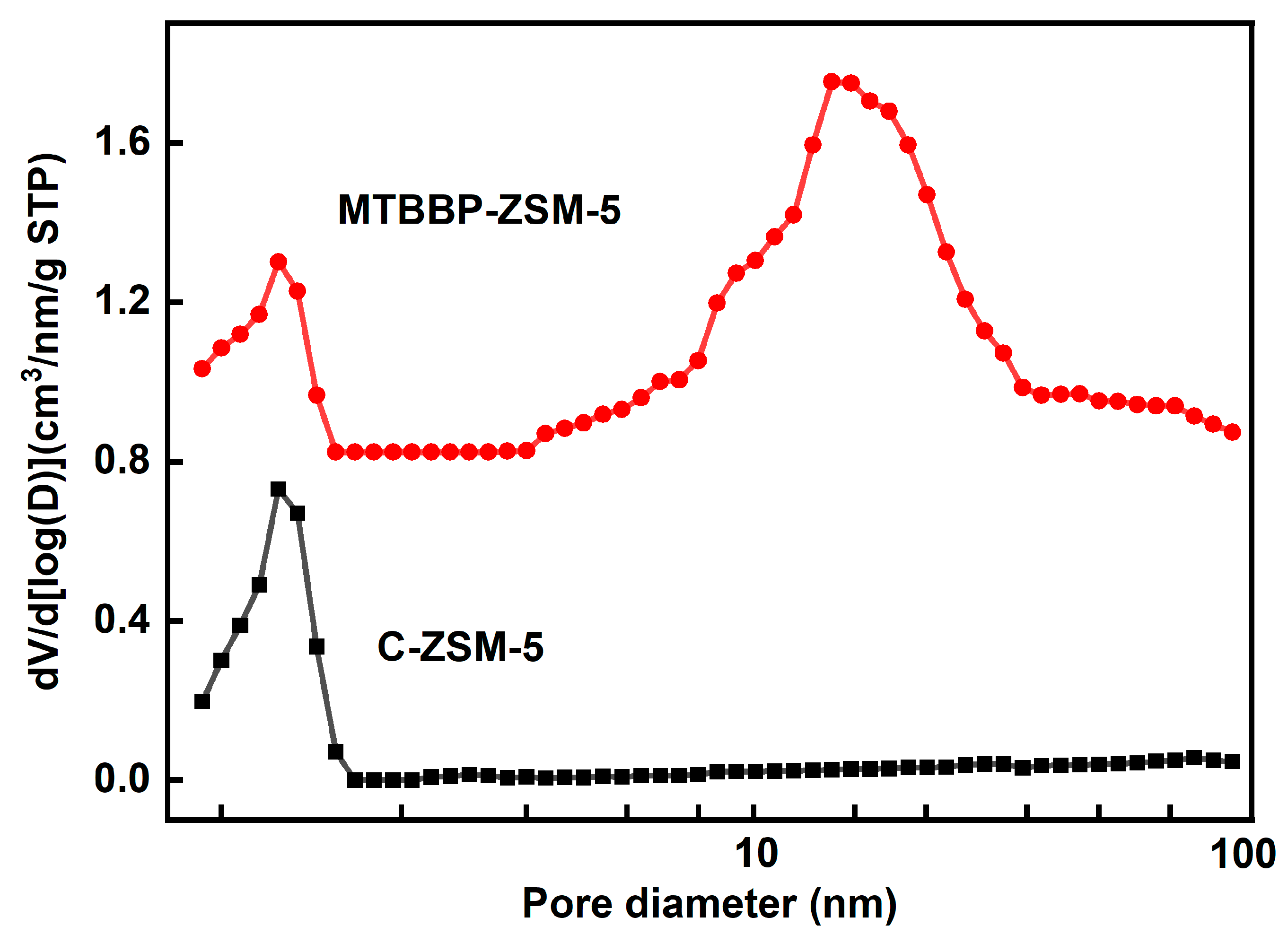

3.1.1. Texture Properties

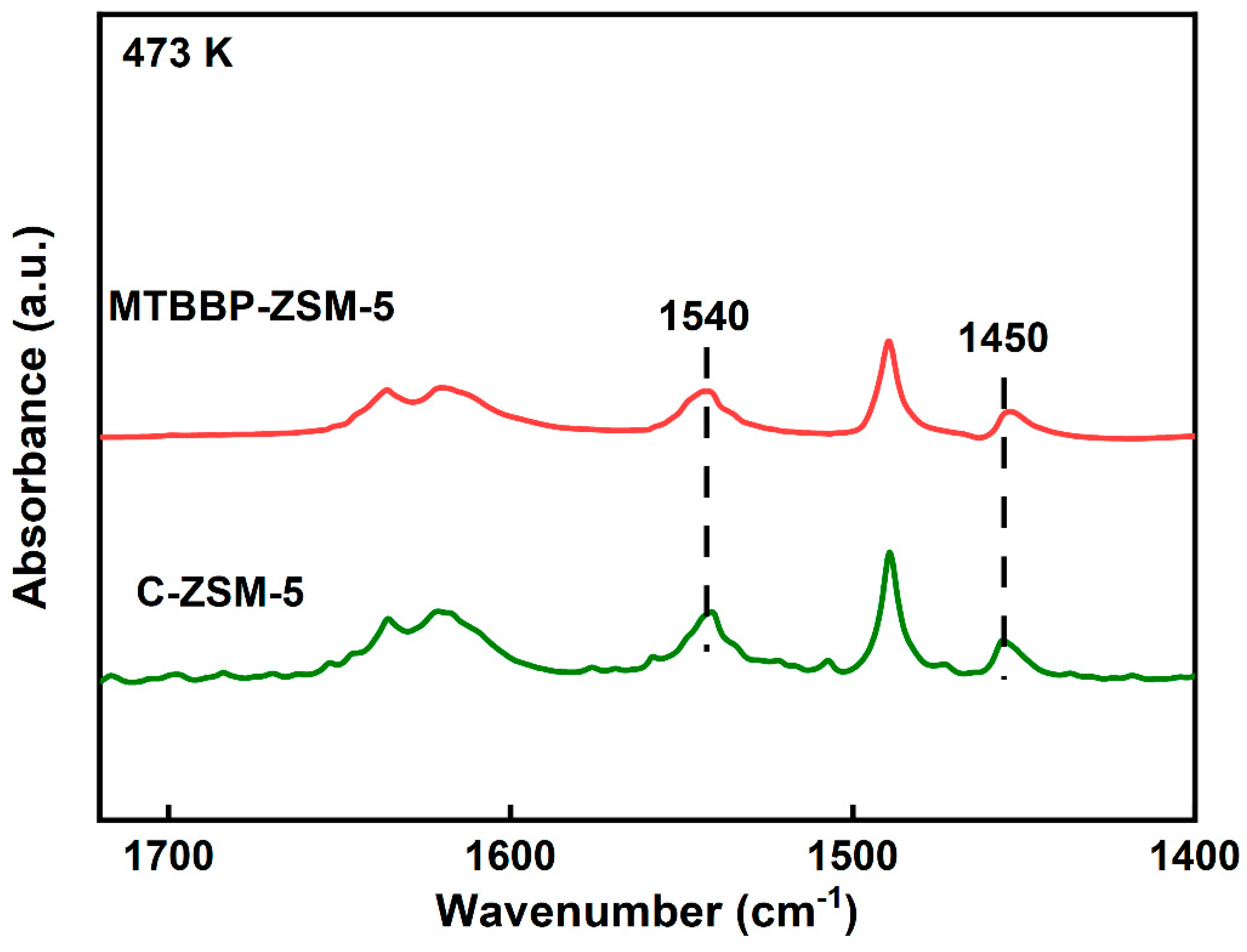

3.1.2. Acidic Properties

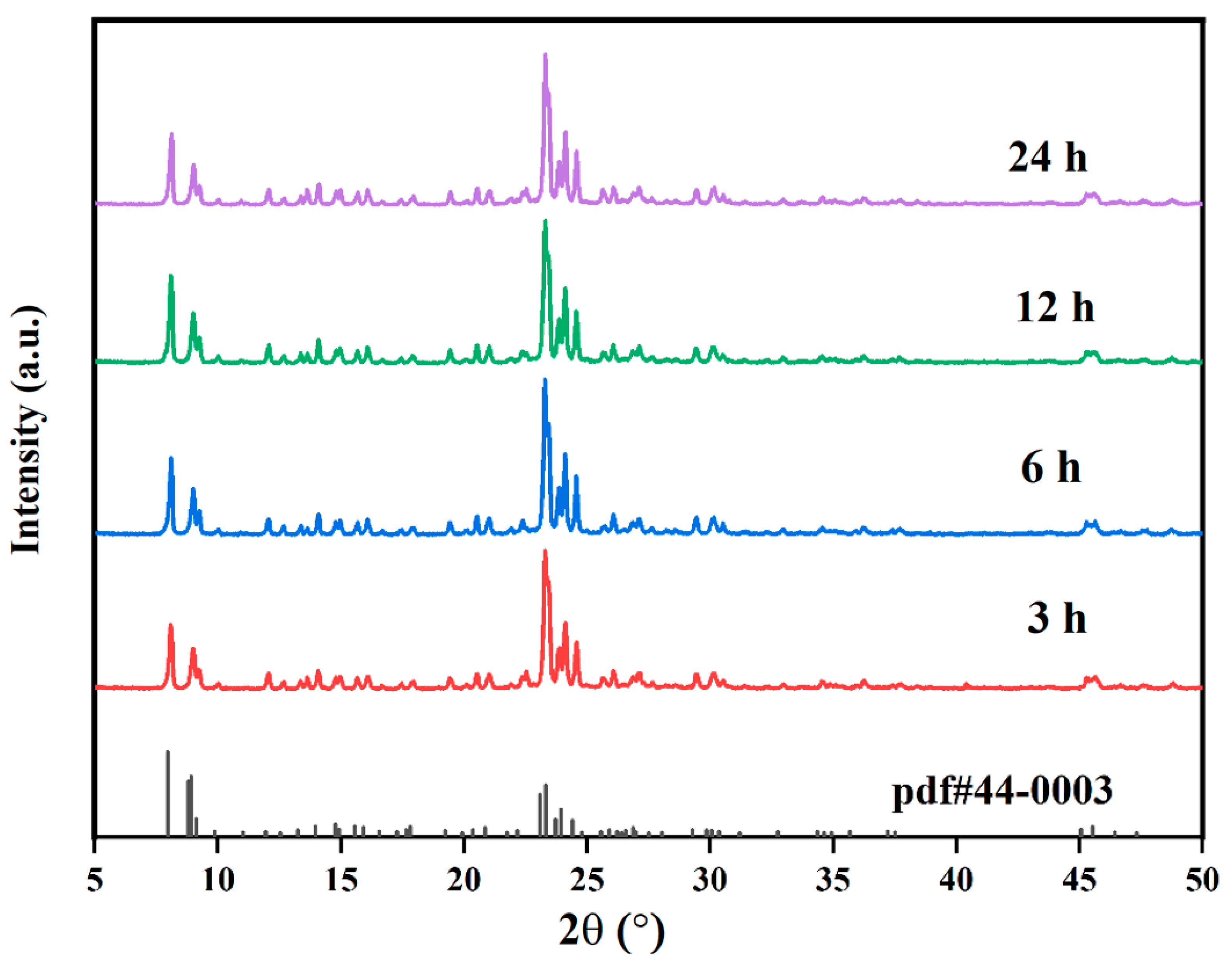

3.2. Crystallization Process Analysis

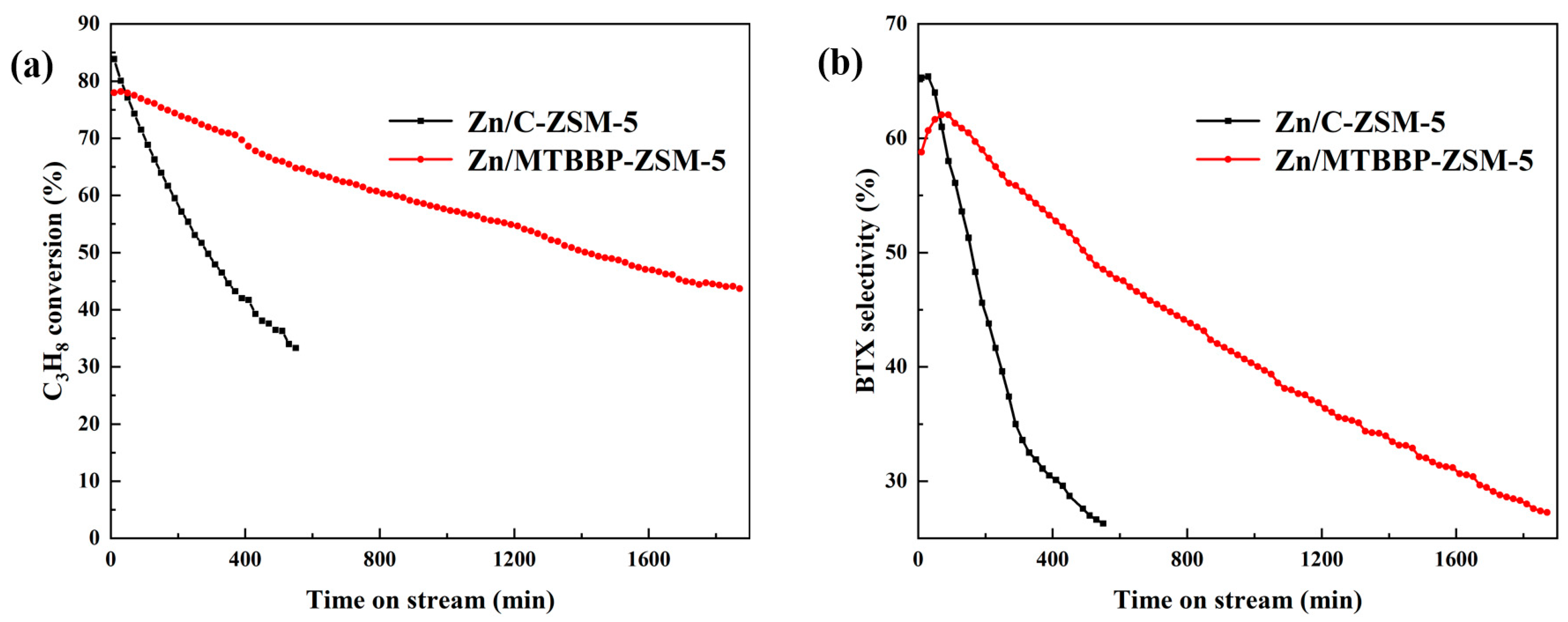

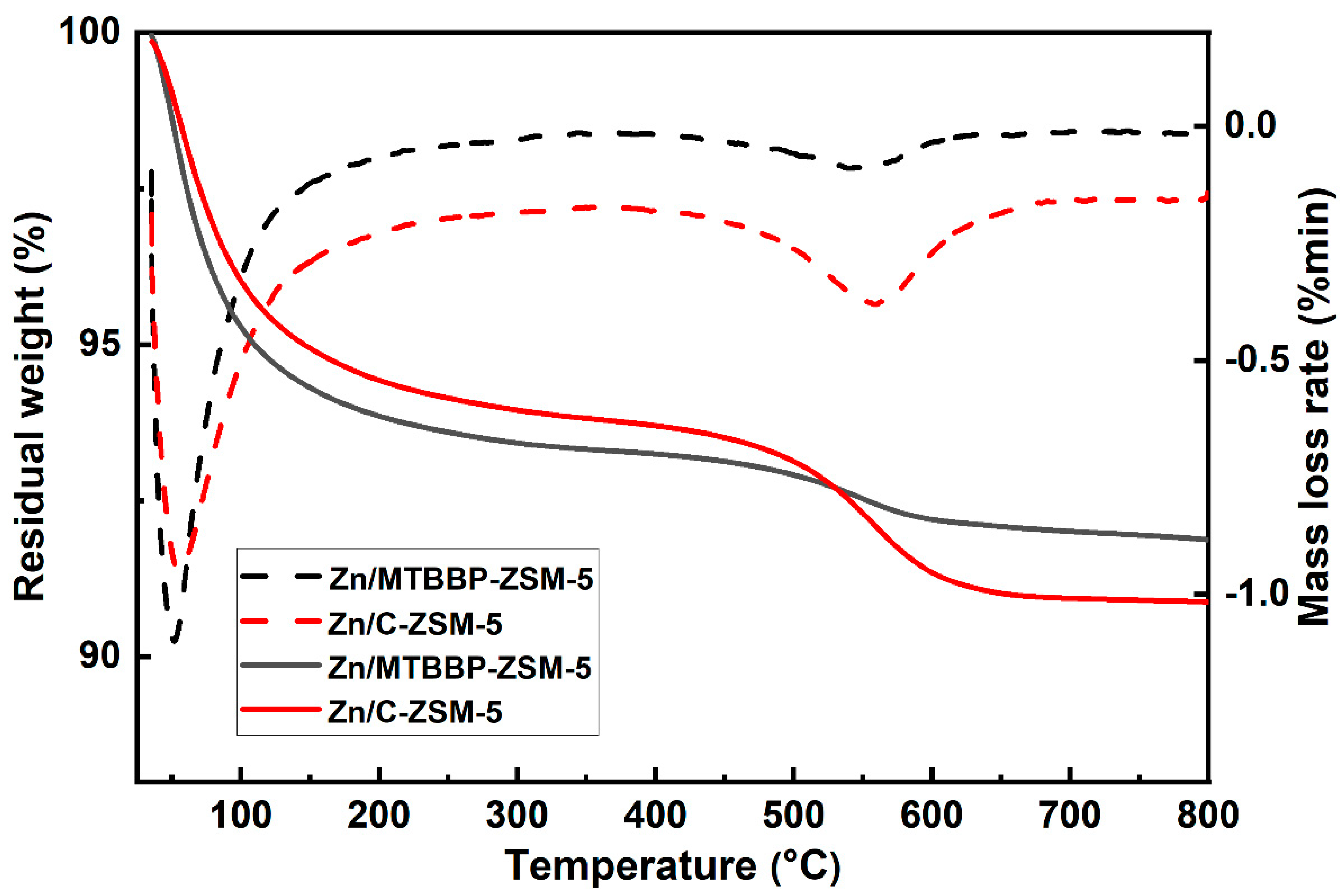

3.3. Catalytic Performance Evaluation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xiang, Y.Z.; Wang, H.; Cheng, J.H.; Matsu, J. Progress and prospects in catalytic ethane aromatization. Cat. Sci. Technol. 2018, 8, 1500–1516. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, S.D.; Xu, X.; Jiang, H.Q. Ethane aromatization and evolution of carbon deposits over nanosized and microsized Zn/ZSM-5 catalysts. Cat. Sci. Technol. 2020, 10, 835–843. [Google Scholar] [CrossRef]

- Cheng, J.J.; Zhao, Y.T.; Xu, G.H.; Zhang, P.; Zhu, X.D.; Yang, F. ZnxZr/HZSM-5 as efficient catalysts for alkylation of benzene with carbon dioxide. Front. Chem. Sci. Eng. 2023, 17, 404–414. [Google Scholar] [CrossRef]

- Zhang, D.; Yang, M.B.; Feng, X.; Yang, Y.F. Integration of Methanol Aromatization with Light Hydrocarbon Aromatization toward Increasing Aromatic Yields: Conceptual Process Designs and Comparative Analysis. ACS Sustain. Chem. Eng. 2020, 8, 11376–11388. [Google Scholar] [CrossRef]

- Rodrigues, V.D.O.; Júnior, A.C.F. On catalyst activation and reaction mechanisms in propane aromatization on Ga/HZSM5 catalysts. Appl. Catal. Gen. 2012, 435, 68–77. [Google Scholar] [CrossRef]

- Zhou, W.; Liu, J.; Wang, J.; Lin, L.; He, N.; Zhang, X.; Guo, H. Transformation of Propane over ZnSnPt Modified Defective HZSM-5 Zeolites: The Crucial Role of Hydroxyl Nests Concentration. Catalysts. 2019, 9, 571. [Google Scholar] [CrossRef]

- Akhtar, M.N. Transformation of Light Alkanes into High-Value Aromatics. Catalysts 2024, 14, 196. [Google Scholar] [CrossRef]

- Bhan, A.; Nicholas Delgass, W. Propane Aromatization over HZSM-5 and Ga/HZSM-5 Catalysts. Catal. Rev. 2008, 50, 19–151. [Google Scholar] [CrossRef]

- Sattler, J.J.H.B.; Ruiz-Martinez, J.; Santillan-Jimenez, E.; Weckhuysen, B.M. Catalytic Dehydrogenation of Light Alkanes on Metals and Metal Oxides. Chem. Rev. 2014, 114, 10613–10653. [Google Scholar] [CrossRef] [PubMed]

- Guisnet, M.; Gnep, N.S.; Alario, F. Aromatization of short chain alkanes on zeolite catalysts. Appl. Catal. Gen. 1992, 89, 1–30. [Google Scholar] [CrossRef]

- Biscardi, J.A.; Iglesia, E. Structure and function of metal cations in light alkane reactions catalyzed by modified H-ZSM5. Catal. Today 1996, 31, 207–231. [Google Scholar] [CrossRef]

- Sattler, J.J.H.B.; Gonzalez-Jimenez, I.D.; Luo, L.; Stears, B.A.; Malek, A.; Barton, D.G.; Kilos, B.A.; Kaminsky, M.P.; Verhoeven, T.W.G.M.; Koers, E.J.; et al. Platinum-Promoted Ga/Al2O3 as Highly Active, Selective, and Stable Catalyst for the Dehydrogenation of Propane. Angew. Chem. Int. Ed. 2014, 53, 9251–9256. [Google Scholar] [CrossRef]

- Erofeev, V.I.; Khasanov, V.V.; Dzhalilova, S.N.; Reschetilowski, W.P.; Syskina, A.A.; Bogdankova, L.A. Acidic and Catalytic Properties of Zeolites Modified by Zinc in the Conversion Process of Lower C3–C4 Alkanes. Catalysts 2019, 9, 421. [Google Scholar] [CrossRef]

- Shim, H.; Hong, J.; Ha, K.-S. Efficient Utilization of Hydrocarbon Mixture to Produce Aromatics over Zn/ZSM-5 and Physically Mixed with ZSM-5. Catalysts 2022, 12, 501. [Google Scholar] [CrossRef]

- Nagamori, Y.; Kawase, M. Converting light hydrocarbons containing olefins to aromatics (Alpha Process). Microporous Mesoporous Mater. 1998, 21, S1387–S1811. [Google Scholar] [CrossRef]

- He, P.; Jarvis, J.; Liu, L.J.; Song, H. The promoting effect of Pt on the co-aromatization of pentane with methane and propane over Zn-Pt/HZSM-5. Fuel 2019, 239, 946–954. [Google Scholar] [CrossRef]

- Guisnet, M.; Gnep, N.S. Aromatization of propane over GaHMFI catalysts. Reaction scheme, nature of the dehydrogenating species and mode of coke formation. Catal. Today 1996, 31, 275–292. [Google Scholar] [CrossRef]

- Zhang, H.X.; Wei, L.H.; Sun, Y.W.; Liang, F.G.; Wang, C. Transformation of metal species and catalytic reaction mechanism of metal modified ZSM-5 in alkane aromatization. Fuel Process. Technol. 2023, 245, 107739. [Google Scholar] [CrossRef]

- Wang, Y.H.; Zhang, Y.Y.; Wu, Q.; Shi, D.X.; Chen, K.C.; Li, H.S. Research progress of gallium modified HZSM-5 catalysts for aromatization of light alkanes. Chem. Ind. Eng. Process 2023, 42, 5162–5178. [Google Scholar] [CrossRef]

- Gao, X.; Zhang, L.; Tao, Z.C.; Chen, H.M.; Zhang, Y.; Gong, H.Y.; Wen, X.D.; Yang, Y.; Li, Y.W. New insight into seeding process leading to improved zeolitic acidity and surface properties for its catalytic application in propane aromatization. Catal. Today 2021, 368, 232–242. [Google Scholar] [CrossRef]

- Li, H.; Zhang, Y.; Diao, J.; Qiang, M.; Chen, Z. Synthesis and Photocatalytic Activity of Hierarchical Zn-ZSM-5 Structures. Catalysts. 2021, 11, 797. [Google Scholar] [CrossRef]

- Yu, Y.; Xi, Z.; Zhou, B.; Jiang, B.; Liao, Z.; Yang, Y.; Wang, J.; Huang, Z.; Sun, J.; Yang, Y. Enhancing Methane Conversion by Modification of Zn States in Co-Reaction of MTA. Catalysts 2021, 11, 1540. [Google Scholar] [CrossRef]

- Ding, H.; Zhang, J.; Feng, W.; Yao, Q.; Zhang, L.; Ren, Y.; Ye, L.; Yue, B.; He, H. Precise Confinement and Position Distribution of Atomic Cu and Zn in ZSM-5 for CO2 Hydrogenation to Methanol. Nanomaterials 2023, 13, 3053. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.W.; Wei, L.H.; Zhang, Z.; Zhang, H.X.; Li, Y.L. Coke Formation over Zeolite Catalysts in Light Alkanes Aromatization and Anti-Carbon-Deposition Strategies and Perspectives: A Review. Energy Fuels 2023, 37, 1657–1677. [Google Scholar] [CrossRef]

- Campo, P.; Martínez, C.; Corma, A. Activation and conversion of alkanes in the confined space of zeolite-type materials. Chem. Soc. Rev. 2021, 50, 8511–8595. [Google Scholar] [CrossRef] [PubMed]

- Choudhary, V.R.; Sivadinarayana, C.; Devadas, P.; Sansare, S.D.; Magnoux, P.; Guisnet, M. Characterization of coke on H-gallosilicate (MFI) propane aromatization catalyst.: Influence of coking conditions on nature and removal of coke. Microporous Mesoporous Mater. 1998, 21, 91–101. [Google Scholar] [CrossRef]

- Milina, M.; Mitchell, S.; Crivelli, P.; Cooke, D.; Perez-Ramirez, J. Mesopore quality determines the lifetime of hierarchically structured zeolite catalysts. Nat. Commun. 2014, 5, 3922. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, C.; Li, T.; Bao, X.; Yue, Y. Nitrogen- and Halogen-Free Multifunctional Polymer-Directed Fabrication of Aluminum-Rich Hierarchical MFI Zeolites. Nanomaterials 2022, 12, 1633. [Google Scholar] [CrossRef] [PubMed]

- Niu, X.; Feng, F.; Yuan, G.; Zhang, X.; Wang, Q. Hollow MFI Zeolite Supported Pt Catalysts for Highly Selective and Stable Hydrodeoxygenation of Guaiacol to Cycloalkanes. Nanomaterials 2019, 9, 362. [Google Scholar] [CrossRef]

- Hu, J.; Zhu, C.; Xia, F.; Fang, Z.; Yang, F.; Weng, J.; Yao, P.; Zheng, C.; Dong, H.; Fu, W. Acidic Mesoporous Zeolite ZSM-5 Supported Cu Catalyst with Good Catalytic Performance in the Hydroxysulfurization of Styrenes with Disulfides. Nanomaterials 2017, 7, 459. [Google Scholar] [CrossRef]

- Shamzhy, M.; Opanasenko, M.; Concepcion, P.; Martinez, A. New trends in tailoring active sites in zeolite-based catalysts. Chem. Soc. Rev. 2019, 48, 1095–1149. [Google Scholar] [CrossRef]

- Verboekend, D.; Nuttens, N.; Locus, R.; Van Aelst, J.; Verolme, P.; Groen, J.C.; Pérez-Ramírez, J.; Sels, B.F. Synthesis, characterization, and catalytic evaluation of hierarchical faujasite zeolites: Milestones, challenges, and future directions. Chem. Soc. Rev. 2016, 45, 3331–3352. [Google Scholar] [CrossRef]

- Panasenko, A.E.; Shichalin, O.O.; Yarusova, S.B.; Ivanets, A.I.; Belov, A.A.; Drankov, A.N.; Azon, S.A.; Fedorets, A.N.; Buravlev, I.Y.; Shlyk, D.K.; et al. A novel approach for rice straw agricultural waste utilization: Synthesis of solid aluminosilicate matrices for cesium immobilization. Nucl. Eng. Technol. 2022, 54, 3250–3259. [Google Scholar] [CrossRef]

- Hoff, T.C.; Gardner, D.W.; Thilakaratne, R.; Proano-Aviles, J.; Tessonnier, J.P. Elucidating the effect of desilication on aluminum-rich ZSM-5 zeolite and its consequences on biomass catalytic fast pyrolysis. Appl. Catal. Gen. 2017, 529, 68–78. [Google Scholar] [CrossRef]

- Choi, M.; Cho, H.S.; Srivastava, R.; Venkatesan, C.; Choi, D.H.; Ryoo, R. Amphiphilic organosilane-directed synthesis of crystalline zeolite with tunable mesoporosity. Nat. Mat. 2006, 5, 718–723. [Google Scholar] [CrossRef] [PubMed]

- Shichalin, O.O.; Papynov, E.K.; Ivanov, N.P.; Balanov, M.I.; Dran’kov, A.N.; Shkuratov, A.L.; Zarubina, N.V.; Fedorets, A.N.; Mayorov, V.Y.; Lembikov, A.O.; et al. Study of adsorption and immobilization of Cs+, Sr2+, Co2+, Pb2+, La3+ ions on Na-Faujasite zeolite transformed in solid state matrices. Sep. Purif. Technol. 2024, 332, 125662. [Google Scholar] [CrossRef]

- Emeis, C.A. Determination of integrated molar extinction coefficients for infrared absorption bands of pyridine adsorbed on solid acid catalysts. J. Catal. 1993, 141, 347–354. [Google Scholar] [CrossRef]

- Derouane, E.G.; Determmerie, S.; Gabelica, Z.; Blom, N. Synthesis and characterization of ZSM-5 type zeolites I. physico-chemical properties of precursors and intermediates. Appl. Catal. 1981, 1, 201–224. [Google Scholar] [CrossRef]

- Sing, K.S.W. Reporting Physisorption Data for Gas/Solid Systems with Special Reference to the Determination of Surface Area and Porosity. Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Zhang, W.; Huang, B.; Yu, X.; Zhang, J. Interpretation of BJH method for calculating aperture distribution process. Univ Chem. 2020, 35, 98–106. [Google Scholar] [CrossRef]

- Khaledi, K.; Haghighi, M.; Sadeghpour, P. On the catalytic properties and performance of core-shell ZSM-5@MnO nanocatalyst used in conversion of methanol to light olefins. Microporous Mesoporous Mater. 2017, 246, 51–61. [Google Scholar] [CrossRef]

- Liu, X.H.; Yan, C.; Wang, Y.L.; Zhang, P.; Yan, S.Y.; Zhuang, J.G.; Zhu, X.D.; Yang, F. Simultaneously enhanced aromatics selectivity and catalyst lifetime in methanol aromatization over [Zn, Al]-ZSM-5 via isomorphous substitution with optimized acidic properties and pore structure. Fuel 2023, 349, 128758. [Google Scholar] [CrossRef]

- Lin, F.; Ye, Z.; Kong, L.; Liu, P.; Zhang, Y.; Zhang, H.; Tang, Y. Facile Morphology and Porosity Regulation of Zeolite ZSM-5 Mesocrystals with Synergistically Enhanced Catalytic Activity and Shape Selectivity. Nanomaterials 2022, 12, 1601. [Google Scholar] [CrossRef] [PubMed]

- Al-Dughaither, A.S.; Lasa, H. HZSM-5 Zeolites with Different SiO2/Al2O3 Ratios. Characterization and NH3 Desorption Kinetics. Ind. Eng. Chem. Res. 2014, 53, 15303–15316. [Google Scholar] [CrossRef]

- Zhang, L.L.; Song, Y.; Li, G.D.; Zhang, Q.; Zhang, S.L.; Xu, J.; Deng, F.; Gong, Y.J. F-assisted synthesis of a hierarchical ZSM-5 zeolite for methanol to propylene reaction: A b-oriented thinner dimensional morphology. RSC Adv. 2015, 5, 61354–61363. [Google Scholar] [CrossRef]

- Barzetti, T.; Selli, E.; Moscotti, D.; Forni, L. Pyridine and ammonia as probes for FTIR analysis of solid acid catalysts. J. Chem. Soc. Faraday Trans. 1996, 92, 1401–1407. [Google Scholar] [CrossRef]

- Dauda, I.B.; Yusuf, M.; Gbadamasi, S.; Bello, M.; Atta, A.Y.; Aderemi, B.O.; Jibril, B.Y. Highly Selective Hierarchical ZnO/ZSM-5 Catalysts for Propane Aromatization. ACS Omega 2020, 5, 2725–2733. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.S.; Jiang, R.L.; Gao, Y.; Zhou, Z.H.; Wang, X.W. Synthesis of nano-ZSM-5 zeolite via a dry gel conversion crystallization process and its application in MTO reaction. CrystEngComm 2021, 23, 2793–2800. [Google Scholar] [CrossRef]

- Bij, H.E.; Weckhuysen, B.M. Phosphorus promotion and poisoning in zeolite-based materials: Synthesis, characterization and catalysis. Chem. Soc. Rev. 2015, 44, 7406–7428. [Google Scholar] [CrossRef]

- Bhan, A.; Hsu, S.H.; Blau, G.; Caruthers, J.M.; Venkatasubramanian, V.; Delgass, W.N. Microkinetic modeling of propane aromatization over HZSM-5. J. Catal. 2005, 235, 35–51. [Google Scholar] [CrossRef]

- Krishnamurthy, G.; Bhan, A.; Delgass, W.N. Identity and chemical function of gallium species inferred from microkinetic modeling studies of propane aromatization over Ga/HZSM-5 catalysts. J. Catal. 2010, 271, 370–385. [Google Scholar] [CrossRef]

- Oseke, G.G.; Atta, A.Y.; Mukhtar, B.; El-Yakubu, B.J.; Aderemi, B.O. Synergistic effect of Zn with Ni on ZSM-5 as propane aromatization catalyst: Effect of temperature and feed flowrate. J. Porous Mater. 2022, 29, 1839–1852. [Google Scholar] [CrossRef]

- Biscardi, J.A.; Iglesia, E. Reaction pathways and rate-determining steps in reactions of alkanes on H-ZSM5 and Zn/H-ZSM5 catalysts. J. Catal. 1999, 182, 117–128. [Google Scholar] [CrossRef]

- Almutairi, S.M.T.; Mezari, B.; Magusin, P.C.M.M.; Pidko, E.A.; Hensen, E.J.M. Structure and Reactivity of Zn-Modified ZSM-5 Zeolites: The Importance of Clustered Cationic Zn Complexes. ACS Catal. 2012, 2, 71–83. [Google Scholar] [CrossRef]

- Biscardi, J.; Meitzner, G.; Iglesia, E. Structure and Density of Active Zn Species in Zn/H-ZSM5 Propane Aromatization Catalysts. J. Catal. 1998, 179, 192–202. [Google Scholar] [CrossRef]

- Choudhary, V.R.; Kinage, A.K.; Choudhary, T.V. Simultaneous aromatization of propane and higher alkanes or alkenes over H-GaAlMFI zeolite. Chem. Commun. 1996, 22, 2545–2546. [Google Scholar] [CrossRef]

- Xue, T.; Liu, H.; Zhang, Y.; Wu, H.; He, M. Synthesis of ZSM-5 with hierarchical porosity: In-situ conversion of the mesoporous silica-alumina species to hierarchical zeolite. Microporous Mesoporous Mater. 2017, 242, 190–199. [Google Scholar] [CrossRef]

| Sample | SBET (m2·g−1) | Sext (m2·g−1) | Smicro (m2·g−1) | Vtotal (cm3·g−1) | Vmicro (cm3·g−1) | Vmeso (cm3·g−1) |

|---|---|---|---|---|---|---|

| MTBBP-ZSM-5 | 373 | 195 | 178 | 0.40 | 0.11 | 0.29 |

| C-ZSM-5 | 322 | 141 | 181 | 0.23 | 0.11 | 0.12 |

| Sample | Total Acidity Amount (μmol·g−1) |

|---|---|

| MTBBP-ZSM-5 C-ZSM-5 Zn/MTBBP-ZSM-5 | 242.8 264.8 267.5 |

| Zn/C-ZSM-5 | 286.8 |

| Sample | Brønsted Acid Amount (μmol·g−1) | Lewis Acid Amount (μmol·g−1) |

|---|---|---|

| MTBBP-ZSM-5 C-ZSM-5 Zn/MTBBP-ZSM-5 | 264.6 297.2 91.5 | 70.2 76.4 368.8 |

| Zn/C-ZSM-5 | 107.6 | 392.5 |

| Catalyst | Conversion (%) | Selectivity (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| CH4 | C2H4 | C2H6 | C3H6 | C6H6 | C7H8 | C8H10 | Total Aromatics | ||

| Zn/MTBBP-ZSM-5 (300 min) | 71.7 | 10.8 | 6.8 | 25.4 | 4.1 | 23.5 | 21.6 | 7.8 | 52.9 |

| Zn/C-ZSM-5 (300 min) | 48.9 | 17.4 | 9.5 | 33.6 | 5.2 | 14.1 | 13.3 | 6.9 | 34.3 |

| Zn/C-ZSM-5 (90 min) | 71.5 | 11.6 | 3.3 | 26.0 | 3.5 | 24.1 | 23.0 | 8.5 | 55.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Zhuang, J.; Yu, J.; Guan, Y.; Zhu, X.; Yang, F. Disinfectant-Assisted Preparation of Hierarchical ZSM-5 Zeolite with Excellent Catalytic Stabilities in Propane Aromatization. Nanomaterials 2024, 14, 802. https://doi.org/10.3390/nano14090802

Zhang P, Zhuang J, Yu J, Guan Y, Zhu X, Yang F. Disinfectant-Assisted Preparation of Hierarchical ZSM-5 Zeolite with Excellent Catalytic Stabilities in Propane Aromatization. Nanomaterials. 2024; 14(9):802. https://doi.org/10.3390/nano14090802

Chicago/Turabian StyleZhang, Peng, Jianguo Zhuang, Jisheng Yu, Yingjie Guan, Xuedong Zhu, and Fan Yang. 2024. "Disinfectant-Assisted Preparation of Hierarchical ZSM-5 Zeolite with Excellent Catalytic Stabilities in Propane Aromatization" Nanomaterials 14, no. 9: 802. https://doi.org/10.3390/nano14090802

APA StyleZhang, P., Zhuang, J., Yu, J., Guan, Y., Zhu, X., & Yang, F. (2024). Disinfectant-Assisted Preparation of Hierarchical ZSM-5 Zeolite with Excellent Catalytic Stabilities in Propane Aromatization. Nanomaterials, 14(9), 802. https://doi.org/10.3390/nano14090802